Treatment process combining H acid mother solution and T acid mother solution

A treatment process and acid mother technology, applied in the field of H acid production wastewater treatment, to achieve the effect of saving energy and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

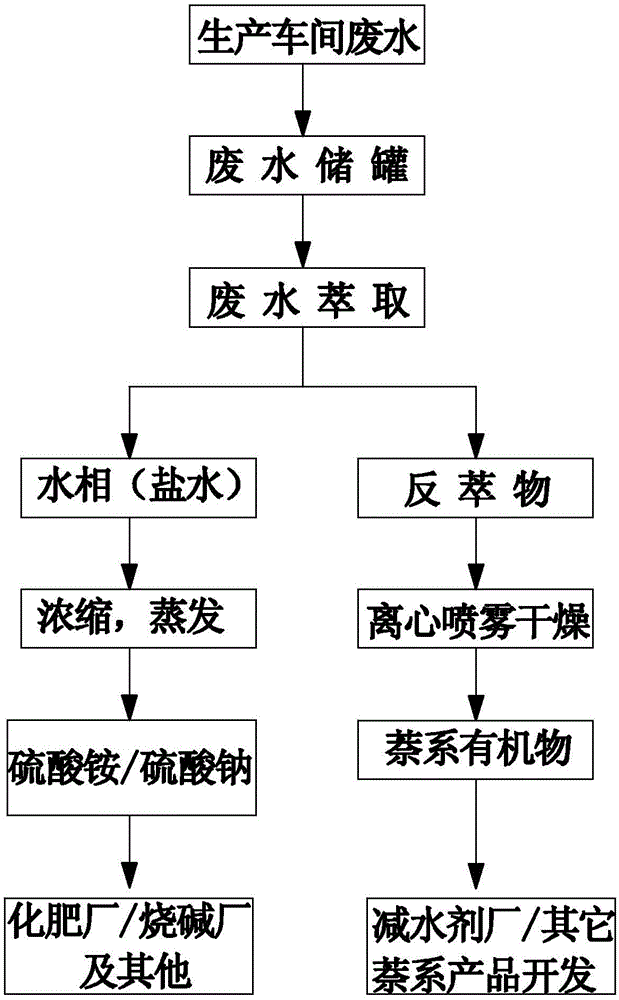

[0026] A kind of processing technology of present embodiment has H acid mother liquor and T acid mother liquor concurrently, combines figure 1 , including the following steps:

[0027] (1) Separation of inorganic salts: After adding an acidic complexing agent to the collected 4000ml wastewater for pretreatment, the aqueous phase obtained by extraction is a salt-containing substance; among them, the acidic complexing agent consists of 500ml trioctyl, decanyl tertiary amine, 400ml sulfonated kerosene, 100ml n-octanol mixed.

[0028] (2) Recovery of inorganic salts: the water phase of step (1) is directly put into the MVR equipment, concentrated and crystallized, and centrifuged to obtain inorganic salts.

[0029] (3) Recovery of organic by-products: Add sodium hydroxide to the extract solution other than the aqueous phase in step (1), and adjust the temperature and pH for back extraction. During the back extraction process, slowly add about 1.4 moles of NaOH (mass percentage is...

Embodiment 2

[0034] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0035] (1) Separation of inorganic salts: After adding an acidic complexing agent to the collected 4000mL wastewater for pretreatment, the aqueous phase obtained by extraction is a salt-containing substance; among them, the acidic complexing agent is composed of 500ml trioctyl, decanyl tertiary amine , 400ml sulfonated kerosene, 100ml n-octanol mixed.

[0036] (2) Recovery of inorganic salts: the water phase of step (1) is directly put into the MVR equipment, concentrated and crystallized, and centrifuged to obtain inorganic salts.

[0037] (3) Recovery of organic by-products: Add sodium hydroxide to the extract solution other than the aqueous phase in step (1), and adjust the temperature and pH for stripping. During the stripping process, slowly add about 1.4 moles of ammonia solution (mass percentage 25%), keep the pH of the organic aqueous phase at 9....

Embodiment 3

[0039] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0040] (1) Separation of inorganic salts: After adding an acidic complexing agent to the collected 3650mL wastewater for pretreatment, the aqueous phase obtained by extraction is a salt-containing substance; among them, the acidic complexing agent is composed of 600ml trioctyl, decanyl tertiary amine , 700ml sulfonated kerosene, 150ml n-octanol mixed.

[0041] (2) Recovery of inorganic salts: the water phase of step (1) is directly put into the MVR equipment, concentrated and crystallized, and centrifuged to obtain inorganic salts.

[0042] (3) Recovery of organic by-products: Add sodium hydroxide to the extract solution other than the aqueous phase in step (1), and adjust the temperature and pH for stripping. During the stripping process, slowly add about 1.4 moles of ammonia solution (mass percentage 20%), make the pH of the organic aqueous phase 9.0-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com