Heat dissipation coating and preparation method thereof

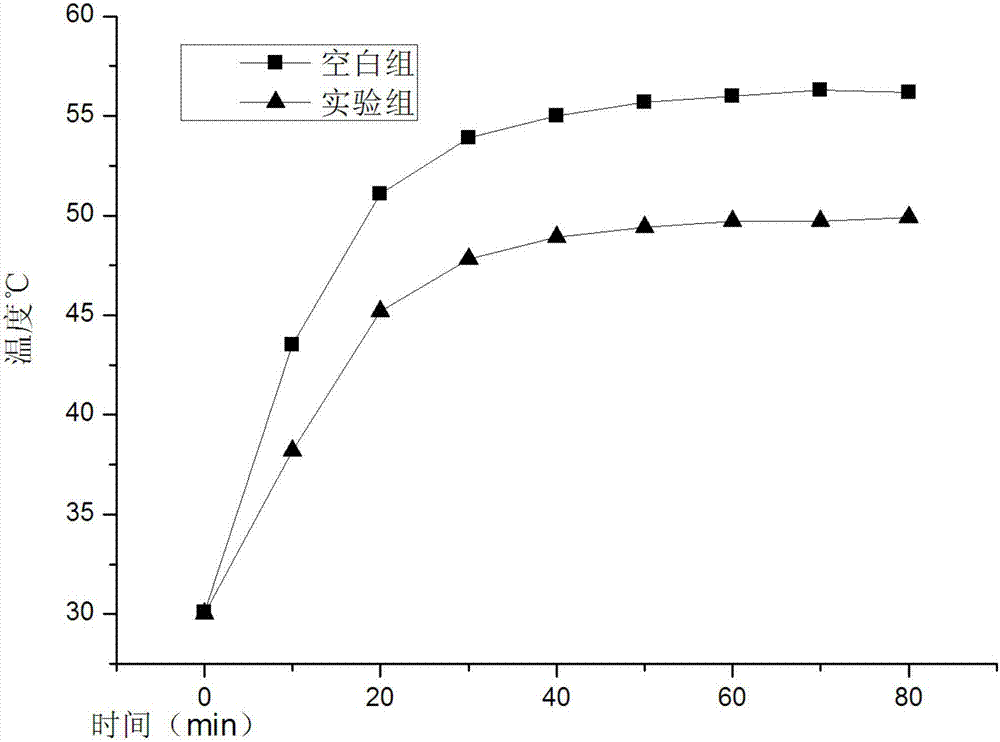

A technology for heat-dissipating coatings and raw materials, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of low refrigeration efficiency, immature technology, and easy damage, and achieve the effects of simple and convenient construction, good heat dissipation effect, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

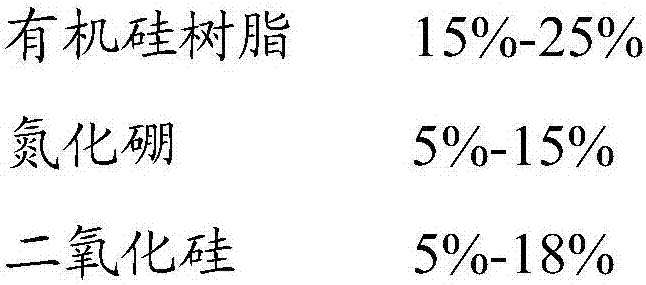

[0035] A heat-dissipating coating made from the following raw materials in mass fraction:

[0036]

[0037] The preparation method of above-mentioned heat-dissipating coating is as follows:

[0038] Dissolve the above-mentioned silicone resin in the above-mentioned solvent, then add boron nitride, silicon dioxide, dispersant, leveling agent, and adhesion promoter, mix thoroughly, then add bentonite, and stir evenly to obtain heat-dissipating coating A.

Embodiment 2

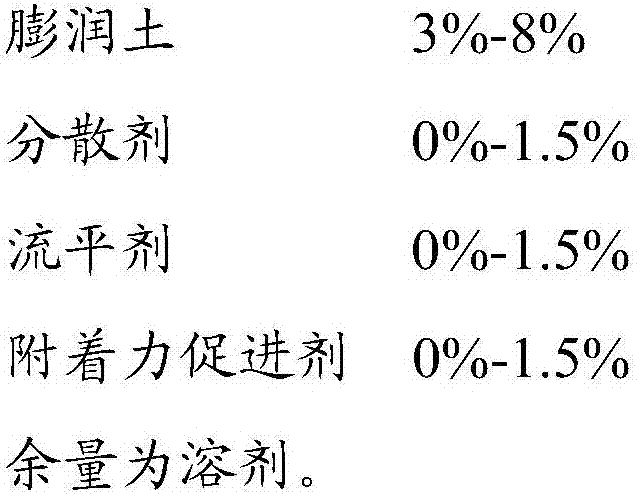

[0040] A heat-dissipating coating made from the following raw materials in mass fraction:

[0041]

[0042] The preparation method of above-mentioned heat-dissipating coating is as follows:

[0043] Dissolve the above-mentioned silicone resin in the above-mentioned solvent, then add boron nitride, silicon dioxide, dispersant, leveling agent, and adhesion promoter, mix thoroughly, then add bentonite, and stir evenly to obtain heat-dissipating coating B.

Embodiment 3

[0045] A heat-dissipating coating made from the following raw materials in mass fraction:

[0046]

[0047] The preparation method of above-mentioned heat-dissipating coating is as follows:

[0048] Dissolve the above-mentioned silicone resin in the above-mentioned solvent, then add boron nitride and silicon dioxide, mix thoroughly, then add bentonite, and stir evenly to obtain heat-dissipating coating C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com