Intelligent three-view linkage method and intelligent three-view linkage system for production line

A technology of intelligent linkage and production line, applied in general control system, control/adjustment system, comprehensive factory control, etc., can solve the problems of complex design process of personalized customized production line, large time occupation, site capital, large investment in production line research and development, etc. Achieve the effect of saving production input costs, reducing input costs, and shortening the debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

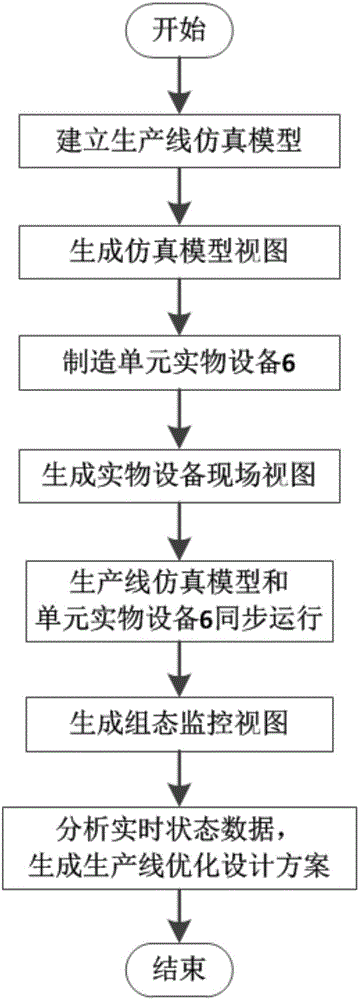

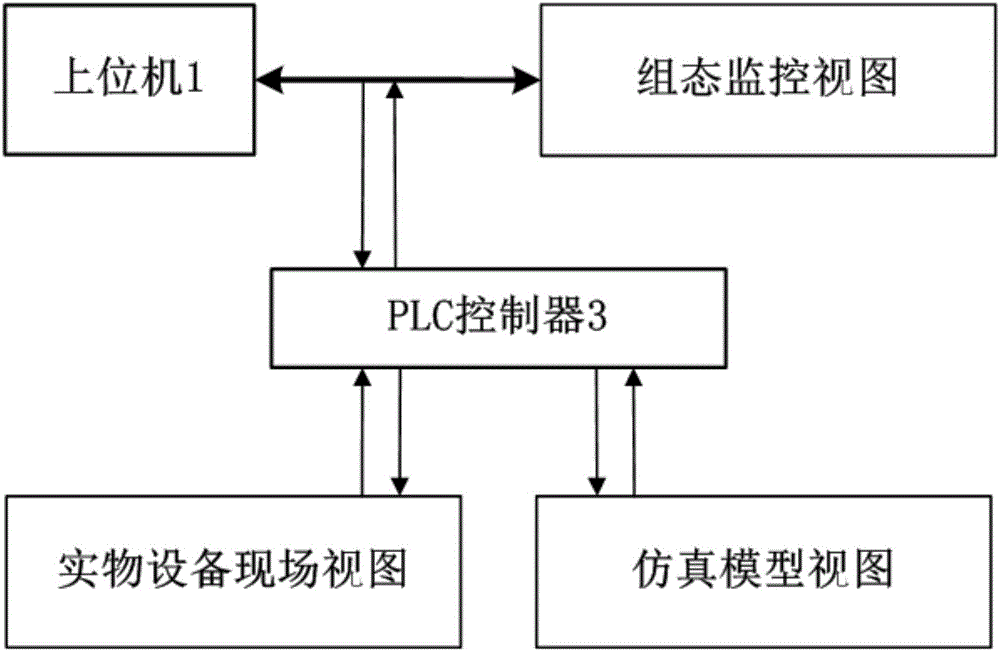

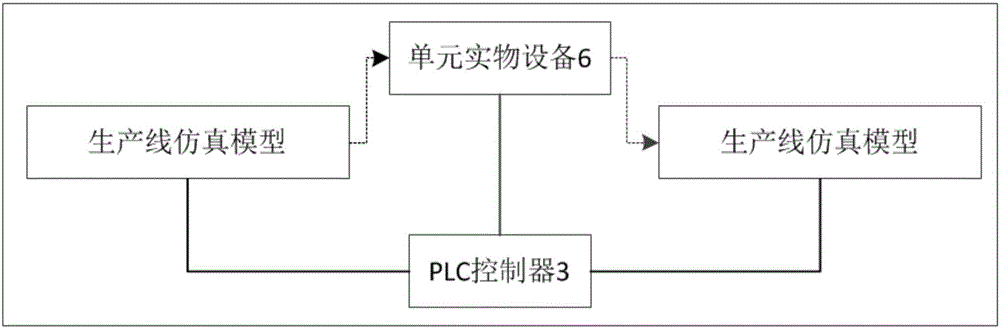

[0062] The three-view intelligent linkage method of the production line in this embodiment, such as figure 1 , Figure 5 shown, including the following steps:

[0063] Step A, obtain and perform three-dimensional modeling in the simulation system 2 according to the design requirements information of the production line, establish a simulation model of the production line, and form a simulation model view on the host computer 1 to view the motion state of the simulation model of the production line, such as figure 2 shown;

[0064] Step B, according to the production line simulation model, manufacture the unit physical equipment 6 of the unit to be tested in the production line, the unit physical equipment 6 is completely consistent with the corresponding unit in the production line simulation mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com