Alkyd resin composition preparation method, and alkyd resin composition prepared therethrough

A technology of alkyd resin and composition, applied in the field of alkyd resin composition, which can solve the problems of environmental pollution, easy leakage of molecules, waste of resources and energy, etc., and achieve the effect of reducing cost, reducing dosage, and benefiting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

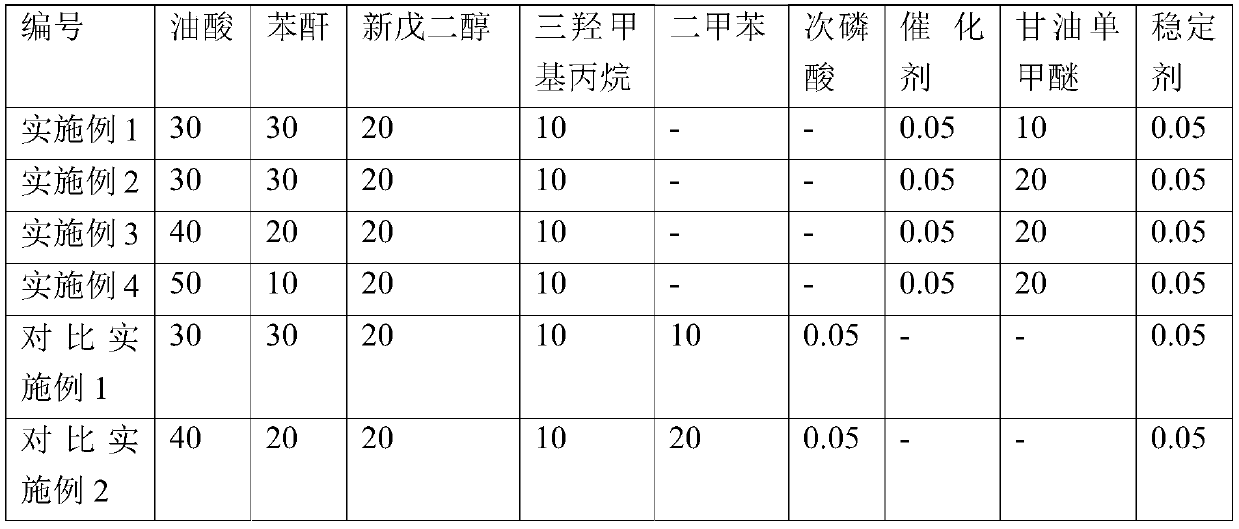

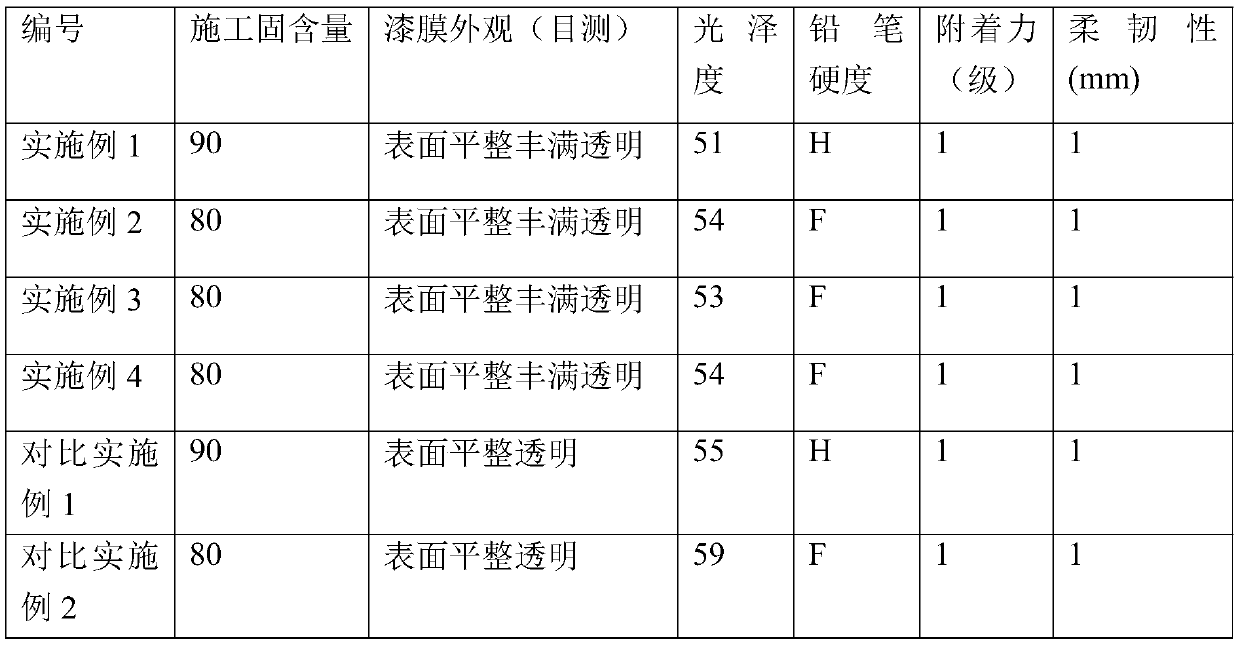

Embodiment 1

[0047] Prepare a high-solid, low-viscosity, low-VOC alkyd resin composition as follows:

[0048] (1) 30 parts of oleic acid, 30 parts of phthalic anhydride, 20 parts of neopentyl glycol, 10 parts of trimethylolpropane, 0.05 parts of catalyst, 10 parts of glycerol monomethyl ether and 0.05 parts of antioxidant 1098 are put into the reaction in turn in the cauldron.

[0049] (2) Introduce high-purity nitrogen or carbon dioxide protective gas into the stainless steel reaction kettle, vacuumize three times continuously to remove the oxygen in the reaction kettle, then raise the temperature to 150°C, keep the temperature for 1h, then rise to 160°C, keep the temperature for 1h, Then rise to 170°C, hold the temperature for 1 hour, then rise to 180°C, hold the temperature for 1 hour, then rise to 190°C, hold the temperature for 1 hour, then rise to 200°C, hold the temperature for 1 hour, and finally rise to 210°C.

[0050] (3) The reaction system carries out the esterification reacti...

Embodiment 2

[0053] Prepare a high-solid, low-viscosity, low-VOC alkyd resin composition as follows:

[0054](1) 30 parts of oleic acid, 30 parts of phthalic anhydride, 20 parts of neopentyl glycol, 10 parts of trimethylolpropane, 0.05 parts of catalyst, 20 parts of glycerol monomethyl ether and 0.05 parts of antioxidant 1098 are put into the reaction in turn in the cauldron.

[0055] (2) Introduce high-purity nitrogen or carbon dioxide protective gas into the stainless steel reaction kettle, vacuumize three times continuously to remove the oxygen in the reaction kettle, then raise the temperature to 150°C, keep the temperature for 1h, then rise to 160°C, keep the temperature for 1h, Then rise to 170°C, hold the temperature for 1 hour, then rise to 180°C, hold the temperature for 1 hour, then rise to 190°C, hold the temperature for 1 hour, then rise to 200°C, hold the temperature for 1 hour, and finally rise to 210°C.

[0056] (3) The reaction system carries out the esterification reactio...

Embodiment 3

[0059] Prepare a high-solid, low-viscosity, low-VOC alkyd resin composition as follows:

[0060] (1) 30 parts of oleic acid, 30 parts of phthalic anhydride, 20 parts of neopentyl glycol, 10 parts of trimethylolpropane, 0.05 parts of catalyst, 20 parts of glycerol monomethyl ether and 0.05 parts of antioxidant 1098 are put into the reaction in turn in the cauldron.

[0061] (2) Introduce high-purity nitrogen or carbon dioxide protective gas into the stainless steel reaction kettle, vacuumize three times continuously to remove the oxygen in the reaction kettle, then raise the temperature to 150°C, keep the temperature for 1h, then rise to 160°C, keep the temperature for 1h, Then rise to 170°C, hold the temperature for 1 hour, then rise to 180°C, hold the temperature for 1 hour, then rise to 190°C, hold the temperature for 1 hour, then rise to 200°C, hold the temperature for 1 hour, and finally rise to 210°C.

[0062] (3) The reaction system carries out the esterification reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com