Patents

Literature

228results about How to "Reduce production input costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

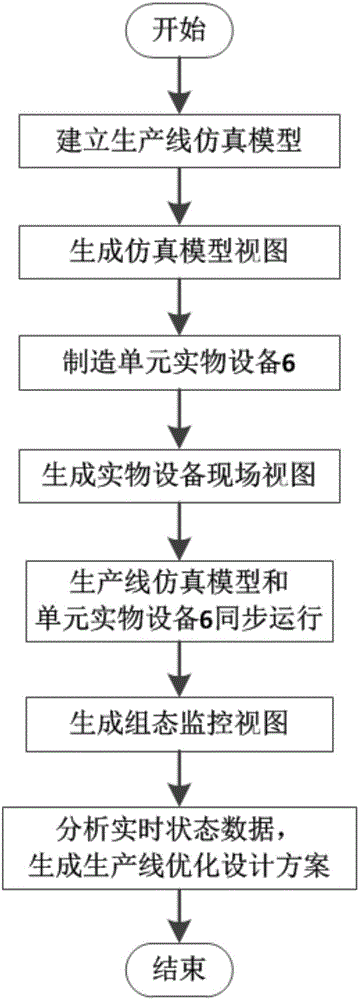

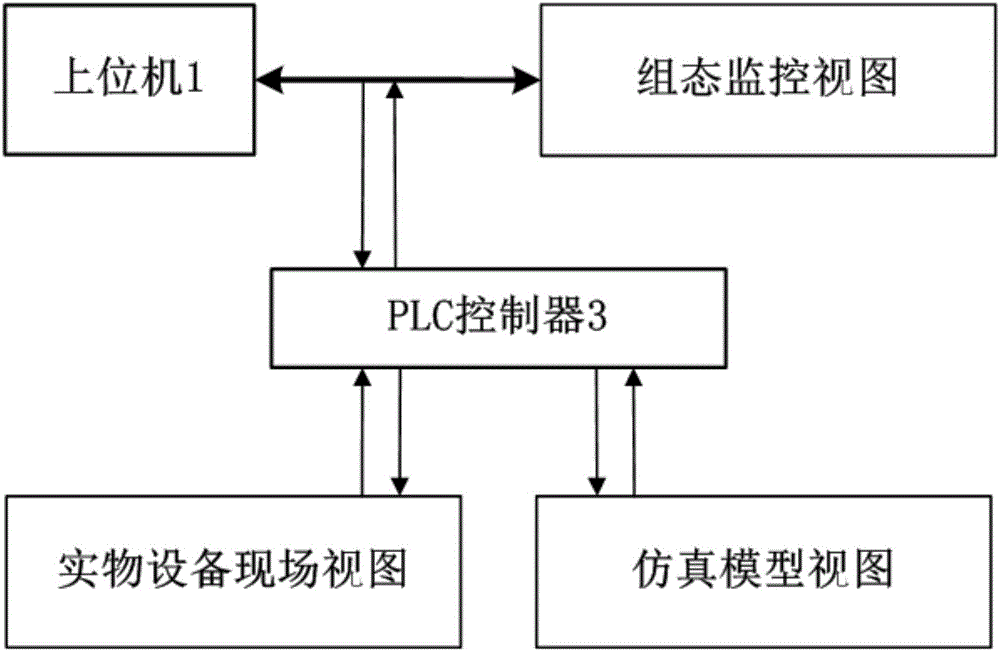

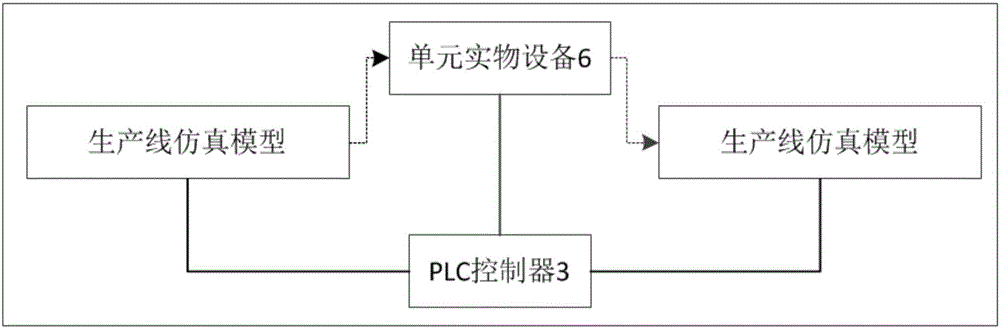

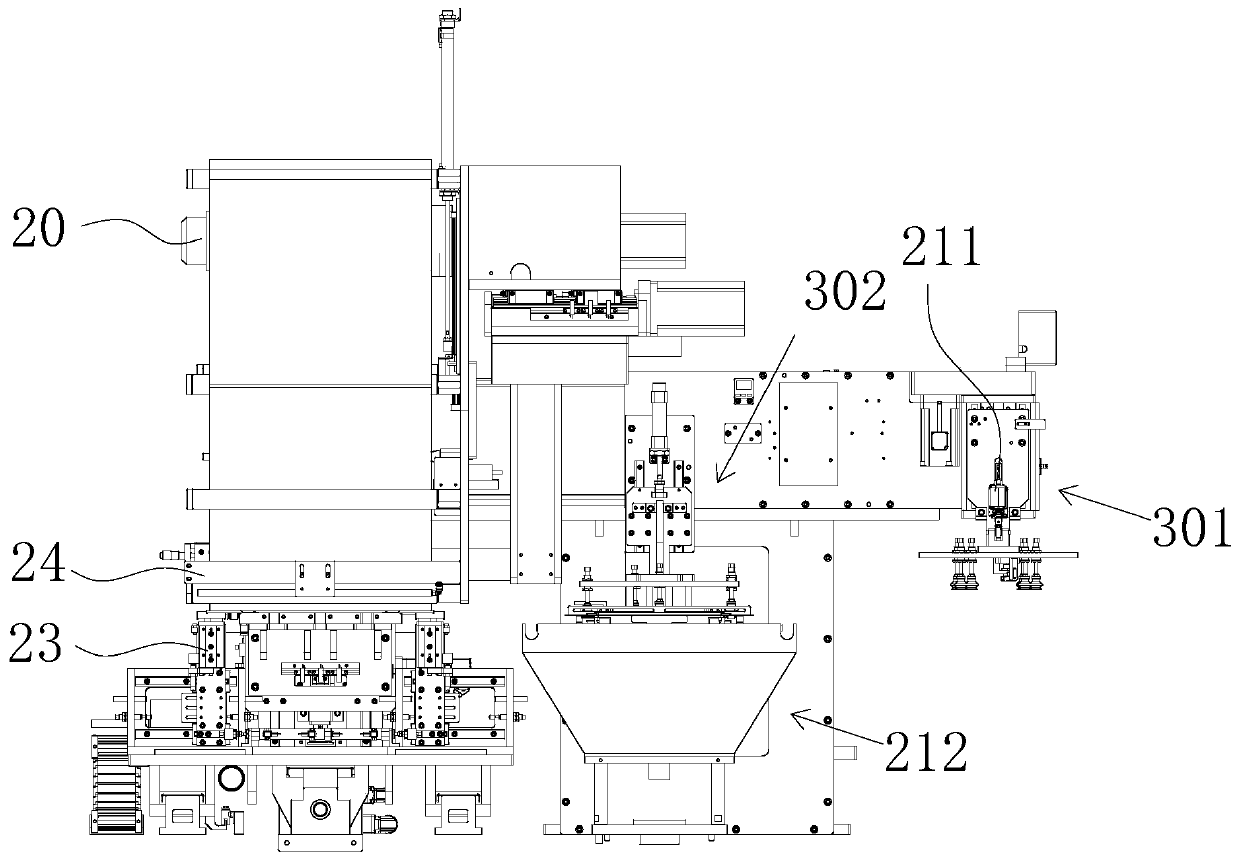

Intelligent three-view linkage method and intelligent three-view linkage system for production line

ActiveCN106774223AImprove rationalityReduce production input costsTotal factory controlProgramme total factory controlData synchronizationIntegration testing

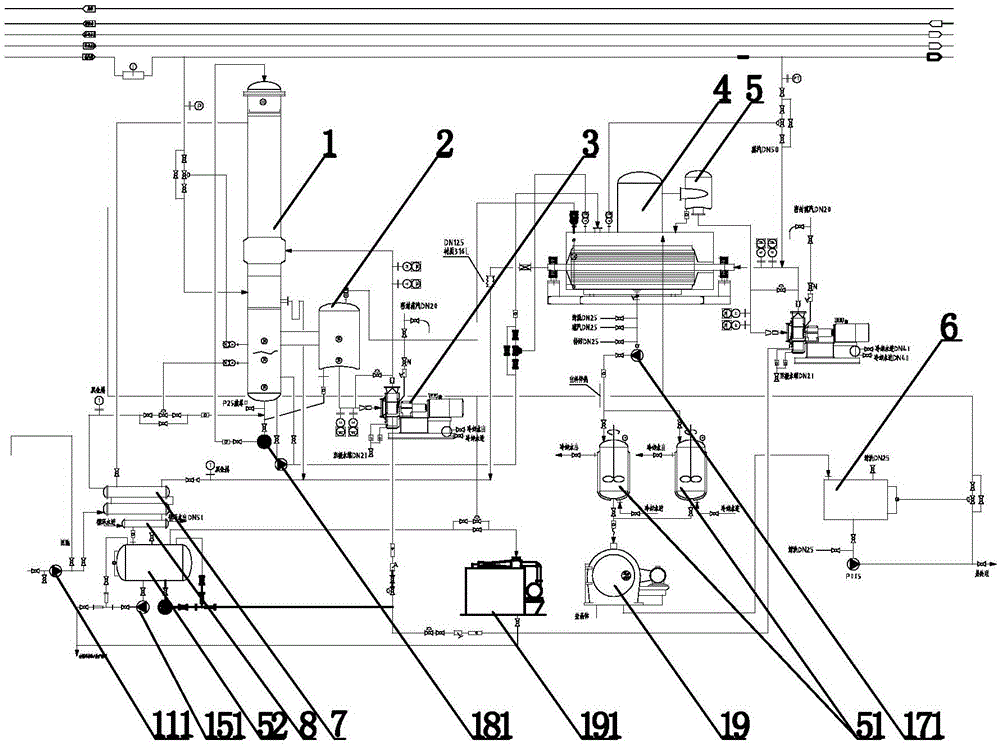

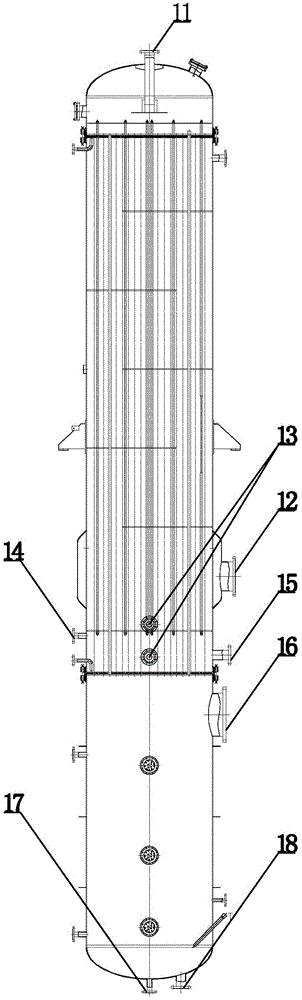

The invention discloses an intelligent three-view linkage method and an intelligent three-view linkage system for a production line. The intelligent three-view linkage method includes the steps of acquiring design requirement information of the production line, subjecting a simulation system to three-dimensional modeling, setting up production line simulation model views, setting up or partially setting up the production line or unit physical system views and establishing configuration monitoring views; developing a management and control system, setting up a control network and establishing data and information channels between the management and control system and the control network. The intelligent three-view linkage method is capable of driving physical equipment, configuration monitoring interfaces and a simulation model to move simultaneously through data synchronization so as to achieve synchronous linkage of three views. An integrated platform integrating design, assembly, debugging, optimization and monitoring of the production line is achieved by means of the three-view linkage. The intelligent three-view linkage method for the production line has the advantages that all units are subjected to unit testing and integrated testing in a production line design and manufacturing process, so that production design schemes are optimized timely, a debugging period is shortened, input cost is reduced and value chains of a whole enterprise are superposed together effectively.

Owner:广州秉优信息科技有限公司

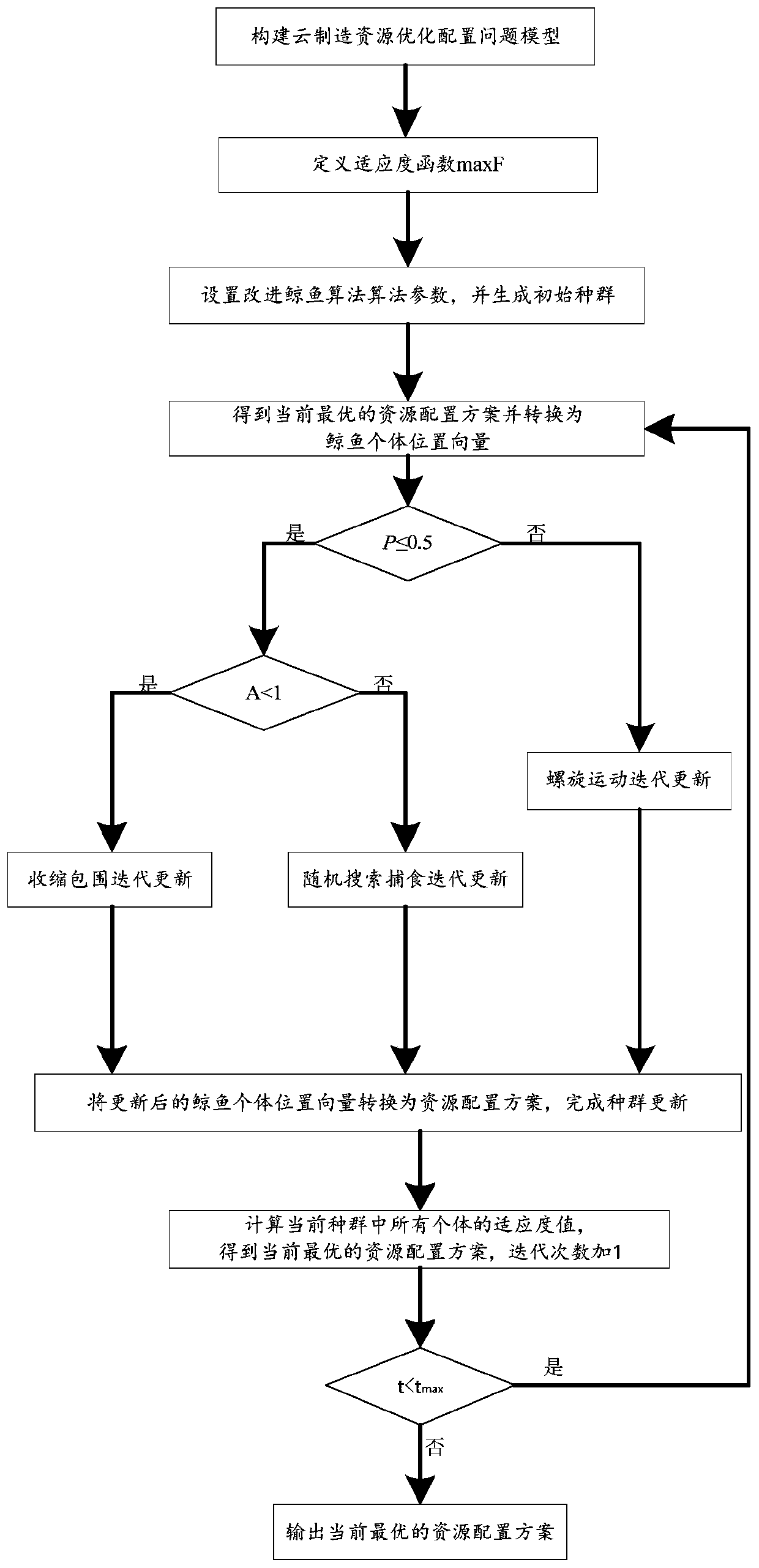

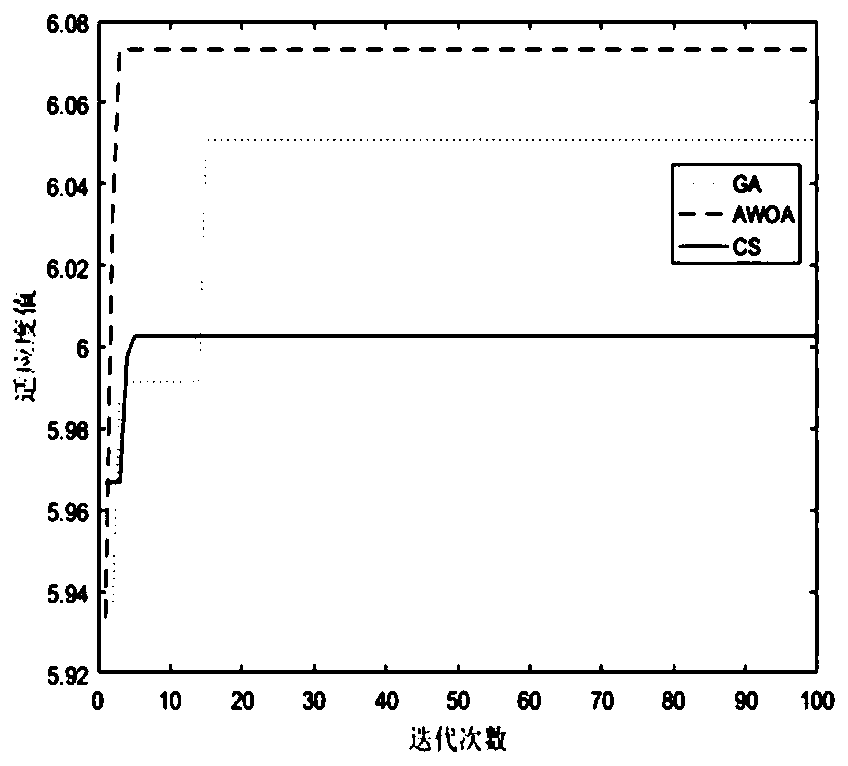

A cloud manufacturing resource configuration method based on an improved whale algorithm

PendingCN109902873AImprove local search capabilitiesImprove convergence accuracyForecastingBiological modelsPredationAlgorithm convergence

The invention discloses a method for cloud manufacturing resource optimization configuration based on an improved whale algorithm, and the method comprises the steps: building a problem model, and defining a fitness function; setting improved whale algorithm parameters, and generating an initial population; Calculating fitness values of all individuals in the population, obtaining a current optimal resource allocation scheme and converting the current optimal resource allocation scheme into whale individual position vectors; Introducing a parameter p, and judging whether p is less than or equal to 0.5; If not, performing spiral motion iteration updating to complete population updating; If yes, whether the value A (1) of the coefficient vector of the improved whale algorithm is met or not is judged; If yes, performing shrinkage encircling iteration updating; If not, performing random search predation iteration updating; Obtaining a current optimal resource configuration scheme; Adding 1to the number of iterations, and judging whether the current number of iterations is smaller than the maximum number of iterations; If yes, repeating the operation; And if not, outputting the currentoptimal resource configuration scheme. The whale algorithm is improved, so that the algorithm convergence speed is higher, the optimal solution is easier to achieve, and a new method is provided forsolving the problem of resource allocation.

Owner:CHANGAN UNIV

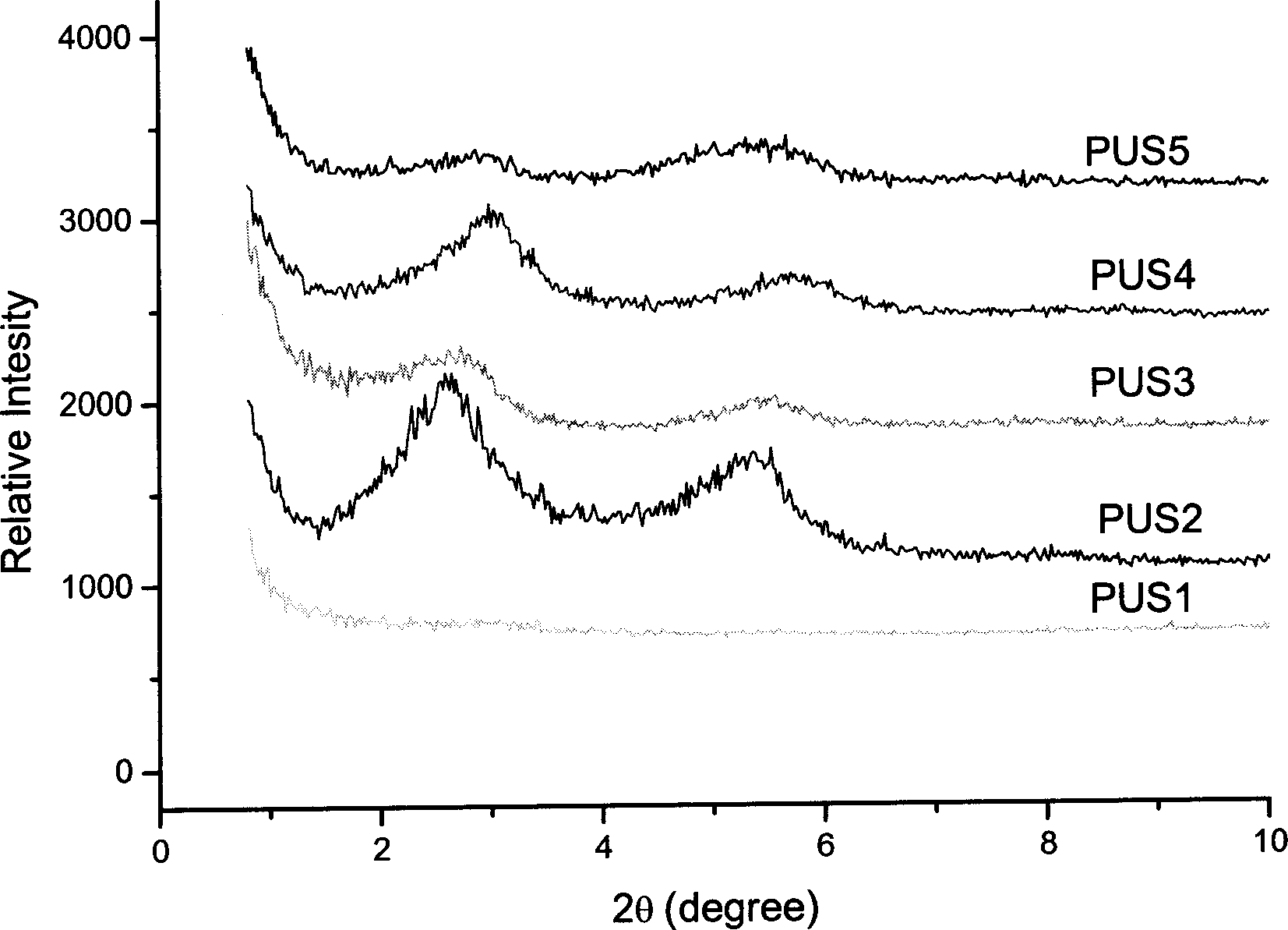

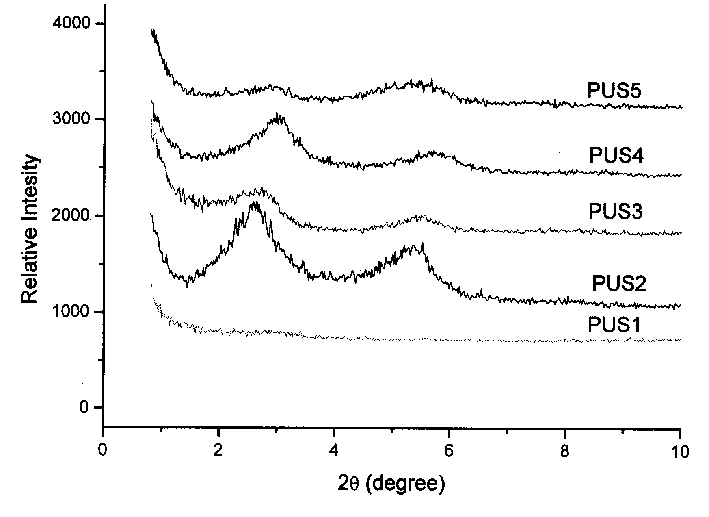

Detaching type polymer/montmorillonite composite material and preparing method thereof

The present invention relates to a separable polymer / montmorillonite nano composite material and its preparation method. The selected polymer is polyamide, acid anhydridized polypropylene, acid anhydridized polyethylene, polyurethane, polystyrene, acid anhydridized ethylene-propylene rubber, nitrile rubber, SBR rubber or silicon rubber or polymer blend polypropylene / polyamide, polypropylene / acid anhydridized polypropylene, polyethylene / acid anhydridized polyethylene, polyamide / acid anhydrized polypropylene or polyurethane / acid anhydridized polypropylene, and the organic modified montmorillonite is formed from montmorillonite, cationite primary amine, secondary amine or tertiary amine. The dose of modification agent is seriously limited below the ion exchange capacity of montmorillonite, then the polymer and modified montmorillonite can be directly molten and mixed so as to obtain the invented product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing graphene by chemical vapor deposition

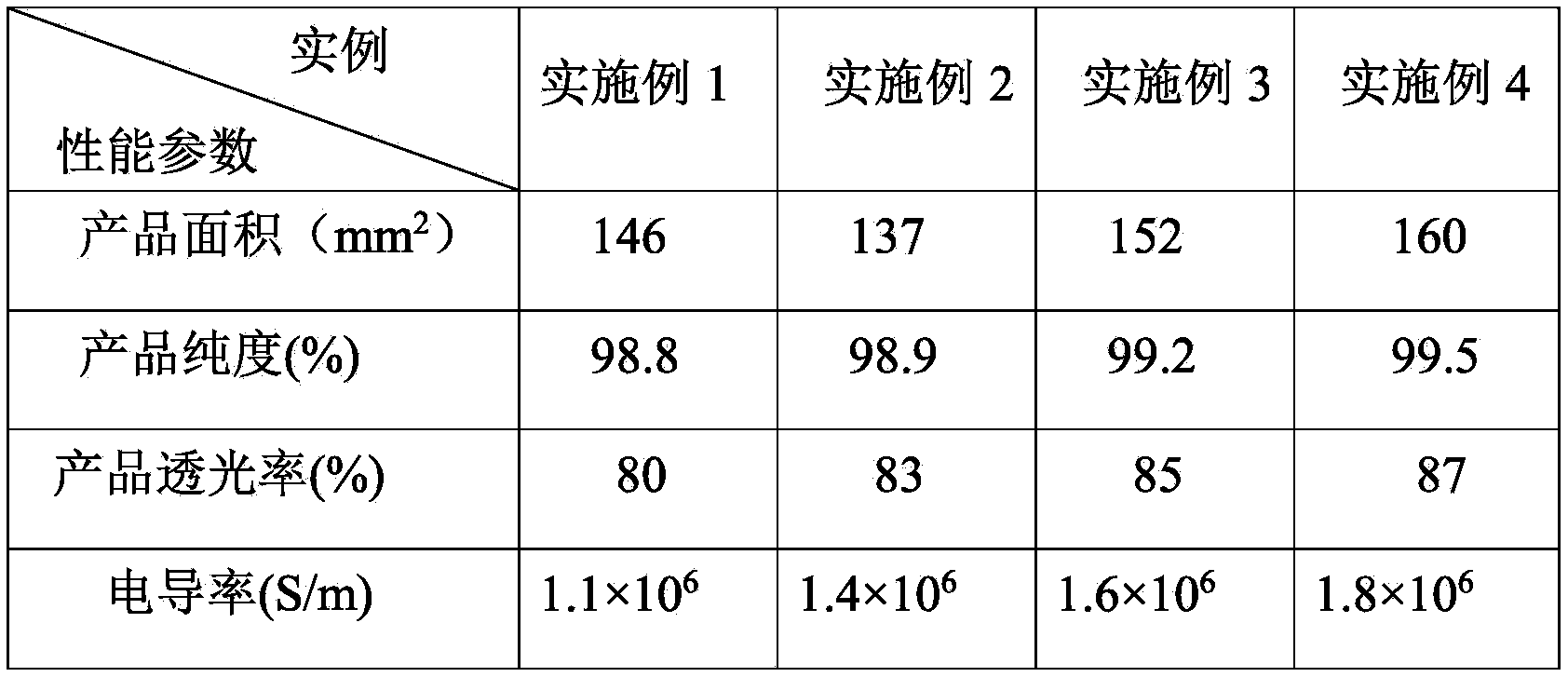

InactiveCN104030277ASimple processReduce production input costsGrapheneCvd grapheneHigh transmittance

The invention discloses a method for preparing graphene by chemical vapor deposition. The method comprises the steps of firstly, purifying a copper alloy substrate; secondly, placing a copper alloy in a chemical vapor deposition (CVD) device; thirdly, removing an oxide film on the surface of the copper alloy; fourthly, preparing graphene: maintaining the pressure within the CVD device to be 0.1-90Torr and the temperature of the copper alloy substrate to be 800-980 DEG C, then introducing hydrogen and methane gas, wherein the flow ratio of hydrogen to methane gas is (1:1) to (1:10) and continuously introducing hydrogen and methane gas for 50-70 minutes; fifthly, obtaining a graphene product; and sixthly, purifying the graphene product to obtain graphene. The preparation method disclosed by the invention is simple in preparation process and low in cost and is suitable for large-scale production and large-area graphene products with high transmittance, high quality and high purity can be produced by the method.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

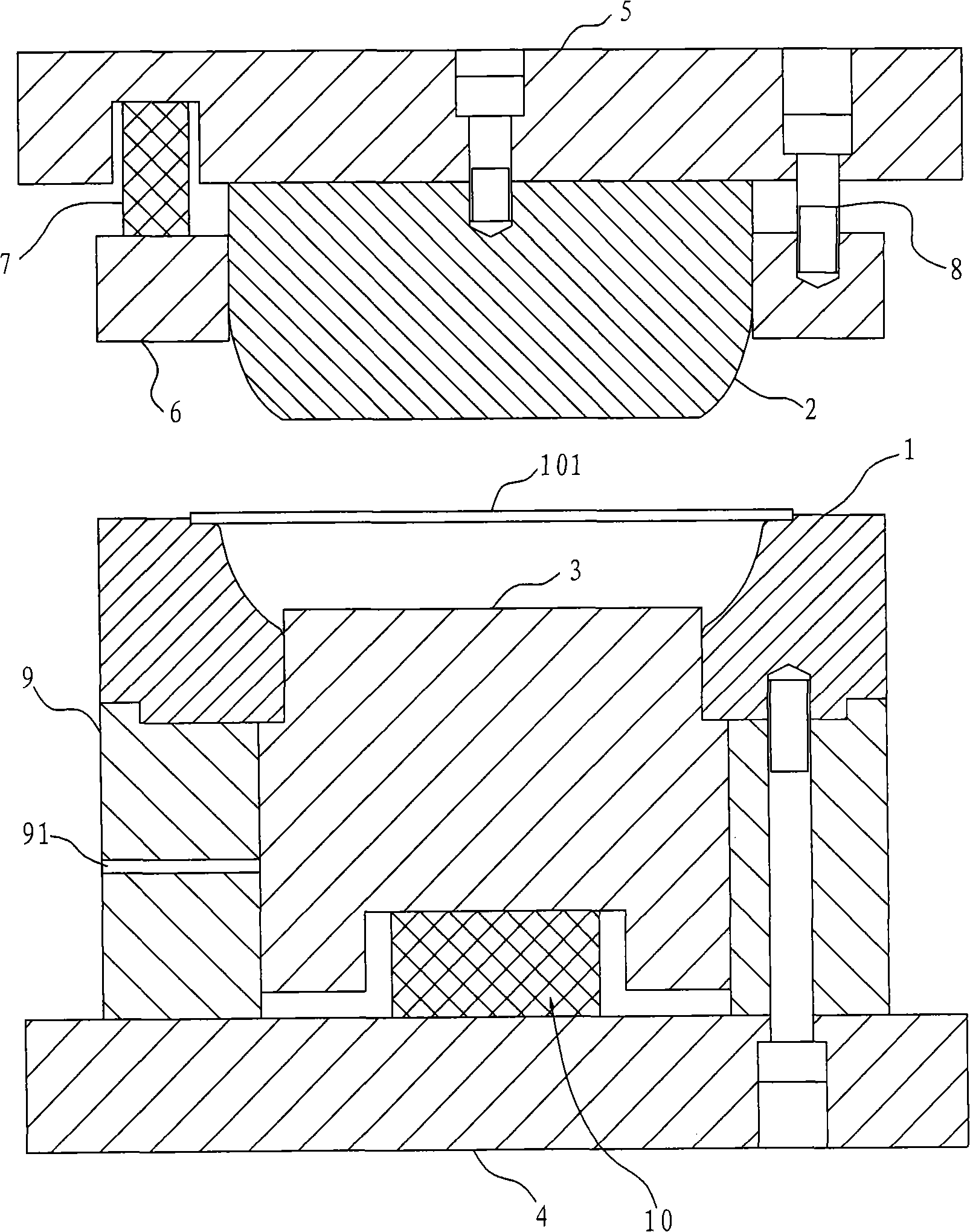

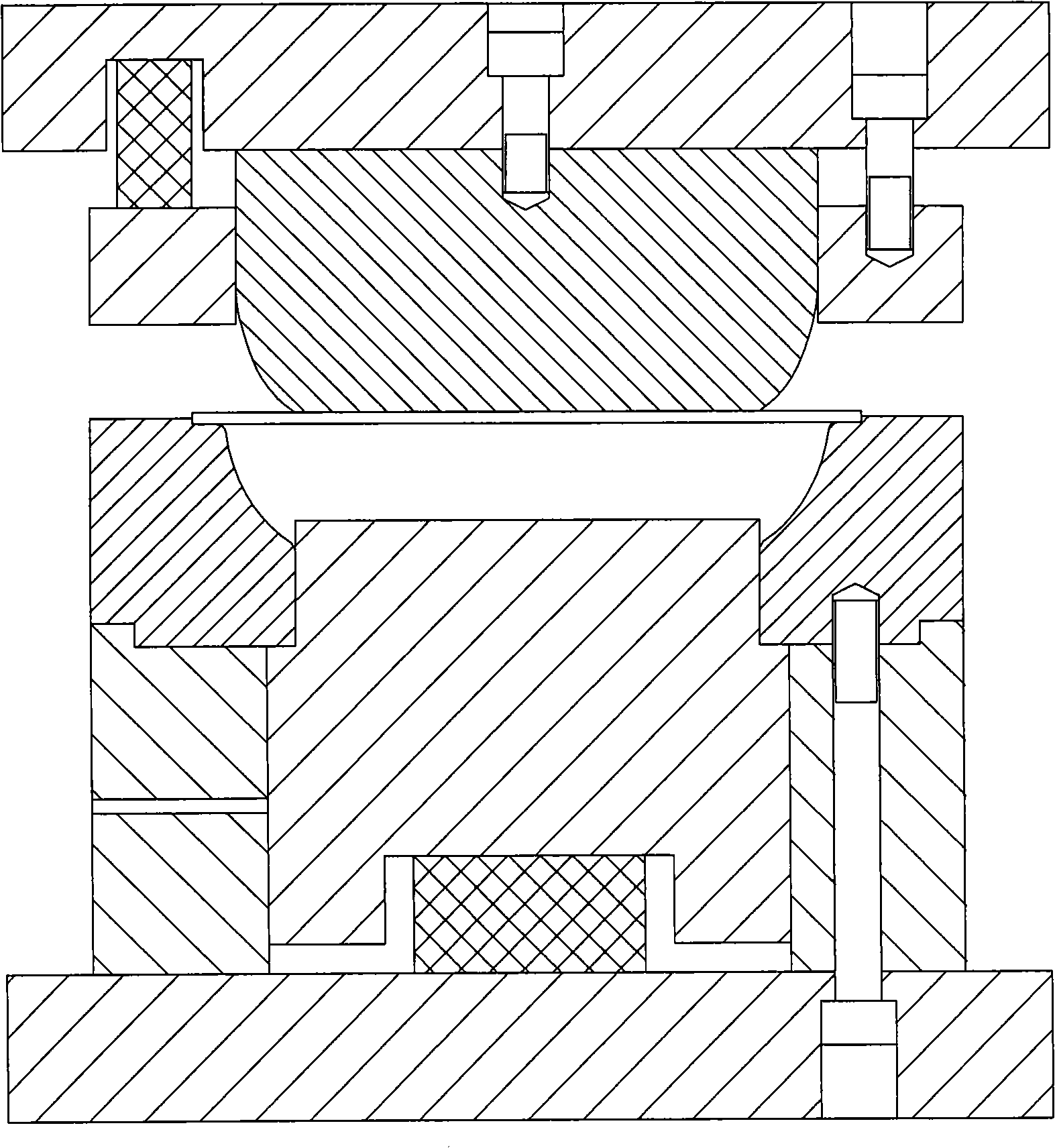

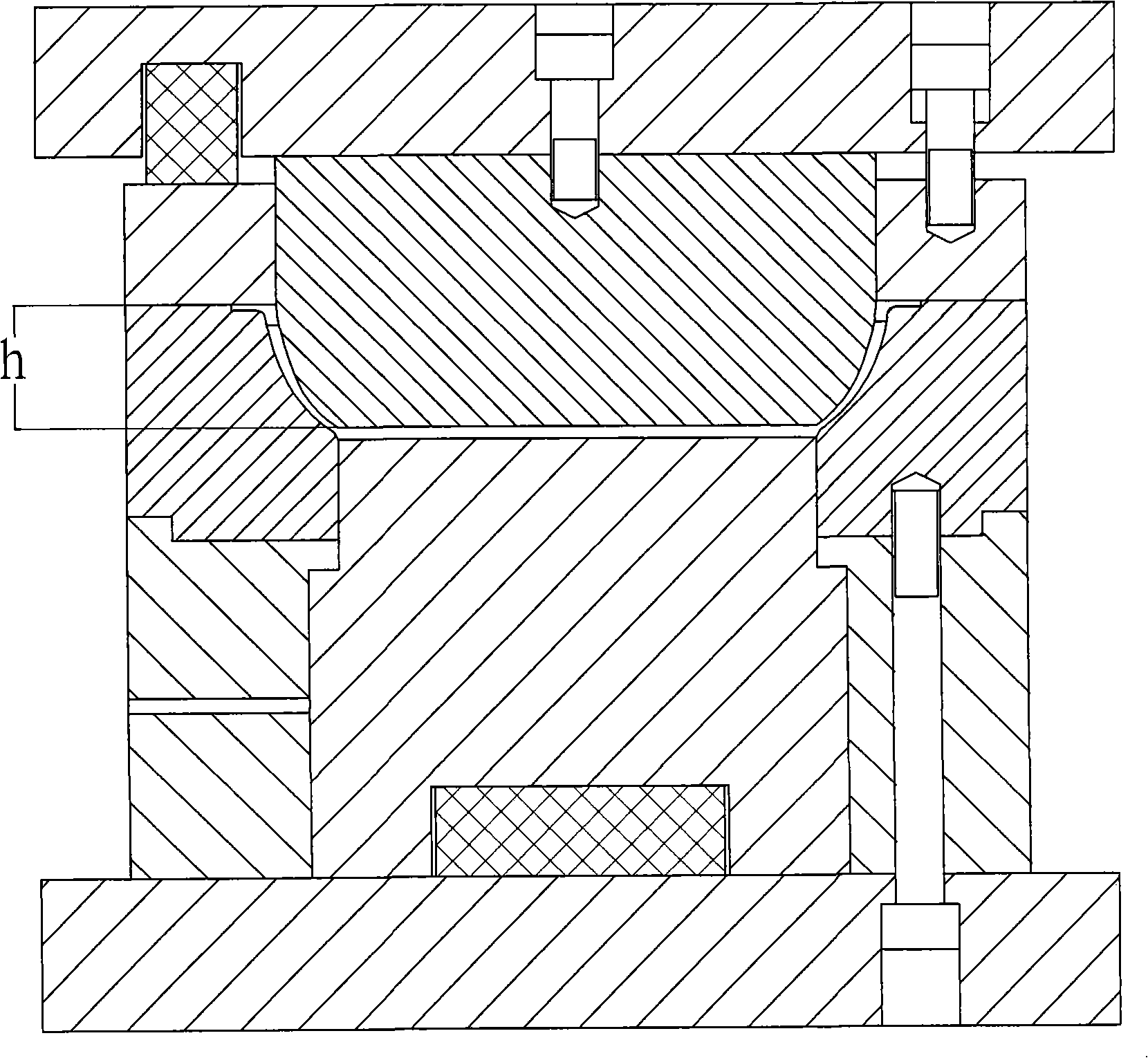

Post forming method of aluminum pot body

InactiveCN101279338ALow costIncreased thinningShaping toolsStripping-off devicesInvestment costAluminium

A secondary shaping method for an aluminum boiler body includes the following steps: (1) an aluminum sheet that is sheared to be punched is taken and placed into a holding domain of a first cavity die and a first convex die is pressed down to the depth of h, so as to be shaped into a rough aluminum boiler body; (2) the rough aluminum boiler body is taken and inversely placed on a second convex die and a second cavity die is pressed down to the deepest point of H, so as to be shaped into a finished aluminum boiler body; wherein, the inner wall of the first cavity die and the outer wall of the first convex die are all matched with the wall of the aluminum boiler body; the first convex die is arranged above the first cavity die; the middle part of the first cavity die is provided with a first pushing block that can descend after being stressed; the opening part of the first cavity die is provided with the holding domain along the edge; the outer wall of the second convex die and the inner wall of the second cavity die are all matched with the wall of the aluminum boiler body; the second cavity die is arranged above the second convex die; the middle part of the second cavity die is provided with a second push block that can life after being stressed; the opening part of the second cavity die is provided with an aluminum forming domain along the edge; besides, h is more than or equal to 0.7H and is less than or equal to 0.95H. The method of the invention has the advantages of large attenuation and low device investment cost, etc.

Owner:王勇

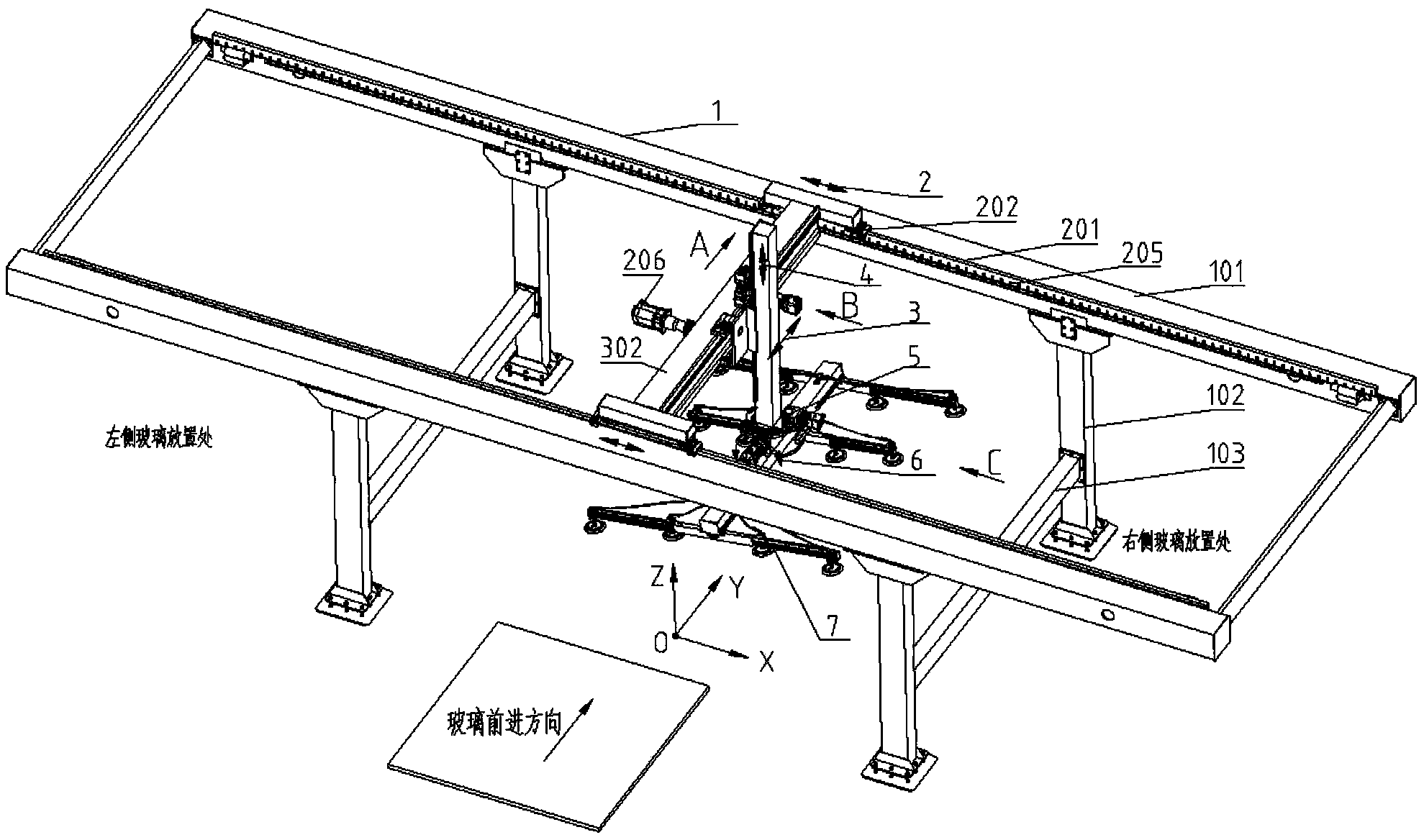

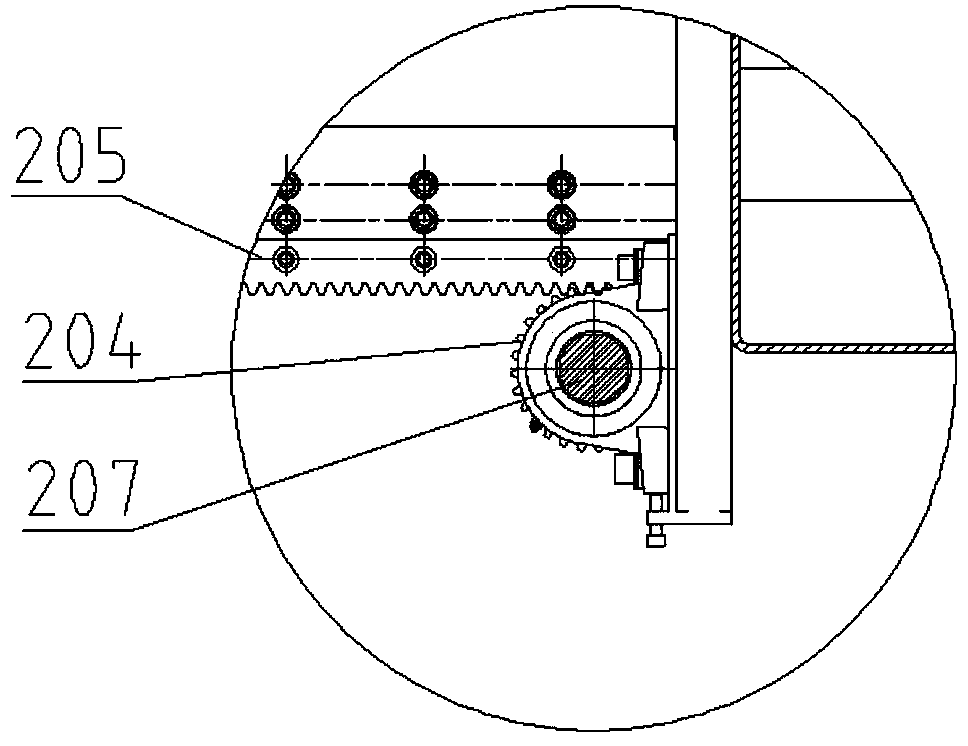

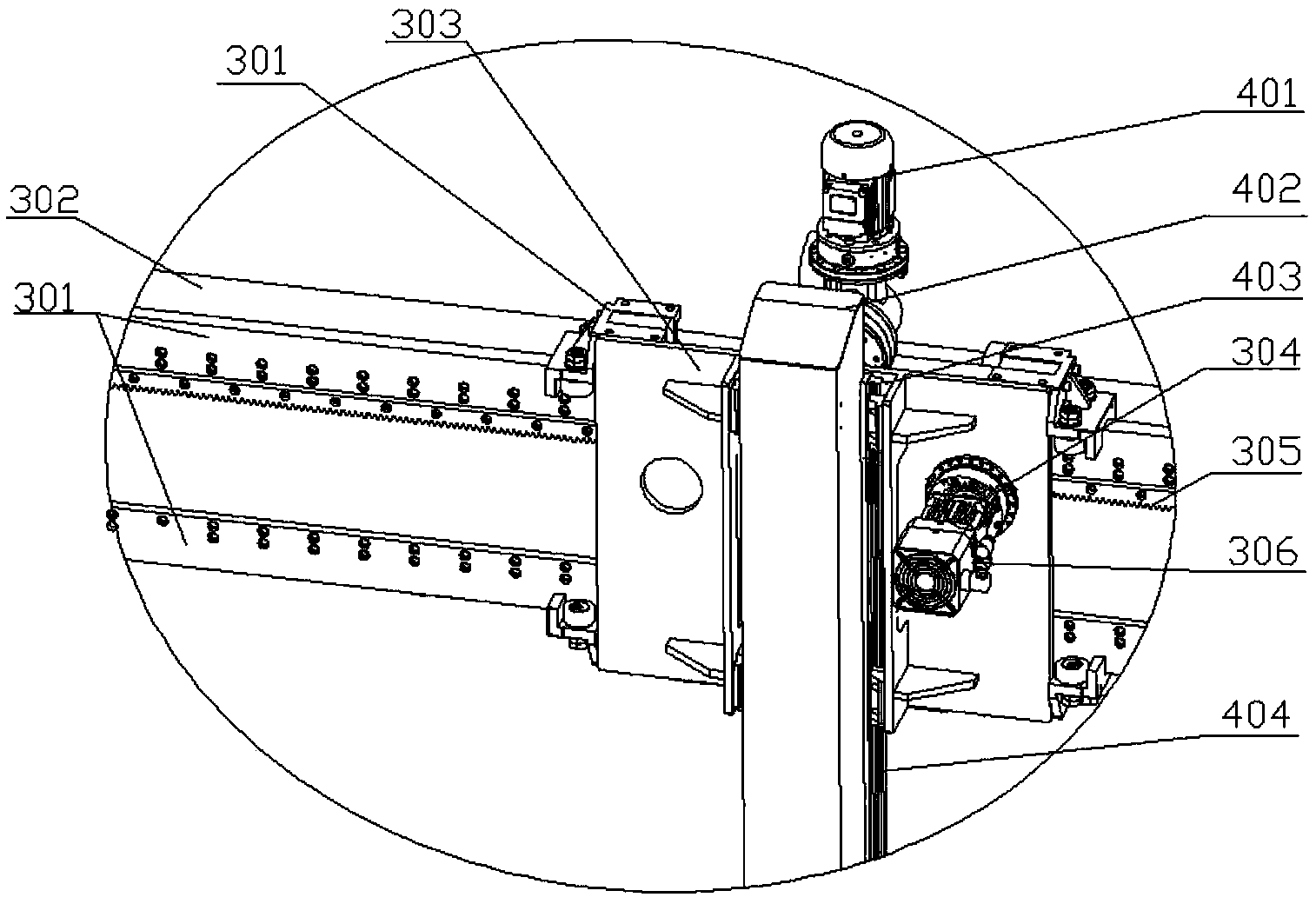

Five-axis bridge type glass stacking robot

ActiveCN104071580AReduce site space requirementsReduce automatic stackingStacking articlesDe-stacking articlesBridge typeEngineering

The invention discloses a five-axis bridge type glass stacking robot. The five-axis bridge type glass stacking robot comprises a stand fixed on the ground and a vacuum grabbing unit for grabbing glass. The glass stacking robot comprises a five-axis automatic mechanism capable of moving in five directions, the five-axis automatic mechanism is arranged at the stand, and the vacuum grabbing unit is arranged at the five-axis automatic mechanism. The five-axis bridge type glass stacking robot is capable of realizing full-automatic stacking, has low requirement for workshop space, enables the production cost to be lowered and enables the production efficiency to be improved.

Owner:CHINA TRIUMPH INT ENG

Coated slow-release urea containing double inhibitors and preparation method thereof

InactiveCN101580444ADoes not fall offHigh organic contentAgriculture gas emission reductionUrea compound fertilisersHuskNitrogen

The invention provides a method for preparing mushroom culturing material. The mushroom culturing material comprises the following compositions by weight percentage: 35 to 55 percent of cotton seed hulls, 25 to 45 percent of rice bran, 10 to 16 percent of bran, 1.5 to 2 percent of bean cakes, 0.5 to 1 percent of lees, 0.5 to 1 percent of peanut shells, 0.5 to 1 percent of gypsum, 1.5 to 2 percent of sorghum husks, 0.1 to 0.3 percent of Sanmate, 0.1 to 0.3 percent of nitrogen phospho potash complex fertilizer, 0.1 to 0.3 percent of oxygenation powder, and 0.5 to 0.8 percent of corn meal. The method comprises the following steps: combining the cotton seed hulls, the rice bran, the bran and the bean cakes together according to the proportion; pouring the mixture into a crushing mill to be crushed into particles with about 120 meshes; adding the lees, the peanut shells, the gypsum, the sorghum husks, the Sanmate, the nitrogen phsopho potash complex fertilizer, the oxygenation powder and the corn meal into the particles according to the proportion after the particles are taken out; and pouring the mixture into a mixer to be mixed for 60 minutes and taken out, adding water according to the proportion of 1:1.3-1:1.5 into the mixture to be evenly piled and fermented for 6 hours to produce a qualified culturing material.

Owner:PANJIN STRONG FERTILIZER +1

Synergistic additive for fertilizer and application of synergistic additive

InactiveCN102757283AImprove the micro-domain environmentPromote absorptionFertilizer mixturesSoil scienceTrisodium citrate

The invention provides a synergistic additive for a fertilizer and application of the synergistic additive, and relates to the synergistic technology for fertilizers, in particular to a synergistic additive for a fertilizer and application of the synergistic additive. The synergistic additive for the fertilizer comprises, by weight, from 1 to 20% of polyglutamic acid, from 1 to 10% of sodium citrate, from 10 to 30% of diatomaceous earth and from 40 to 60% of zeolite powder. The synergistic additive is a polymerized and purified substance of amino acid, can be biologically degraded into amino acid monomers to be absorbed by plants, and is free of residues and pollution, and the fertilizer produced by the synergistic additive is applicable to various crops and soils in various regions.

Owner:辽宁中科生物工程股份有限公司

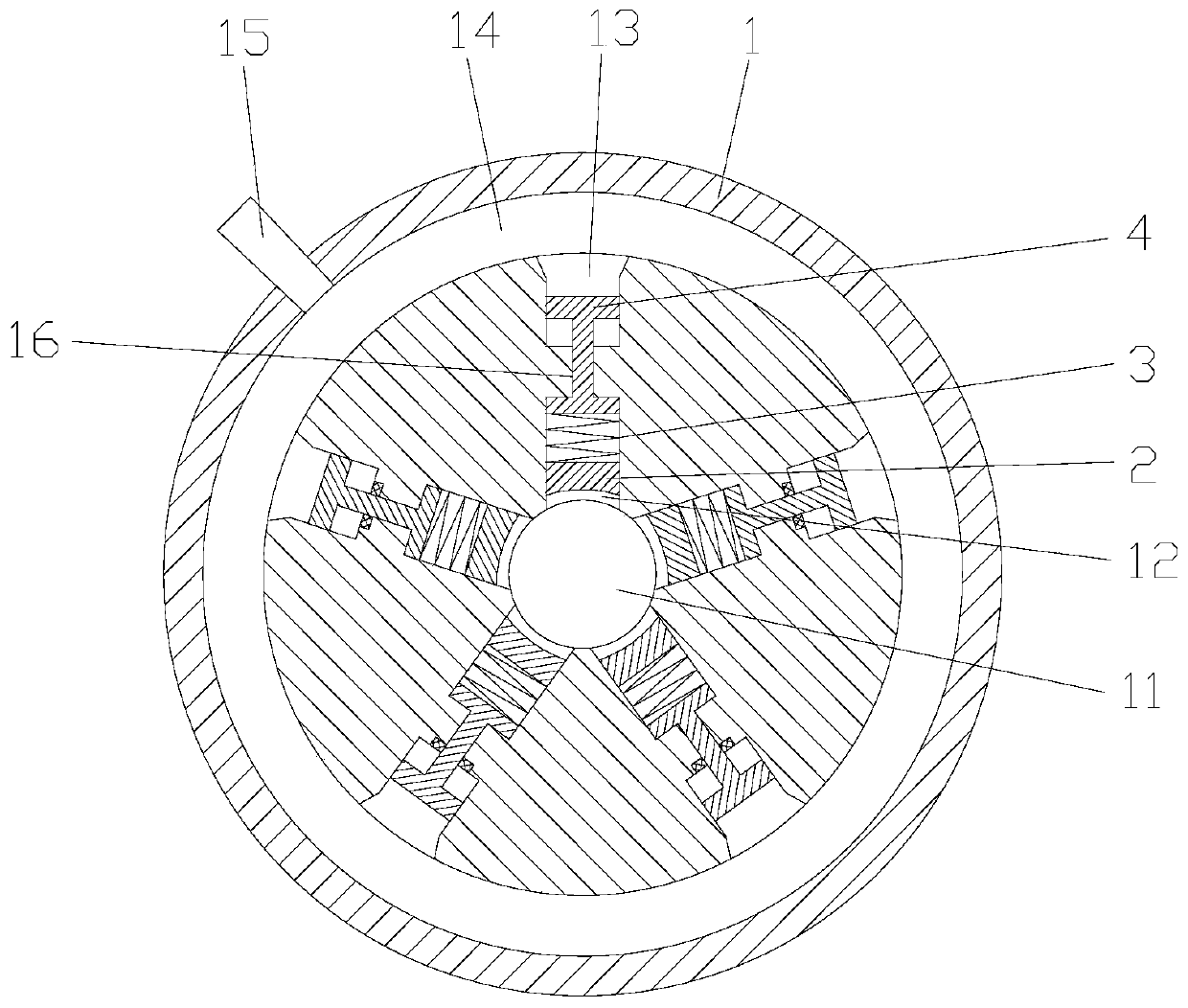

Circular-handle cutter rapid clamp

InactiveCN110142617ALarge clamping forceImprove clamping effectPositioning apparatusMetal-working holdersEngineeringAtmospheric pressure

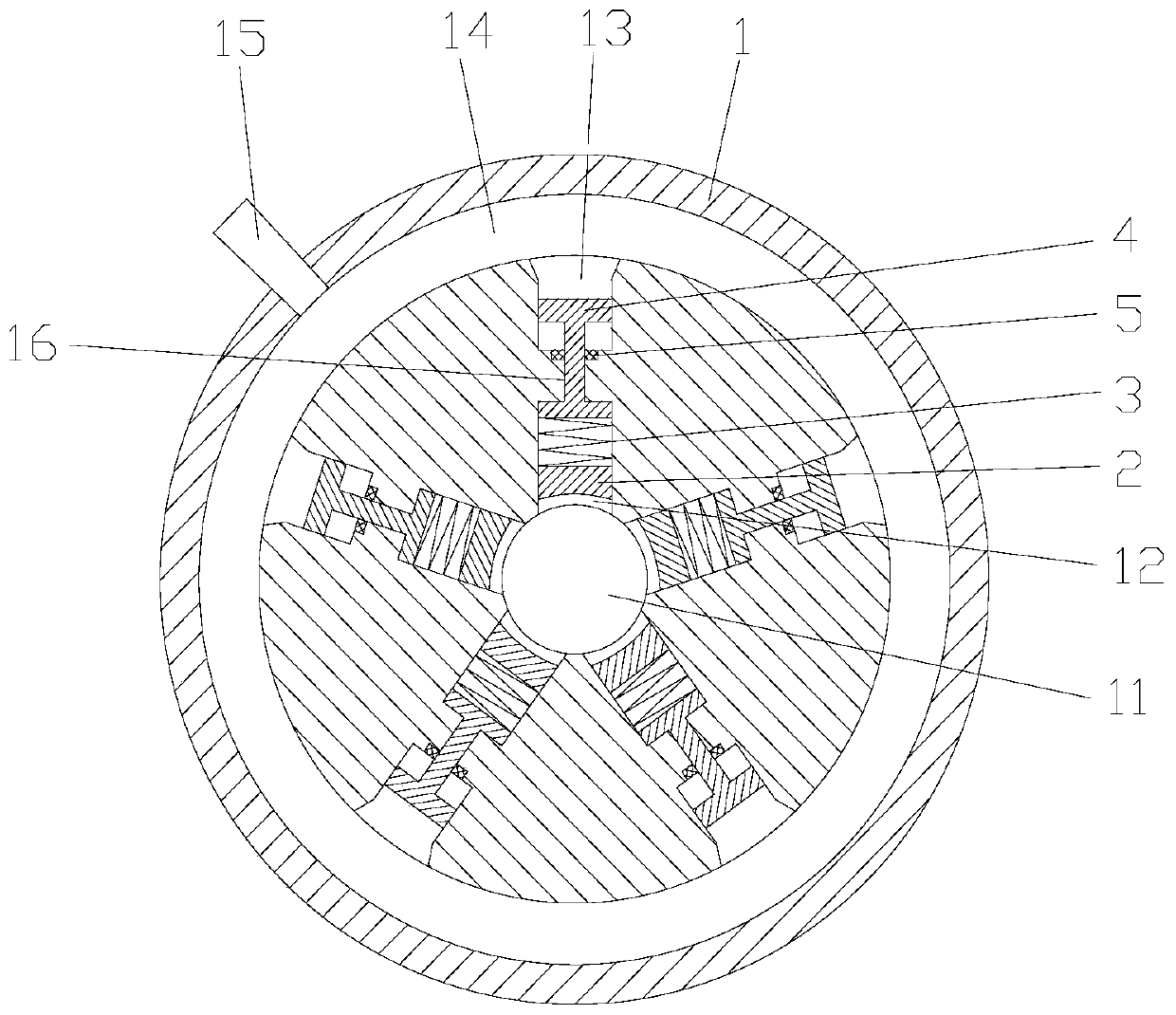

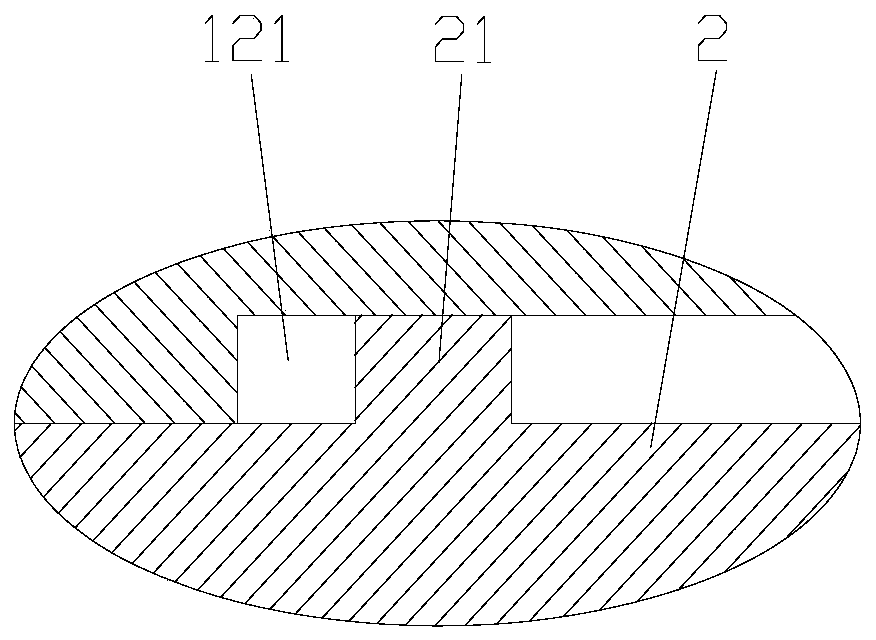

The invention relates to the technical field of mechanical clamps, in particular to a circular-handle cutter rapid clamp. The circular-handle cutter rapid clamp comprises a clamp body, a plurality ofclamping heads capable of synchronously moving are arranged on the clamp body, a clamping hole for containing a round handle cutter is formed in the middle of the clamp body, a plurality of sliding grooves in the radial direction are formed in the periphery of the clamping hole, the sliding grooves are uniformly distributed in the circumferential direction, the front ends of the sliding grooves are in communication with the clamping hole, air pressure cavities are formed in the rear sides of the sliding grooves, the axes of the air pressure cavities and the axes of the sliding grooves are in the same radial straight line, one ends of the clamping heads are correspondingly arranged in the sliding grooves and is in sliding fit with the sliding grooves, springs are arranged at the rear partsof the clamping heads in the sliding grooves, ejector rods are arranged in the air pressure cavities and are in sliding fit with the air pressure cavities, the front ends of the ejector rods extend tothe rear ends of the springs and are connected with the rear end of the springs, and an annular air pressure chamber communicating with the air pressure cavities is arranged on the clamp body corresponding to the rear parts of the air pressure cavities. The circular-handle cutter rapid clamp is high in clamping efficiency and can be applied to circular-handle cutters with different outer diameters.

Owner:常州国锐工具有限公司

Book printing production technology and book printing production line

ActiveCN110450532AImprove product qualityIncrease productivityBook making processesRotary pressesProduction linePulp and paper industry

The invention discloses a book printing production technology and a book printing production line, and relates to the technical field of book printing. The production line comprises a bookblock manufacturing assembly, a book cover manufacturing assembly and an adhesive binding machine, the bookblock manufacturing assembly comprises a bookblock printer, a folding machine and a collating machine, the collating machine is connected with the adhesive binding machine, the book cover manufacturing assembly comprises a book cover printer and a paper cutting machine, and further comprises a mark folding device connected with the paper cutting machine, the mark folding device comprises a rack and a supporting sheet, and the rack is provided with a middle seam folding assembly and an adhesive-binding face folding assembly; the middle seam folding assembly comprises a connecting plate and a pressing plate, and the connecting plate is provided with a measuring assembly; and the adhesive-binding face folding assembly comprises two indentation plates, an abutting plate is arranged at the end, away from the indentation plates, of the supporting sheet, two positioning plates are arranged on the two sides of the abutting plate, a crossbeam is fixed to the upper end of the rack and provided with a sliding groove, and the abutting plate and the pressing plate are slidably connected to the slidinggroove. Binding of bookblocks and covers is facilitated, generation of defective books is effectively reduced, and the phenomenon of waste of raw materials is reduced.

Owner:湖北金港彩印有限公司

Composite calcium-sulfonate-base lubricating grease and preparation method thereof

ActiveCN103122266ASimple processing methodEasy to operateLubricant compositionTotal Base NumberHazardous substance

The invention relates to the technical field of a composite calcium-sulfonate-base grease and preparation thereof, particularly a composite calcium-sulfonate-base lubricating grease and a preparation method thereof. The preparation method of the composite calcium-sulfonate-base lubricating grease comprises the following step: 1. respectively weighing 20-30 parts by weight of high-base-number petroleum calcium sulfonate with the total base number of 200-400 mg KOH / g, and 44-55 parts by weight of high-viscosity-index base oil with the viscosity index of 90-120. The invention has the advantages of simple technique, accessible raw materials and safe working environment, is convenient for operation, and effectively lowers the energy consumption; the product obtained by the method provided by the invention has excellent properties, and can satisfy the product index requirements without adding any additive, and thus, the production input cost of the product is lower than that of any other high temperature grease; no harmful substance is generated in the product production and use process, so the composite calcium-sulfonate-base grease is harmless to the human body; and the composite calcium-sulfonate-base grease can be recycled and reutilized to maximize the use of energy sources, thereby completely satisfying the requirements of energy saving and environmental protection.

Owner:新疆金雪驰科技股份有限公司 +1

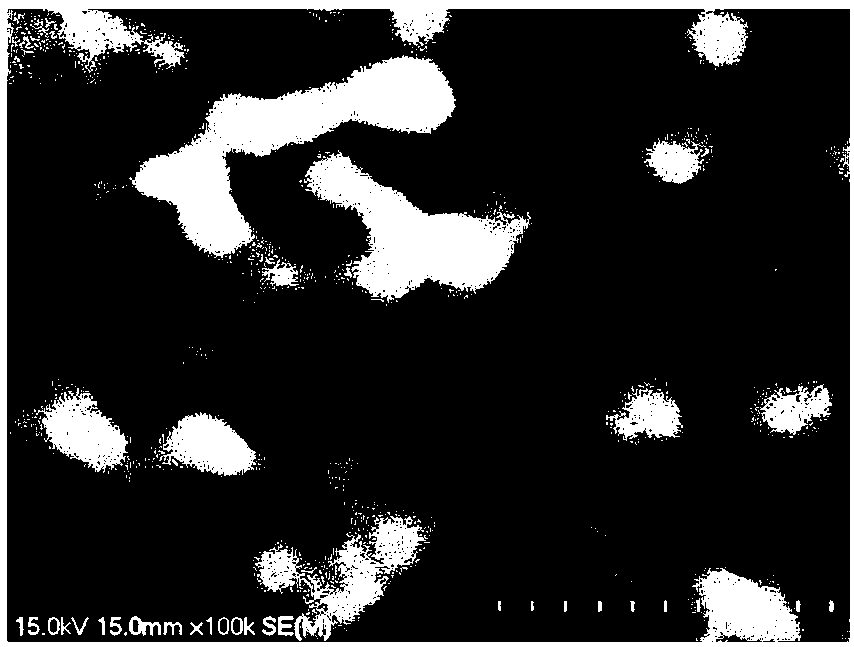

Preparation and encapsulation method of a low-temperature fast-bonding pre-sintered nano-network silver film

ActiveCN108847395AGuaranteed flexibilitySolve the shortcoming of not being able to quickly sinter large-area solder joints in a short timeSemiconductor/solid-state device manufacturingScreen printingSilver paste

The invention provides a preparation and encapsulation method of a low-temperature fast-bonding pre-sintered nano-network silver film, which comprises the following steps: S1, preparing nano-silver particles with specific size; S2, dissolving the nano-silver particles in an organic solvent, and performing chemical cutting on the nano-silver particles; S3, mechanically mixing the obtained nano silver precipitate with a binder, a dispersant and an organic solvent according to a certain proportion to obtain a nano silver paste; S4: the silver paste is printed into a film on a flexible substrate by means of steel screen printing or coating, and the pre-sintered nano-network silver film is obtained after heating. The nano-network silver film solves the problem that the traditional nano-silver solder paste can not realize the rapid preparation of large-area solder joints, and overcomes the disadvantage of poor sintering performance of silver particles in the ordinary silver film. The invention simplifies the sintering process of the nano silver solder joint, obtains good joint performance and no solder residue, the process is green and environmentally friendly, and can be used as the interconnecting material of a new generation of large-size and high-power chip packaging.

Owner:深圳市先进连接科技有限公司

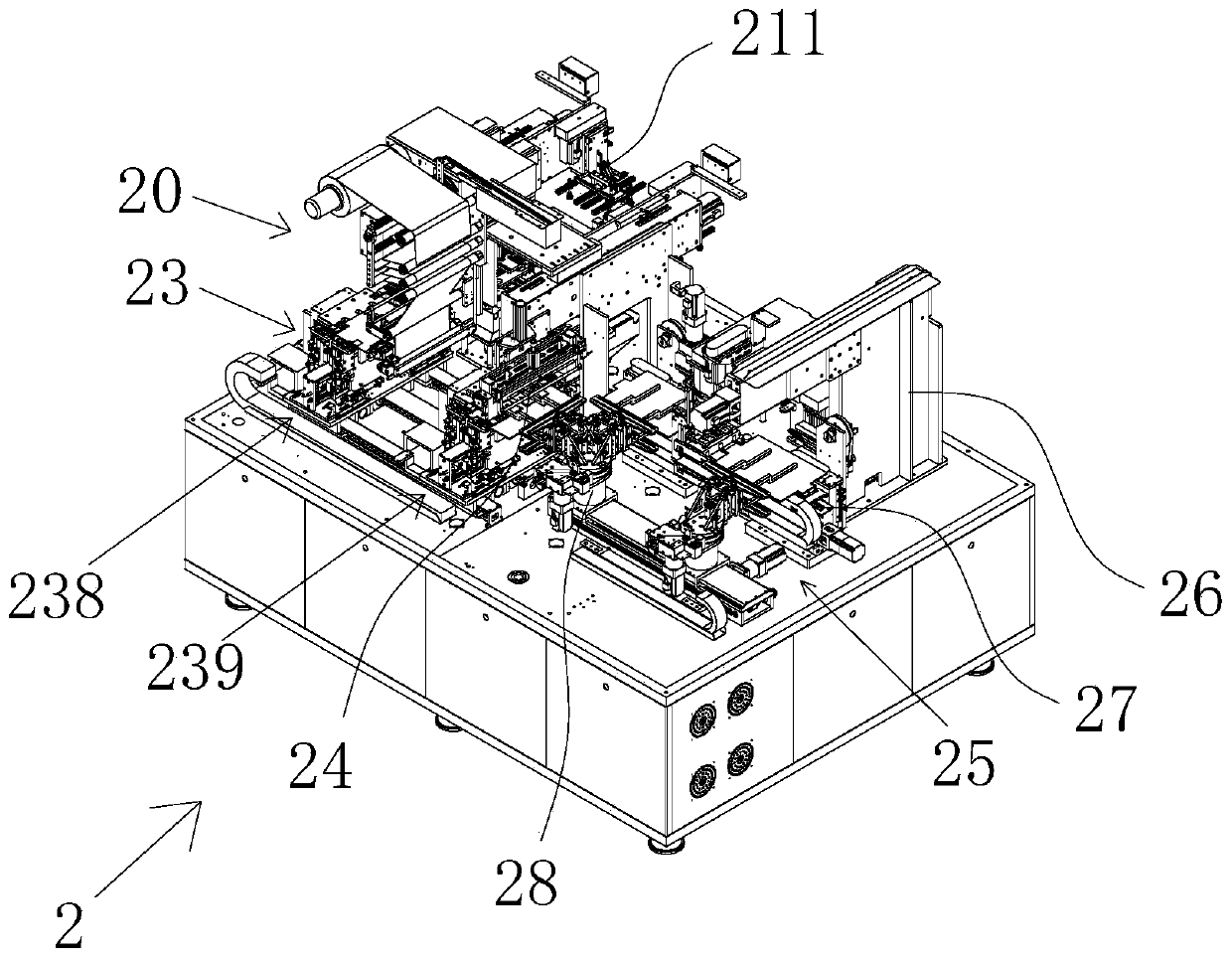

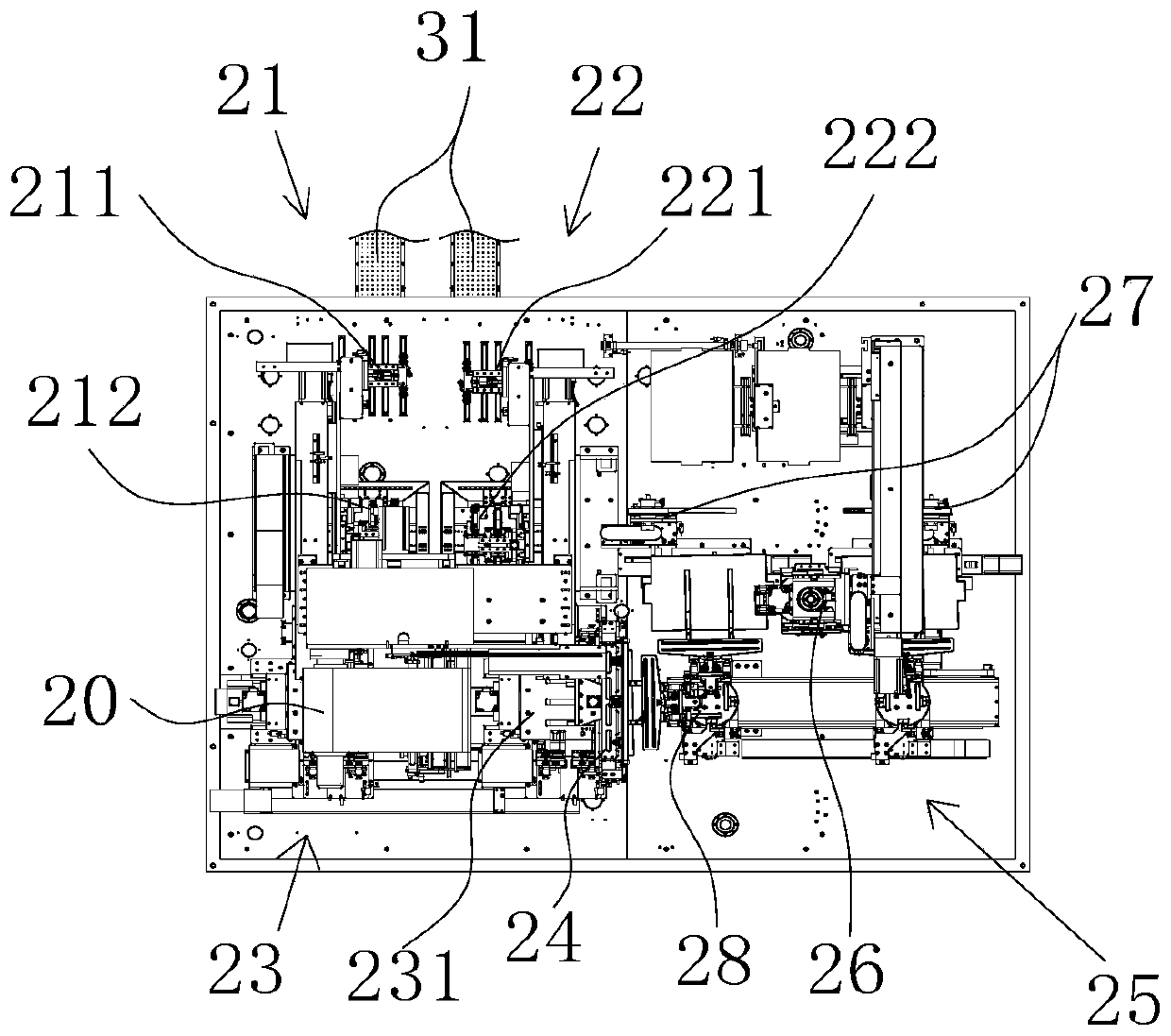

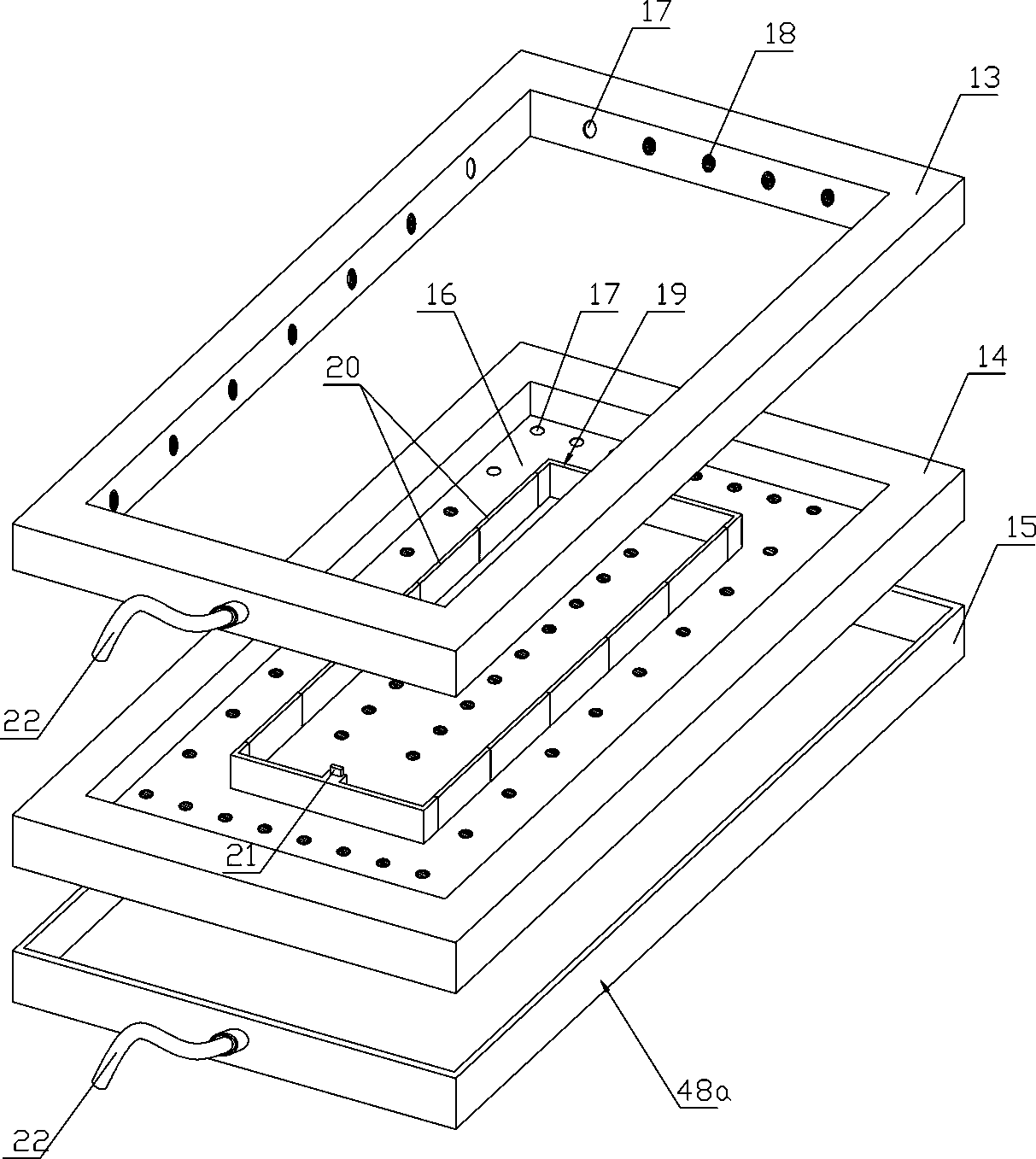

Laminating device and integrated die laminating device

PendingCN110492181AQuality improvementReduce defective rateFinal product manufactureSecondary cellsUltimate tensile strengthMechanical engineering

The invention discloses a laminating device. The laminating device comprises a diaphragm conveying mechanism for discharging and conveying rolled diaphragms; a positive electrode feeding mechanism which is used for continuously conveying single positive electrode plates; a negative electrode feeding mechanism which is used for continuously conveying single negative electrode plates; a laminating mechanism which reciprocates between the positive electrode feeding mechanism and the negative electrode feeding mechanism and receives the diaphragms, the positive electrode plates and the negative electrode plates, so that the diaphragms are pressed on the laminating mechanism and then move along with the laminating mechanism to form a Z-shaped diaphragm, wherein the positive electrode plates andthe negative electrode plates are alternately laminated on the Z-shaped diaphragm to form a Z-shaped laminated sheet; a diaphragm cutting mechanism which is used for cutting off the diaphragm supplyof the diaphragm conveying mechanism to the laminating mechanism after the laminating mechanism finishes laminating; and a rubberizing mechanism which is used for rubberizing the Z-shaped laminated sheet to form a battery cell. The defects of low speed and high labor intensity of manual feeding are overcome, the production cost is reduced, the lamination efficiency is improved, and modern automatic production integrated with die cutting and lamination is realized.

Owner:哈工大机器人(中山)无人装备与人工智能研究院

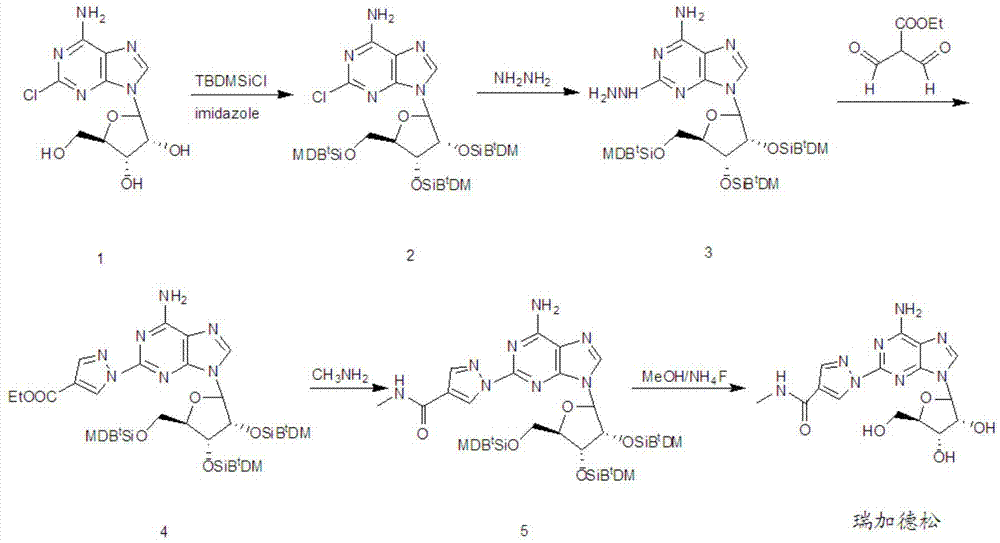

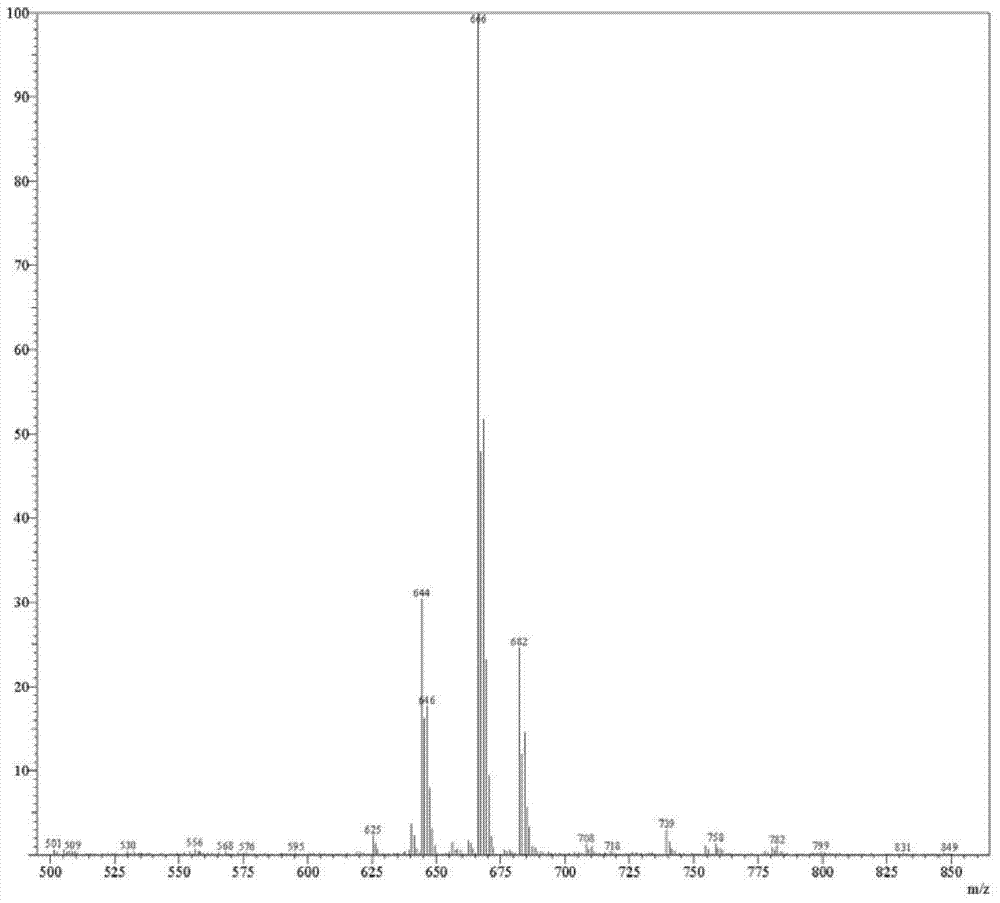

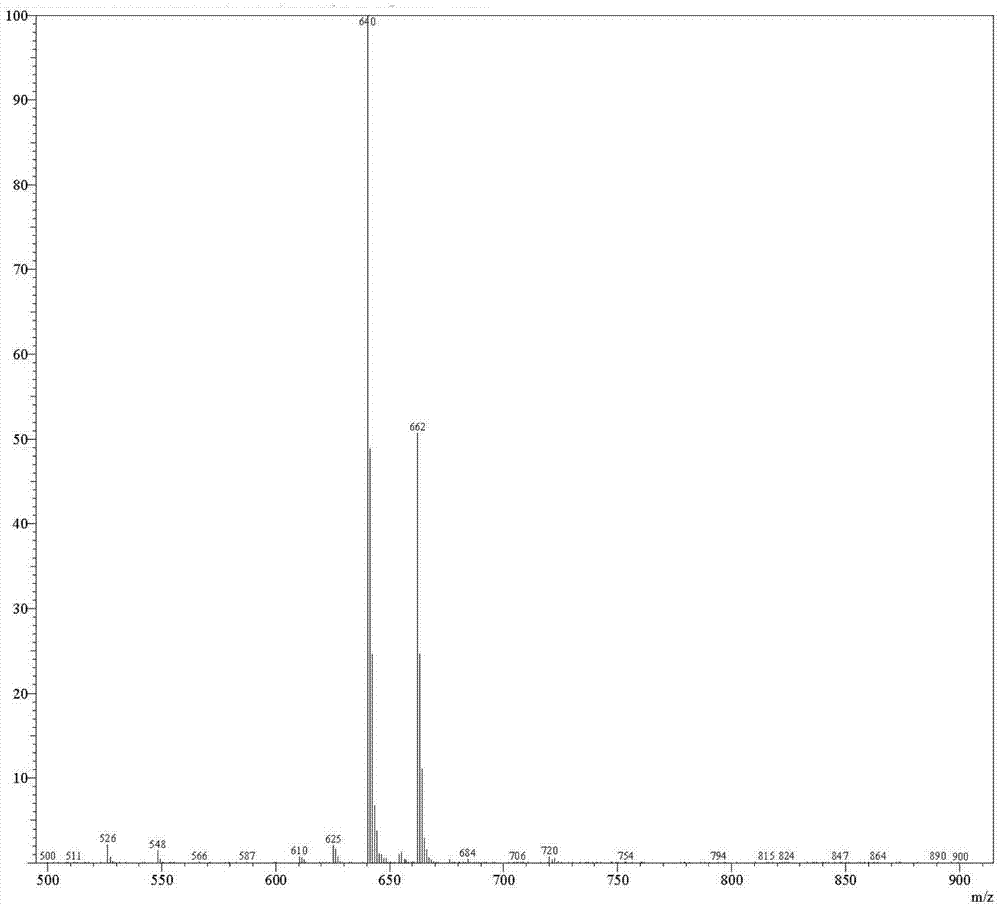

Preparation method for regadenoson

InactiveCN104744540AHigh purityFew reaction stepsSugar derivativesSugar derivatives preparationCarboxylic acidOxygen

The invention discloses a preparation method for regadenoson, belonging to the field of pharmaceutical chemistry. The preparation method for regadenoson comprises the following steps: with a compound as shown in a formula III as a reaction raw material, subjecting the compound and 2-formyl-3-oxoethyl propanoate to a cyclization reaction in isopropanol so as to produce a compound as shown in a formula IV; then with the compound as shown in the formula IV as a substrate, subjecting the substrate and a methanol solution of methylamine to an acylation reaction so as to produce a compound as shown in a formula V; and reacting the compound as shown in the formula V with tetrabutyl ammonium fluoride in a methanol solution to remove hydroxyl protection so as to prepare regadenoson. According to the preparation method in the invention, the methanol solution of methylamine is used as a reaction medium and reagent, a methanamide compound is produced through one-step reaction under normal pressure, and the acylation reaction is carried out without hydrolysis for formation of a carboxylic acid derivative; thus, reaction steps are reduced, high pressure reaction equipment is not used, cost for production input is lowered, the safety factor of production is increased, and the method is more applicable to large scale production.

Owner:SHANGHAI ZIYUAN PHARMA

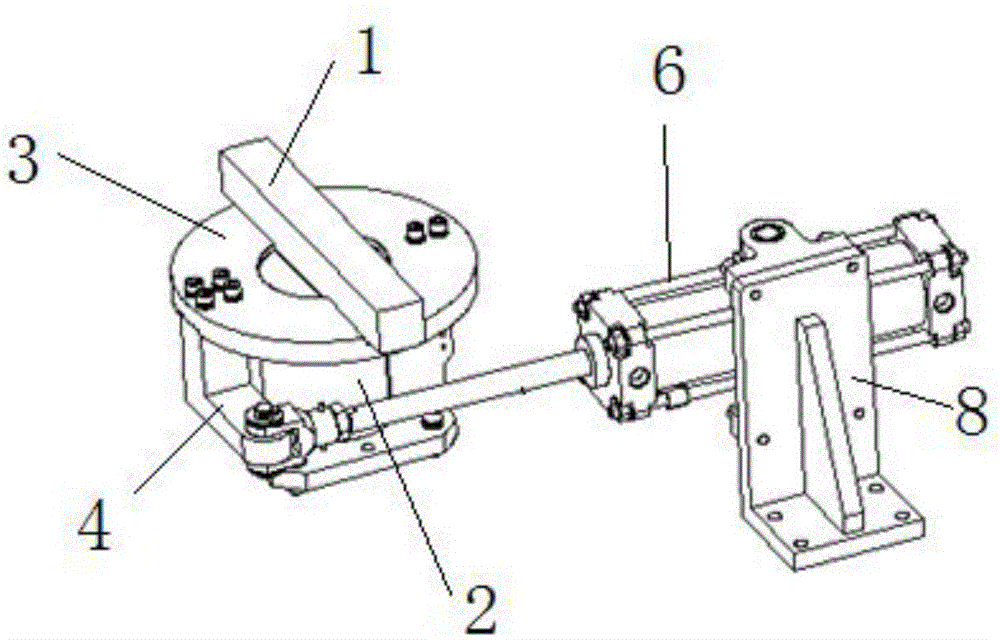

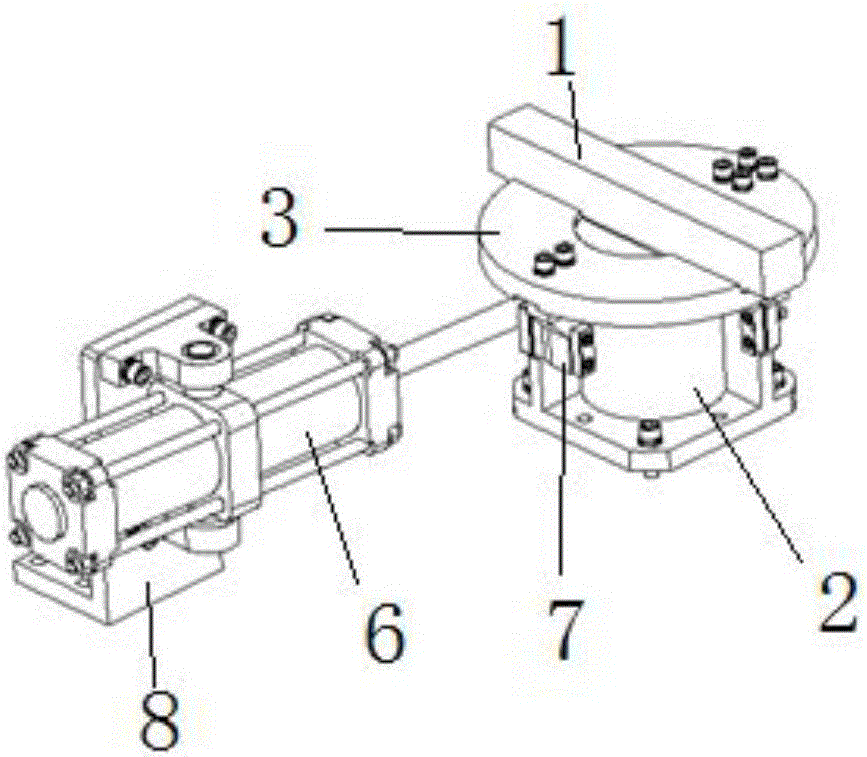

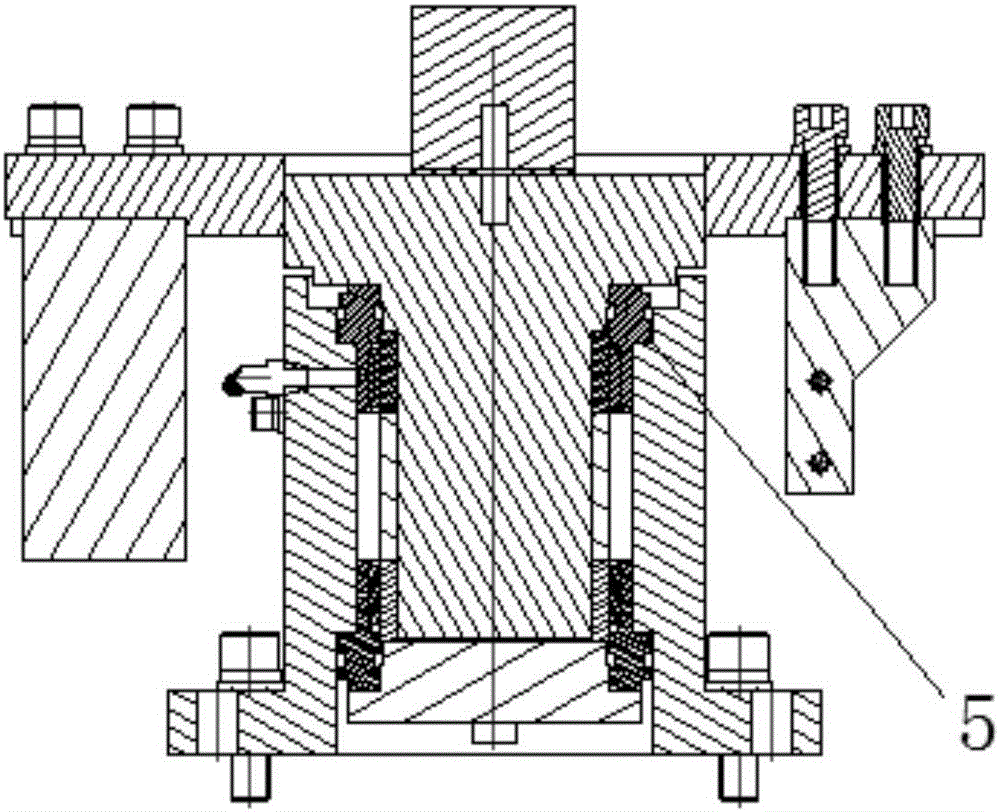

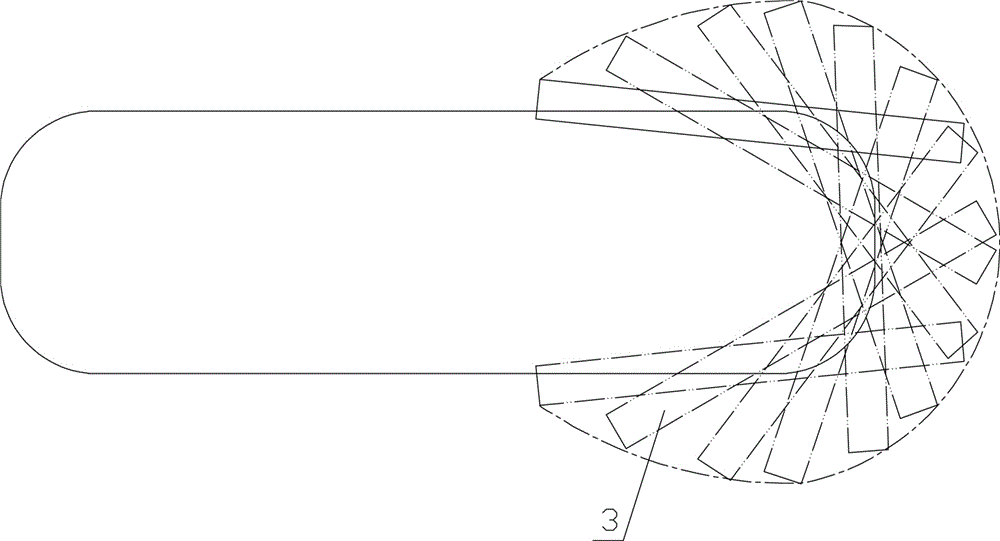

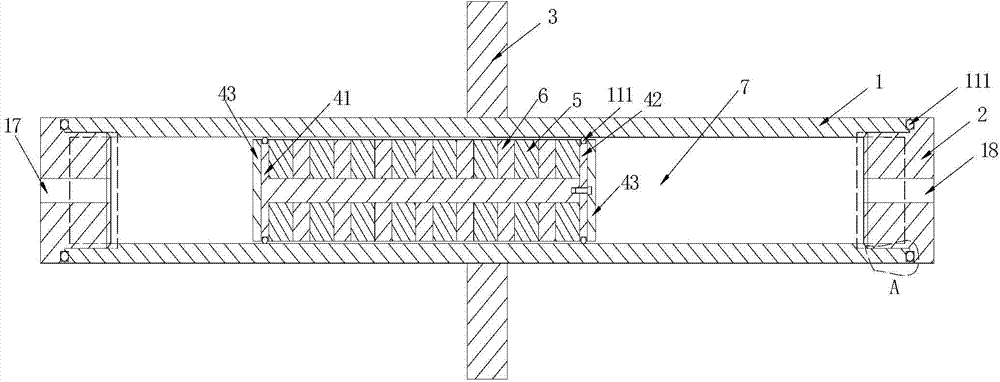

Switching mechanism for butt-jointing crossing rails and switching method thereof

The invention discloses a switching mechanism for butt-jointing crossing rails. The switching mechanism comprises a rail arm and a rail arm support mechanism for driving the rail arm to rotate, wherein the rail arm support mechanism is connected with a hauling mechanism. A switching method of the switching mechanism comprises the following steps: setting the switching mechanism for butt-jointing crossing rails at an intersection of horizontal and longitudinal transportation rails; filling rail sections of the horizontal and longitudinal transportation rails on the rail arm of the switching mechanism shaft plate; while switching the transportation direction of the transportation rails, stretching a cylinder piston rod so as to drive a bent arm to move, thereby driving the shaft plate to rotate on a shaft base and realizing the transportation direction switching of the transportation rails. The switching mechanism and the switching method provided by the invention have the advantages that the device can change the moving direction at the intersection of the rails through the rotating function of the switching mechanism, the device can be shifted to a storage position from a working position, the rails can reciprocate and rotate under the driving of the stretching of the cylinder and the accurate butt joint of the rotating rails and two crossing rails can be guaranteed through the positioning of a limiting block.

Owner:ANHUI RUIXIANG IND

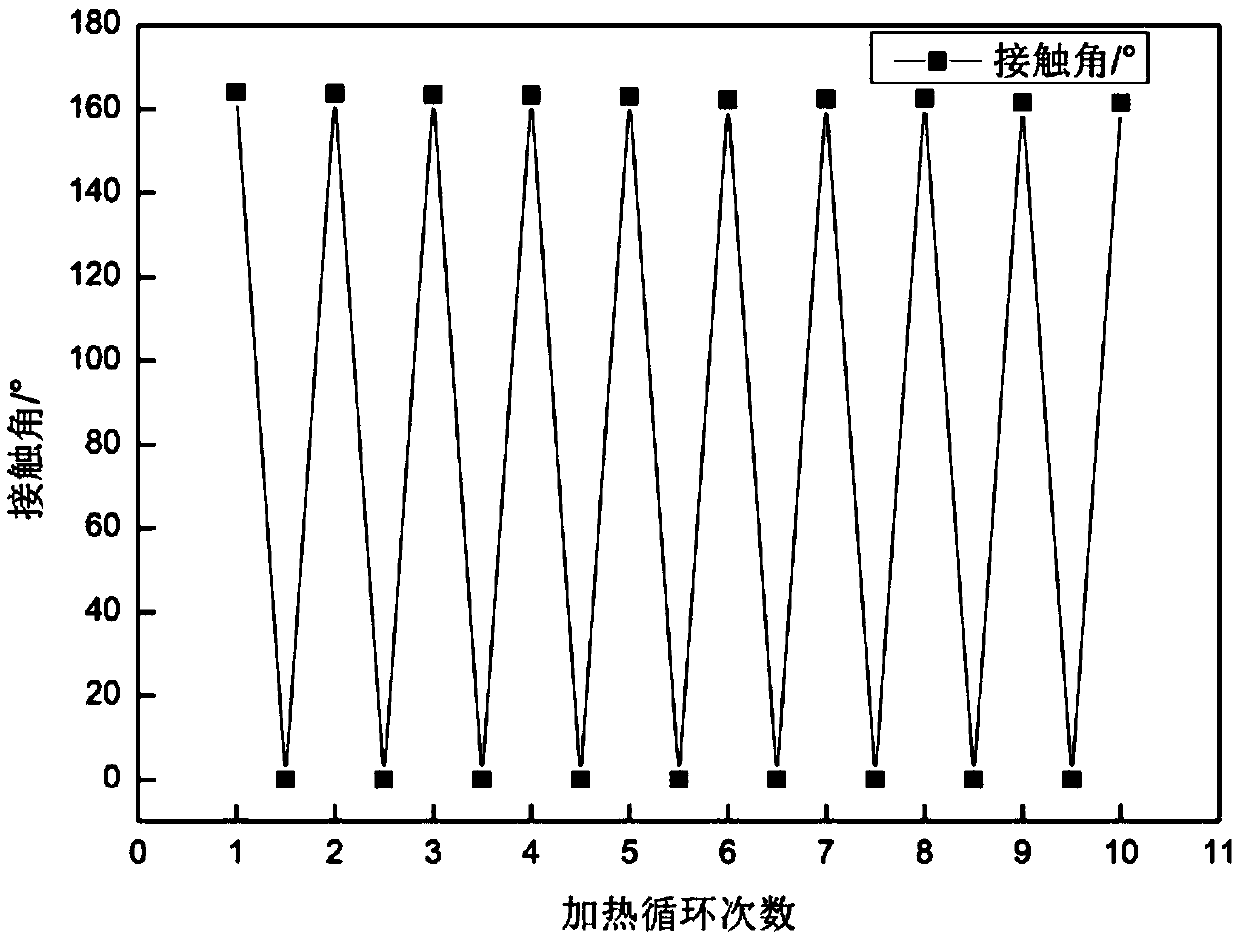

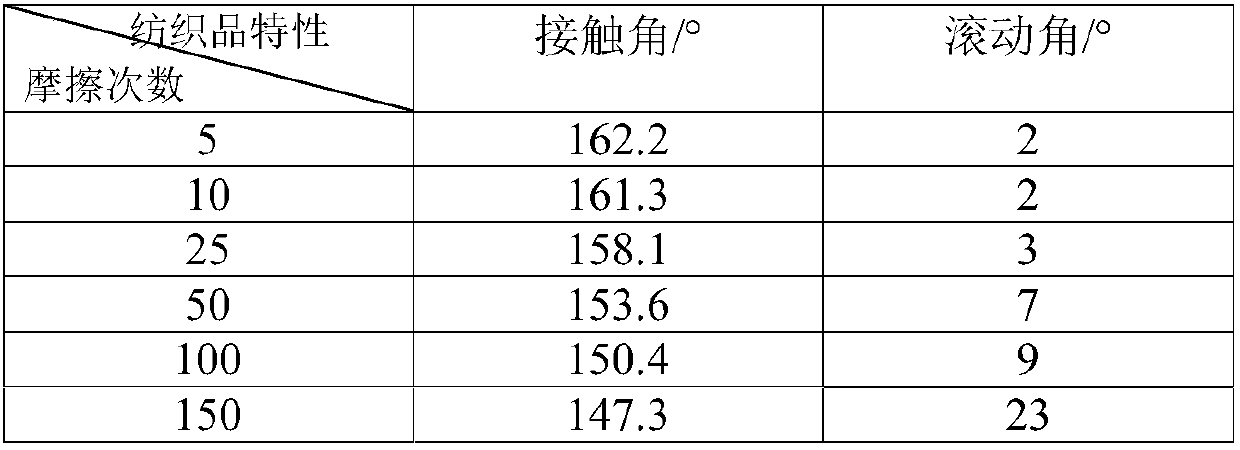

Preparation method of temperature-responsive self-repairing super-hydrophobic fabric

ActiveCN109576997AWith temperature responseMeet the requirements of superhydrophobicityLiquid repellent fibresPolymer scienceCotton cloth

The invention discloses a preparation method of a temperature-responsive self-repairing super-hydrophobic fabric, and belongs to the field of super-hydrophobic fabrics. In the method, dopamine hydrochloride and tris(hydroxymethyl)aminomethane are adopted to prepare a bionic polydopamine solution, the high adhesion, namely, the role of double-faced adhesive tape of the polydopamine is utilized to make polycarbonate firmly adhere to the fabric surface, a good rough structure is constructed on fabric cotton cloth as polycarbonate can swell in paraxylene, then low-surface-energy substances octadecylamine and 1-dodecanethiol are adopted to modify the fabric surface, and the temperature-responsive self-repairing super-hydrophobic fabric is obtained. Tests show that the fabric still can meet thesuper-hydrophobicity requirement after being subjected to 100 times of fabrication and 30 times of washing, the fabric has no super-hydrophobic property when wetted by water, but the super-hydrophobicproperty of the fabric can be restored after the fabric is dried for 80 min at 60 DEG C, and thus conversion between a super-hydrophobic fabric and a non-super-hydrophobic fabric is realized.

Owner:厦门市北顶纺织科技有限公司

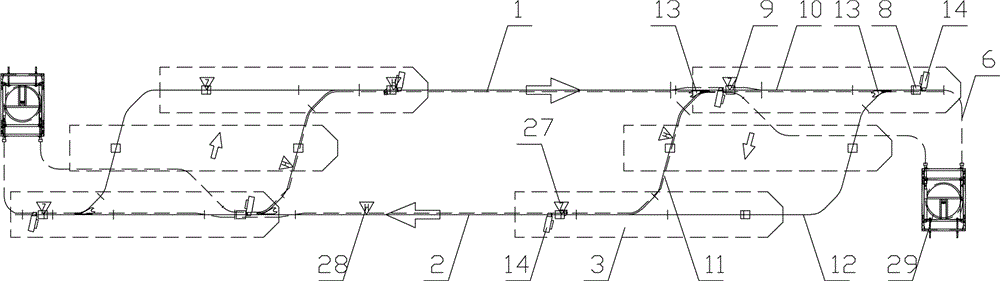

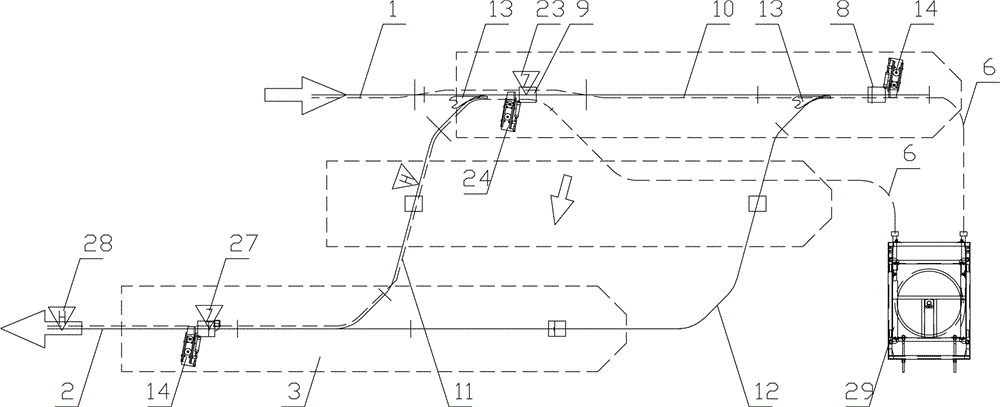

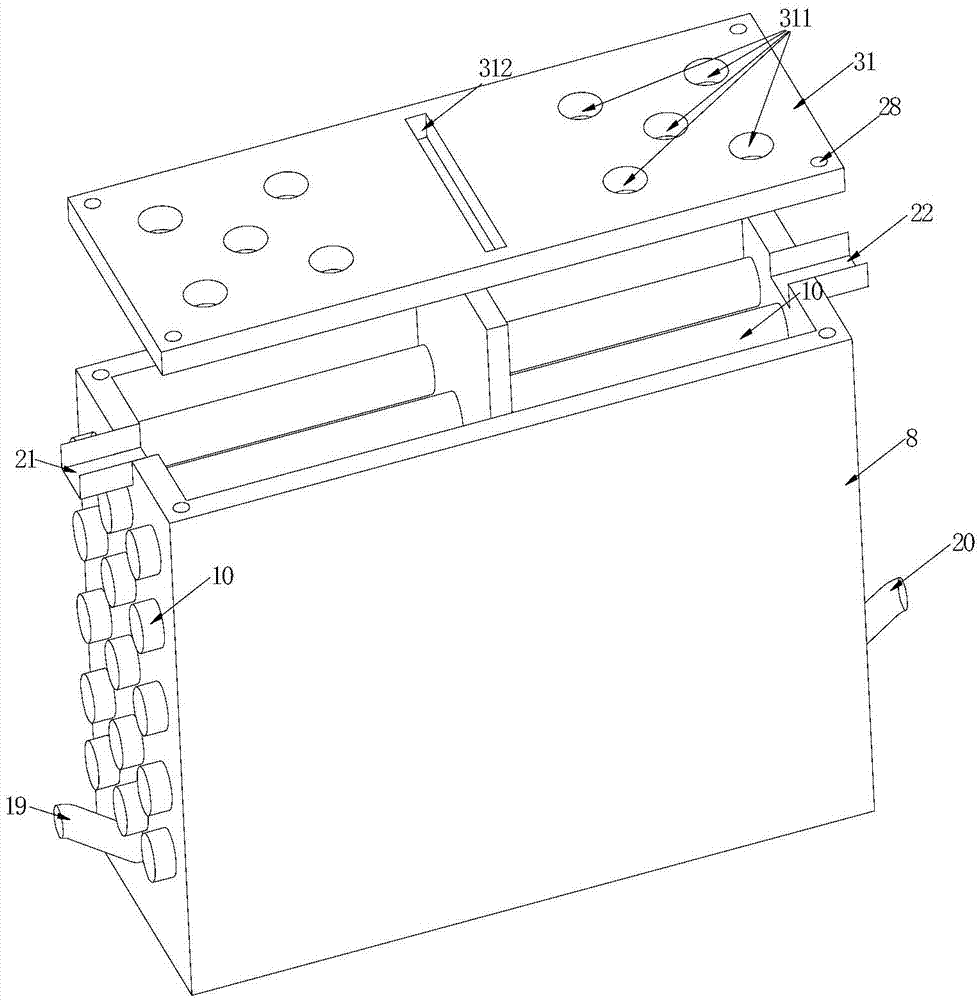

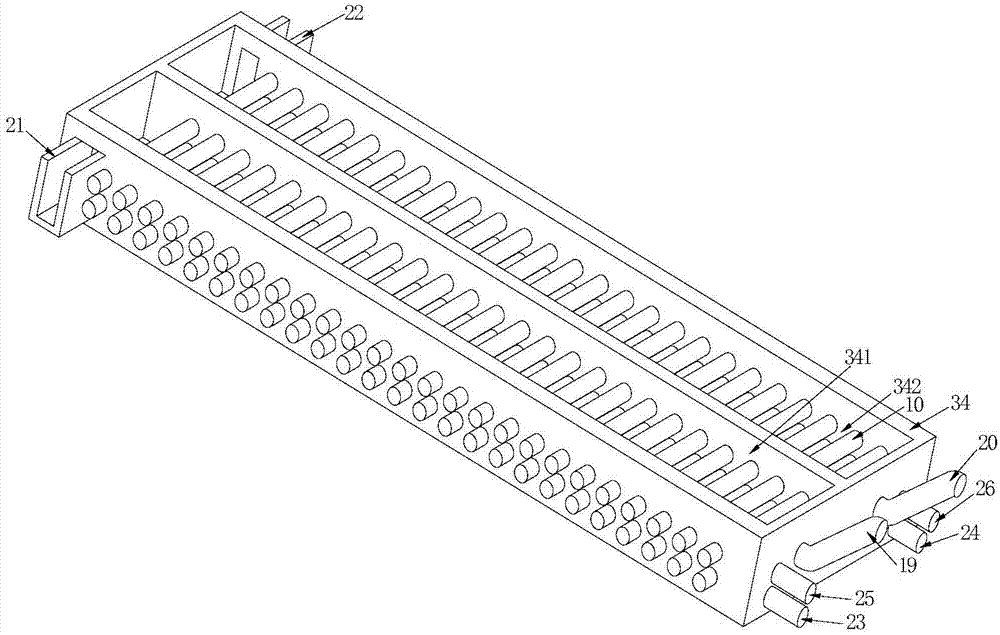

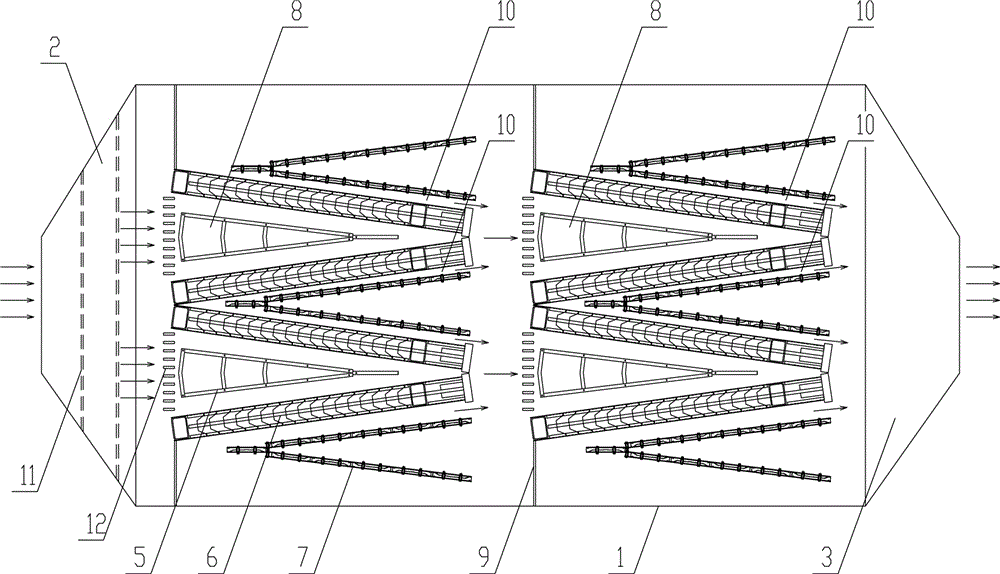

Heavy-load power and free chain conveying system used for conveying big long workpieces

ActiveCN106516612ASmall footprintShorten the horizontal lengthMechanical conveyorsButt jointEngineering

A heavy-load power and free chain conveying system used for conveying big long workpieces comprises a conveying track and multiple heavy-load vehicle groups. The conveying track comprises at least two conveying track bodies arranged in parallel in a linear manner and transverse translation track groups arranged at the ends of the adjacent conveying track bodies arranged in the linear manner. Each transverse translation track group is of a square structure formed by a reversing rail, a cross traction rail, a turnout and a cross traction-free rail. The reversing rail is in butt joint with one of the conveying rail bodies arranged in the linear manner. Each turnout is formed by the corresponding reversing rail, one end of the corresponding transverse traction rail and one end of the corresponding traction-free rail. A turnout tongue is mounted at each of the two turnouts. The other end of the corresponding transverse traction rail and the other end of the transverse traction-free rail are in butt joint with the other adjacent conveying rail body arranged in the linear manner. By the adoption of the heavy-load power and free chain conveying system, the purpose that a heavy-load vehicle group conducts transverse translation between the two adjacent linear conveying track bodies is achieved, and the space occupied when the big long workpieces turn around and rotate is reduced, so that the transverse length of an industrial plant is reduced, and the production input cost is lowered.

Owner:HUBEI SANFENG INTELLIGENT CONVEYING EQUIP

Magnetic rod with movable magnets and iron removal device applying magnetic rod

InactiveCN103657846ASimple structureStrong magnetismHigh gradient magnetic separatorsInlet channelIron removal

The invention discloses a magnetic rod with movable magnets. The magnetic rod is characterized by comprising a shell part and a piston part, wherein a magnetic rod piston cavity is formed in the shell part and is a columnar space, one end of the magnetic rod piston cavity is communicated with a first air inlet channel, and the other end of the magnetic rod piston cavity is communicated with a second air inlet channel; the piston part comprises a plurality of permanent magnets, a plurality of concentrating flux plates and connecting pieces used for connecting the permanent magnets with the concentrating flux plates; the two adjacent permanent magnets are distributed in a manner that like poles repel, and each concentrating flux plate is arranged between the two adjacent permanent magnets; the piston part is arranged in the magnetic rod piston cavity, is in leak-proof fit with the magnetic rod piston cavity and does a straight reciprocating motion in the magnetic rod piston cavity. The magnetic rod with movable magnetic regions disclosed by the invention is simple in structure. The iron removal device applying the magnetic rod achieves continuous iron removal of slurry and powder, and is simpler in structure, longer in service life and high in iron removal efficiency.

Owner:廖明勇

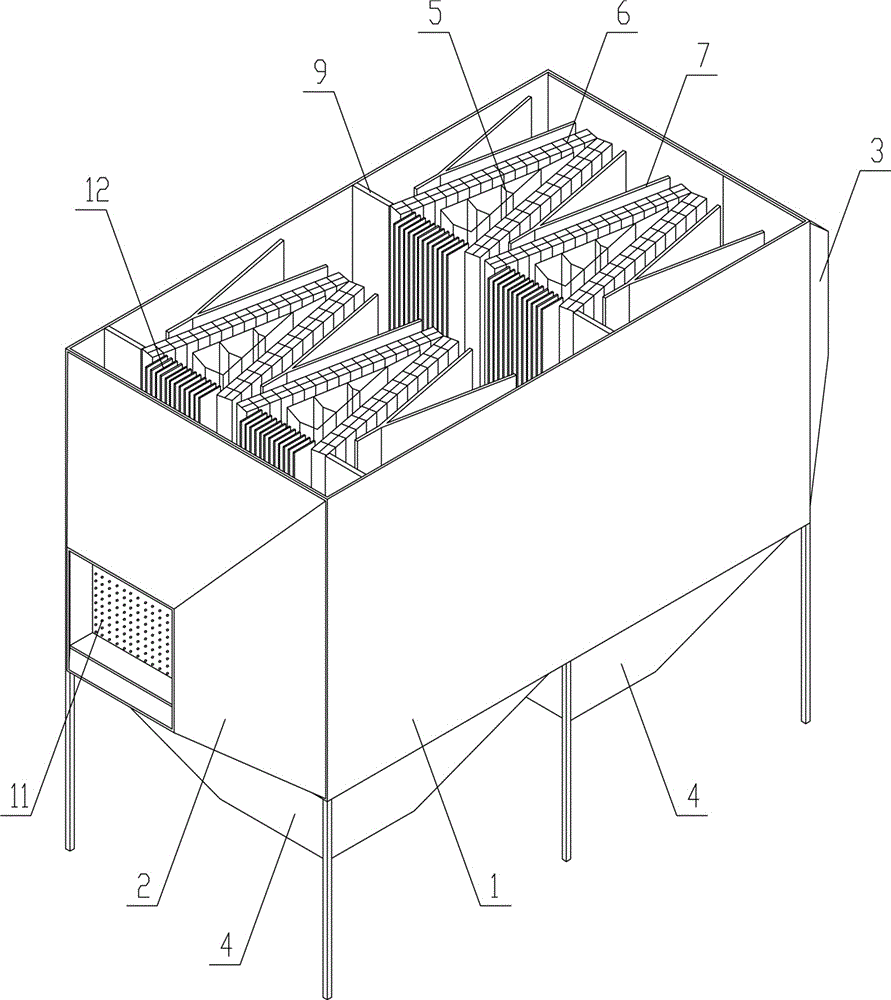

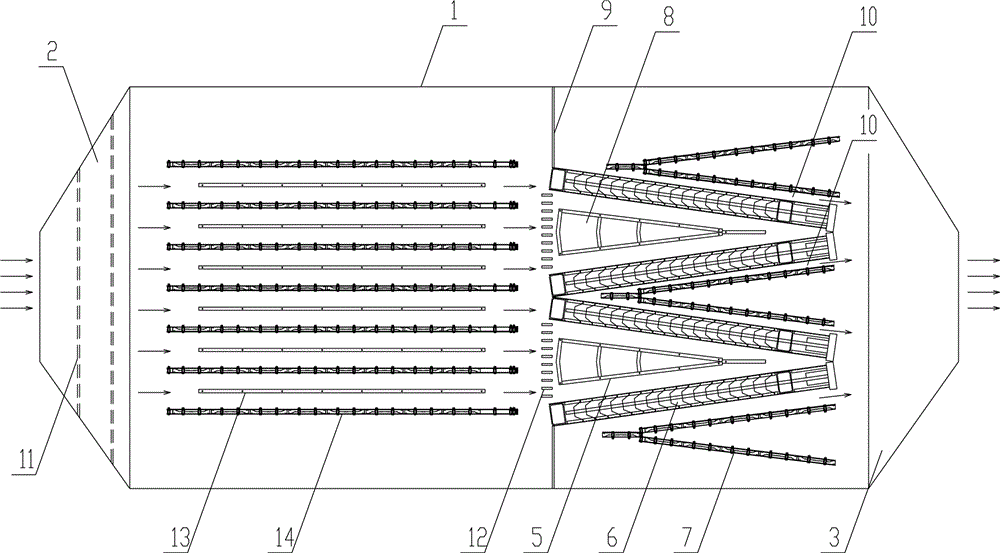

Efficient electrostatic dust collector

ActiveCN105689140ASmall footprintReduce flow rateParticle charging/ionising stationsFlue gasEngineering

The invention discloses an efficient electrostatic dust collector which comprises a dust collector body, an inlet seal, an outlet seal and an ash collection hopper. A plurality of sets of electric field structures are distributed on the dust collector body from the inlet end to the outlet end. Each set of electric field structure comprises a plurality of sets of three-electrode breeze dedusting units distributed side by side. Each set of three-electrode breeze dedusting unit is composed of a cathode suspension rack, a left shutter polar plate, a right shutter polar plate, a left anode plate and a right anode plate, wherein the anode plates, the shutter polar plates and the cathode suspension rack form a two-stage electric field structure; in each set of three-electrode breeze dedusting unit, an air flue inlet is formed between the left shutter polar plate and the right shutter polar plate; the ends, facing the outlet side of the dust collector body, of the left shutter polar plate and the right shutter polar plate are connected with each other; and an air flue outlet is formed between each shutter polar plate and the corresponding anode plate adjacent to the shutter polar plate. The efficient electrostatic dust collector is small in size and low in production input cost, the flow velocity of dust-contained flue gas is greatly decreased, the dust duration time is prolonged, the dust deposition effect is enhanced, and the dust collection efficiency is effectively improved.

Owner:HUBEI QIANGDA ENVIRONMENTAL PROTECTION TECH CO LTD

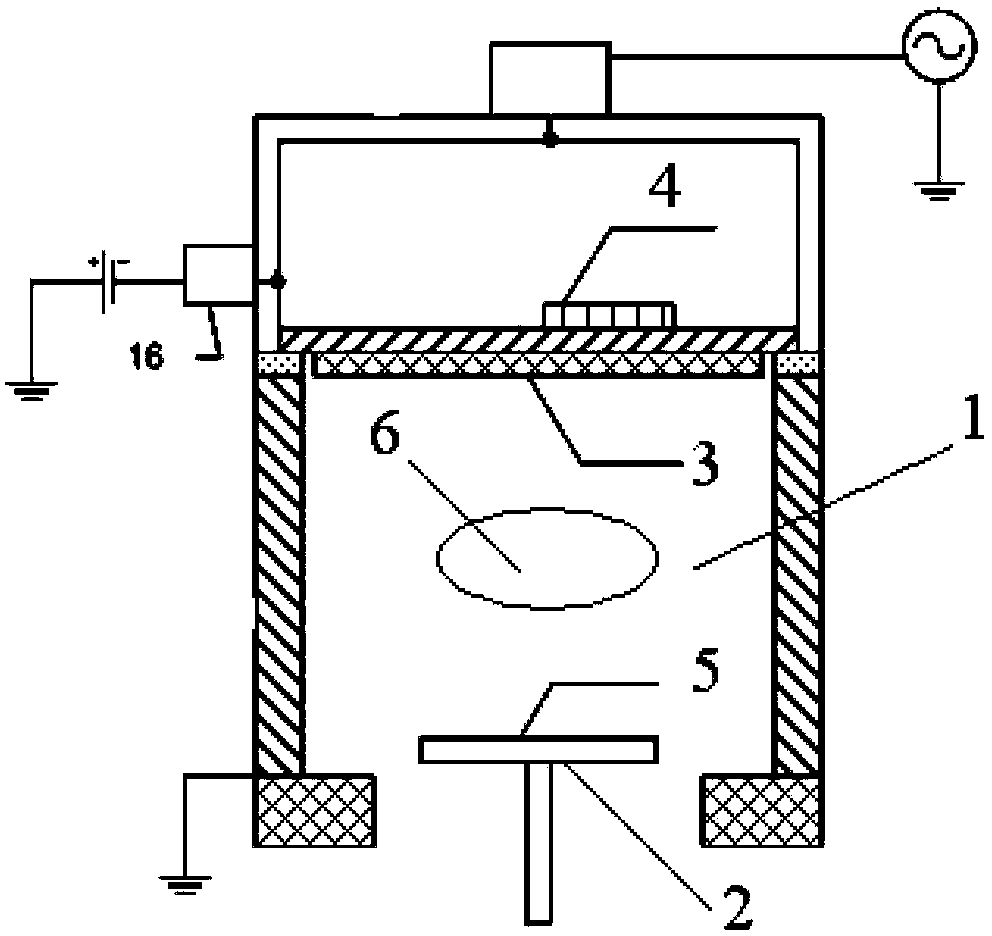

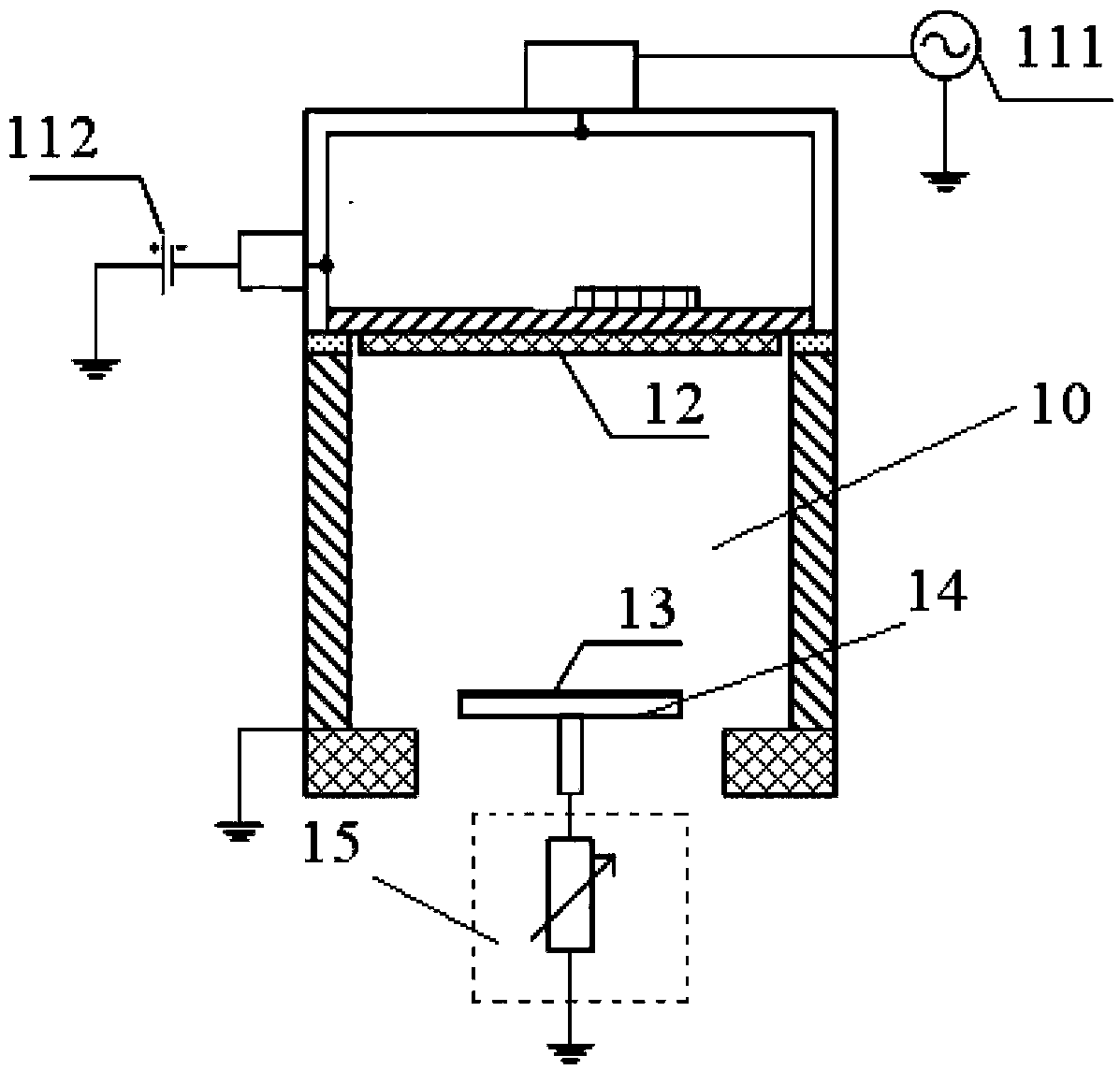

Magnetron sputtering equipment and method

ActiveCN104164653APrevent peelingSolve peelingVacuum evaporation coatingSputtering coatingBack biasSputter deposition

The invention provides magnetron sputtering equipment and method. The equipment and method are used for bombarding a thin film layer surface deposited on a machined workpiece surface after magnetron sputtering deposition, and therefore the thin film layer surface is made to be roughened. The magnetron sputtering equipment comprises a reaction cavity, a sputtering power source, a base, a target material, a bombardment gas source and a bias voltage unit, the sputtering power source is electrically connected with the target material, and is used for outputting sputtering power to the target material, and after magnetron sputtering deposition is completed, the bombardment gas source is used for leading bombardment gas which does not react with a thin film deposited on the machined workpiece surface into the reaction cavity, and the bombardment gas is excited by the bias voltage unit and / or the sputtering power source to form plasmas. The bias voltage unit is used for loading back bias voltages to the base so as to enable the plasmas to bombard the thin film surface, formed after magnetron sputtering deposition, of a machined workpiece. The magnetron sputtering equipment can solve the metal electrode layer peeling problem, the production investment cost is low, and the original technological process can be kept basically unchangeable.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

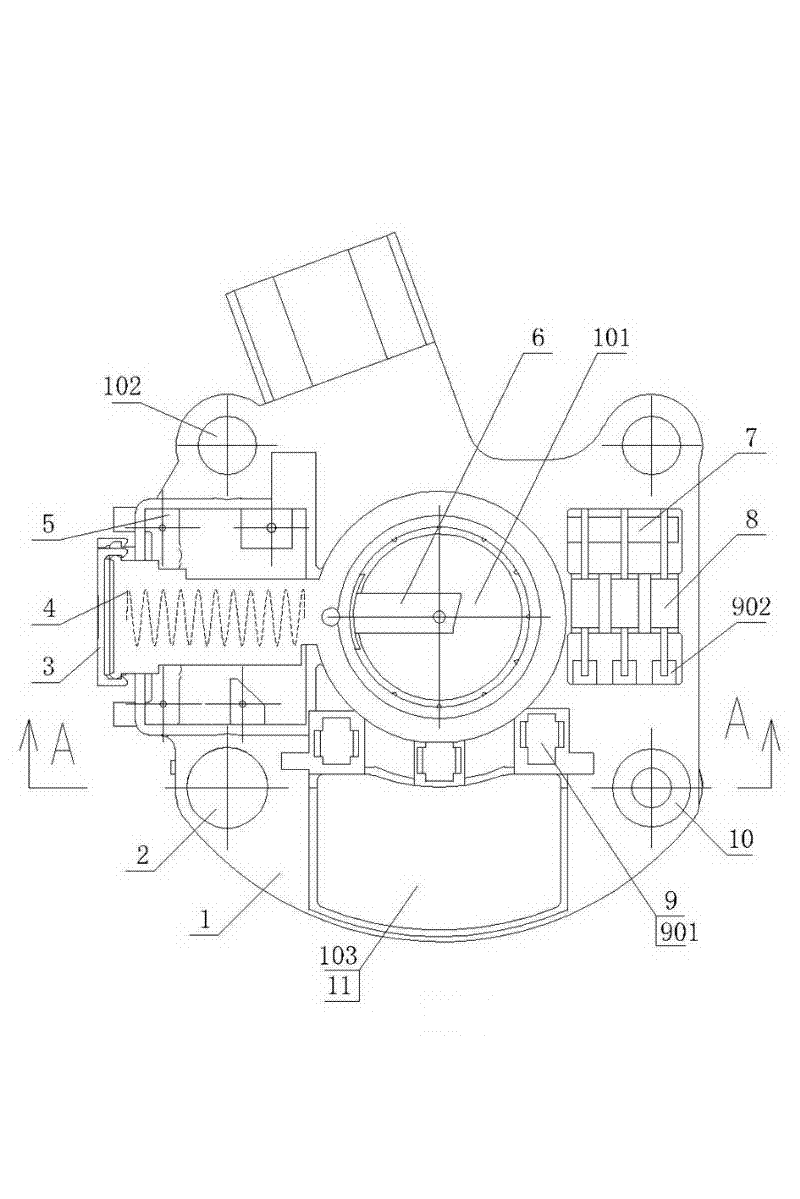

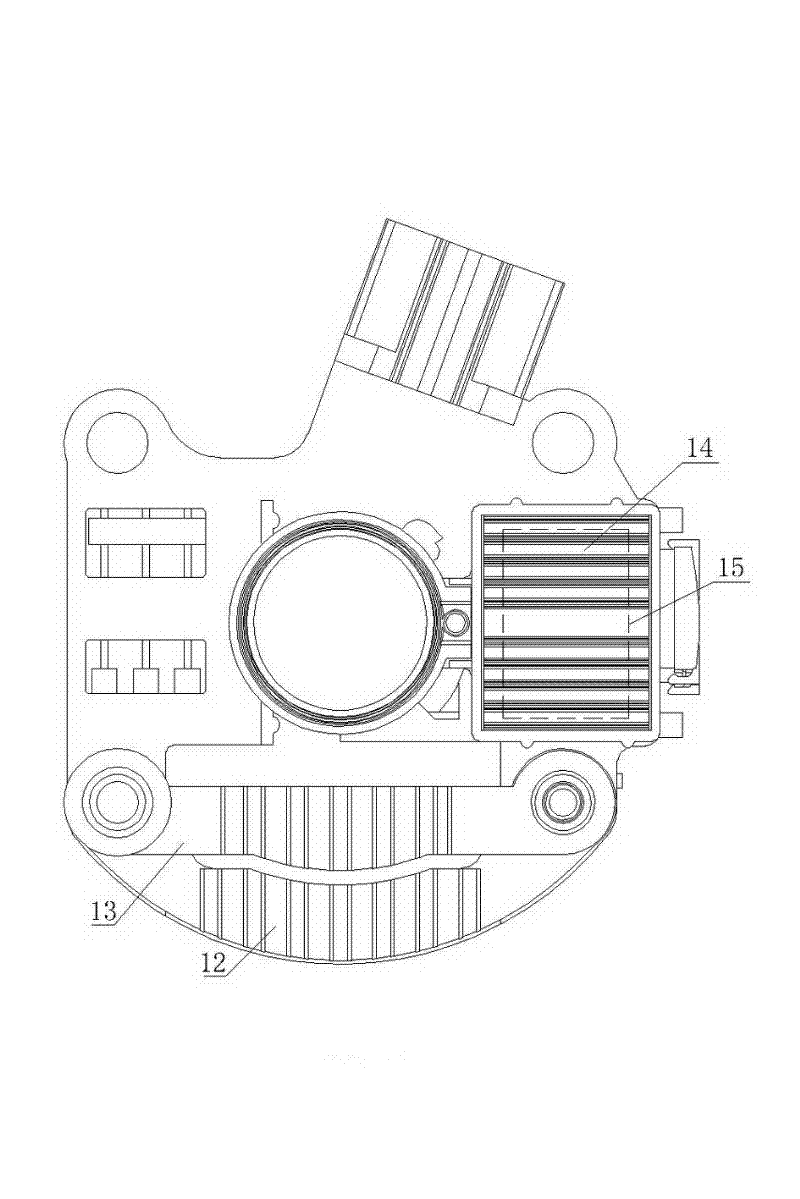

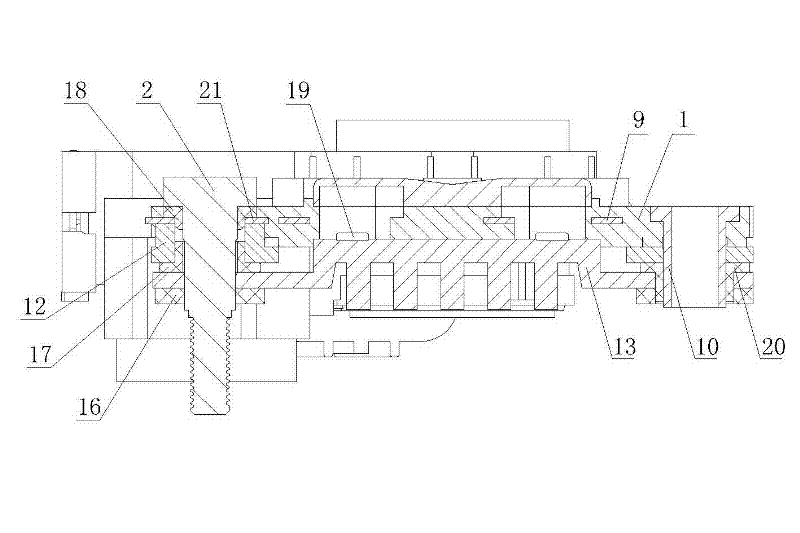

Integrated adjustor, namely rectifier bridge of automobile alternating-current generator

ActiveCN102510174ARealize integrationEliminates packagingAssociation for rectificationStator coilRectifier diodes

The invention relates to an integrated adjustor, namely a rectifier bridge of an automobile alternating-current generator. The integrated adjustor comprises an adjustor frame, wherein a hybrid integrated circuit, adjustor heat radiating sheets, a carbon brush, a spring and a rectifier embedded sheet are arranged on the adjustor frame. The integrated adjustor is characterized in that a rectifier bridge comprising three excitation diodes, two heat radiating sheets, two sets of rectifier diode chips and B+ bolts is installed on the adjustor frame; each set of the rectifier diode chips is respectively welded on the two heat radiating sheets; a packaging hole is arranged on the adjustor frame; the first end of the rectifier embedded sheet is a wire-connecting end of three phase positions of an alternating-current generator stator coil respectively; the second end of the rectifier embedded sheet is respectively connected with anodes of the excitation diodes; the third end of the rectifier embedded sheet is led out through the packaging hole; two ends of the heat radiating sheets are respectively sleeved on a metal sleeve and the B+ bolts; and the rectifier diode chips are packaged in the packaging hole and electrically connected with the third end of the rectifier embedded sheet respectively. The integrated adjustor has the advantages of simple structure, small volume, low production investment, low manufacture cost, convenience for installation and capability of saving the internal space of the generator.

Owner:锦州万得汽车电器电子科技有限公司

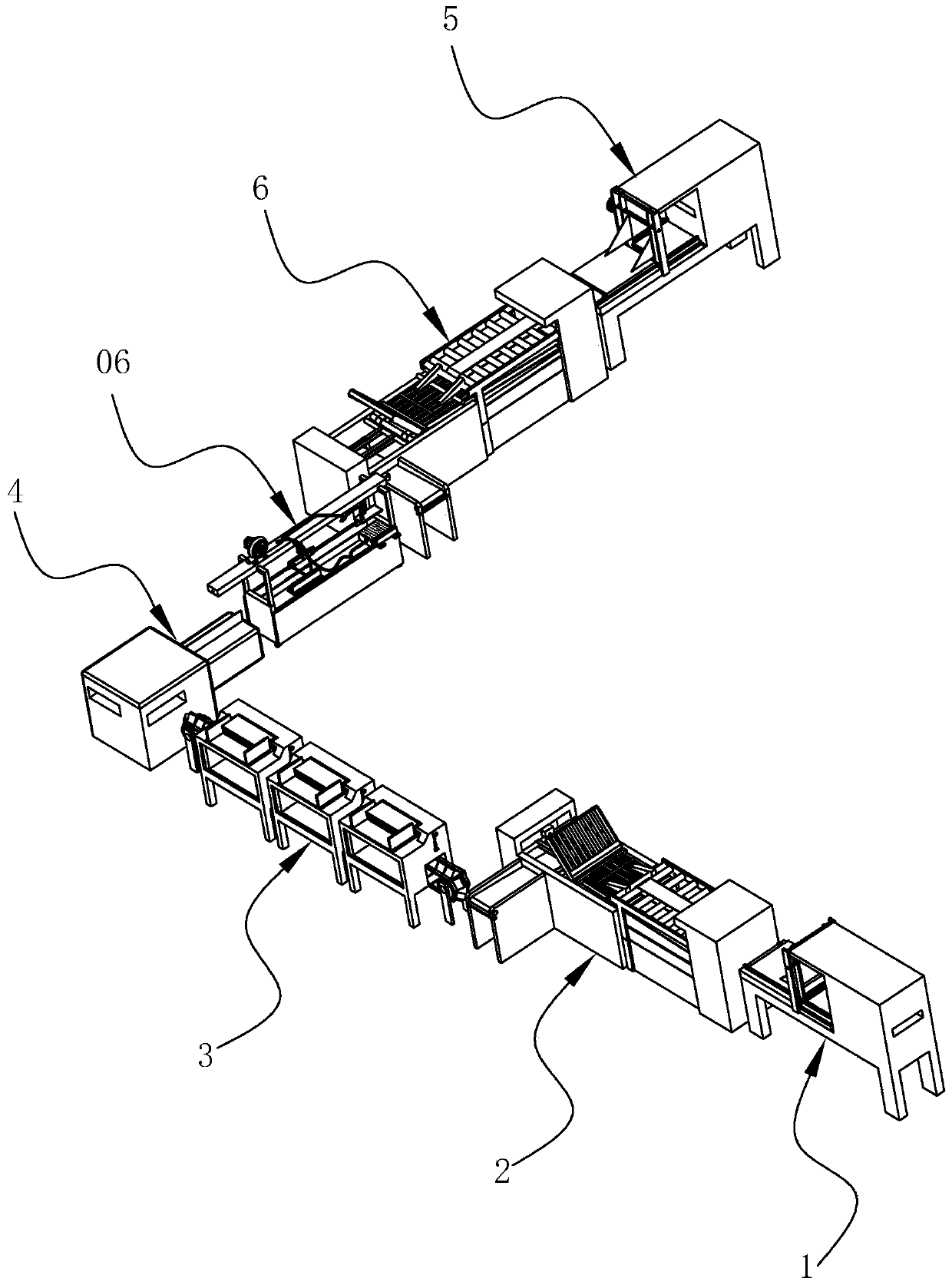

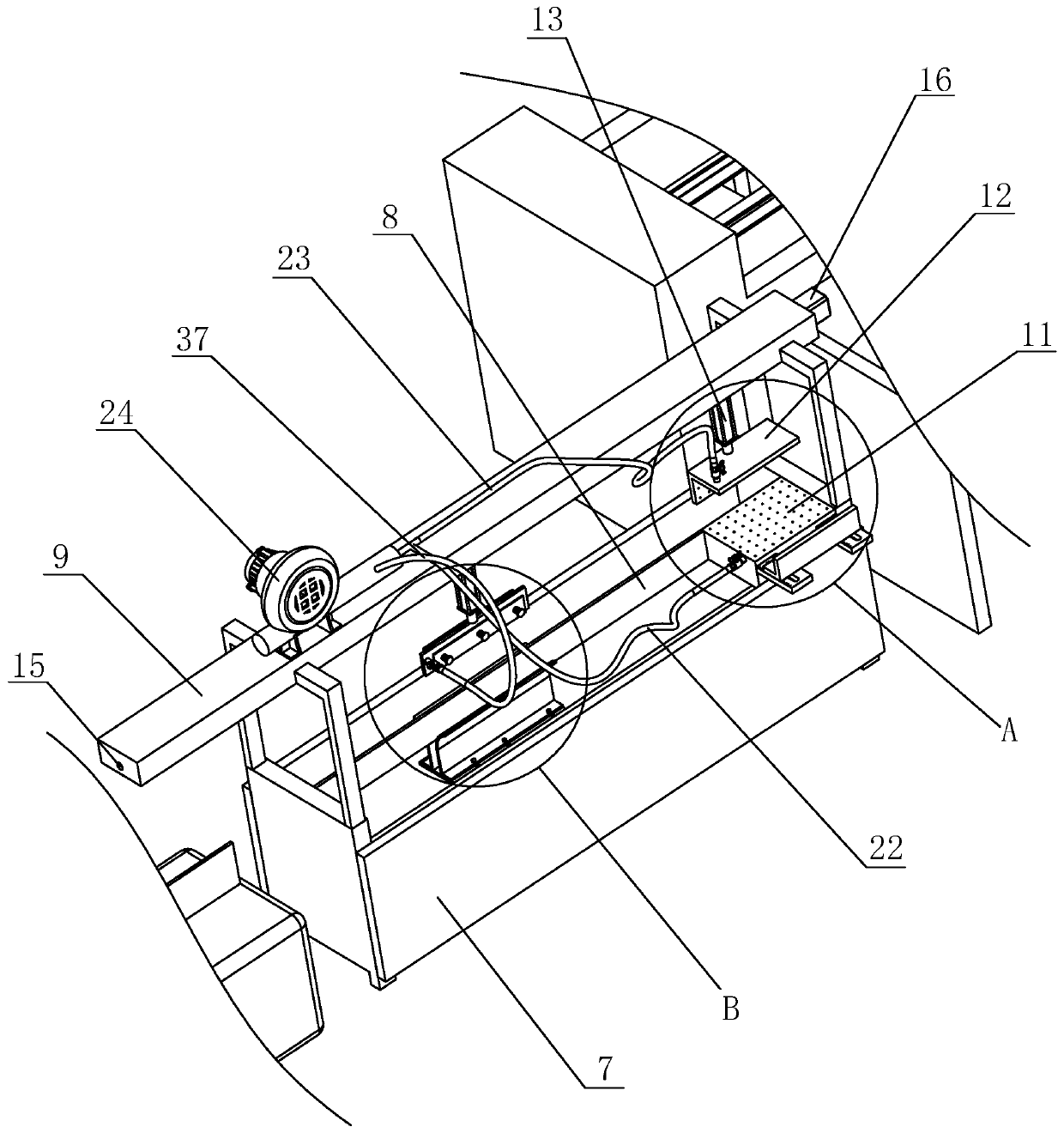

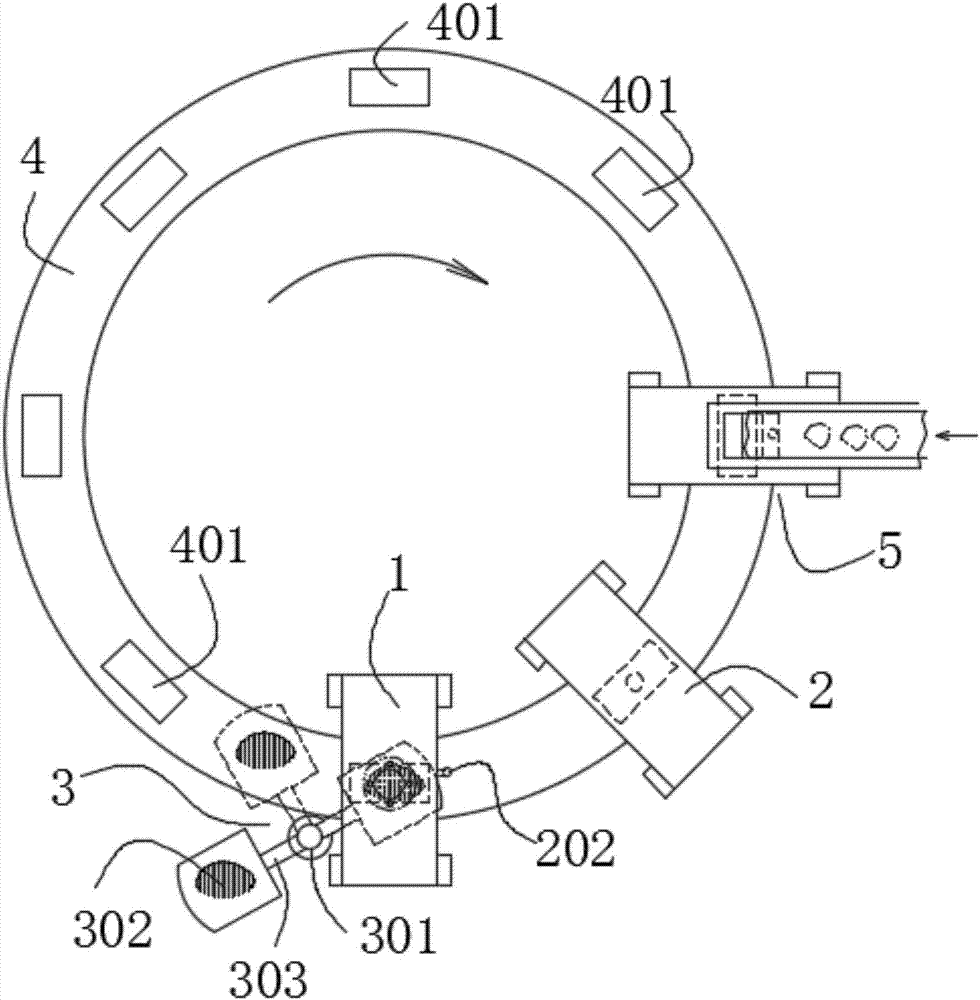

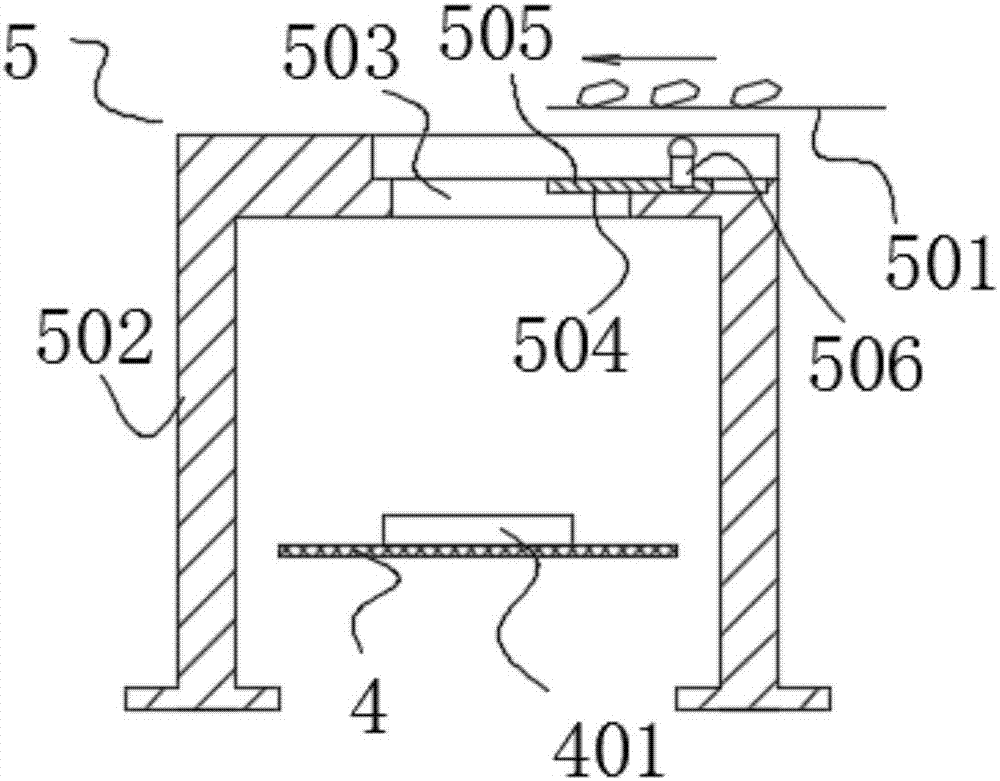

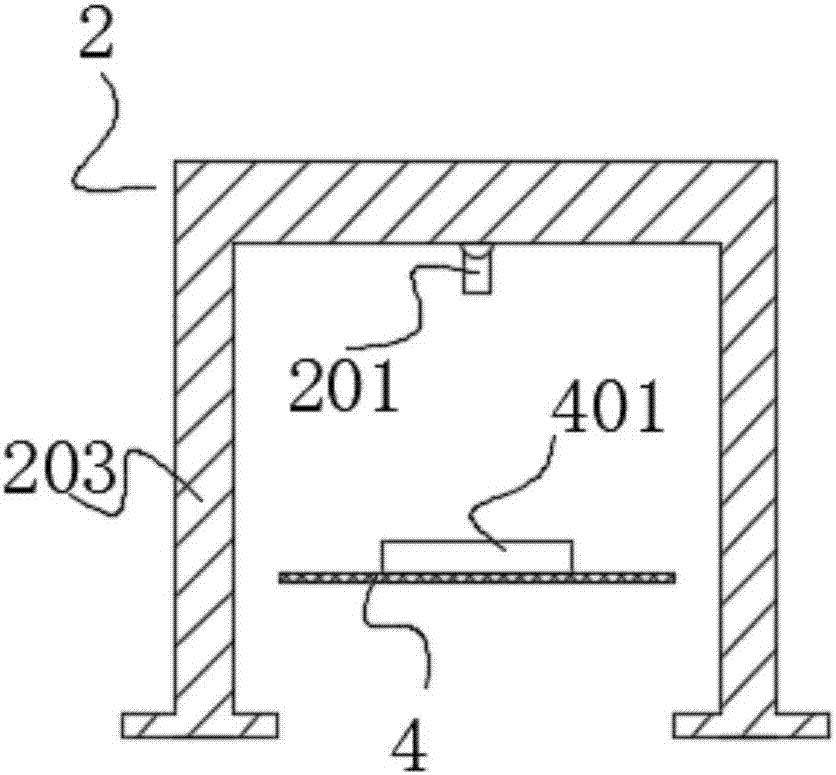

Food material slicing production line and slicing method thereof

ActiveCN107186764AEasy to fixImprove slice qualityMetal working apparatusProduction lineControl system

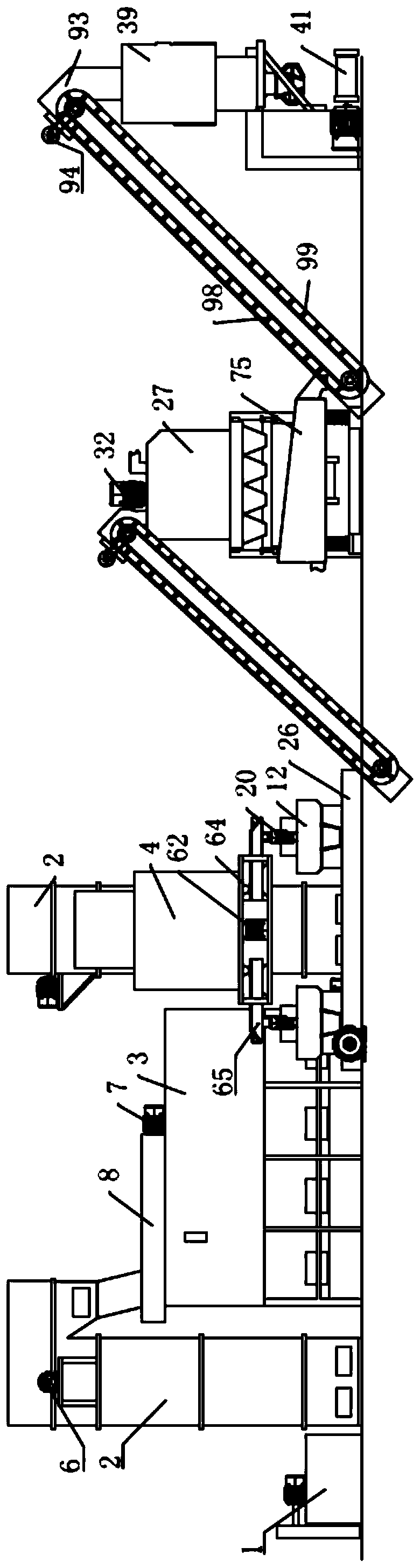

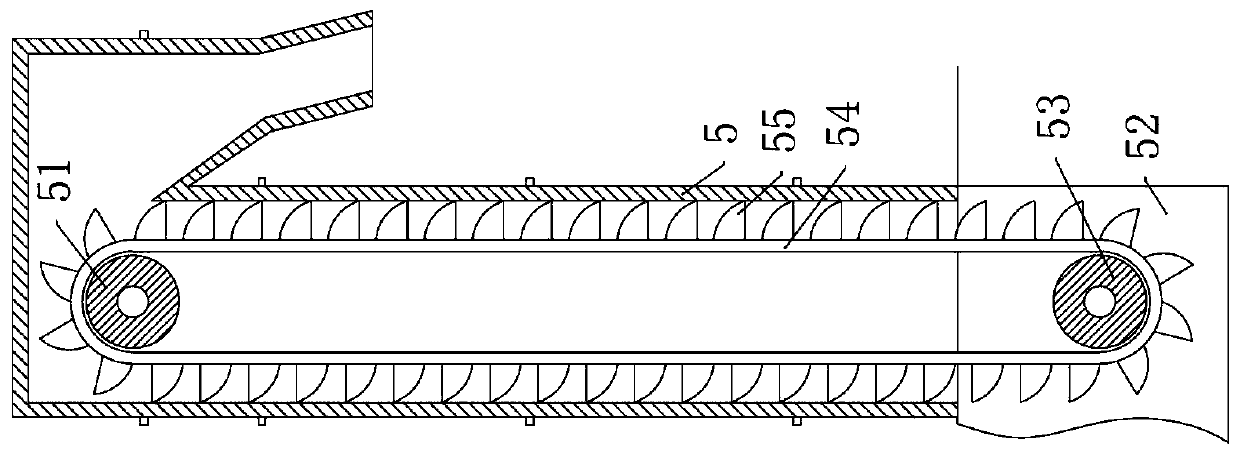

The invention discloses a food material slicing production line and a slicing method thereof. The food material slicing production line comprises a feeding mechanism, a data acquiring mechanism, a slicing mechanism, a discharging mechanism, an annular conveyor belt and a control system. A plurality of cutting boards are evenly arranged on the annular conveyor belt along a circle line, a plurality of stations are divided on the annular conveyor belt along the circle line according to the positions of the cutting boards, and the food material slicing production line rotates by one station every time. The slicing mechanism comprises a first n-shaped support, a cutter assembly and a pressing assembly. The cutter assembly comprises a blade fixing plate, a blade and a blade drive air cylinder. The blade drive air cylinder is fixed to the middle portion of a frame of the first n-shaped support, and the end portion of a piston of the blade drive air cylinder is detachably fixed to the blade fixing plate. The pressing assembly comprises a pressing plate and a pressing drive air cylinder. The slicing method comprises the steps of feeding, data acquiring, slicing, discharging and the like. The food material slicing production line can carry out uninterrupted slicing operation on any food material, production continuity and processing universality are achieved, the food processing efficiency and the quality can be greatly improved, and the production invest and the use cost can be greatly reduced.

Owner:HUANGGANG NORMAL UNIV

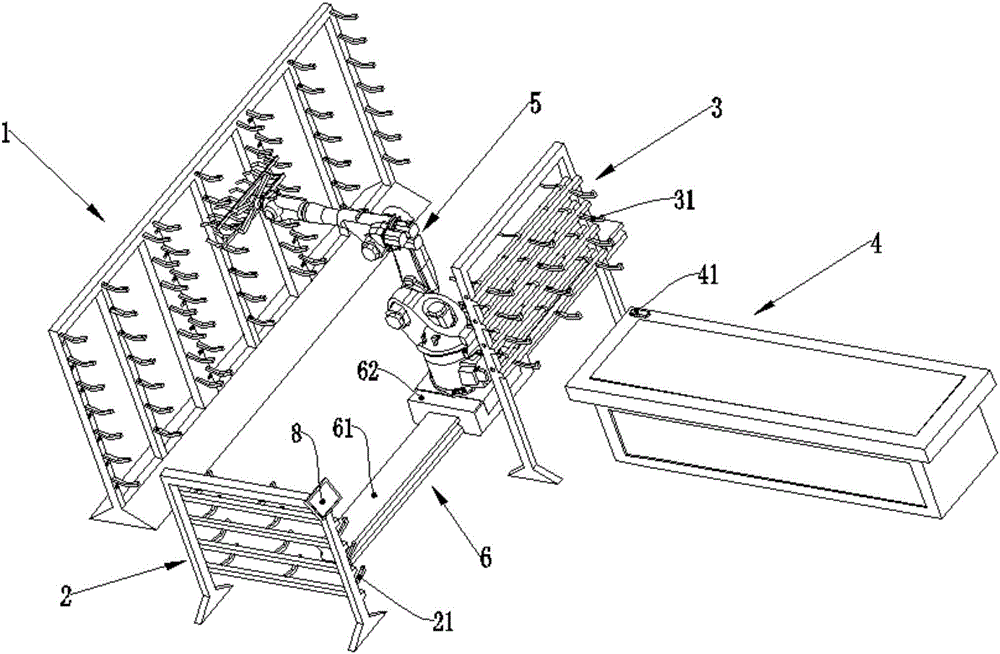

Cutting system capable of charging and discharging intelligently and charging and discharging method of cutting system

ActiveCN106044200AReduce labor intensityRealize mechanical automationMetal working apparatusStorage devicesEngineeringUltimate tensile strength

The invention discloses a cutting system capable of charging and discharging intelligently and a charging and discharging method of the cutting system. The cutting system comprises a material storage cabinet, a cutting bed, and a charging cabinet arranged between the material storage cabinet and the cutting bed. The cutting system further comprises a charging and discharging robot, wherein the charging and discharging robot is arranged between the material storage cabinet and the charging cabinet; the material storage cabinet comprises a plurality of material storage racks; the material storage racks are arranged at one side, facing the charging and discharging robot, of the material storage cabinet; the charging cabinet comprises a plurality of charging racks; and the charging racks are arranged at the two sides of the charging cabinet. The cutting system capable of charging and discharging intelligently is used to carry and cut a flexible material, so that mechanical automation of charging and discharging is realized, the labor intensity of workers is reduced greatly, the layout is reasonable, the charging and discharging are orderly and efficient, and the production efficiency is improved greatly.

Owner:FOSHAN SHIKE INTELLIGENT TECH CO LTD +2

Preparation method of tert-alkynol polyether

ActiveCN109970964ASmooth responseMild conditionsEther preparation by compound dehydrationReaction temperatureFine chemical

The invention relates to a preparation method of tert-alkynol polyether, and belongs to the field of fine chemical engineering. The preparation method comprises following steps: (1) adding a catalystand tert-alkynol into a reactor, carrying out degassing for 1 hour at a certain temperature under a certain pressure, controlling the reaction temperature and reaction pressure, slowly and evenly adding part of olefin oxide into the reactor within a certain period, and after addition, maintaining the temperature until the pressure becomes stable; and (2) keeping on adding olefin oxide at a certaintemperature until the reactions are finished, maintaining the temperature until the pressure becomes stable, cooling to remove a little of unreacted olefin oxide, adding an acid to carry out neutralization, and discharging obtained tert-alkynol polyether. The invention provides a preparation method of tert-alkynol polyether, which has the advantages of light color, high unsaturation degree, narrow distribution, low residual raw materials, and low PEG / PPG content.

Owner:ZHEJIANG HUANGMA TECH +3

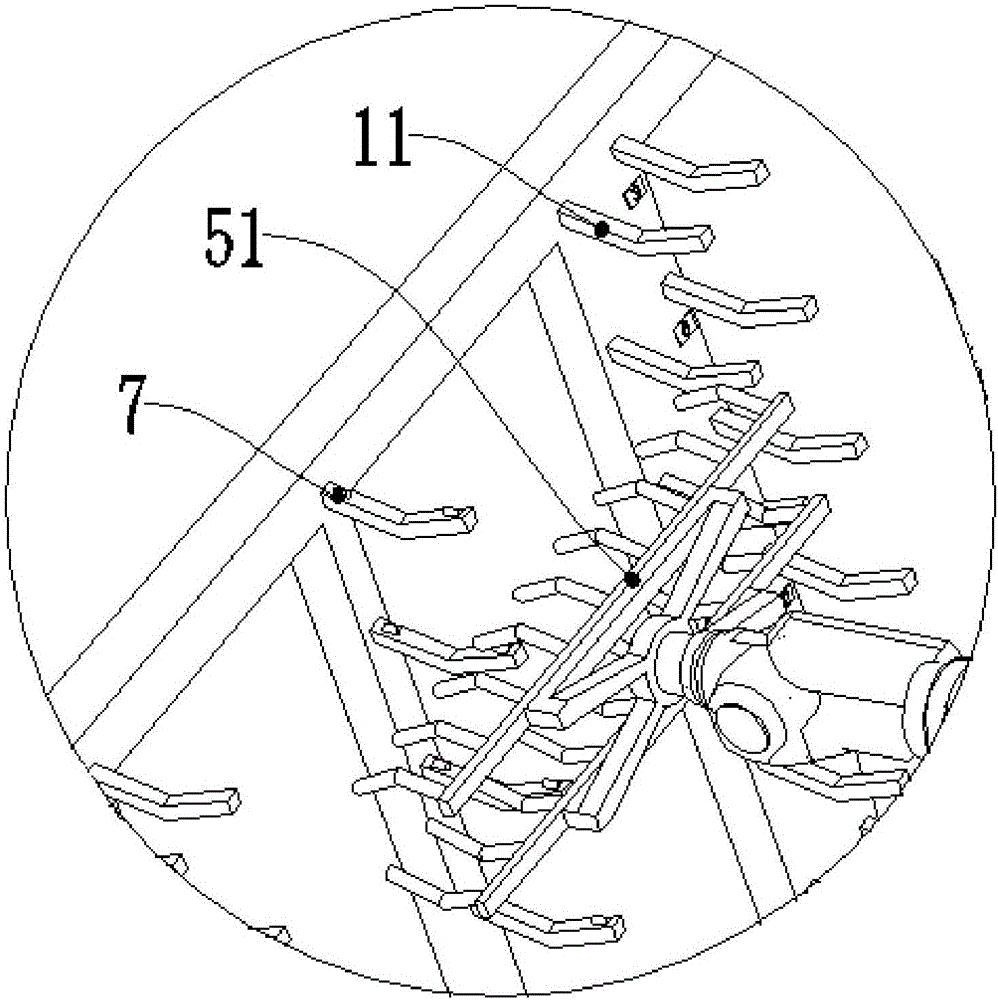

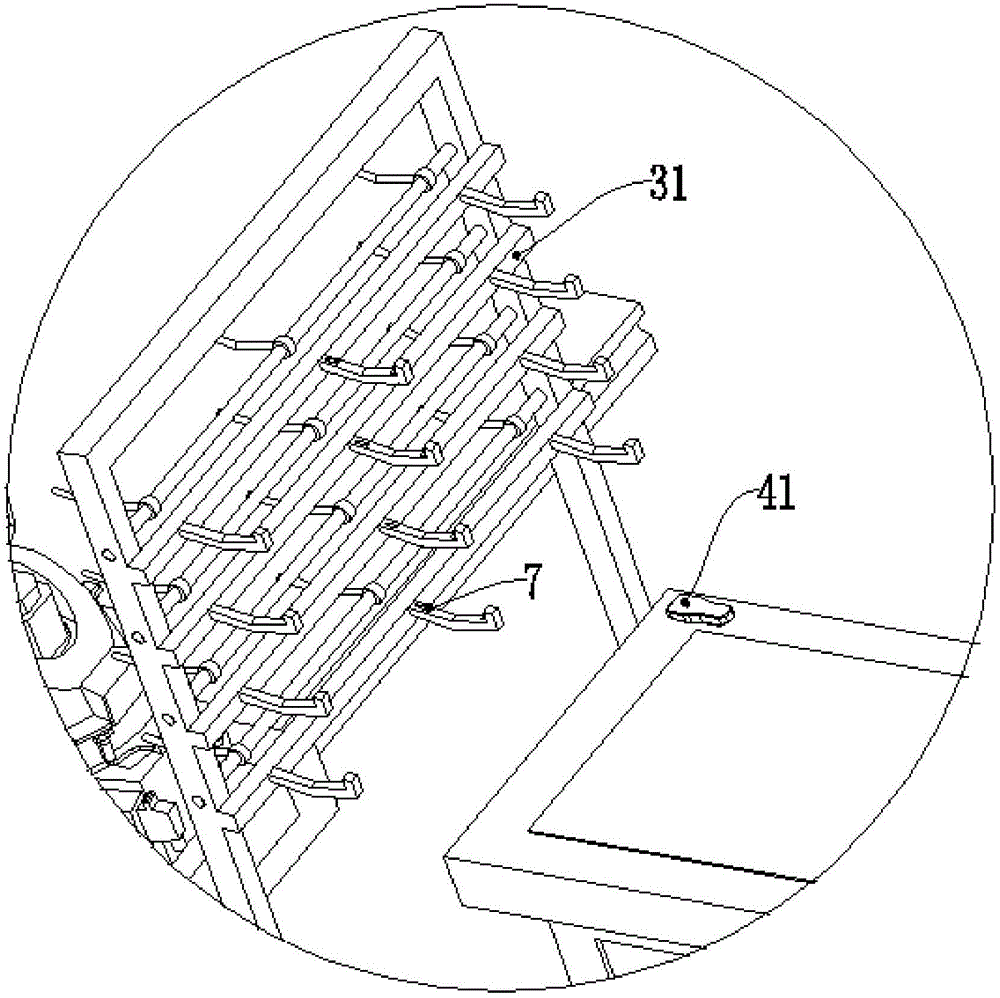

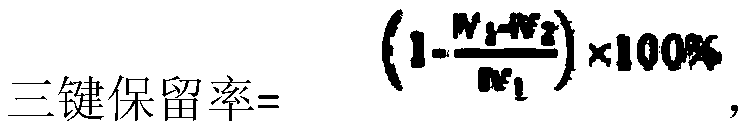

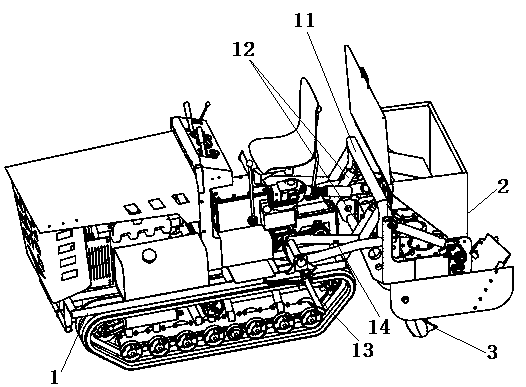

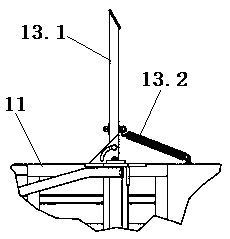

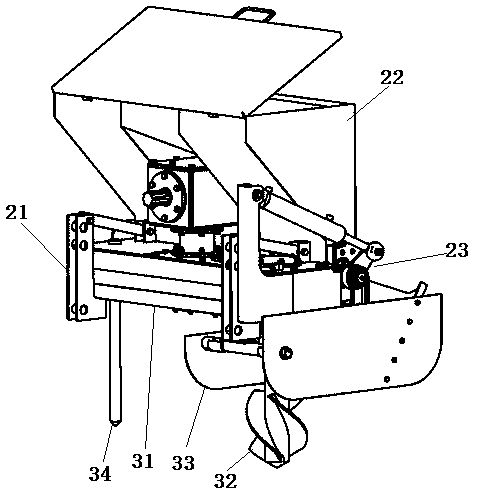

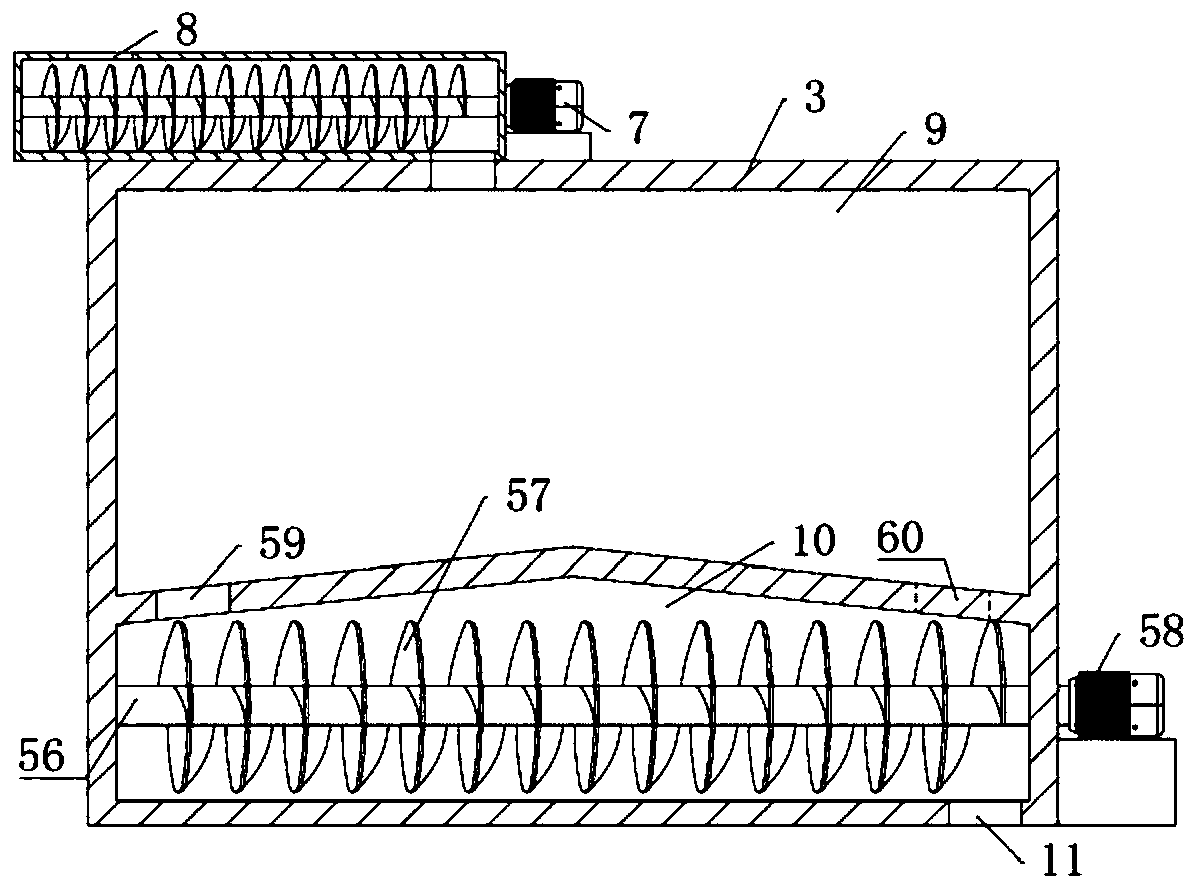

Fixed-point quantitative intelligent fertilizer applicator

ActiveCN108770421ARealize automatic intelligent fertilizationReduce production input costsPlantingFertiliser distributersFailure rateAgricultural engineering

The invention discloses a fixed-point quantitative intelligent fertilizer applicator. The fixed-point quantitative intelligent fertilizer applicator comprises a bracket, a diesel-driven system, a crawler-type walking chassis, an operating platform, a driver seat and a fertilizer applicator which is arranged at the front end of the bracket and is in transmission connection with the diesel-driven system. The fixed-point quantitative intelligent fertilizer applicator is characterized in that the front end of the bracket is articulated with a hook frame; the fertilizer applicator is arranged on the hook frame; a lifting oil cylinder for driving the hook bracket to ascend and descend is arranged between the hook frame and the bracket; the side edge of the bracket is equipped with a tree contactswitch which is connected with the diesel-driven system and used for controlling the extension and retraction of the lifting oil cylinder; the front end of the bracket is equipped with a fertilizer application switch which is connected with the diesel-driven system and is used for controlling the on / off of the fertilizer applicator; in the initial state, the lifting oil cylinder fully extends, and the hook frame and the fertilizer applicator are at the highest position. By adopting the fixed-point quantitative intelligent fertilizer applicator, intelligent fertilization is realized through contact between the tree contact switch and trees, the structure is simpler, the accuracy of fixed-point fertilization is high, the failure rate is low, the production cost of the fertilizer applicatorcan be lowered effectively, and the use reliability and practicability of the fertilizer applicator are enhanced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

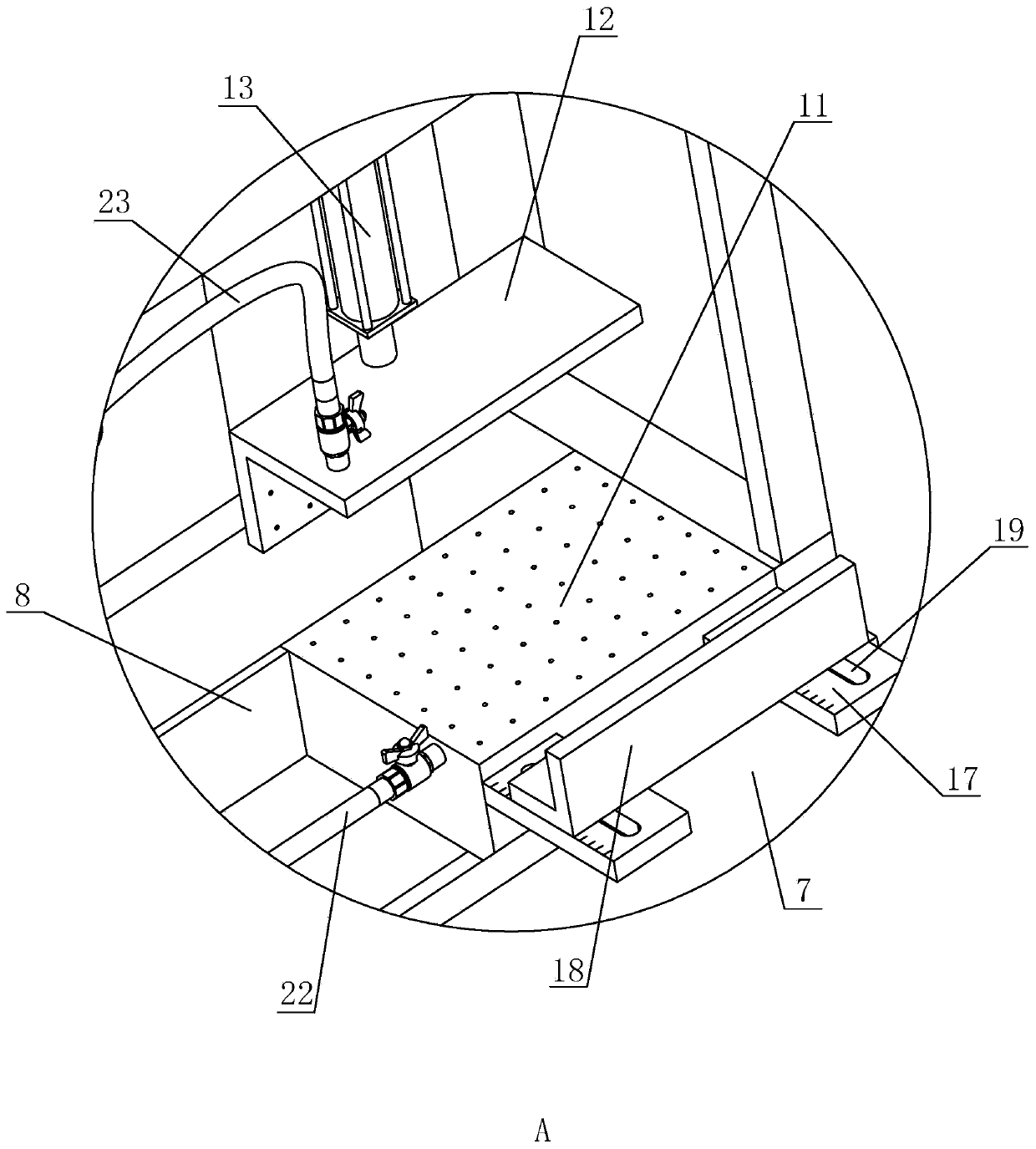

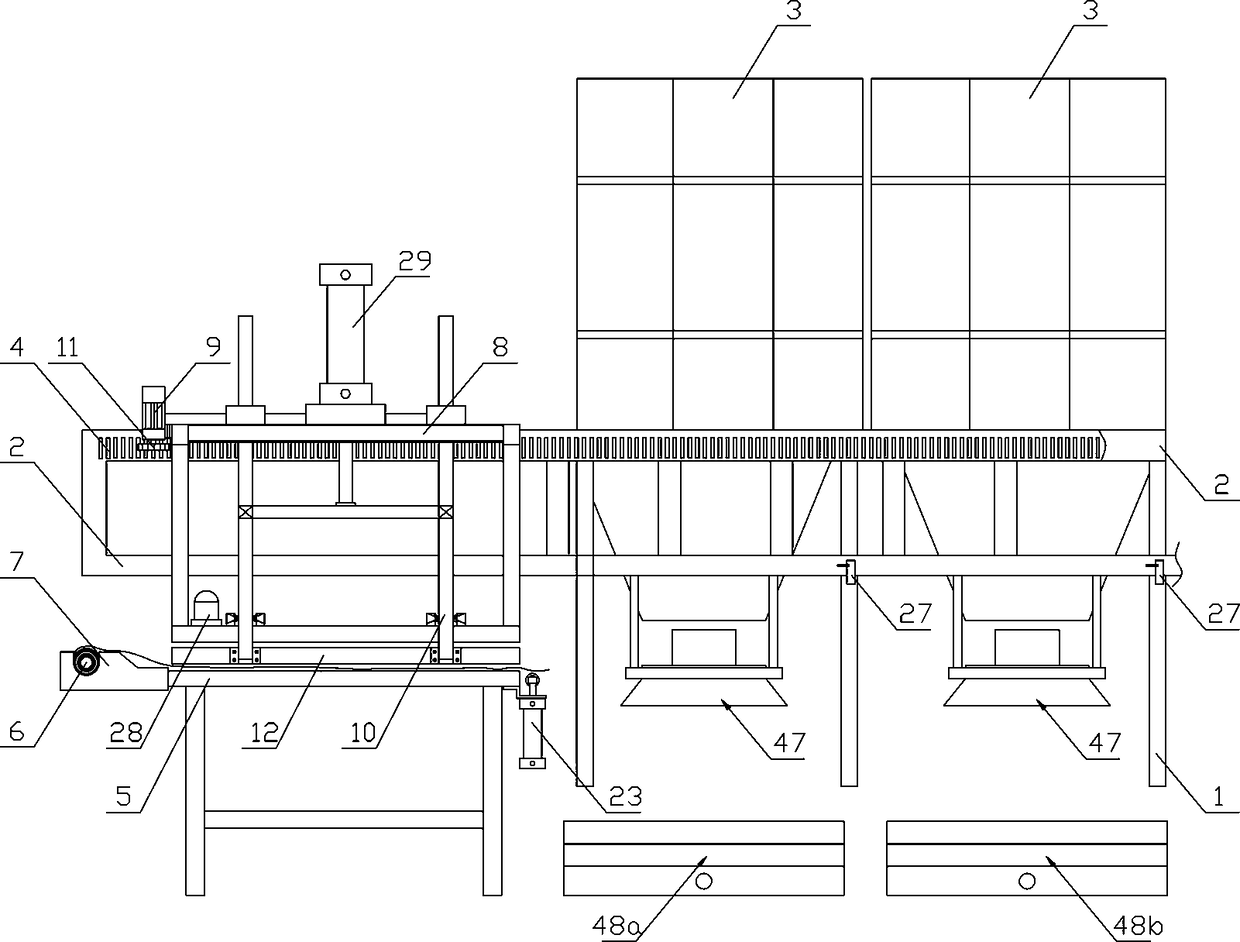

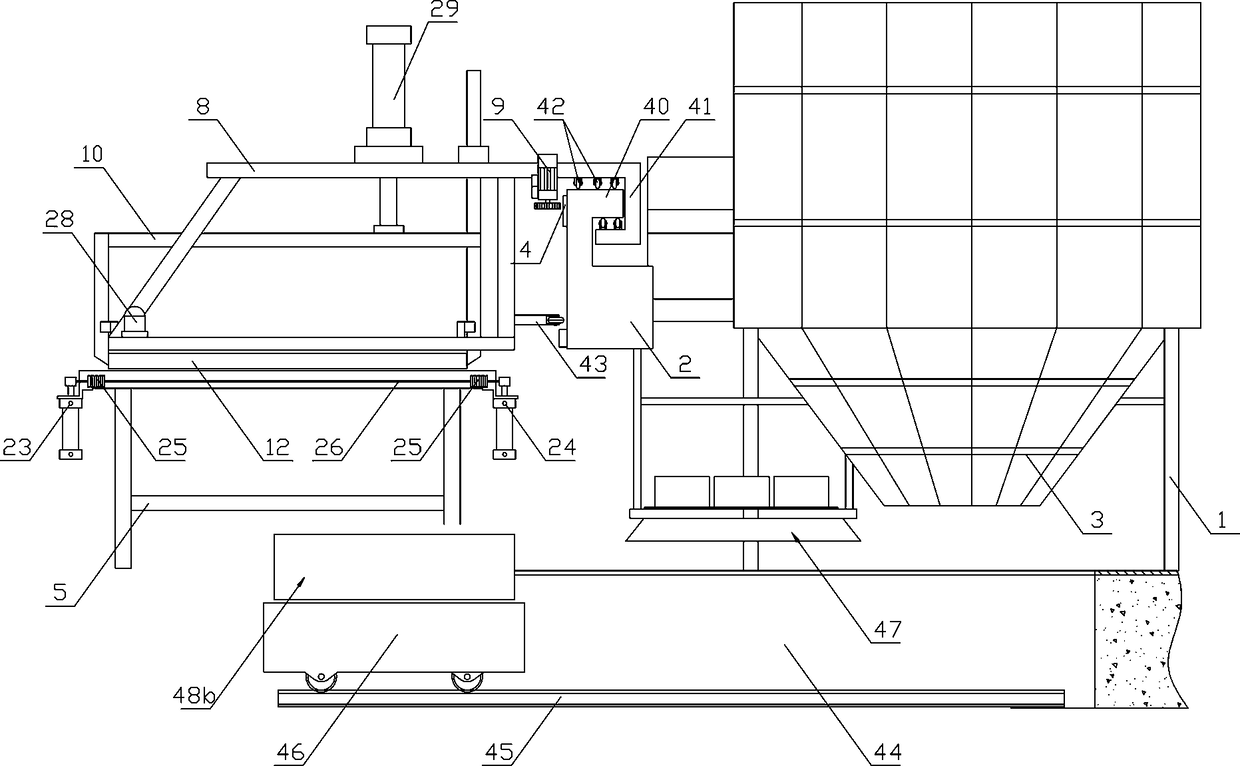

Automatic vacuumized negative pressure molding machine

The invention discloses an automatic vacuumized negative pressure molding machine. The automatic vacuumized negative pressure molding machine is provided with a rack, wherein a guide rail and at leasttwo molding sand feeding hoppers are arranged on the rack, and a film laminating machine and a molding mould are arranged at the front side of the rack; a gear rack is arranged on the guide rail; thefilm laminating machine is provided with a support platform, a left side supporting seat and a right side thin film cutting device are arranged on the support platform, a transverse movement supporthung on the guide rail is arranged at the upper side of the support platform, a driving motor and a longitudinal movement support are arranged on the transverse movement support, a gear meshed with the gear rack is arranged at the output terminal of the driving motor, and a negative pressure frame is arranged at the lower end of the longitudinal movement support; and a transmission mechanism is arranged between the molding mould and the molding sand feeding hoppers, and a baking mechanism is arranged at the front side of each molding sand feeding hopper. The automatic vacuumized negative pressure molding machine disclosed by the invention is simple in structure, high in automation degree and easy to operate, molding sand in a sand box is compacted by adopting a vacuumizing manner, the smoothness of the surface of a cavity of a sand mould is guaranteed, and further the yield of cast and moulded castings is guaranteed.

Owner:武汉重冶集团大冶重型装备有限公司

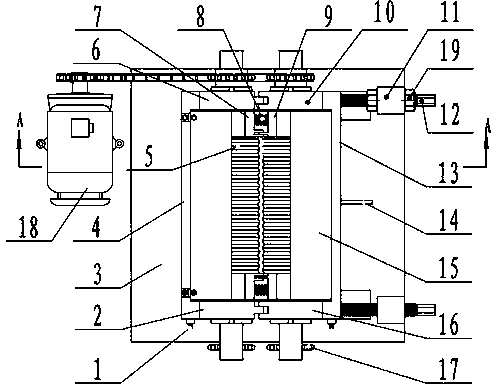

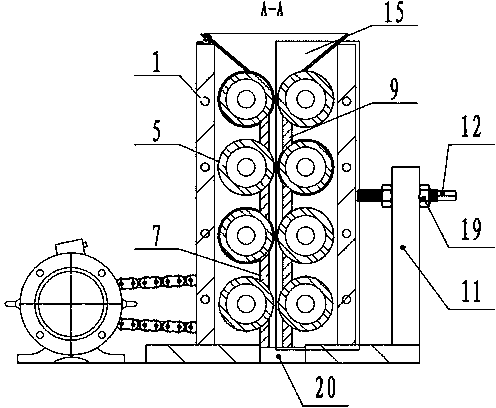

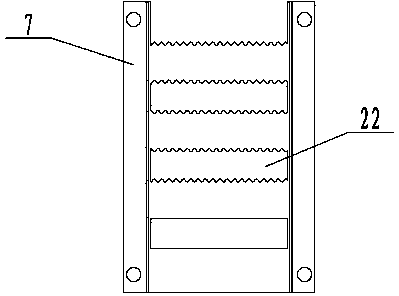

Fiber reinforced thermoplastic composite material pair-roller mixing equipment

Fiber reinforced thermoplastic composite material pair-roller mixing equipment relates to fiber reinforced thermoplastic composite material processing production equipment. A front left panel, a left side panel and a rear left panel of the mixing equipment are fixed on a bottom plate, mixing rollers are longitudinally arranged on the front left panel and the left side panel and a front right panel and a rear right panel; a left middle plate and a right middle plate which are vertically placed are arranged between the left and right mixing rollers. The mixing roller outer wall is a corrugated circular arc structure, and reduces the shear abrasion to enhanced fiber; an intermediate plate can play the role of a scraper; after feeding of the mixing equipment is stopped, a mixed material in the mixing equipment still can flow out, no accumulation of waste material is produced, the waste of raw materials can be reduced; the mixed material can be directly sent to a press for mould pressing production, fiber silk, fiber cloth, fibrofelt and other reinforced materials in various forms can be used, diversified product demands can be met, one machine has multi functions, and the equipment has the advantages of simple structure, convenient maintenance, and effective reduction of the production cost and maintenance cost.

Owner:SHANDONG GRAD GROUP

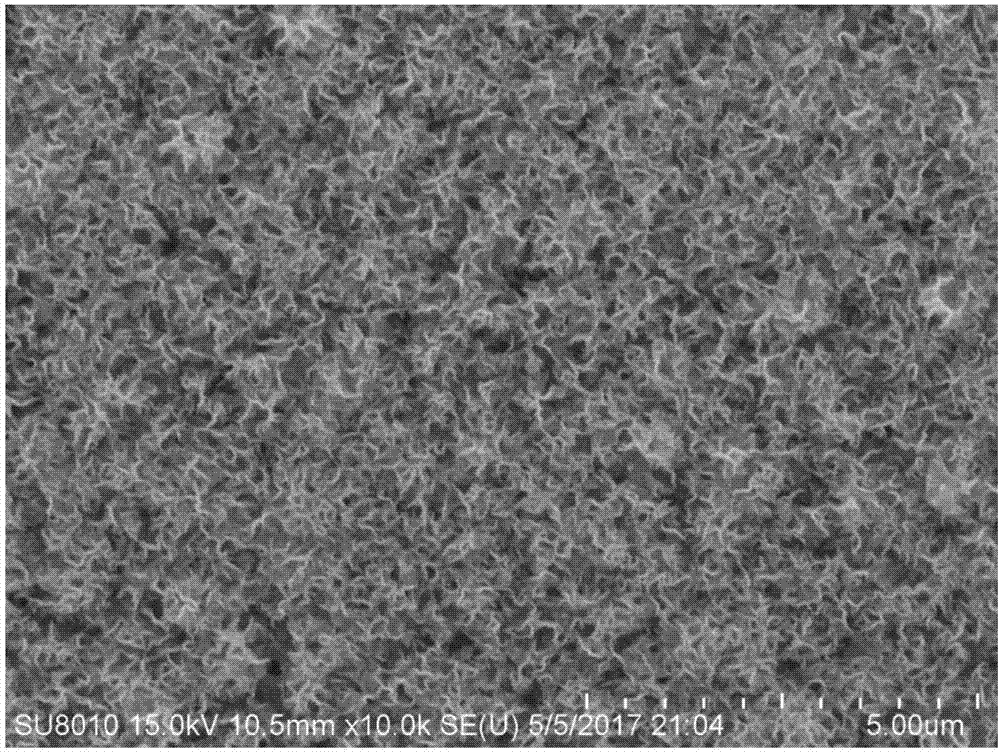

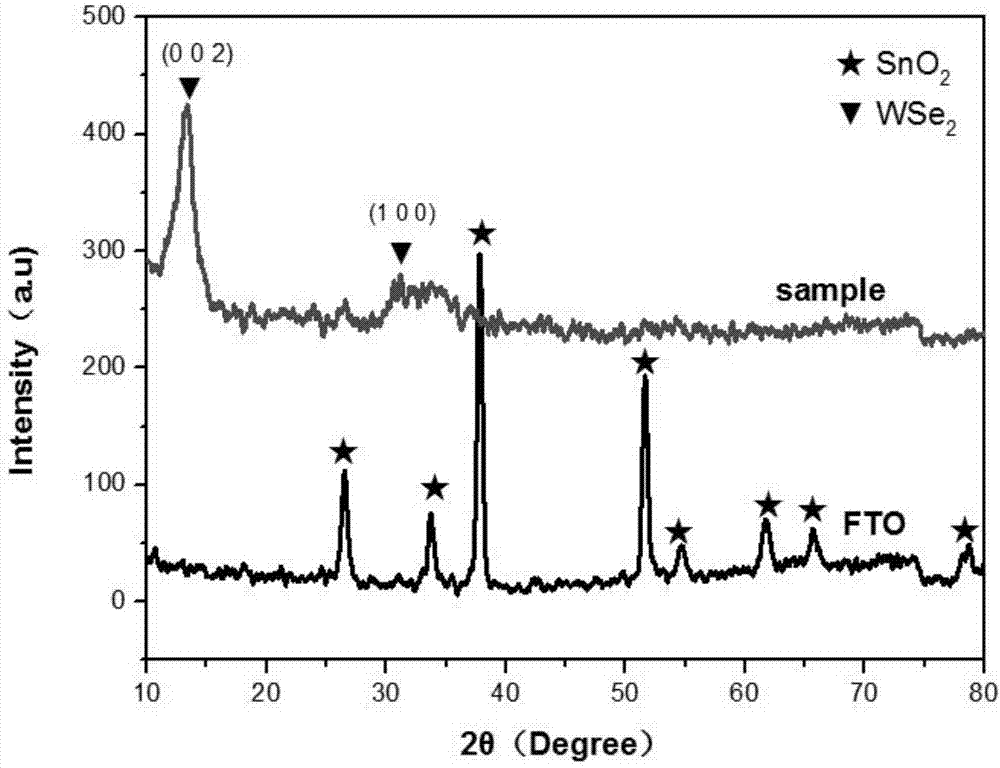

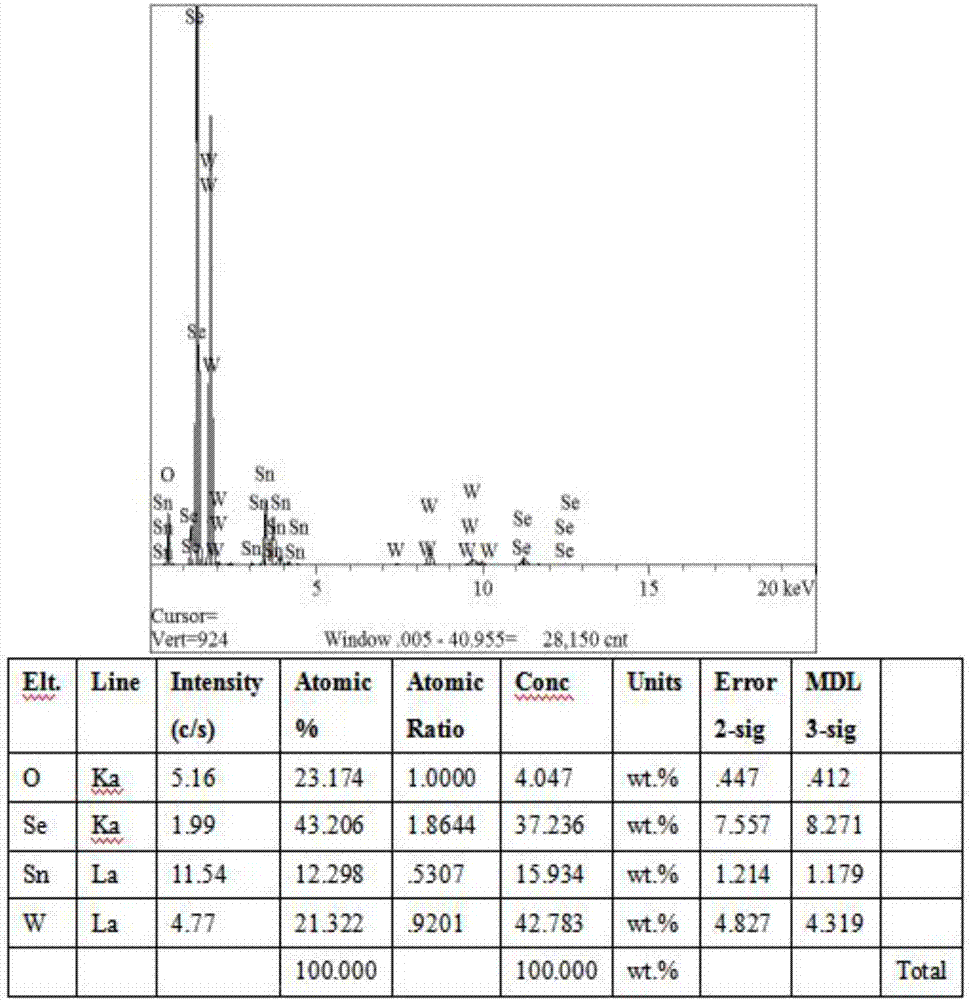

Method for preparing tungsten diselenide semiconductor film on FTO substrate and application of method

ActiveCN107475694ASimple preparation processUniform phaseLight-sensitive devicesLiquid/solution decomposition chemical coatingSolventHigh pressure

The invention discloses a method for preparing a tungsten diselenide semiconductor film on an FTO substrate. The method for preparing the tungsten diselenide semiconductor film on the FTO substrate is characterized in that the method comprises the following steps that S1, a reaction precursor solution is prepared, specifically, a solvent, a selenium source, a tungsten source and a reductive agent are evenly mixed to prepare the reaction precursor solution; S2, FTO conductive glass is pretreated, specifically, the FTO conductive glass is subjected to preliminary surface washing treatment; and S3, the tungsten diselenide semiconductor film is prepared, specifically, the treated FTO conductive glass after the step S2 makes contact with the reaction precursor solution prepared in the step S1, and after a sufficient reaction under a high-temperature and high-pressure condition, the tungsten diselenide semiconductor film is prepared on the FTO conductive glass. The method for preparing the tungsten diselenide semiconductor film has the advantages of being simple in preparing technology, low in cost and capable of obtaining the tungsten diselenide semiconductor film which is even in physical phase, good in crystallization and high in purity; and the WSe2 semiconductor film has good prospects in manufacturing of dye-sensitized solar cells and thin-film solar cells.

Owner:GUANGDONG UNIV OF TECH

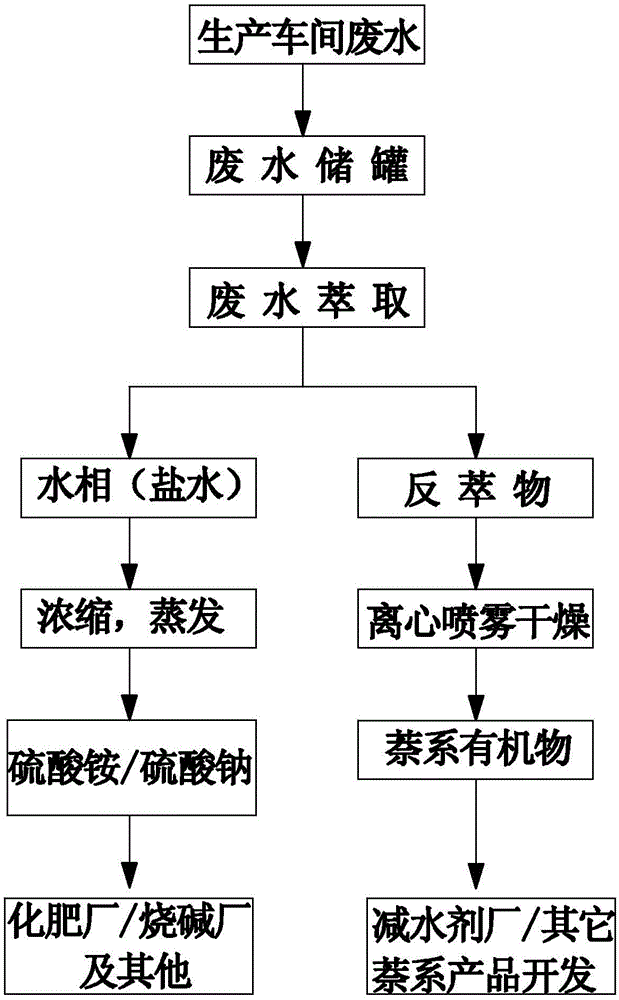

Treatment process combining H acid mother solution and T acid mother solution

PendingCN105130079AReduce solid wasteEnsure healthy and sustainable developmentAmmonium sulfatesMultistage water/sewage treatmentInorganic saltsPre treatment

The invention relates to a treatment process combining an H acid mother solution and a T acid mother solution and belongs to the technical field of treatment of H acid production wastewater. The treatment process comprises the following steps: adding an acidic complexing agent into collected wastewater and pre-treating; extracting an obtained water phase; directly adding the water phase into MVR equipment, and concentrating and crystallizing; centrifuging and separating to obtain inorganic salt; adding sodium hydroxide into an extracting solution except the water phase and adjusting temperature and pH to carry out reverse extraction; separating a reverse extraction product obtained by the reverse extraction from an extraction agent, and drying the reverse extraction product to obtain an organic byproduct. The treatment process is applied to the production of H acid, so that the production of solid wastes is avoided and the operation is simple and convenient; recycled products also can be put into secondary utilization so that the production cost is effectively reduced.

Owner:JIANGXI MADE FINE CHEM IND

Biomass particle fuel forming screening and split charging production line

InactiveCN110239138AImprove pass rateReduce labor intensitySievingScreeningProduction lineControl system

The invention provides a biomass particle fuel forming screening and split charging production line. An elevating mixing device, a forming device, a drying screening device, a split charging device and an elevating conveying device are included. The elevating mixing device comprises a first feeder, two elevators, a raw material bin and a mixing flow dividing machine. Each elevator is internally provided with a first conveying mechanism driven by a first drive motor. A first mixing mechanism is arranged in the raw material bin. A second mixing mechanism is arranged in the mixing flow dividing machine. An extrusion material stirring mechanism and a speed reduction mechanism are arranged in the forming device. The drying screening device comprises a drying machine and a vibration screen. The split charging device comprises a weighing machine, a packaging machine, a conveyor and a control system. A partition mechanism, an iron removal mechanism, a weight sensor and a fixing mechanism are arranged in the weighing machine. The biomass particle fuel forming screening and split charging production line has the characteristics that raw material mixing is uniform and sufficient, running stability is good, the production efficiency is high, the drying effect is good, and the finished product quality and the qualification rate are high.

Owner:山东马王芳凤新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com