Patents

Literature

222 results about "Cloud manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

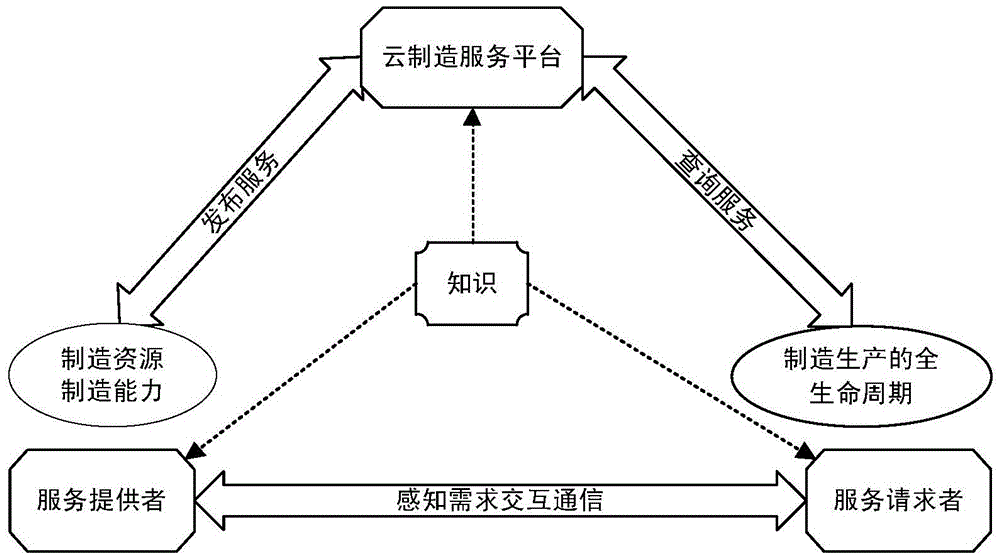

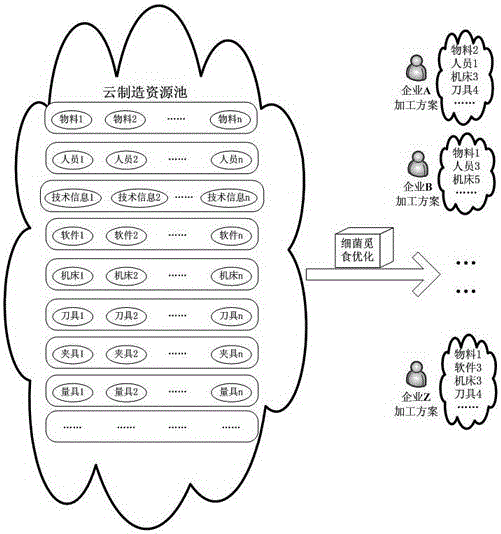

Cloud manufacturing (CMfg) is a new manufacturing paradigm developed from existing advanced manufacturing models (e.g., ASP, AM, NM, MGrid) and enterprise information technologies under the support of cloud computing, Internet of Things (IoT), virtualization and service-oriented technologies, and advanced computing technologies. It transforms manufacturing resources and manufacturing capabilities into manufacturing services, which can be managed and operated in an intelligent and unified way to enable the full sharing and circulating of manufacturing resources and manufacturing capabilities. CMfg can provide safe and reliable, high quality, cheap and on-demand manufacturing services for the whole lifecycle of manufacturing. The concept of manufacturing here refers to big manufacturing that includes the whole lifecycle of a product (e.g. design, simulation, production, test, maintenance).

Information security management and control method under cloud manufacturing environment

InactiveCN102710605ASolve the problem of update and maintenanceAvoid complex proceduresPublic key for secure communicationUser identity/authority verificationConfidentialityPrivate network

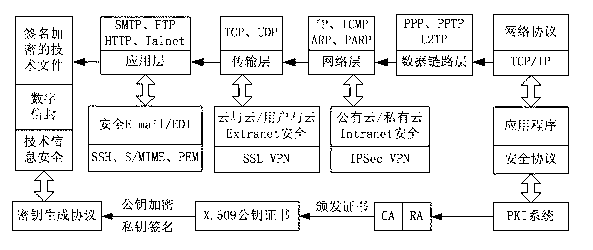

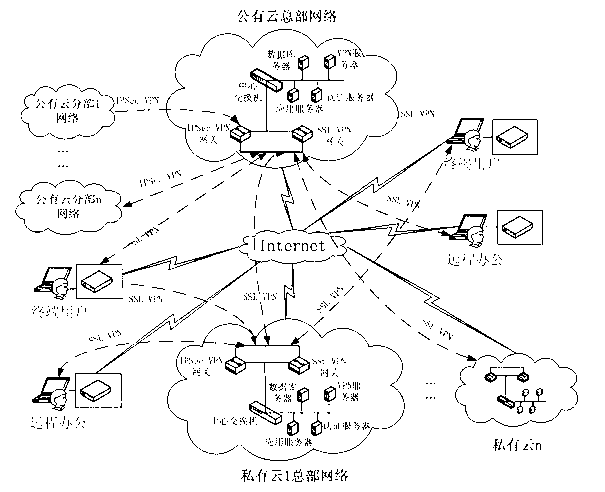

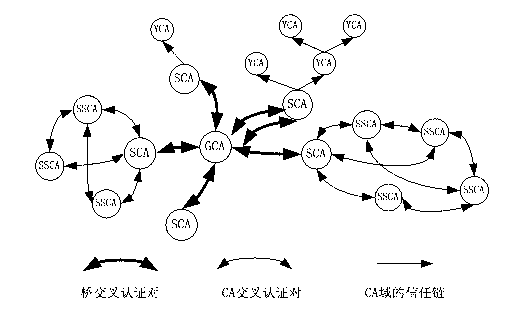

The invention discloses an information security management and control method under a cloud manufacturing environment. On the basis of a network security protocol, a password technology and a public key infrastructure (PKI), comprehensive security guarantee is supplied to information interaction among cloud internal networks, between one cloud and another cloud, and between a user and each cloud by using implementation technologies and methods, such as a virtual private network (VPN) based on multiple layers of protocols, a digital envelope and a password algorithm; Intranet, Extranet and Internet of a cloud manufacturing system are covered; comprehensive management and control technical information files are stored and transmitted to each used loop; a session key (SK) which is randomly produced by using a key production protocol is used for symmetrically encrypting the technical information files; and a receiver public key obtained according to a PKI digital certificate asymmetrically encrypts the SK to form the digital envelope for protecting the technical information files and the SK. The information security management and control method has the characteristics of being high in confidentiality, high inefficiency, flexible in arrangement and the like and can be widely applied to the cloud manufacturing system and other network manufacturing systems.

Owner:CHONGQING UNIV

Manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities

InactiveCN102176723ARealize analysisAchieving processing powerTransmissionSoftware simulation/interpretation/emulationInformatizationResource utilization

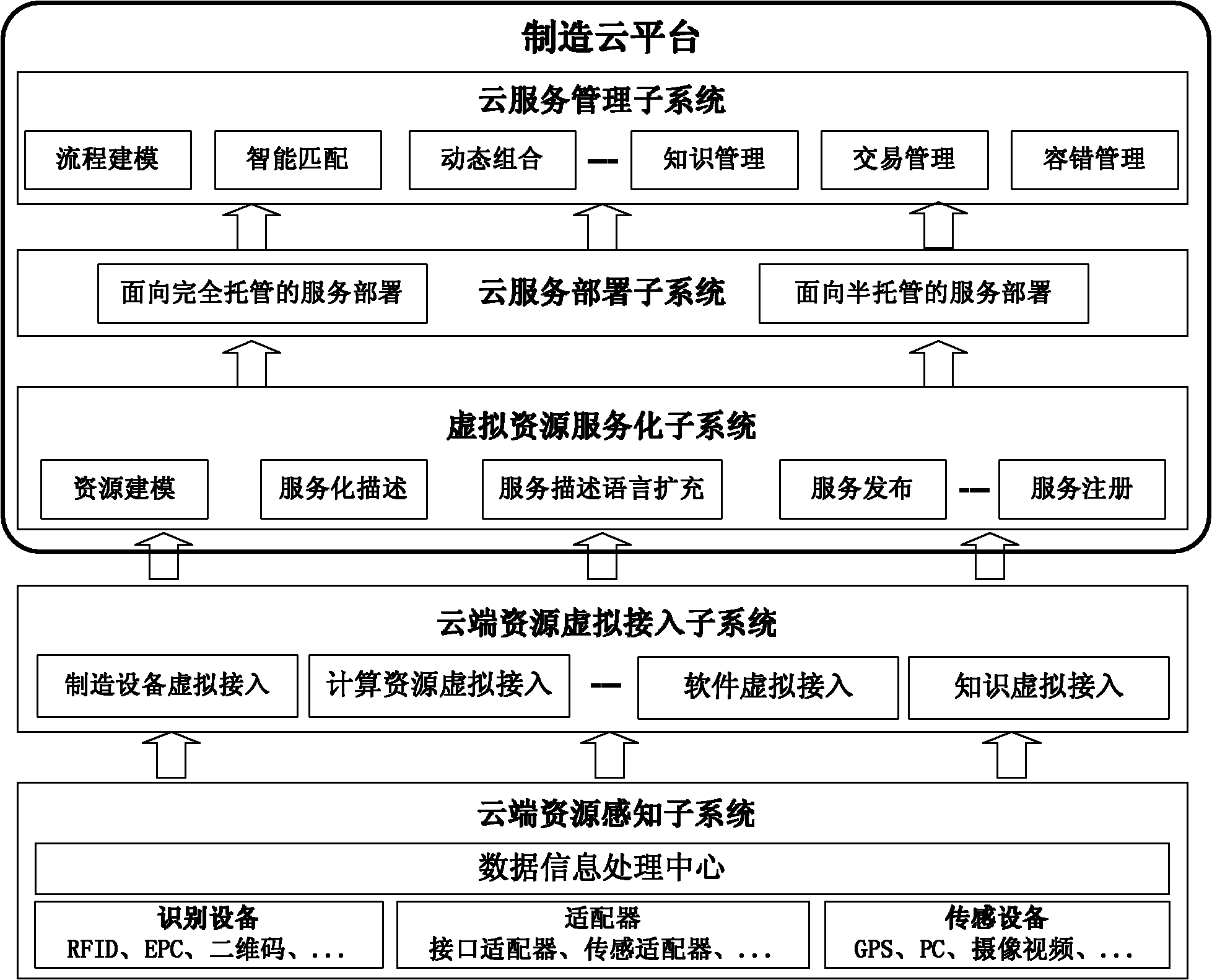

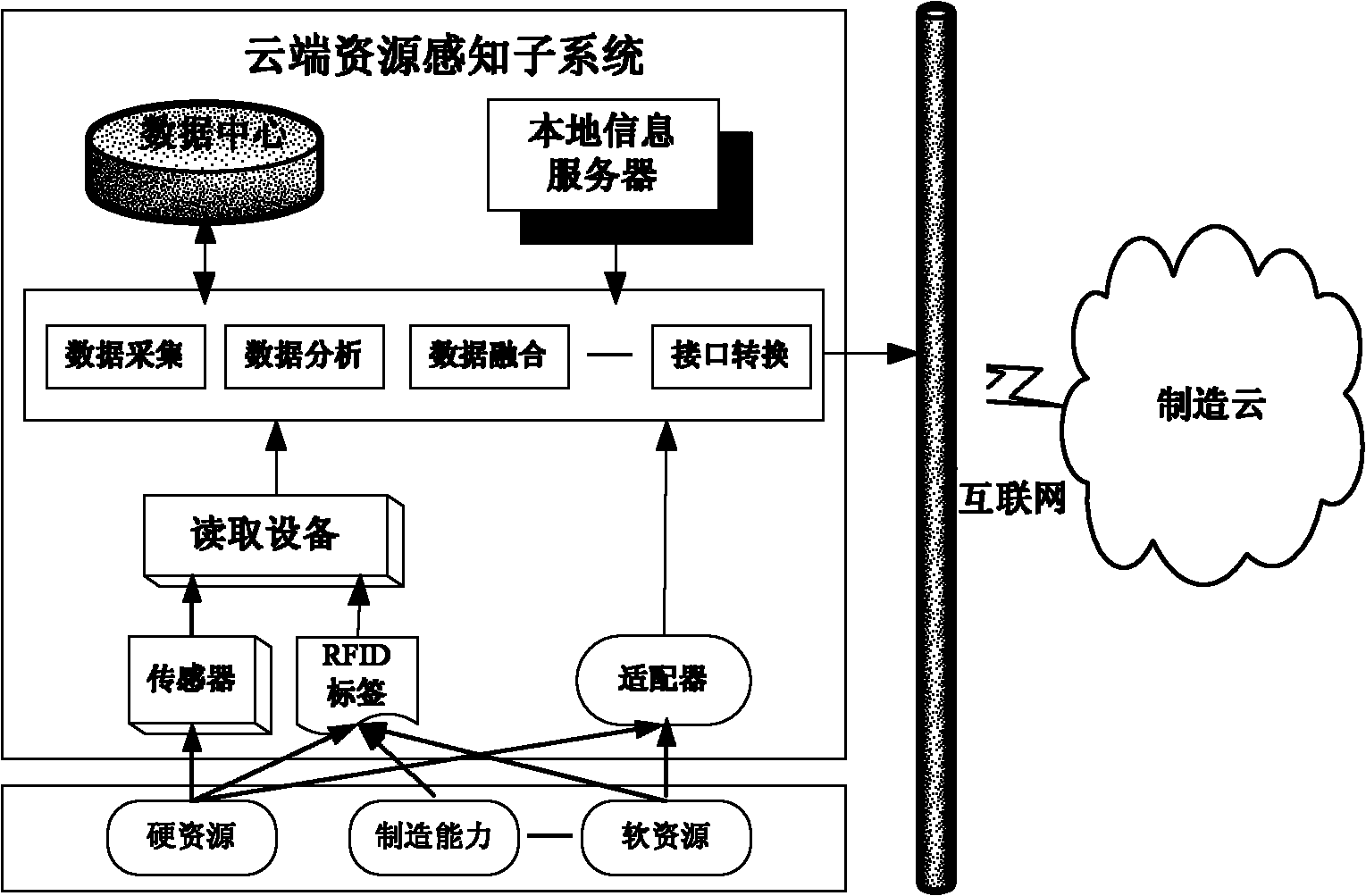

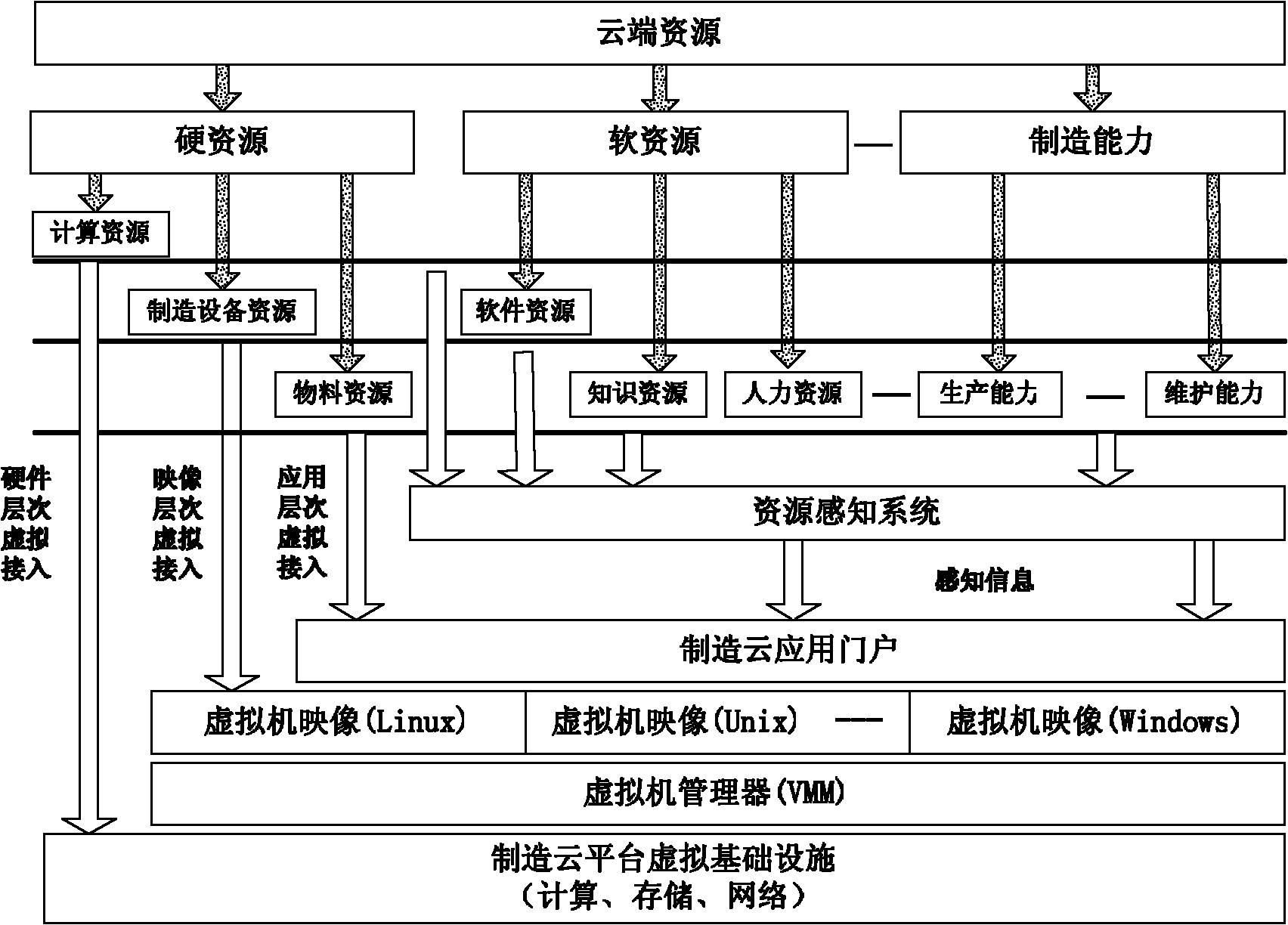

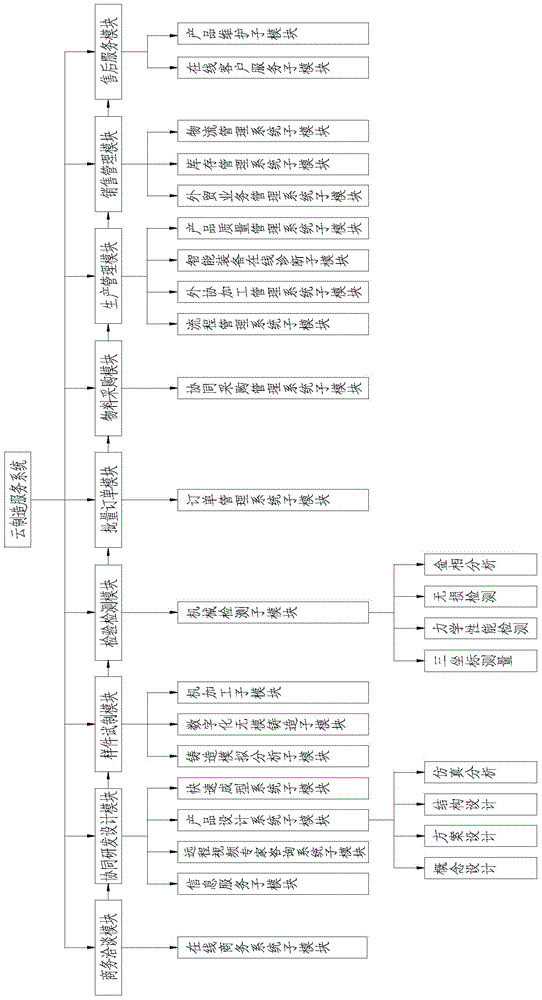

The invention provides a manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities, which is used for solving the problems that the use ratio of resources is low, the sharing of the manufacturing capacities is insufficient, effective business operation management measures are short and the like in the process of manufacturing enterprise informatization in China. Aiming at the characteristics of the manufacturing resources and the actual demands of an enterprise for a cloud manufacturing service platform, and according to the lifeline of a cloud service life cycle, the manufacturing resources and the manufacturing capacity in the manufacturing cloud system are designed and stated in five system modules namely intellisense, virtual access, virtual resource servicesation, deployment of cloud services, and integrated management of the cloud services, thus meeting the demand of the on-demand use and the dynamic collaboration of the manufacturing resources and the manufacturing capacities. The manufacturing cloud system has the advantages that the intellisense, the servicesation of the manufacturing capacities and service life cycle demands which are accessed to the manufacturing resources are supported, the intelligence is supported, the services are shared on demand, the system structure is flexible, the levels are distinct, and the expandability is strong.

Owner:BEIHANG UNIV

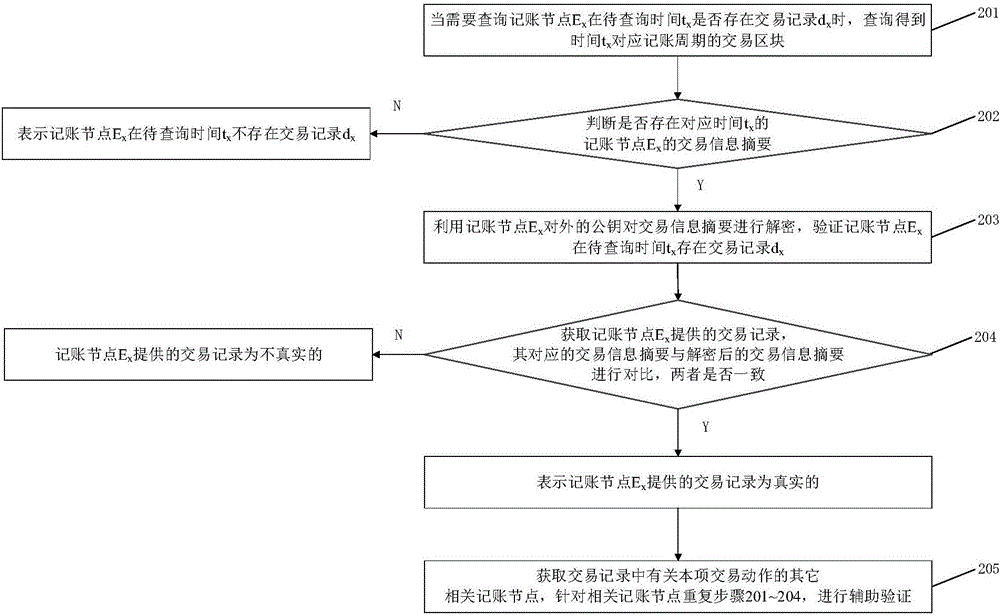

Cloud manufacturing service transaction information recording system and method based on block chain

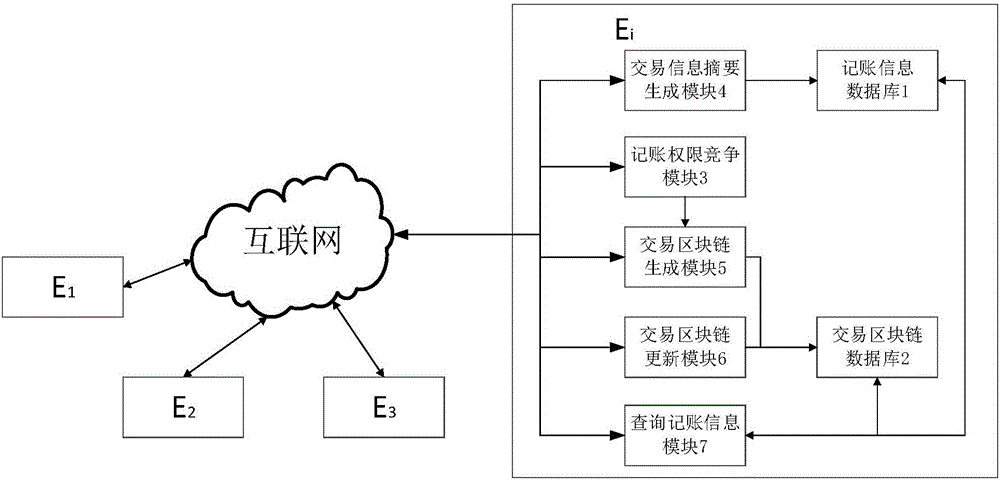

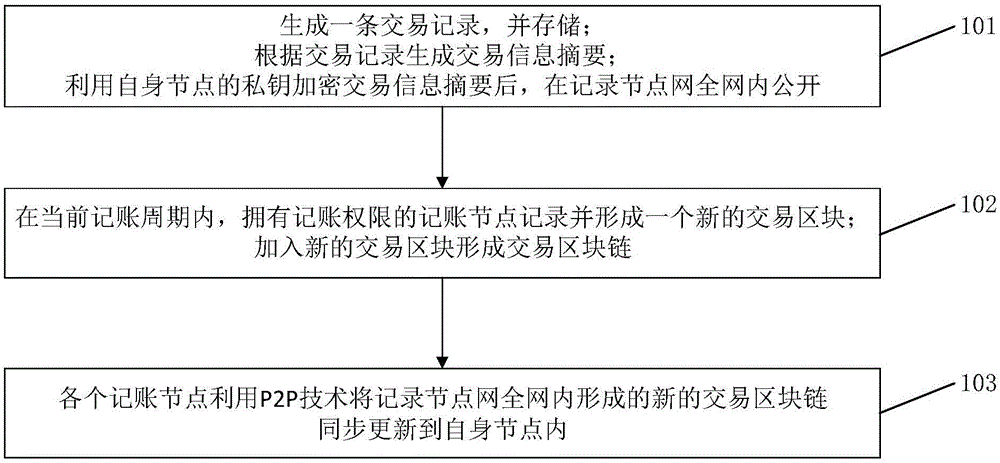

ActiveCN106790431AOvercome opacityOvercoming data discrepanciesResourcesTransmissionComputer moduleData recording

The invention relates to a cloud manufacturing service transaction information recording system and method based on a block chain. The system comprises a plurality of book keeping nodes; a plurality of book keeping nodes are communicated with each other to form a recording node network; each book keeping node comprises a book keeping information database, a transaction block chain database, a book keeping permission competition module, a transaction information abstract generation module, a transaction block chain generation module and a transaction block chain updating module; the method is applied to the recording node network; recording node network comprises a plurality of book keeping nodes communicated with each other; each book keeping node contests for book keeping permissions in different book keeping periods in a competing mode; and the method comprises a transaction information recording process and a transaction information inquiry verification process. Compared with the prior art, according to the cloud manufacturing service transaction information recording system and method disclosed by the invention, a data recording method and a data structure in the cloud manufacturing service transaction process are improved, and non-repudiation and inquiry verification of transaction can be conveniently implemented.

Owner:TONGJI UNIV

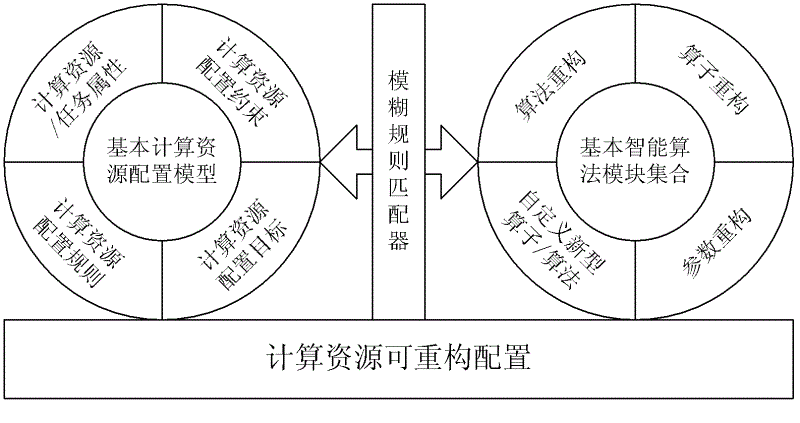

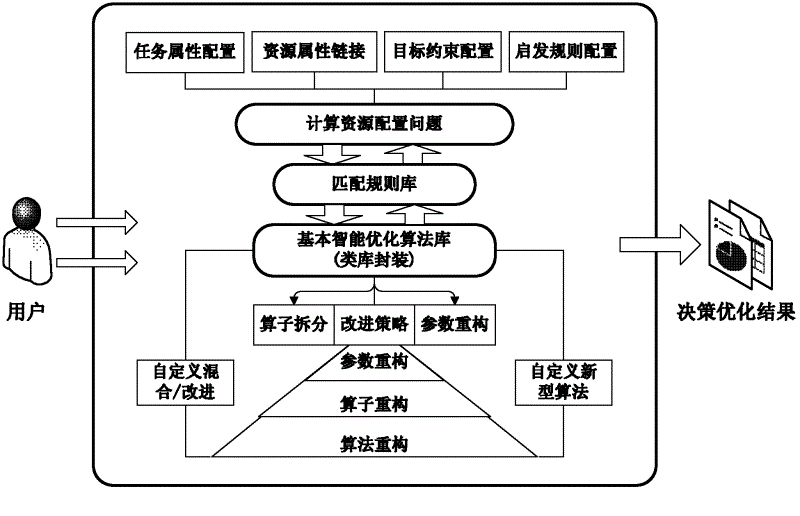

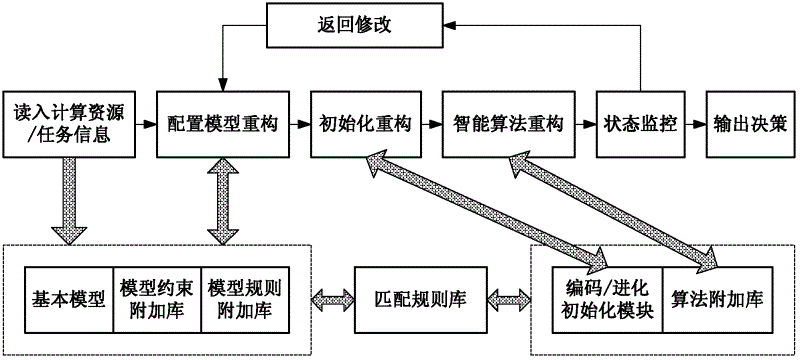

Intelligent optimization algorithm based cloud manufacturing computing resource reconfigurable collocation method

InactiveCN102624870ASolve the singularityIncrease flexibilityTransmissionCollocationStationary model

The invention relates to an intelligent optimization algorithm based cloud manufacturing computing resource reconfigurable collocation method, in particular to a method for modifying relevant collocation attributes and algorithms online according to different collocation conditions on the basis of multiple intelligent optimization algorithms, which aims to realize flexible, extendible and efficient policy solution of massive computing resource collocation in the cloud manufacturing mode and flexible disintegration, integration and reconfiguration of model demands, input / output and policy operators in a modularization and servicisation manner, and solves the bottleneck problems of singleness and non-portability and the like caused by regular constraint, fixed models and regular algorithms in computing resource collocation. The intelligent optimization algorithm based cloud manufacturing computing resource reconfigurable collocation method has the following advantages that separation of collocation models and algorithms for the computing resources is realized, modularization reconfiguration inside the models and the algorithms is supported, integration is efficient, levels are clear and extendibility is high.

Owner:BEIHANG UNIV

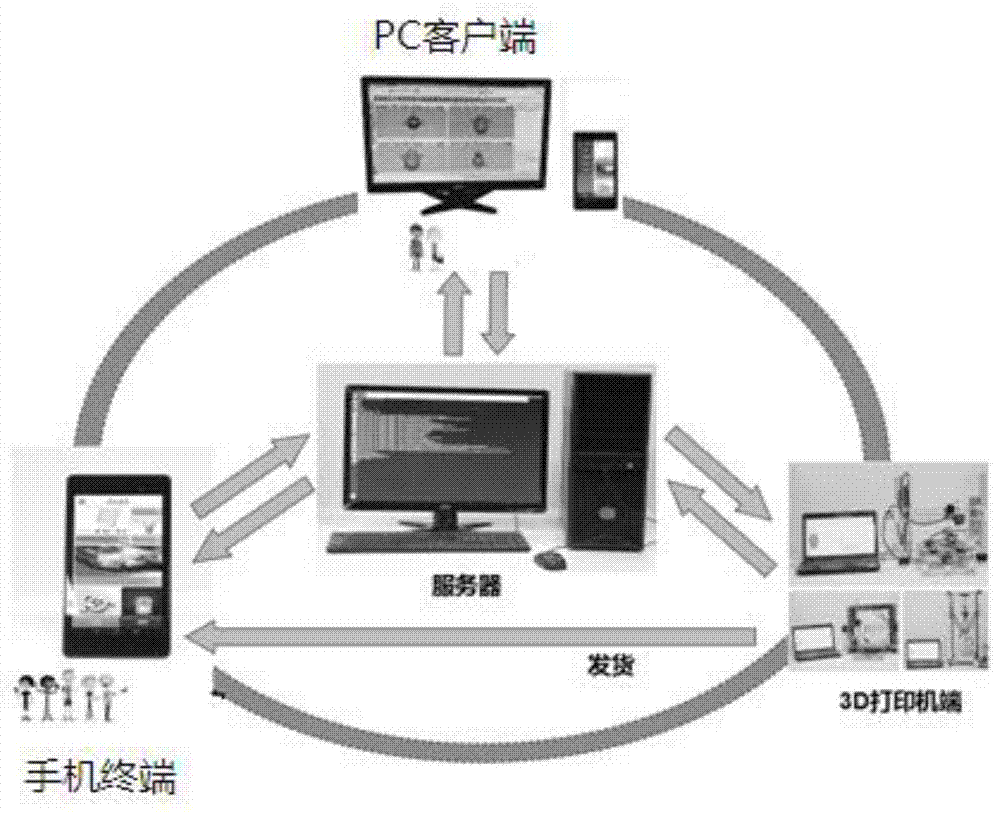

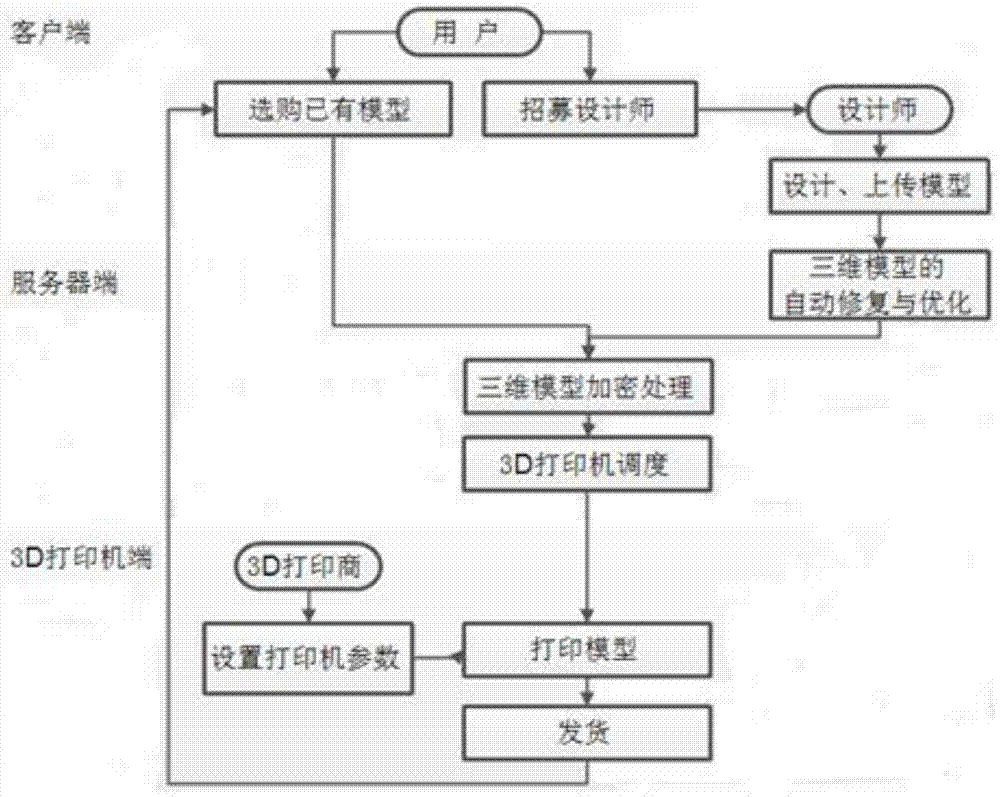

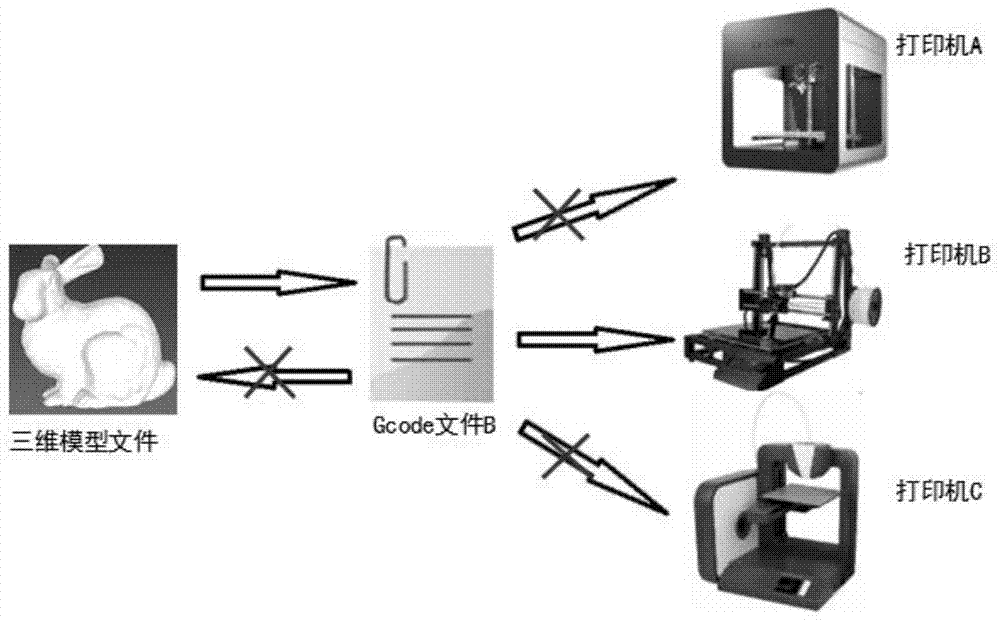

Cloud manufacturing system and method based on cloud computing and three-dimensional printing

ActiveCN104780214ACentralized schedulingScheduling is efficient and preciseTransmissionGenetic algorithmMaximum efficiency

The invention discloses a cloud manufacturing system and a cloud manufacturing method based on cloud computing and three-dimensional printing. The cloud manufacturing system comprises a client, a server side and a 3D printer side, wherein the server side is connected with the 3D printer side; the 3D printer side comprises a plurality of printers; the server side encrypts the 3D model to be printed through section engine processing to obtain a Gcode file of the 3D model, and then provides a single irreversible Gcode file for printing to the 3D printer side; the server side dispatches the printers according to a printer dispatching algorithm based on a genetic algorithm. According to the cloud manufacturing system and a cloud manufacturing method based on cloud computing and three-dimensional printing disclosed by the invention, the server side and the printer side are collaboratively established to achieve the purpose of utilizing hardware resources at the maximum efficiency, the hardware resources are utilized at the maximum efficiency, the fault freedom is good, and the printers are dispatched based on the genetic algorithm in the whole network range to fully consider about the factors influencing the printer dispatching, acquire the computing resources according to the requirement, and achieve the extendibility and the reliability of the distributed system.

Owner:上海汲臻智能科技有限公司

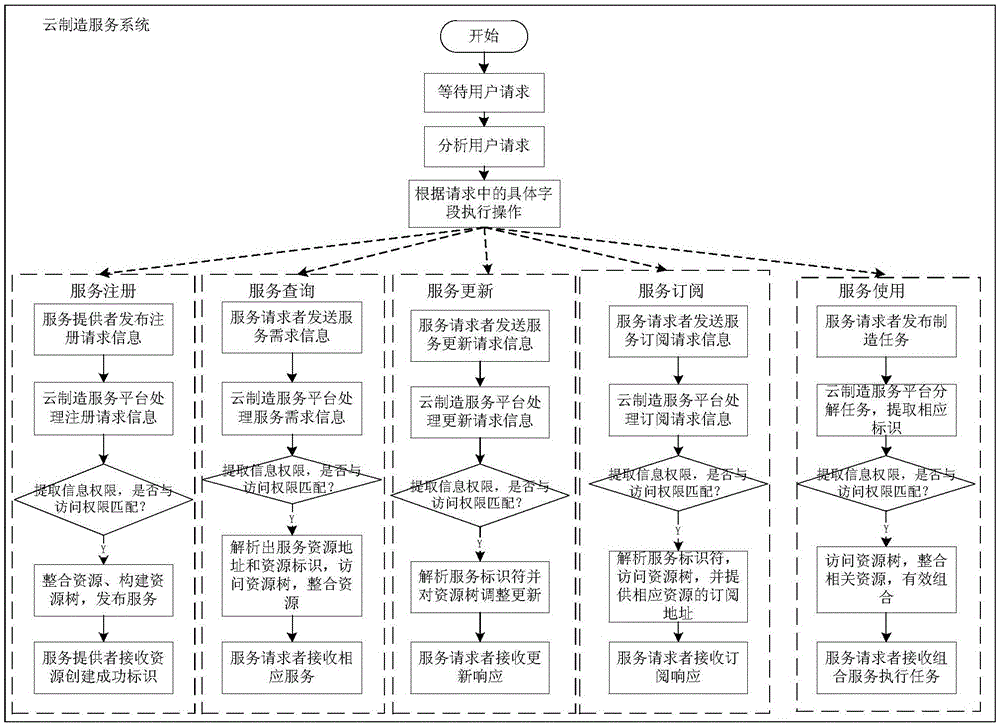

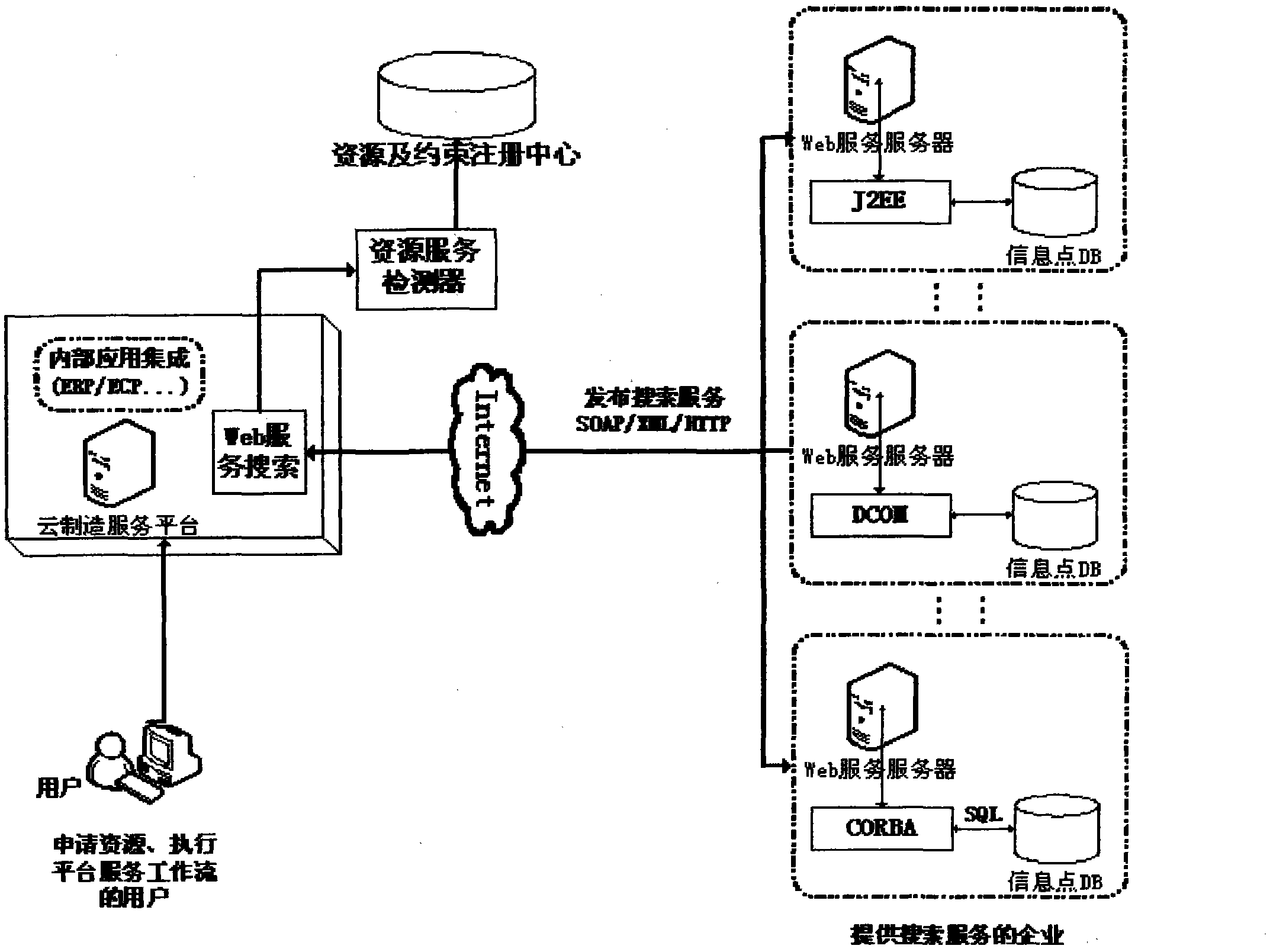

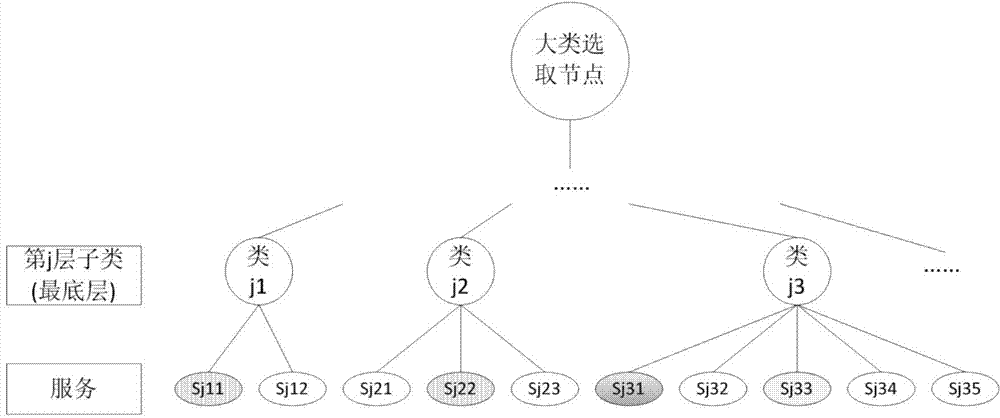

Organization and management and using method and system for cloud manufacturing service

InactiveCN105635283AEffective organizational managementActive service registrationTransmissionResource utilizationManagement efficiency

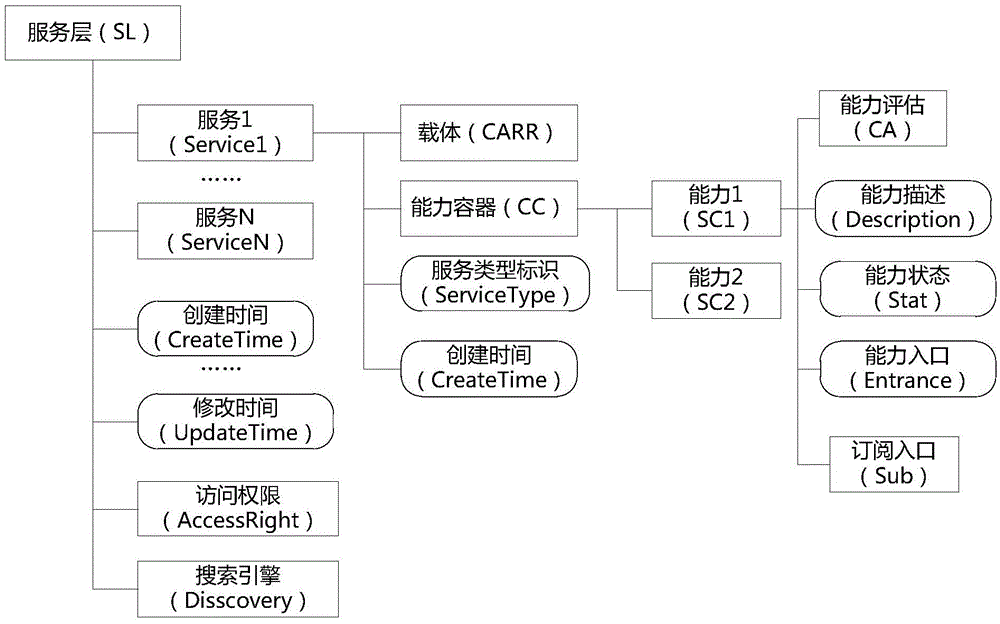

The invention discloses an organization and management and using method and system for a cloud manufacturing service. According to the method, on the basis of the internet of things technology and the cloud computing technology, interaction among a service provider, a service requester, and a cloud manufacturing service platform is described by using correlated network technologies like an XML language or an HTTP protocol; and modeling is carried out on the service based on description of the network technologies and a resource tree is constructed, so that the management efficiency and the resource utilization rate are effectively improved. Therefore, high-efficiency sharing of the resources and capabilities is realized; repeated building of the same kind of manufacturing resources and capability can be avoided; and the manufacturing energy and cost can be effectively saved. In a cloud manufacturing service system, a server is set to be in a user request waiting state; when a user request is received, the user request is analyzed; and corresponding operations of service registration, querying, updating, subscription, and usage are executed based on specific fields in the request.

Owner:NANJING UNIV OF POSTS & TELECOMM

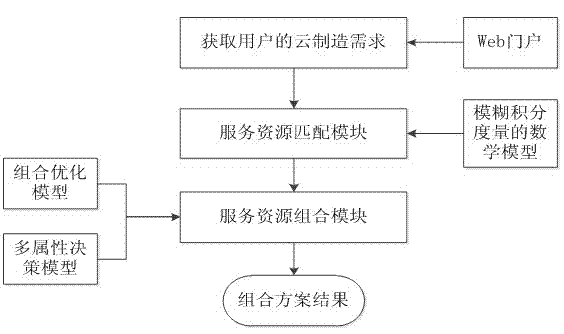

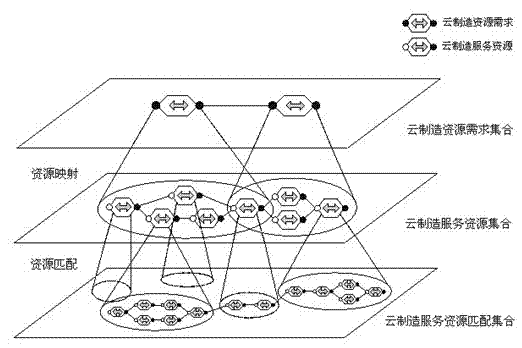

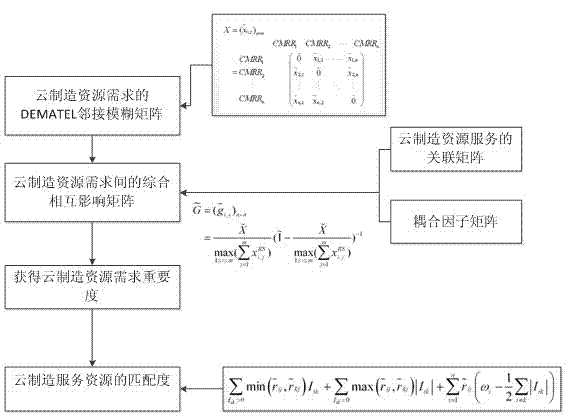

Cloud manufacturing service resource match and combination method based on performance fusion

The invention discloses a cloud manufacturing service resource match and combination method based on performance fusion. According to a relationship between cloud manufacturing service resources and cloud manufacturing resource requirements of users, a cloud manufacturing service resource combination is divided into two stages of match and combination, a performance fusion model of the match and the combination is constructed, and combination schemes are evaluated and sequenced by means of a dynamic multi-attribute decision-making method to filter an optimal cloud service resource combination scheme. According to the cloud manufacturing service resource match and combination method based on performance fusion, the problem that current networking manufacturing resource match methods can't be directly used for achieving cloud manufacturing service match; and simultaneously, idle manufacturing cloud can be used for automatic rent-seeking on a cloud platform and is convenient, fast, safe and cheap for customers to use, a many-to-many mapping relationship of requirements and services is n:1:m, and by means of the many-to-many mapping relationship, a multi-layer and three-dimensional manufacturing service is provided for manufacturing industries.

Owner:ZHEJIANG UNIV

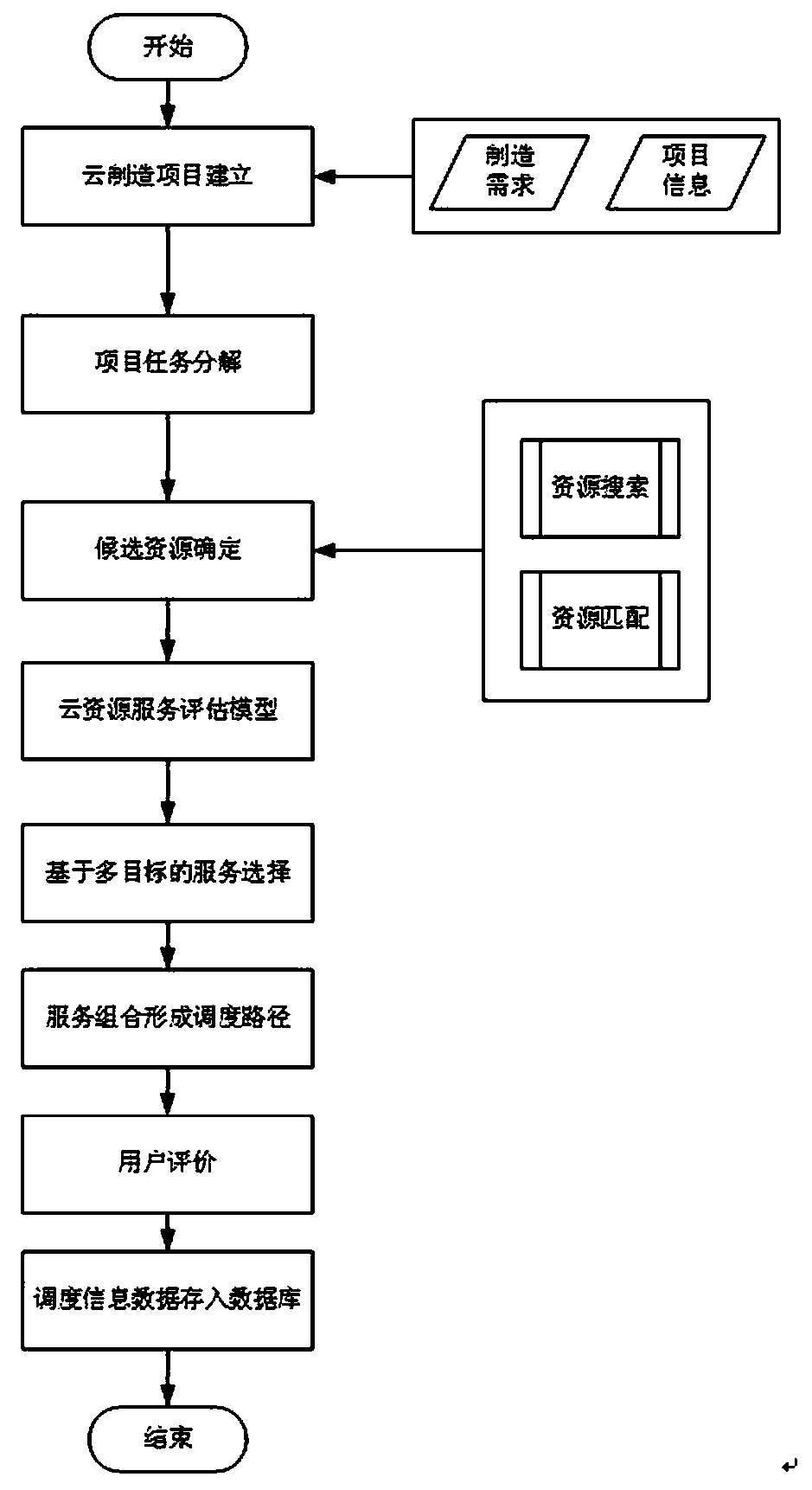

Cloud manufacturing resource service optimization scheduling method based on fuzzy multi-objective optimization

The invention provides a cloud manufacturing resource service optimization scheduling method based on fuzzy multi-objective optimization. The cloud manufacturing resource service optimization scheduling method comprises the steps that step 1, a service demander proposes project requirements; step 2, project task decomposition is performed; step 3, candidate resources are determined; step 4, cloudresource scheduling is performed; step 5, service selections are made based on a scheduling result.: corresponding services are selected according to a production scheduling scheme and operation is performed; step 6, user evaluations are made: the service demander evaluates the scheme after the task solution is executed; step 7, scheduling information is sorted into a database by storing the scheduling information and the user information into the database for next use. A fuzzification mechanism is added in the multi-objective optimization process to carry out fuzzification processing on service reliability evaluation. Therefore, the whole scheduling process finds the optimal scheduling combination scheme faster, and the technical problem that enough good service support cannot be providedfor the service demander due to narrow resource acquisition surface and opaque resources in the traditional manufacturing scheduling process is solved.

Owner:NANJING UNIV OF POSTS & TELECOMM

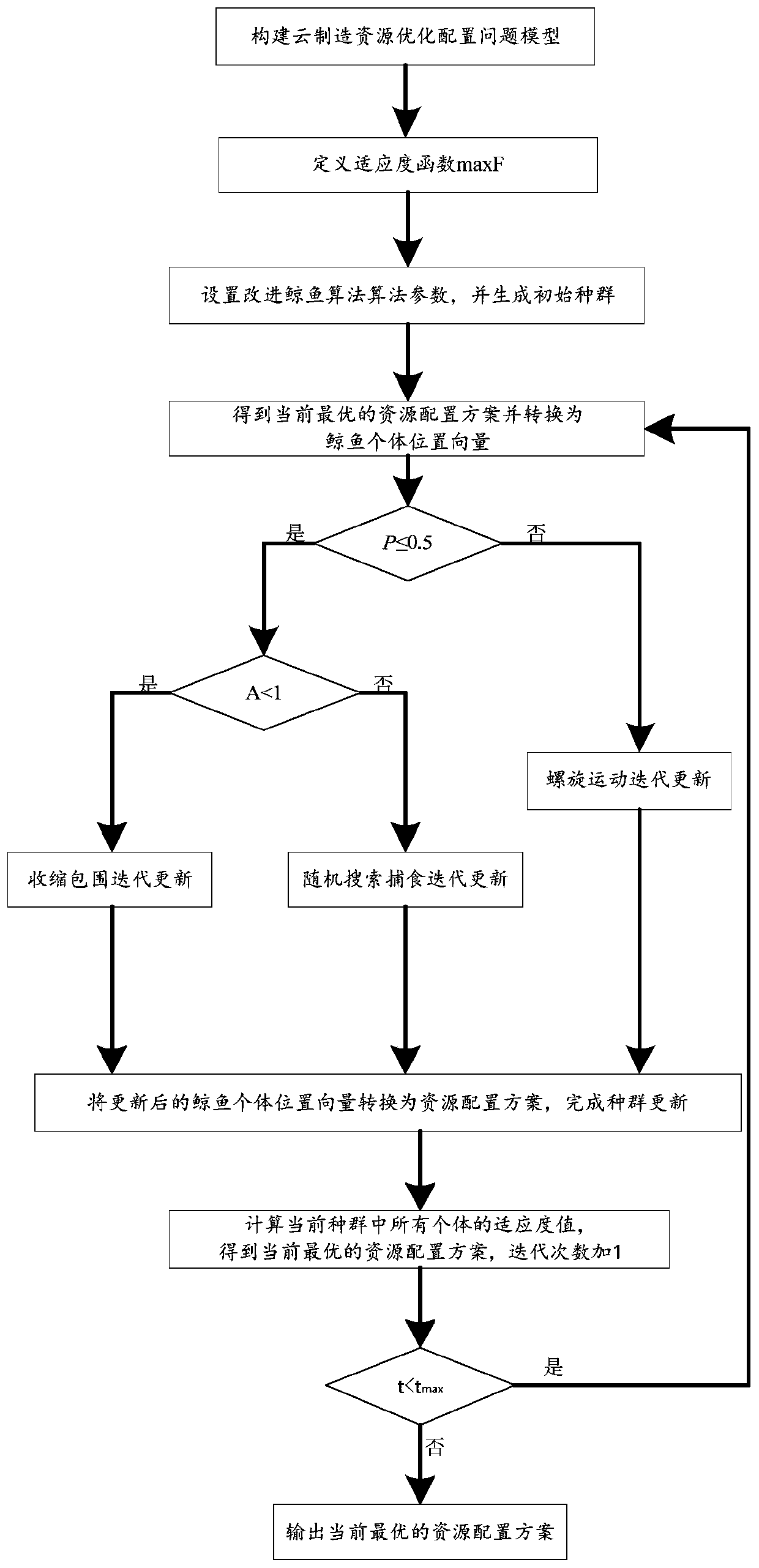

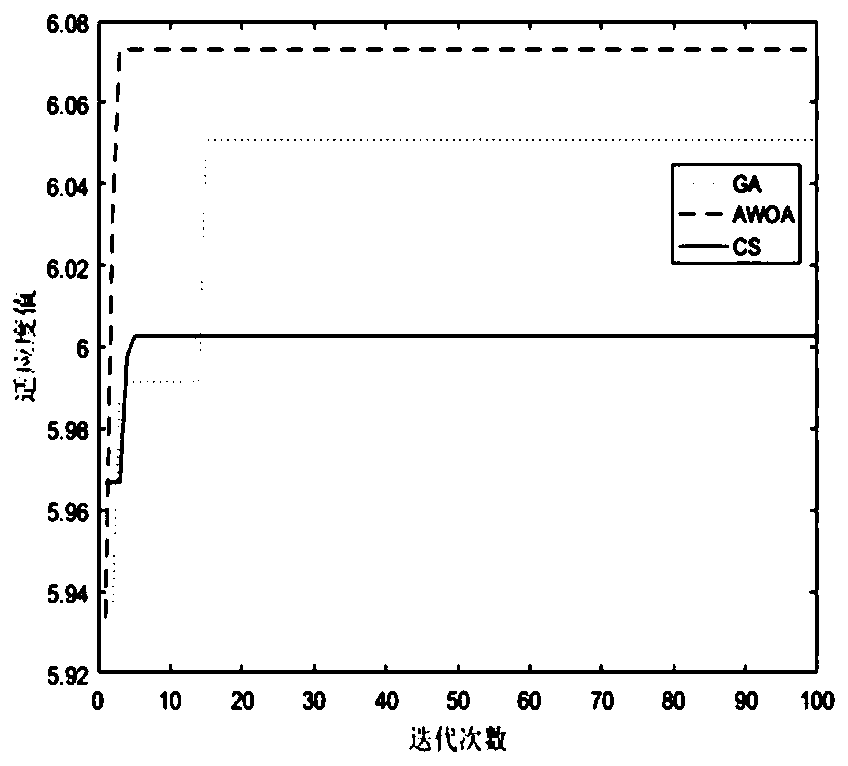

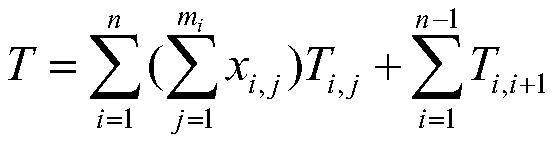

A cloud manufacturing resource configuration method based on an improved whale algorithm

PendingCN109902873AImprove local search capabilitiesImprove convergence accuracyForecastingBiological modelsPredationAlgorithm convergence

The invention discloses a method for cloud manufacturing resource optimization configuration based on an improved whale algorithm, and the method comprises the steps: building a problem model, and defining a fitness function; setting improved whale algorithm parameters, and generating an initial population; Calculating fitness values of all individuals in the population, obtaining a current optimal resource allocation scheme and converting the current optimal resource allocation scheme into whale individual position vectors; Introducing a parameter p, and judging whether p is less than or equal to 0.5; If not, performing spiral motion iteration updating to complete population updating; If yes, whether the value A (1) of the coefficient vector of the improved whale algorithm is met or not is judged; If yes, performing shrinkage encircling iteration updating; If not, performing random search predation iteration updating; Obtaining a current optimal resource configuration scheme; Adding 1to the number of iterations, and judging whether the current number of iterations is smaller than the maximum number of iterations; If yes, repeating the operation; And if not, outputting the currentoptimal resource configuration scheme. The whale algorithm is improved, so that the algorithm convergence speed is higher, the optimal solution is easier to achieve, and a new method is provided forsolving the problem of resource allocation.

Owner:CHANGAN UNIV

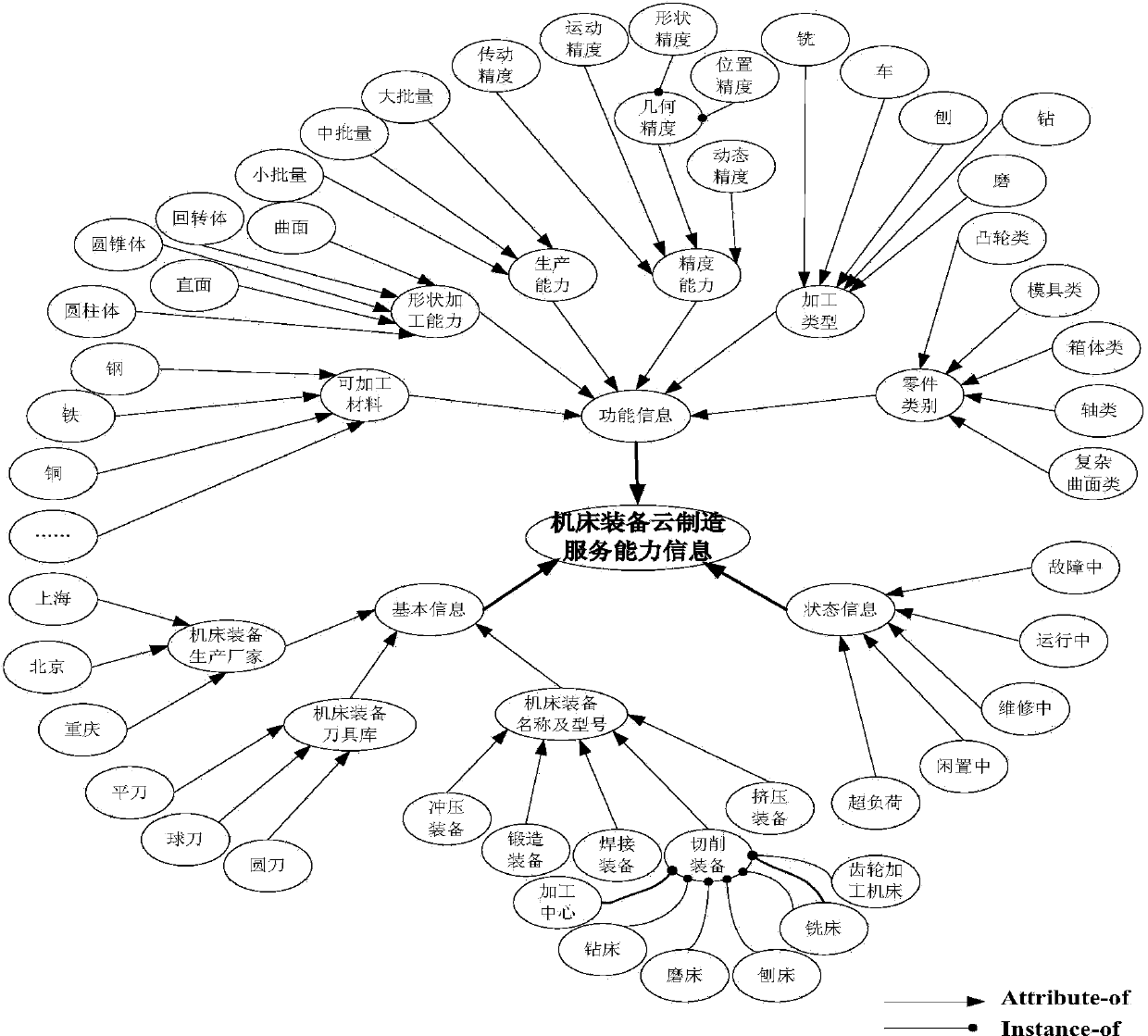

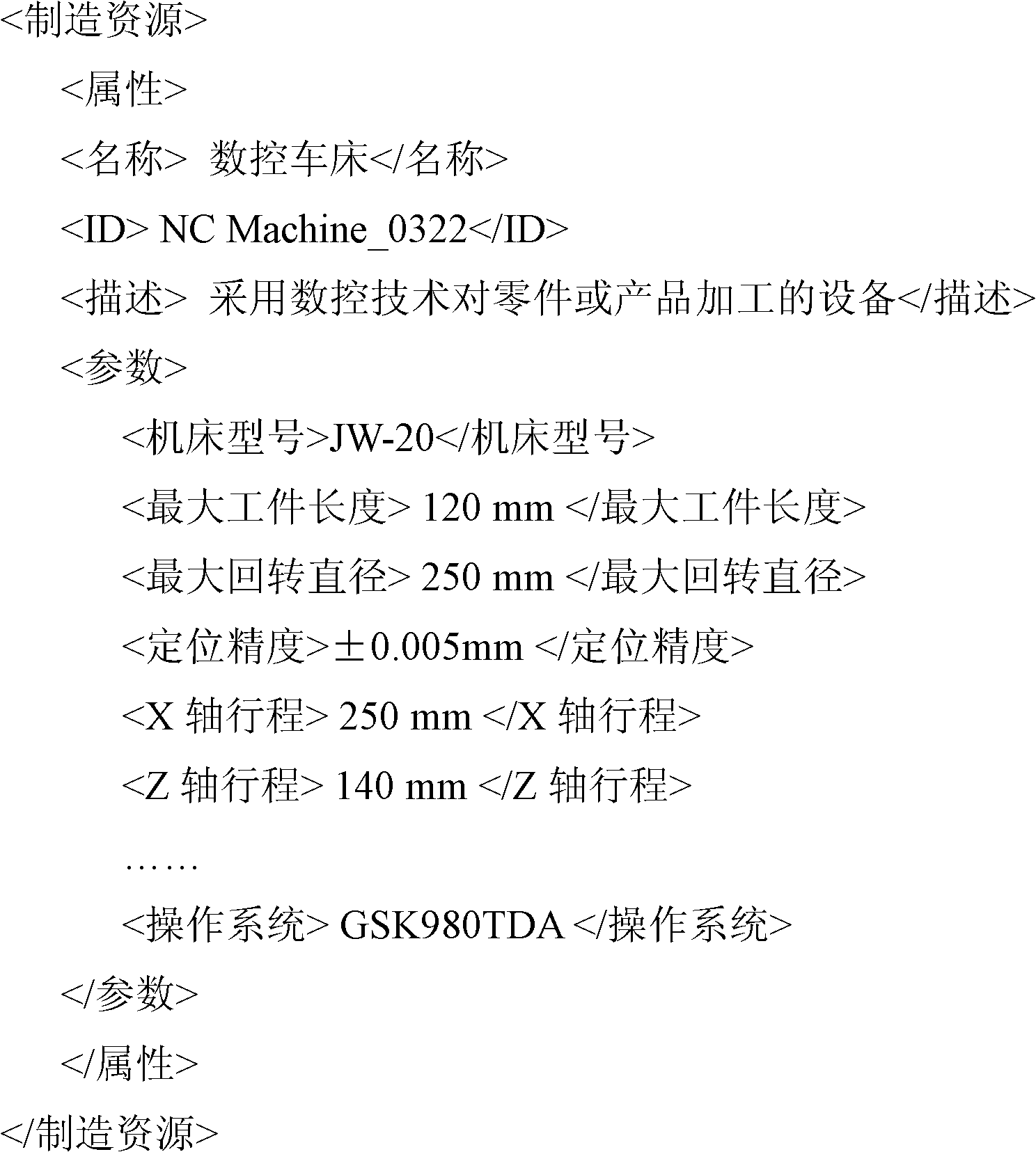

Machine tool equipment service capability modeling method in cloud manufacturing environment

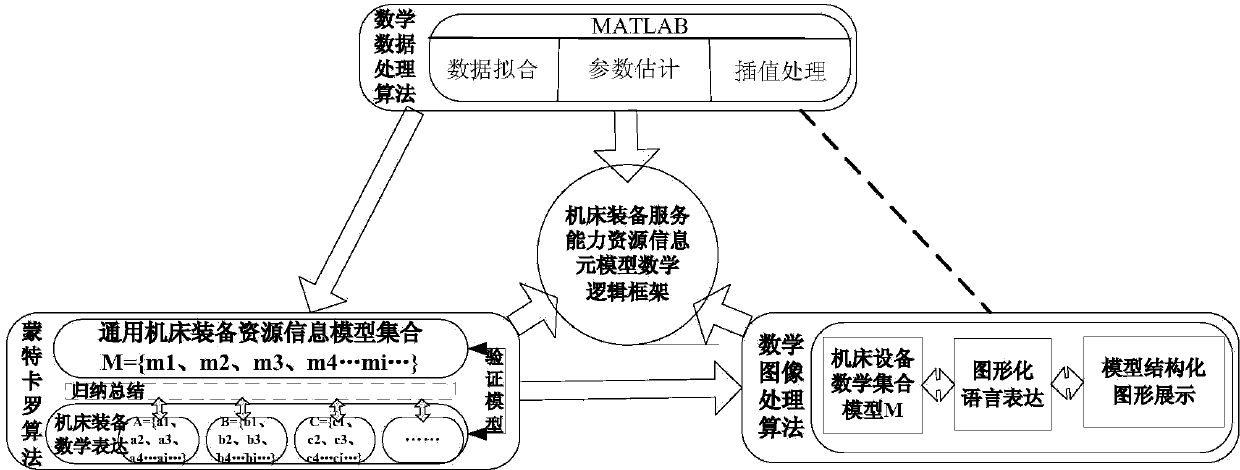

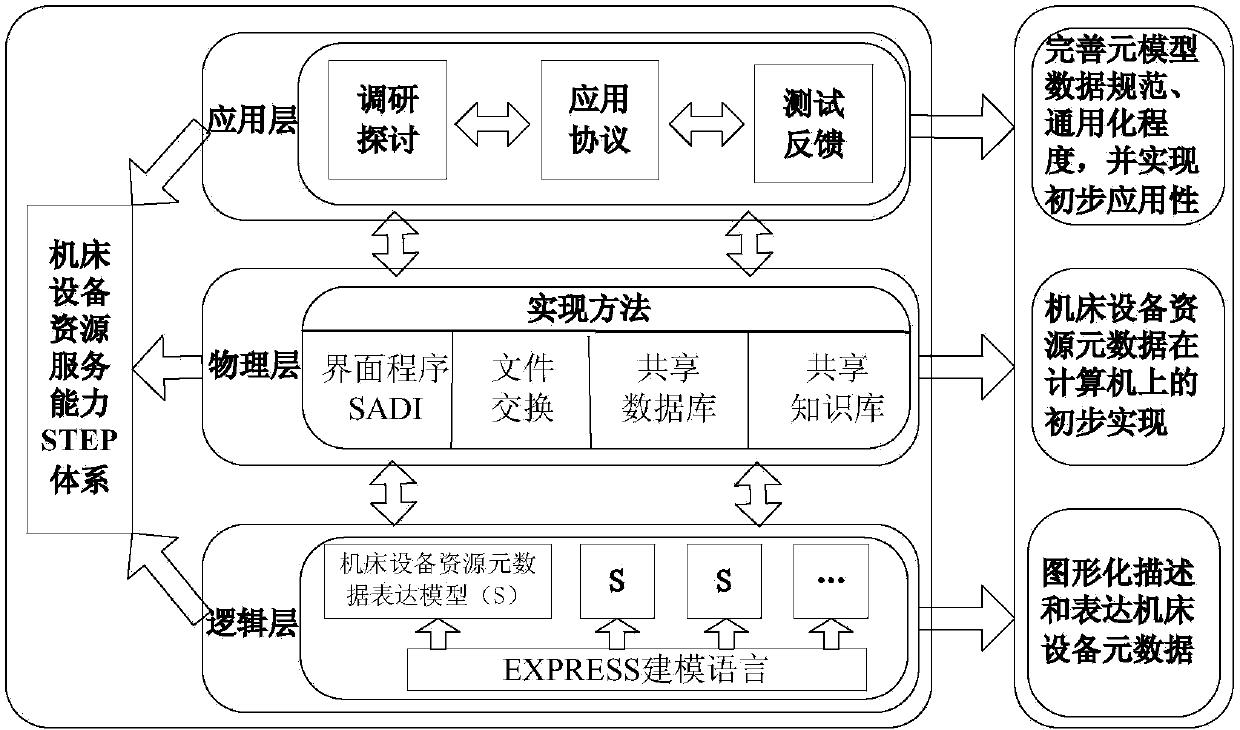

InactiveCN103473407ASolve the problem of how to display graphicallyImprove data normalizationSpecial data processing applicationsPersonalizationVirtualization

The invention relates to a machine tool equipment service capability modeling method in a cloud manufacturing environment, and belongs to the technical field of information. The machine tool equipment service capability modeling method is a machine tool equipment information standardization description method including a substance information analyzing and extracting method, a mathematical modeling technique and an STEP (standard for the exchange of product model data) technique. The machine tool equipment service capability modeling method includes creating a uniform machine tool equipment cloud manufacturing service capability model through analyzing and extracting, logic framework building and virtual standardization describing of machine tool equipment information, and configuring model information parameters in an individualized way. The machine tool equipment service capability modeling method can lay a foundation for realization of techniques like visualized packaging and displaying of machine tool equipment, establishing of machine tool equipment resource libraries and intelligent semantic-based matching of machine tool equipment resources in the cloud manufacturing environment. The machine tool equipment service capability modeling method has the advantages of high virtualized simulation degree, high universality and good expandability; by the machine tool equipment service capability modeling method, service enterprises can be effectively supported to provide cloud manufacturing services conveniently and users can be effectively supported to find and match better resources intelligently.

Owner:CHONGQING UNIV

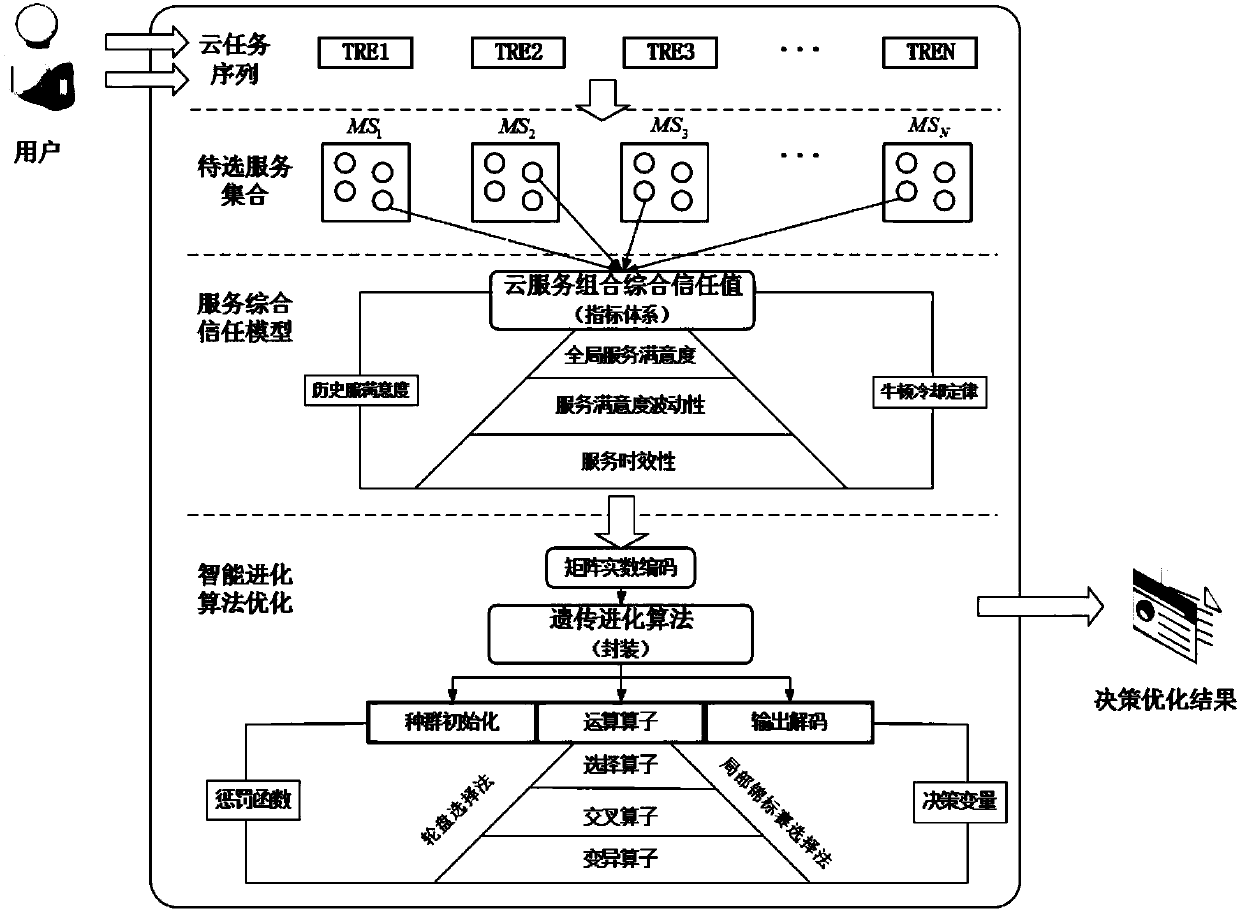

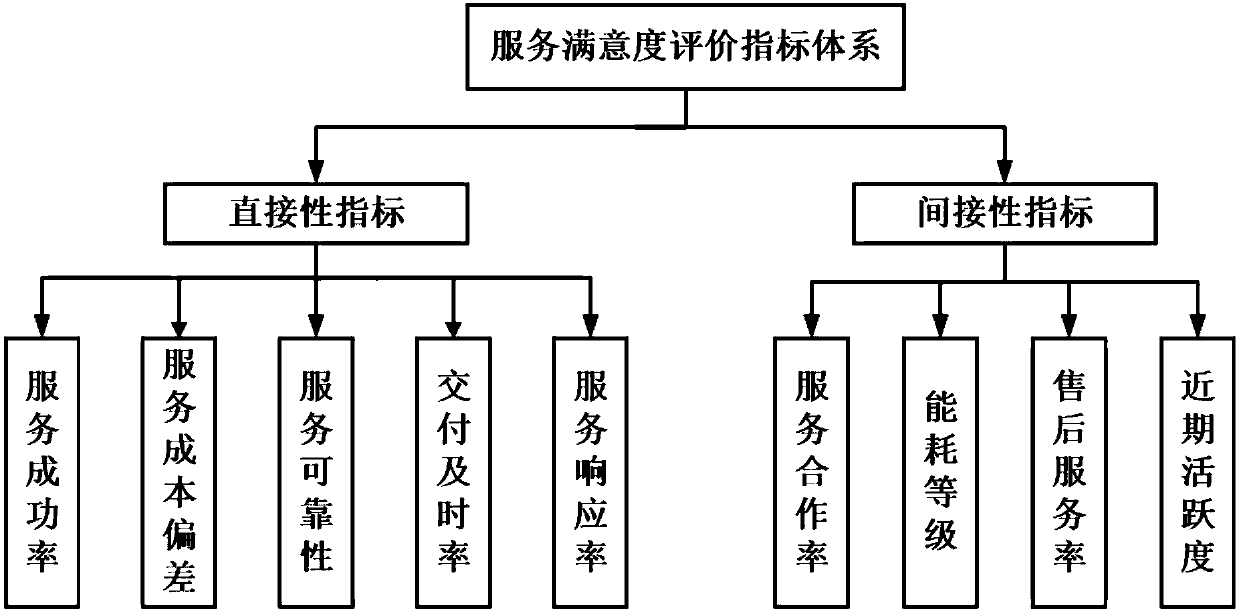

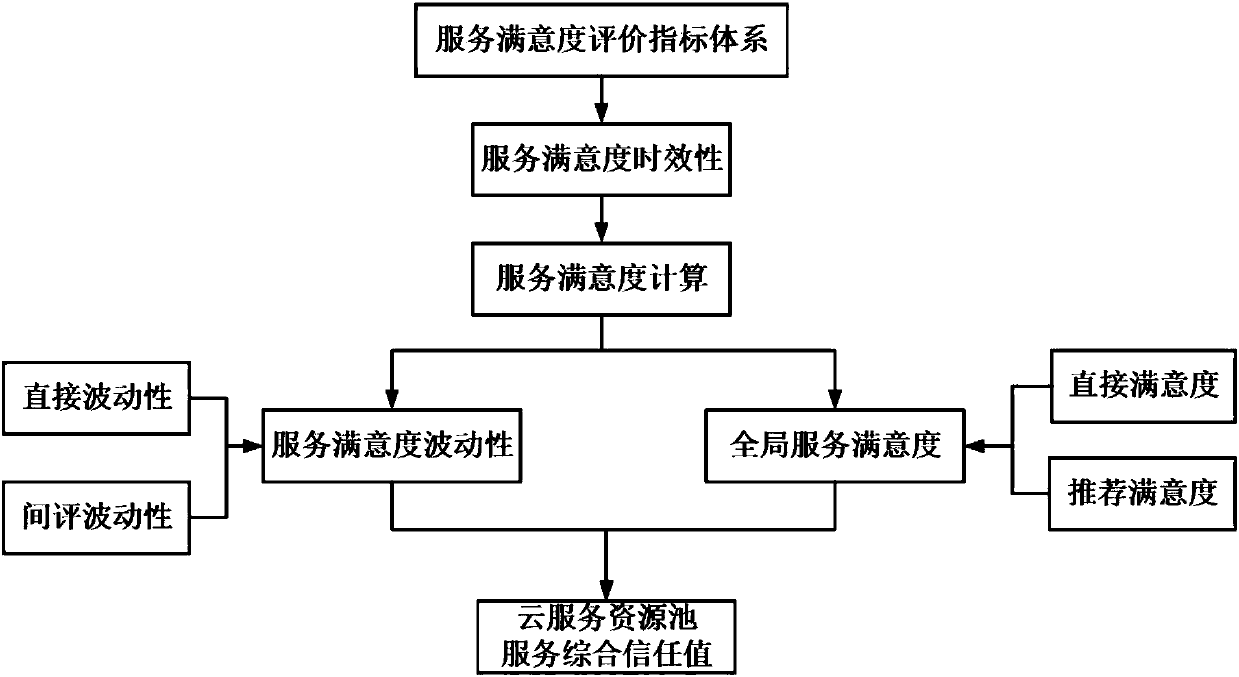

Trust model-based cloud manufacturing service evaluation and matching method

InactiveCN107944602AAchieve matchingImprove stabilityForecastingResourcesTournament selectionTrust relationship

The invention discloses a trust model-based cloud manufacturing service evaluation and matching method. A trust model-based service combination evaluation method for a cloud manufacturing environmentis proposed, so that the matching between service demands and service resources is realized; a cloud manufacturing service combination sequence is constructed, and a matching degree is quantized by using a service comprehensive trust value, so that the problem of incapability of actually fitting real cloud manufacturing service matching in an existing service evaluation method is solved; a mutualevaluation mechanism is introduced for improving the reliability of a trust relationship of both service parties, the trust relationship of the both service parties in a long-term interactive processis represented with a service satisfaction timeliness function to improve the decision-making timeliness of a cloud platform, and a service satisfaction fluctuation evaluation index also improves thestability and flexibility of the platform; and an improved matrix real-coded genetic evolution algorithm is proposed, a penalty function is introduced for correcting a target function of a fitness value, and evaluation and optimization are performed in combination with policies of a roulette wheel selection method and a local tournament selection method, so that the reliability of cloud manufacturing service combination matching is enhanced.

Owner:CHONGQING UNIV

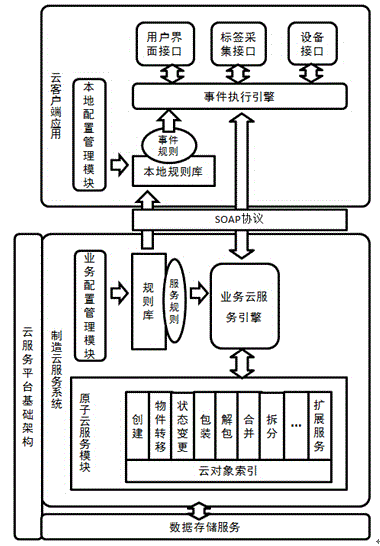

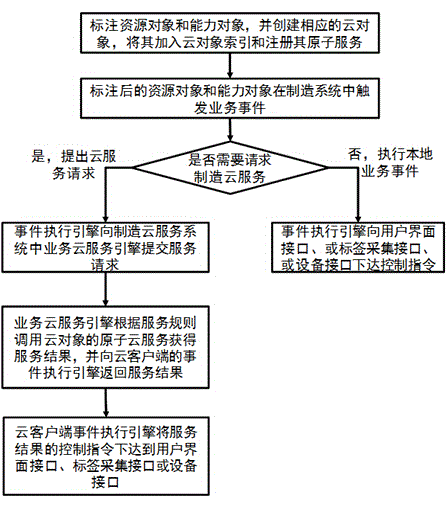

Cloud manufacturing execution system and method based on cloud services

The invention discloses a cloud manufacturing execution system and method based on cloud services. The cloud manufacturing execution system comprises a cloud service manufacturing system and a cloud client application, wherein the cloud service manufacturing system is deployed on a cloud service platform infrastructure and used for providing cloud services for a service manufacturing request of the cloud client application, and the cloud client application is deployed on a mobile terminal or a computer and used for collecting field data of the manufacturing execution process in real time, triggering a local control instruction or requesting cloud service manufacturing according to event rules, and feeds the result back to a user interface or a label collection interface or an equipment interface. According to the cloud manufacturing execution system adopting the infrastructure of the cloud service manufacturing system and the cloud client application, virtualization and distributed computing resources and the computing power are used as services through the internet to be provided for a user, system services are deployed in the cloud service platform infrastructure, management is carried out by a small number of professionals, and the problems that enterprise human resource shortage, informatization foundation shortage, fund shortage and the like are solved.

Owner:GUANGDONG UNIV OF TECH

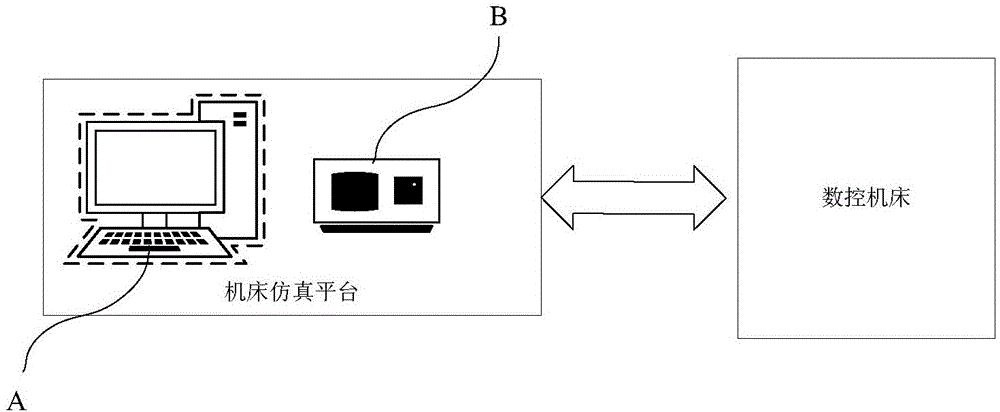

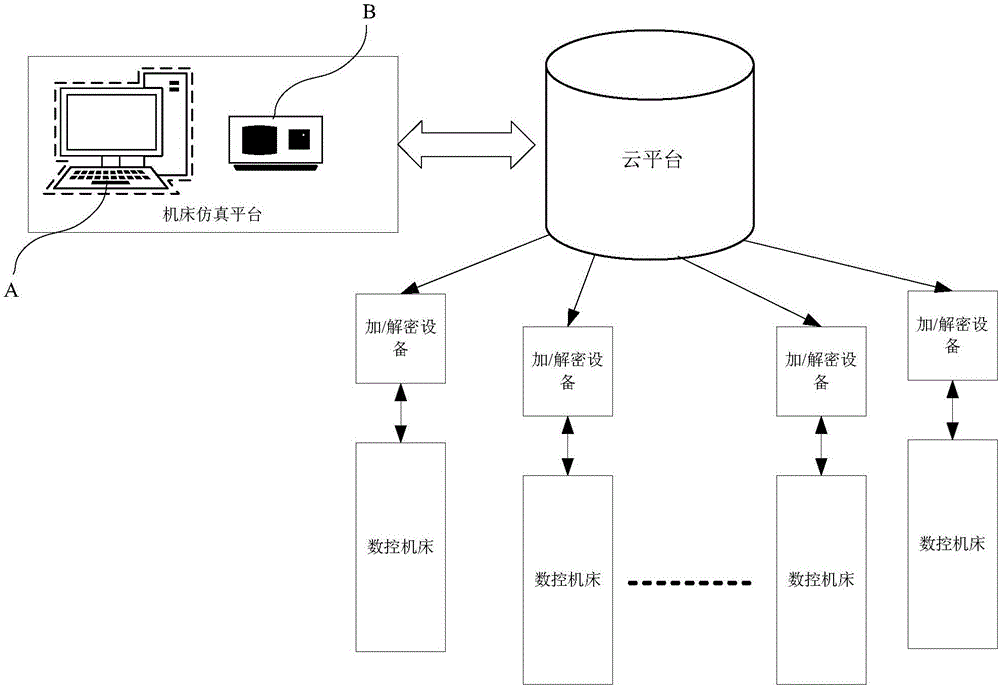

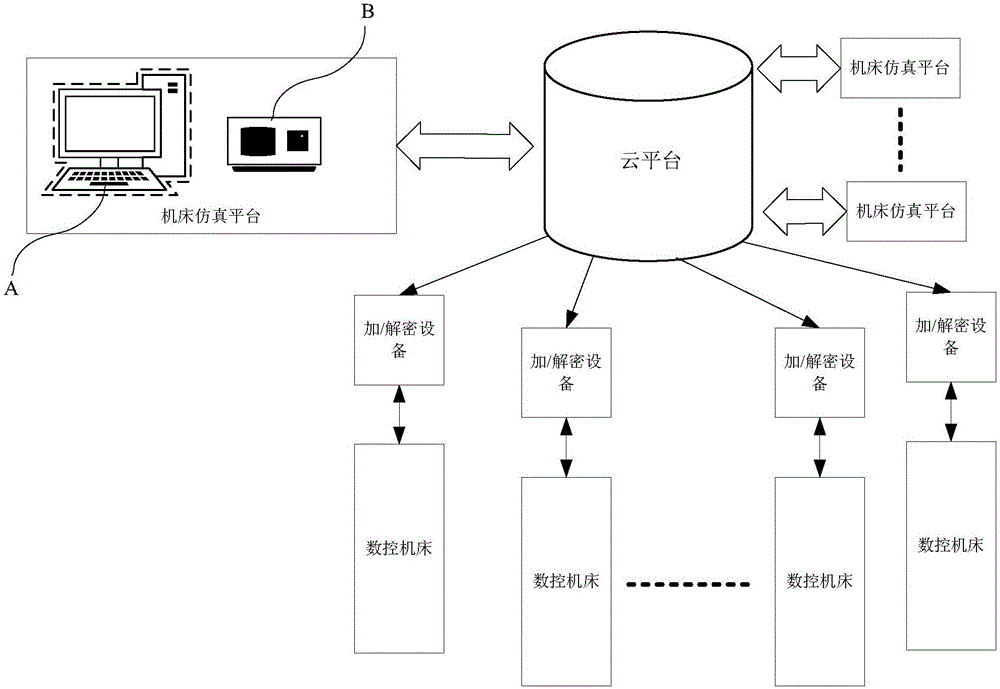

Numerical control machine tool machining system and cloud platform-based numerical control machine tool machining system

ActiveCN106292535AReal-time monitoring of running processEasy to control workProgramme controlComputer controlNumerical controlEngineering

The invention discloses a numerical control machine tool machining system and a cloud platform-based numerical control machine tool machining system. The numerical control machine tool machining system comprises a numerical control machine tool, a machine tool simulation platform and a cloud platform which is used for transmitting a workpiece machining program to the numerical control machine tool; the machine tool simulation platform can perform analogue simulation on the workpiece machining program, and transmit the workpiece machining program of which the analogue simulation is verified successfully by the cloud platform, or directly transmit the workpiece machining program to the cloud platform, and simultaneously display various types of state information and parameters in a numerical control machine tool machining process. The system can simulate a using process of the machine tool, so that the using process of the machine tool is convenient to learn; the danger of operating the machine tool of a beginner is reduced; the using process of the machine tool can be simulated, so that the loss caused by errors in machining are reduced; the operating process of the machine tool can be monitored directly in real time, so that the machine tool is more controllable in work; the numerical control machine tool machining system can be remotely connected to one or more machine tools, the machining can be performed in real time, and the operating processes can be monitored in real time; therefore, cloud machining and cloud manufacturing are realized.

Owner:皿智实业有限公司

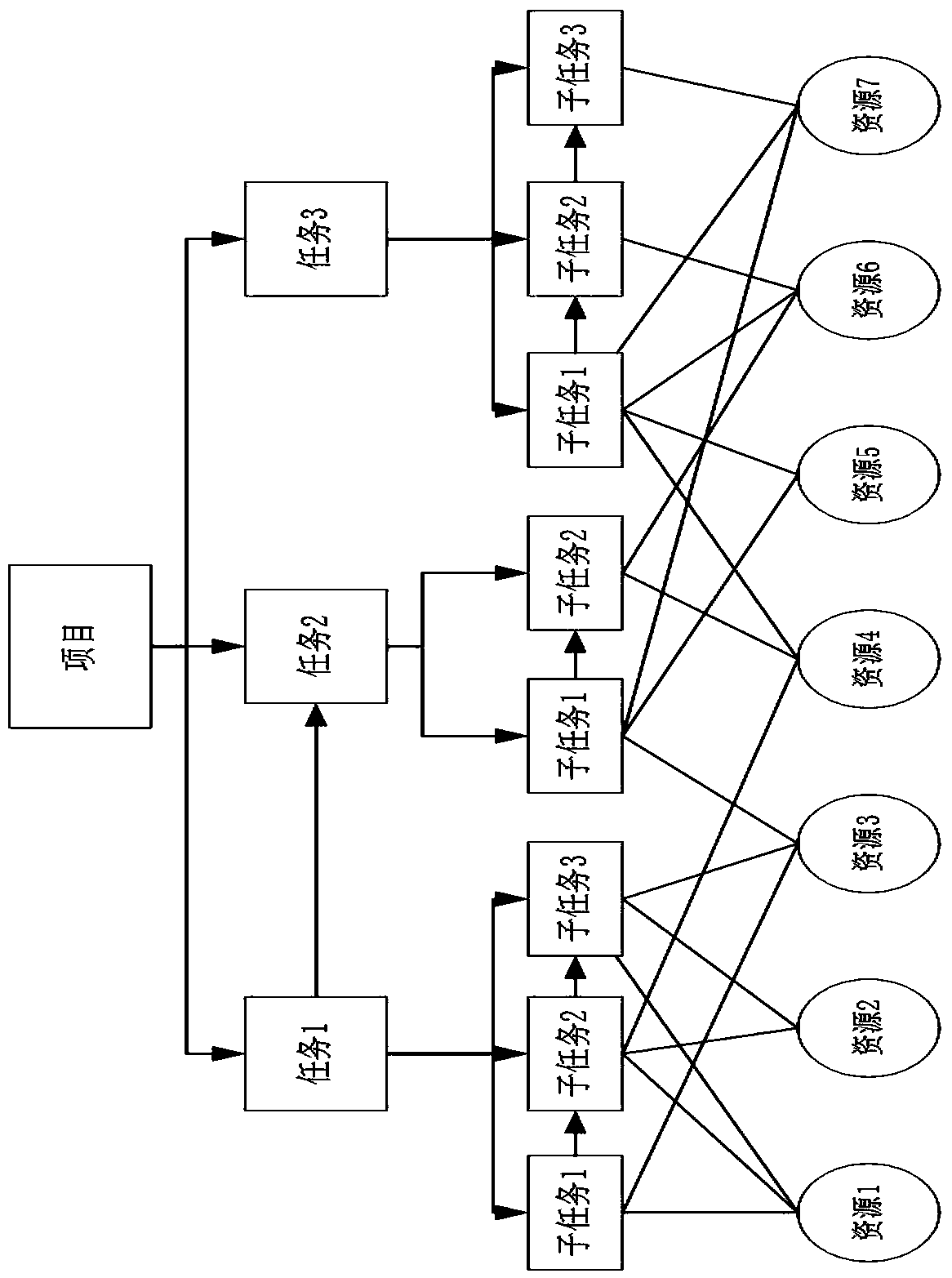

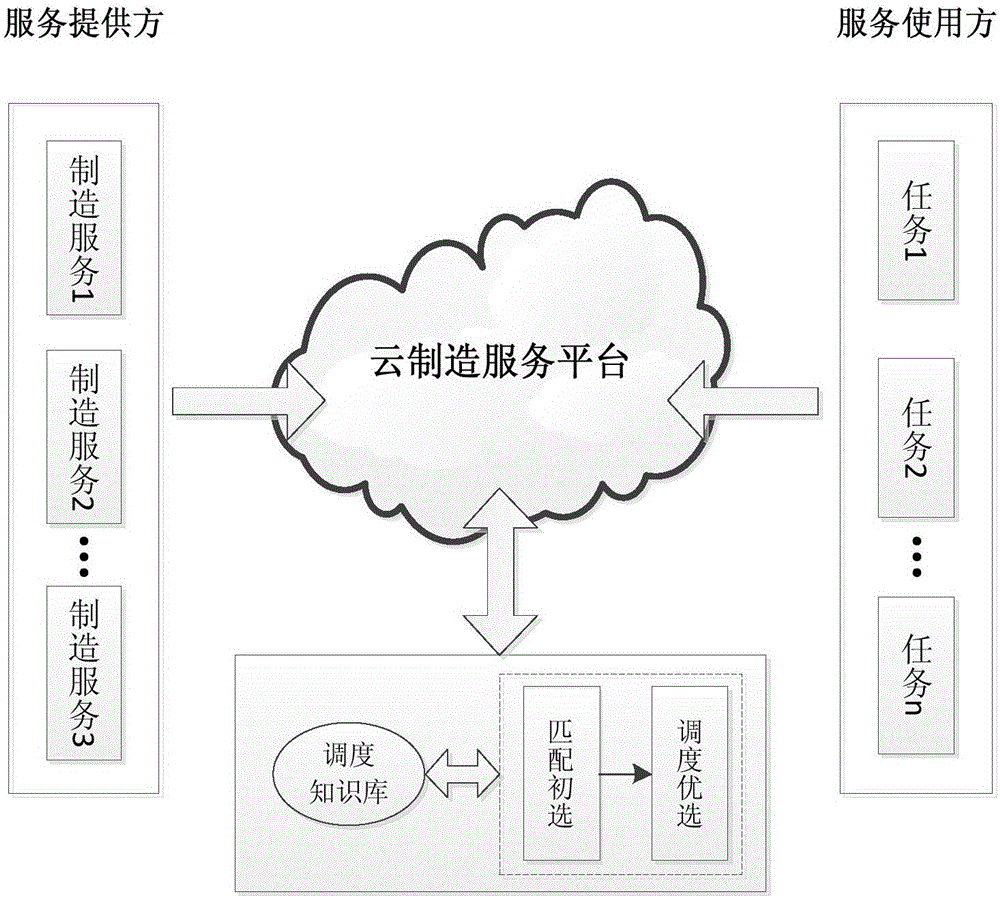

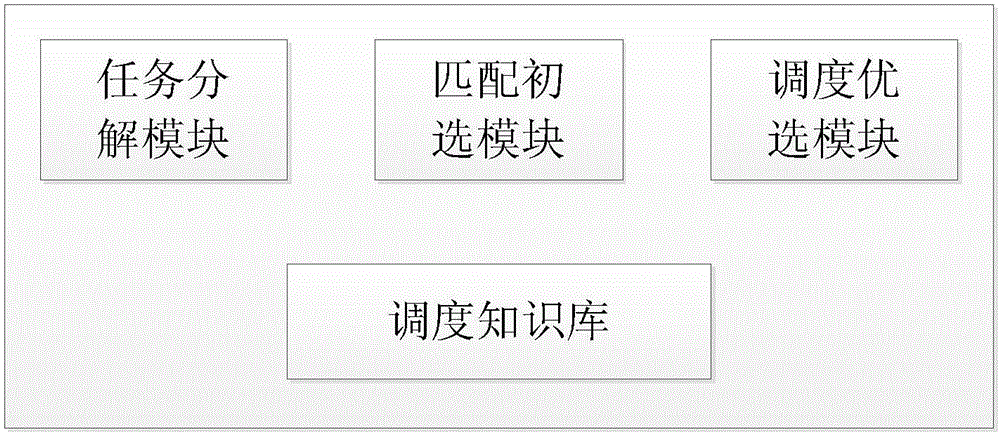

Cloud manufacturing service scheduling method and system

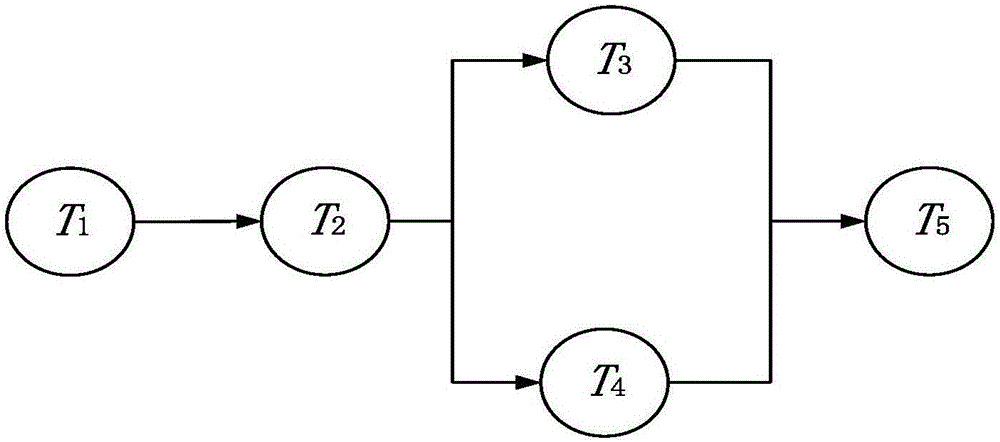

The invention provides a cloud manufacturing service scheduling method and system. A service use direction cloud manufacturing service platform submits a manufacturing task. A task decomposition module in the cloud manufacturing service platform acquires all subtasks corresponding to the task type from the subtask database in a scheduling knowledge base according to the task name and the task type. All subtasks of the task type are pushed to a service consumer on a human-computer interaction interface. The service consumer selects subtasks according to the requirements. Each subtask comprises the subtask name and the subtask identifier. A matching primitive selection module finds a manufacturing service matching the subtask identifier in the scheduling knowledge base according to the subtask identifier, so that each subtask has a separate manufacturing service set. A scheduling optimization selection module carries out optimization selection on manufacturing services in each manufacturing service set according to the restriction condition submitted by the service consumer, so as to complete scheduling finally. The scheduling knowledge base updates manufacturing services registered on the cloud manufacturing service platform according to a service provider.

Owner:SUNWAVE COMM

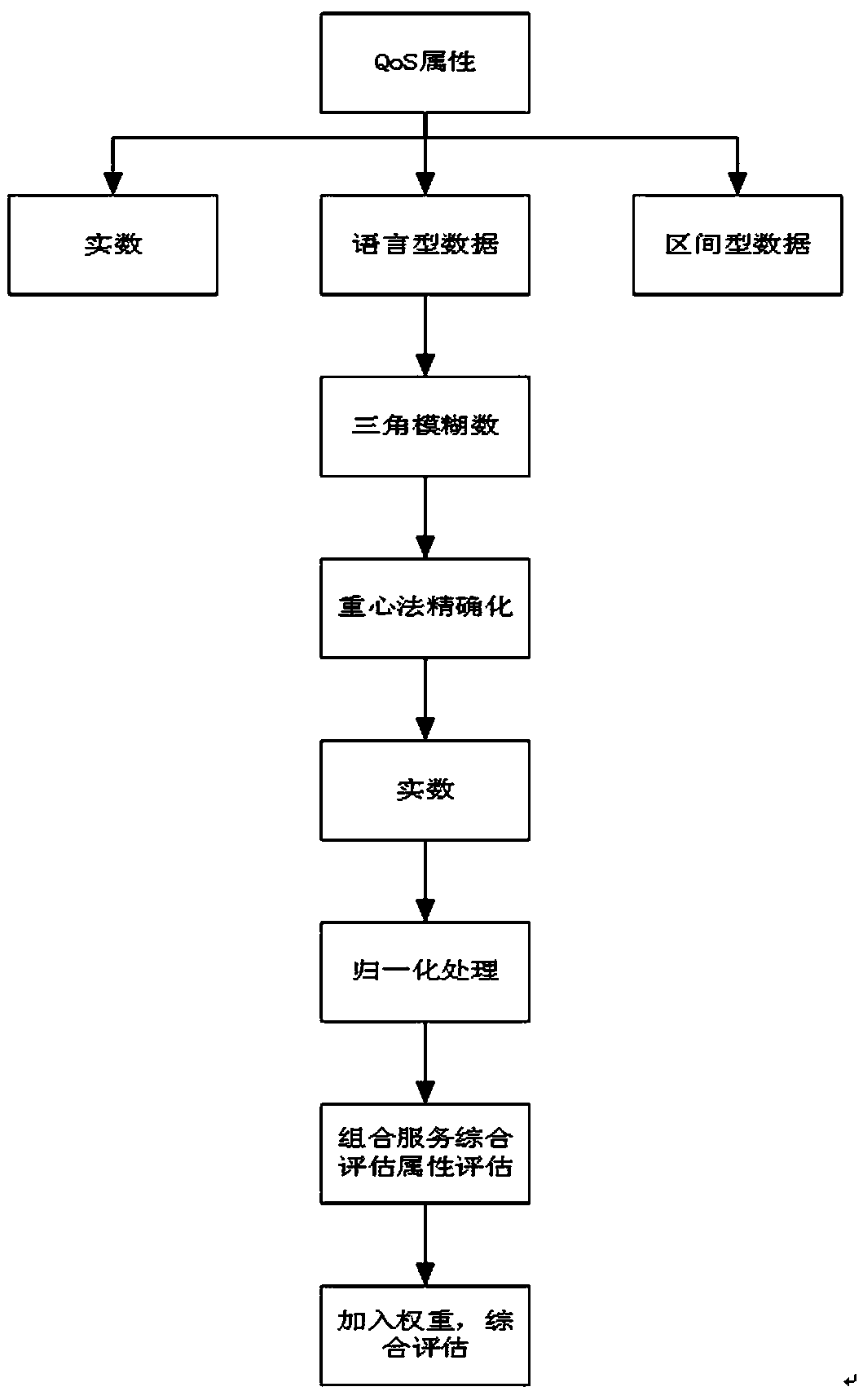

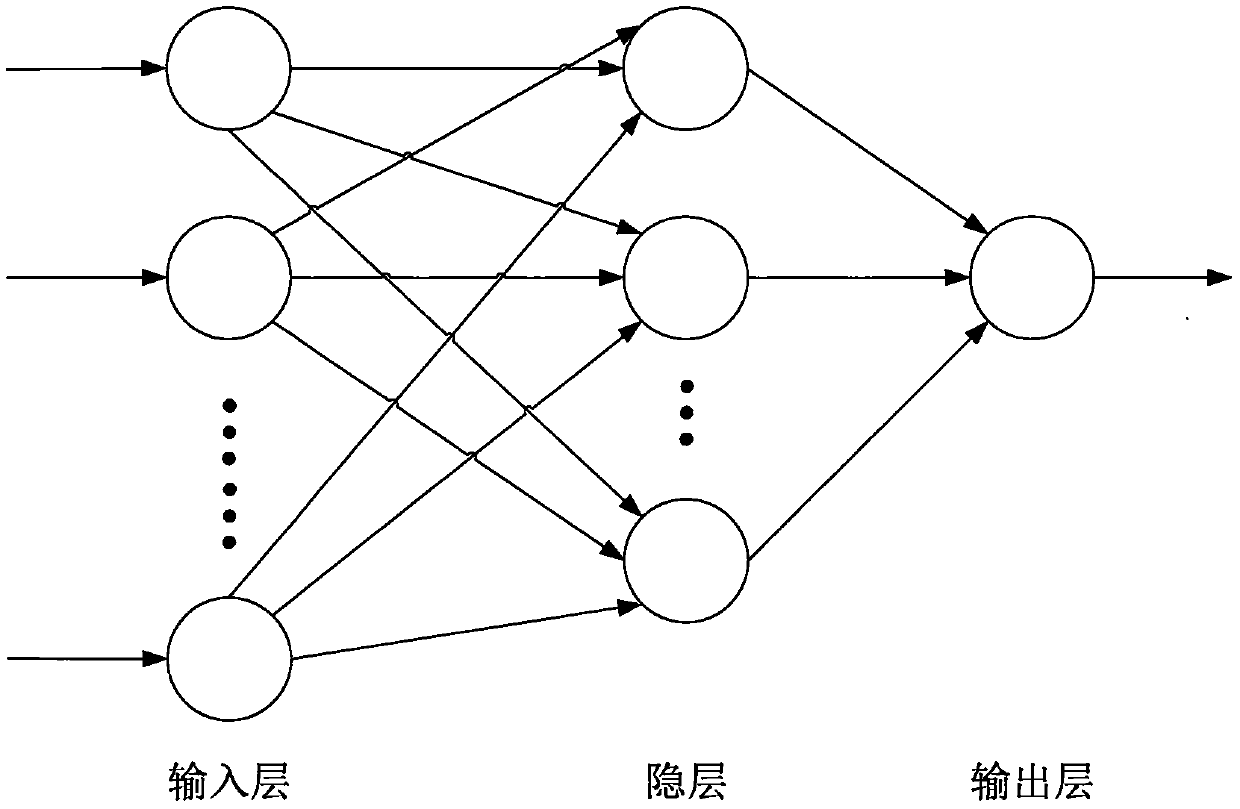

Prediction method for combinations of cloud manufacturing service quality of service (QoS)

InactiveCN106600058AImprove estimation accuracyReliability predictionForecastingManufacturing computing systemsService compositionDependability

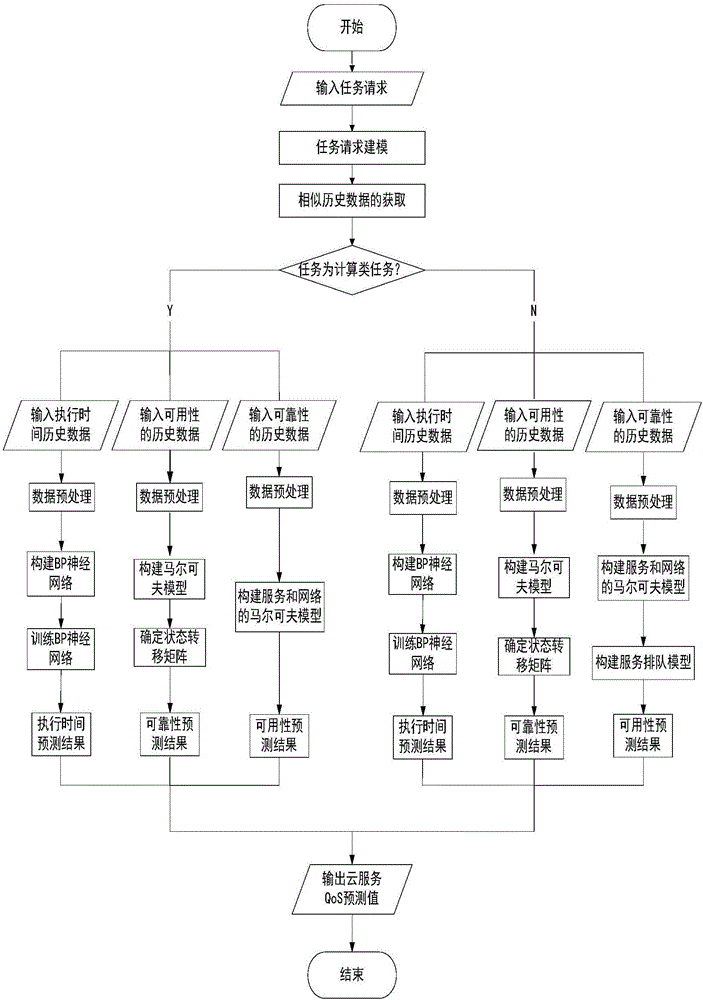

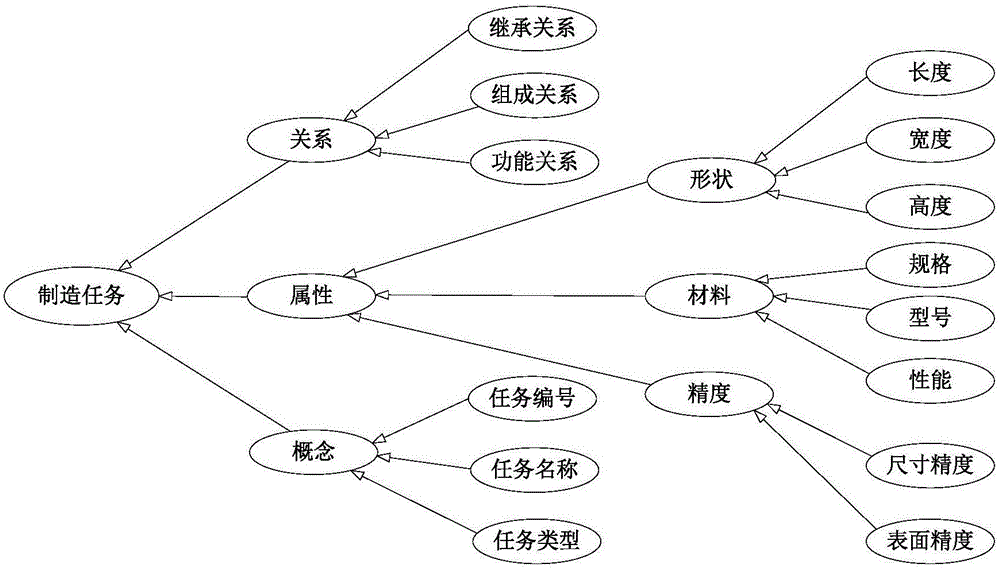

The invention relates to a prediction method for combinations of cloud manufacturing service quality of service (QoS), which belongs to the networked manufacturing field and comprises the steps of cloud manufacturing task modeling, cloud manufacturing service execution time predicting, cloud manufacturing service reliability predicting and service availability predicting. In the invention, the cloud manufacturing task is divided into a computer type task and a manufacturing and processing task; and based on this, predictions are made on the cloud manufacturing service QoS; a BP neural network is used to predict the cloud manufacturing service execution time; and a discrete Markov model is used to predict the service reliability; in combination with the continuous Markov model and a queuing model, predictions are made on the service availability. As different QoS indicators have different influential factors, different prediction methods are employed for the different indicators so that the prediction model is better than one individual model in terms of both efficiency and quality, the prediction accuracy is increased and that important data support can be provided for the service combination, resource optimized allocation and management in a cloud manufacturing environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Cloud manufacturing system-oriented method for measuring and enhancing flexibility of resource service composition

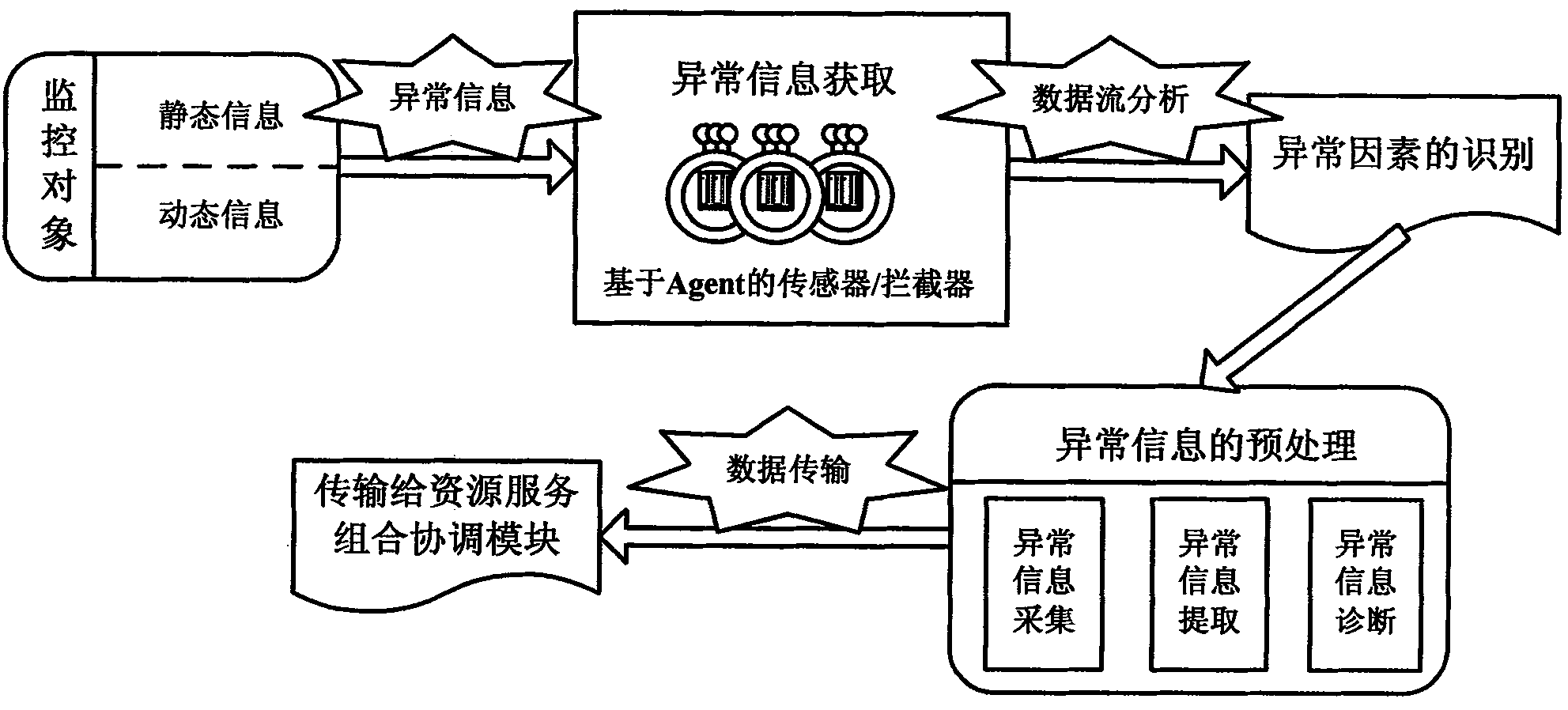

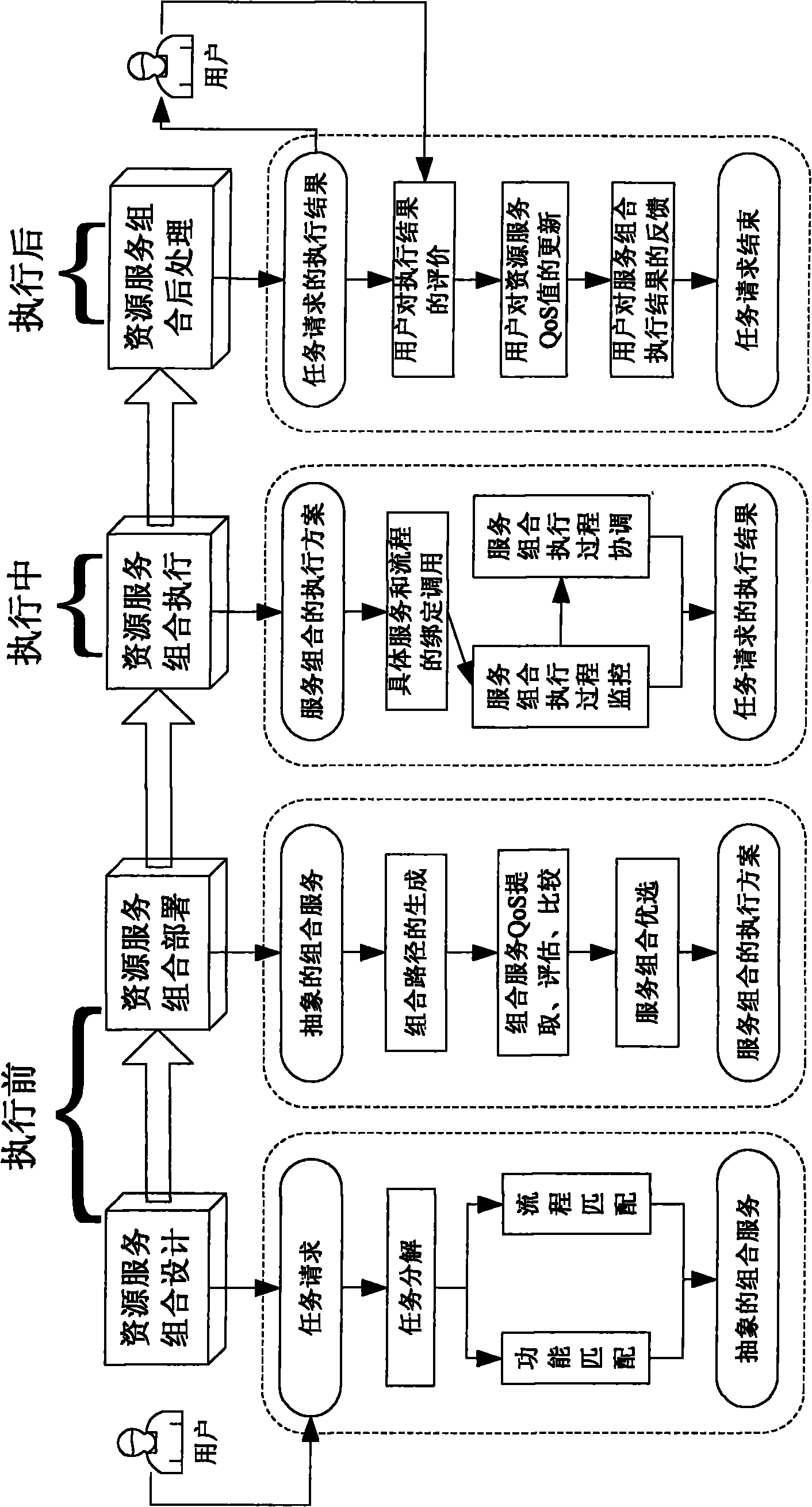

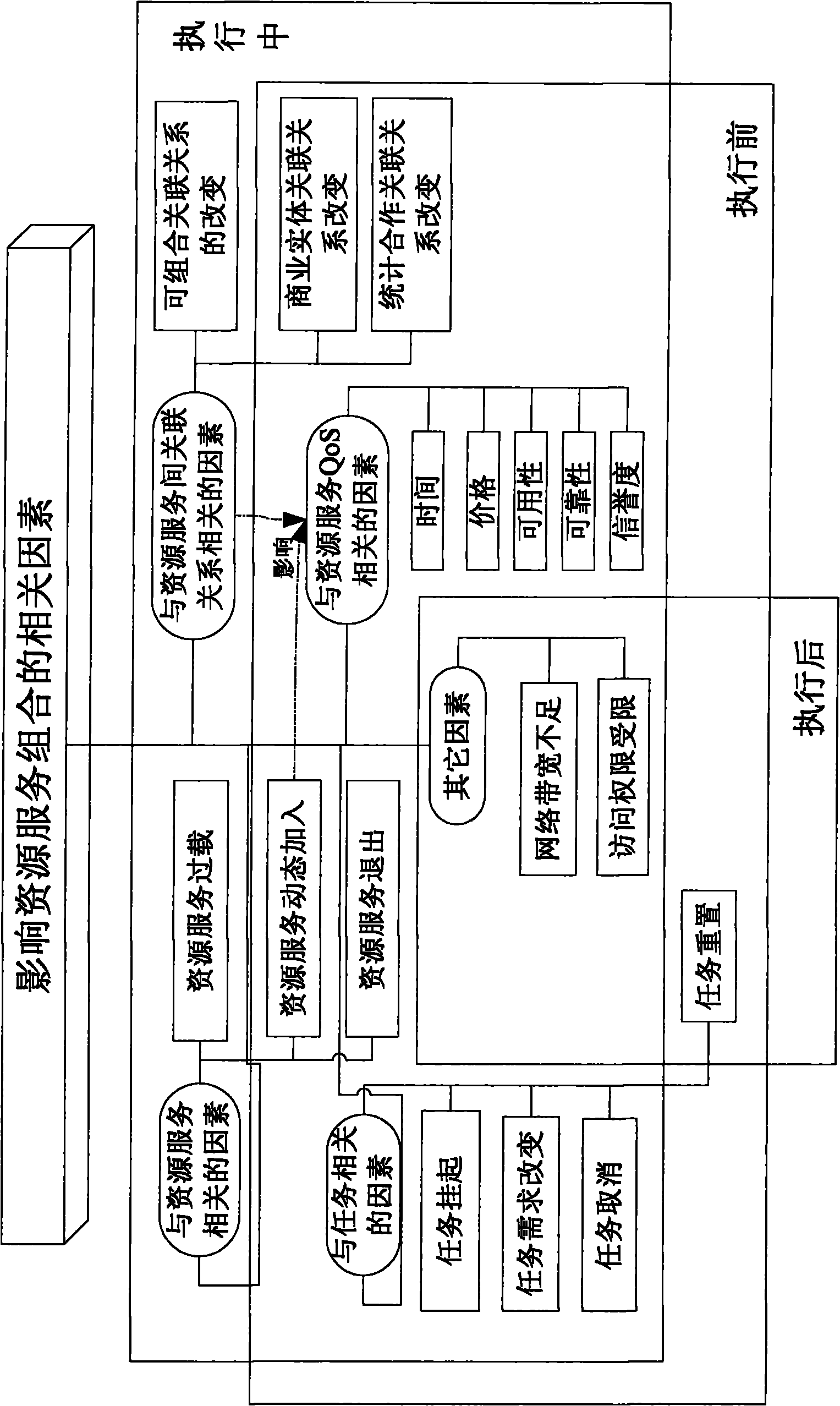

ActiveCN101958917ARealize quantitative descriptionRealize evaluationData switching networksService compositionComputer science

The invention relates to a cloud manufacturing system-oriented method for measuring and enhancing the flexibility of resource service composition, in particular to a method for establishing an effective system for evaluating the flexibility of the resource service composition and realizing dynamic re-configurability and change adaptability of the resource service composition in the current resource service-oriented networked manufacturing. The method comprises the following steps of: classifying and measuring the flexibility of the resource service composition respectively by analyzing relevant factors affecting the life cycle of the resource service composition so as to realize quantitative assessment of the flexibility of the resource service composition; and monitoring each resource service node in the resource service composition and a run task and a running environment of the resource service node by establishing a flexibility management system framework for the resource service composition and coordinating abnormalities by using an electronic control amplifier (ECA) rule base so as to finally realize stable, healthy and transparent operation of the resource service composition. The method has the advantages of supporting the flexibility of the resource service composition, realizing a compact measuring method and high adaptability and improving the generality and expansibility of a strategy.

Owner:BEIHANG UNIV

Cloud manufacturing service system based on product life cycle

InactiveCN104463502AReduce operating costsHighly innovativeBuying/selling/leasing transactionsResourcesPurchasingService module

The invention discloses a cloud manufacturing service system based on the product life cycle. The cloud manufacturing service system comprises a business negotiation module, a collaborative design and development design module, a sample piece trial-manufacturing module, a checkout detection module, a bulk ordering module, a material purchasing module, a production management module, a sale management module and an after-sales service module. By means of the cloud manufacturing service system, the efficiency and the quality in the product life cycle including research and development design, material purchasing, product production, selling and the like are better improved, management in the product life cycle including product research and development design, material purchasing, product production, selling and the like is specified, the product research and development period is shortened, the operating cost of an enterprise is reduced, improving of the product innovation capability in the manufacturing industry is promoted, the market competitiveness of the manufacturing enterprise is strengthened, and the rapid development of the manufacturing industry in China is pushed.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

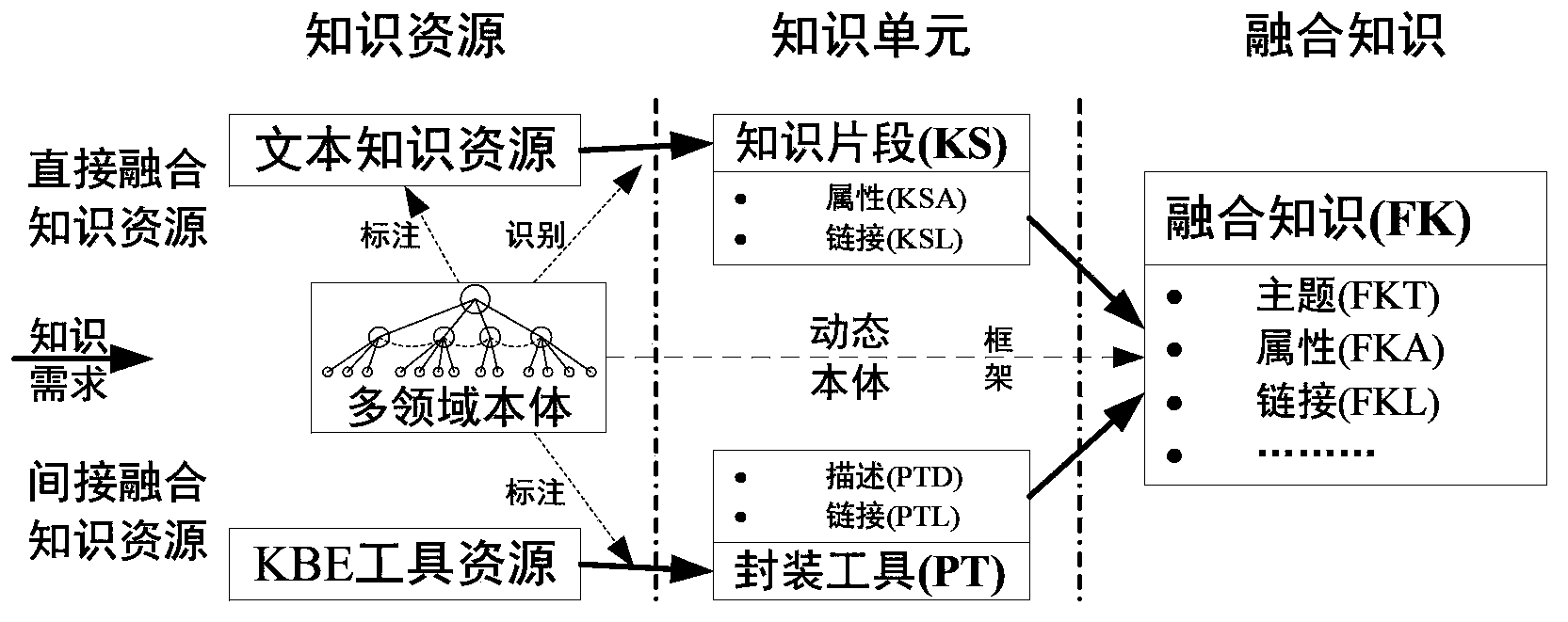

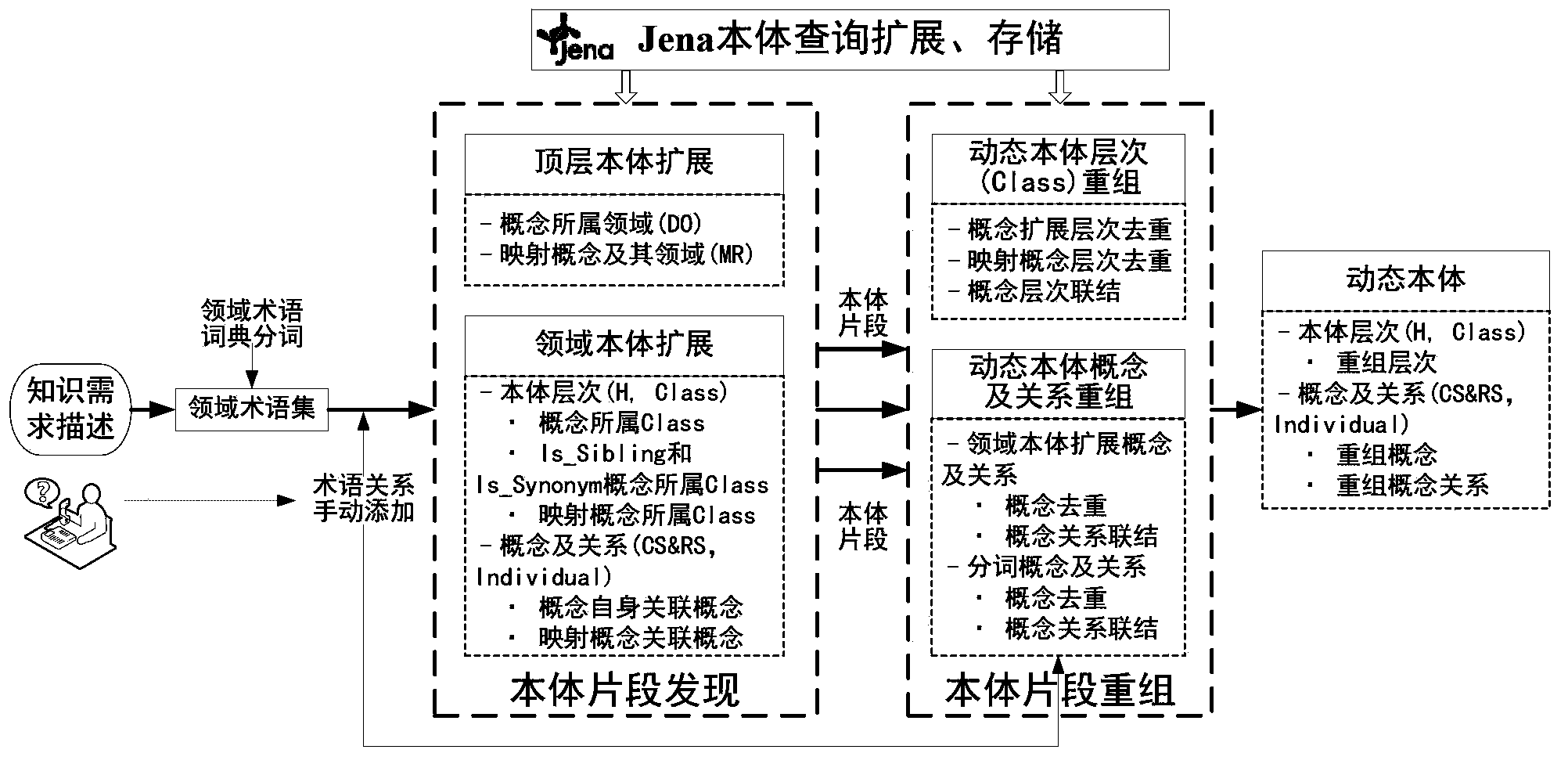

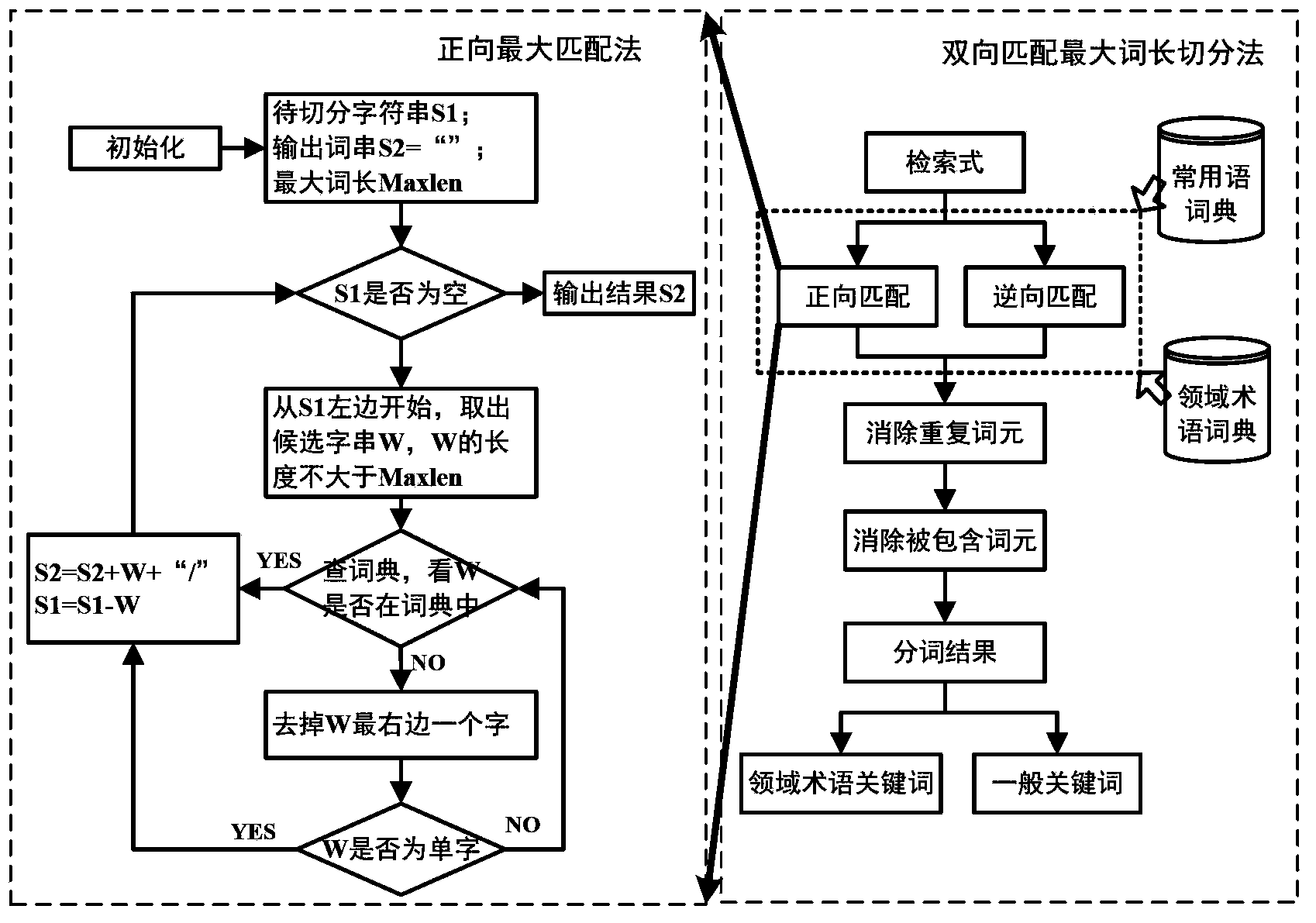

Knowledge fusion method based on dynamic body in cloud manufacturing mode

ActiveCN104239660AImprove matchSpecial data processing applicationsManufacturing technologyMulti field

The invention provides a knowledge fusion method based on a dynamic body in a cloud manufacturing mode and belongs to research contents of modern manufacturing technologies in the technical field of advanced manufacture. The method is a solution method for integrated application of heterogeneous resource distributed in the cloud manufacturing mode and is based on the dynamic body established by a multi-field body to form fused knowledge resources. The method comprises the steps of firstly performing semantic analysis on knowledge demand, obtaining field term key words; then finding relevant body segments from the multi-field body according to the key words, and restructuring the body segments to form the dynamic body; utilizing dynamic body terms to analyze the knowledge resources implied in files on the basis so as to obtain knowledge fragments with paragraphs as representations, calculating themes of the knowledge fragments, enabling the themes to be associated with the dynamic body to form the fused knowledge resources. By means of the method, unified access and management on multi-source heterogeneous knowledge resources distributed in group enterprises is achieved to some degree, dynamic fusion of existing knowledge resources is achieved, and continuous update and change of knowledge resources and knowledge demands of the enterprises are effectively met.

Owner:BEIHANG UNIV

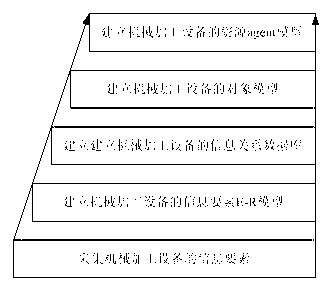

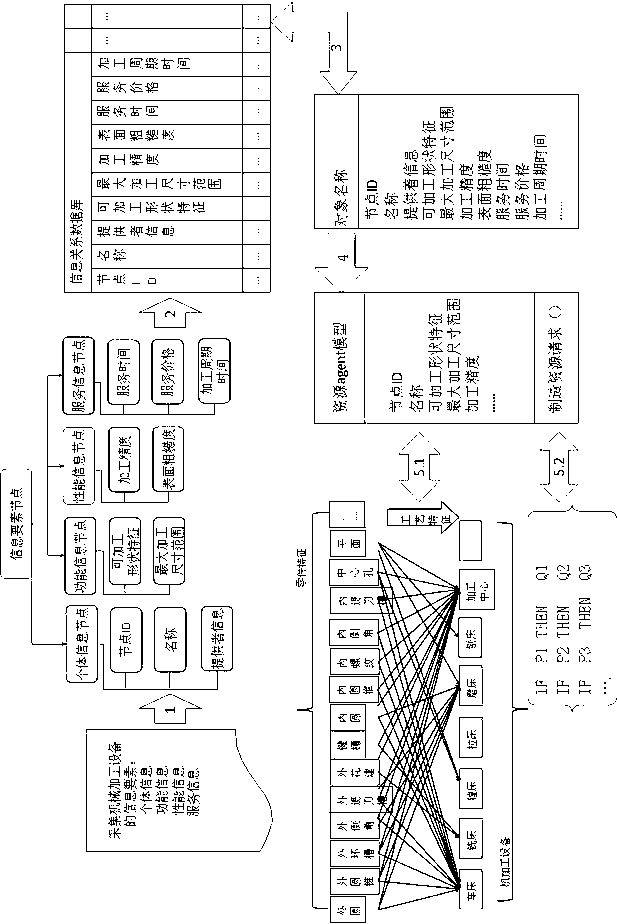

Machining equipment resource informationizing method for cloud manufacturing

ActiveCN103268542AResource information is convenientResource informationization is fastOffice automationTransmissionInformatizationRelational database

The invention provides a machining equipment resource informationizing method for cloud manufacturing. The method includes the steps of collecting information elements of machining equipment, abstractly forming an information relation database and a resource agent model of the machining equipment, enabling the information relation database and the resource agent model to be integrated in a cloud computing server, responding manufacturing resource requests from the outside through utilization of the cloud computing server, providing machining equipment resource information services to the outside, and realizing resource informatization of the machining equipment on the basis of the cloud computing server. The method can provide a good resource information publishing interface, improves convenience and speed of resource informatization, and can well provide the machining equipment resource information meeting the outside formulating requirements to the outside. The machining equipment resource informationizing method for cloud manufacturing achieves the purpose of resource convergence in development of a cloud manufacturing system for manufacturing links, and provides technical support for development of the cloud manufacturing system.

Owner:CHONGQING UNIV

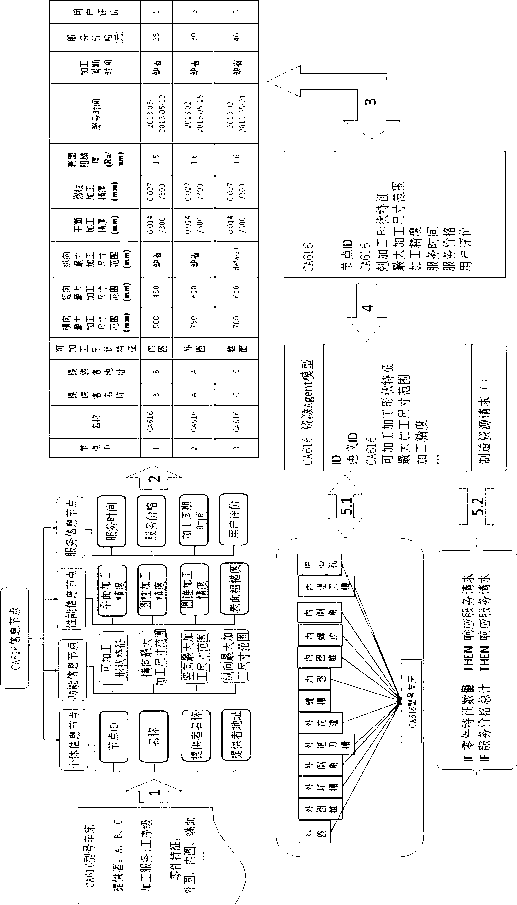

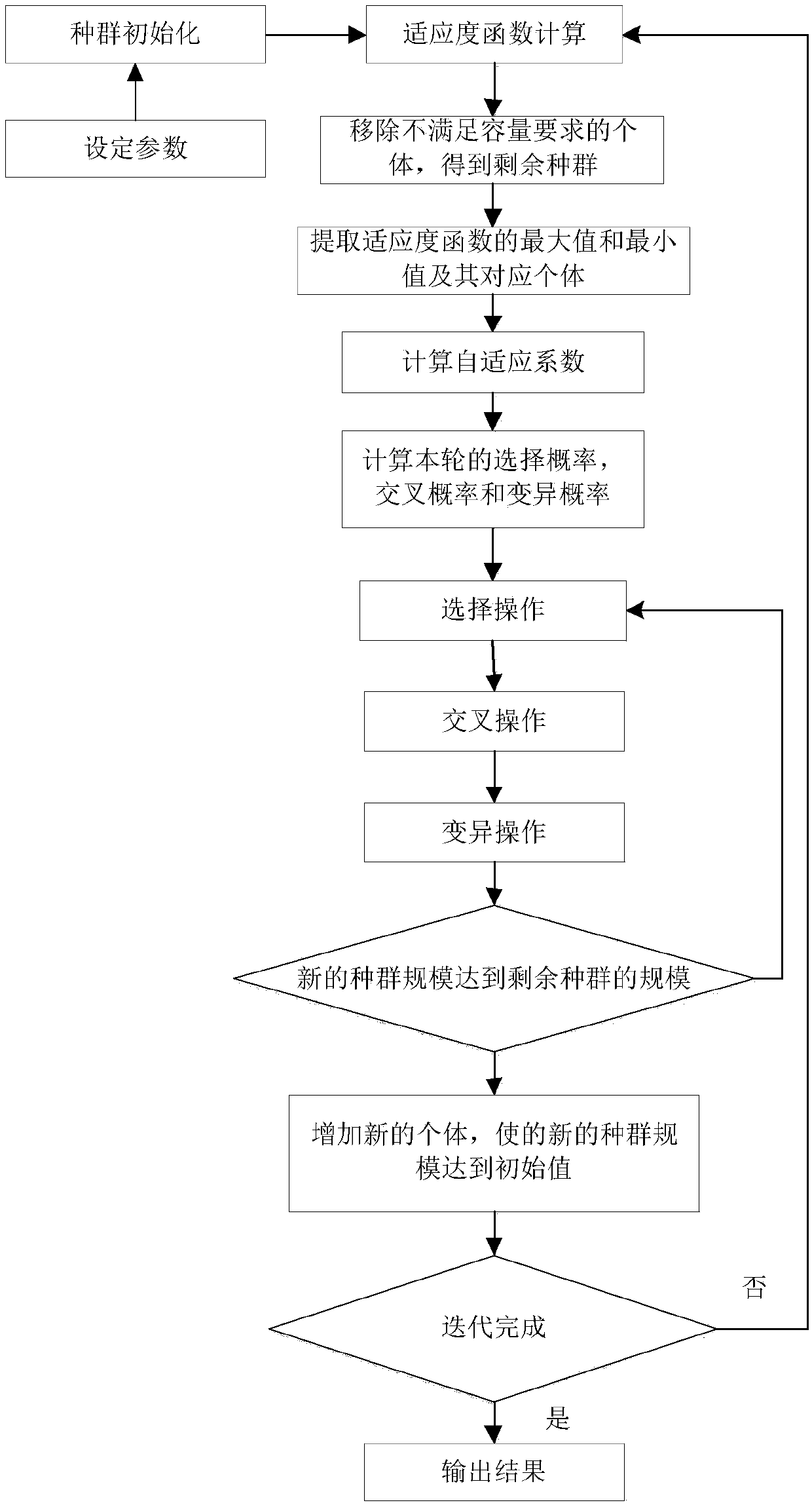

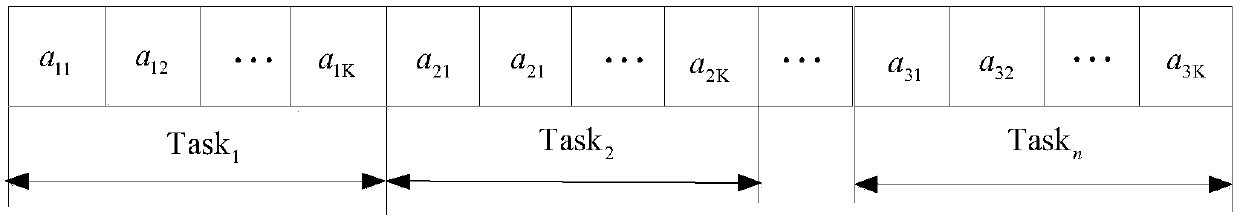

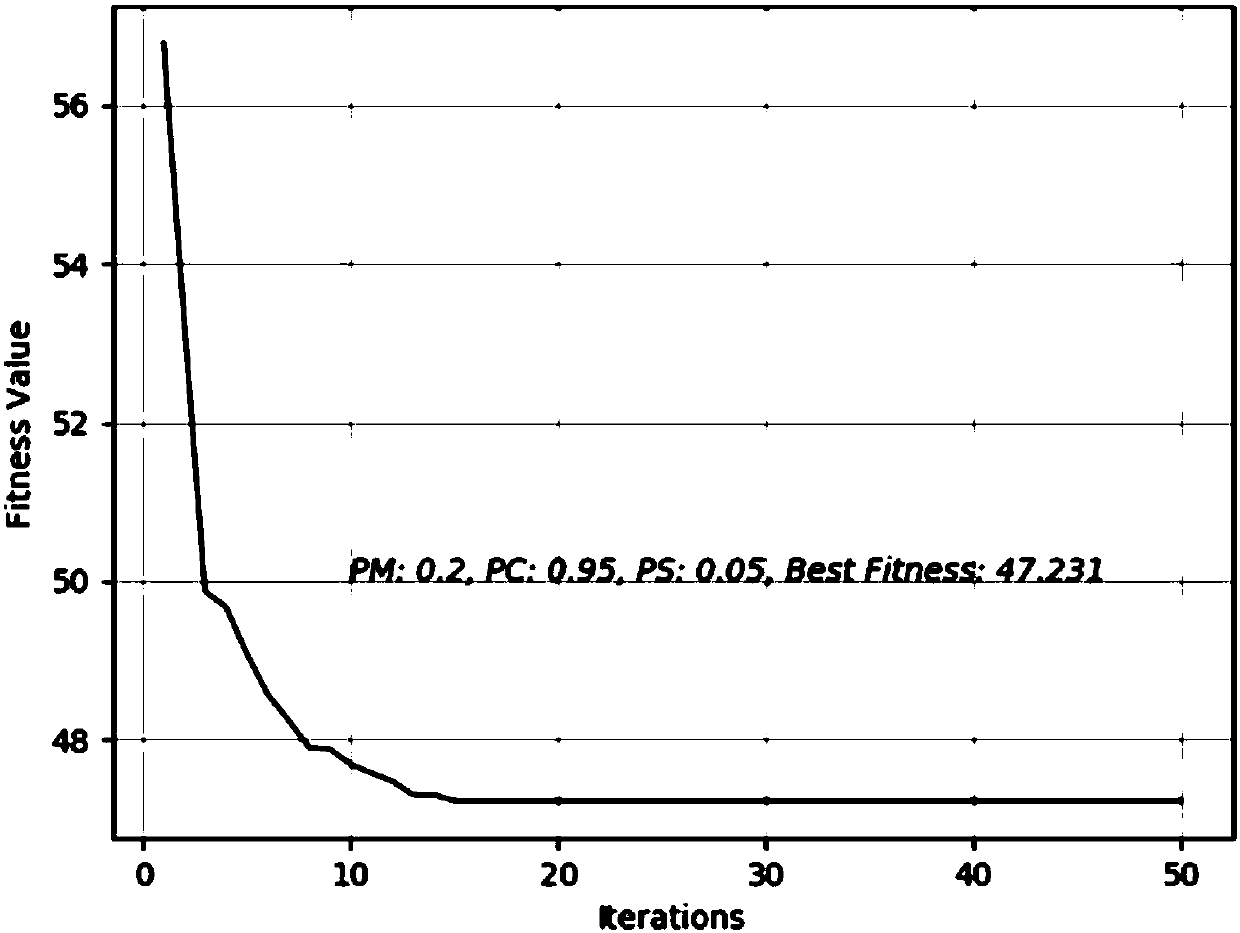

Adaptive coefficient genetic algorithm-based cloud manufacturing service resource matching method

ActiveCN107679750AMeet capacity constraintsAvoid waiting in lineArtificial lifeResourcesLocal optimumGenetic algorithm

The present invention discloses an adaptive coefficient genetic algorithm-based cloud manufacturing service resource matching method. According to the method, the value of the objective function of each individual in a population is calculated, and the capacity limit of each individual is judged; individuals which do not meet capacity requirements are discarded; an adaptive coefficient is calculated; the selection probability, crossover probability and mutation probability of iteration of a current round are calculated; genetic evolution is carried out according to the probabilities, so that anew population can be generated; and the population is supplemented with new individuals. According to the method of the invention, an optimal resource service combination matched with the task requirement of a cloud manufacturing user is solved according to the task requirement of the cloud manufacturing user; it can be ensured that the sum of the products of the cost and time of all tasks is minimum; the capacity limitation of resource services is satisfied, so that queuing and waiting can be avoided; and since an improved genetic algorithm has high robustness and fast convergence rate andwill not be trapped in local optimum, the diversity of the population can be significantly improved, and the accuracy of resource matching can be improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

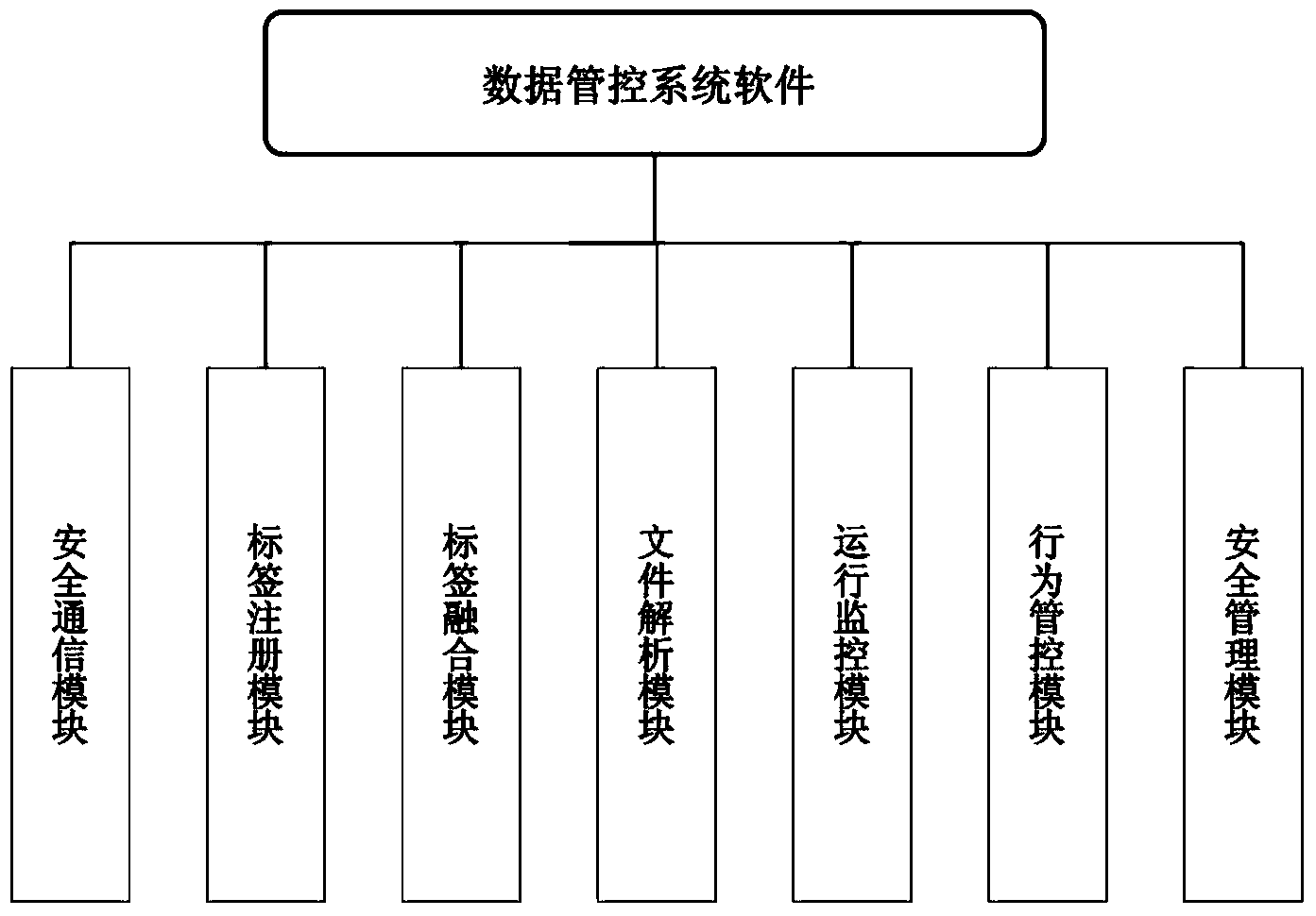

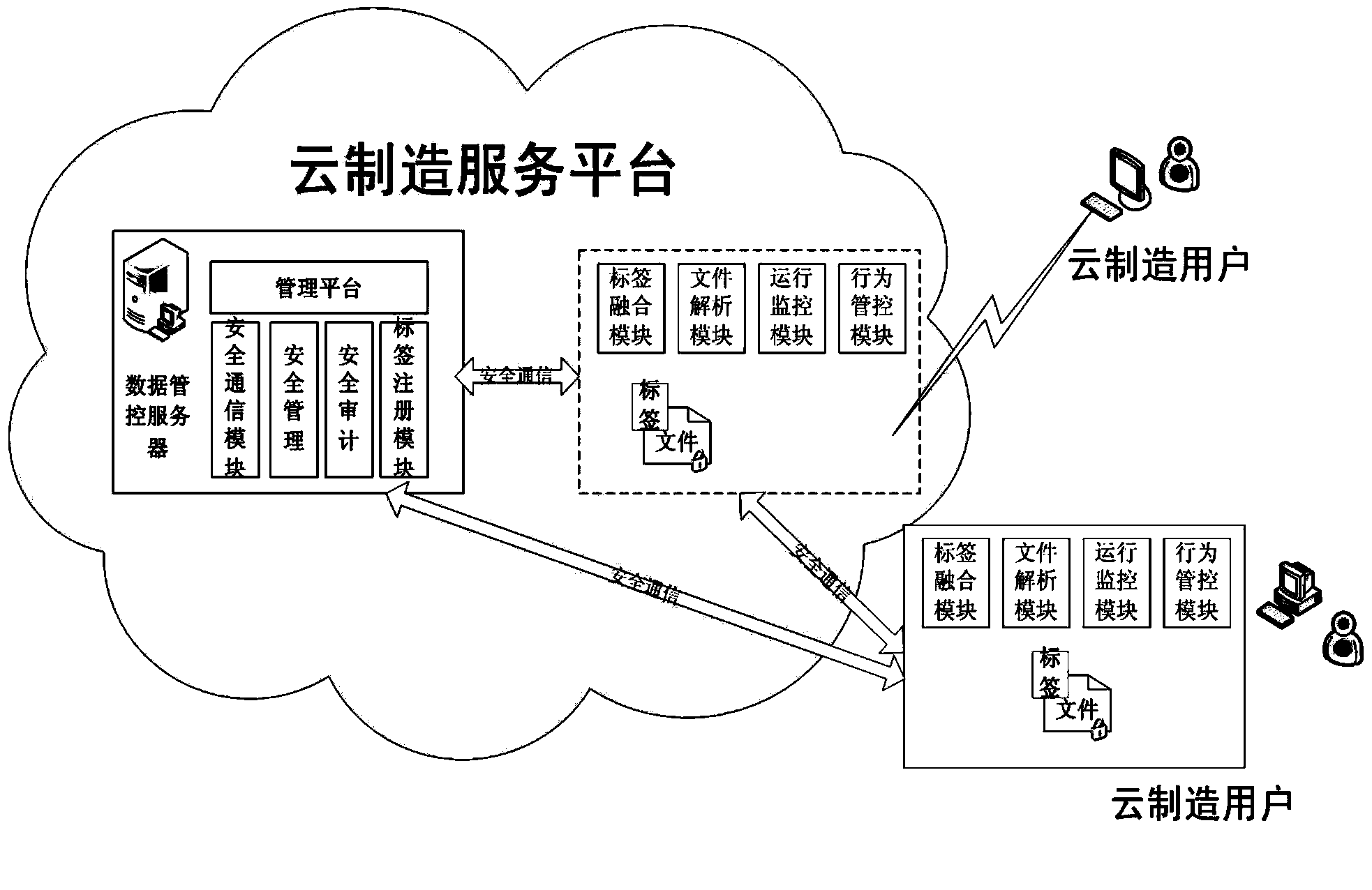

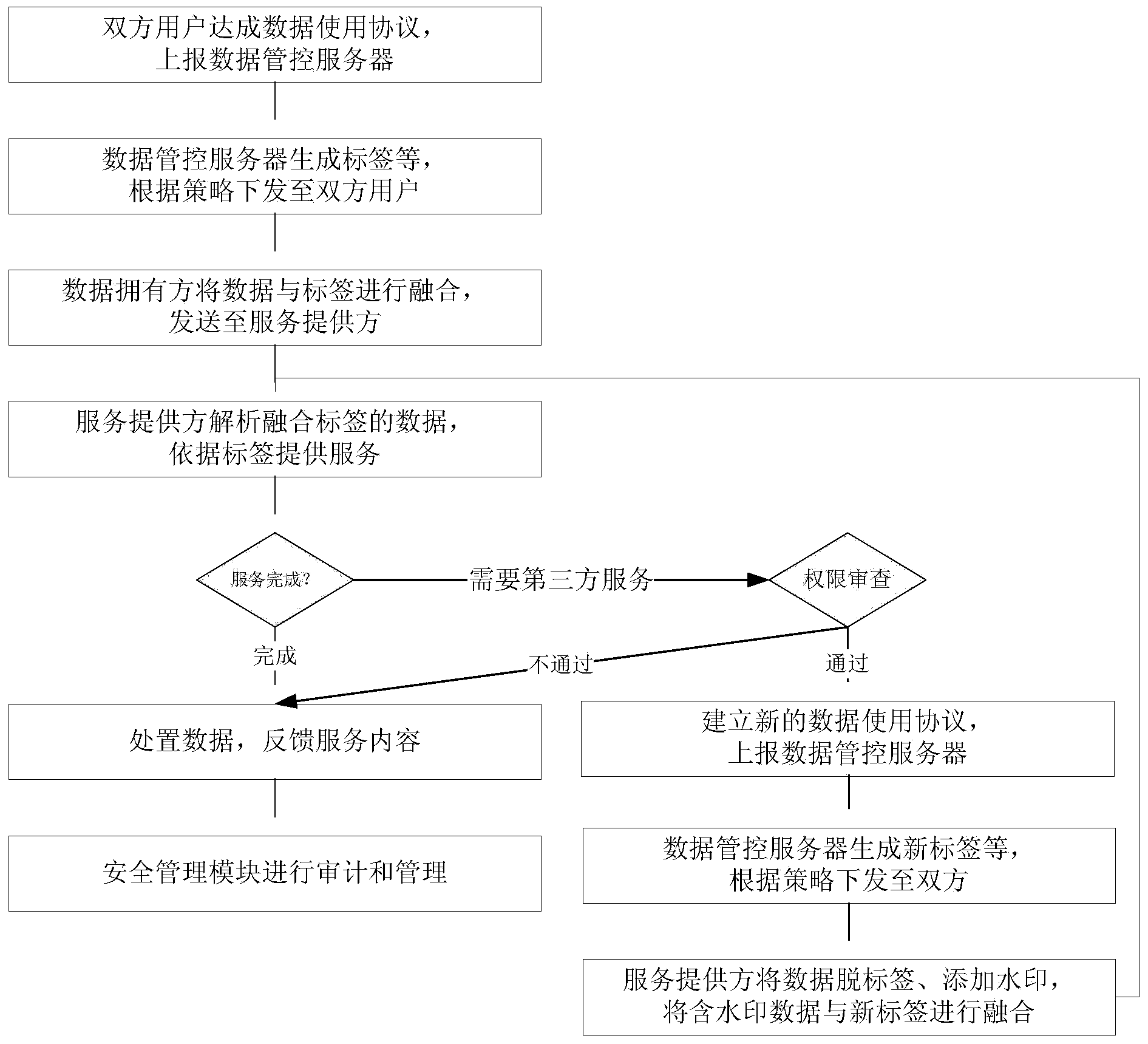

A cloud manufacturing user data management and control method based on labels

The invention discloses a cloud manufacturing user data management and control method based on labels and belongs to the technical field of data management and control. In order to resolve various safety problems existing in user data transmission, share, and use processes in cloud manufacturing data chain, the invention provides a management and control method for transmitting, sharing, and using data between cloud manufacturing users under the circumstance of unconsolidated data storage. Using digital label technology, the method performs inseparable fusion on data and digital labels so as to guarantee the safety and the controllability in the use, the share, and the transmission processes of user data, achieve control and management of the full life circle of the data, and trace the source of a data leakage behavior.

Owner:706 INST SECOND RES INST OF CHINAAEROSPACE SCI & IND

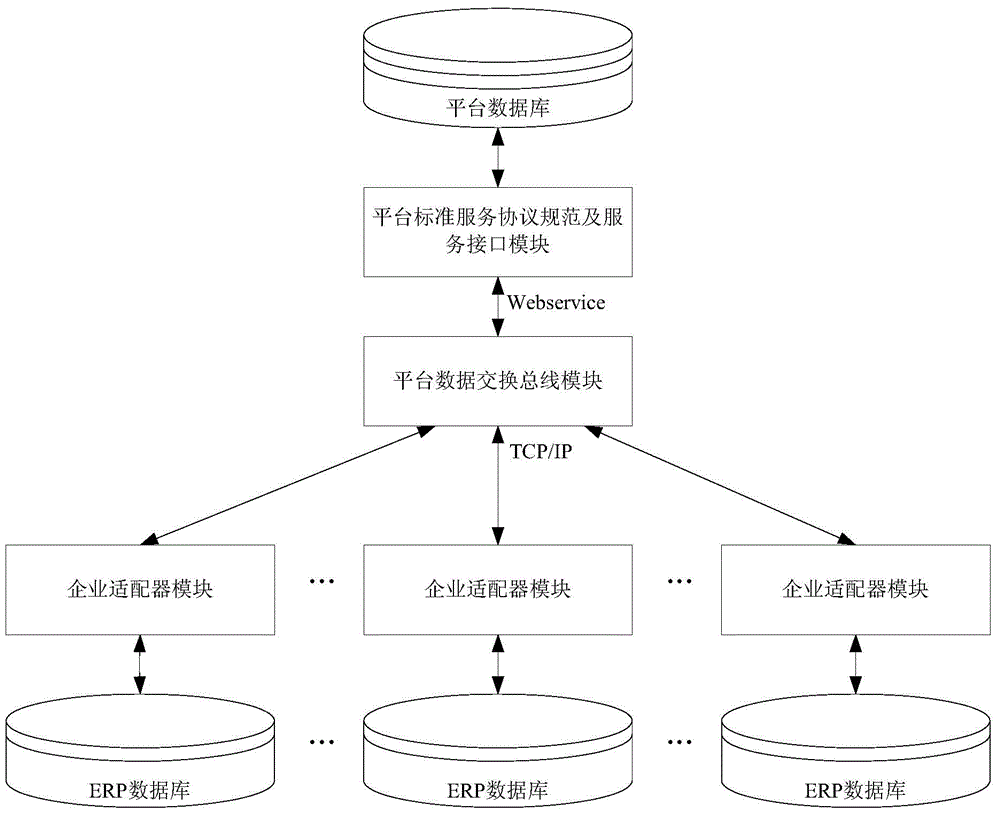

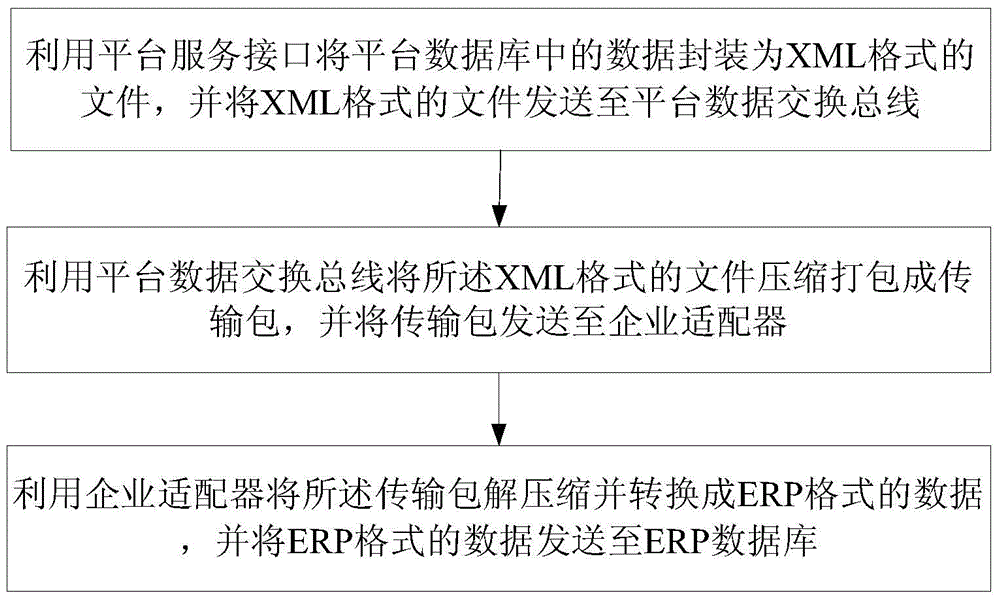

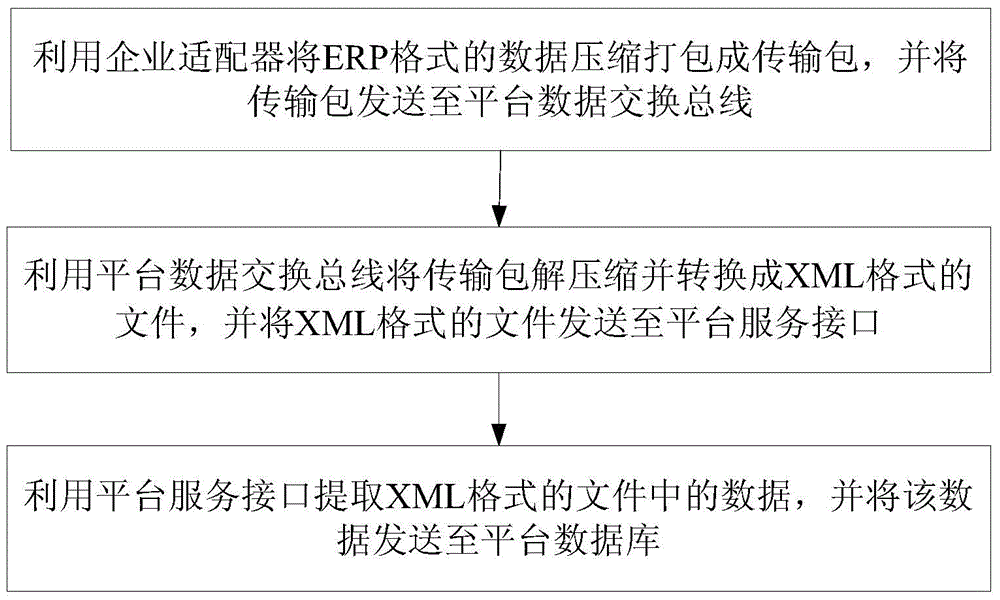

Cloud manufacturing platform oriented ERP integrated database service interface encapsulation system and method

InactiveCN105786913AImprove efficiencyImprove the level ofTransmissionSpecial data processing applicationsDatabase servicesInformation integration

The invention discloses a cloud manufacturing platform oriented ERP integrated database service interface encapsulation system and method. The system comprises a platform standard service protocol specification and service interface encapsulation module for defining a standard format of external exchange data of a cloud manufacturing platform and performing data exchange between a platform database and a platform data exchange bus module; a platform data exchange bus module for defining transformation relation between the standard format of external exchange data of the cloud manufacturing platform and ERP data format, and by a transformation protocol, performing data exchange between the platform standard service protocol specification and service interface encapsulation module and the platform data exchange bus module through a network; an enterprise service adapter module for performing data exchange between the platform data exchange bus module and an ERP database. According to the cloud manufacturing platform oriented ERP integrated database service interface encapsulation system and method, a problem of integration of an enterprise information system and a cloud manufacturing platform in a cloud manufacturing engineer application is solved, and enterprise internal and external information integration is supported.

Owner:BEIJING SIMULATION CENT

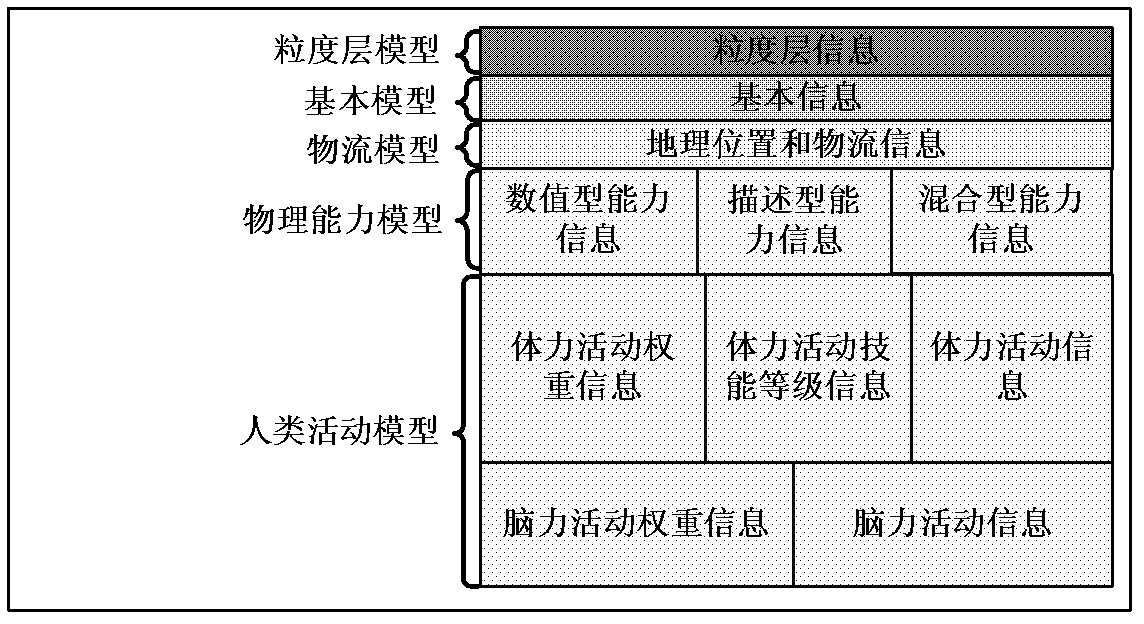

Virtual resource model based on cloud manufacturing and modeling method thereof

InactiveCN102360462APrecise and precise modelingImprove accuracyData processing applicationsData informationData access

The invention, which belongs to the information security technology field, relates to an information collection storage and encryption retrieval system based on a cloud platform, especially to a system that is used for intelligently collecting interaction information on a network as well as encrypting and storing the information, so that information retrieval can be realized without decryption. More particularly, the model comprises a data information collection module, a data information encryption module, a data information retrieval module and a data access interface module. According to the invention, information that is needed for a user is intelligently collected; according to the encrypted information retrieval method, information that is needed for a user can be retrieved without a decryption process, so that the user can access and obtain the needed information anywhere and anytime; therefore, efficiency can be improved and lots of time can be saved; meanwhile, information security can be ensured; and the model is suitable for application individually, in a company or in an organization and an institution; and the model can be installed on a personal computer or mobile equipment and it is convenient for collection, storage, encryption and retrieval of data information.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

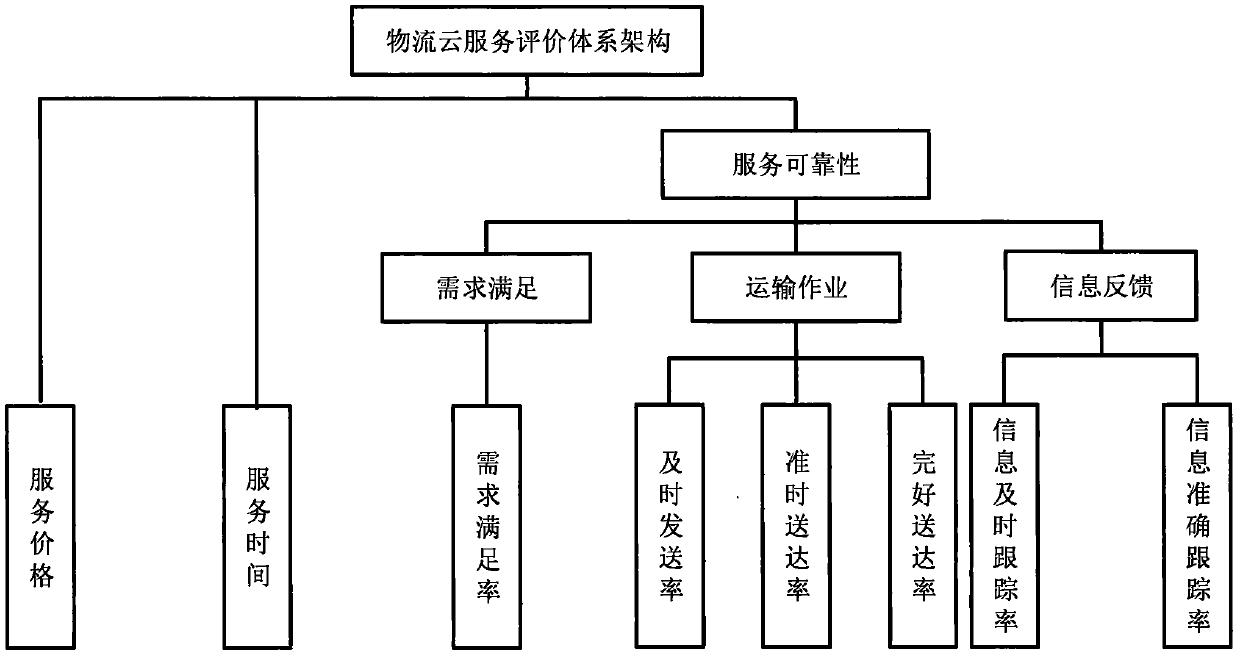

Cloud manufacturing service combination optimal selection method giving consideration to regional logistics service capability

InactiveCN107590623AIndex weights conform toResourcesTransmissionLogistics managementGenetic algorithm

The invention discloses a cloud manufacturing service combination optimal selection method giving consideration to regional logistics service capability, and the method comprises the steps: S1, constructing a logistics cloud service evaluation system framework and describing a logistics cloud service QoS index; S2, determining an index weight through a neural network; S3, calculating a combined service comprehensive index through a subjective and objective comprehensive weight method; S4, solving a cloud manufacturing service combination optimal selection problem through a genetic algorithm. The invention aims at carrying out the cloud manufacturing service combination based on the QoS comprehensive index, and an index weight employed in the combination process is determined through the neural network. Moreover, the logistics cloud service and regional logistics capability are considered in the combination process, thereby enabling the obtained comprehensive evaluation index to be moreaccurate and enabling the logistics cloud evaluation to be adaptive.

Owner:袁宏斌

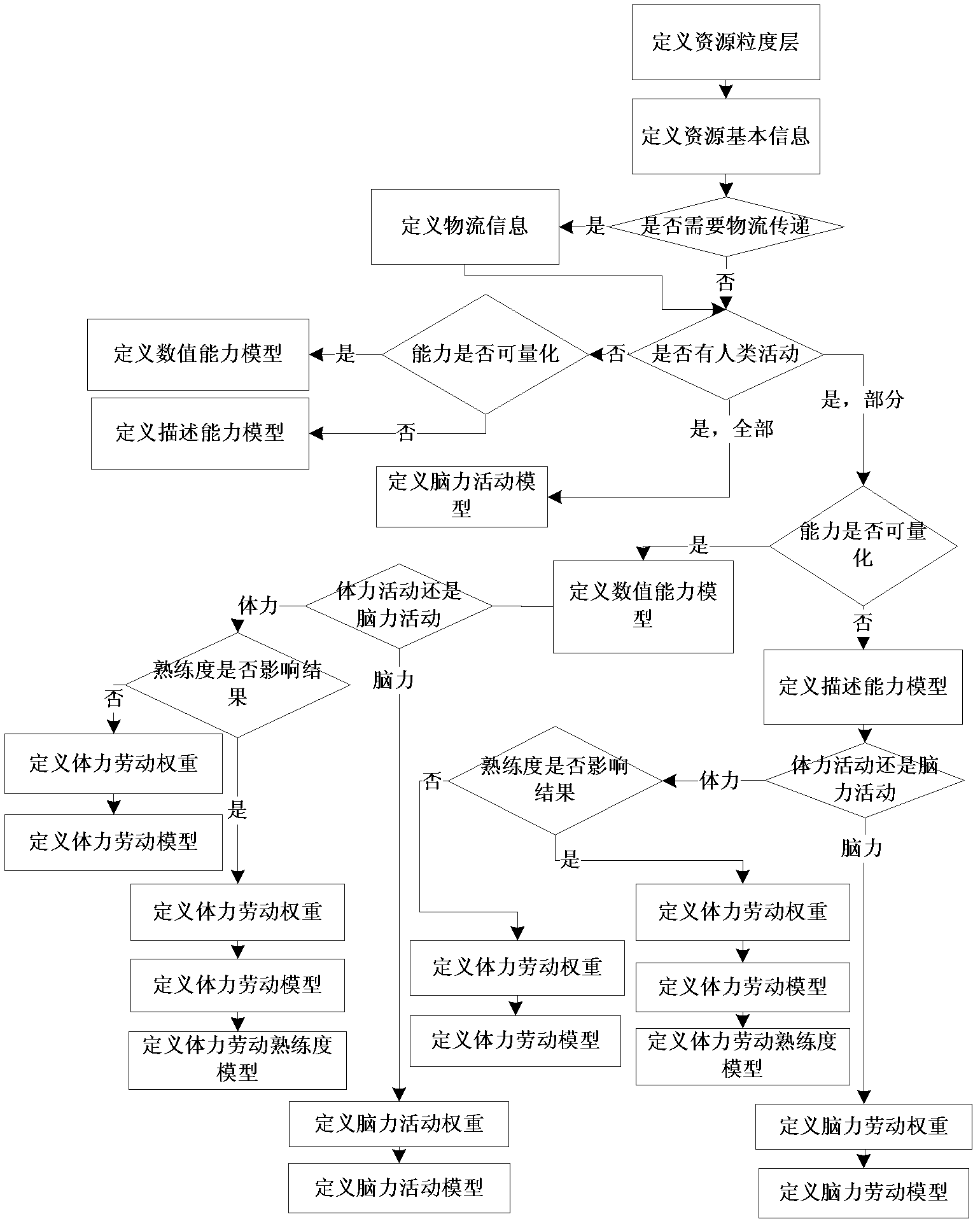

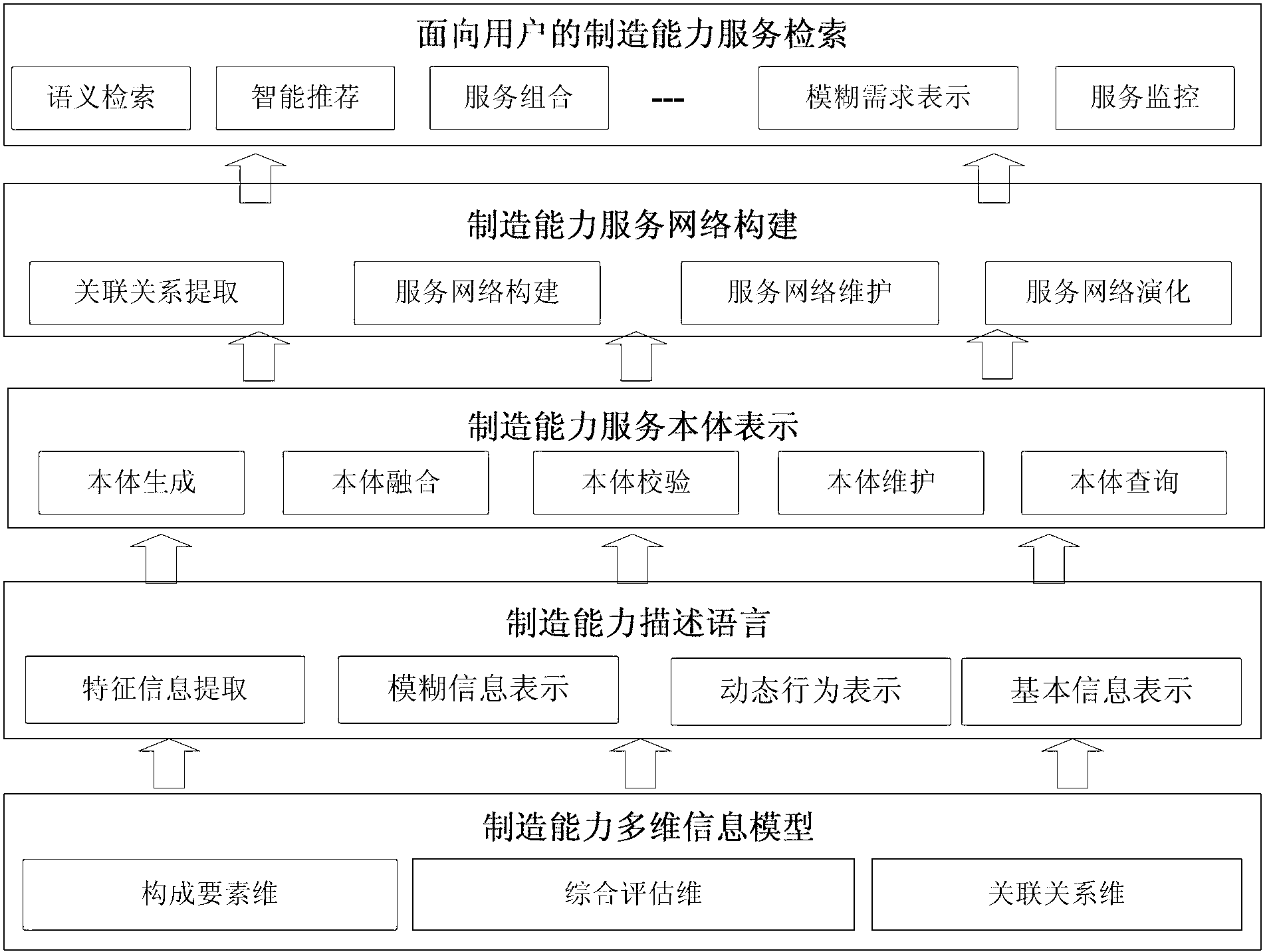

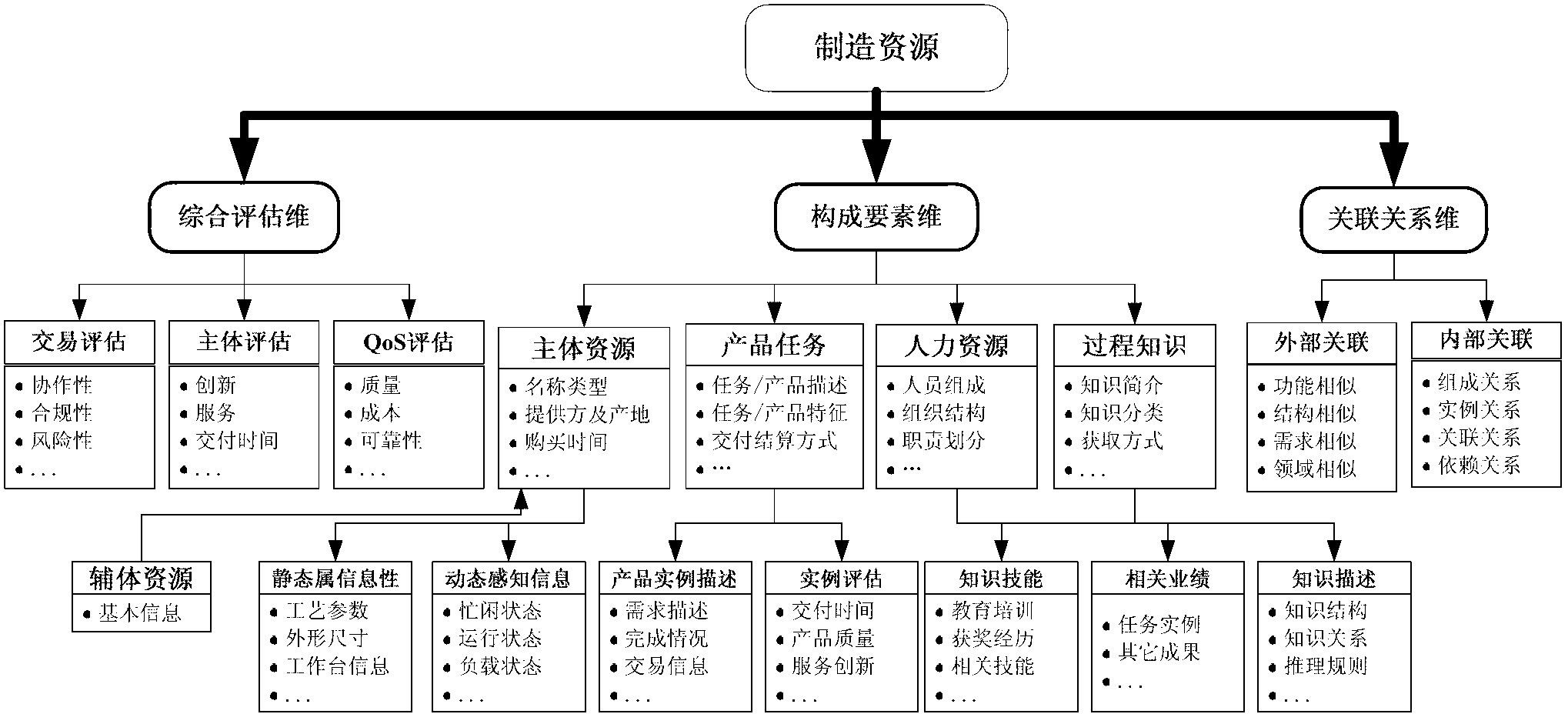

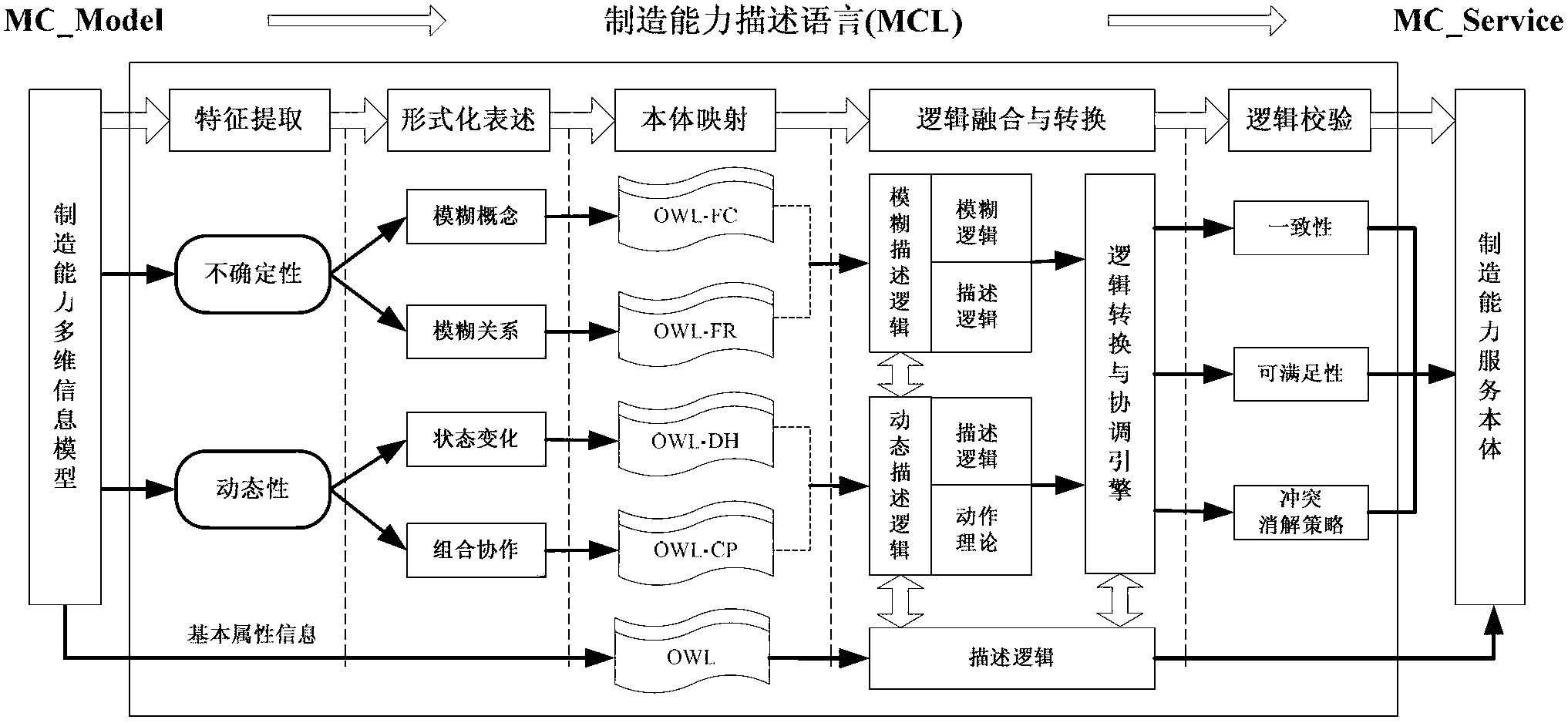

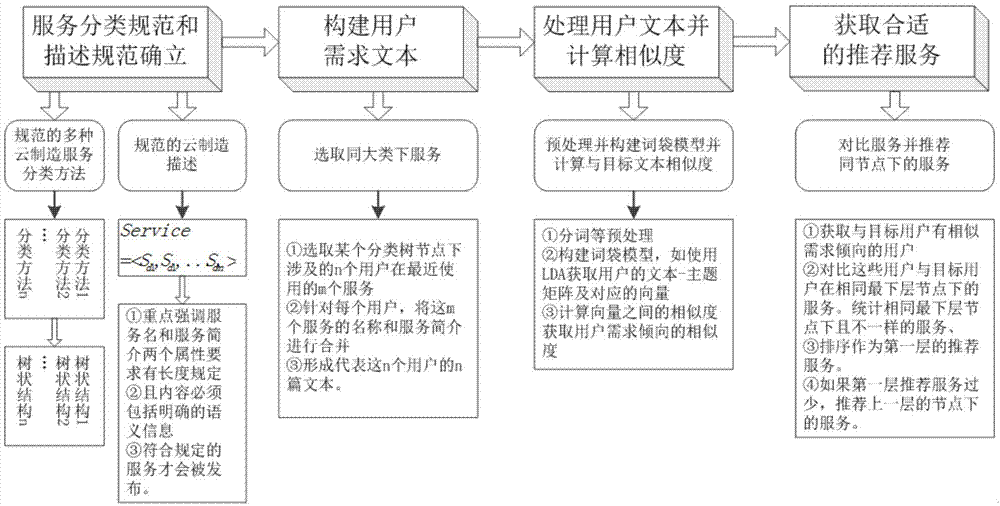

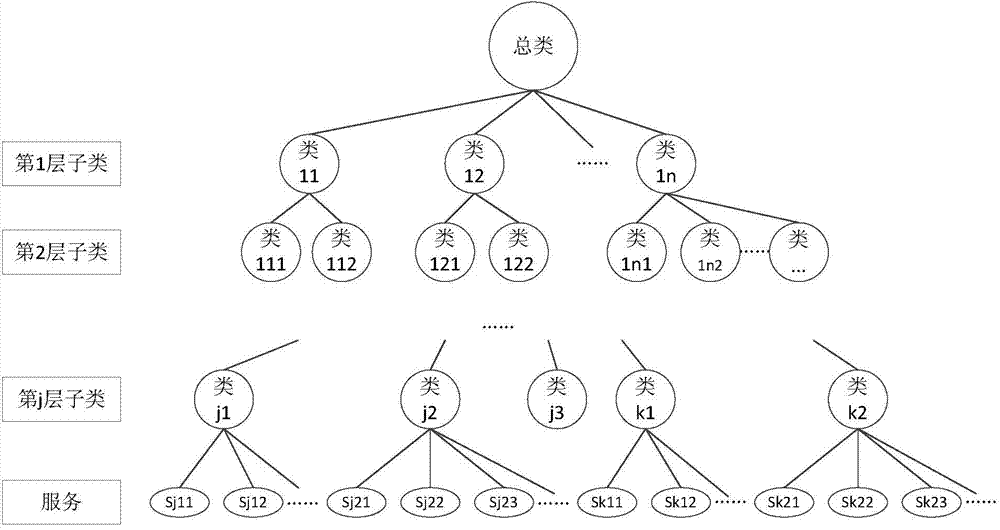

Cloud manufacturing capability description method supporting use on demand and sharing circulation of manufacturing capability

ActiveCN103020722ARealize intelligent recommendationRealize "Secondary RecommendationData processing applicationsTransmissionComputer scienceInformation model

The invention provides a cloud manufacturing capability description method supporting use on demand and sharing circulation of manufacturing capability. The method comprises the following steps of: extracting and classifying fuzzy information and dynamic behavior information in a knowledge-based manufacturing capability description model (namely a multi-dimension manufacturing capability information model); formalizing a fuzzy concept and a fuzzy role relationship according to a fuzzy description logic; describing service state change and dynamic combination flow according to a dynamic description logic; and giving an intelligent search and recommendation mechanism of the manufacturing capability based on the description method. According to the cloud manufacturing capability description method, the qualitative and quantitative properties of each dimension and each level of manufacturing capability can be taken into sufficient consideration, and a knowledge-based manufacturing capability language is provided, so that manufacturing capability services are stored in a cloud manufacturing service platform in an ontology mode, and a manufacturing capability service network is formed on the basis of various relationships among the services and supports the intelligent search and the use on demand of users.

Owner:BEIHANG UNIV

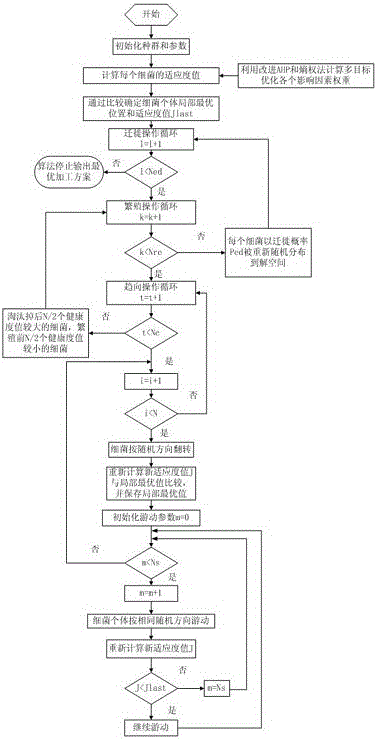

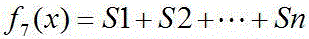

A processing scheme optimal selection method in a cloud manufacturing environment

InactiveCN106228298AGood serviceResourcesManufacturing computing systemsBacteria foragingBacteria foraging algorithm

A processing scheme optimal selection method in a cloud manufacturing environment belongs to the technical field of manufacturing resource optimization. The aim of the invention is to acquire the basic attribute of the cloud manufacturing resources as an evaluation index of the selection of the cloud manufacturing resources, and to establish a processing scheme selection mathematical model based on the optimization of bacteria foraging and to produce an optimal selection method in the cloud manufacturing environment. In the invention, a multi-objective optimization mathematical model is constructed by a production cost objective function, a production time objective function, a processing quality objective function and other evaluation index objective functions, and then optimal selection of the processing scheme in the cloud manufacturing environment is carried out. The invention aims at designing a processing scheme selection method based on a bacteria foraging algorithm for manufacture resource selection in a machinery manufacturing process in the cloud environment so as to provide a reasonable suggest for an enterprise decider in processing scheme selection and to further raise the product quality and the enterprise profit.

Owner:CHANGCHUN UNIV OF TECH

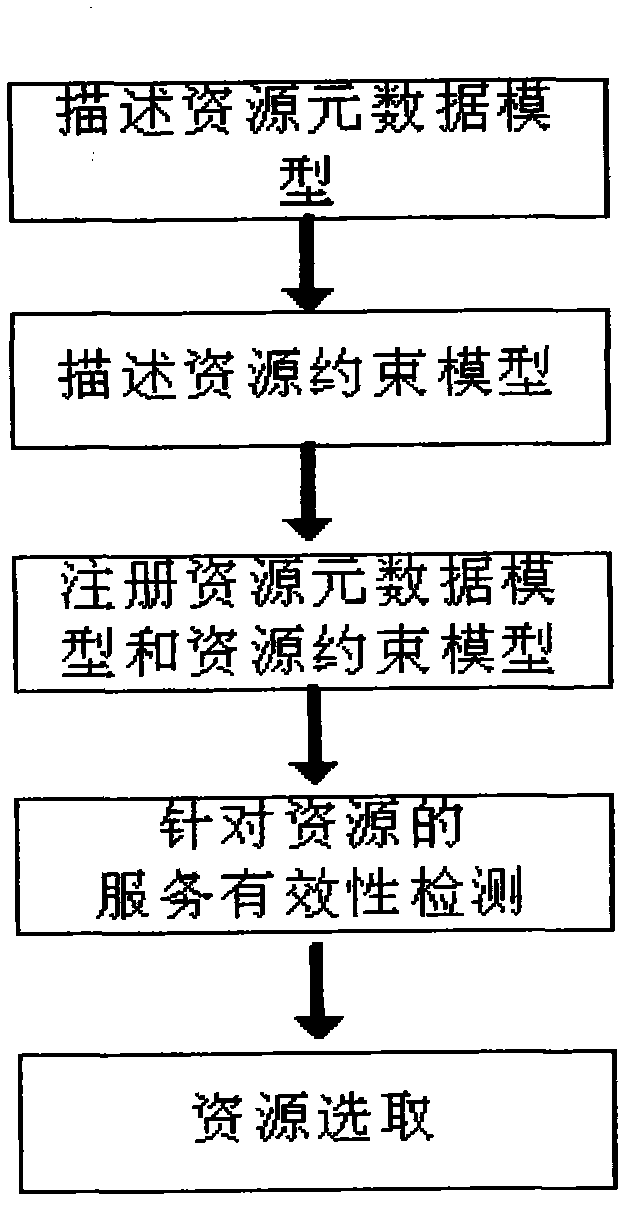

Service selection method based on resource constraint in cloud manufacturing environment

InactiveCN102664915ADetectable validityImprove the efficiency of application integrationTransmissionSpecial data processing applicationsResource poolEnterprise application integration

The invention discloses a service selection method based on a resource constraint in a cloud manufacturing environment. The method is characterized by: formalizing an enterprise resource and storing as a XML format based on a metadata form so as to form a resource metadata model; formalizing the resource constraint and describing as the XML format through the form of a relational expression and a logical expression so as to form a resource constraint model; registering the resource metadata model and the resource constraint model on a cloud manufacturing platform, serving as an item of resource pool configuration, wherein when workflow operates, enterprise management and enterprise interaction are started, at this time, a workflow engine can acquire a resource constraint template through reading a workflow model and combine the resource metadata registered by the enterprise during operation so as to carry out satisfaction detection on all the resource constraints; using a detection result to carry out validity identification of the resource service and serving as a direct basis of the service selection. By using the method of the invention, efficiency of enterprise application integration can be improved. The method possesses high flexibility.

Owner:李海波

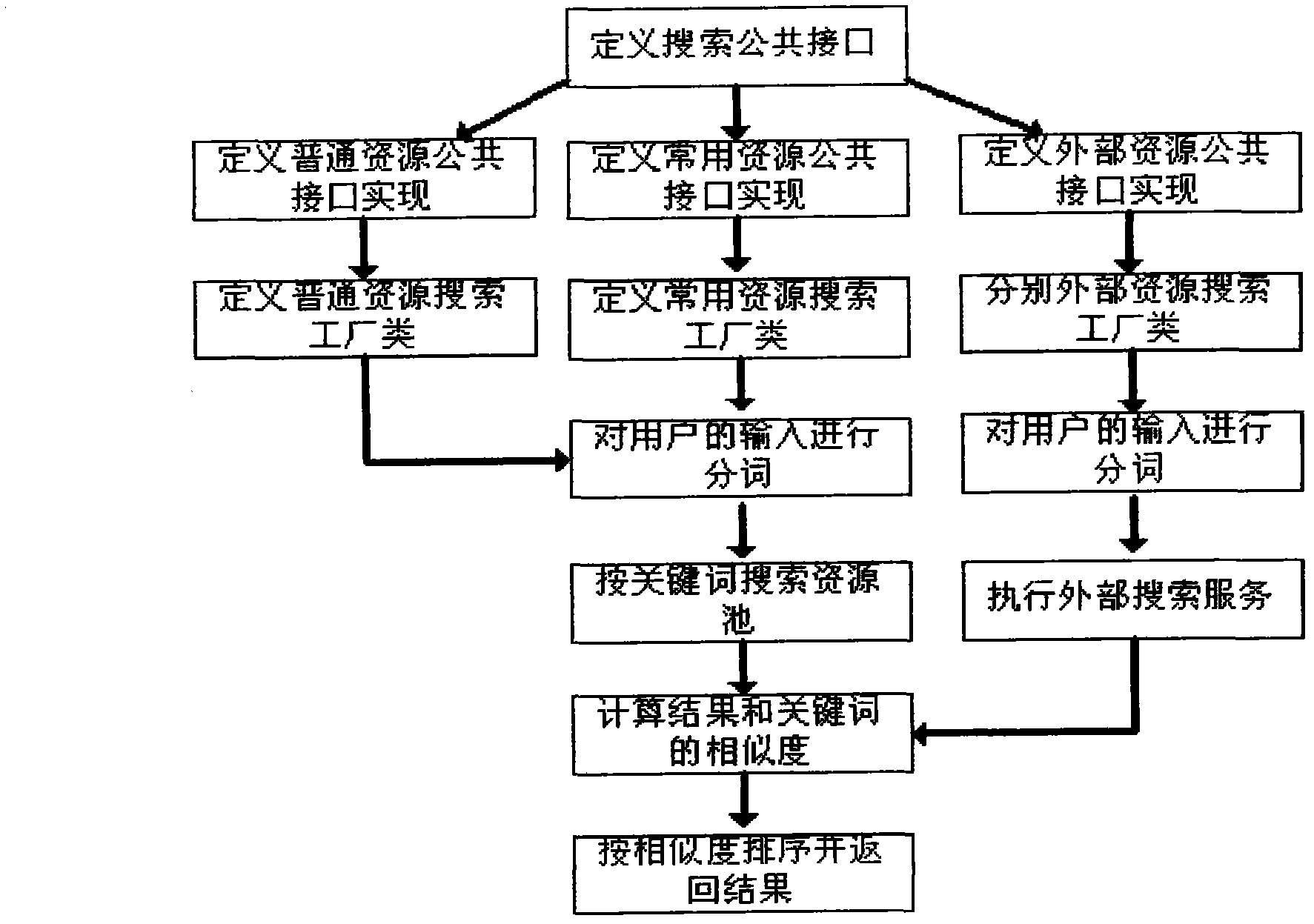

User-demand-oriented cloud manufacturing service recommendation method

ActiveCN104731958AStrong targetingGuaranteed reliabilitySpecial data processing applicationsMarketingLibrary scienceType of service

The invention provides a user-demand-oriented cloud manufacturing service recommendation method. According to the method, firstly, part of information of classification and service description of cloud manufacturing is standardized; secondly, a certain number of users in some field and all services used by the users within a period of time are selected, and the names and brief introductions of the services are combined to texts for the users; the users with the similar demands are determined through the method of comparing the similarity of the texts; some users with the similarity approaching to some user are selected, and the service using situation of the user at some service type are compared; the services which are not used by the user but used by the similar users are recommended to the user. According to the method, the character similarity of all the users with the similar user demands on the demand for all types of services is taken into consideration, and the recommended services must be applied by other enterprises. The user-demand-oriented cloud manufacturing service recommendation method is very high in accuracy.

Owner:BEIHANG UNIV

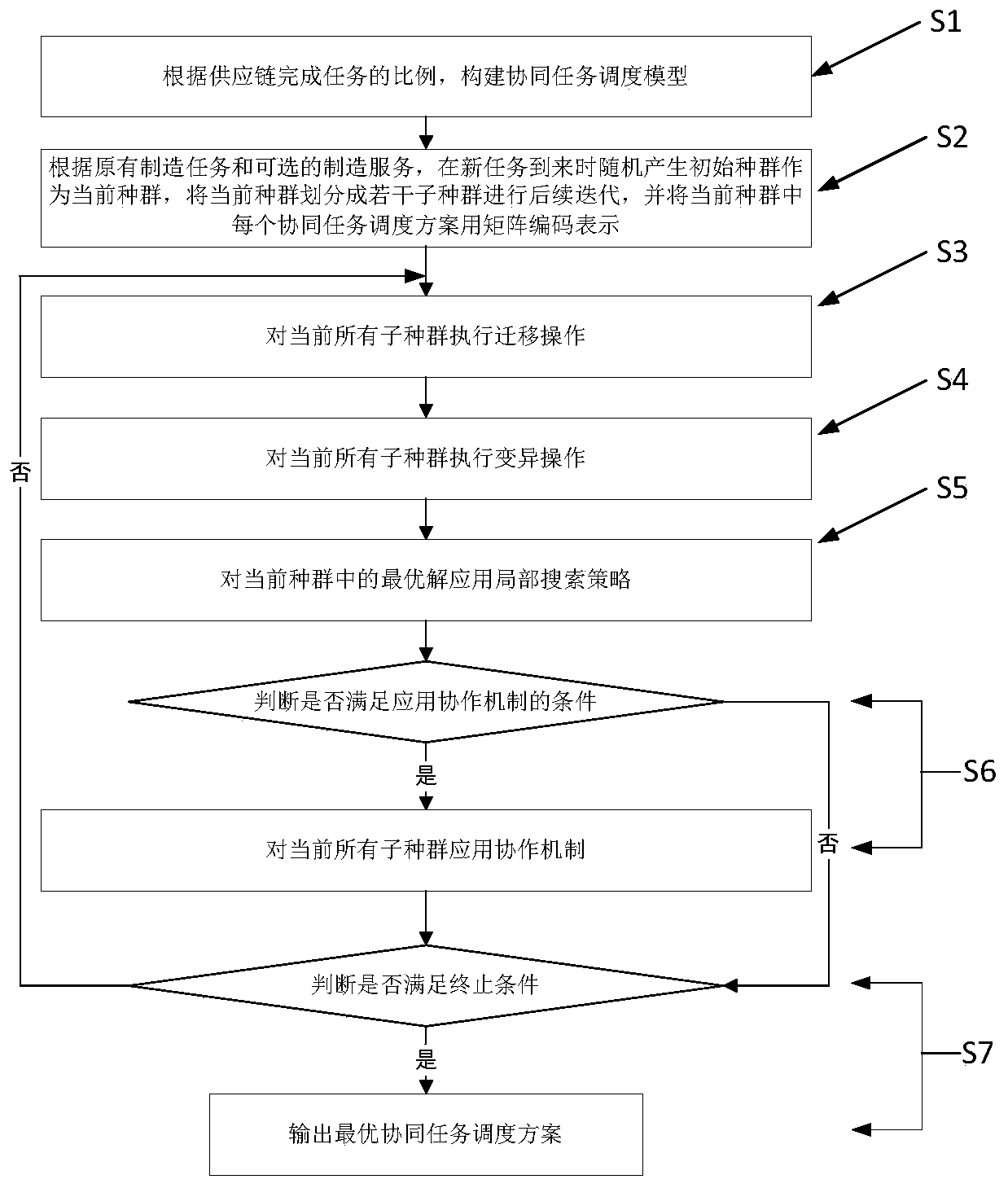

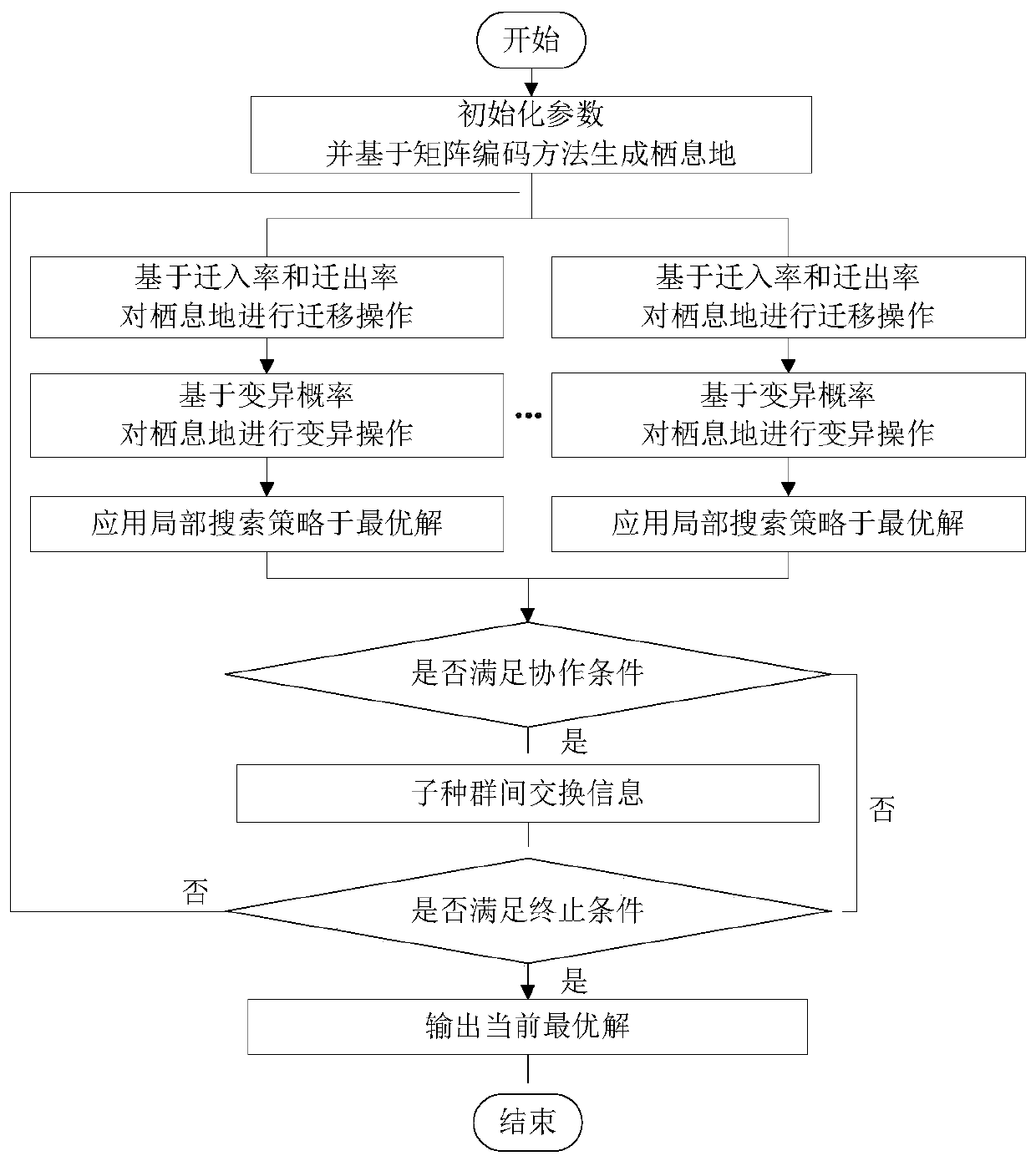

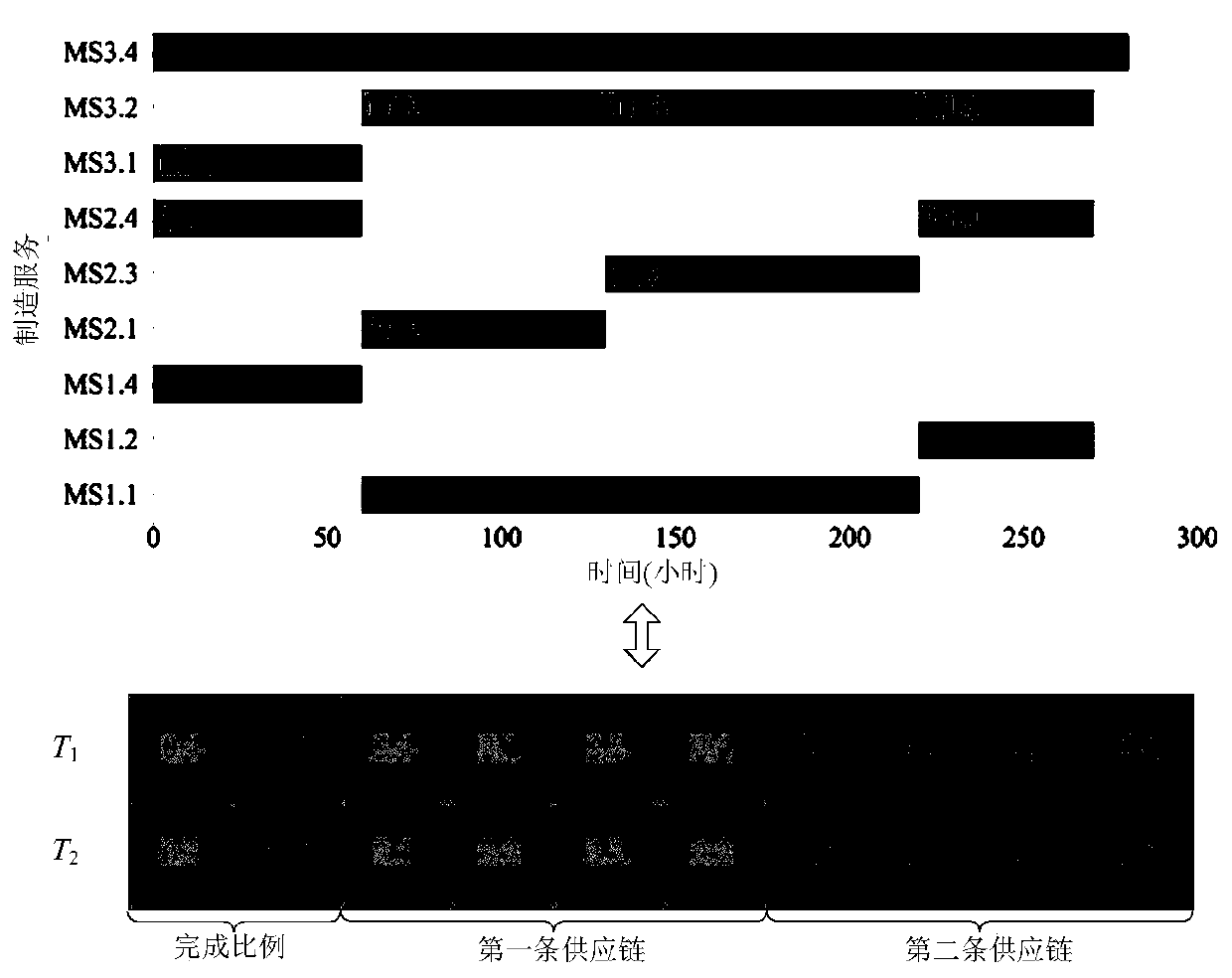

A dynamic task perception-oriented cloud manufacturing collaborative task scheduling method

InactiveCN109816243AImproving Performance in Solving Task Scheduling ProblemsOptimal Scheduling SchemeGenetic modelsForecastingSub populationsBiogeography

The invention discloses a dynamic task perception-oriented cloud manufacturing collaborative task scheduling method, which comprises the following steps of firstly, constructing a collaborative task scheduling model according to the proportion of tasks completed by a supply chain; generating an initial population as a current population when a new task arrives according to an original manufacturing task and an optional manufacturing service, dividing the current population into a plurality of sub-populations for subsequent iteration, and representing each collaborative task scheduling scheme in the current population by using matrix coding; and finally, solving is performed through an improved multi-population biogeography optimization algorithm, and fusing a multi-population strategy, a local search strategy and a cooperation mechanism, so that the task scheduling problem solving performance of the algorithm is improved. According to the method, a better scheduling scheme can be obtained in the scheduling stage and the re-scheduling stage.

Owner:ZHEJIANG UNIV OF FINANCE & ECONOMICS

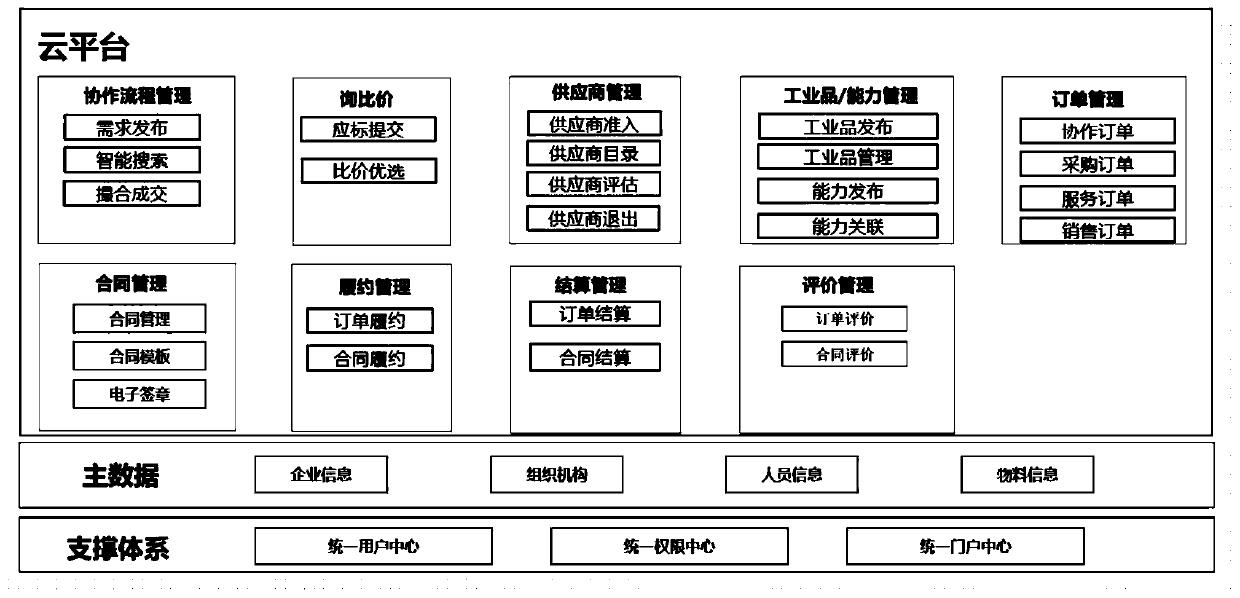

A cloud manufacturing service system based on industrial cooperation matching and resource sharing services

PendingCN109784669AReduce operating costsHighly innovativeBuying/selling/leasing transactionsResourcesThe InternetMarket competition

The invention relates to a cloud manufacturing service system based on industrial cooperation matching and resource sharing services. The system comprises a cooperation flow management module, a priceinquiry and comparison module, a supplier management module, an industrial product / capability management module, an order management module, a contract management module, a contract performing management module, a settlement management module and an evaluation management module. Modern information technologies such as Internet, Internet of Things, cloud computing and big data are applied, a cloudservice platform based on outsourcing matching and resource sharing is established, and full-process service from demand docking, price inquiry and comparison, order placing, contract signing and performance execution to mutual evaluation of two parties is provided for the service demands of manufacturing enterprises; The efficiency and quality of the external coordination and product full-life process are improved, the management of the product full-life process is standardized, the product research and development design period is shortened, the enterprise operation cost is reduced, the product innovation capability of the manufacturing industry is improved, and the market competitiveness of the manufacturing enterprise is enhanced.

Owner:北京航天智造科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com