Post forming method of aluminum pot body

A secondary molding and aluminum pot technology, which is applied in the direction of forming tools, metal processing equipment, stripping devices, etc., can solve the problems of large investment, space saving and improvement, so as to reduce production input costs, increase thinning, precision and The effect of low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

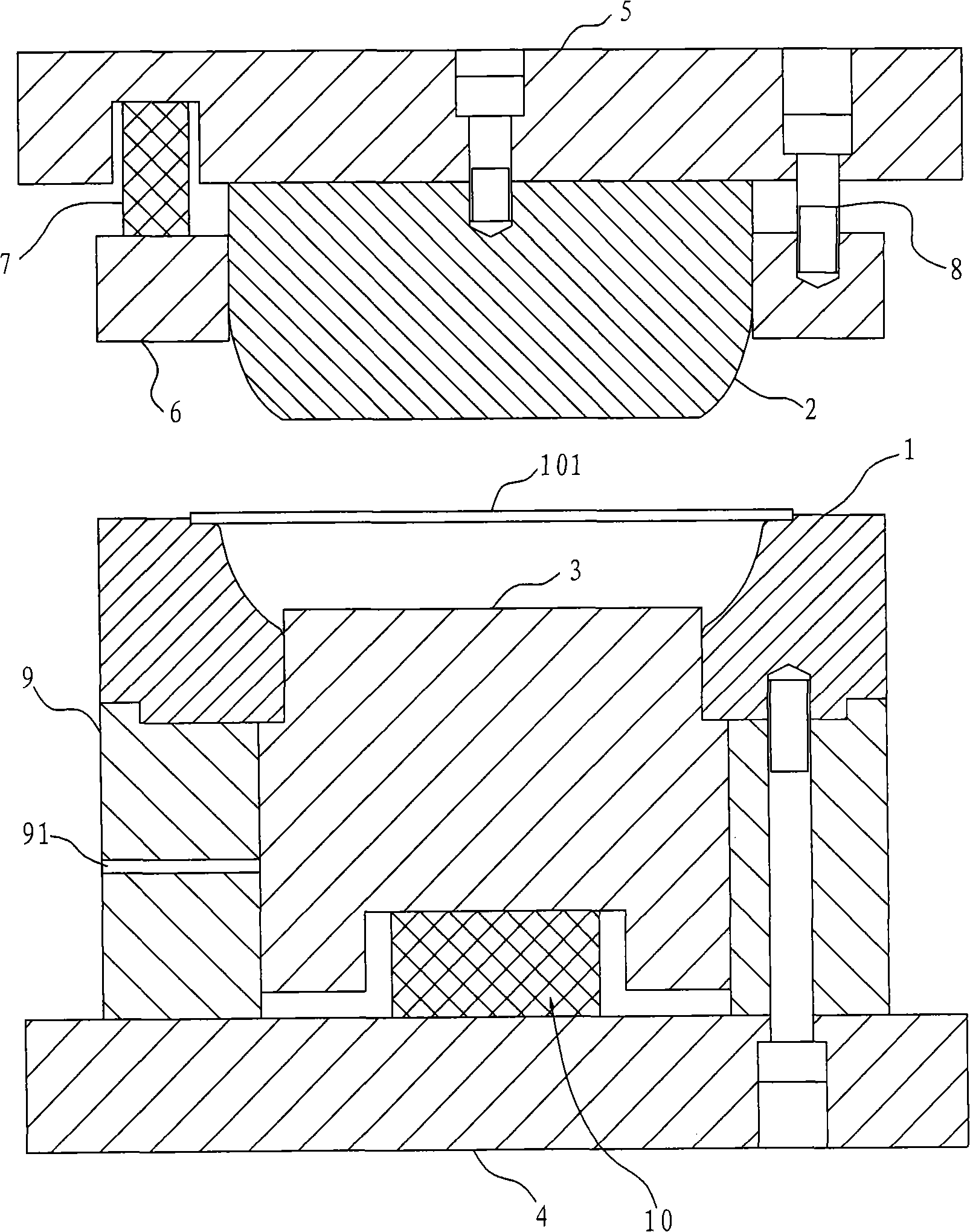

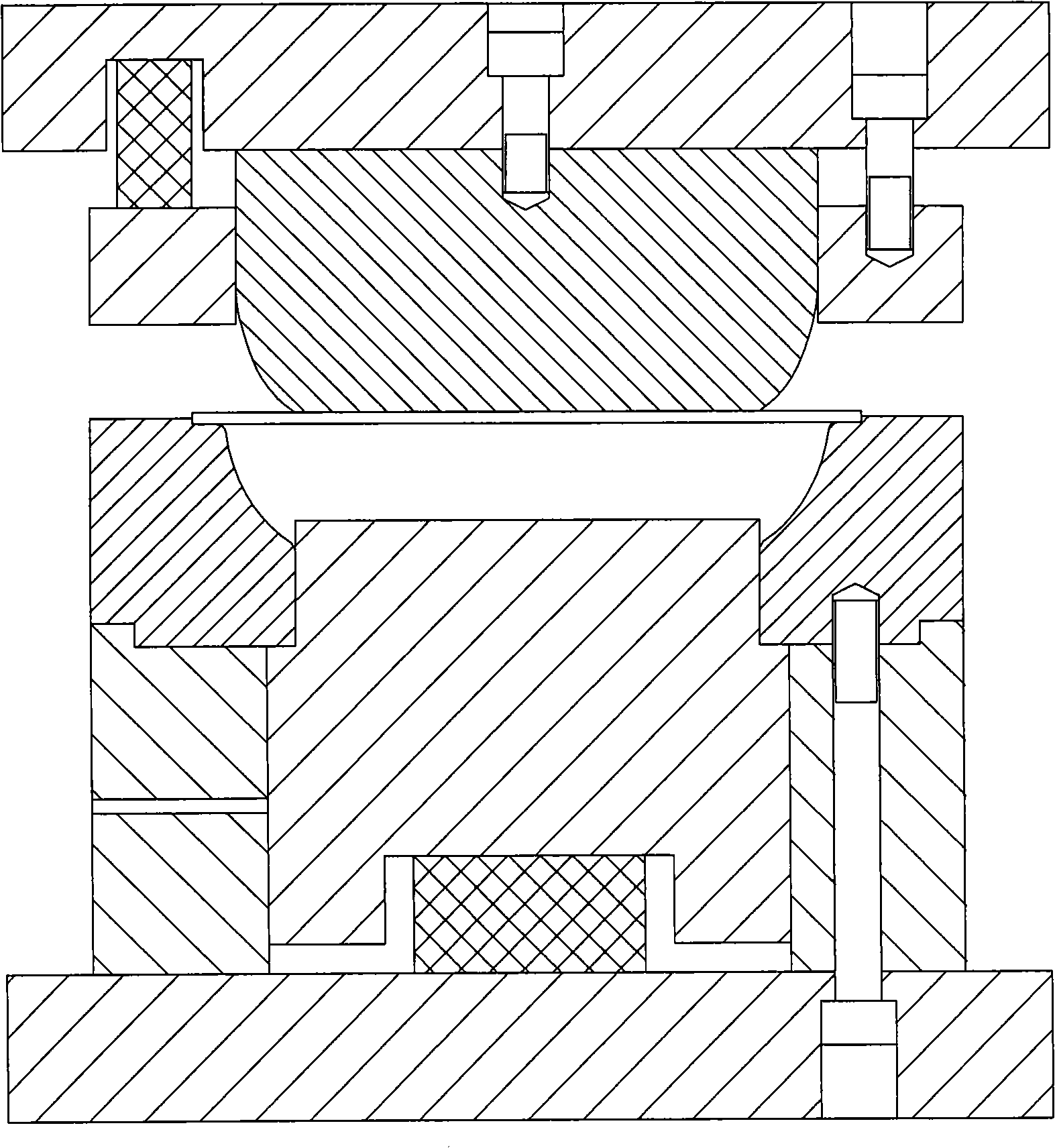

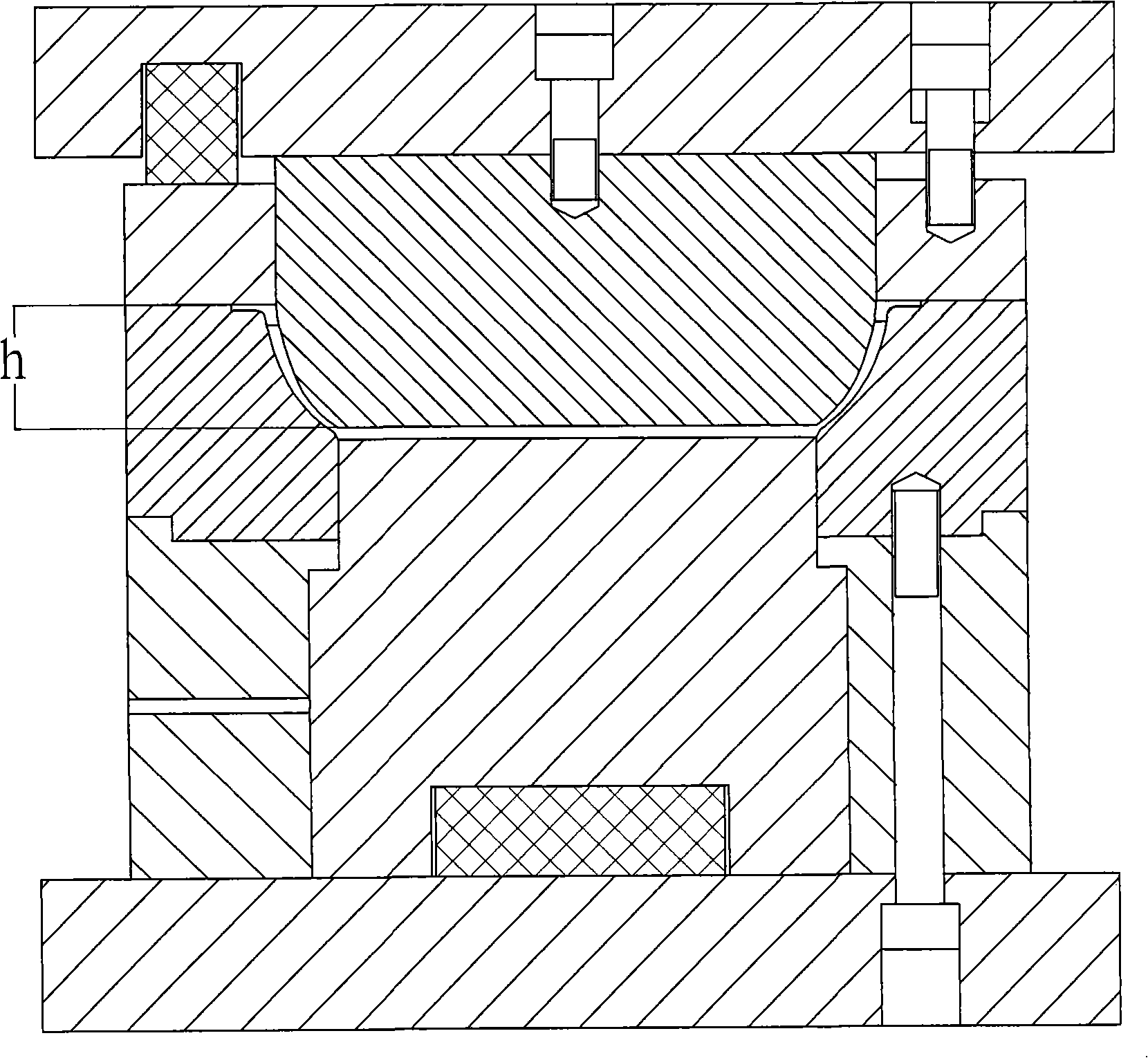

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The mold used for the secondary molding of the aluminum pan body includes a first mold and a second mold.

[0023] refer to figure 1 , the first mold is composed of the first concave mold 1 and the first convex mold 2, the inner wall of the first concave mold 1 and the outer wall of the first convex mold 2 are consistent with the wall of the aluminum pot body, and the first convex mold 2 is located at the second Above a die 1, the first die 1 is set on the first lower template 4 through a first base 9 with a first vent hole 91, and the middle part of the first die 1 is provided with a first force that can be lowered. Push block 3, the bottom of the first push block 3 is provided with elastic first polyurethane rubber 10, the first punch 2 is set on the first upper template 5, and the periphery of the first punch 2 is closely attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com