Magnetic rod with movable magnets and iron removal device applying magnetic rod

A magnetic bar and magnet technology, applied in the magnetic field, can solve problems such as damage, uneven distribution of magnetic force lines, weak magnetic field, etc., and achieve the effects of reduced use, simple structure, and strong magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

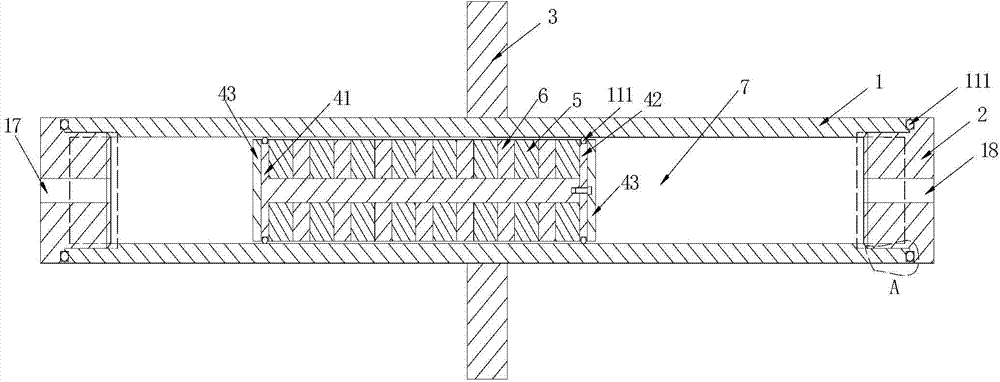

[0031] Embodiment 1: as figure 1 As shown in the magnetic bar, in the first embodiment, the shell part is composed of a cylindrical shell 1 and two sealing covers 2 . Both ends of the housing 1 are open, and an annular first sealing groove 11 is provided on the end surface. Internal threads are processed at the openings at both ends of the housing 1 . A baffle 3 is also provided on the shell 1 , and the baffle 3 is set in the middle of the shell 1 . The sealing cover 2 is a T-shaped cylindrical member, including a flange 12 and a protruding end 13 . The flange 12 is provided with a second sealing groove 14 corresponding to the first sealing groove 11 on the housing 1 . The protruding end 13 is processed with an external thread matching the internal thread at the opening of the housing 1 . Both sides of the sealing cover 2 are also provided with air intake passages, which are respectively a left air intake hole 17 and a right air intake hole 18 . A magnetic rod piston cham...

Embodiment 2

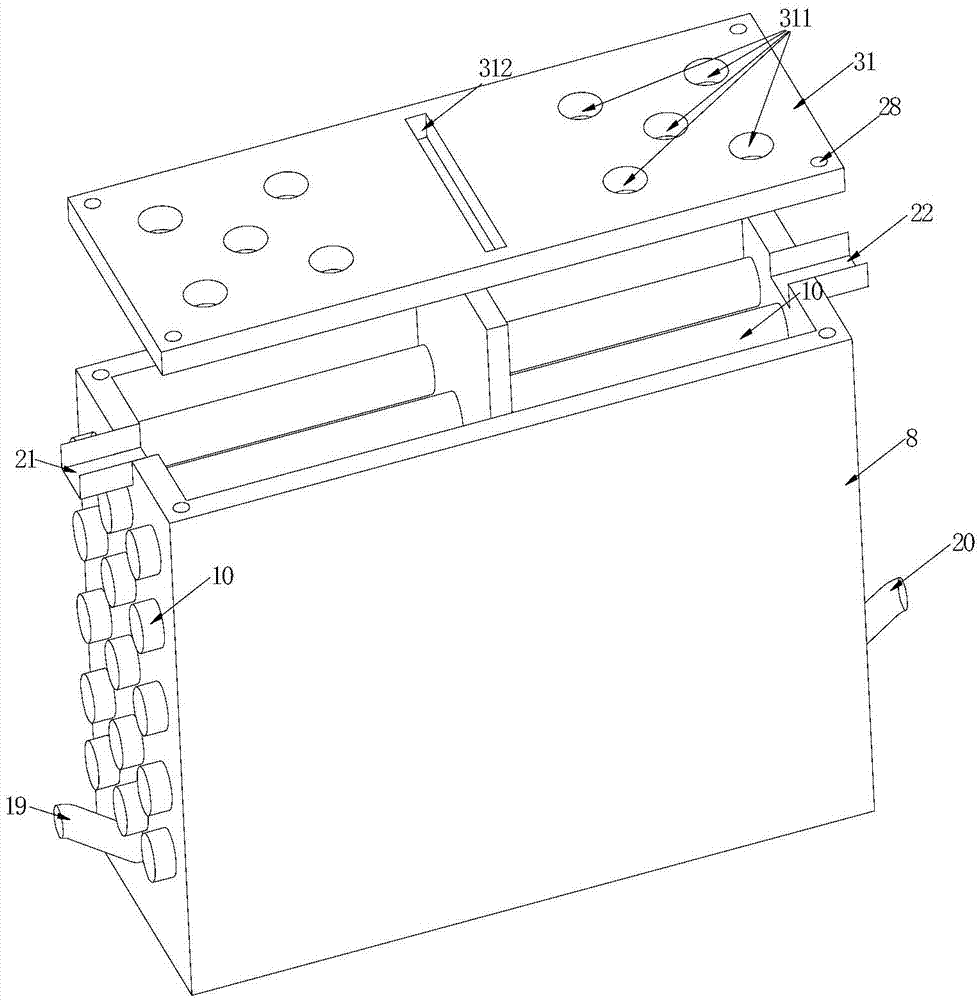

[0035] Embodiment 2: as figure 2 , 5 , 6, 7, 8, 9, a slurry iron removal device, including a working chamber 8. The working chamber 8 is a cuboid structure with an opening at the top and a partition 9 in the middle of the chamber. The height of the partition 9 is higher than that of the working chamber 8 and divides the working chamber 8 equally into two parts, which are respectively a left working chamber 81 and a right working chamber 82 . The side of the working chamber 8 is provided with 2 stock inlets, which are respectively the left stock port 19 and the right stock port 20, and the top of the working chamber 8 is provided with 2 stock outlet channels, which are respectively the left stock port 21 and the right stock port 20. The right pulp outlet channel 22, and the bottom of the working chamber 8 are also provided with two pulp return ports, which are respectively the left pulp return port 23 and the right pulp return port 24, 1 pulp inlet port, 1 pulp outlet channe...

Embodiment 3

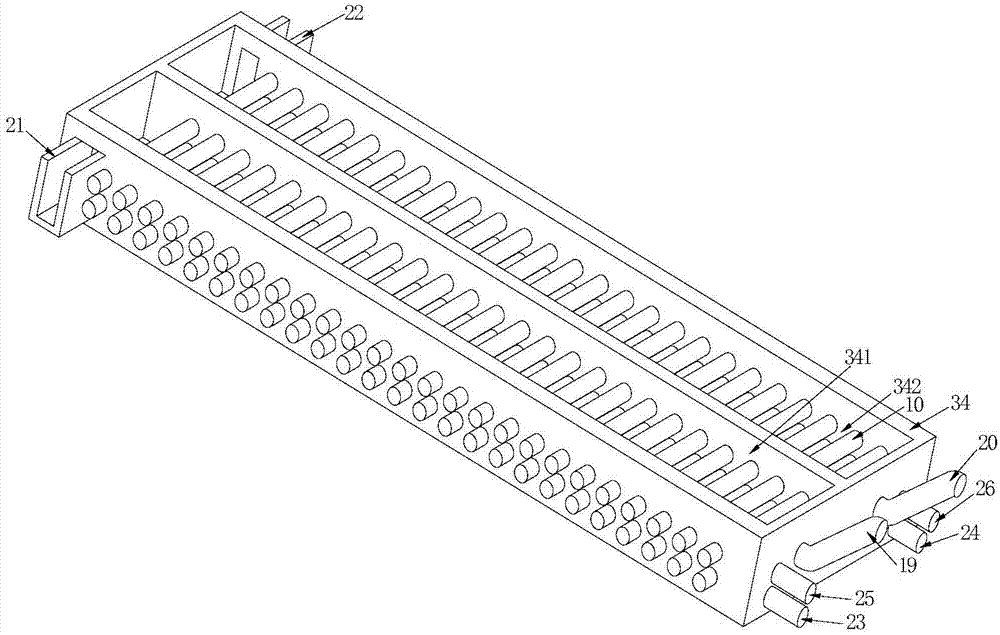

[0043] Embodiment 3: as image 3 As shown, a trough-type iron removal device includes a trough body 34 having a general trough structure, and a partition 9 is provided in the middle of the trough body 34 . The height of the partition plate 9 is flush with the tank body 34 , and the cavity of the tank body 34 is equally divided into two parts, namely the left flow groove 341 and the right flow groove 342 . The initial end of the tank body 34 is provided with two pulp inlets, which are respectively the left pulp inlet port 19 and the right pulp inlet port 20, and the end of the tank body 34 is provided with two pulp outlet channels, which are respectively the left pulp outlet channel 21 And the right pulp outlet channel 22, the end of the tank body 34 is also provided with two return ports, which are respectively the left return port 23 and the right return port 24. One stock inlet, one return port and one A group of pulp outlet flow channels is distributed symmetrically with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com