Low emission high-power staged-combustion gas burner and gas collocation method thereof

A gas burner, segmented combustion technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., to achieve stable combustion, not easy to defire, and suppress the formation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

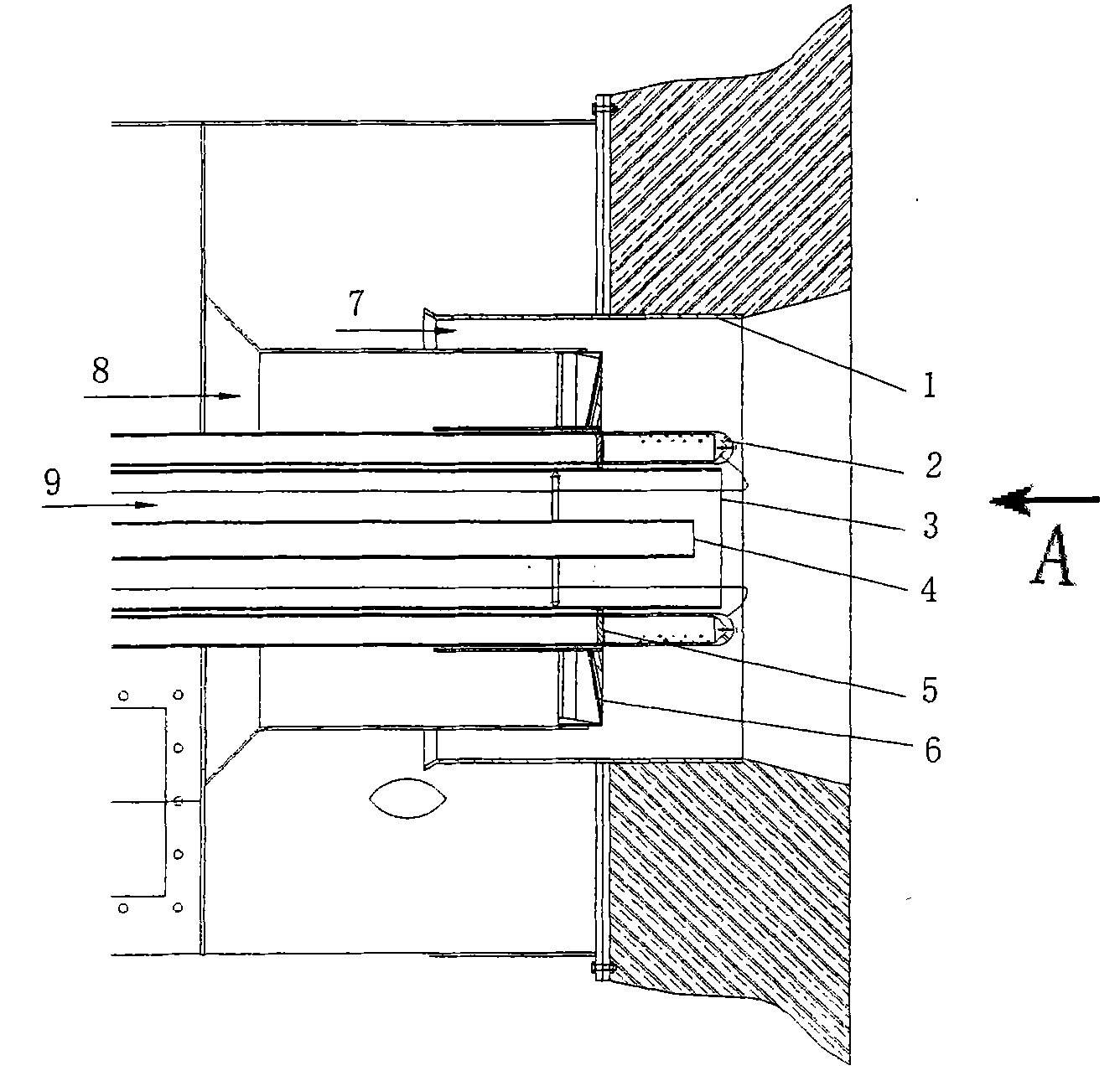

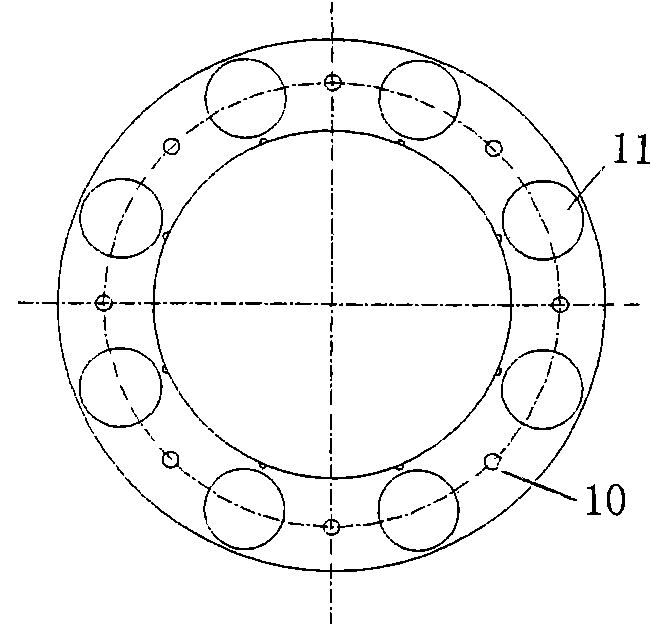

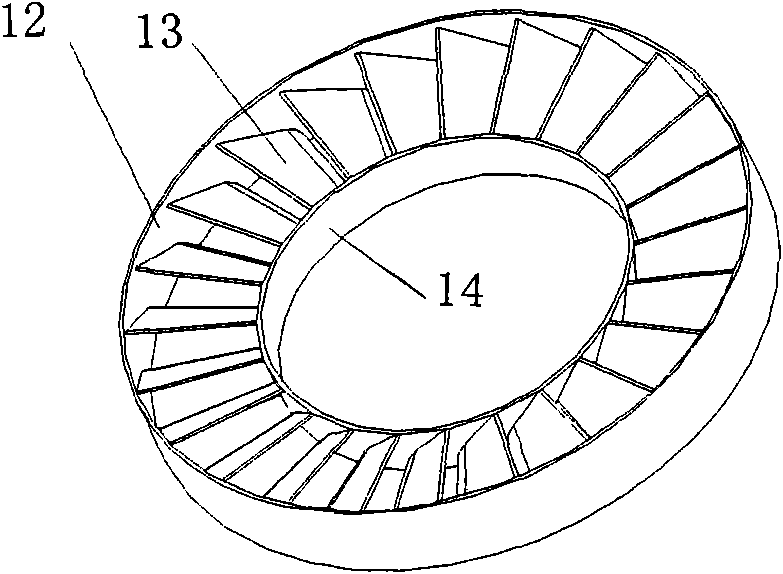

[0018] Such as figure 1 As shown in the schematic diagram of the structure of the throat part of the burner body of the present invention, a low-emission high-power segmented combustion gas burner includes a burner body, a swirler 6 and a flame stabilizing plate 5, and is characterized in that: the burner body In the throat 1 of the throat, from the outside to the inside, a swirler 6, a flame stabilizing disk 5, a central tube 3, and an intermediate tube 4 are sequentially and coaxially arranged. The swirler inner ring 14 and the flame stabilizing disk 5 The outer periphery is connected, the inner periphery of the flame stabilizing plate 5 is connected with the outer surface of the central tube 3, the isodiameter is uniformly distributed on the flame stabilizing plate 5, and the gas gun 2 is fixed axially and fixedly arranged between the gas guns 2 There is a small gas hole A 10, the gas gun 2 is radially arranged with small gas holes B 15 staggered up and down toward the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com