Inorganic adhesive for forming expanded silicate material and preparation method thereof

An inorganic adhesive and expanded silicate technology, applied in the field of high temperature resistant adhesives, can solve the problems of poor heat resistance, waterproof adhesion and other problems of adhesives, and achieve the effects of increasing the curing speed, improving the film-forming reaction, and enriching resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

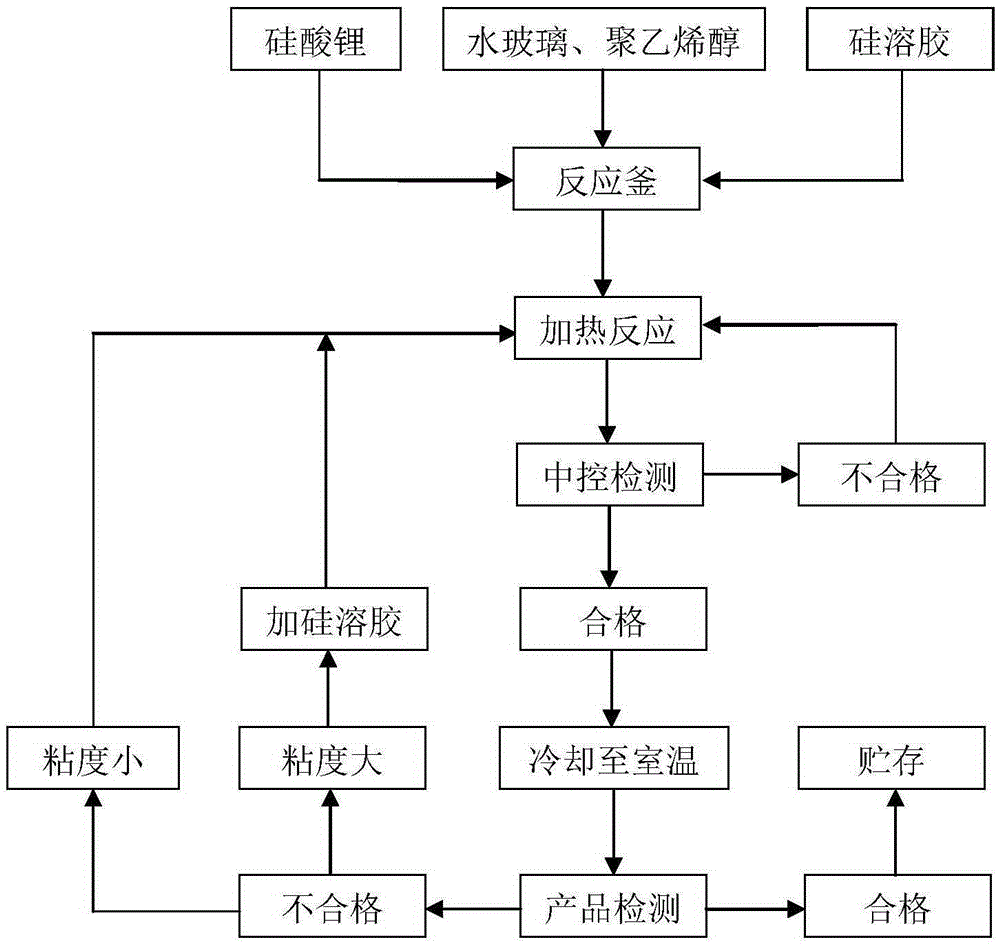

Method used

Image

Examples

Embodiment 1

[0031] Put the silica sol and lithium hydroxide powder into the reaction kettle at a weight ratio of 3:1, and mix and react at 60°C for 1h-1.5h under stirring to obtain a stable micro-emulsion white lithium silicate solution (the silicic acid used in the following reaction Lithium aqueous solution is prepared by this method).

[0032] Add 100 parts (parts by weight, the same below) of water glass with a modulus of 3.4 and 15 parts of lithium silicate aqueous solution into the reaction kettle and stir evenly, and the heating temperature is 65°C. Add 15 parts of silica sol and 2 parts of polyvinyl alcohol, and continue heating with stirring for 0.5-1h. Remove from heat and cool to room temperature. Then add 3 parts of waterproofing agent and 4 parts of curing agent (the curing agent is firstly ground by a ball mill to more than 1000 mesh), and stir evenly. The modulus of the adhesive is 3.4-3.6, the solid content is 38-41%, the Baume degree is 38-42, and the viscosity measured...

Embodiment 2

[0039] Add 100 parts (parts by weight, the same below) of water glass with a modulus of 3.4 and 10 parts of lithium silicate aqueous solution into the reaction kettle and stir evenly, and the heating temperature is 65°C. Add 20 parts of silica sol and 2 parts of polyvinyl alcohol, and continue heating with stirring for 0.5-1h. Remove from heat and cool to room temperature. Then add 3 parts of waterproofing agent and 4 parts of curing agent (the curing agent is firstly ground by a ball mill to more than 1000 mesh), and stir evenly. The modulus of the adhesive is 3.4-3.6, the solid content is 38-41%, the Baume degree is 38-42, and the viscosity measured by Tu-4 viscometer is 55-65s.

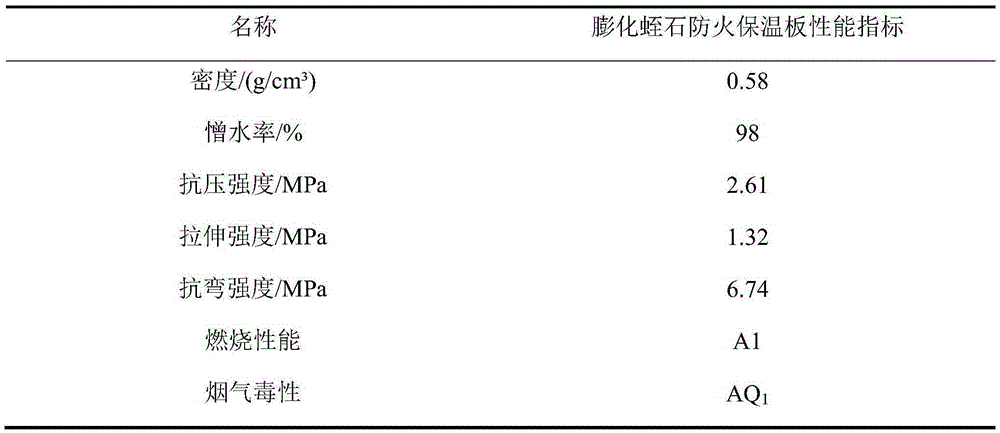

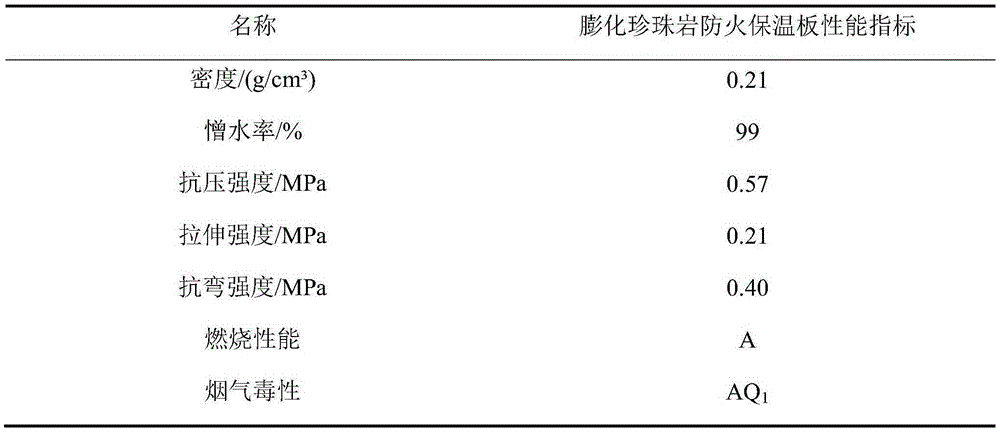

[0040] Put the prepared inorganic adhesive and extruded vermiculite into the mixer according to the mass ratio of 0.6:1, pour it into the mold after stirring evenly, hot press molding, demoulding, and wait until it is lowered to room temperature to obtain a fireproof insulation board . Its perfo...

Embodiment 3

[0046] Add 100 parts (parts by weight, the same below) of water glass with a modulus of 3.4 and 15 parts of lithium silicate aqueous solution into the reaction kettle and stir evenly, and the heating temperature is 65°C. Add 10 parts of silica sol and 2 parts of polyvinyl alcohol, and continue heating with stirring for 0.5-1h. Remove from heat and cool to room temperature. Then add 3 parts of waterproofing agent and 3.5 parts of curing agent (the curing agent is firstly ground by a ball mill to more than 1000 mesh), and stir evenly. The modulus of the adhesive is 3.4-3.6, the solid content is 38-41%, the Baume degree is 38-42, and the viscosity measured by Tu-4 viscometer is 55-65s.

[0047] Put the prepared inorganic adhesive and extruded vermiculite into the mixer according to the mass ratio of 0.6:1, pour it into the mold after stirring evenly, hot press molding, demoulding, and wait until it is lowered to room temperature to obtain a fireproof insulation board . Its per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com