Patents

Literature

333 results about "Collocation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a collocation method is a method for the numerical solution of ordinary differential equations, partial differential equations and integral equations. The idea is to choose a finite-dimensional space of candidate solutions (usually polynomials up to a certain degree) and a number of points in the domain (called collocation points), and to select that solution which satisfies the given equation at the collocation points.

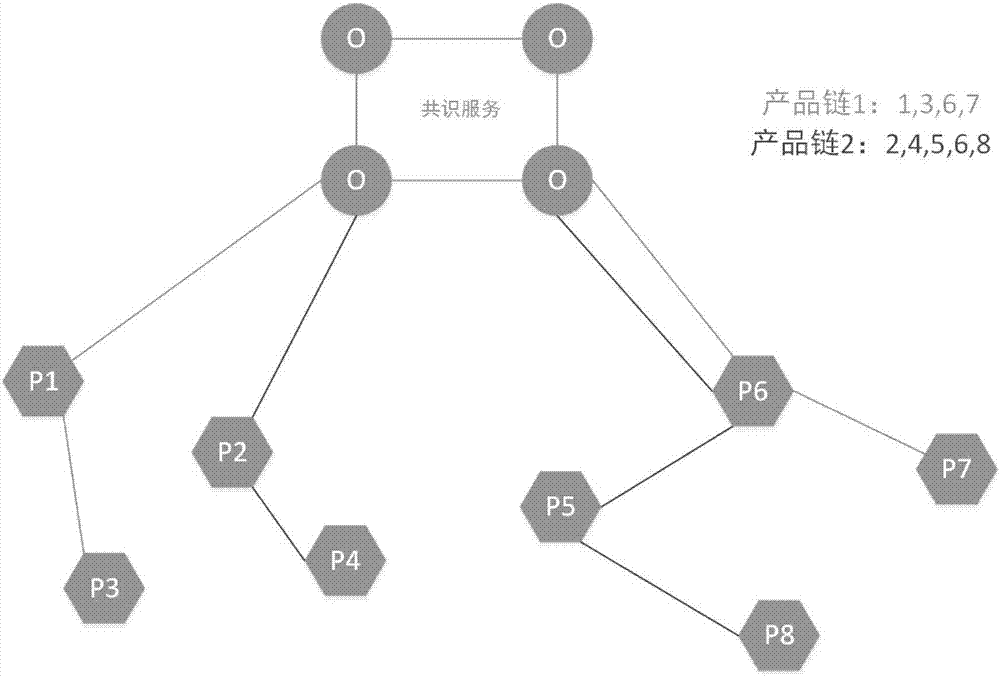

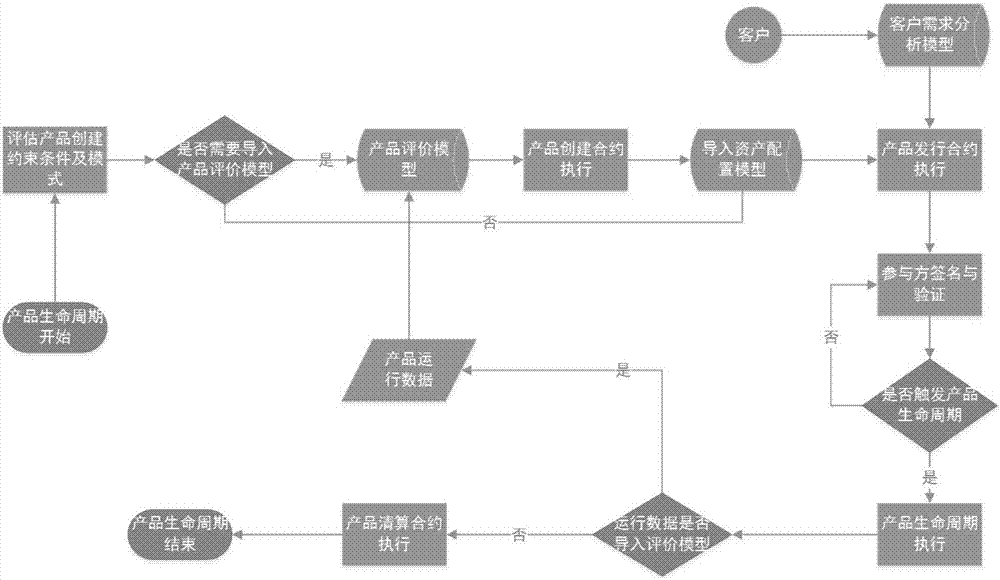

Intelligent investment product collocation method based on block chain intelligent contract technology

InactiveCN107578337AGuarantee authenticityProtection of rights and interestsFinanceRisk ControlTimestamp

The invention discloses an intelligent investment product collocation method based on the block chain intelligent contract technology. According to the method, the authenticity and non tamperability of the data on the chain are guaranteed by block chain consensus, authentication, timestamp and other technical means, and the participants on the chain can see the same and real information; the intelligent contract is automatically executed without artificial interference and supervision in the process of work can be performed to ensure the interests of customers. Being different from the centralized central registration and settlement mechanism, the system of the invention adopts the distributed technical architecture, the participants jointly maintain the product life cycle, thereby ensuring that the products are open and transparent and credible, effectively reducing the credit risk and avoiding the lack of supervision and risk control, resulting from that the product contents and operation means are opaque, and thus the customer rights and interests are not guaranteed.

Owner:HANGZHOU YUNXIANG NETWORK TECH

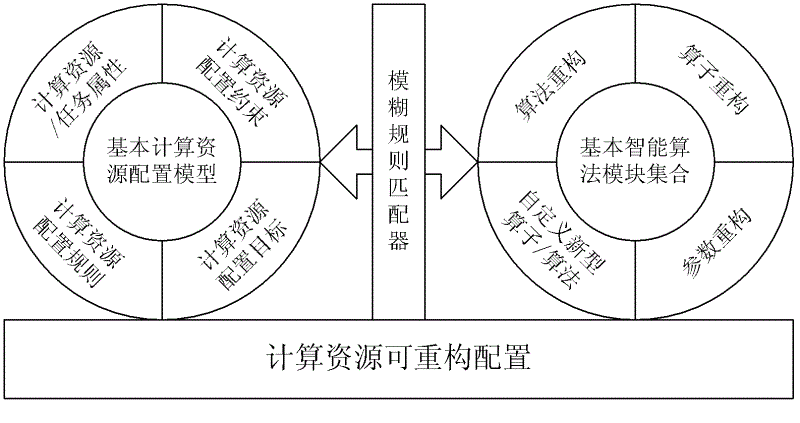

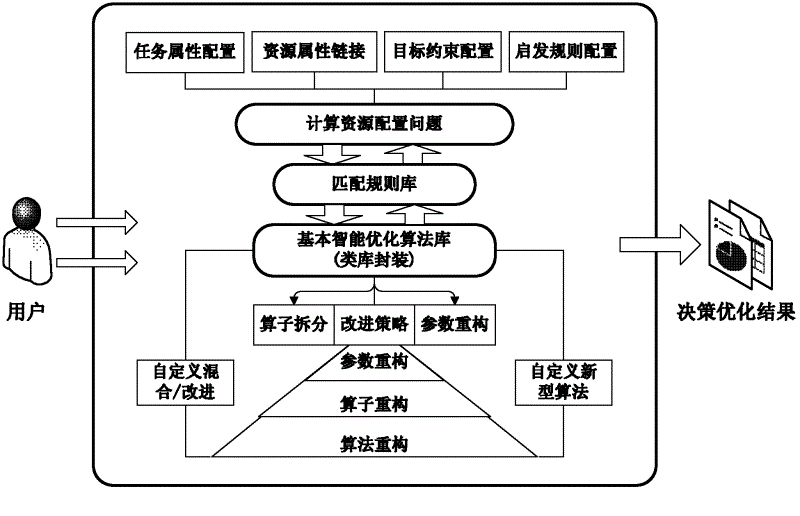

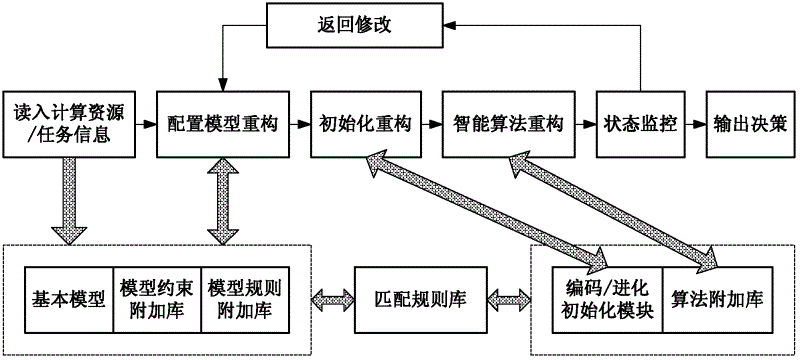

Intelligent optimization algorithm based cloud manufacturing computing resource reconfigurable collocation method

InactiveCN102624870ASolve the singularityIncrease flexibilityTransmissionCollocationStationary model

The invention relates to an intelligent optimization algorithm based cloud manufacturing computing resource reconfigurable collocation method, in particular to a method for modifying relevant collocation attributes and algorithms online according to different collocation conditions on the basis of multiple intelligent optimization algorithms, which aims to realize flexible, extendible and efficient policy solution of massive computing resource collocation in the cloud manufacturing mode and flexible disintegration, integration and reconfiguration of model demands, input / output and policy operators in a modularization and servicisation manner, and solves the bottleneck problems of singleness and non-portability and the like caused by regular constraint, fixed models and regular algorithms in computing resource collocation. The intelligent optimization algorithm based cloud manufacturing computing resource reconfigurable collocation method has the following advantages that separation of collocation models and algorithms for the computing resources is realized, modularization reconfiguration inside the models and the algorithms is supported, integration is efficient, levels are clear and extendibility is high.

Owner:BEIHANG UNIV

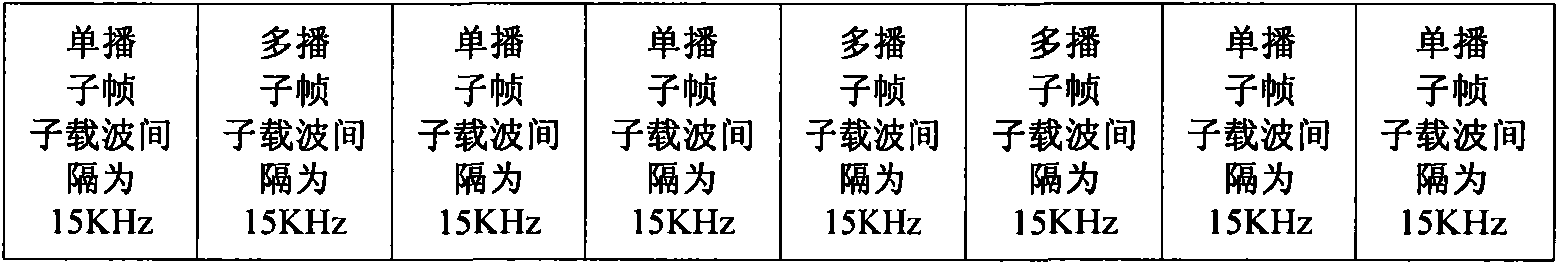

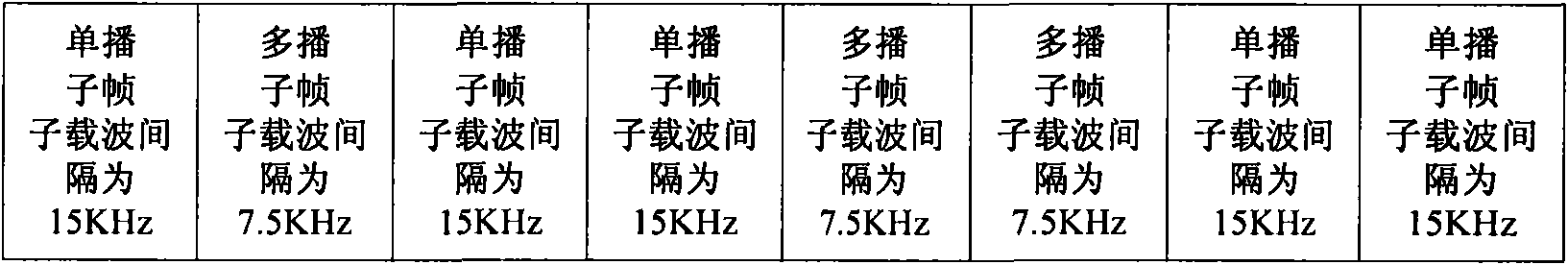

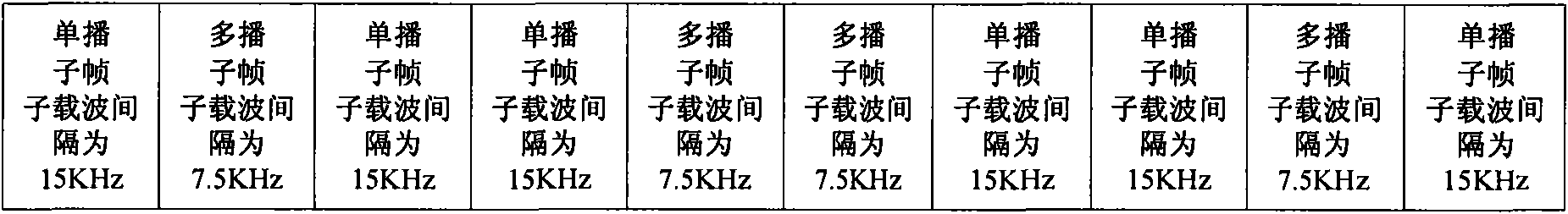

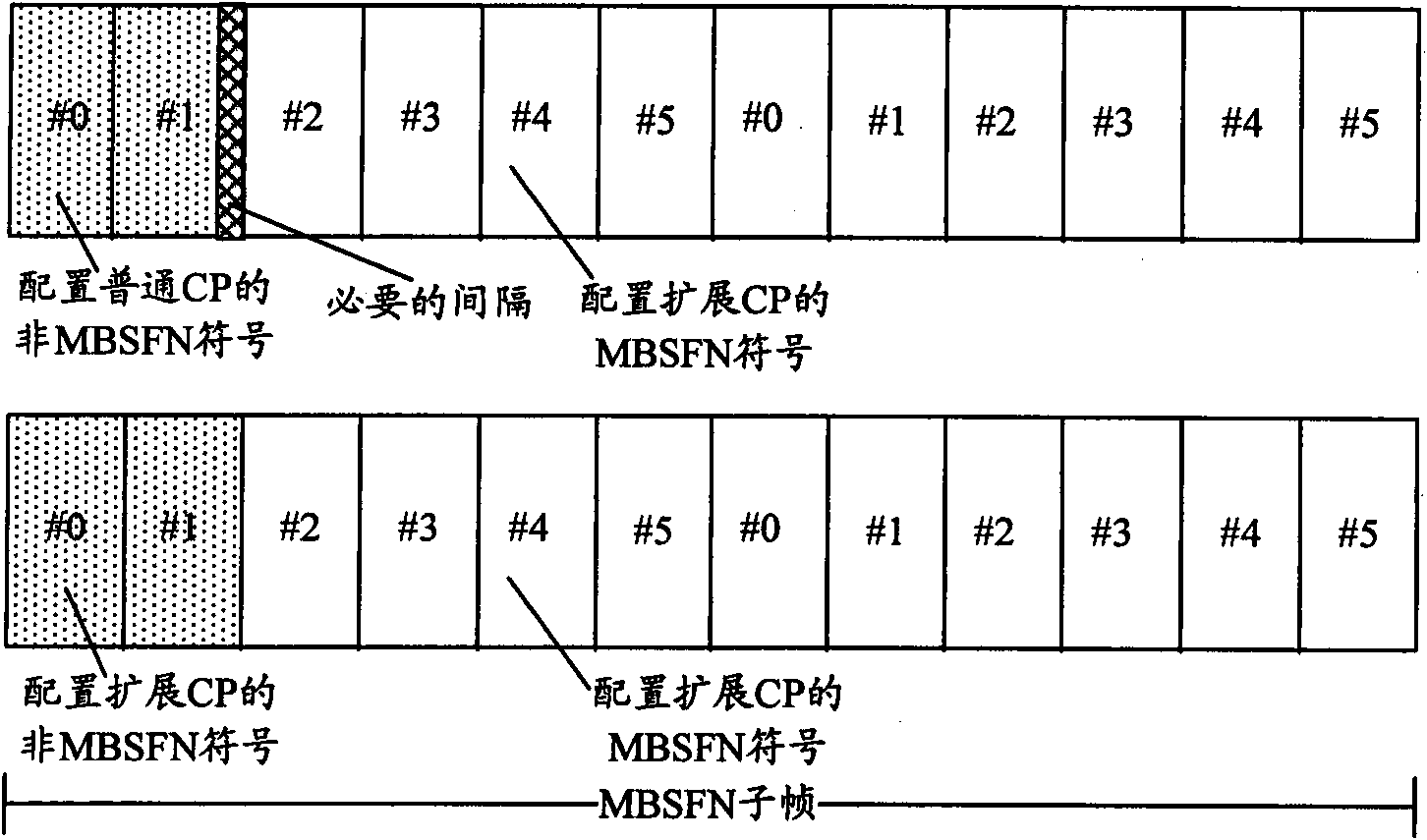

Collocation method, data transmission method and device of multimedia broadcast and multicast service

InactiveCN101577857AImprove link performanceIncrease the combined gainBroadcast service distributionMulti-frequency code systemsData transmissionBroadcast and Multicast Service

The invention provides a collocation method of multimedia broadcast and multicast service. The collocation method which is based on an orthogonal frequency division multiple access system comprises the following steps of collocating different subcarrier distances corresponding to a unicast service subframe and a multicast service subframe in a radio frame. The embodiment of the invention also provides a data transmission method and a device of the multimedia broadcast and multicast service. By adopting the collocating method, the data transmission method and the device, the combined gain is increased, and the link performance of cell-edge users is improved.

Owner:ZTE CORP

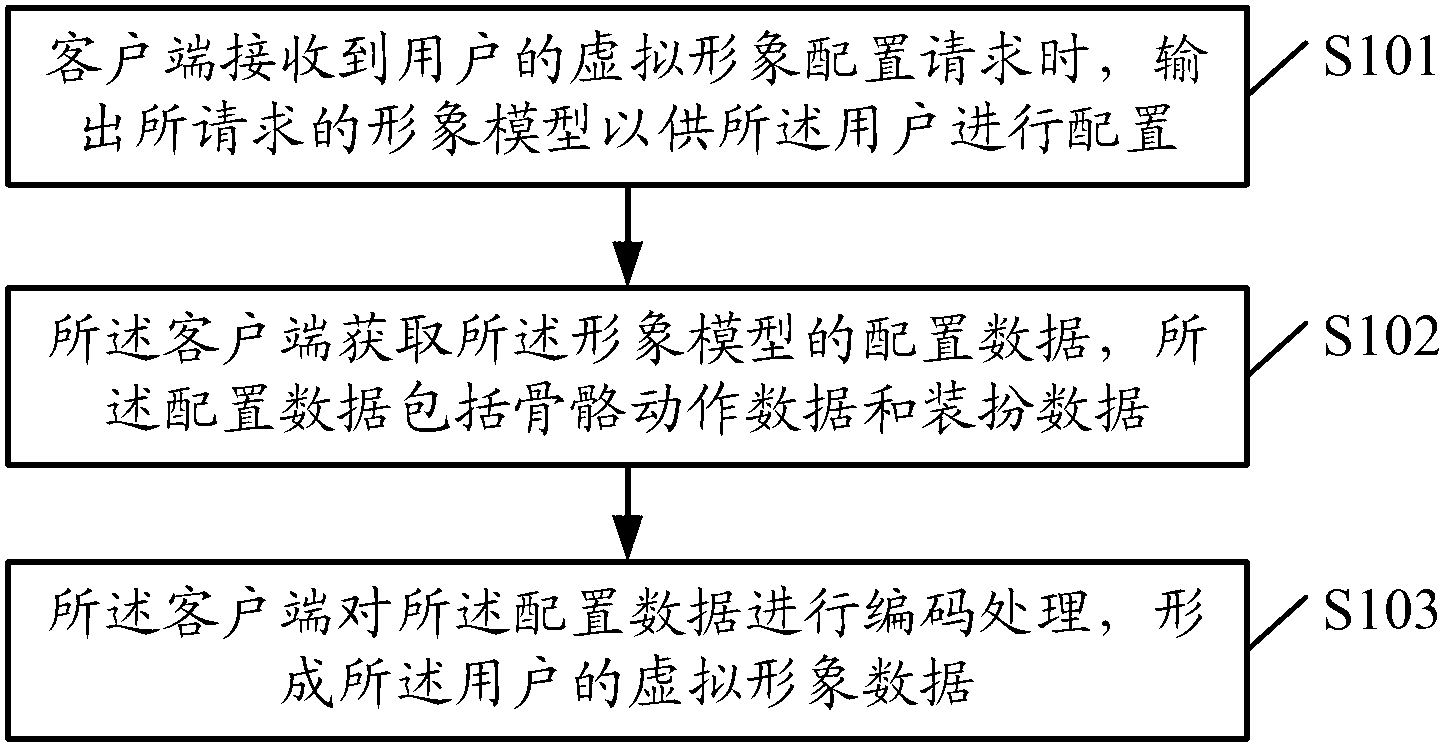

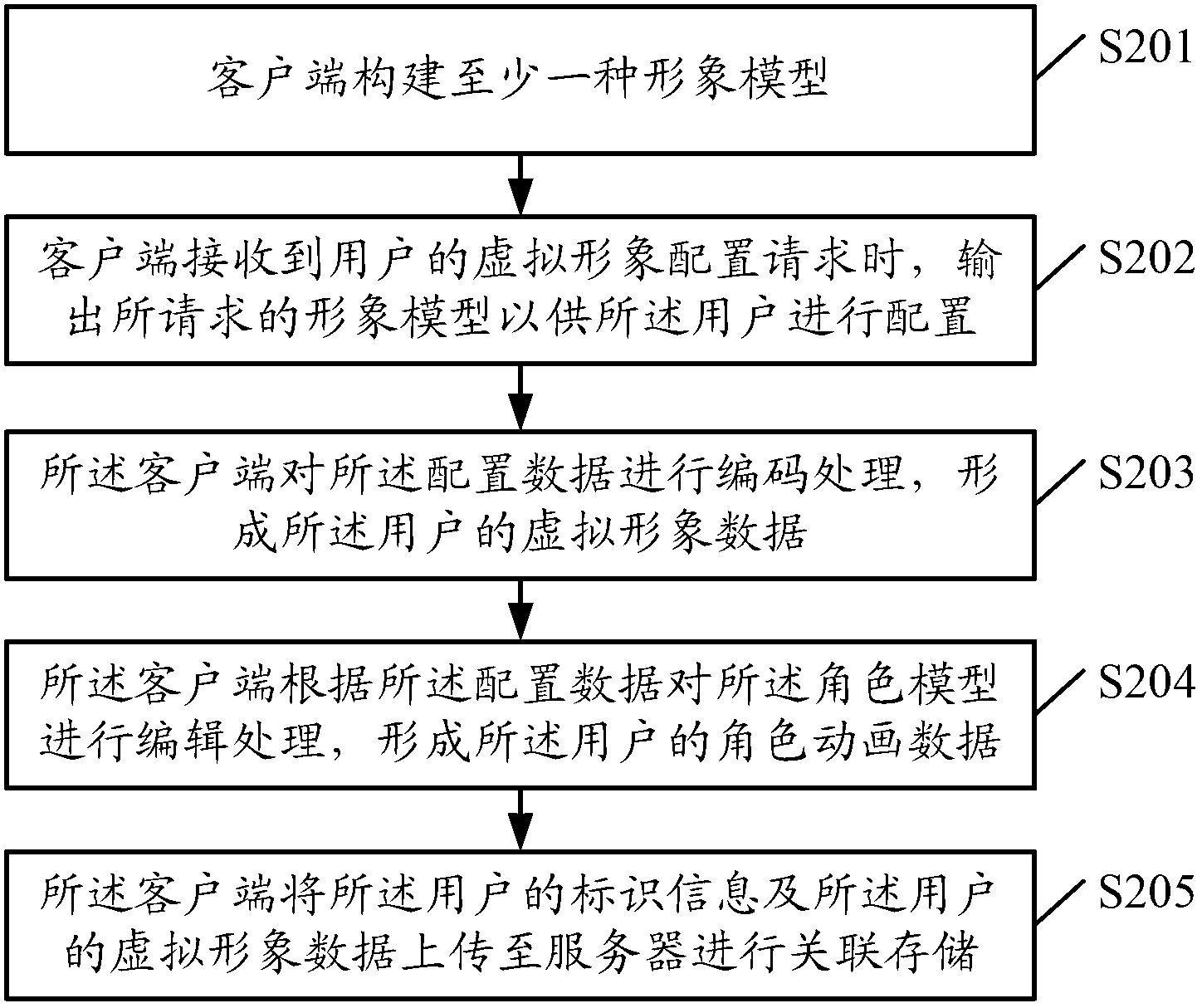

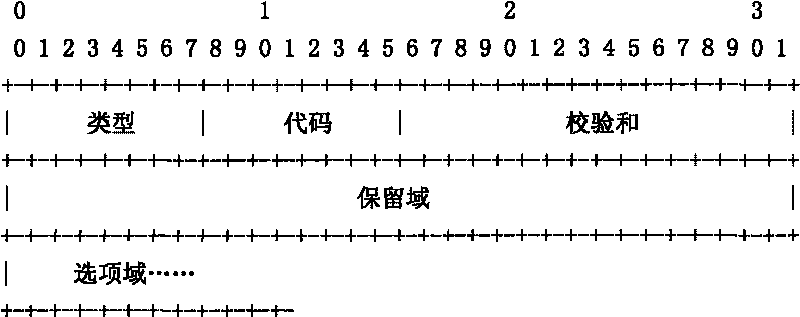

Collocation method, implementation method, client side, server and system of virtual image

ActiveCN103218844AExtended configurationRealize personalized customizationAnimationCollocationClient-side

The embodiment of the invention provides a collocation method of a virtual image, an implementation method of the virtual image, a client side, a server and a management system of the virtual image. The method comprises the following steps that when receiving a virtual image collocation request of a user, the client side outputs and provides a required image model to a user to collocate; the client side acquires collocation data of the image model, wherein the collocation data comprises skeleton movement data and dress-up data; and the client side carries out encoding processing on the collocation data to form virtual image data of the user. According to the collocation method of the extensible virtual image, personalized customization is realized, the showing of the virtual image is close to the actual demand of the user, and an image which the user wants to reflect actually can be accurately expressed.

Owner:TENCENT TECH (SHENZHEN) CO LTD

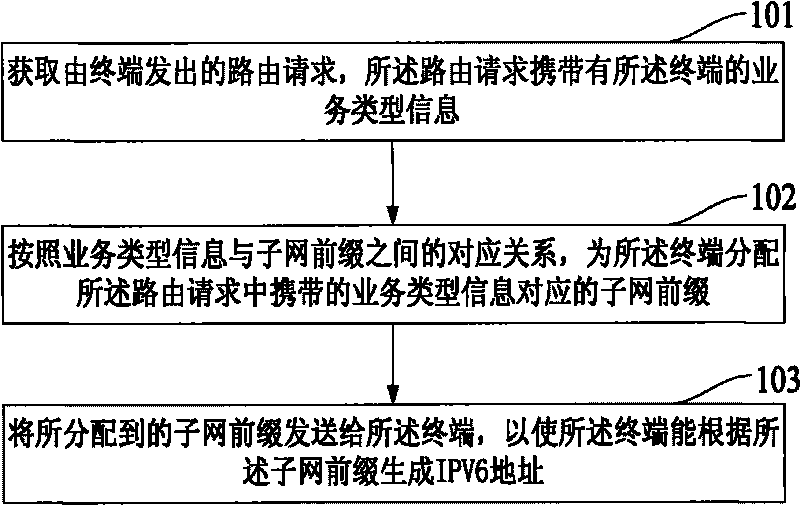

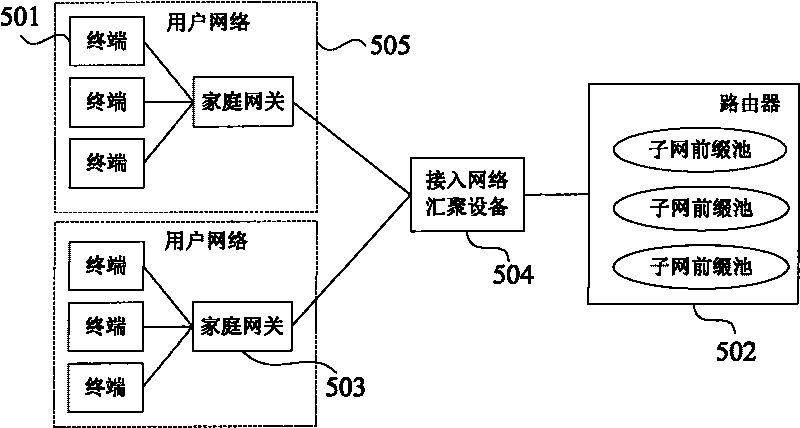

Method and system of collocating IPV6 (internet protocol version 6) addresses

InactiveCN101753635AEasy to achieve unified updateEasy to manageData switching networksInternet protocol suiteComputer science

The embodiment of the invention discloses an IPv6 address collocation method, which comprises the following steps of: acquiring a route request send from a terminal, wherein the route request carries the service type information of the terminal; allocating a subnet prefix corresponding to the service type information carried by the route request for the terminal according to the correspondence relation between the service type information and the subnet prefix; sending the allocated subnet prefix to the terminal so as to ensure that the terminal can generate an IPV6 address according to the subnet prefix. The method for automatically collocating the IPV6 addresses in the embodiment of the invention is convenient for service management. The invention also further discloses an IPV6 address collocating system.

Owner:HUAWEI TECH CO LTD

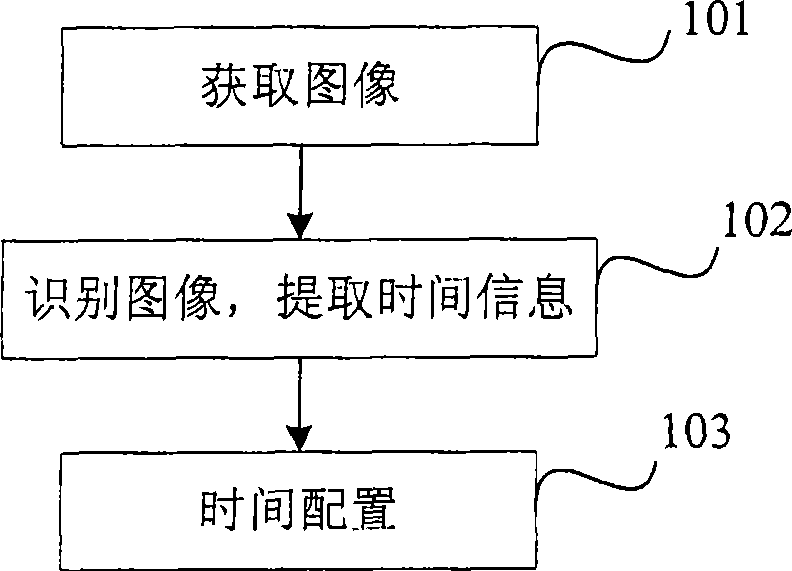

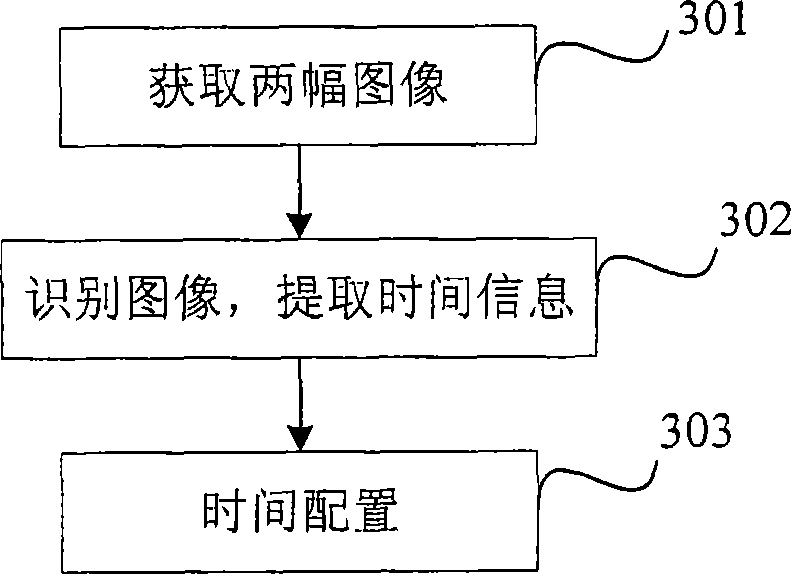

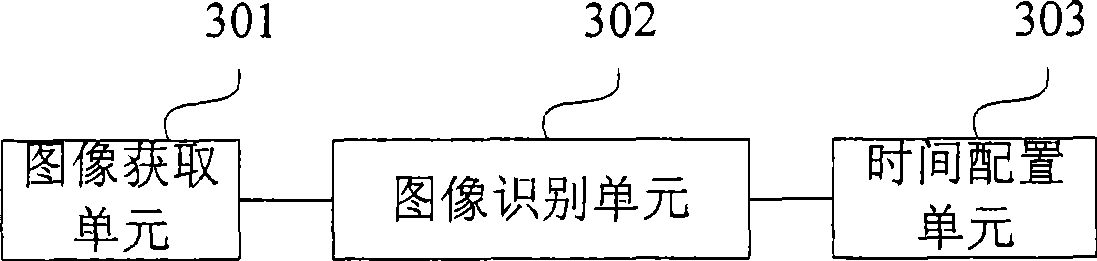

Terminal and time collocation method thereof

ActiveCN101393419AQuite entertainingCharacter and pattern recognitionSetting time indicationTemporal informationComputer terminal

The present invention provides a terminal and a time configuration method thereof. The method comprises the following steps: acquiring at least one frame which comprises a clock image; identifying the time corresponding to the clock image; and configuring the current time based on the identified time. Accordingly, the embodiment of the present invention also provides a terminal for applying the method. The time configuration of the terminal is carried out according to the time information identified from the image containing a clock pattern. The terminal not only is simple, convenient and novel, but also is funny.

Owner:HUAWEI DEVICE CO LTD

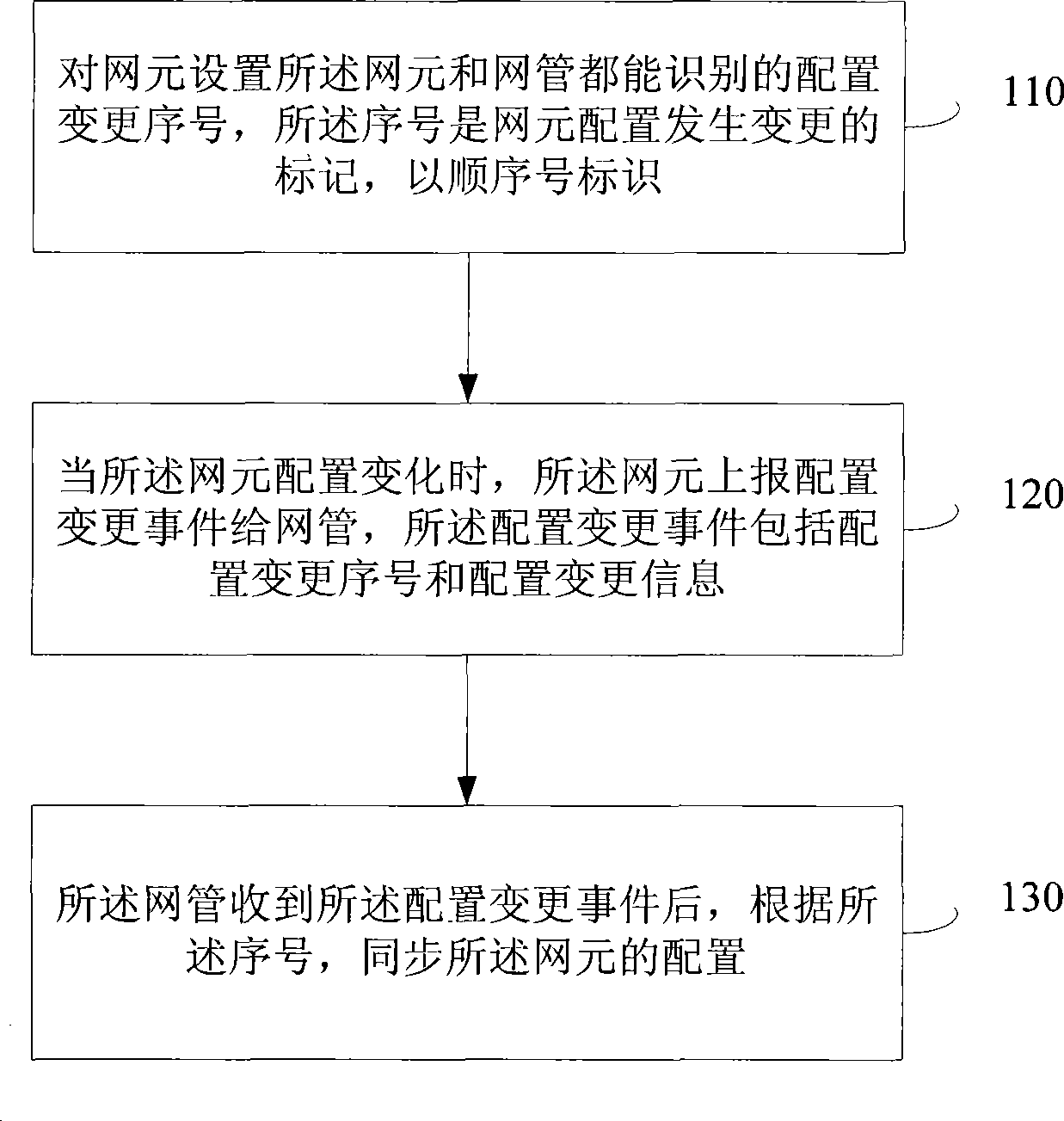

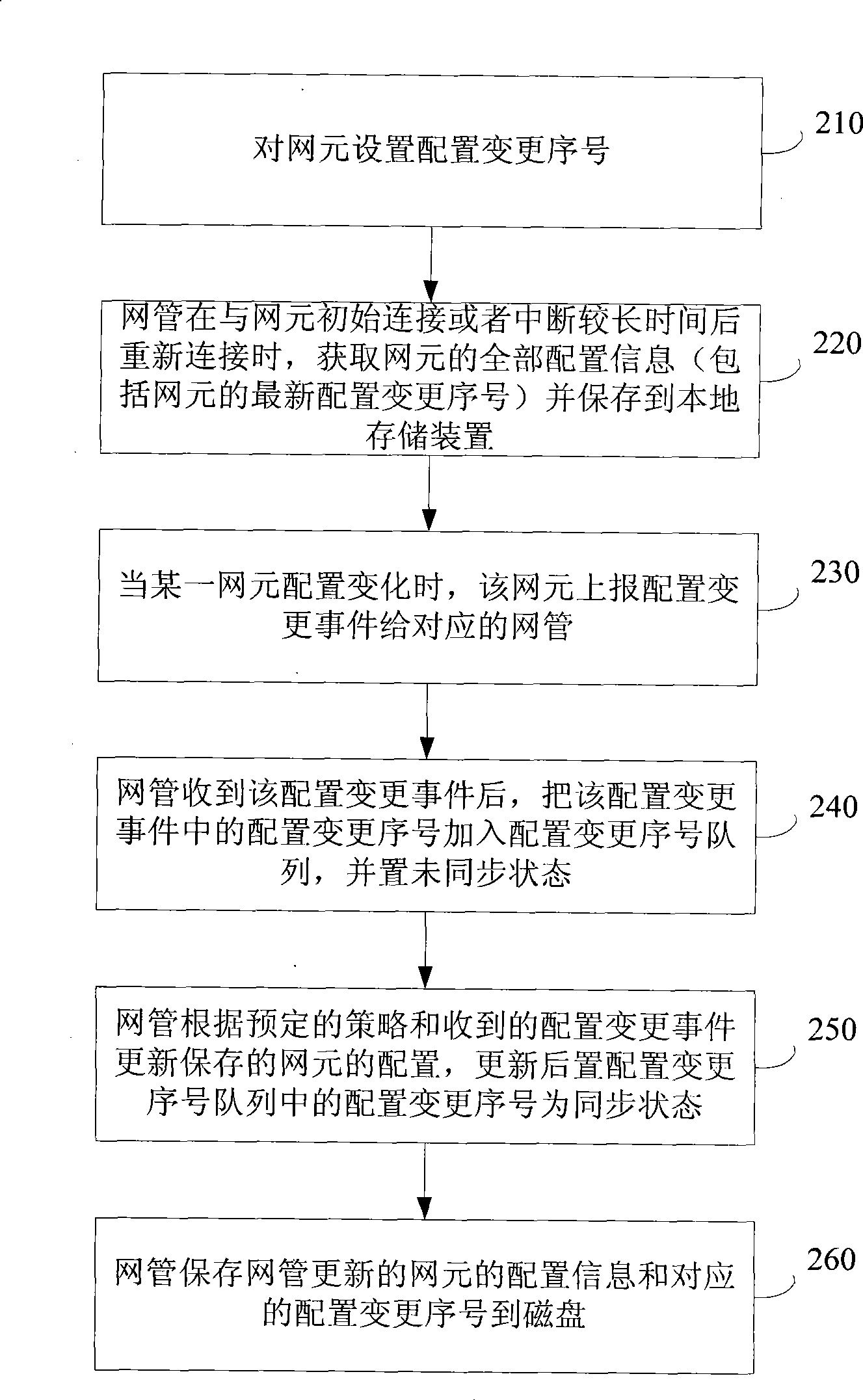

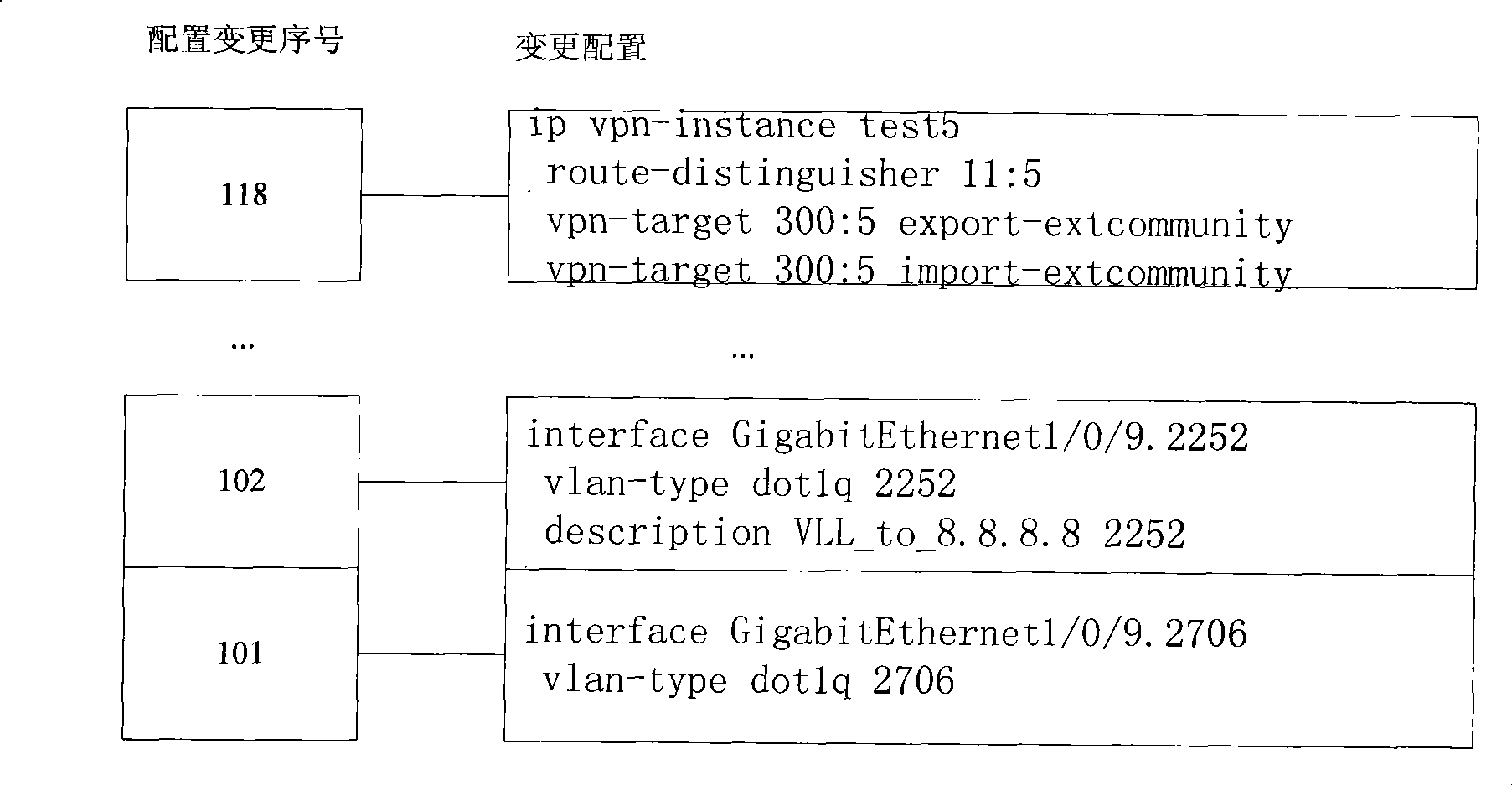

Collocation method for synchronizing network management and network element and device thereof

InactiveCN101447895AReduce overheadImprove reliabilityData switching networksCollocationNetwork management

The invention discloses a collocation method for synchronizing network management and network elements and a device thereof, which belongs to the technical field of the network management. The method comprises the following steps: collocation change serial numbers which can be indentified by network management and network elements are set to the network elements, the serial numbers are markers for the changed network element collocation, and are identified through sequence numbers; when the network element collocation is changed, the network elements report the collocation change event to the network management, and the collocation change event comprises collocation change serial numbers and collocation change information; after receiving the collocation change event, the network management synchronizes the network element collocation according to the collocation change serial numbers. The device comprises a serial number change set module, an event change reporting module and a collocation synchronization module. The method and the device improve the reliability of synchronization, and reduce the system resource cost when synchronizing the network management and the network elements.

Owner:HUAWEI TECH CO LTD

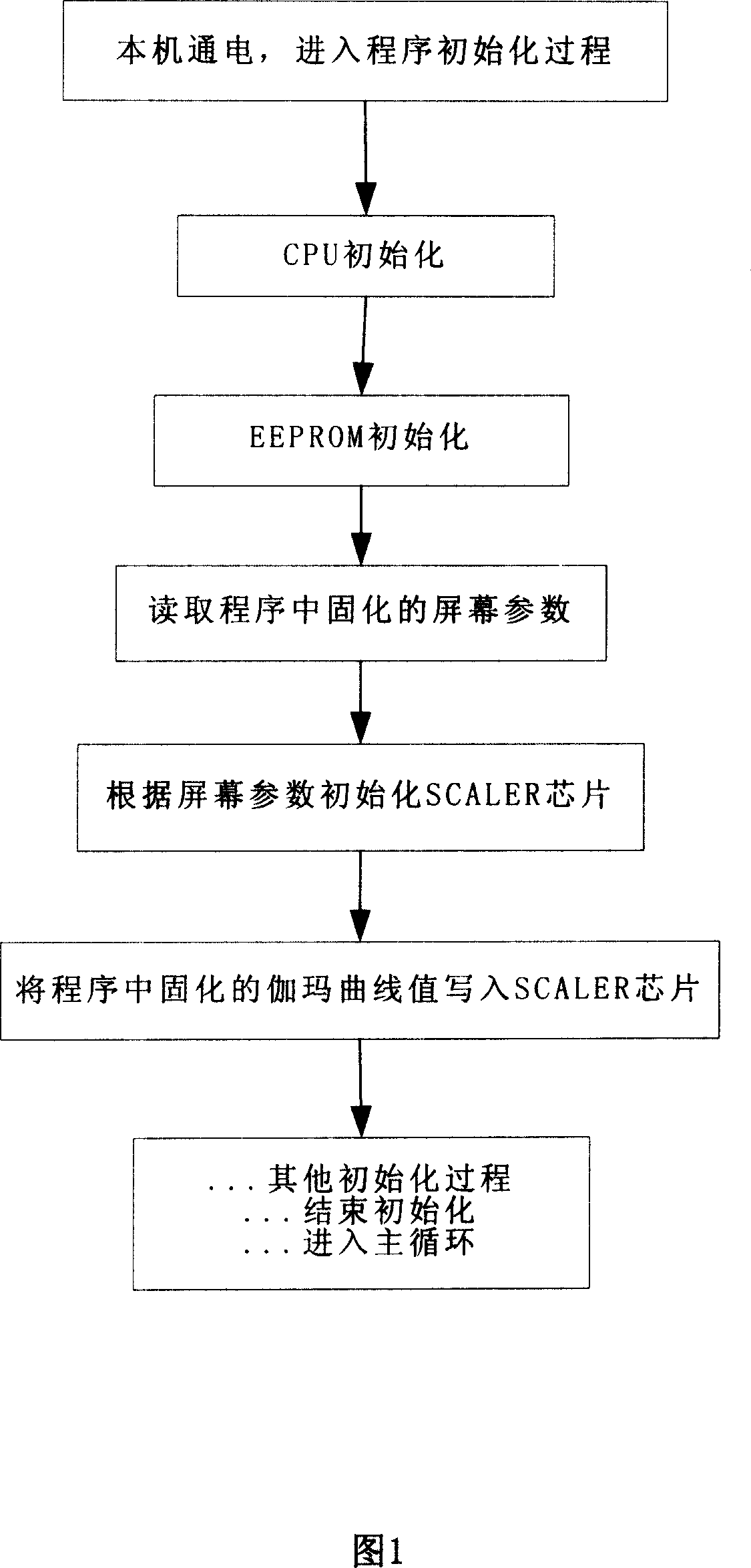

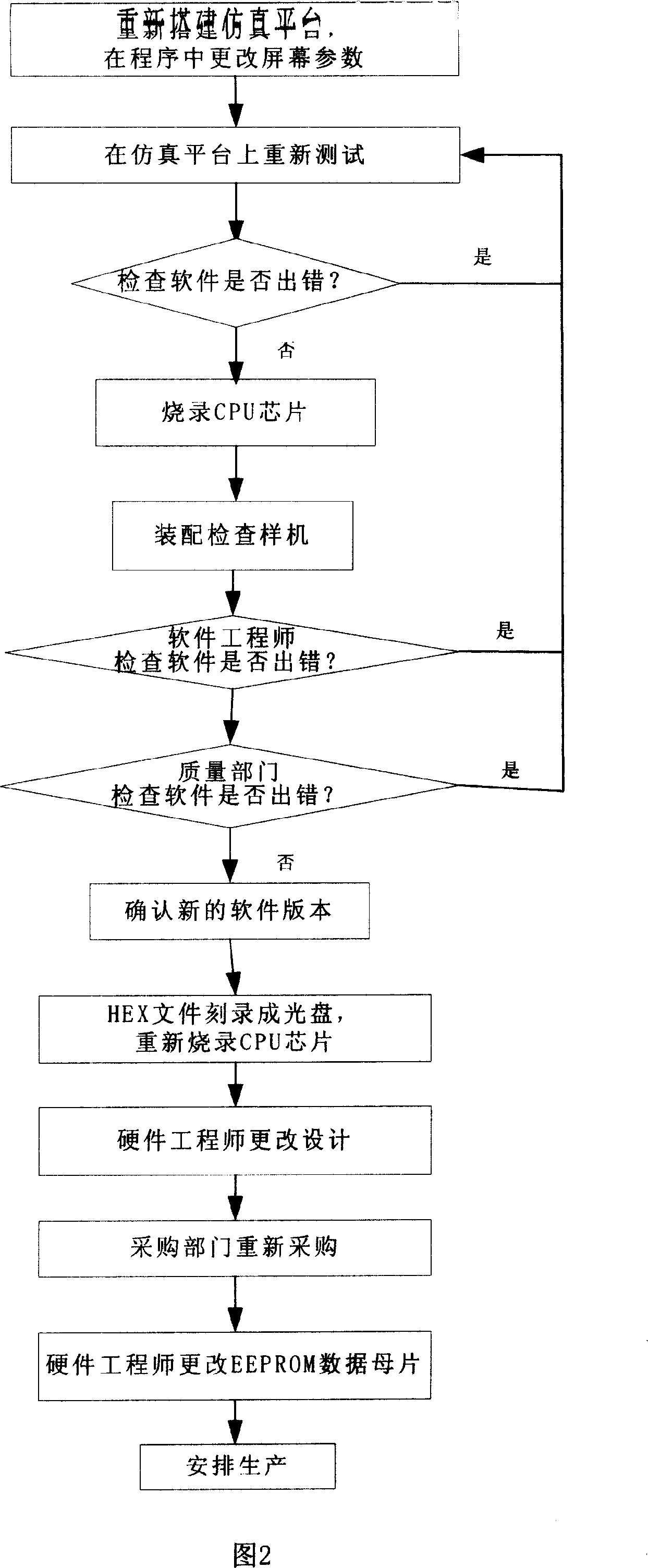

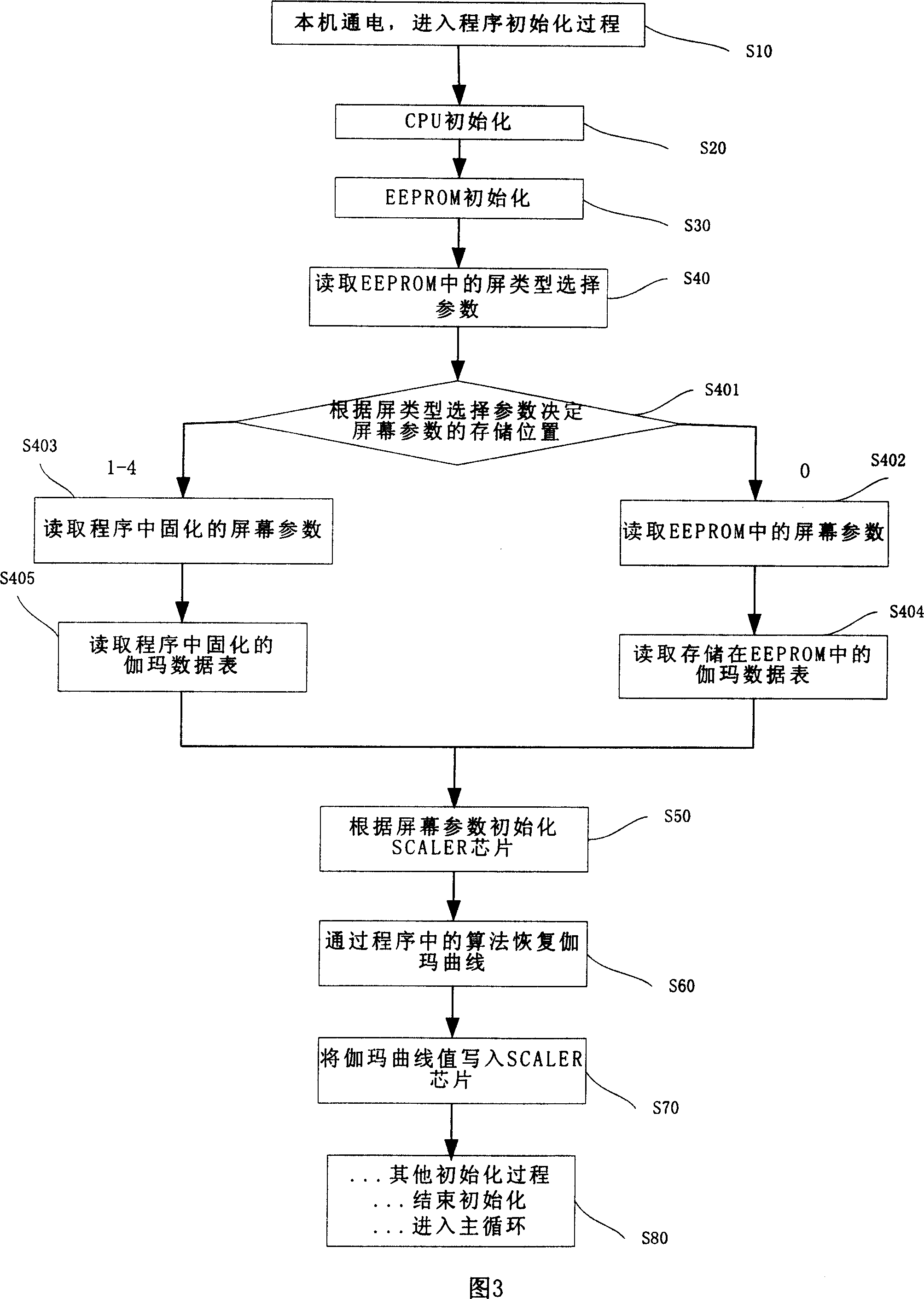

Configuration method of liquid crystal screen parameter

InactiveCN101046939AFulfil requirementsReduce design costStatic indicating devicesComputer scienceLiquid crystal

The present invention provides a collocation method of liquid crystal screen parameters. Said method includes the following steps: in EEPROM presetting at least two screen-type selection parameters, in which one presentation screen parameter is stored in EEPROM, other presentation screen parameters are solidified in program; fetching screen-type selection parameters in EEPROM, judging storage position of every screen parameter; obtaining screen parameter from storage position of screen parameter and gamma list; according to obtained screen parameters collocating liquid crystal screen, and initializing liquid crystal screen control chip; and restoring gamma culve and writing gamma culve value into liquid crystal screen control chip.

Owner:东杰电气(上海)有限公司 +1

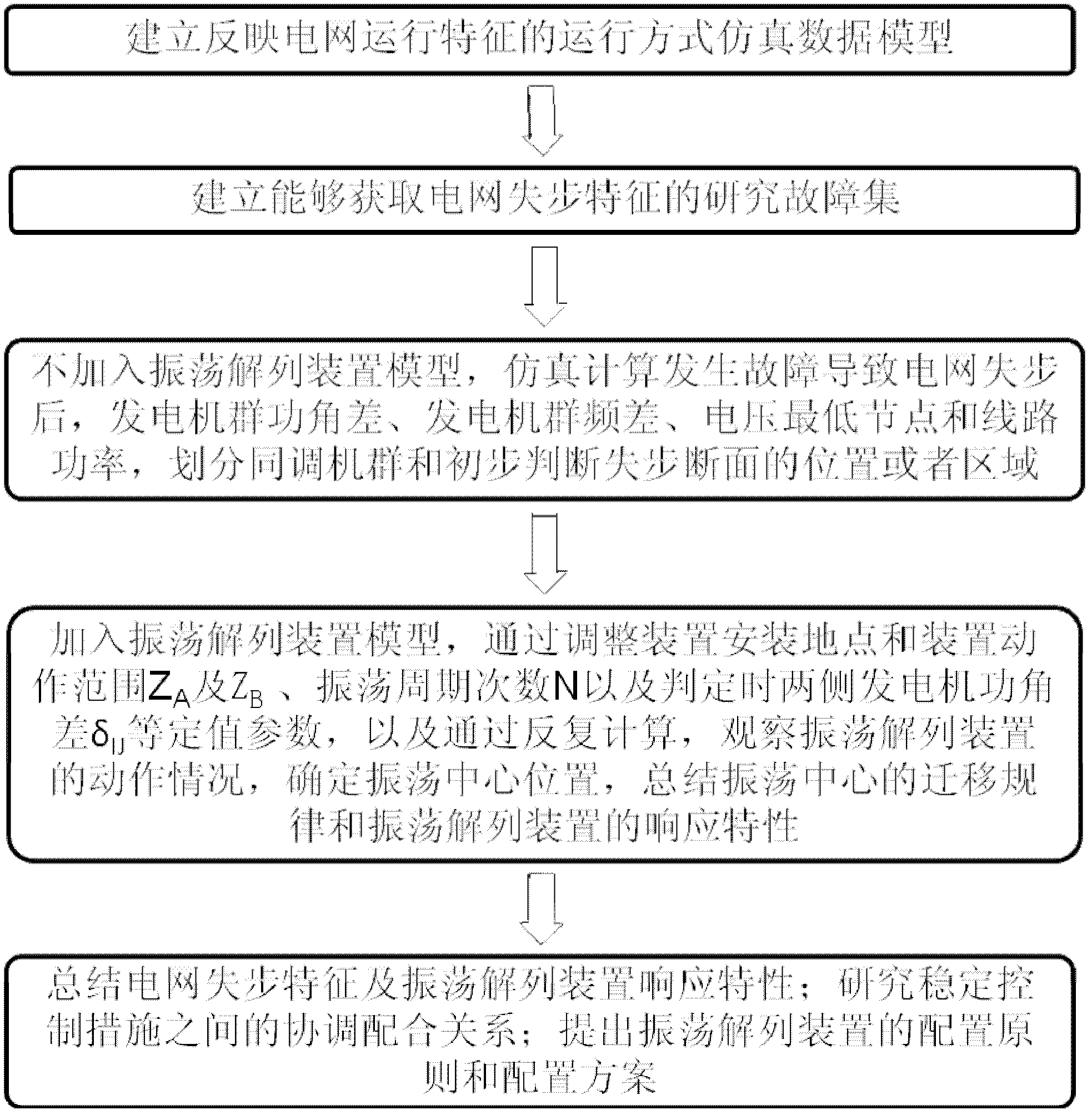

Simulation collocation method for oscillation disconnection device of power system

ActiveCN102570454AEasy to operateComprehensive considerationAc network circuit arrangementsCollocationPower grid

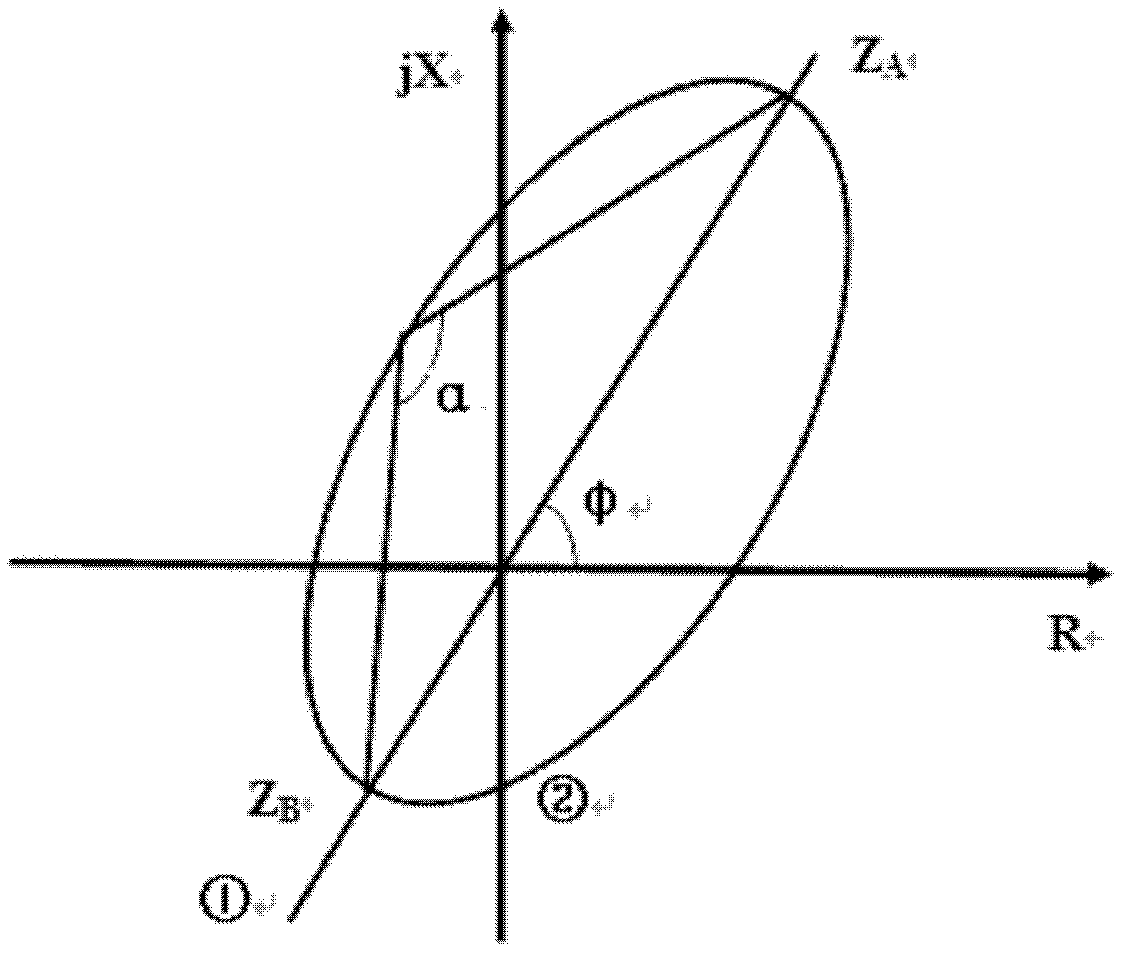

The invention relates to the field of power system stability research, in particular to a simulation collocation method for an oscillation disconnection device of a power system. The method comprises the steps: A. building a simulation data model; B. building a research failure set; C. performing simulation calculation of power grid stability after failure, obtaining out-of-step characteristics of a power grid, determining an oscillation center, and summarizing oscillation center moving laws; D. performing simulation calculation of acting characteristics of the oscillation disconnection device after the failure, and judging acting correctness of the oscillation disconnection device; E. putting forward a preliminary collocation scheme of the oscillation disconnection device; F. studying coordinating relations among stability control measures; and G. putting forward the final collocation scheme of the oscillation disconnection device by combination with the step C, the step D, the step E and the step F. The simulation collocation method has the advantages of being strong in maneuverability, comprehensive in considered factors and reasonable in scheme, and has high practical value and good market prospect.

Owner:STATE GRID CORP OF CHINA +2

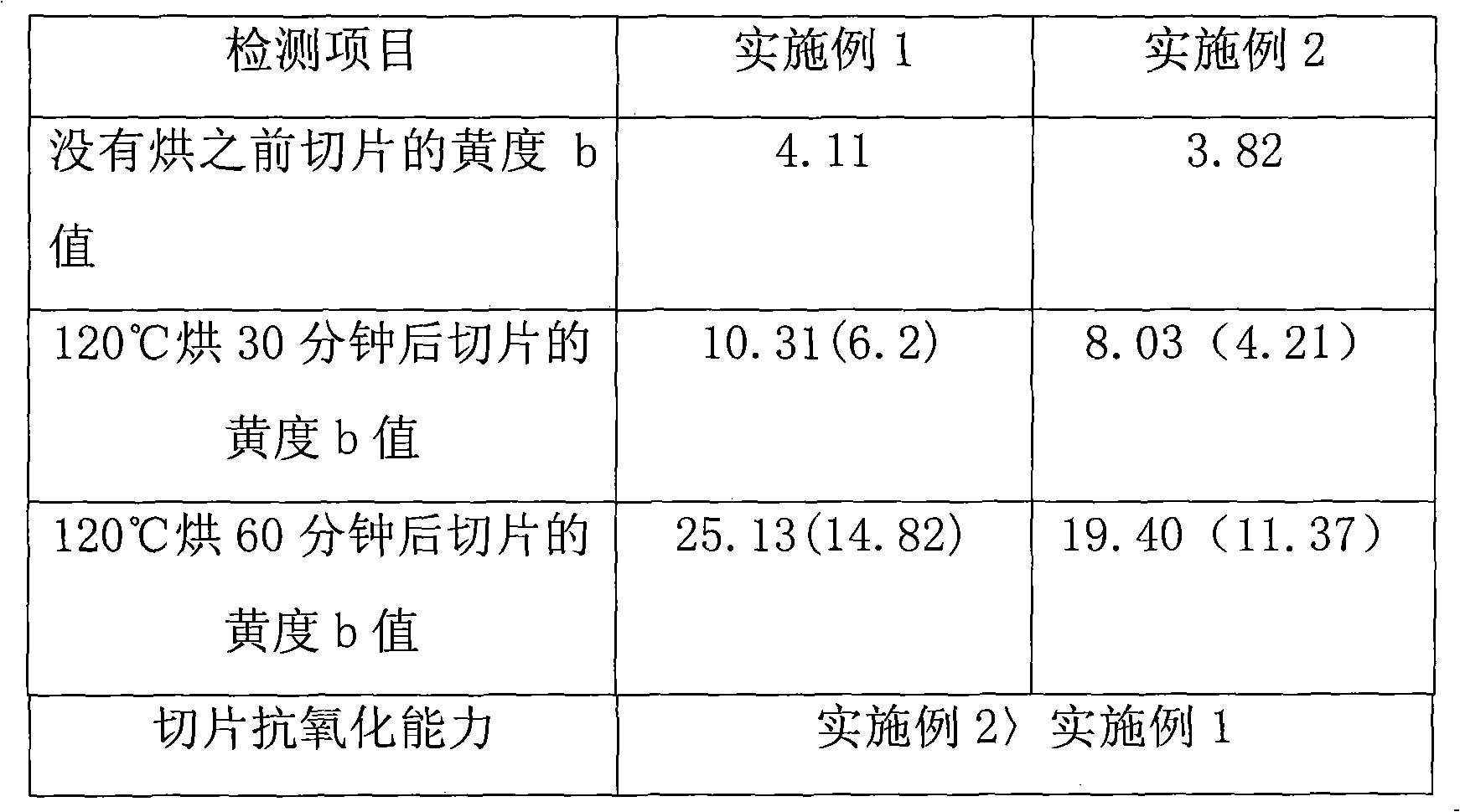

Production method for full-dull nylon 6-slice

ActiveCN101314673AGood dispersionPrevent precipitationArtifical filament manufactureMonocomponent polyamides artificial filamentNylon 6Engineering

The invention provides a method for manufacturing full-dull nylon-6 chips, which belongs to the field of spinning chip, in particular to full-dull nylon-6 chips manufactured by using titanium dioxide (TiO2) as a dulling agent. The method aims to solve the problem in the production of the prior dulling agent solvent. The method has the technical scheme that (1) a proper TiO2 and TiO2 solution collocation method is selected; (2) proper formulation and process are selected; and (3) a stirring device for dispersing TiO2 dulling agent solution is selected. The technical scheme can improve the TiO2 content in the polymerization process of nylon-6, and the polymer melt is filtered to remove large-diameter TiO2. Accordingly, high-performance chips with good dull performance, good TiO2 dispersion and good spinning performance can be obtained.

Owner:GUANGDONG XINHUI MEIDA NYLON

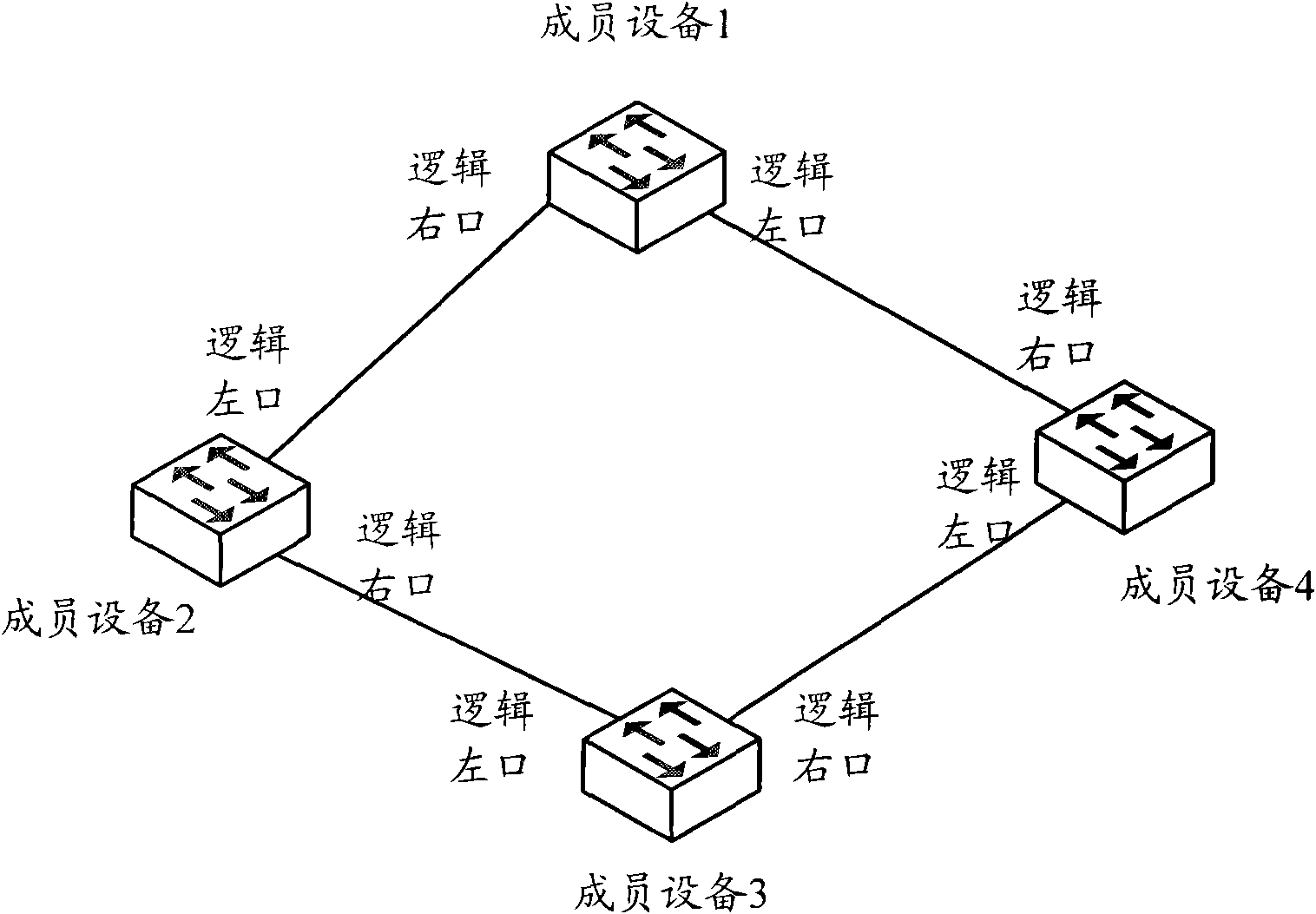

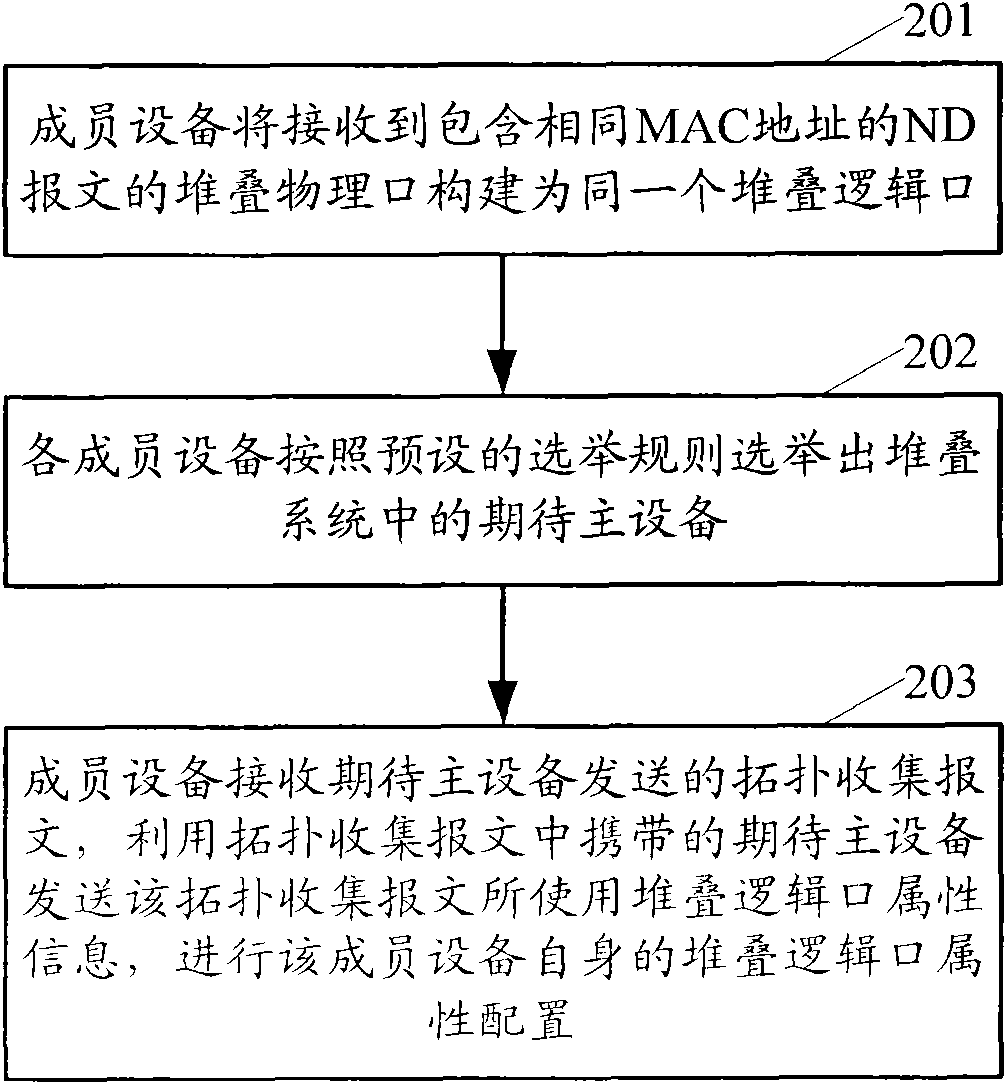

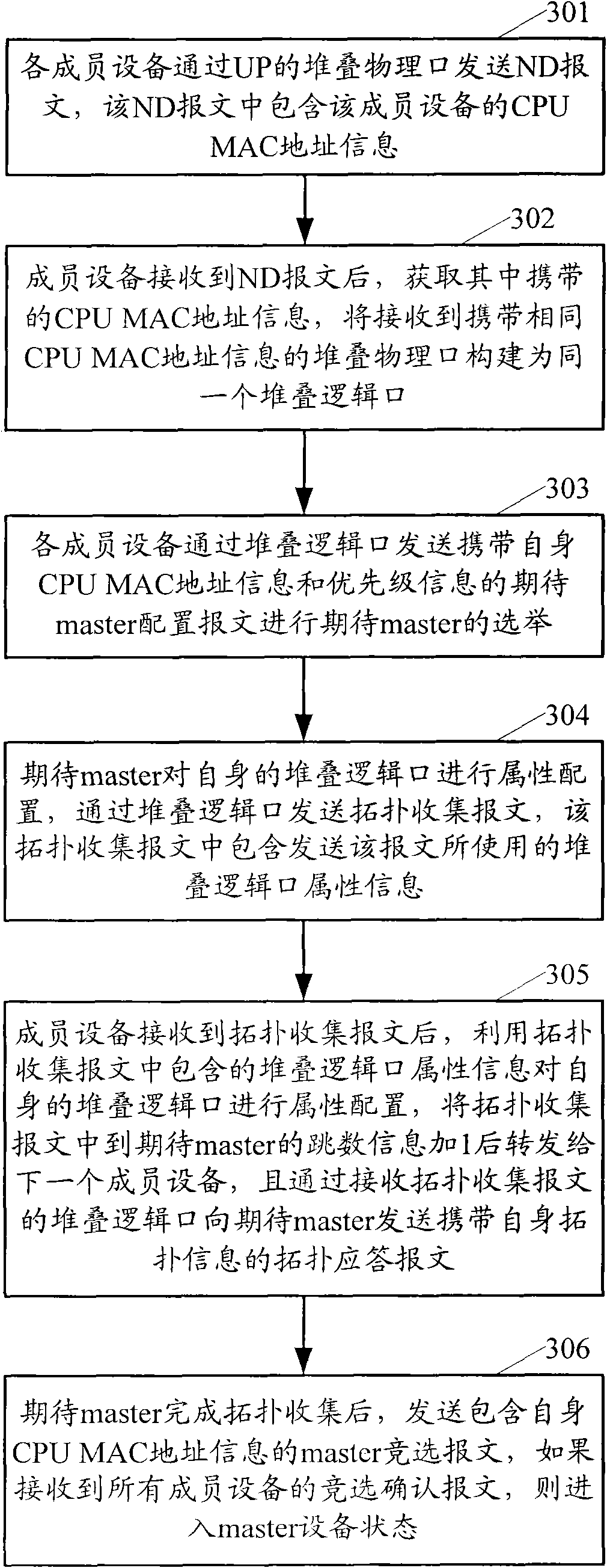

Collocation method and member device of stack logic interface

InactiveCN101572626ASave human resourcesAvoid Stack Heterogeneity ProblemsData switching networksIsomerismsPhysical interface

The invention provides a collocation method and a member device of a stack logic interface. The member device in a stack system builds the received stack physical interface of neighbor discovery message of the same MAC address into a stack logic interface; the member device elects expectant primary device in the stack system according to preset election rules; the member device receives a topology collection message sent by the expectant primary device, the stack logic interface attribute message which is used by the topology collection message is sent by the expectant primary device which is carried in the topology collection message to realize the self stack logic interface attribute configuration. The invention can avoid stack isomerism problem caused by artificial incorrect operation, saves human resource and is more convenient to be realized.

Owner:NEW H3C TECH CO LTD

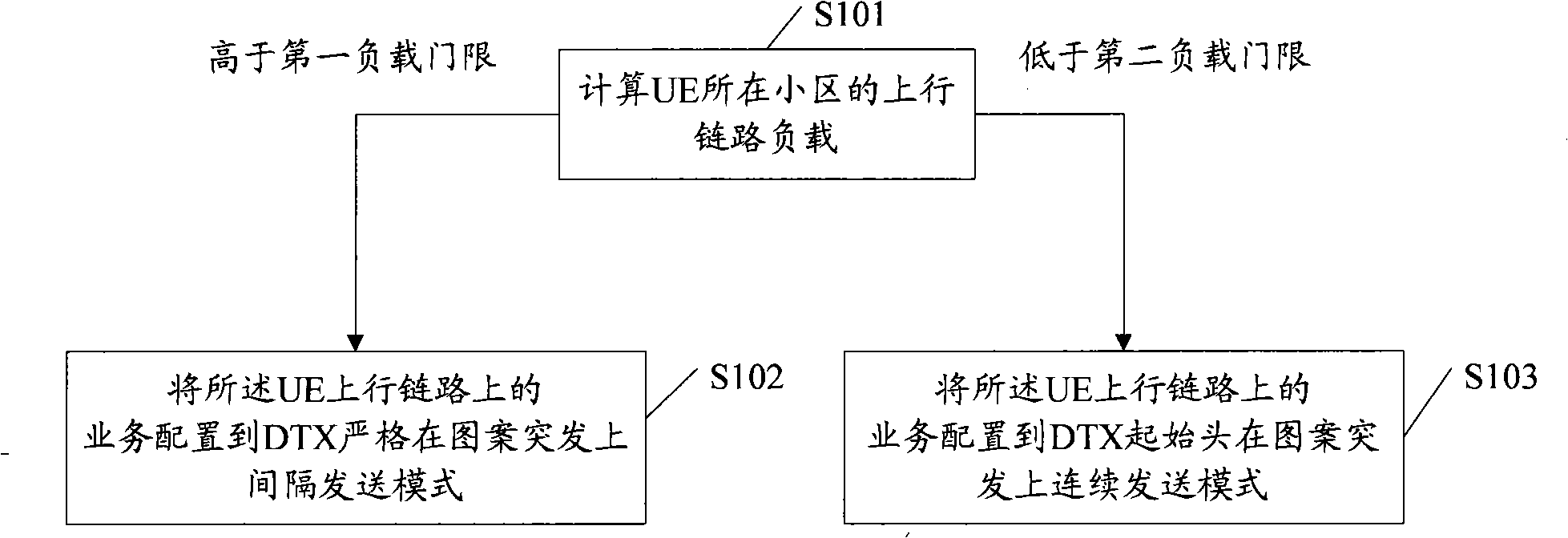

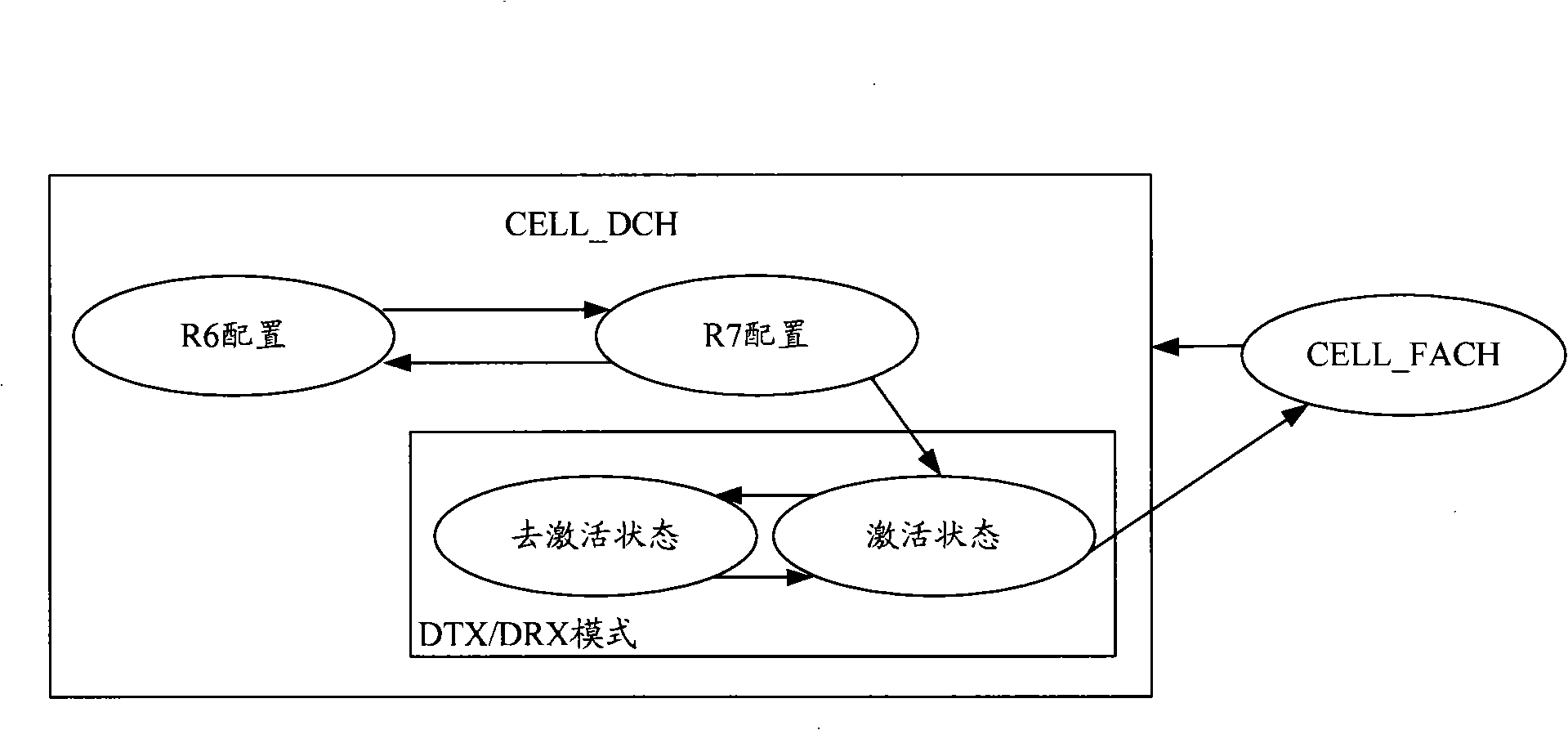

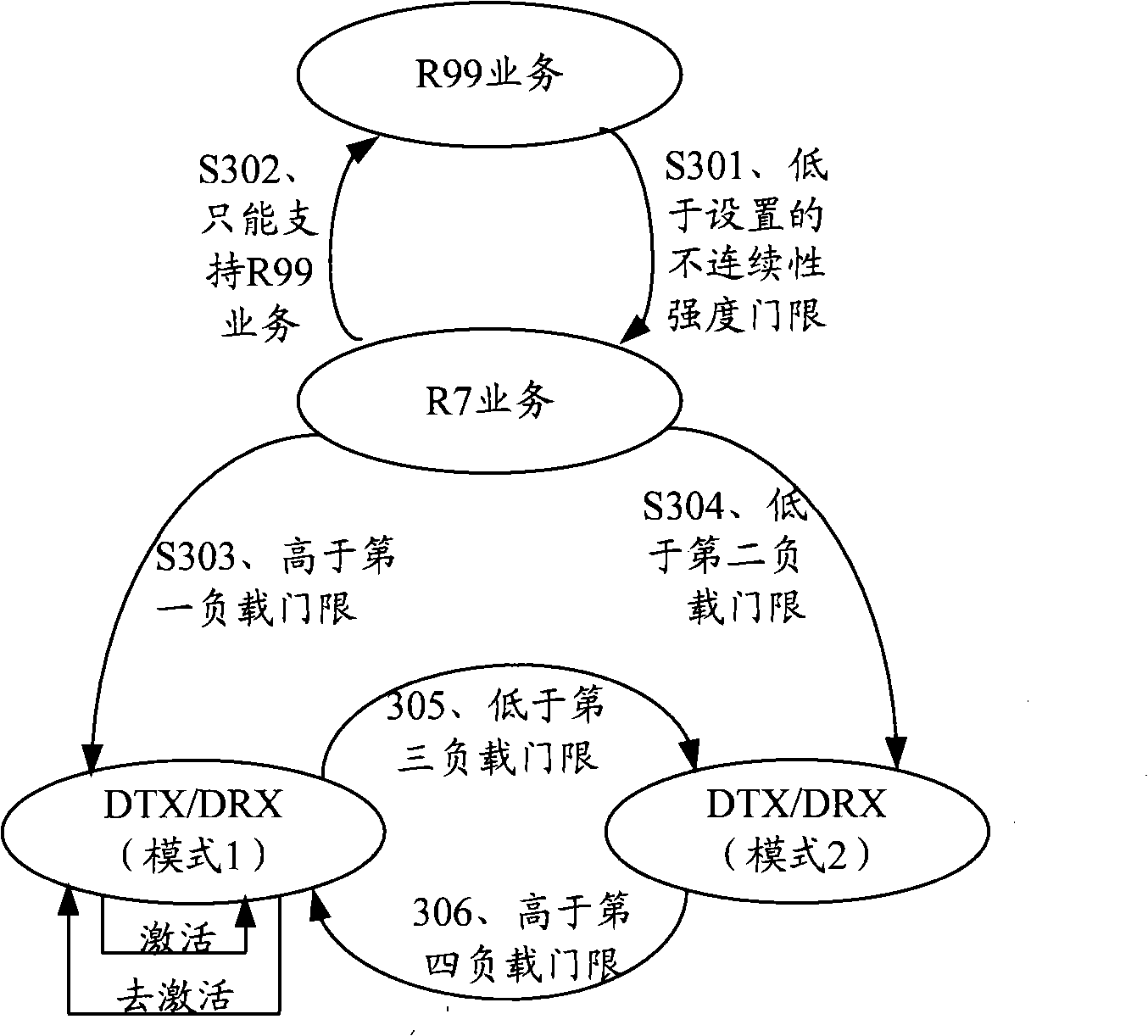

Service configuring method and apparatus

ActiveCN101360340AReduce sending delayImprove QoSNetwork traffic/resource managementConnection managementUser deviceThird generation

The embodiment of the invention provides an operation collocation method and the device thereof. The method includes: when up-load of subdistrict in which the user device UE is positioned exceeds the preplaced first load threshold, the operation on the UE uplink is collocated to the incontinuous transmission DTX first module, namely, the strict interval transmission module on the pattern outburst; when up-load of subdistrict in which the user device UE is positioned lowers the preplaced second load threshold, the operation on the UE up-link is collocated to the DTX second module, namely, the continuous transmission module of the start and end points on the pattern outburst; the operation is the seventh edition 3GPP R7 or the seventh edition 3GPP R7 above edition operationt planned by the third generation cooperation fellows, and the second load threshold is less than or equal to the first load threshold. The method and the device can make a balance of reducing the subdistrict up-load and reducing the operation up time span, thereby improving the operation QoS.

Owner:HUAWEI TECH CO LTD

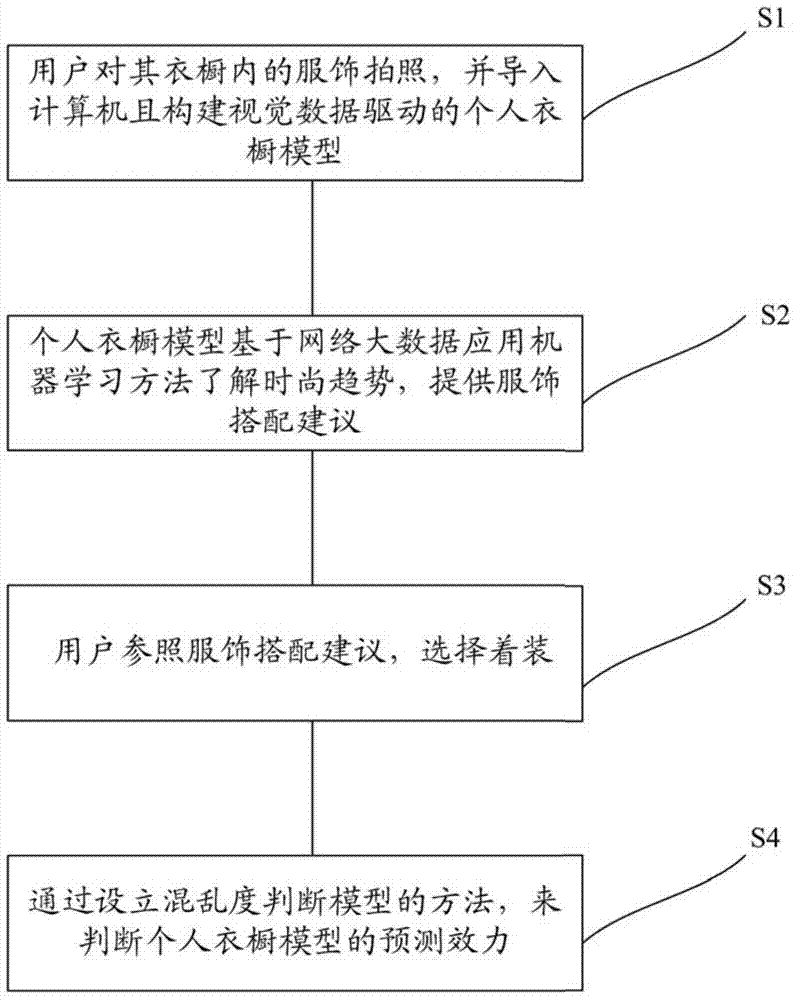

Matching method for personnel garments of user

The invention relates to the technical field of communication, in particular to a matching method for personnel garments of a user. The method comprises the following steps that S1, the user take photos on the garments in a wardrobe, and the photos are guided into a computer for building a visual data driven personnel wardrobe model; S2, the personnel wardrobe model knows fashion trends on the basis of network massive data by using a machine learning method, and garment matching suggestions are provided; S3 the user selects the garments according to the garment matching suggestions. The matching method for the personnel garments of the user provided by the invention has the advantages that mass fashion pictures on Internet are analyzed by the machine learning method, the fashion trends are known on the basis of the network massive data, in addition, the obtained fashion knowledge is used for recommending the garment matching based on the personnel wardrobe for the user, and the customization requirements and fashion requirements of customers are fast met.

Owner:SHANGHAI YUEPU INVESTMENT CENT (LLP)

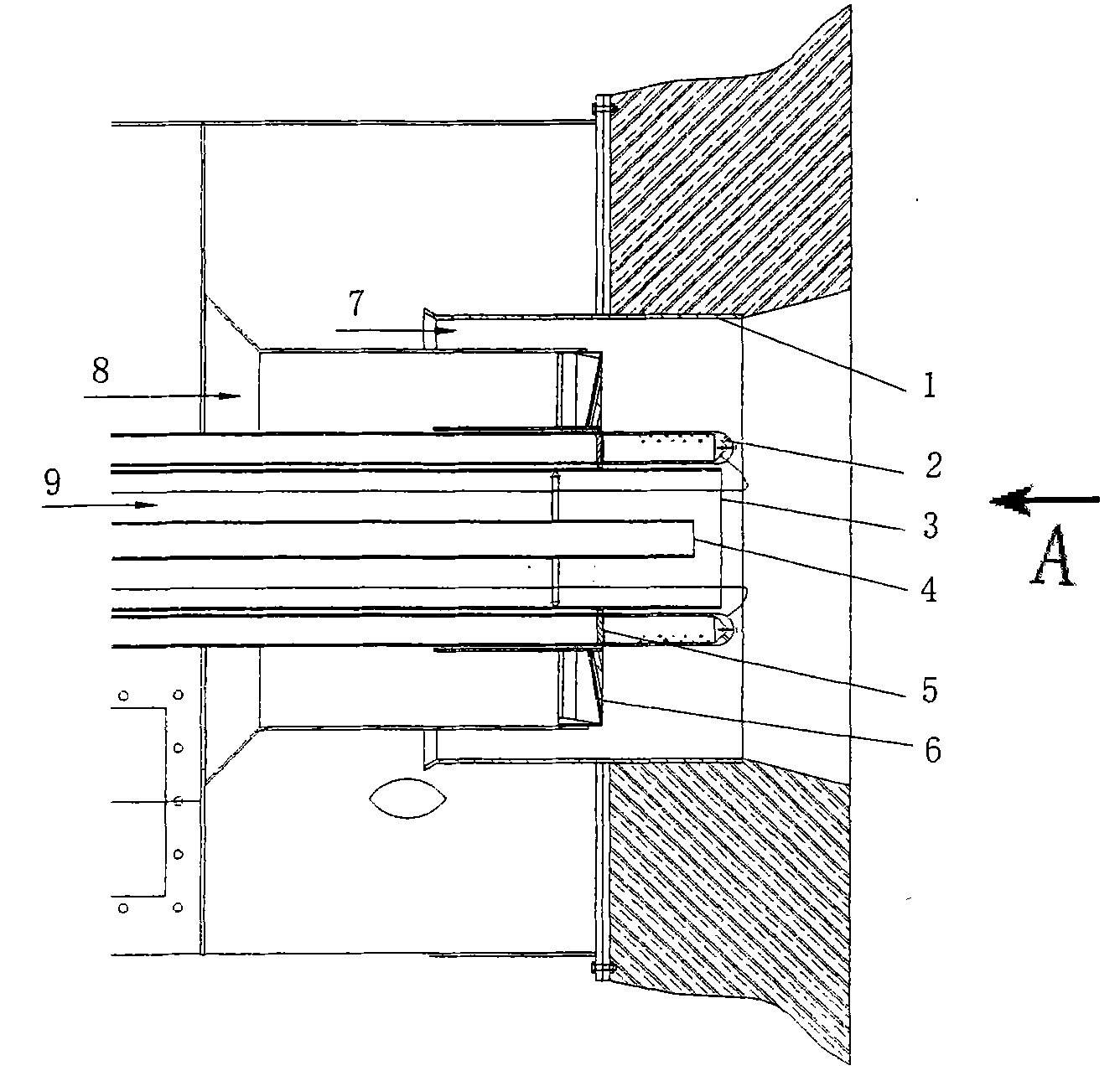

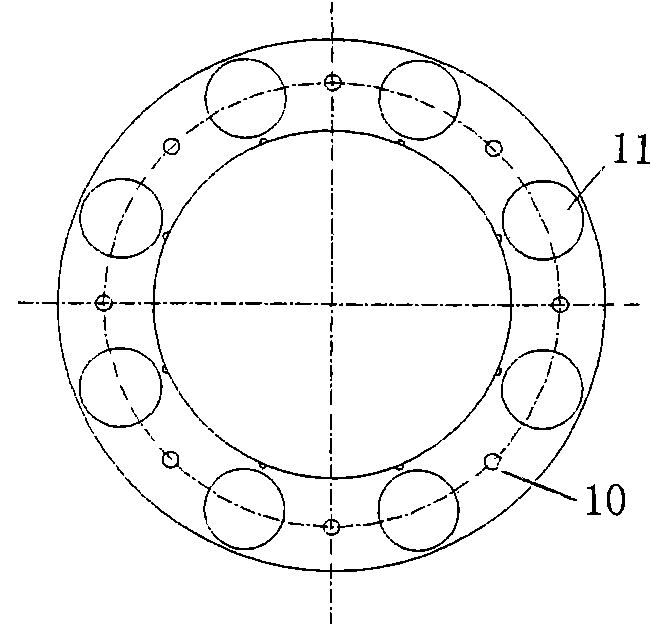

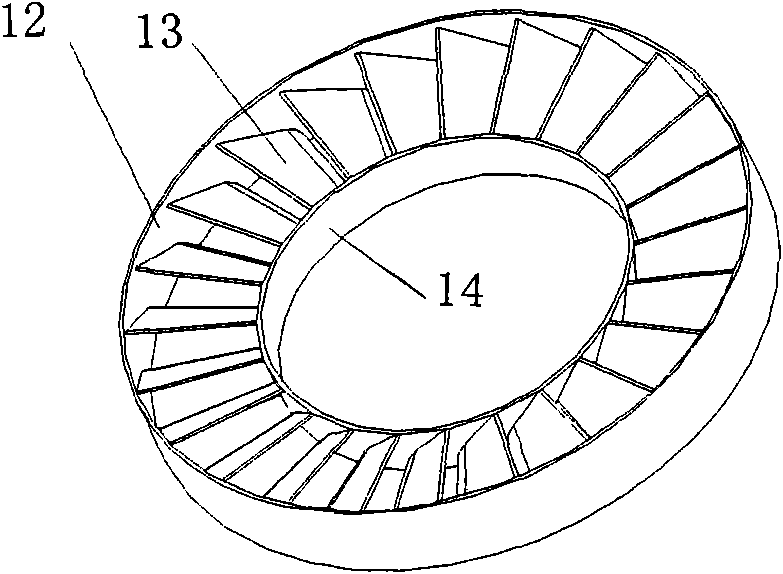

Low emission high-power staged-combustion gas burner and gas collocation method thereof

ActiveCN102003710AReduce the temperatureReduce concentrationGaseous fuel burnerIndustrial gasLow speed

The invention belongs to the technical field of industrial gas burner and relates to a low emission high-power staged-combustion gas burner. The staged-combustion gas burner is characterized in that a swirling machine, a flame stabilizing plate, a central canister and a middle pipe are coaxially arranged in the throat of the burner main body from outer to inner, wherein the flame stabilizing plate is provided with a gas gun which is axially fixed and has same uniformly distributed radial lines. The gas collocation method comprises the following steps: (1) collocating no gas in a direct air channel, in which is low-speed central cooling air, (2) mixing the high-speed swirling air entered from a swirling air channel with the gas jetted from a small gas hole B on the gas gun along the radialdirection till reaching to the semi-premixed state before emerging from the throat of the gas burner, and (3) face-to-face jetting the gas from a big gas hole on the top of the gas gun, the high-speed swirling air and the high-speed peripheral axial air flow so as to form non-premixing diffusion combustion. Because of the air, the staged gas branch supply, the premixing combustion and the non-premixing diffusion combustion, the combustion is uniform and NOx is prevented from being generated. The discharge amount of NOx of the gas burner is 70% lower than that of the common burner in the priorart.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

Method and device for distributing IPv6 (Internet Protocol version 6) addresses

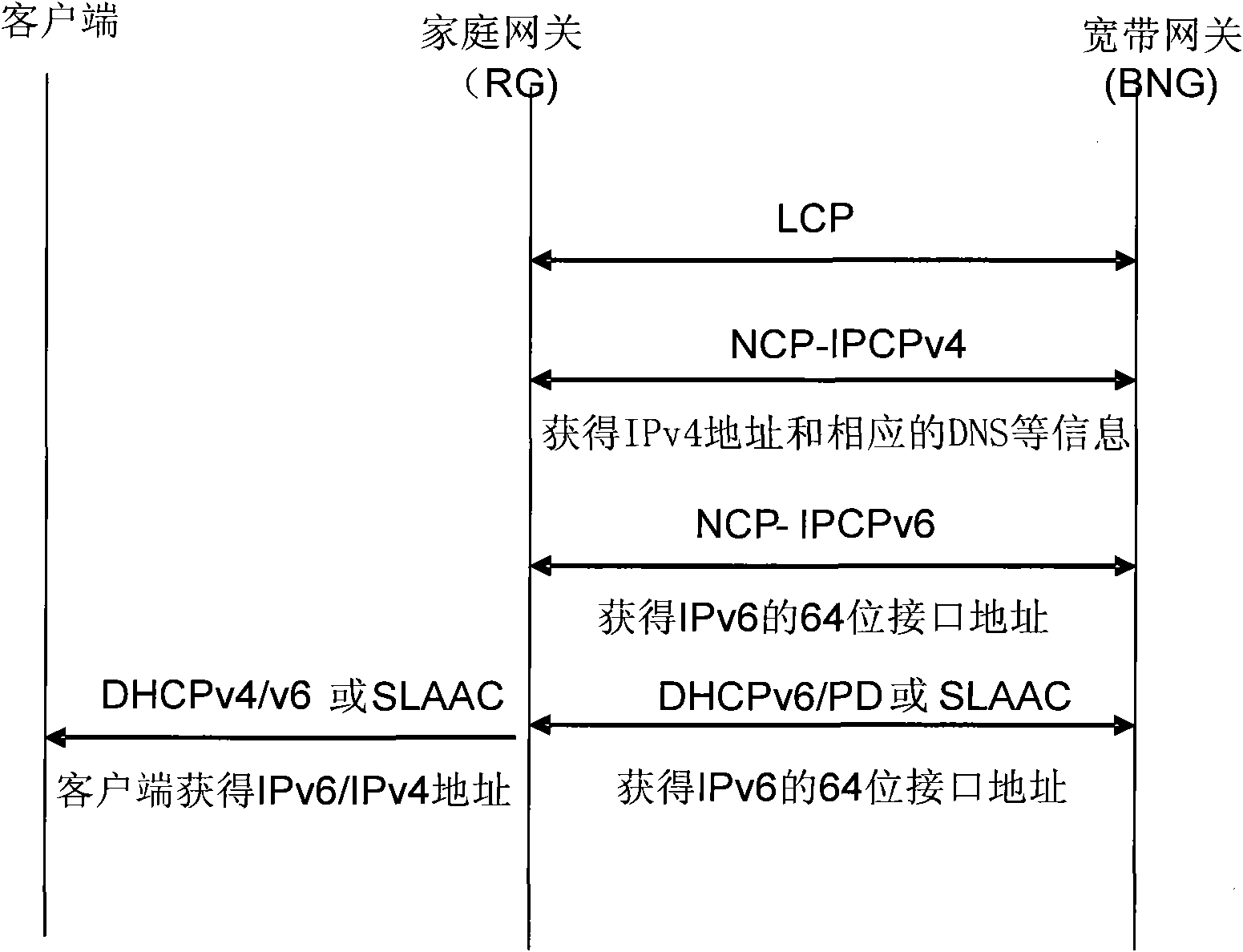

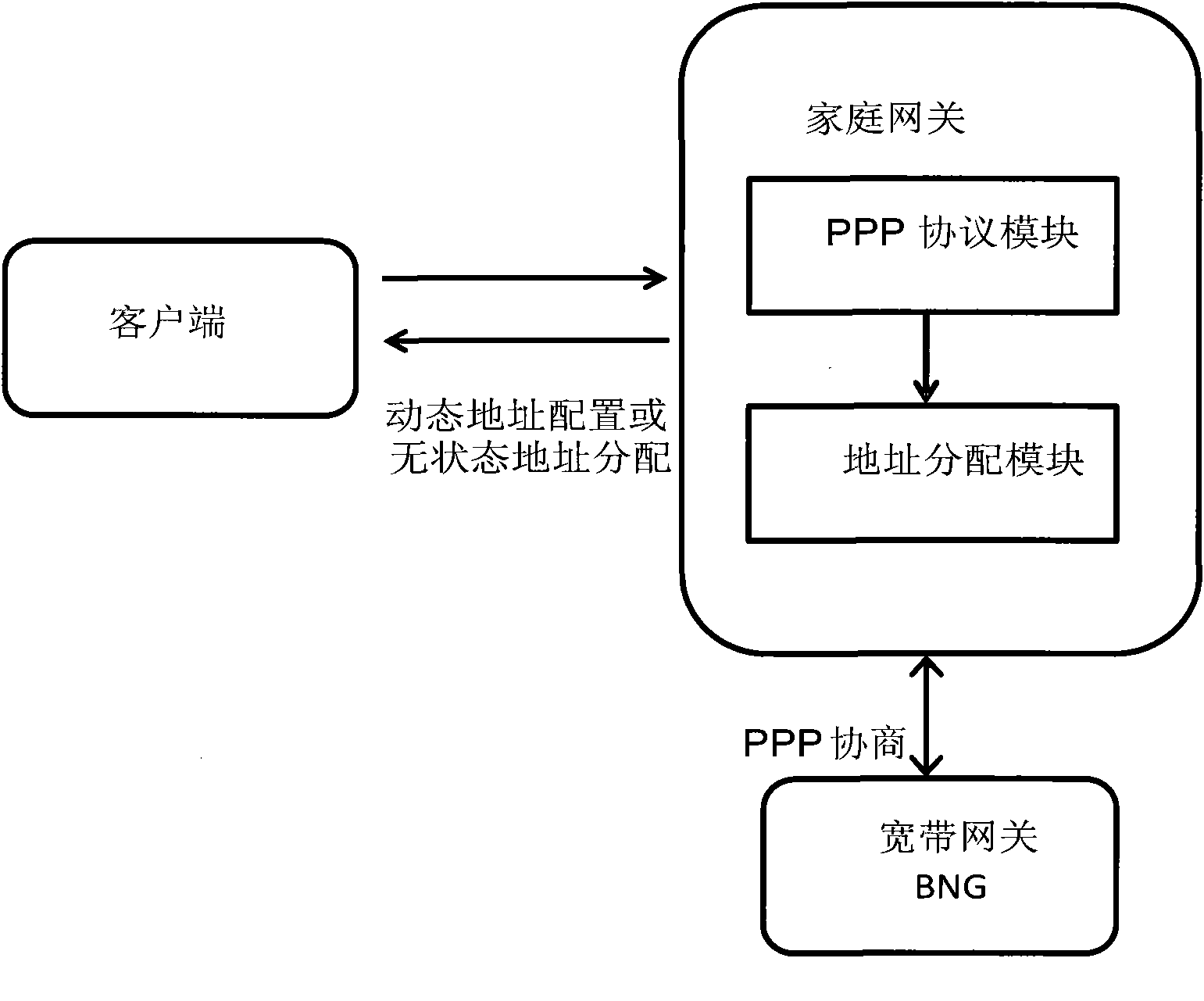

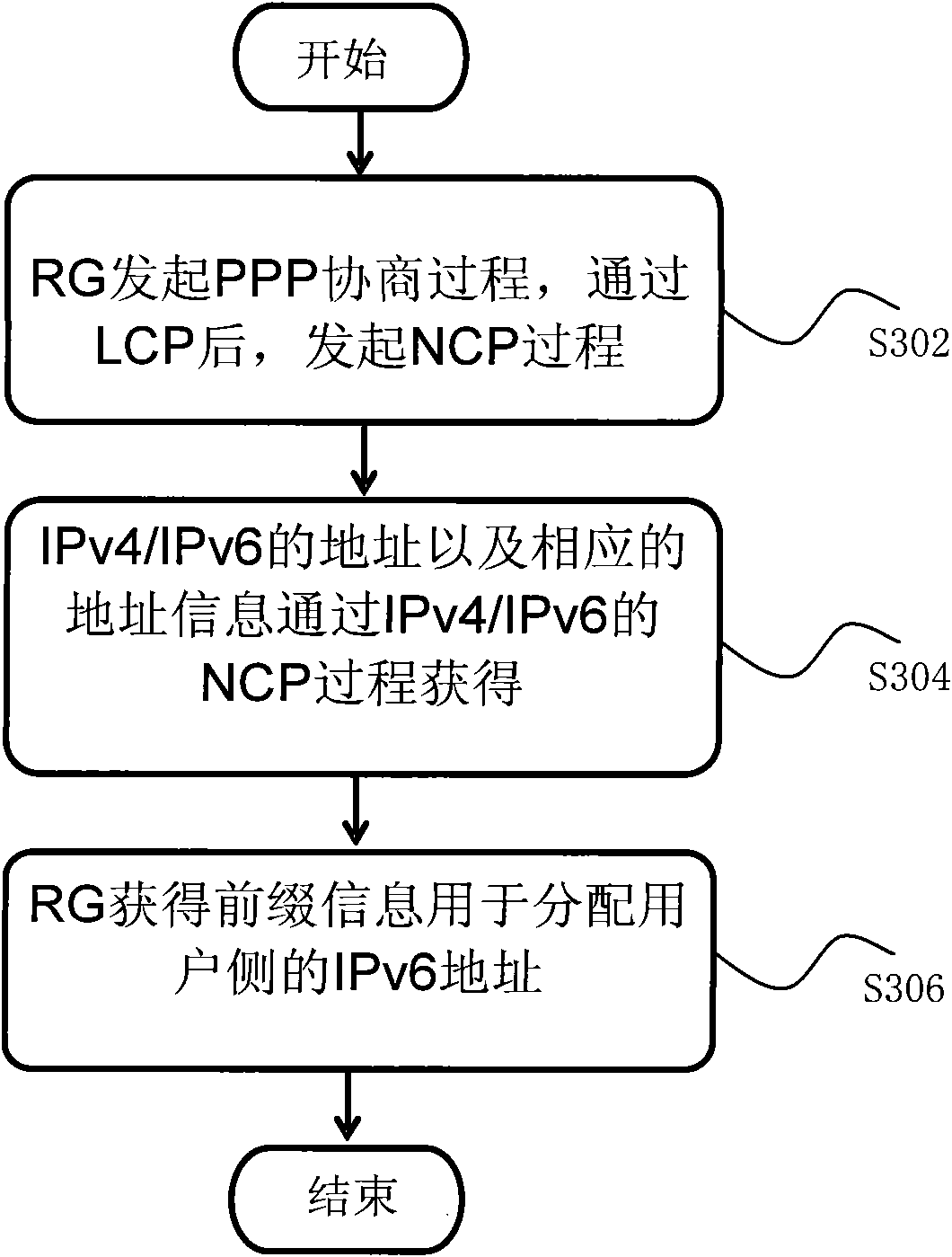

A method of initiating a PPP (Point-to-Point Protocol) on an RG to obtain address information has very wide application demands in practice, and as the existing IPv6 (Internet Protocol version 6) address consultation collocation method can not allocate complete IPv6 addresses through allocation option consultation, the invention provides a simple and vigorous IPv6 address consultation allocation scheme. According to the scheme, the consultation allocation of IPv6 address information is conducted by expanding allocation options of a IPv6 CP (content provider), thereby obtaining the complete IPv6 addresses and corresponding information or prefixed information on a DNS (Domain Name Server) and the like, so that the implementation method is simple and consistent with a related implementation method of an original IPv4, thereby reducing the cost of equipment and leading the running of the equipment to be more stable.

Owner:ZTE CORP

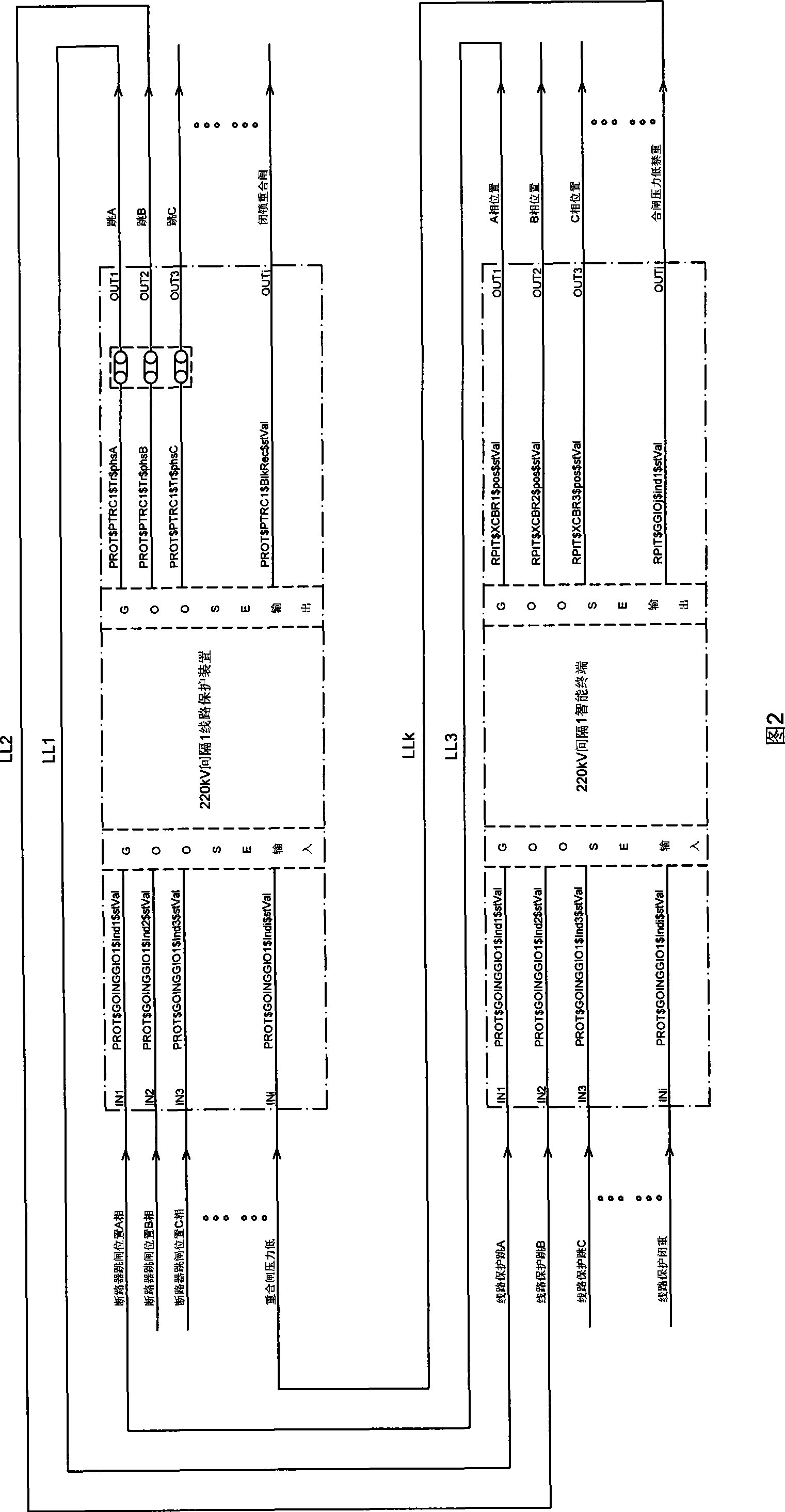

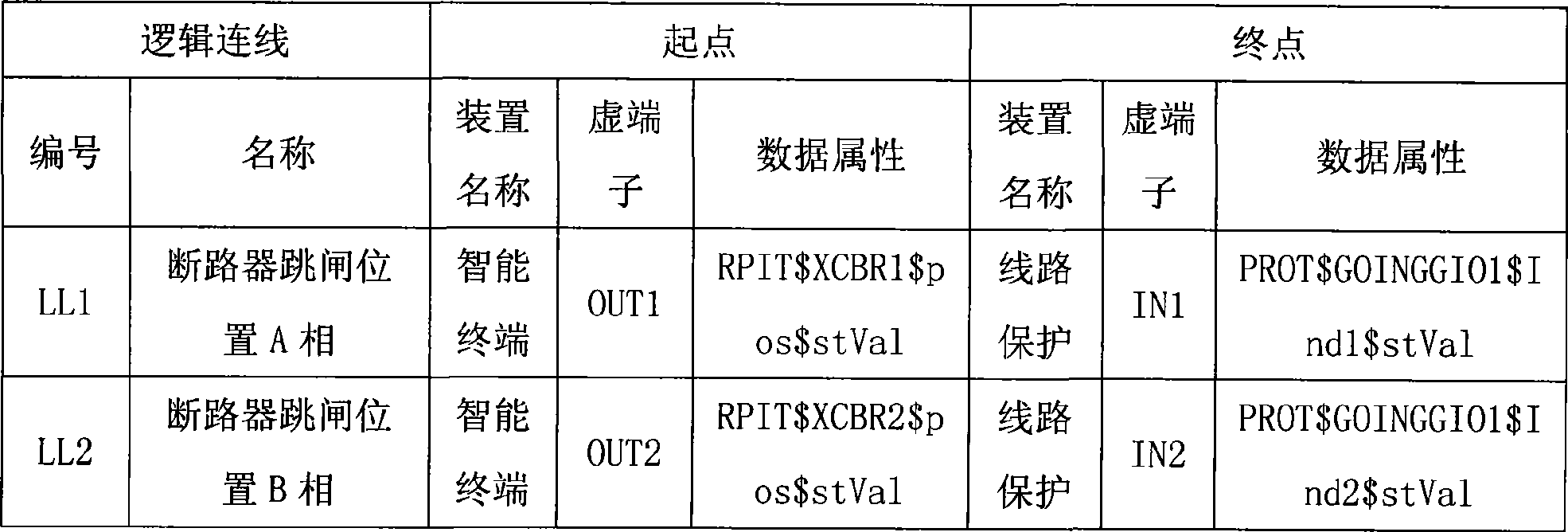

Intelligent apparatus GOOSE virtual terminal collocation method for digitized transforming plant

ActiveCN101431254ASolve problems that are difficult to expressData processing applicationsCircuit arrangementsVirtual terminalConnection number

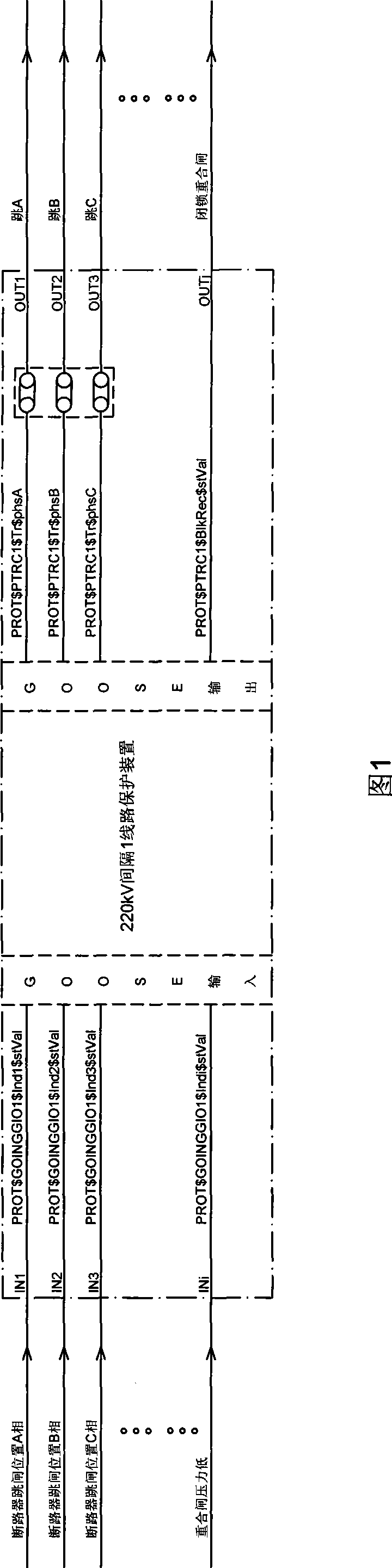

The invention relates to a method for configurating a virtual terminal of an intelligent device GOOSE in a digitalized substation, comprising the following steps: at least respectively defining the opening-inserting logic 1-i of the intelligent device as virtual terminals IN1-INi, and defining the opening-outgoing logic 1-j as virtual terminals OUT1-OUTj; expressing configuration of each intelligent device GOOSE in the form of connection in accordance with the principles of relay protection based on the intelligent device; respectively defining the terminal logic connection 1-k as LL1-LLk; arranging and re-expressing the configuration of the intelligent devices GOOSE in form of a list according to the logic connection based on virtual terminal logic connection; a GOOSE figuration list consists of the virtual terminal logic connection and the corresponding starting point and end point, wherein, the logic connection consists of two lists of the logic connection number LLk and the logic connection name. In this invention, the method can express network-transmission-based GOOSE digital signals in the form of the virtual terminals, so that personnel in charge of designing, construction, debugging, operation and maintenance of the intelligent device can intuitively read the opening-inserting logic, the opening-outgoing logic, exit logic and the like; in addition, the method can successfully solve the problem of difficult expression of GOOSE protective configuration on the drawing board, thus realizing construction according to the drawing, greatly improving efficiency of construction and debugging, meeting the requirement that 'digitalized substation is constructed by designing'.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

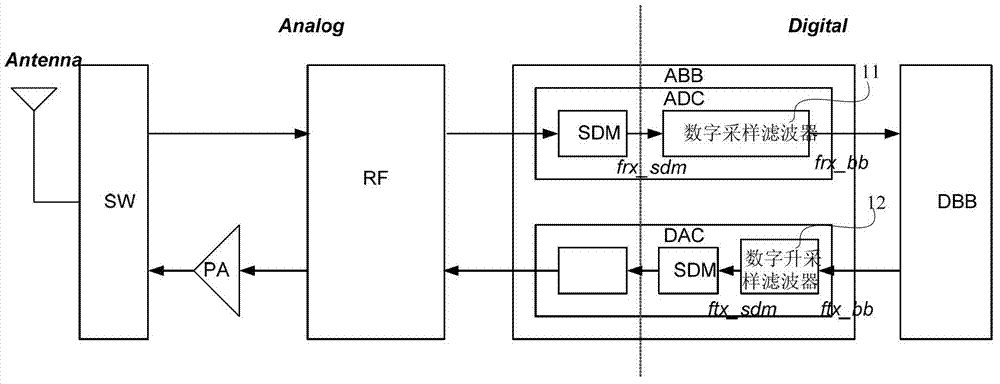

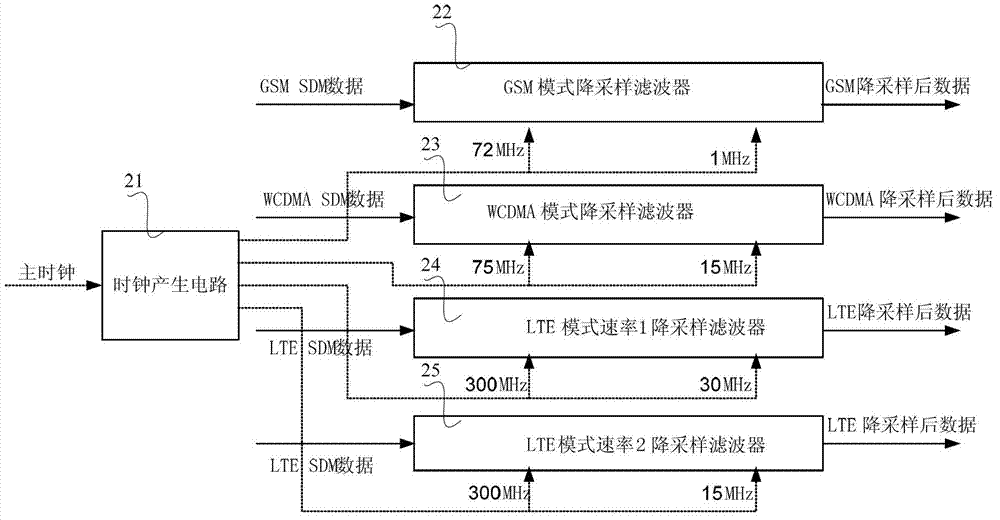

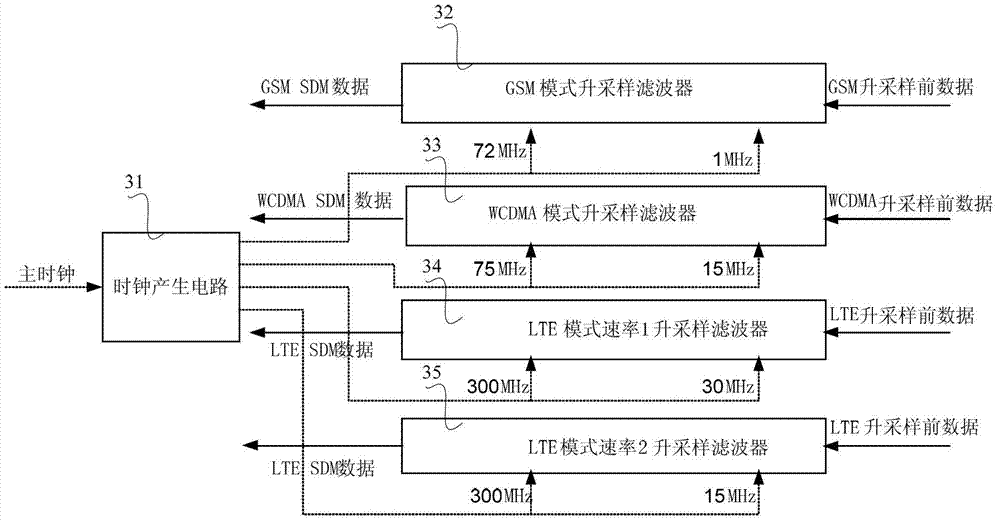

Digital filter, collocation method of digital filter, electronic device and wireless communication system

The invention discloses a digital filter, a collocation method of the digital filter, an electronic device and a wireless communication system. The digital filter comprises a set of cascade integrator comb (CIC) filter group. The collocation method of the digital filter comprises that signals are selected through working modes received by the digital filter, a filter rate configuration value which is stored in a register and corresponds to each working mode is selected, a working clock is confirmed according to a main clock selection signal and a clock frequency dividing ratio selection signal in the filter rate configuration value, each filter can be switched in the different working modes according to the confirmed working clock, the digital filter is configured according to the different working modes, and accordingly the purpose that on the basic that the filter needs not to be re-designed, the different working modes are selected flexibly is achieved. The material waste is avoided when a clock generation circuit and the filter are re-designed in the process of the conversion of the working modes, and accordingly the purposes that cost is reduced and expandability is improved are achieved.

Owner:HUAWEI TECH CO LTD

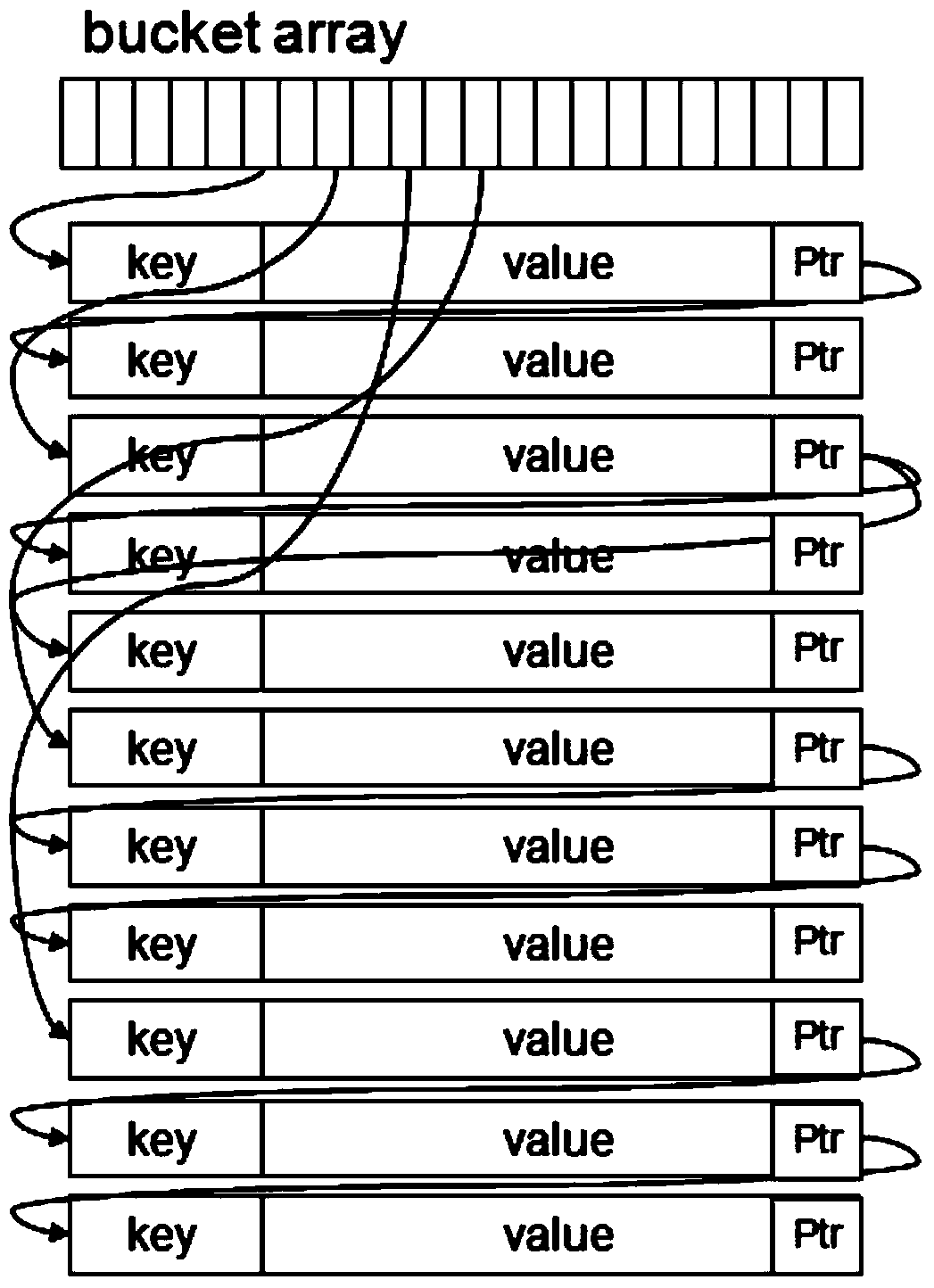

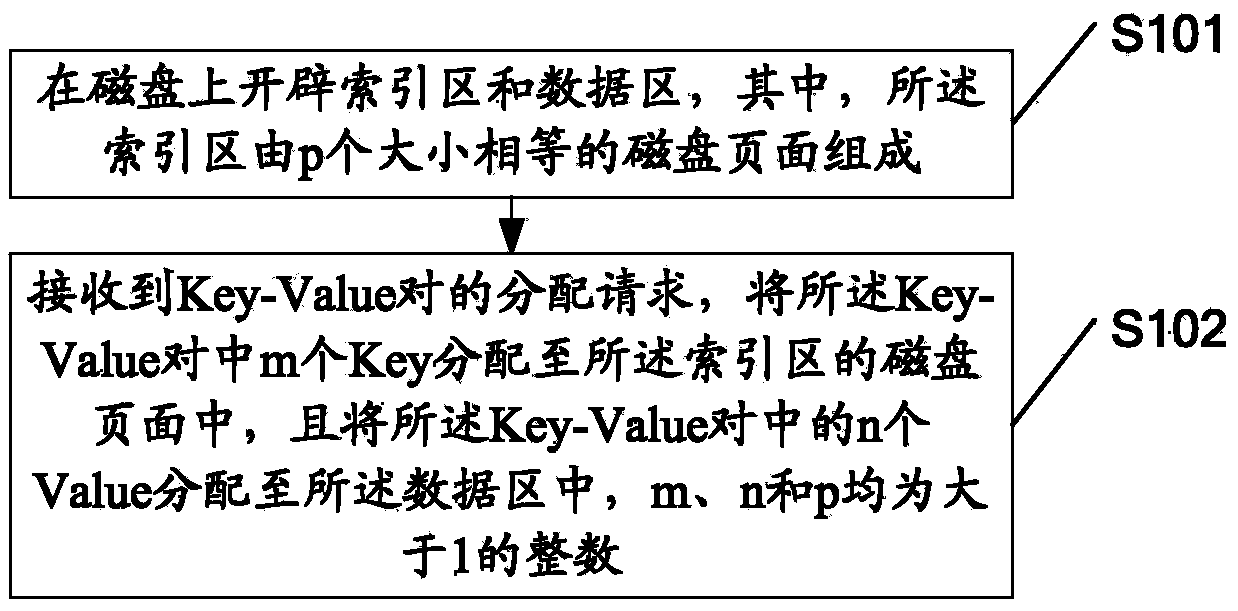

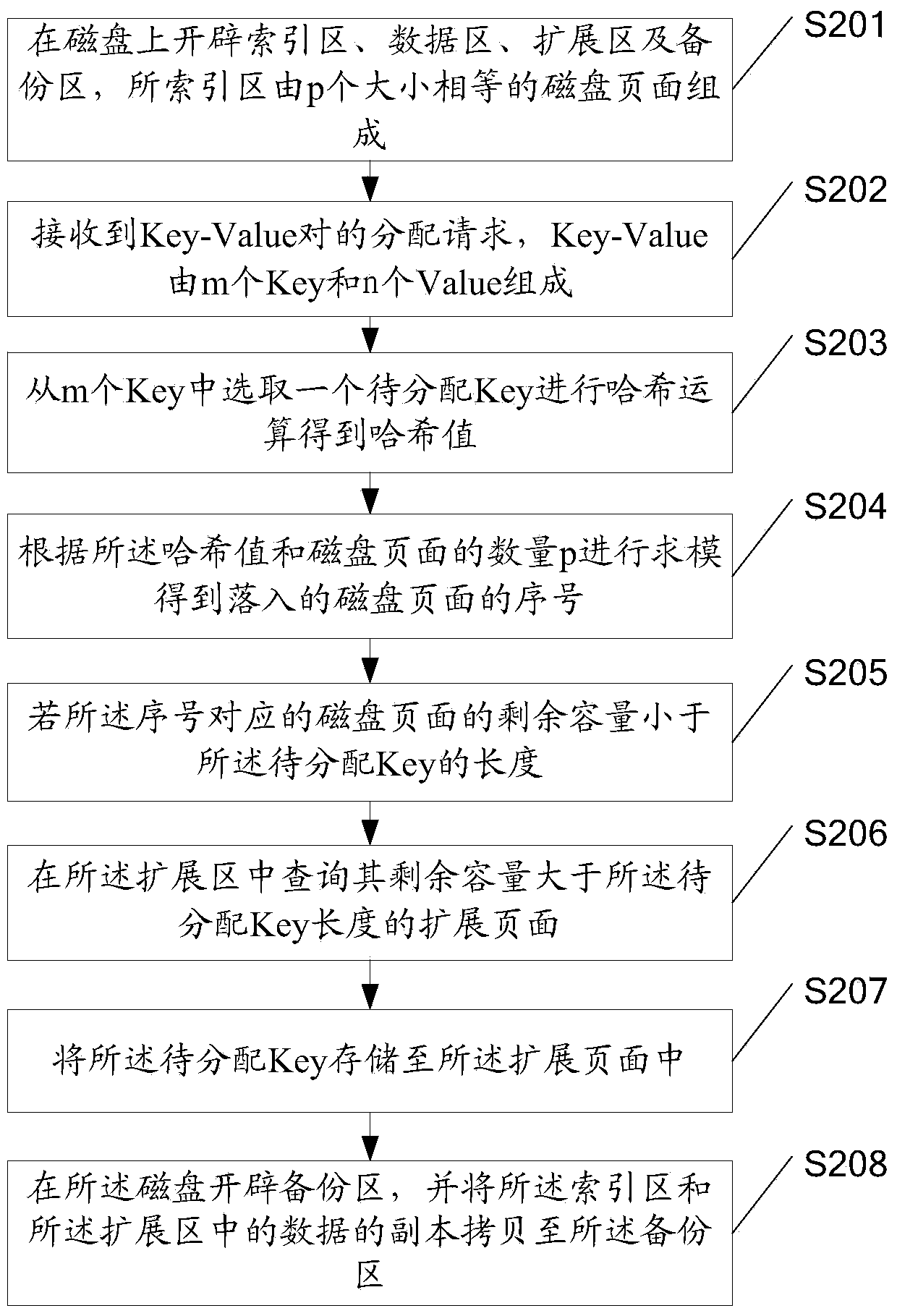

Collocation method and device of Hash database

InactiveCN103593477AImprove operational efficiencyAvoid it happening againSpecial data processing applicationsInput/output processes for data processingCollocationComputer science

The embodiment of the invention discloses a collocation method of a Hash database. The collocation method of the Hash database comprises the steps that an index area and a data area are developed on a disk, wherein the index area is composed of p disk pages with the same size; a collocation request of a Key-Value pair is received; m Keys in the Key-Value pair are distributed into the disk pages of the index area and n Values in the Key-Value pair are distributed into the data area, wherein m, n and p are all integers greater than one. The embodiment of the invention further discloses a collocation device of the Hash database. By the adoption of the collocation method and device of the Hash database, the access efficiency of the Hash database is improved.

Owner:HUAWEI TECH CO LTD

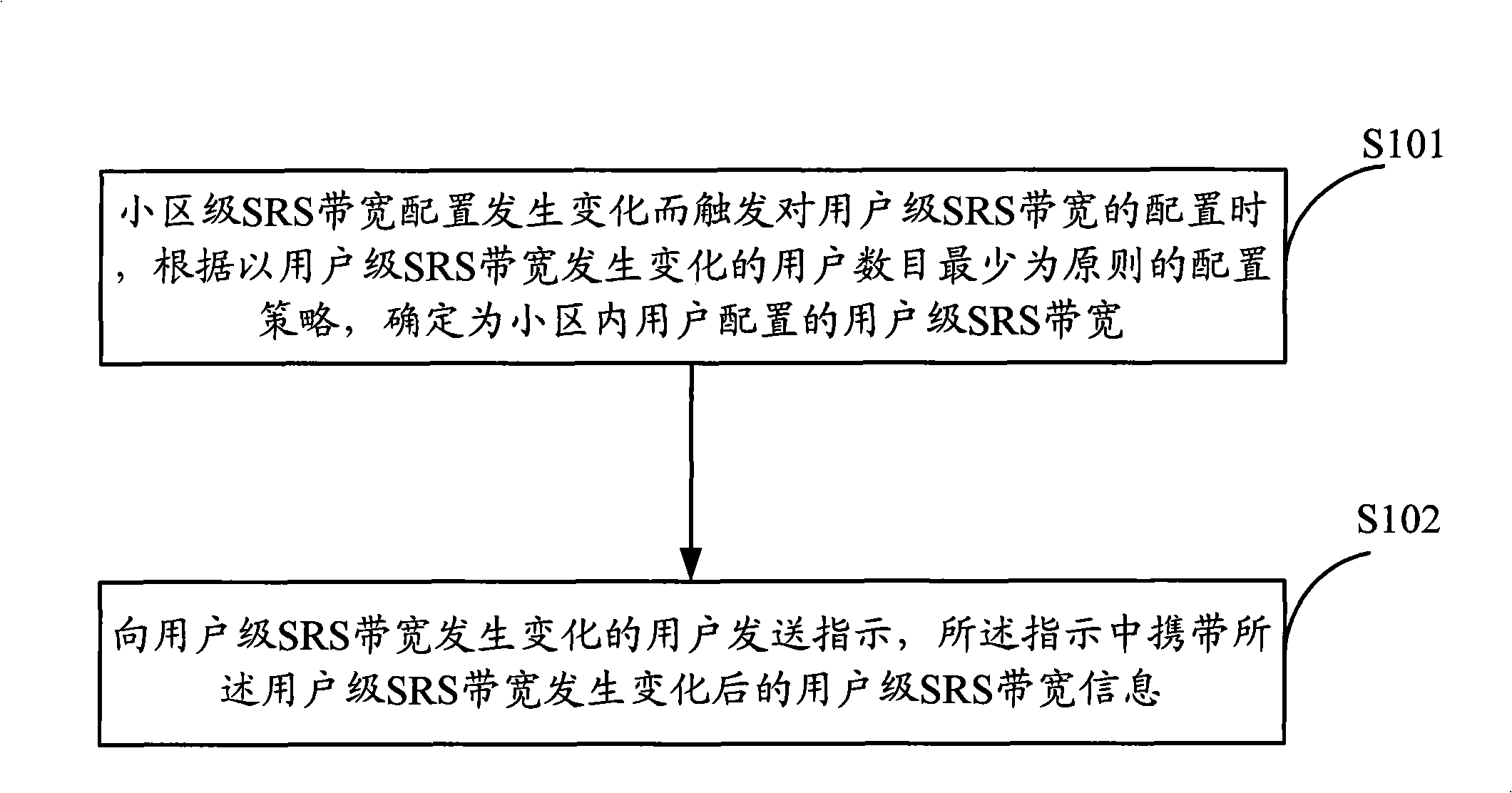

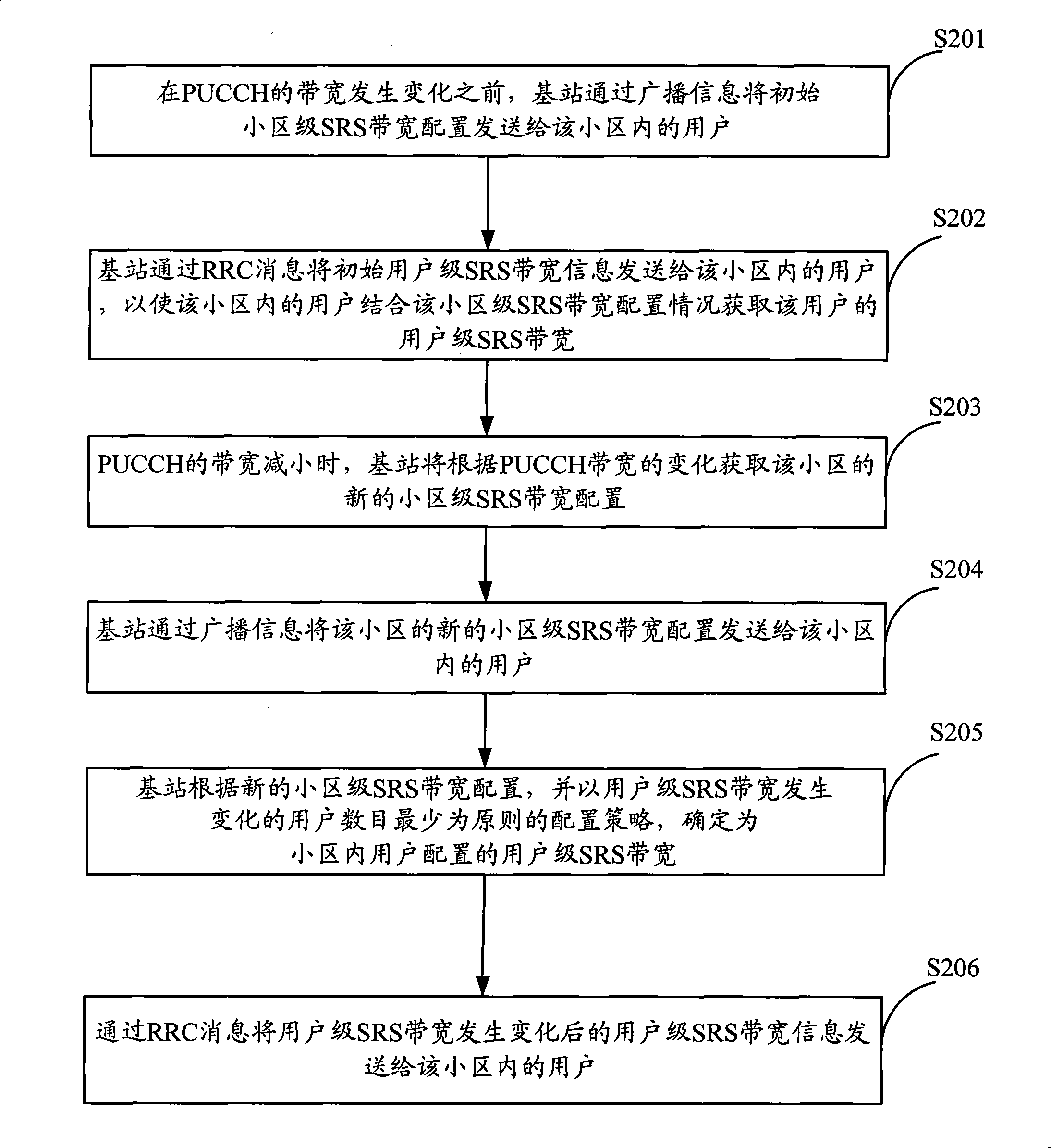

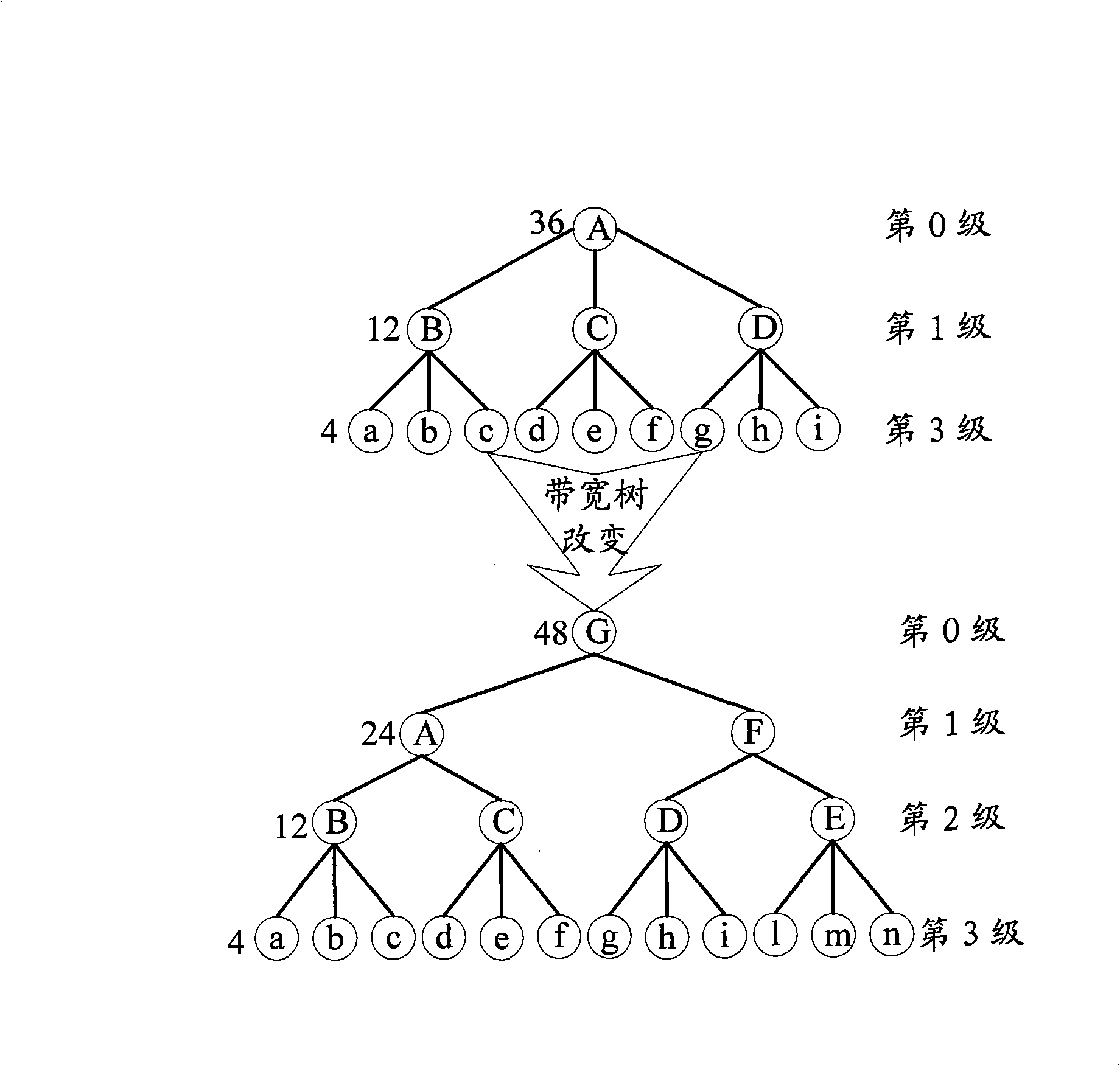

SRS band width collocation method, system and apparatus

ActiveCN101404817ASimplify complexityReduce overheadMessaging/mailboxes/announcementsTransmissionBand widthDistributed computing

The embodiment of the invention discloses a method used for allocating SRS bandwidth, a system and a device thereof. The method comprises the steps as follows: when subdistrict-grade SRS bandwidth allocation is changed so that the allocation of user-grade SRS bandwidth is triggered, the method confirms the user-grade SRS bandwidth for the subdistrict user allocation according to the allocation strategy based on the principle that the quantity of the users with the user-grade SRS bandwidth being changed is the least; the invention sends a command to the users with the user-grade SRS bandwidth being changed; and the command carries user-grade SRS bandwidth information after the user-grade SRS bandwidth is changed. In the invention, the SRS bandwidth of most users is reserved to the greatest extent, so the quantity of the users without change is the most, and the quantity of the users with change is the least; for the whole system, the invention ensures that the signaling cost required for reallocating the user-grade SRS bandwidth is reduced greatly and simplifies the complexity of SRS bandwidth reallocation.

Owner:HUAWEI TECH CO LTD

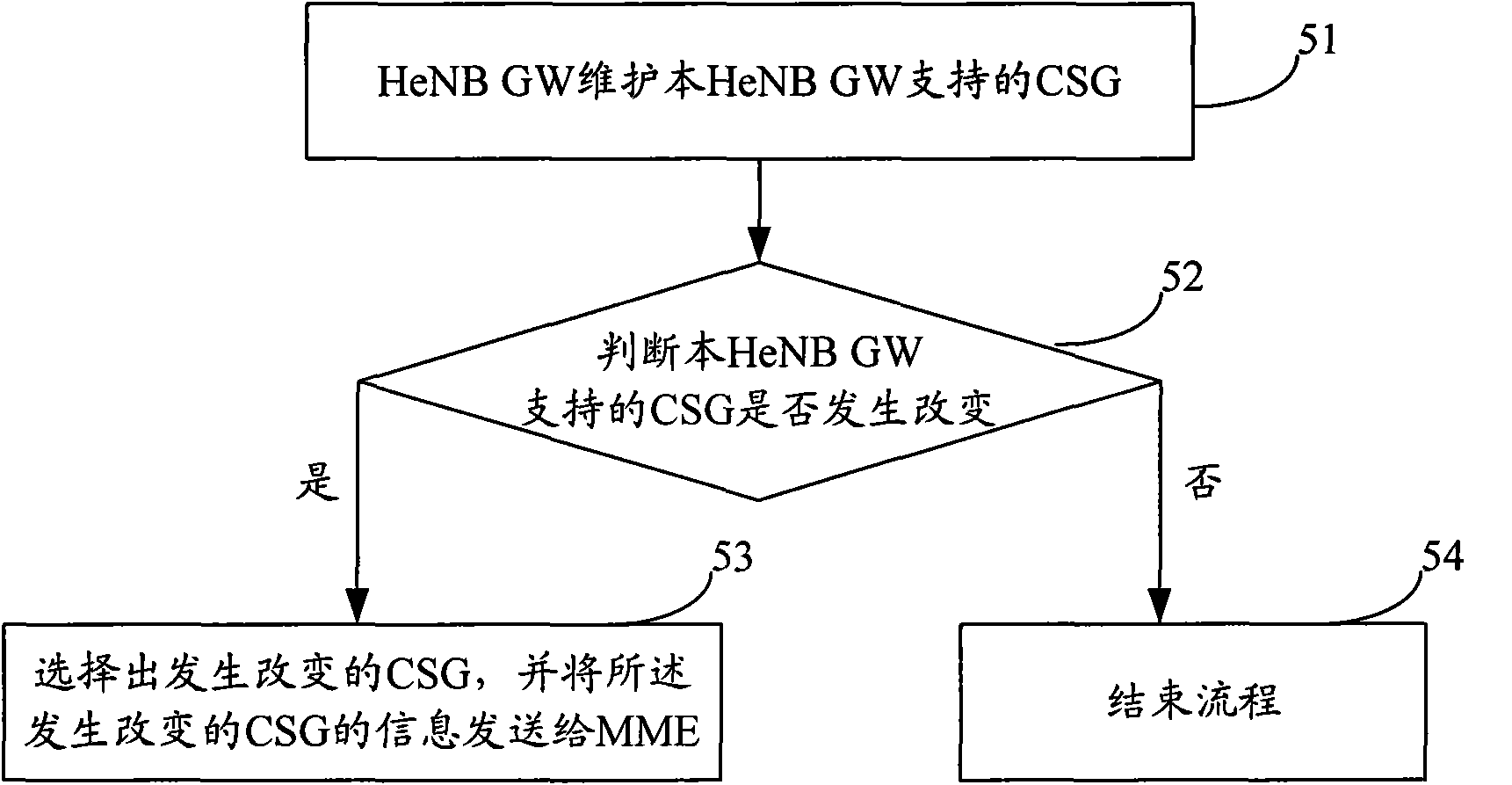

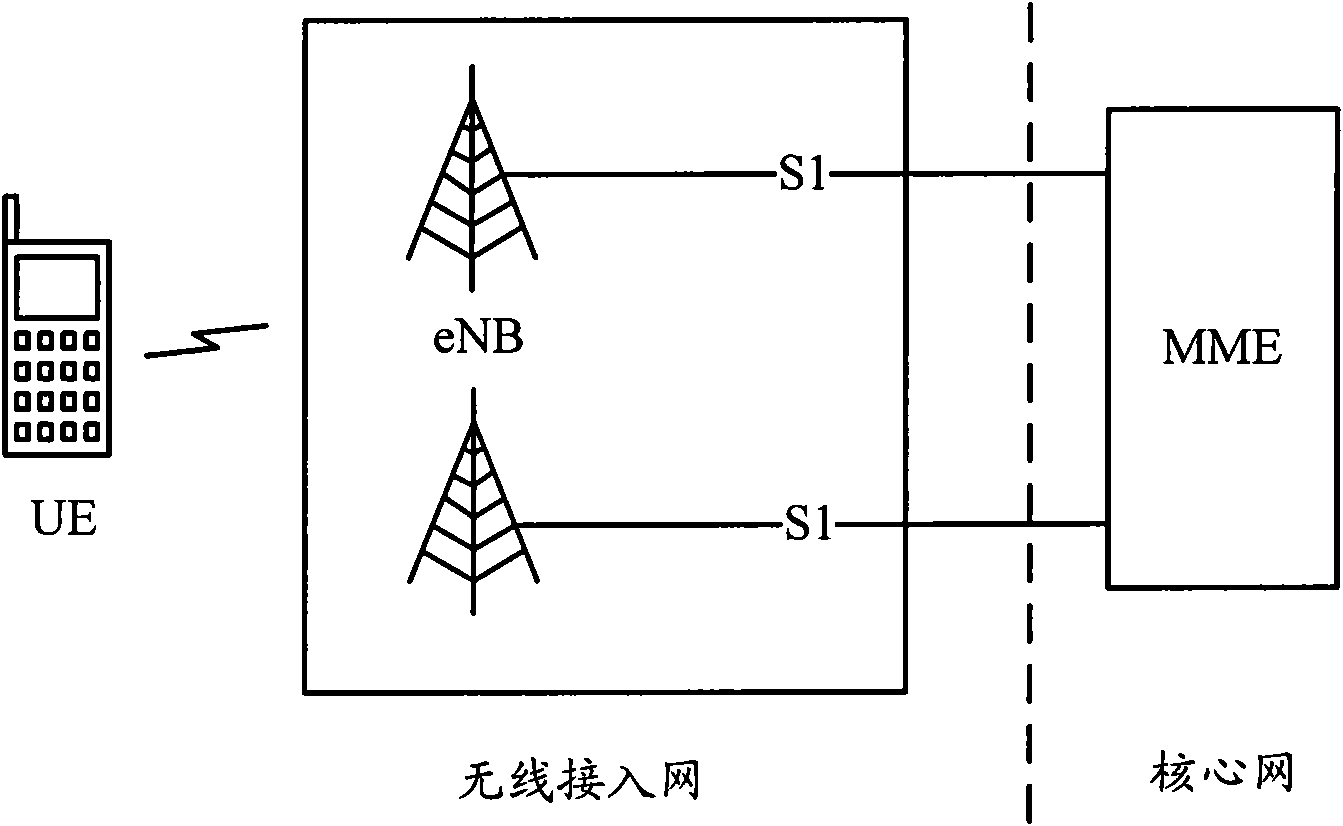

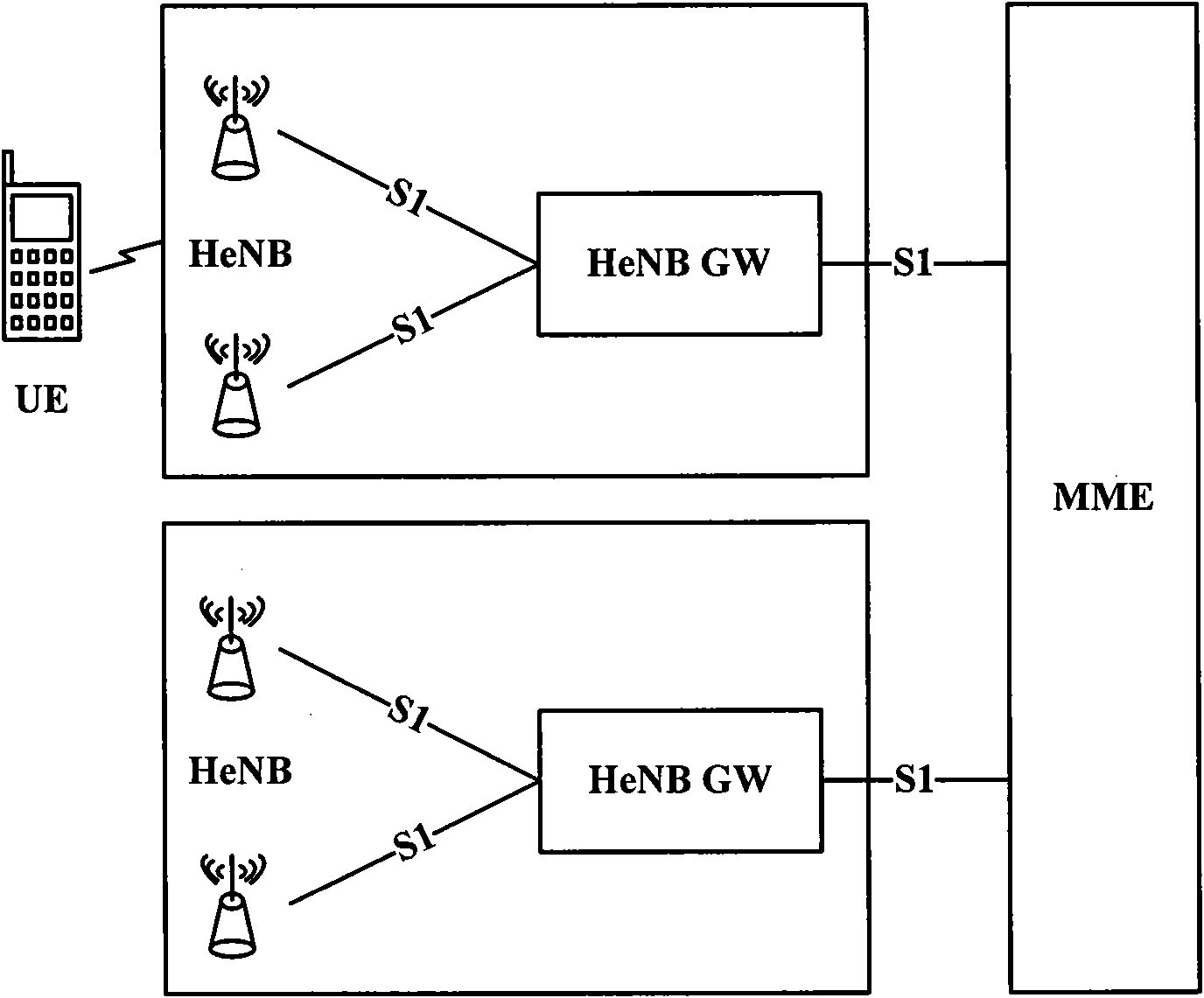

Method and device for transmitting closed subscriber group information

ActiveCN101827427AReduce data transfer volumeReduce wasteAssess restrictionNetwork data managementCollocationWireless transmission

The invention provides a method and a device for transmitting closed subscriber group (CSG) information so as to support paging optimization. The method and the device only transmit the changed CSG information among network entities by combining the access control of the CSG in long term evolution (LTE) and a network frame of an LTE home enode base station (HeNB), so that the data transfer among the network entities is reduced and the cell needing paging can be comprehensively judged by a mobility management entity (MME) with tracking area (TA) information and CSG information so as to prevent redundant paging and reduce the waste of the wire and wireless transmission resource. In addition, the invention also provides a collocation method for a tracking area mark for further optimizing the paging; and the method prevents unnecessary paging from being initiated in a macro cell caused by the paging at a home cell through reasonable collocation of the tracking area mark so as to reduce the waste of the air interface resource of the macro cell. The method and the device can support the paging optimization in the LTE and a further evolution network thereof and effectively support the large-scale deployment and mobility management of the HeNB.

Owner:NTT DOCOMO INC

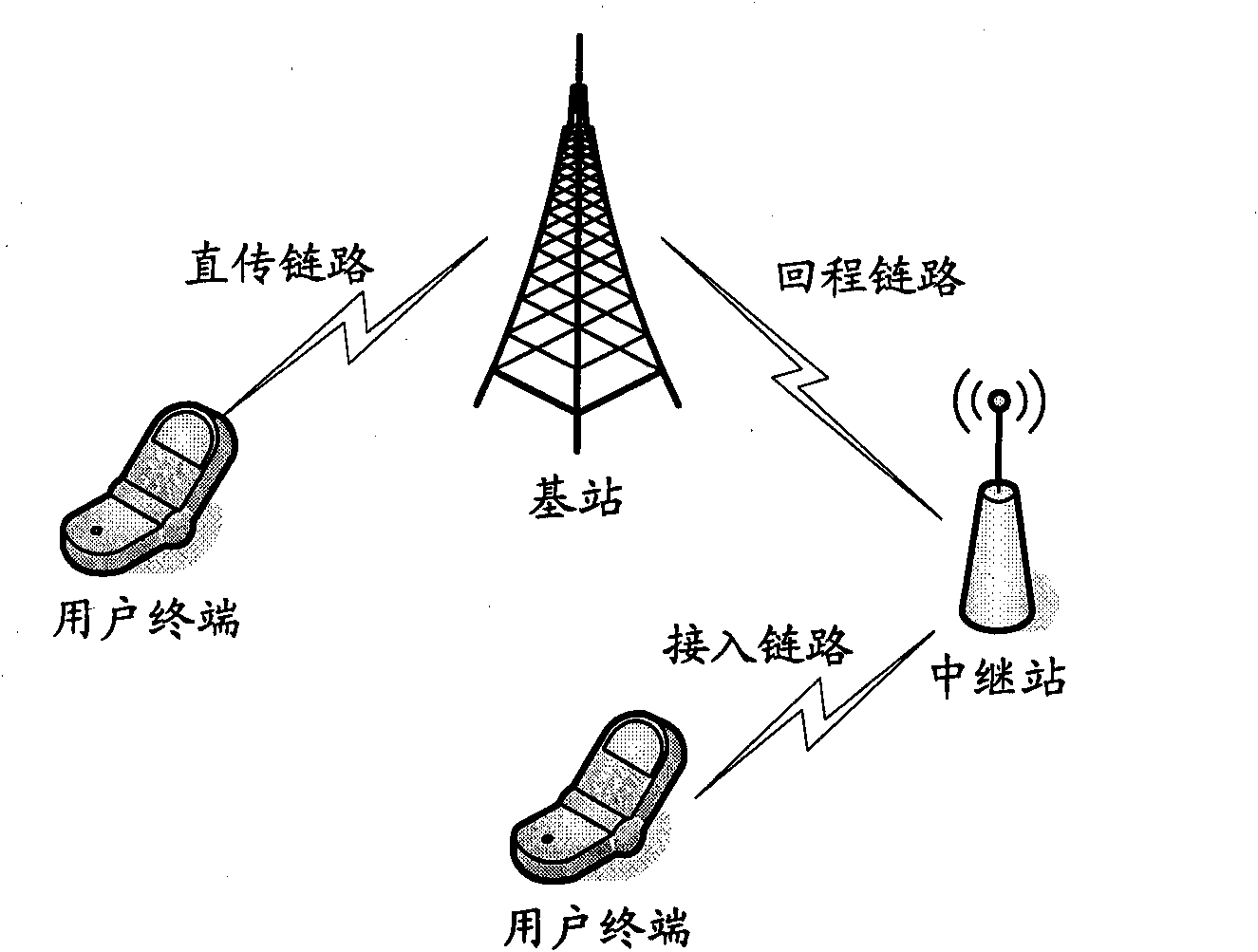

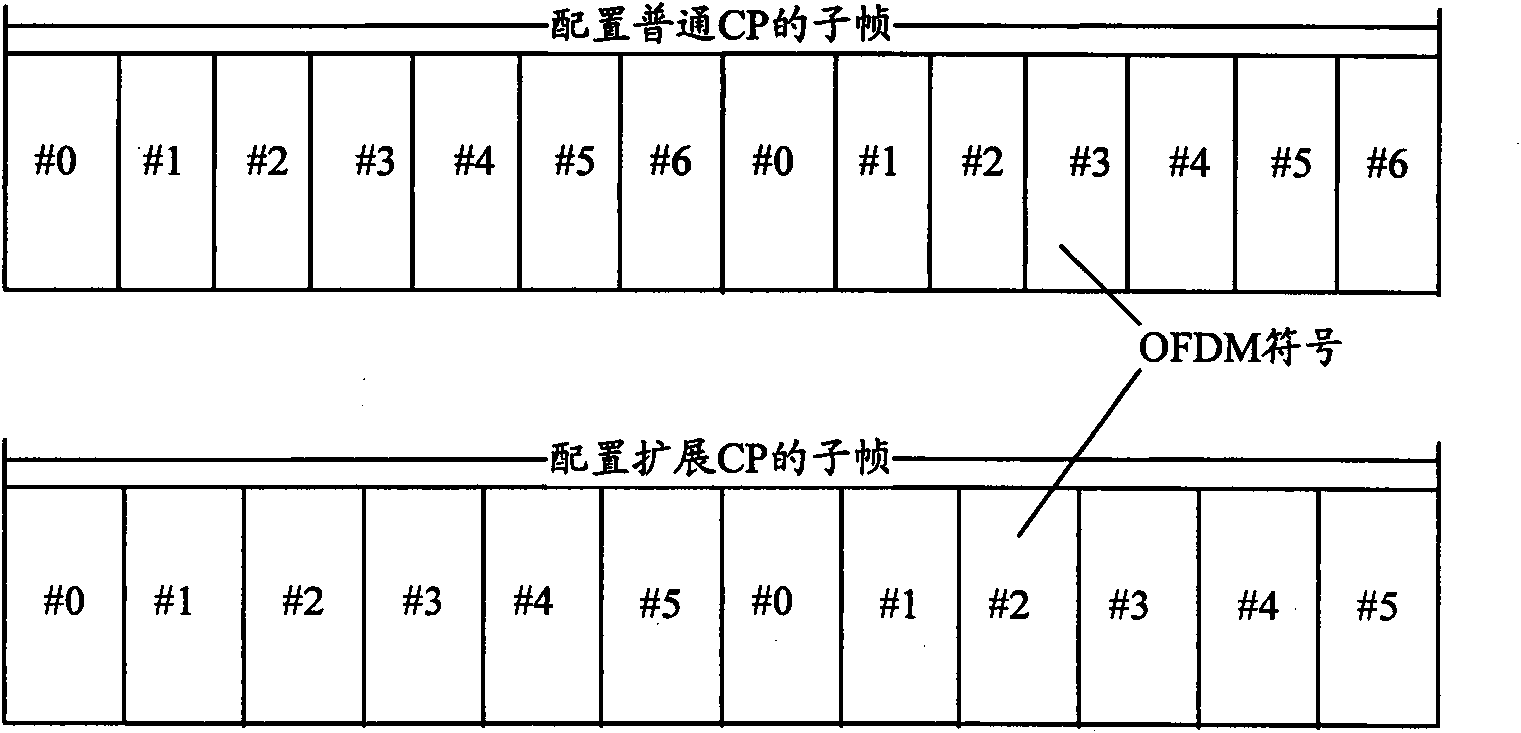

Collocation method and device of backhaul link in long term evolution system

ActiveCN101848420AImprove throughputIncrease system capacityAssess restrictionNetwork topologiesCollocationBase station

The invention discloses a collocation method of a backhaul link in a long term evolution system, comprising the following steps of: collocating a relay subframe into a multicast single frequency network (MBSFN) subframe on a downlink access link when the relay subframe is collocated at a network side, and collocating a unicast subframe on a downlink backhaul link. The invention also discloses a collocation device of the backhaul link in the long term evolution system, comprising a collocation unit which is used for collocating the relay subframe into the multicast single frequency network (MBSFN) subframe on the downlink access link and collocating the unicast subframe on a downlink backhaul link. The invention improves the communication efficiency of the backhaul link and the access flexibility of UE in a cell covered by a base station.

Owner:ZTE CORP

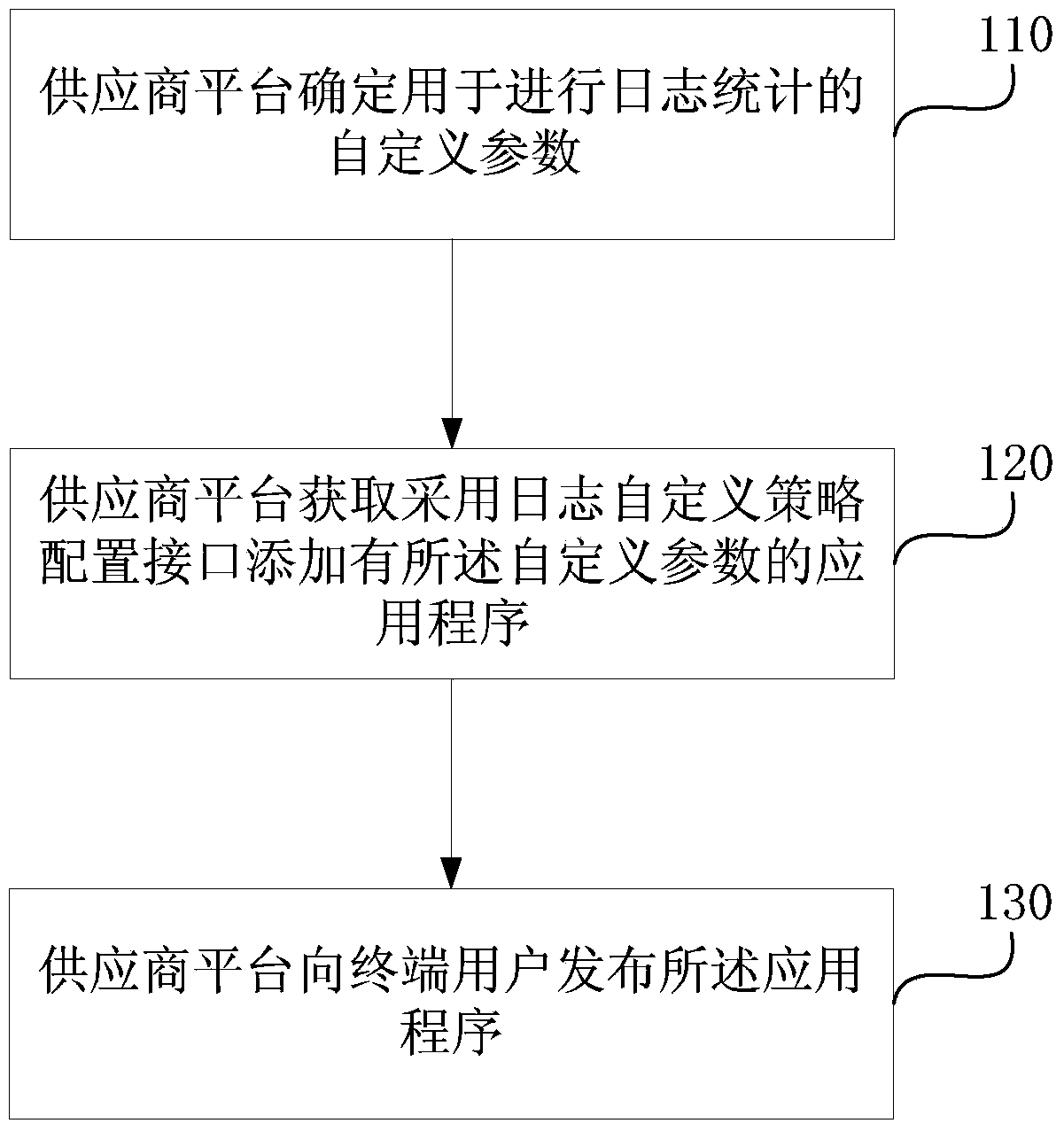

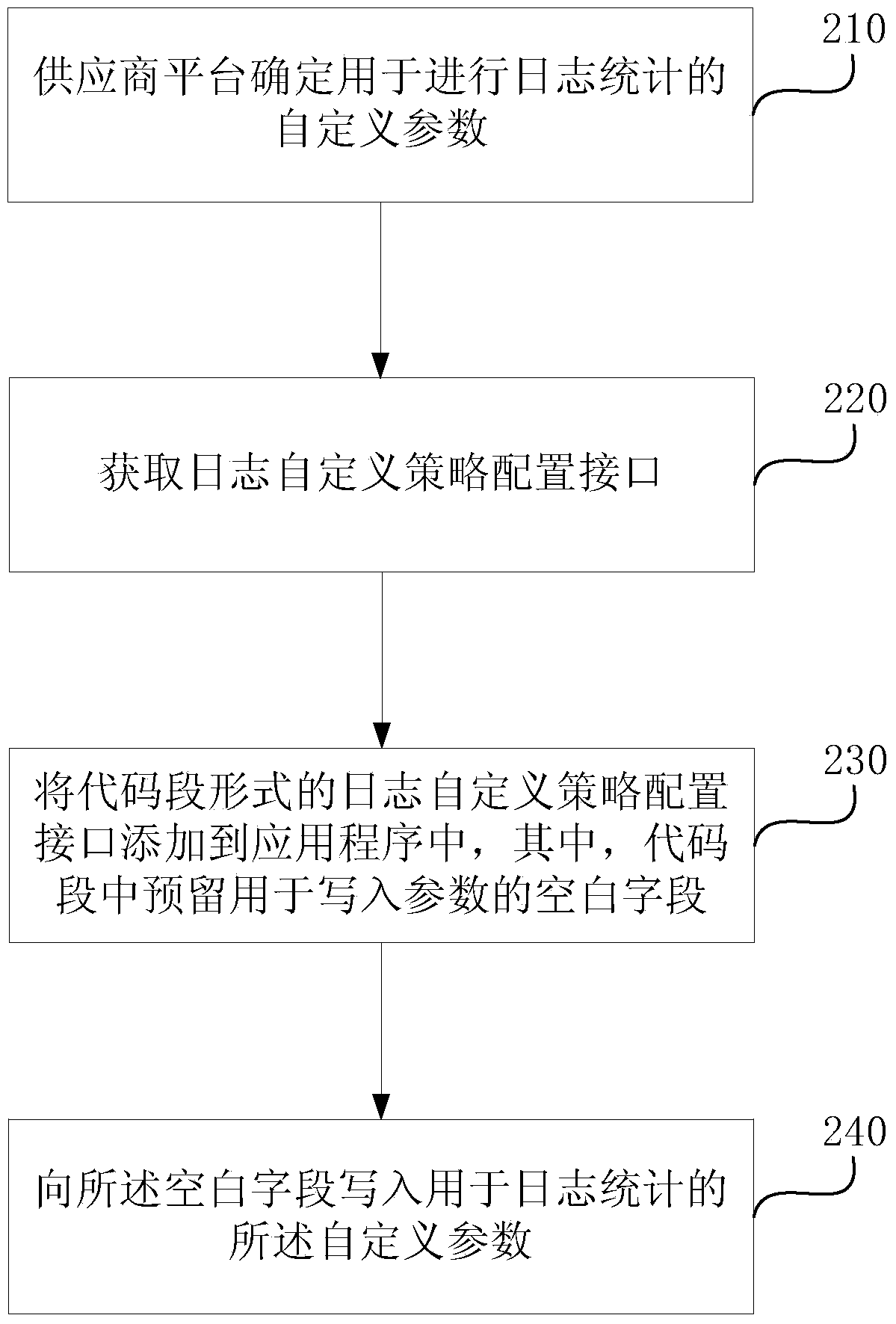

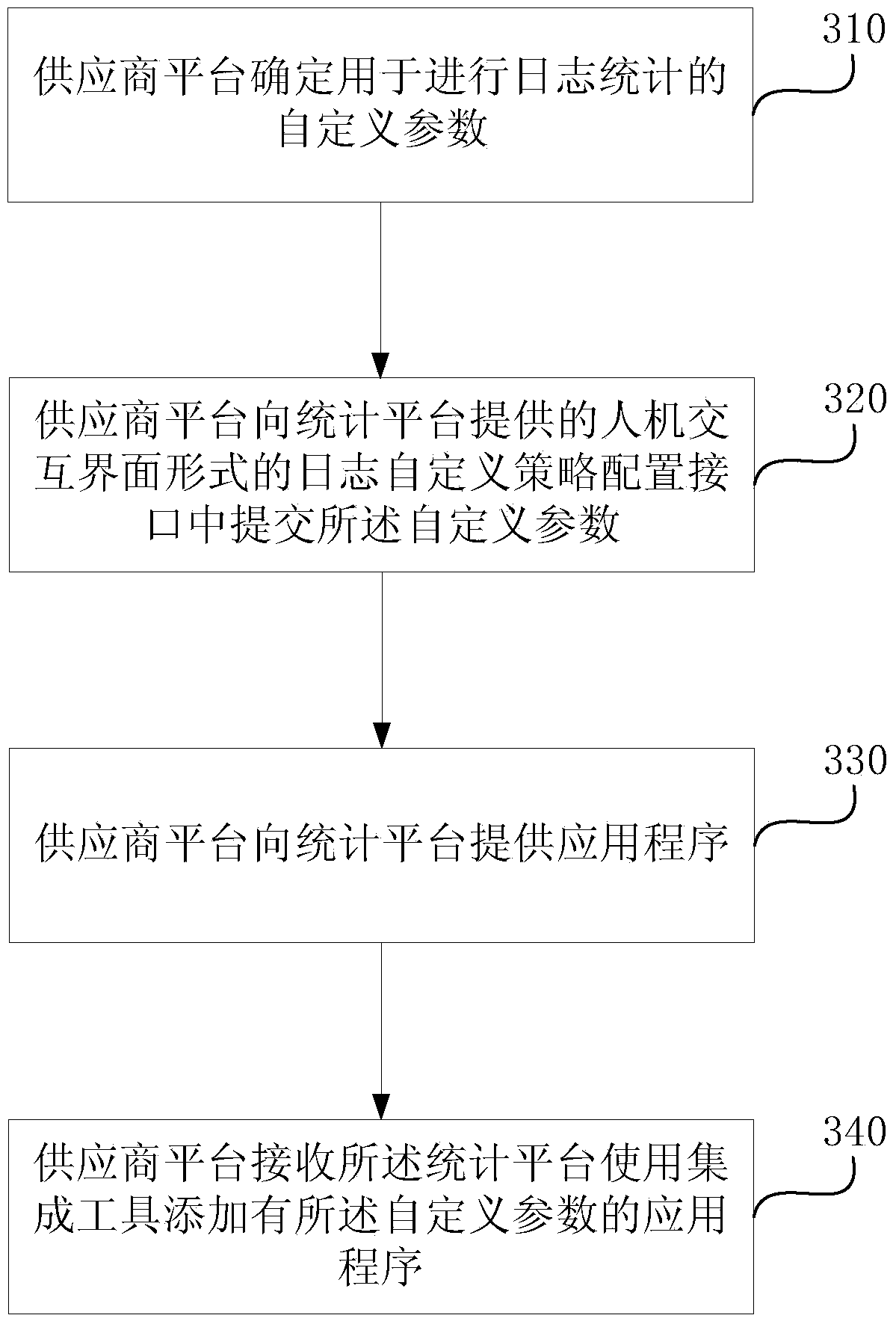

Log statistic strategy collocation method and device and log statistic method and device

ActiveCN103942136AFlexible definitionFreedom to customizeHardware monitoringSpecial data processing applicationsCollocationComputer terminal

Owner:深圳太乐文化科技有限公司

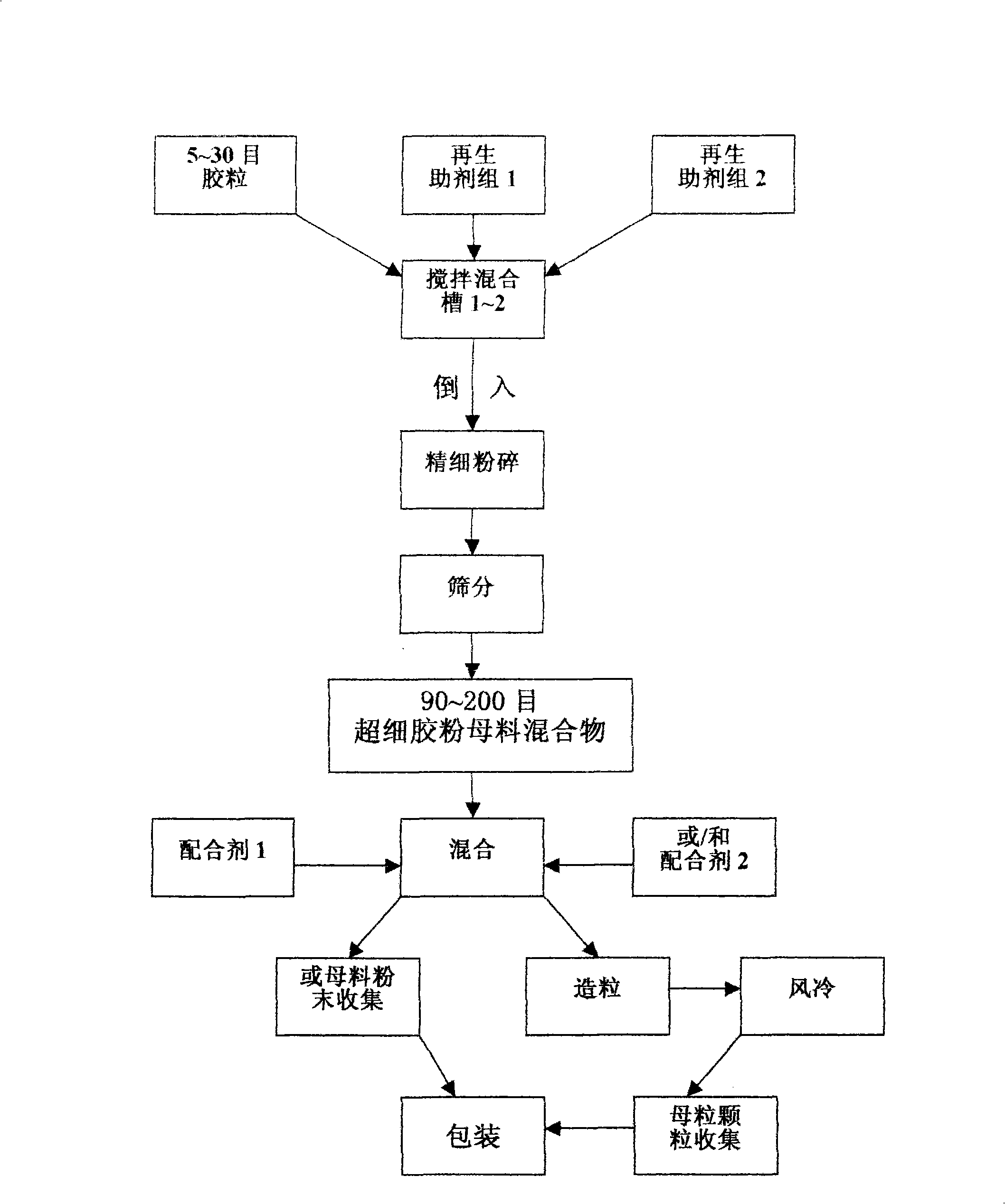

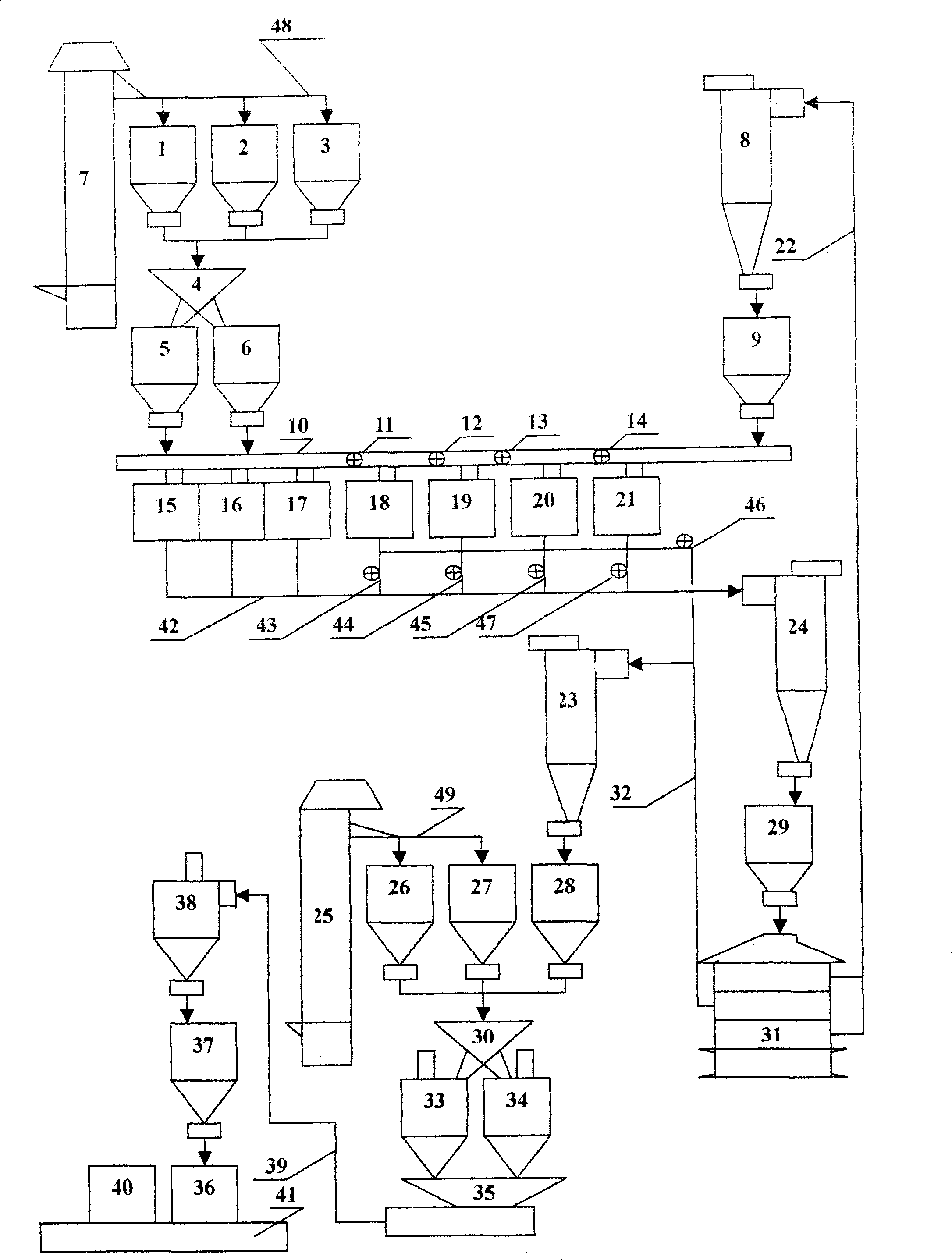

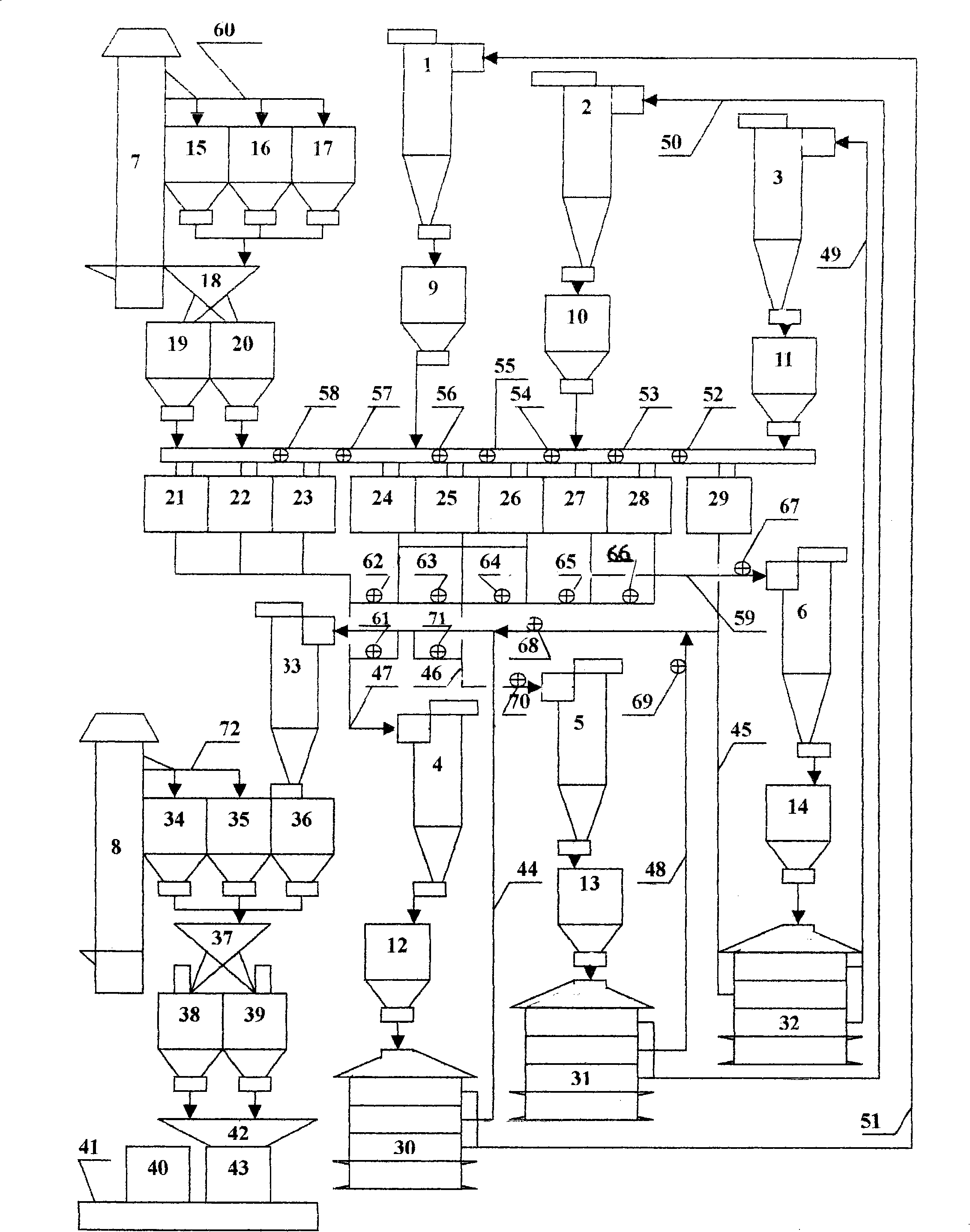

Elastic body fine crushing combined apparatus and collocation method

ActiveCN101269529APromote wettingFine grainPlastic recyclingGrain treatmentsElastomerAutomatic control

The invention provides an elastomer-material fine-breaking combination device that can add accessory materials before or after fine-breaking and can feed stably; the device comprises a feed device arranged before or / and after a fine-breaking machine group unit, a fine-breaking machine group unit which is divided into two groups of a group A and a group B, or three groups of a group A, a group B, and a group C is provided. The invention in particular relates to one feed device or the combination of more than one feed device: a, a machine which can add accessory materials is provided additionally; b, a fine-breaking machine subgroup unit is provided additionally; c, a feed flow-ratio adjusting device is additionally arranged on a feed path; d, a material return machine which can combine the coarse powder material which is classified or is screened out by a screening machine, and the fine powder material, and then can supply the combined material to the fine-breaking group A or fine-breaking group B or fine-breaking group C to make breaking again is additionally provided; e, a more perfect machine is additionally arranged behind the combination device; f, an automatic control electric apparatus is arranged on the combination device; the various adding and arranging adopt the integral combination of general machinery or / and non-standard machinery and electric apparatus in the market.

Owner:陈书怡 +1

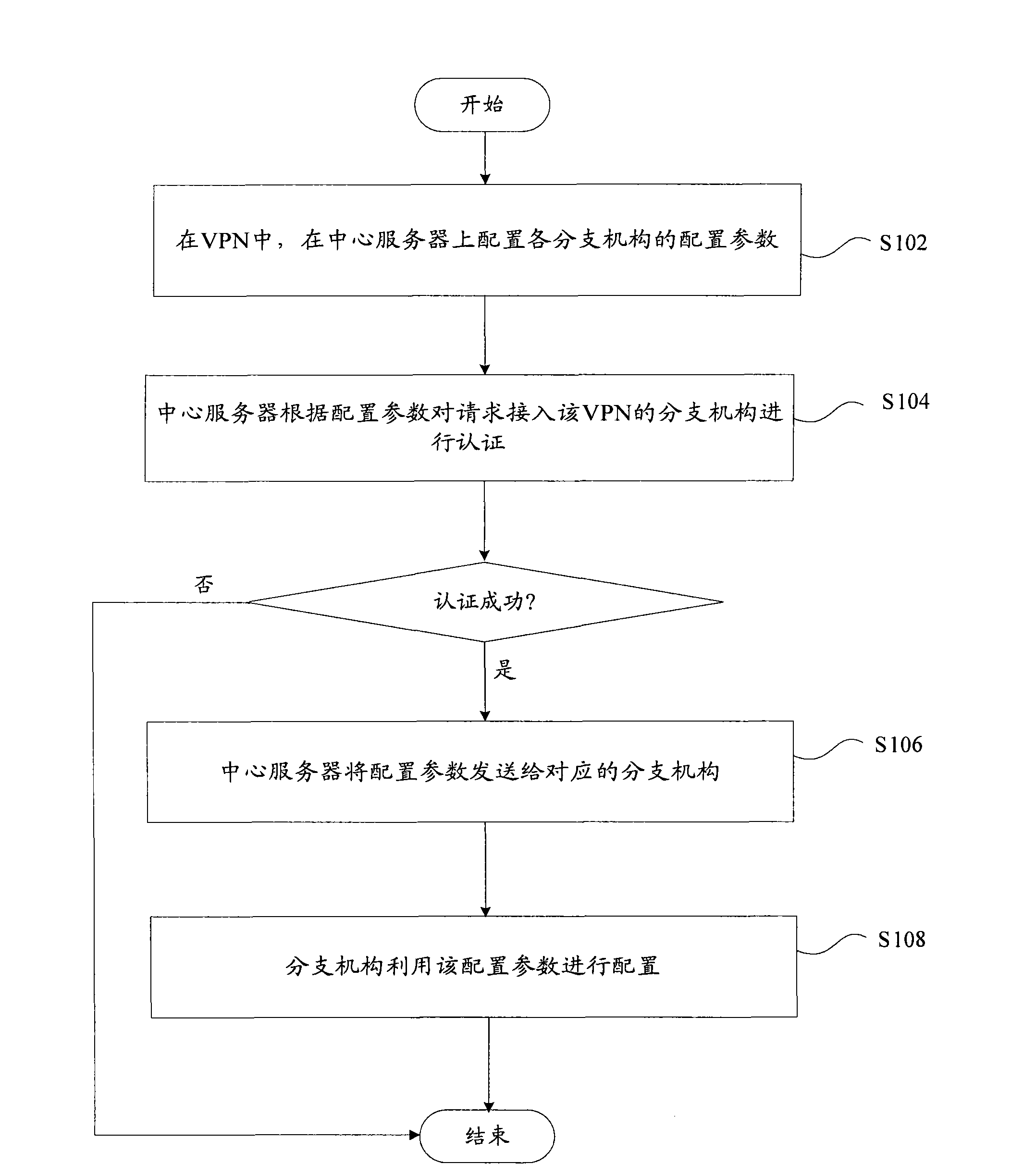

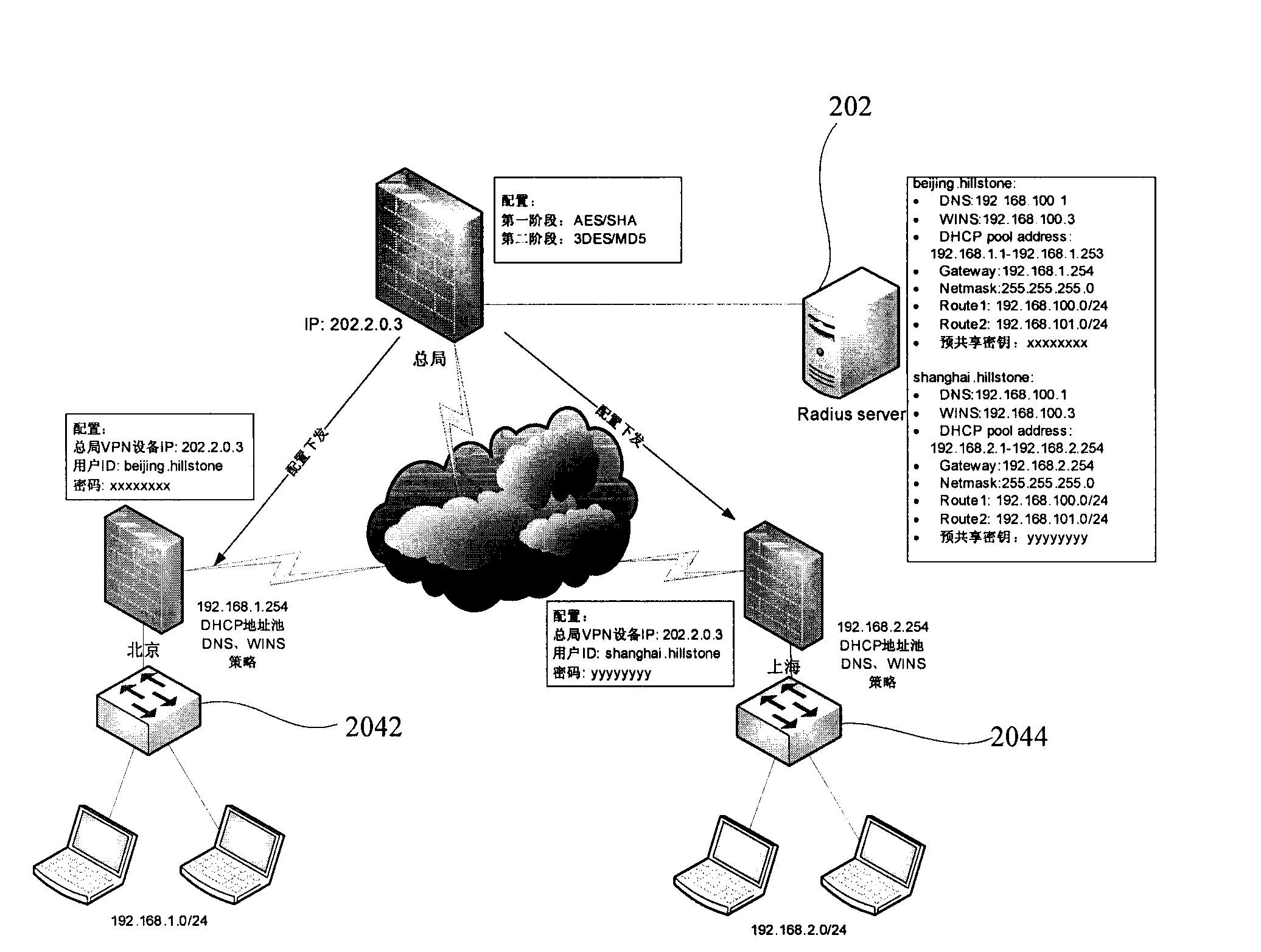

Collocation method of virtual private network based on internet security protocol and system therefor

ActiveCN101640607AOvercoming the problem of configuration becoming cumbersomeEasy to configureUser identity/authority verificationNetworks interconnectionCollocationPrivate network

The invention provides a collocation method of IPSec VPN and a system therefor; the method comprises: in the VPN, a central server is collocated configuration parameters of branch institutions; according to the configuration parameters, the central server can authenticate the branch institutions requiring to be accessed into the virtual private network; if the authentication is successful, the central server sends the configuration parameters into the corresponding branch institution; and the branch institution utilizes the configuration parameters for collocation. The method can realize the technical effect of simply and conveniently collocating the IPSec VPN.

Owner:HILLSTONE NETWORKS CO LTD

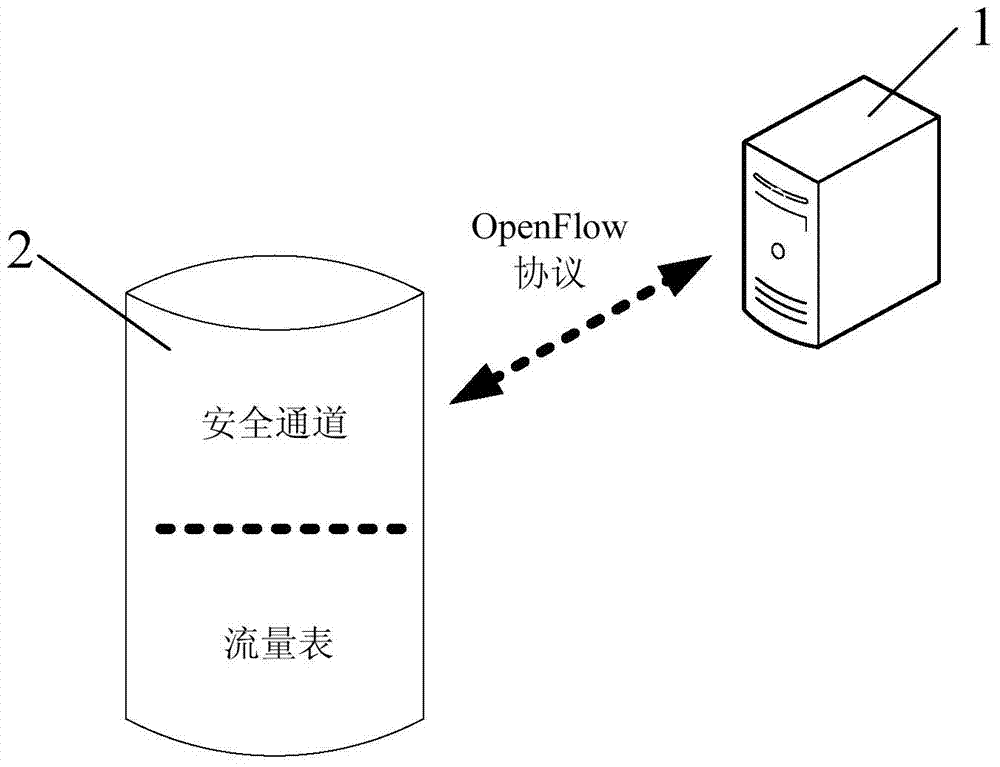

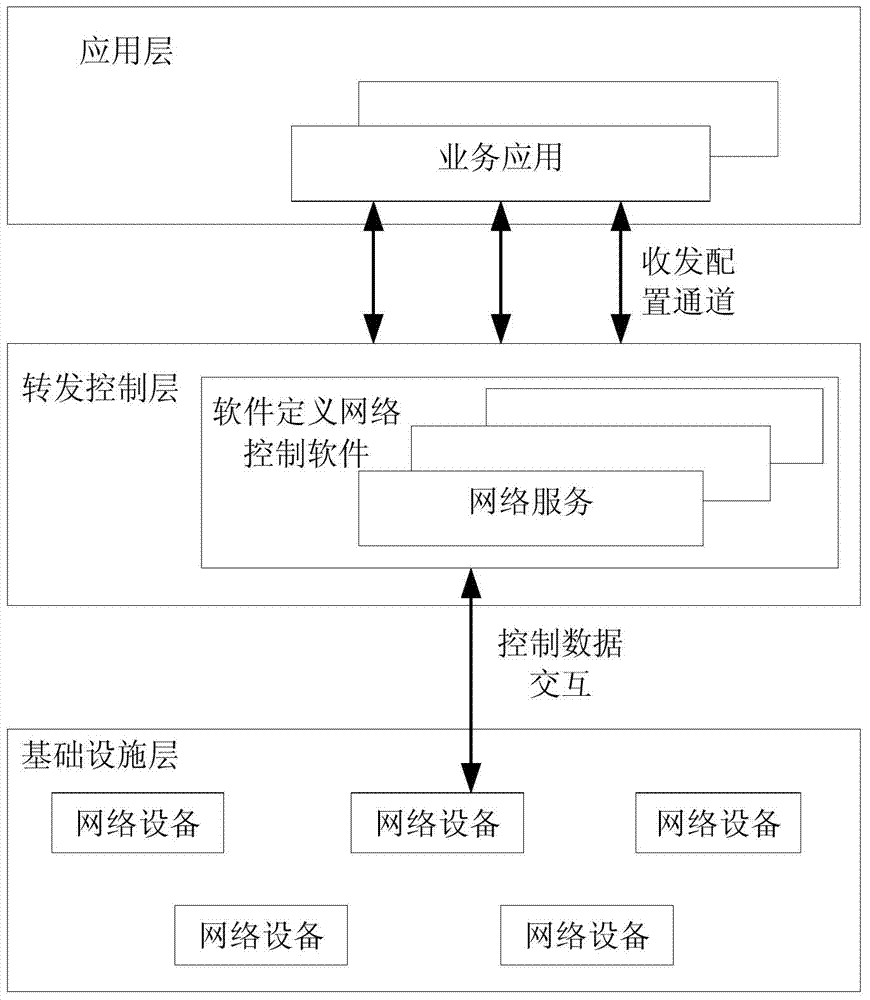

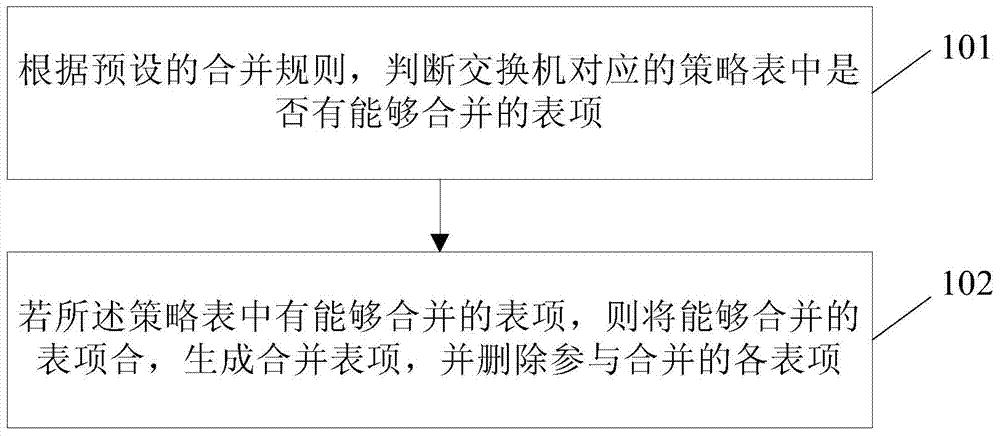

Strategy table entry collocation method, device and system

ActiveCN103795644AReduce the number of entryIncrease profitData switching networksData miningCollocation method

The invention provides a strategy table entry collocation method, device and system. The method comprises the steps that according to a preset combining rule, whether a strategy table corresponding to an exchanger has table entries capable of being combined or not is judged; if the strategy table has the table entries capable of being combined, the table entries capable of being combined are combined to generate combined table entries, and the table entries participating in combining are deleted. According to the technical scheme, by combining the table entries capable of being combined in the strategy table, the number of the table entries in the strategy table can be effectively reduced, and the using rate of strategy table resources can be effectively improved. Compared with an existing method using a TCAM mode for expanding the corresponding strategy table volume of the exchanger, the strategy table entry collocation method has the advantage that cost investment can be reduced.

Owner:RUIJIE NETWORKS CO LTD

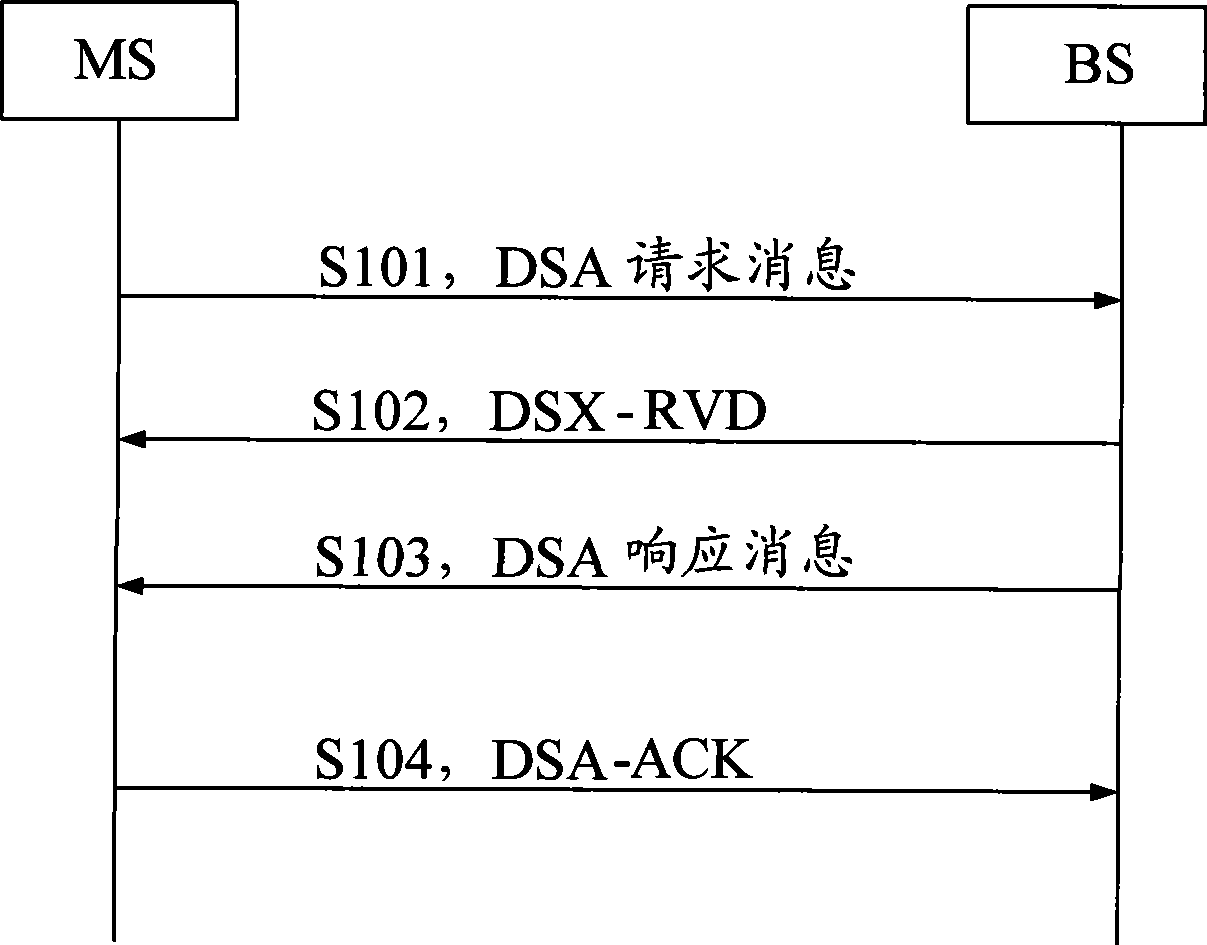

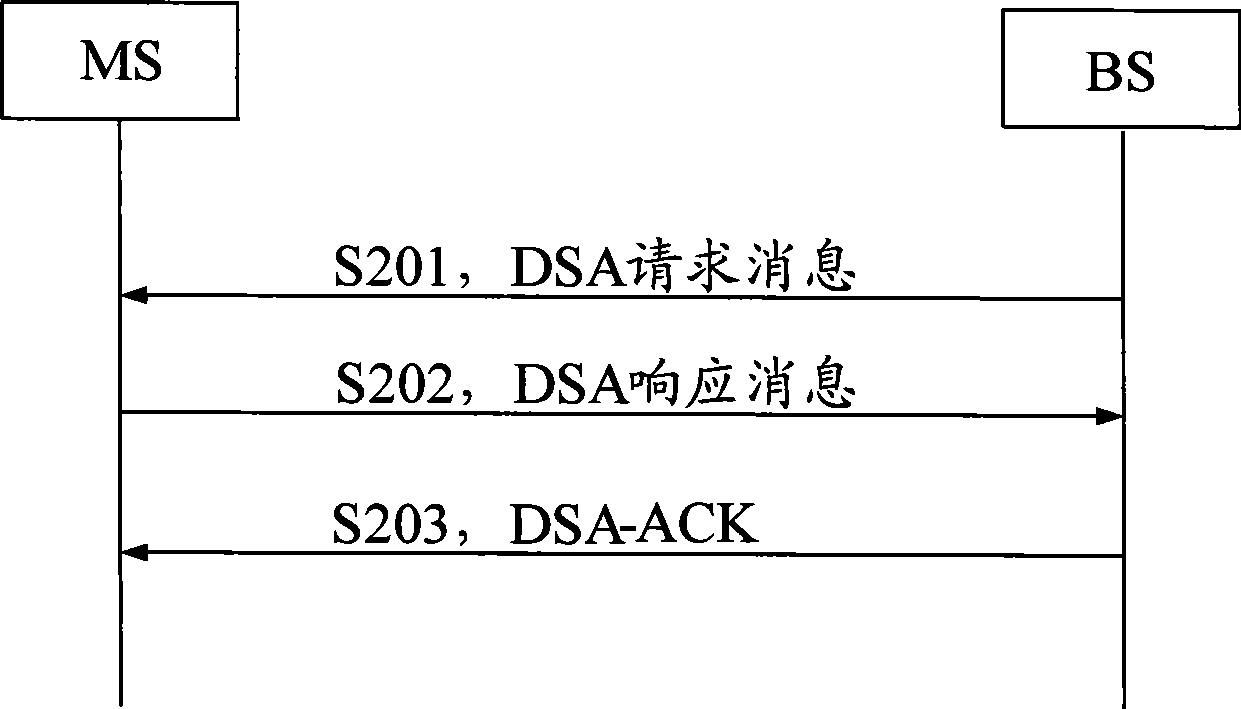

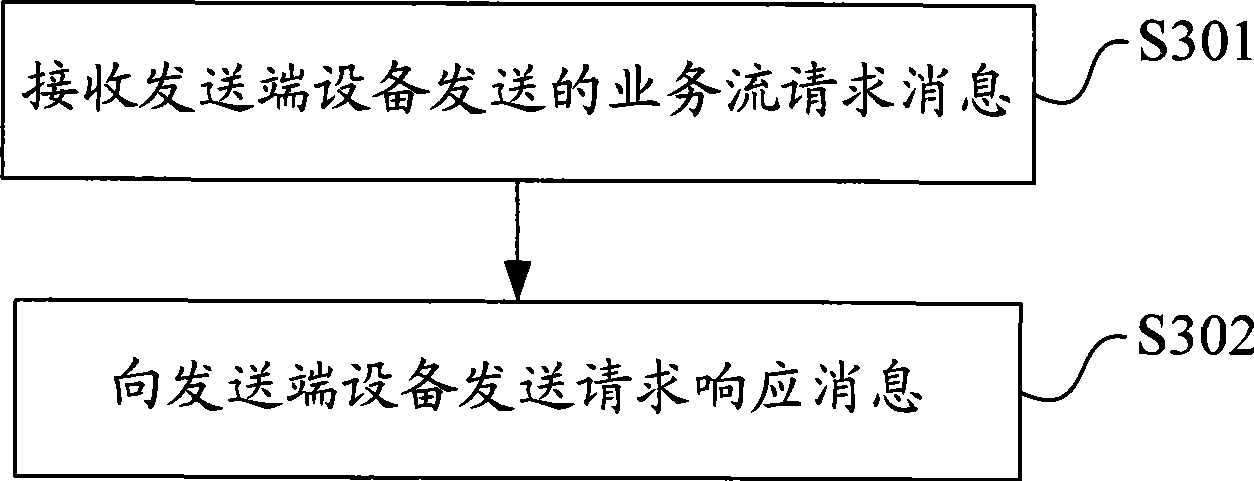

Method, system and apparatus for configuring HARQ parameter

InactiveCN101414899AFlexible Quality of ServiceFlexible Quality of Service QoSError prevention/detection by using return channelNetwork traffic/resource managementService flowHybrid automatic repeat request harq

The invention discloses a collocation method for hybrid automatic repeat request HARQ parameters, and the method comprises the following steps: service flow request information which is sent by a sender is received, and the service flow request information carries the HARQ parameters which are required by a sender device; and a request response message is sent to the sender device. The embodiment of the invention also provides a collocation system and a device for the HARQ parameters. By the embodiment of the invention, different HARQ parameters are collocated for different service flows, thus making up the defect that the HARQ parameters of different service flows are collocated without distinguishing in the prior art and ensuring better quality of service (QoS).

Owner:王广杰

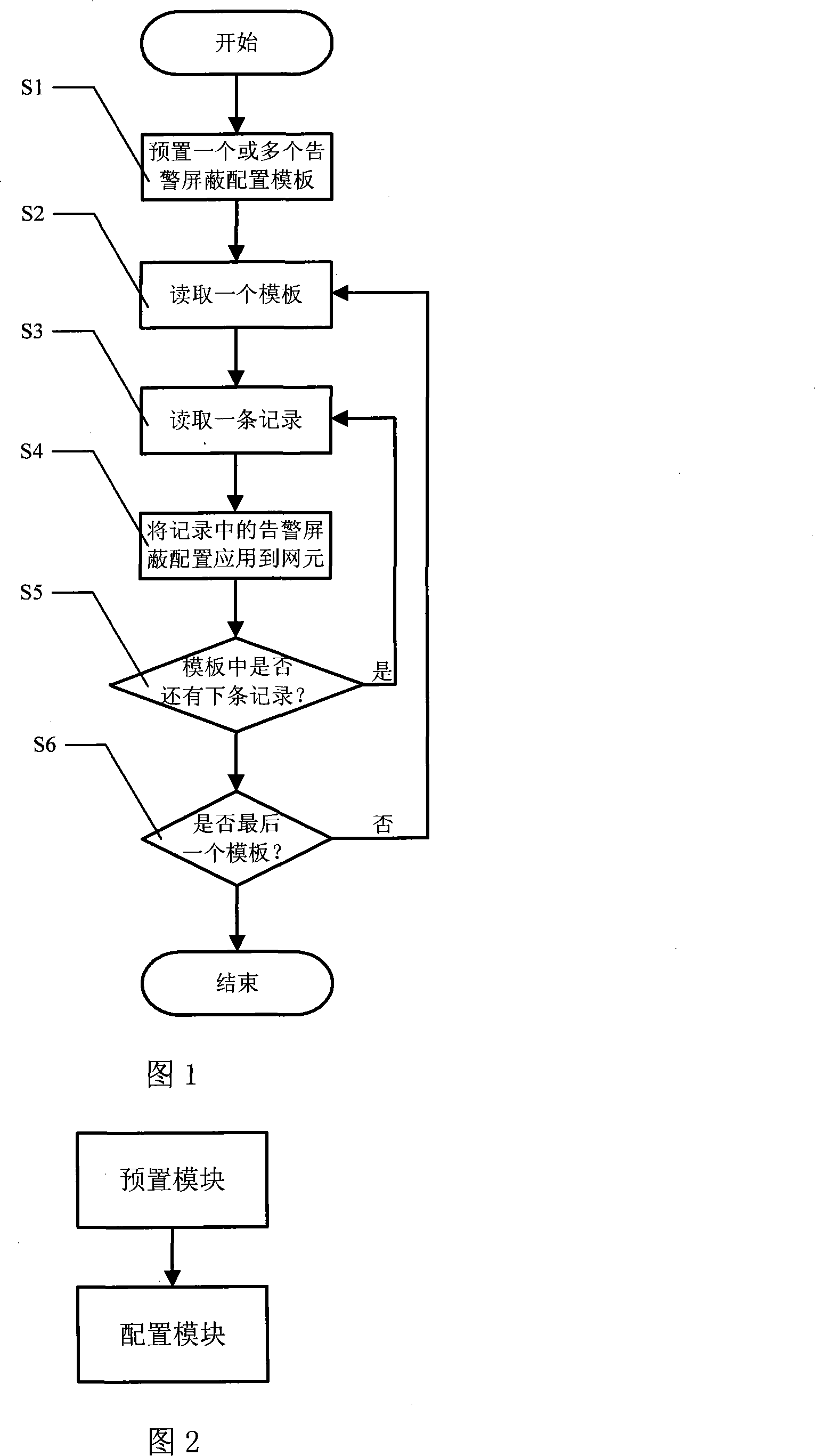

A collocation method and system of alarming shielding

ActiveCN101217315AImprove usabilityImprove efficiencySupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsConfiguration itemEngineering

The invention discloses a configuration method and a configuration system for alarm shielding and comprises following steps: (A) one or more alarm shielding templates which have at least one record are prearranged, and the record comprises at least one alarm shielding configuration item; (B) The invention implements the alarm shielding configuration on an element location to be configured according to the alarm shielding configuration item. The configuration system comprises a prearranging module which is used for prearranging one or a plurality of alarm shielding templates that have at least one record, and the record comprises at least one alarm shielding configuration item, a configuration module which is used for implementing the alarm shielding configuration on an element location to be configured according to the alarm shielding configuration item in the configuration module. By prearranging the alarm shielding configuration templates, the invention can select the element location which needs configuration to implement selected configuration for once, thus remarkably improving the usability and the efficiency of alarm shielding configuration.

Owner:ZTE CORP

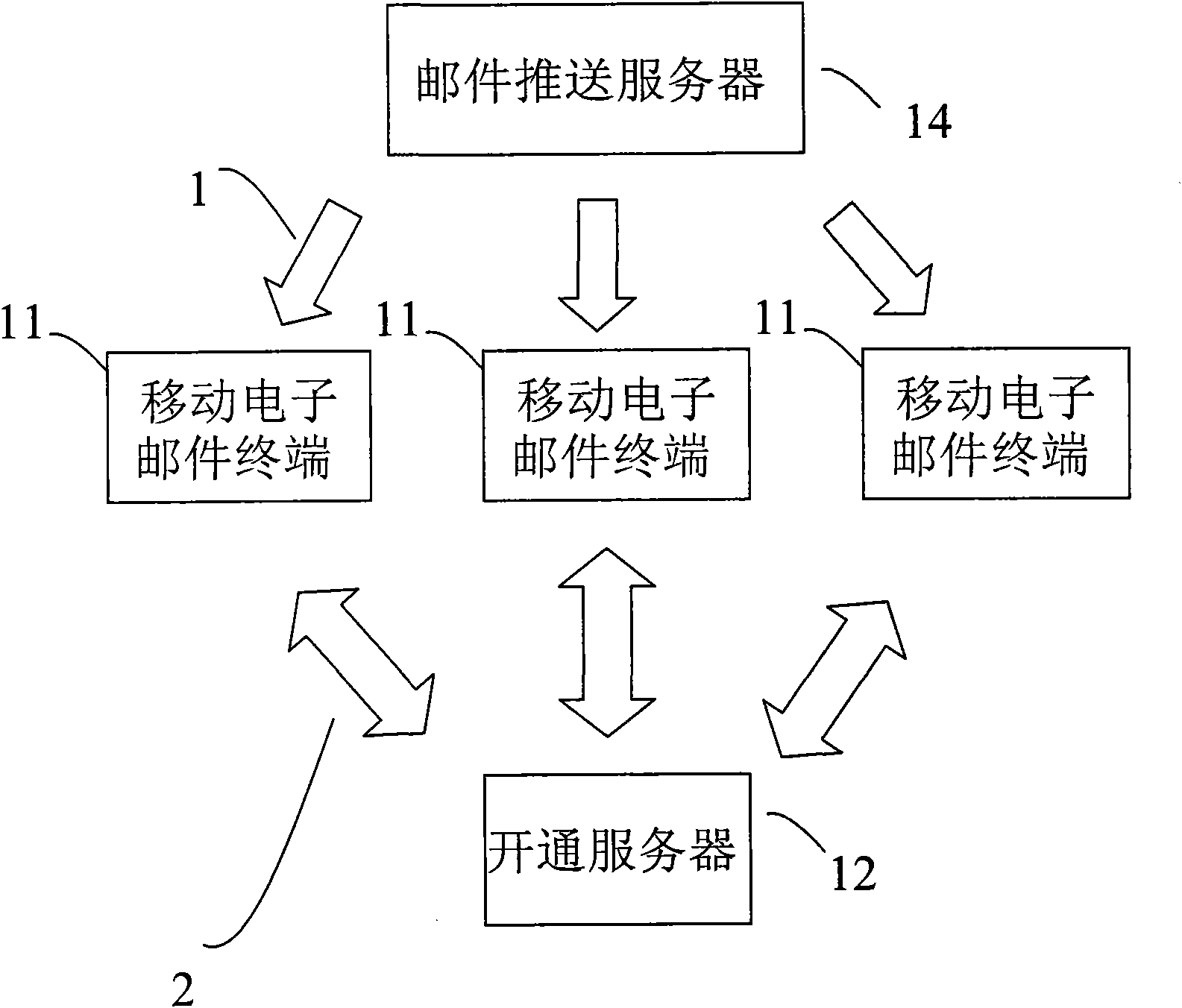

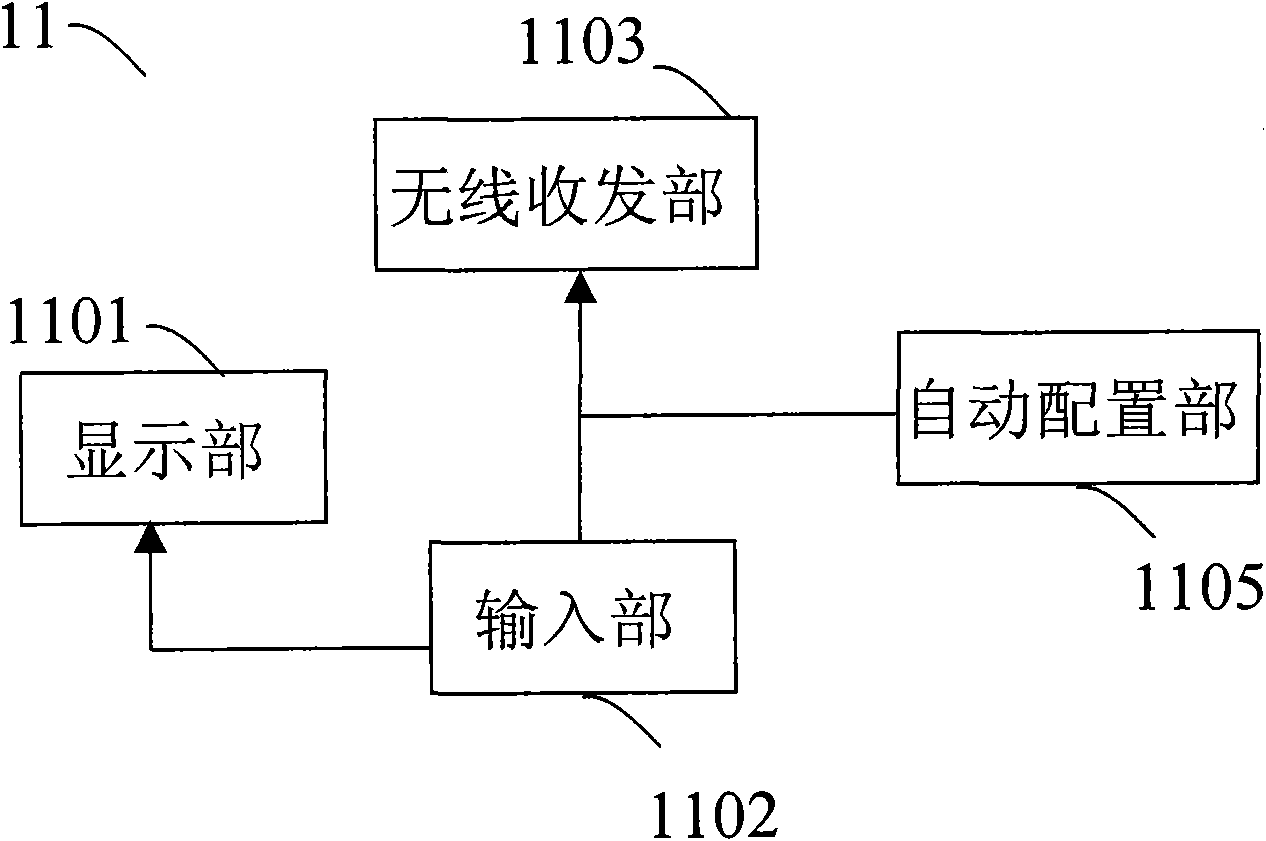

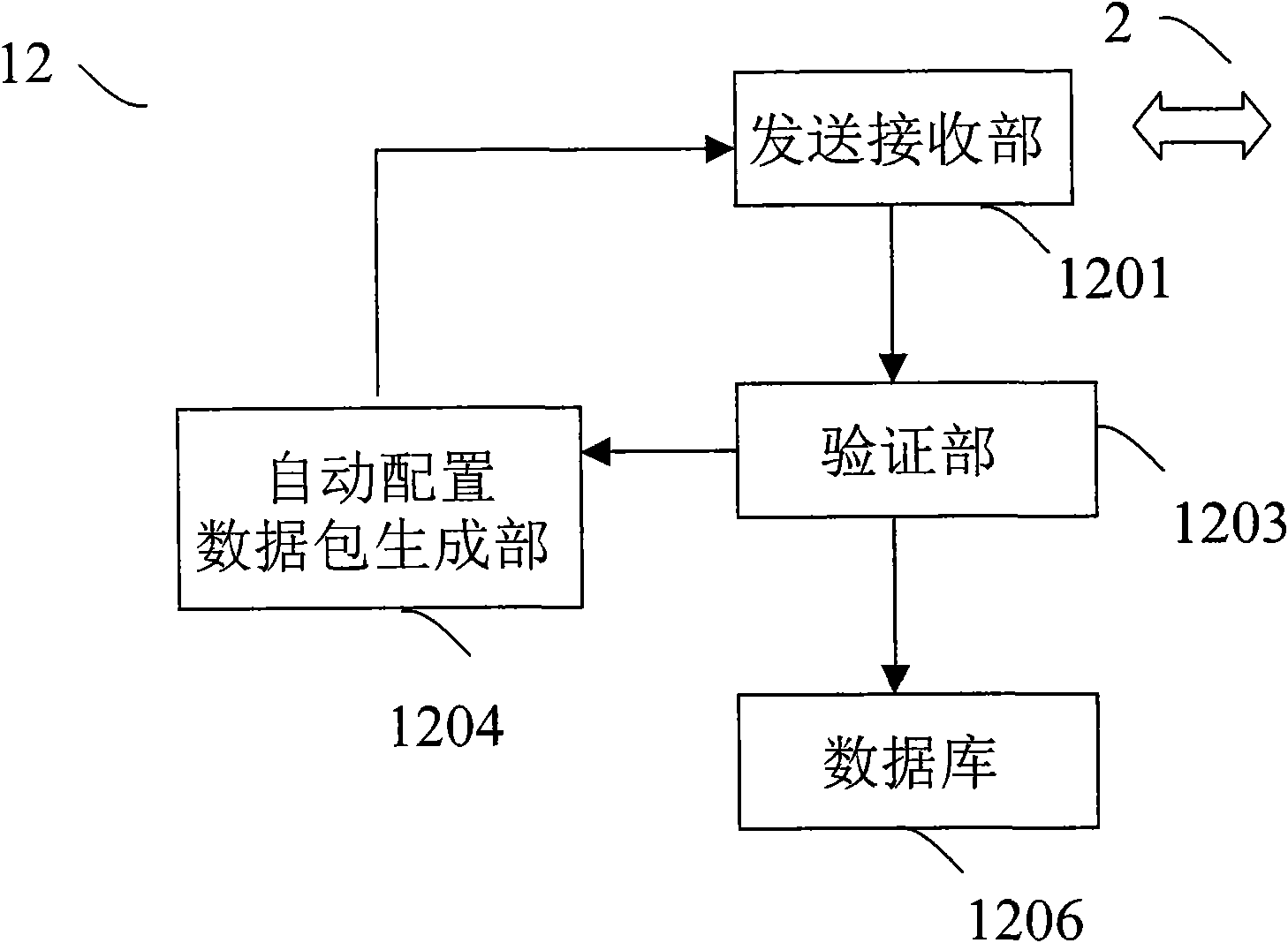

Automatic collocation methods of mobile E-mail system and network

InactiveCN101600166AMessaging/mailboxes/announcementsSecurity arrangementCollocationAuto-configuration

The invention provides an automatic collocation method of a mobile E-mail system. The mobile E-mail system at least comprises a mobile terminal, a mail delivery server for delivering a mail to the mobile terminal, and an opening server for automatically collocating the parameter of the mail delivery server in the mobile terminal. The automatic collocation method of a mobile mail is used for the opening server and comprises the following steps: receiving an opening request from the mobile terminal; validating whether the mobile terminal is legal or not according to the identify information contained in the opening request; sending automatic collocation data containing the parameter of the mail delivery server to the mobile terminal under the condition that the validation is legal and finishing the automatic collocation of a mobile E-mail by the mobile terminal, thus the collocation of various parameters in the mobile terminal can be automatically finished without manual operation by users.

Owner:LENOVO (BEIJING) CO LTD

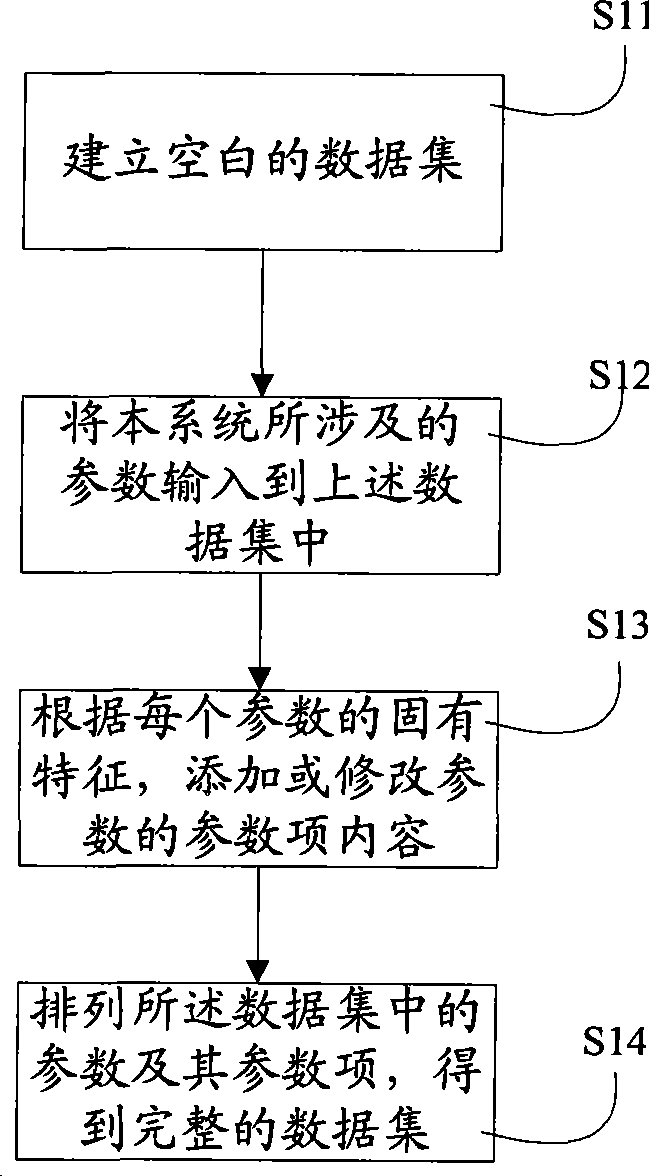

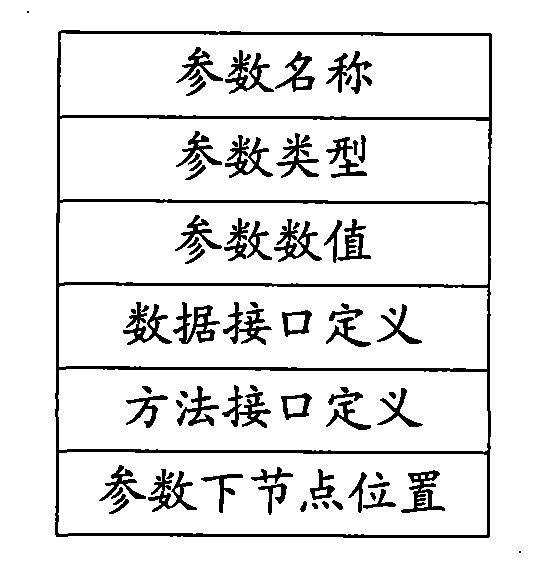

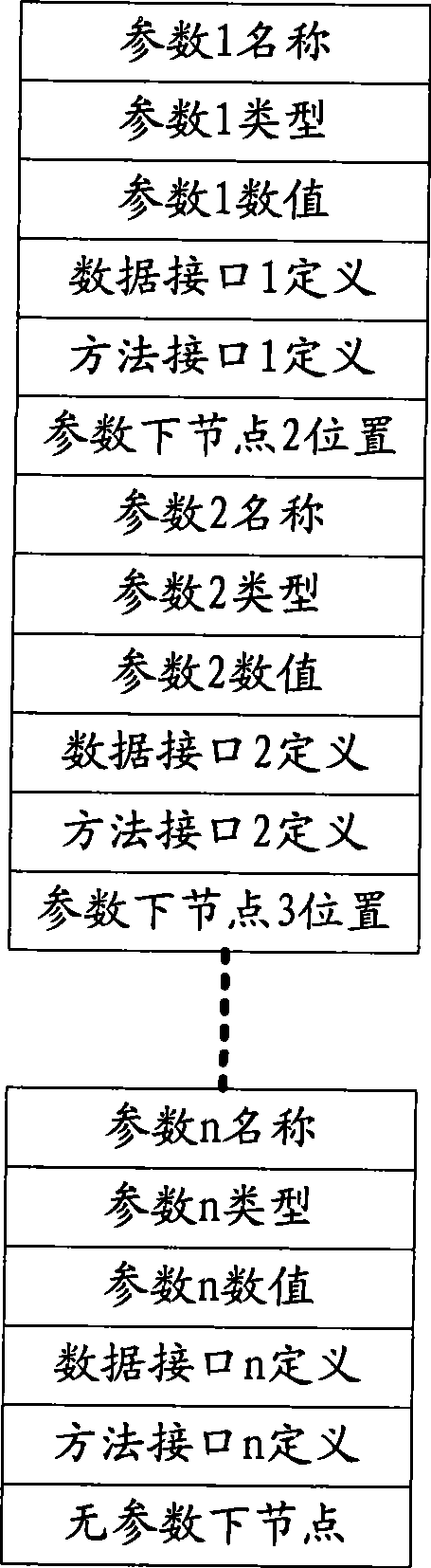

Configuration method and device for embedded system

ActiveCN101364175ARealize unified managementVersatileSpecific program execution arrangementsCollocationData set

The invention relates to a collocation method for an embedded system. The method comprises the following steps: a data set is set, and parameters relevant to the system are stored in the data set; the parameters are described in the data set; a data collocation file is set, and the parameters required in the collocation is put in the collocation file; the parametric description in the data set is called out through reading the parameters in the collocation file, and the parameters is collocated to realize the collocation of the embedded system. The invention also discloses a device for realizing the collocation method for realizing the embedded system. The parameter supervising method and the device in the embedded system have the following advantages: when the supervising method of the equipment is changed, the application and structure part of a software is not required to be rewritten, a hardware interface is not required to be redeveloped, and the unified management of a multifunctional and multi-interface platform can be realized through a unified software platform.

Owner:SHENZHEN GRENTECH RF COMM LTD

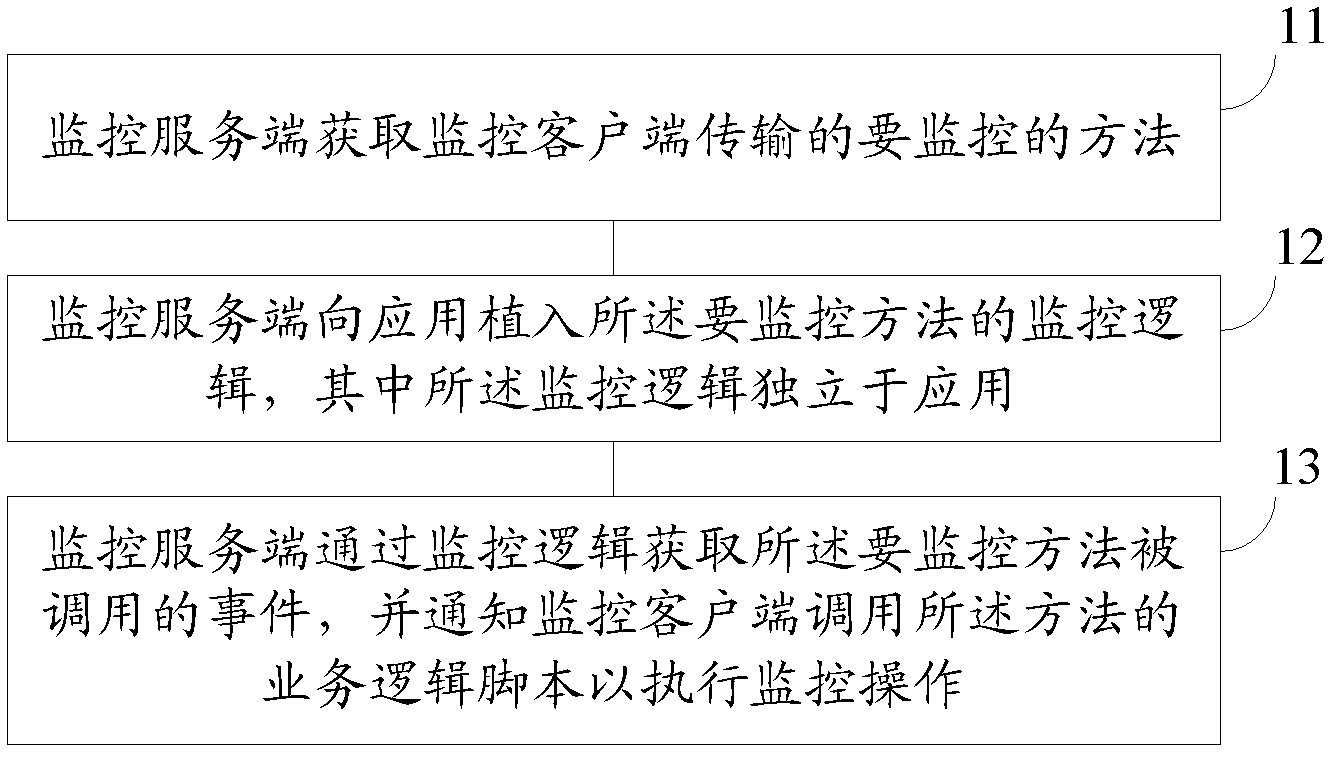

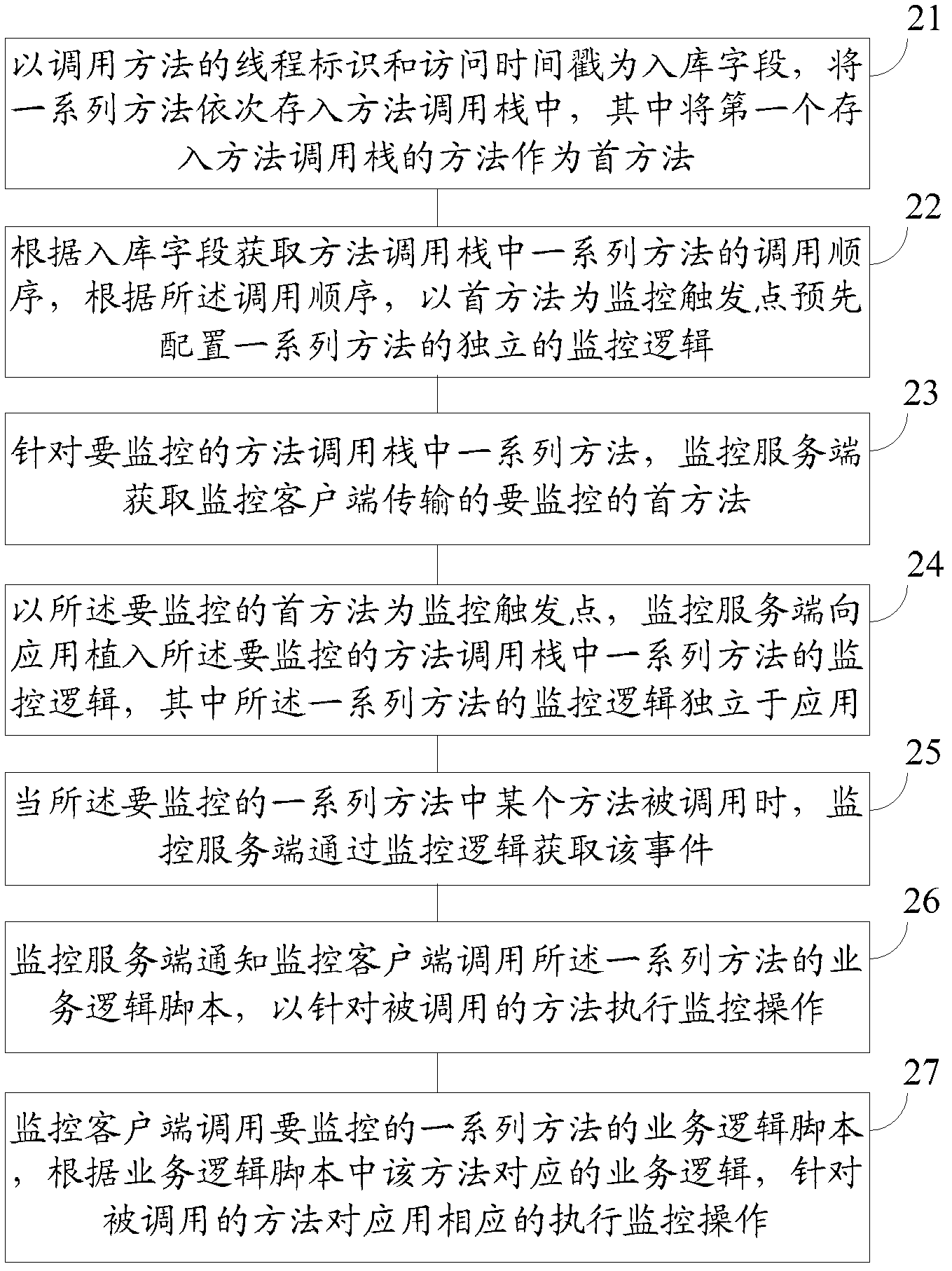

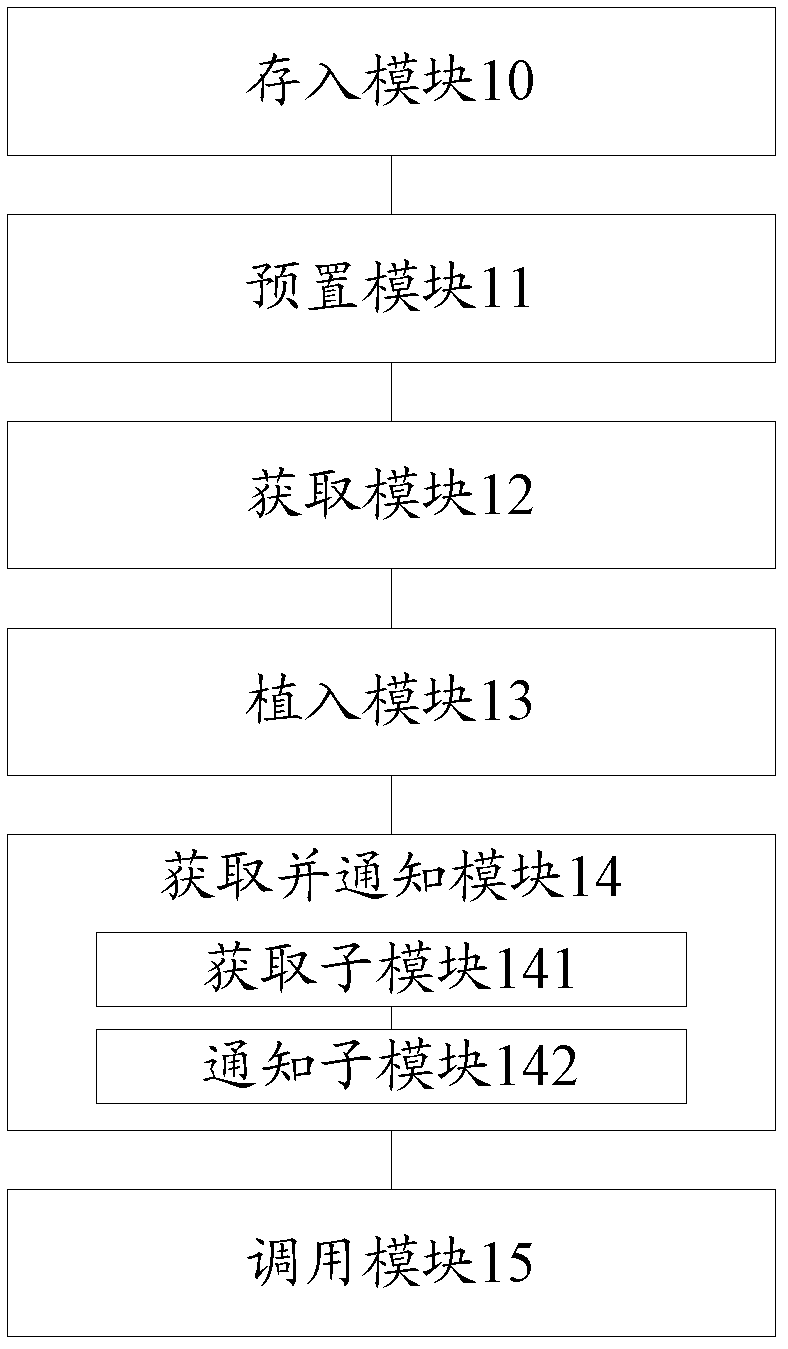

Page monitoring method and system

ActiveCN103176892APerformance is not affectedSimple configurationSoftware testing/debuggingSpecial data processing applicationsClient-sideServer-side

The invention provides a page monitoring method and system and solves the problem that a page monitoring collocation method is complex and wastes time. The method comprises the steps of using a monitoring server side to obtain a method to be monitored transmitted from a monitored client side; using the monitoring server side to plant monitoring logics of the method to be monitored in application, wherein the monitoring logics are independent of the application; and using the monitoring server side to obtain called matters of the method to be monitored through the monitoring logics and notify the monitored client side to call business logic scripts of the method to conduct monitoring operation. The page monitoring method and system is simple in allocation method, saves time, does not need to manually allocate the monitoring logics and business logics directing to the method in the application, cannot influence a structure of the application, and simultaneously has no influences on page performance.

Owner:ALIBABA GRP HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com