Method for preparing graphene by chemical vapor deposition

A chemical vapor deposition and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of loss of electrical conductivity, low quality of graphene, difficult to restore graphite, etc., and achieve excellent electrical conductivity, high light transmittance, and high transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

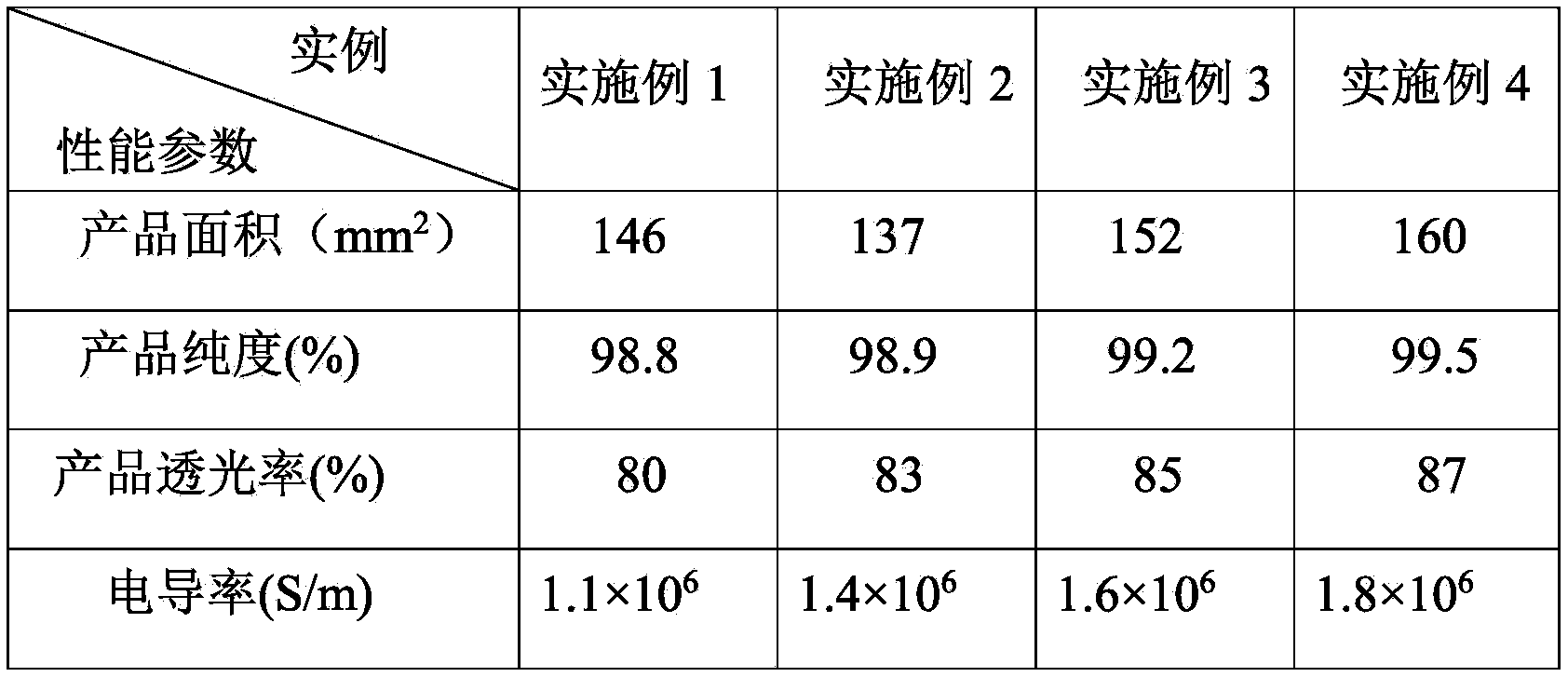

Embodiment 1

[0024] Present embodiment provides a kind of chemical vapor deposition method to prepare graphene, is to make through the following steps:

[0025] 1) Purify the copper alloy substrate: ultrasonically clean the copper alloy in 15% hydrochloric acid solution, 50% acetone and 75% ethanol solution for 10 minutes in sequence, and dry at 80°C in a nitrogen environment;

[0026] 2) Place the copper alloy: place the copper alloy in parallel in the chemical vapor deposition (CVD) equipment, and evacuate the CVD equipment to within 1mTorr;

[0027] 3) Remove the oxide film on the surface of the copper alloy: raise the copper alloy to 980°C within 50 minutes, then inject hydrogen gas with a flow rate of 650 sccm from the bottom inlet of the CVD equipment, keep the pressure in the CVD equipment at 0.1-90 Torr, and remove the oxide film on the surface of the copper alloy. oxide film;

[0028] 4) Preparation of graphene: keep the pressure in the CVD equipment at 0.1 to 90 Torr, and the te...

Embodiment 2

[0032] Present embodiment provides a kind of chemical vapor deposition method to prepare graphene, is to make through the following steps:

[0033] 1) Purify the copper alloy substrate: ultrasonically clean the copper alloy in 10% hydrochloric acid solution, 60% acetone and 65% ethanol solution for 10 minutes in sequence, and dry at 75° C. under nitrogen atmosphere;

[0034]2) Place the copper alloy: place the copper alloy in parallel in the chemical vapor deposition (CVD) equipment, and evacuate the CVD equipment to within 1mTorr;

[0035] 3) Remove the oxide film on the surface of the copper alloy: raise the copper alloy to 980°C within 50 minutes, then inject hydrogen gas with a flow rate of 650 sccm from the bottom inlet of the CVD equipment, keep the pressure in the CVD equipment at 0.1-90 Torr, and remove the oxide film on the surface of the copper alloy. oxide film;

[0036] 4) Preparation of graphene: keep the pressure in the CVD equipment at 0.1 to 90 Torr, and the t...

Embodiment 3

[0040] Present embodiment provides a kind of chemical vapor deposition method to prepare graphene, is to make through the following steps:

[0041] 1) Purify the copper alloy substrate: ultrasonically clean the copper alloy in 18% hydrochloric acid solution, 50% acetone and 65% ethanol solution for 10 minutes in sequence, and dry at 80° C. in a nitrogen environment;

[0042] 2) Place the copper alloy: place the copper alloy in parallel in the chemical vapor deposition (CVD) equipment, and evacuate the CVD equipment to within 1mTorr;

[0043] 3) Remove the oxide film on the surface of the copper alloy: raise the copper alloy to 980°C within 55 minutes, then inject hydrogen gas with a flow rate of 700 sccm from the bottom inlet of the CVD equipment, keep the pressure in the CVD equipment at 0.1-90 Torr, and remove the oxide film on the surface of the copper alloy. oxide film;

[0044] 4) Preparation of graphene: keep the pressure in the CVD equipment at 0.1 to 90 Torr, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com