Lower thermal expansion large-diameter ceramic honeycomb carrier and preparation method thereof

A technology of honeycomb ceramic carrier and low thermal expansion, which is applied in the direction of ceramic products, separation methods, catalyst carriers, etc., can solve the problems of poor water resistance of the outer skin, pulverization, and shedding of the outer skin, and achieve good resistance to dry and wet alternation and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

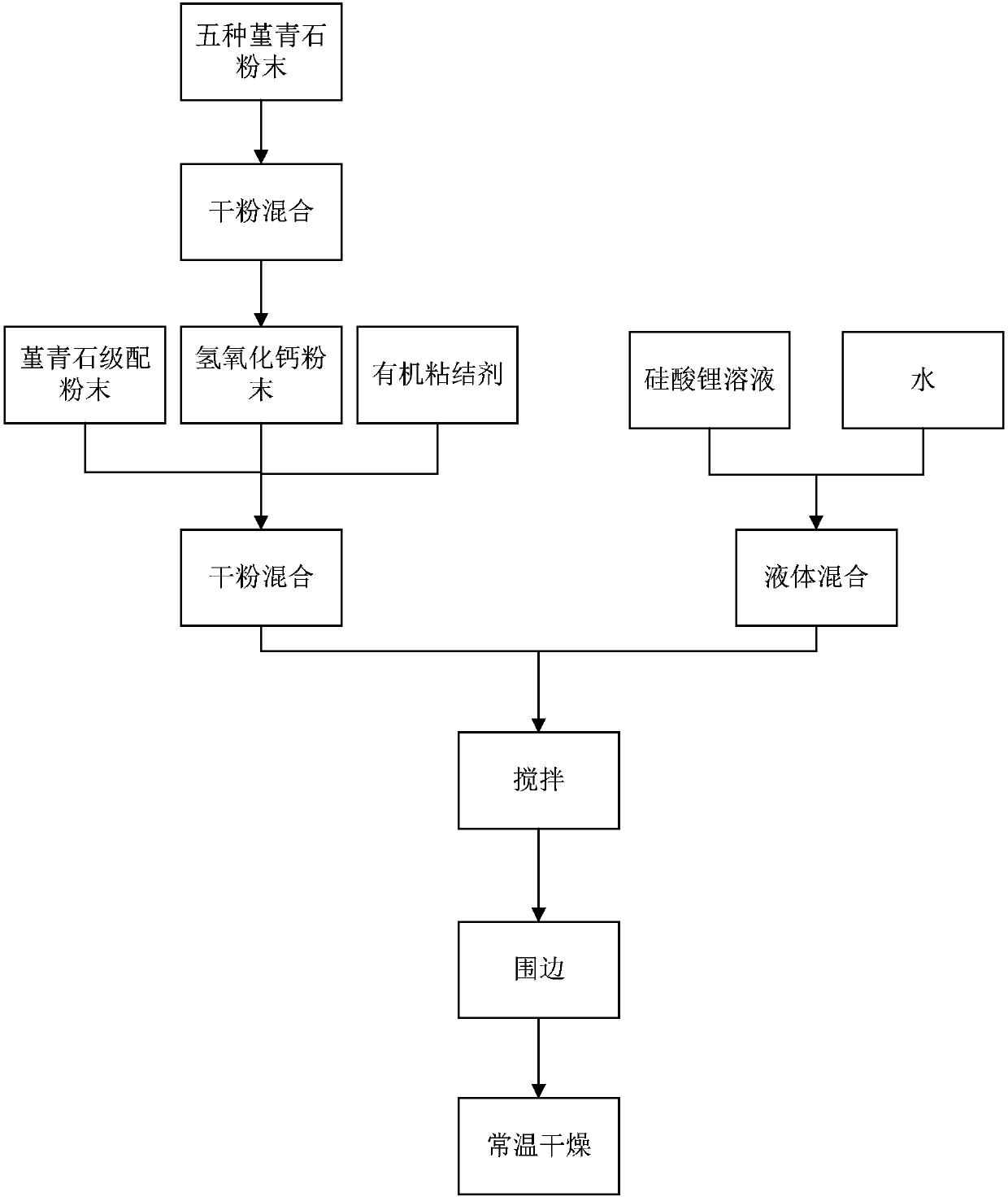

Method used

Image

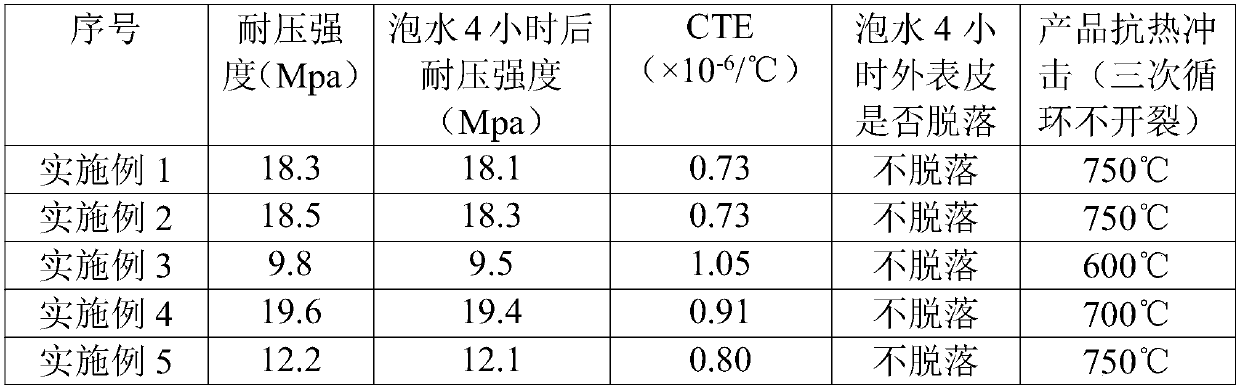

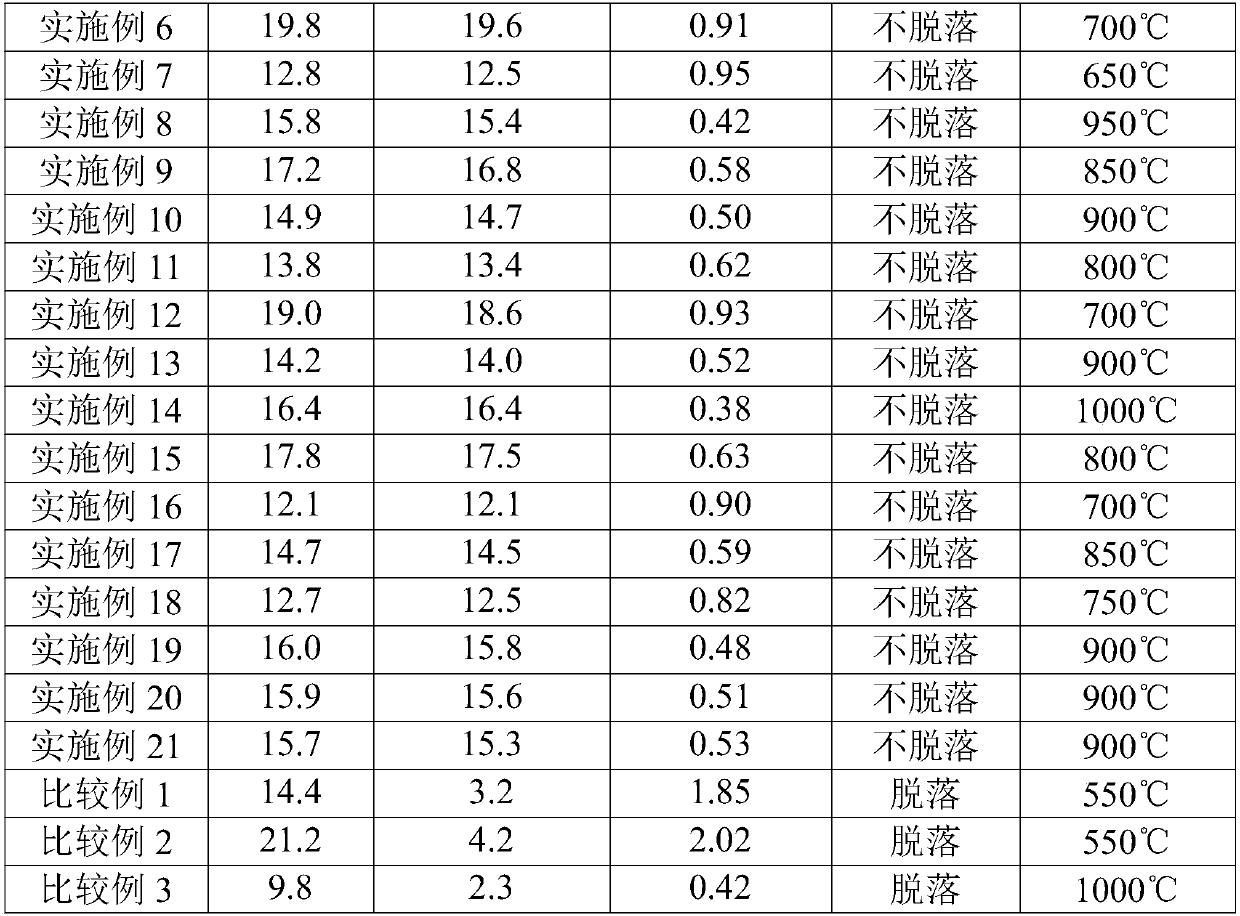

Examples

Embodiment 1

[0045] (1) Adopt dry method to mix 24% by weight of 80-120 mesh cordierite powder, 13% by weight of 120-150 mesh cordierite powder, 10% by weight of 150-180 mesh cordierite powder, 6% by weight of 180-220 mesh Mesh cordierite powder, 47% by weight of cordierite powder below 300 mesh, to obtain closely packed cordierite graded powder;

[0046] (2) V-type mixing of 96% by weight of the cordierite graded powder of step (1), 4% by weight of calcium hydroxide powder with an average particle size of 48 μm, relative to 100 parts by weight of the obtained inorganic powder, plus 0.5% by weight organic binder (hydroxypropyl methylcellulose);

[0047](3) Mixed solution: lithium silicate solution with modulus 4.2 of 35% of the sum of cordierite graded powder and calcium hydroxide powder mass, pure 35% of the sum of cordierite graded powder and calcium hydroxide powder mass water;

[0048] (4) Add the dry powder of step (2) into the mixed solution of step (3), and stir for 5 minutes at a...

Embodiment 2

[0051] (1) Adopt dry method to mix the 80-120 mesh cordierite powder of 22% by weight, the 120-150 mesh cordierite powder of 13% by weight, the 150-180 mesh cordierite powder of 10% by weight, the 180-220 mesh of 6% by weight Mesh cordierite powder, 47% by weight of cordierite powder below 300 mesh, to obtain closely packed cordierite graded powder;

[0052] (2) V-type mixing of 96% by weight of the cordierite graded powder of step (1), 4% by weight of calcium hydroxide powder with an average particle size of 48 μm, relative to 100 parts by weight of the obtained inorganic powder, plus 1.0% by weight organic binder (hydroxypropyl methylcellulose);

[0053] (3) Mixed solution: lithium silicate solution with modulus 4.2 of 35% of the sum of cordierite graded powder and calcium hydroxide powder mass, pure 35% of the sum of cordierite graded powder and calcium hydroxide powder mass water;

[0054] (4) Add the dry powder of step (2) into the mixed solution of step (3), and stir f...

Embodiment 3

[0057] (1) Adopt dry method to mix the 80-120 mesh cordierite powder of 22% by weight, the 120-150 mesh cordierite powder of 13% by weight, the 150-180 mesh cordierite powder of 10% by weight, the 180-220 mesh of 6% by weight Mesh cordierite powder, 47% by weight of cordierite powder below 300 mesh, to obtain closely packed cordierite graded powder;

[0058] (2) V-type mixing of 99% by weight of the cordierite graded powder of step (1), 1% by weight of calcium hydroxide powder with an average particle size of 30 μm, relative to 100 parts by weight of the obtained inorganic powder, plus 1.0% by weight organic binder (hydroxypropyl methylcellulose);

[0059] (3) Mixed liquor: Lithium silicate solution with modulus 4.5 of 20% of the sum of cordierite graded powder and calcium hydroxide powder mass, pure 50% of the sum of cordierite graded powder and calcium hydroxide powder mass water;

[0060] (4) Add the dry powder of step (2) into the mixed solution of step (3), and stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com