Efficient electrostatic dust collector

An electrostatic precipitator and precipitator technology, applied in the direction of electrostatic separation, particle charging/ionization places, etc., can solve the problems of large volume, high cost, low dust removal efficiency, etc., achieve small size, save space, and improve dust removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

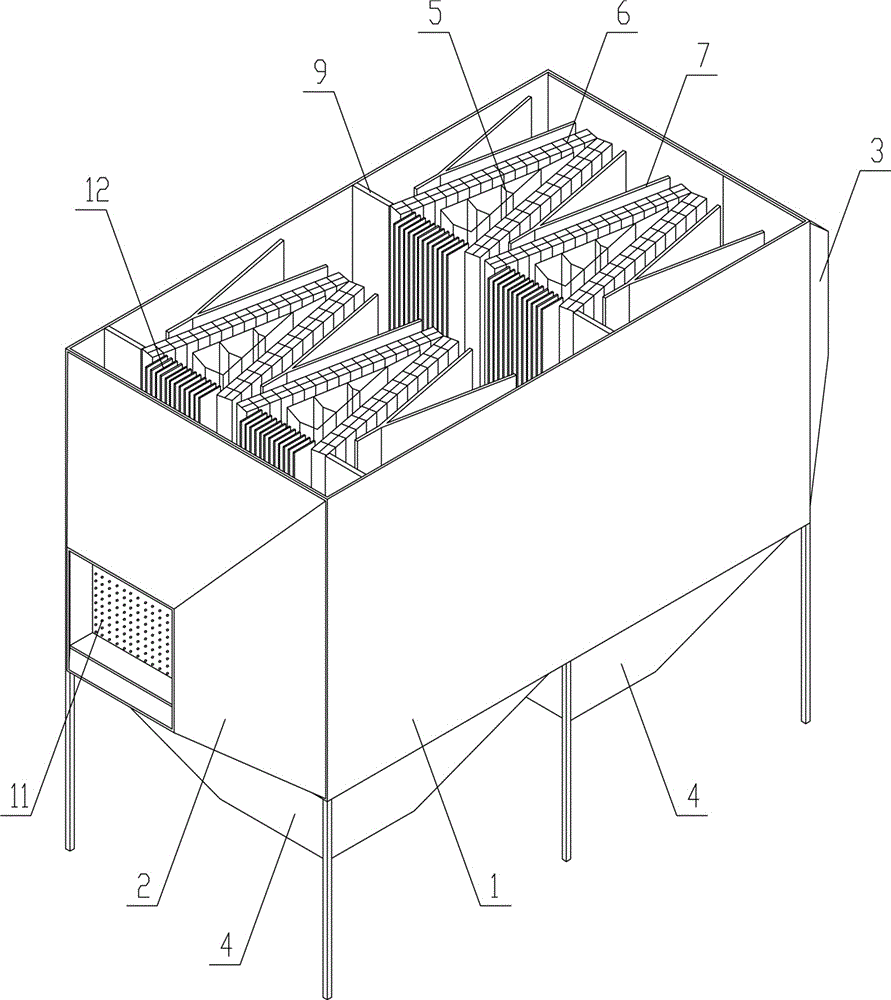

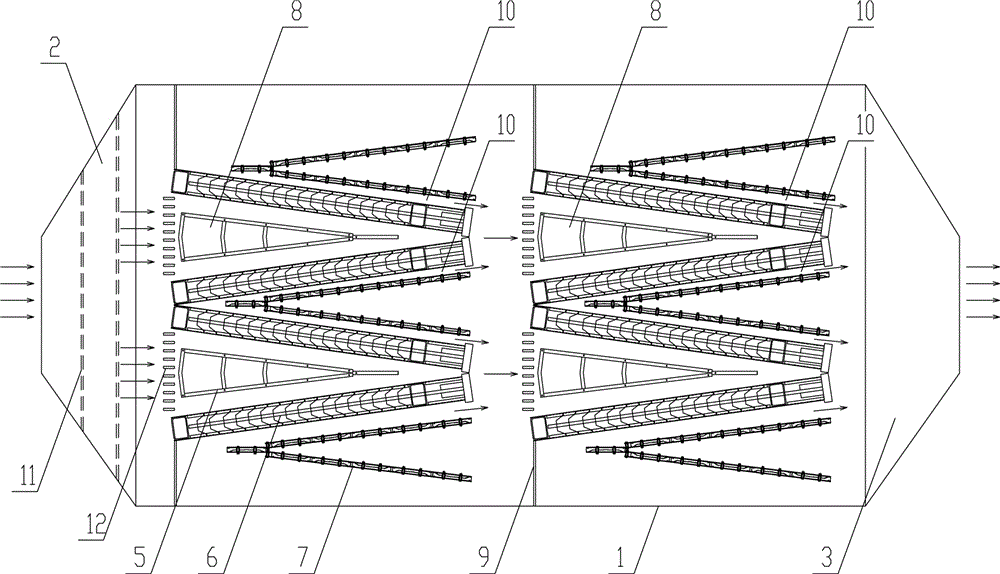

[0018] see figure 1 , figure 2 , the present invention includes a dust collector body 1, an inlet head 2, an outlet head 3 and an ash collecting hopper 4, the inlet head 2 and the outlet head 3 are correspondingly arranged at the inlet end and the outlet end of the dust collector body 1, and the dust collector body The dust collection bucket 4 is arranged at the bottom of 1; several groups of electric field structures are arranged from the inlet end to the outlet end of the dust collector body 1, and each group of electric field structures includes several groups of three-electrode breeze dust removal units arranged side by side, and each group has three The electrode breeze dust removal unit has a cathode suspension 5, left and right louver plates 6 are arranged on both sides of the cathode suspension 5, and left and right anode plates 7 are arranged on the outside of the two louver plates, wherein the anode plate 7. The potentials of the louver plates 6 and the cathode sus...

Embodiment 2

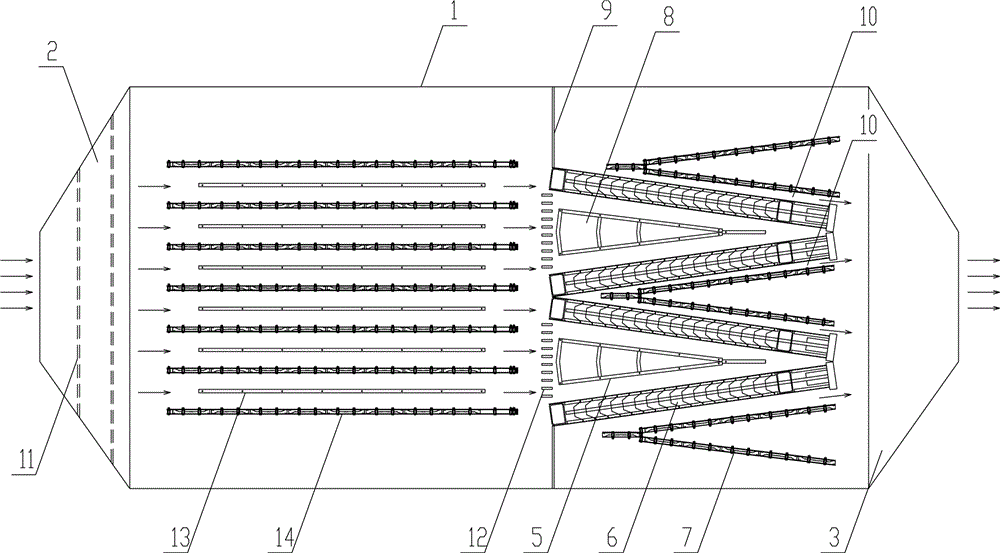

[0027] see image 3 , this embodiment makes improvements on the basis of Embodiment 1, the difference is that: the electric field structure described in this embodiment also includes several groups of two-electrode dust removal units arranged side by side, and the two electrode dust removal units are composed of cathode suspension 13 and Composed of anode plate 14; two electric field structures with two-electrode dust removal unit and three-electrode breeze dust removal unit are combined and arranged in the dust collector body 1, and the flow direction of the dust-laden flue gas in the dust collector is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com