Patents

Literature

33results about How to "Not easy to fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

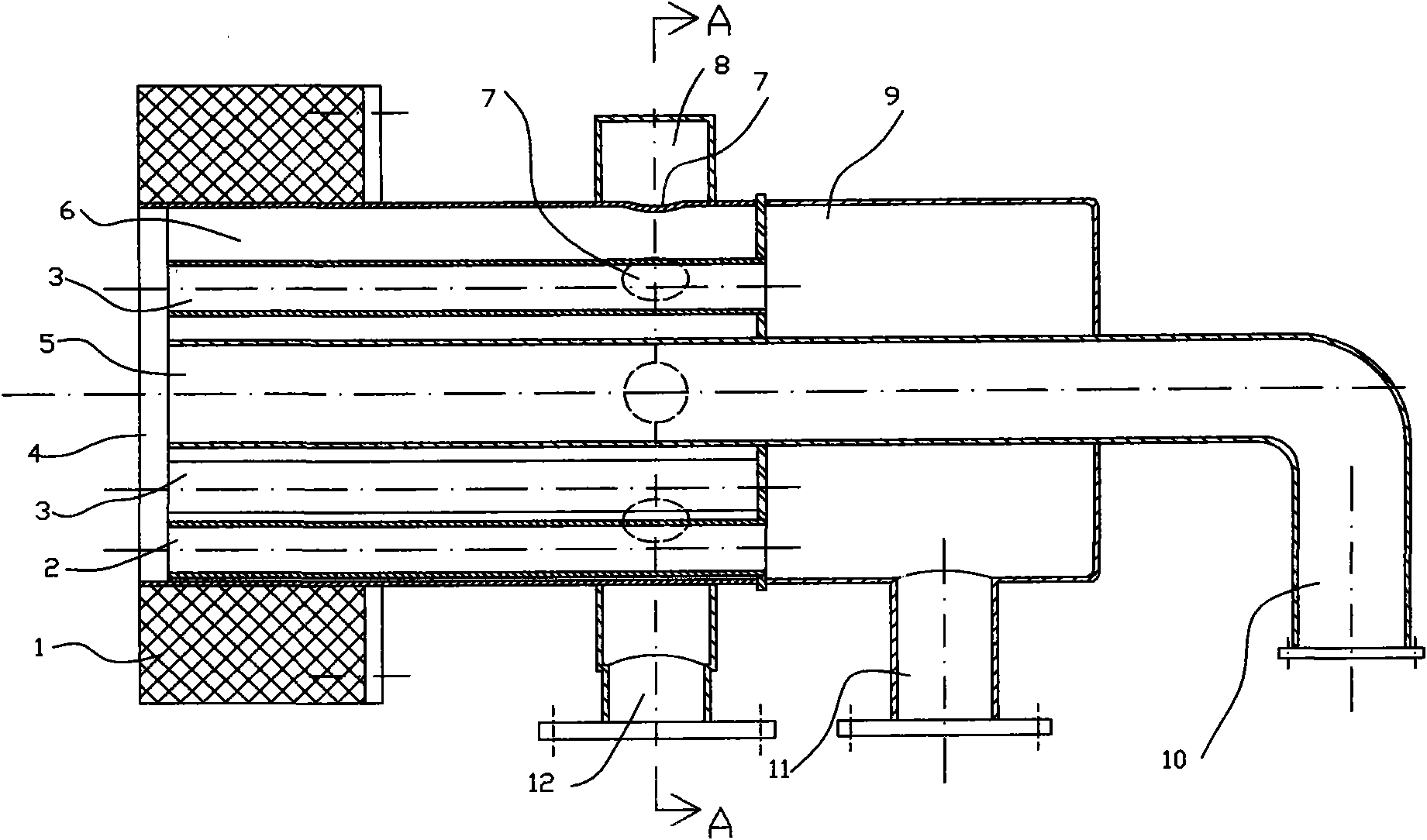

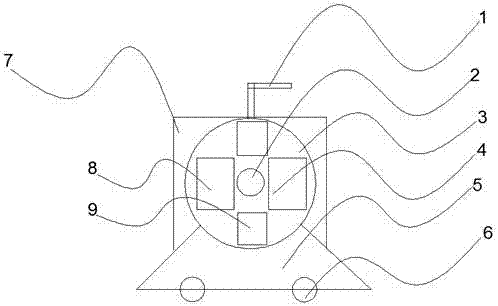

Low emission high-power staged-combustion gas burner and gas collocation method thereof

ActiveCN102003710AReduce the temperatureReduce concentrationGaseous fuel burnerIndustrial gasLow speed

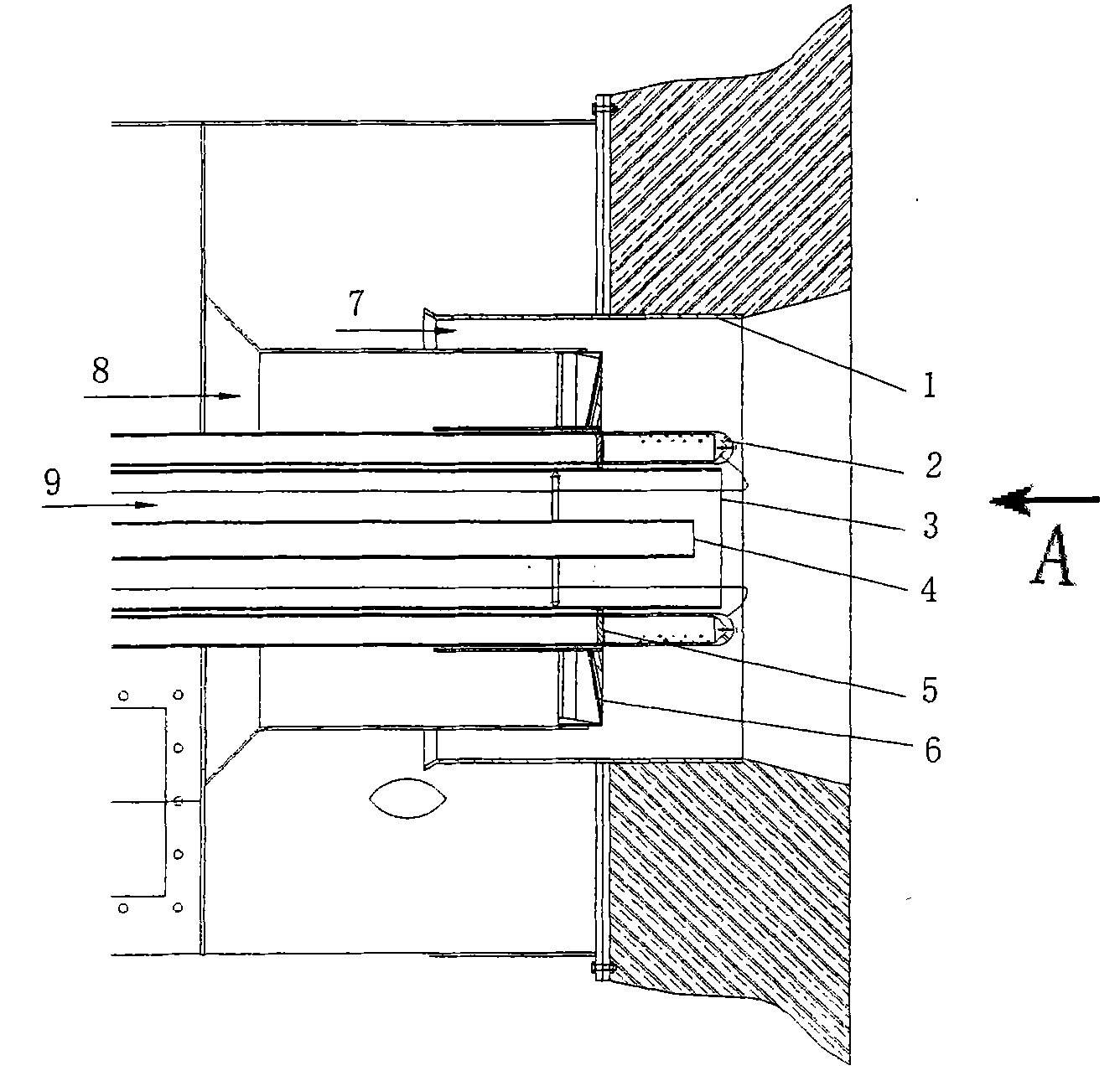

The invention belongs to the technical field of industrial gas burner and relates to a low emission high-power staged-combustion gas burner. The staged-combustion gas burner is characterized in that a swirling machine, a flame stabilizing plate, a central canister and a middle pipe are coaxially arranged in the throat of the burner main body from outer to inner, wherein the flame stabilizing plate is provided with a gas gun which is axially fixed and has same uniformly distributed radial lines. The gas collocation method comprises the following steps: (1) collocating no gas in a direct air channel, in which is low-speed central cooling air, (2) mixing the high-speed swirling air entered from a swirling air channel with the gas jetted from a small gas hole B on the gas gun along the radialdirection till reaching to the semi-premixed state before emerging from the throat of the gas burner, and (3) face-to-face jetting the gas from a big gas hole on the top of the gas gun, the high-speed swirling air and the high-speed peripheral axial air flow so as to form non-premixing diffusion combustion. Because of the air, the staged gas branch supply, the premixing combustion and the non-premixing diffusion combustion, the combustion is uniform and NOx is prevented from being generated. The discharge amount of NOx of the gas burner is 70% lower than that of the common burner in the priorart.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

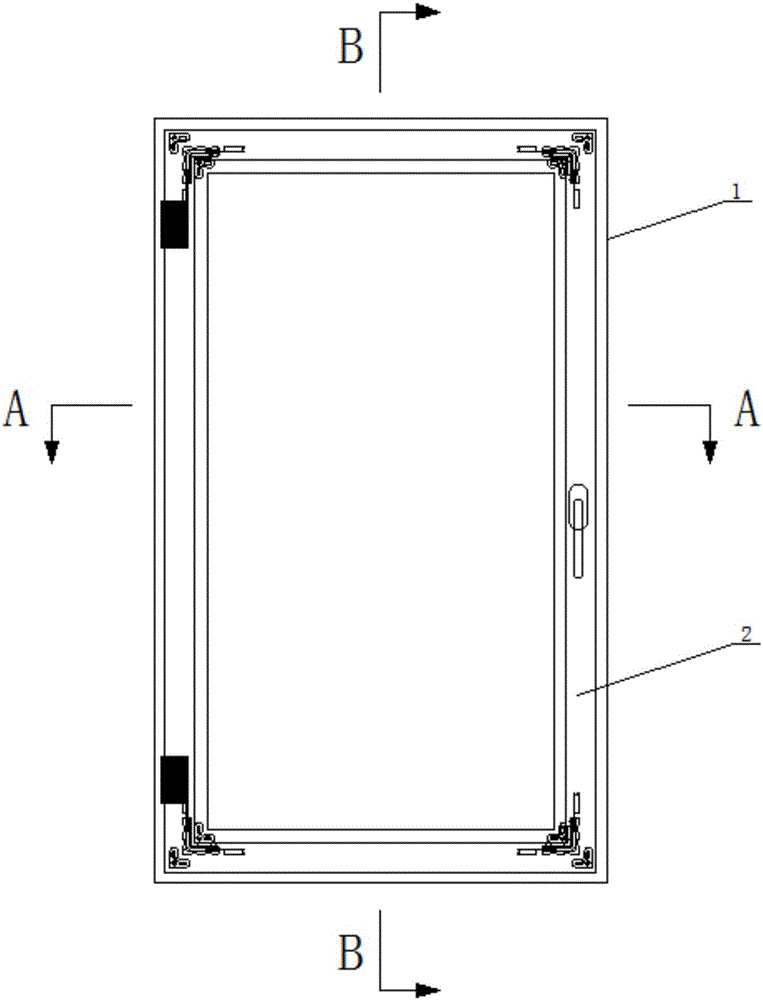

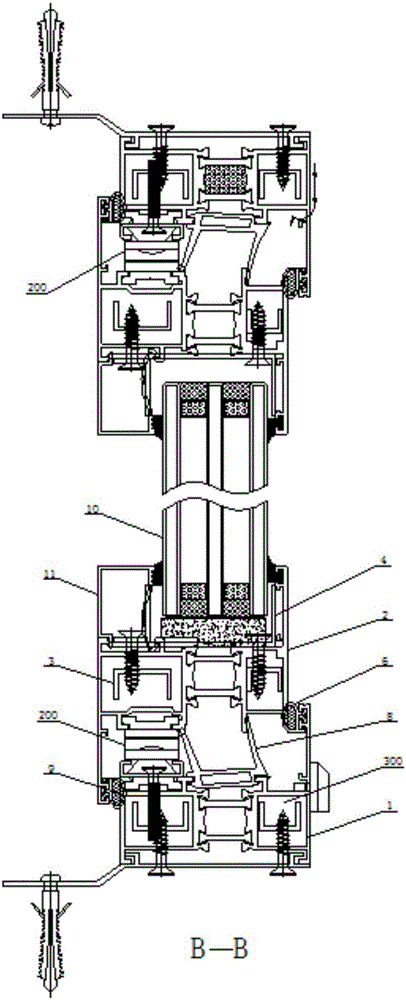

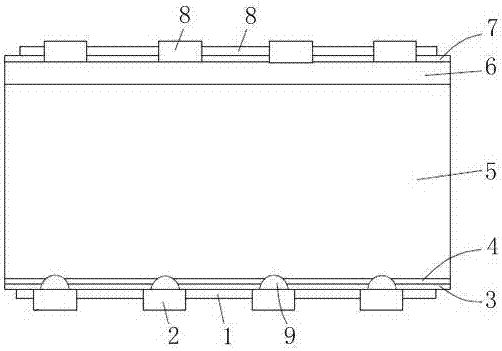

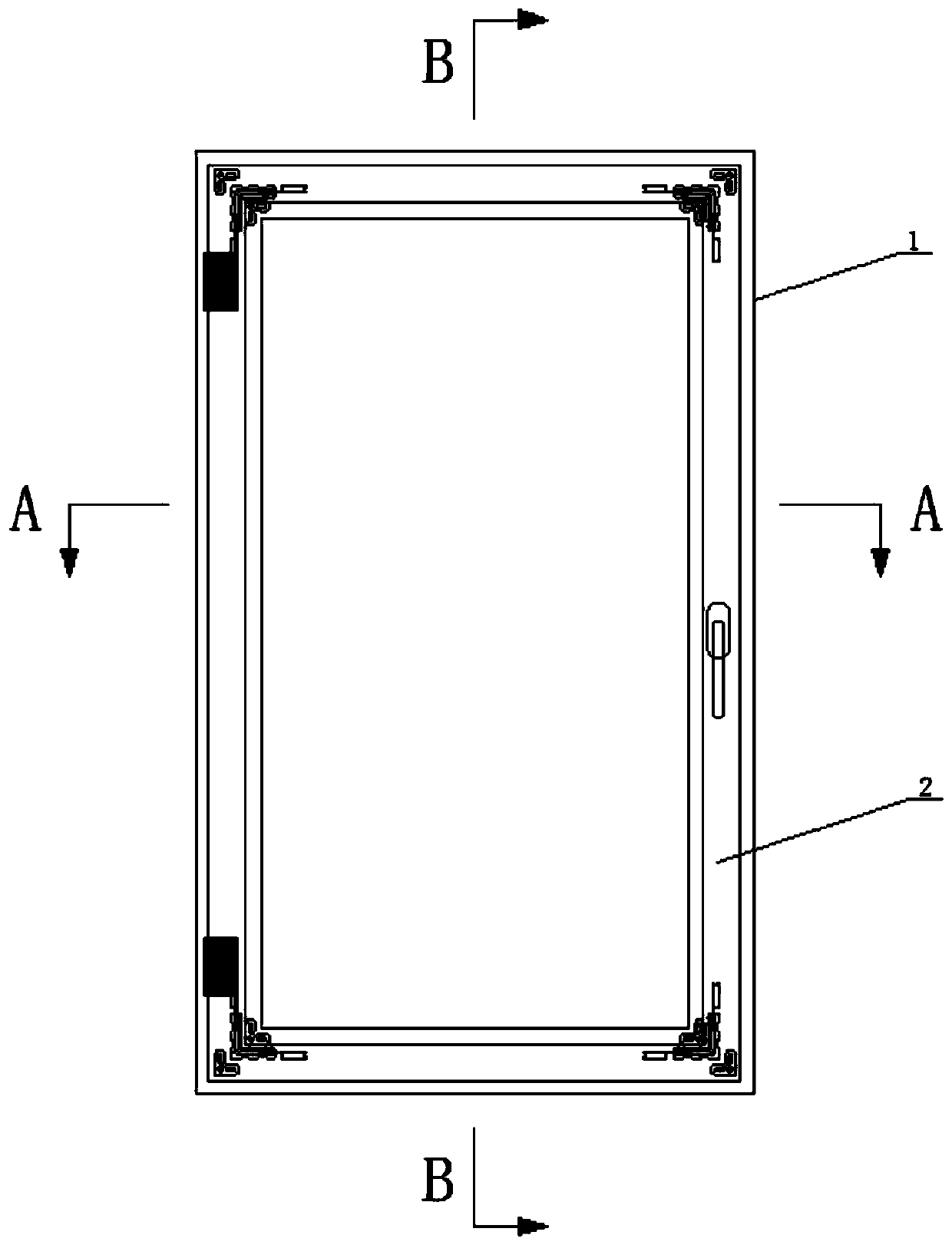

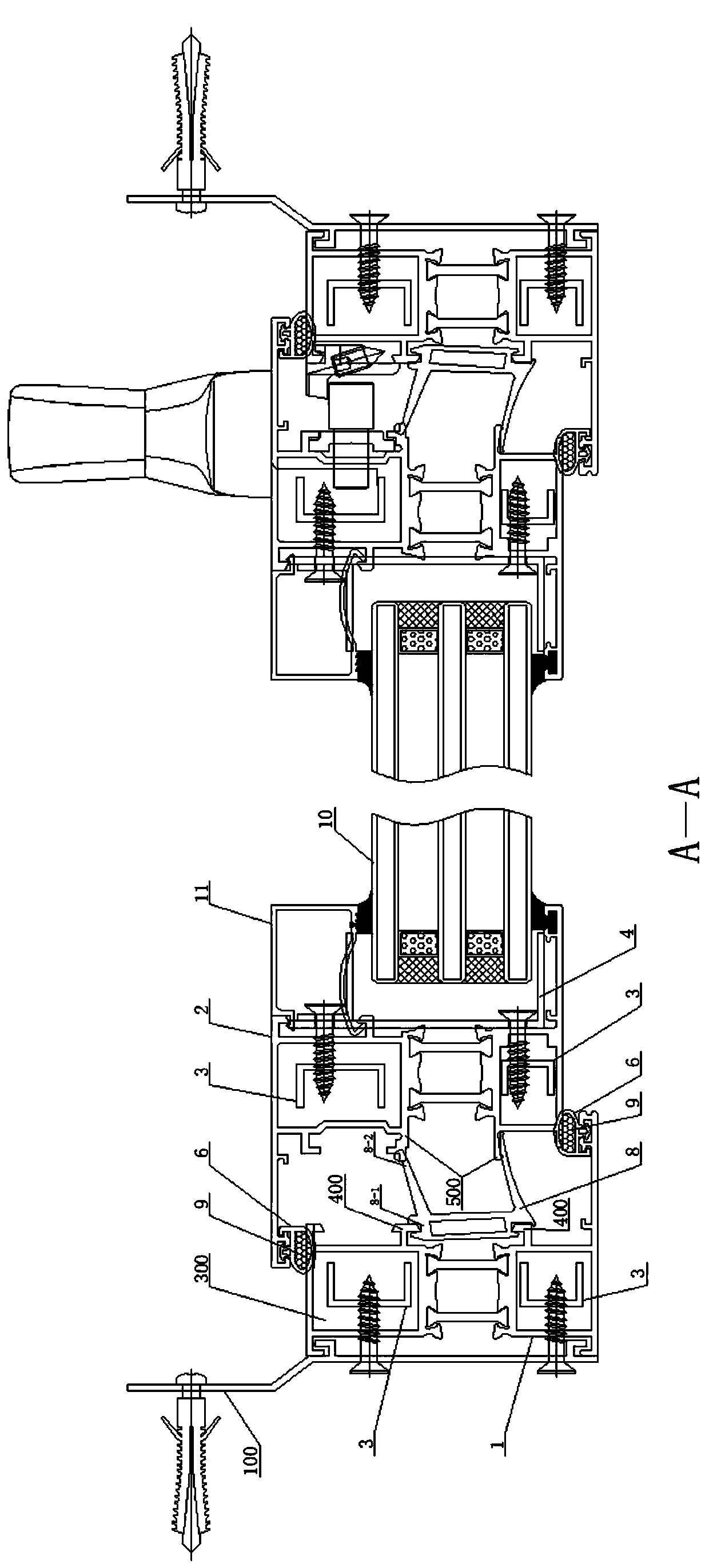

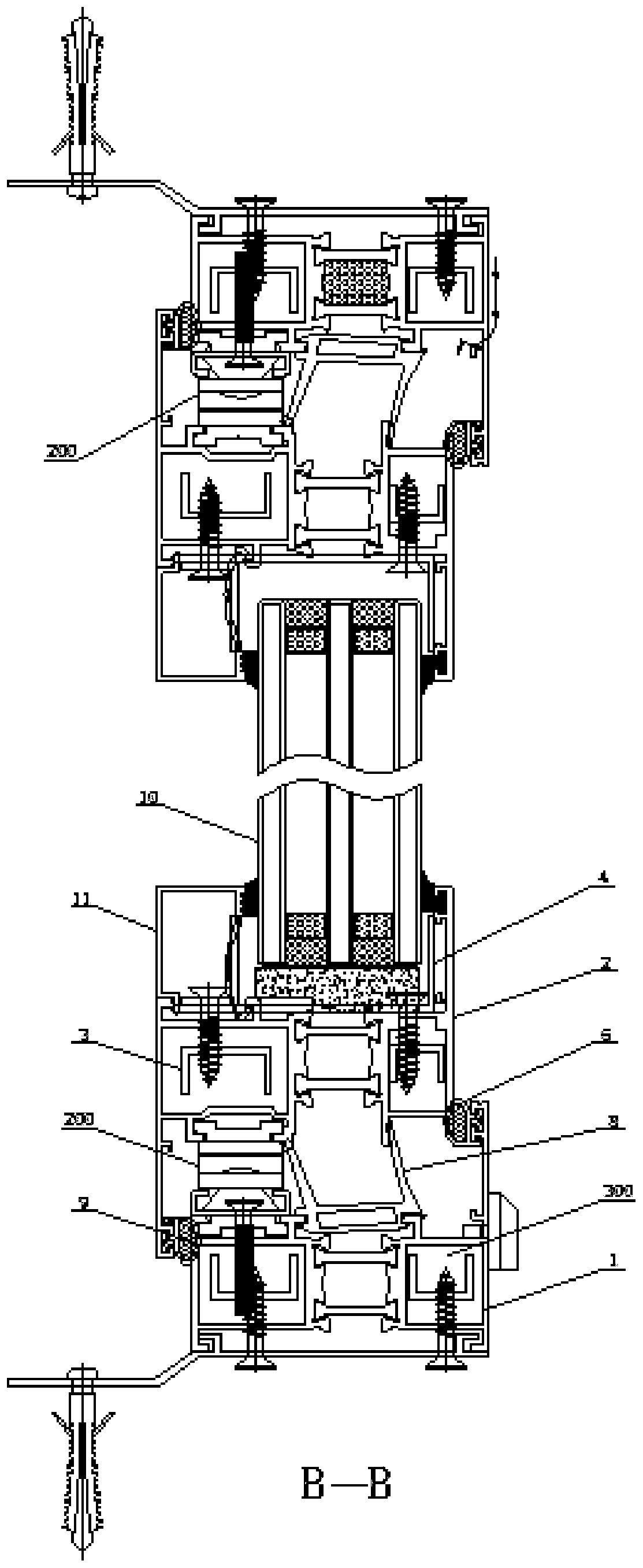

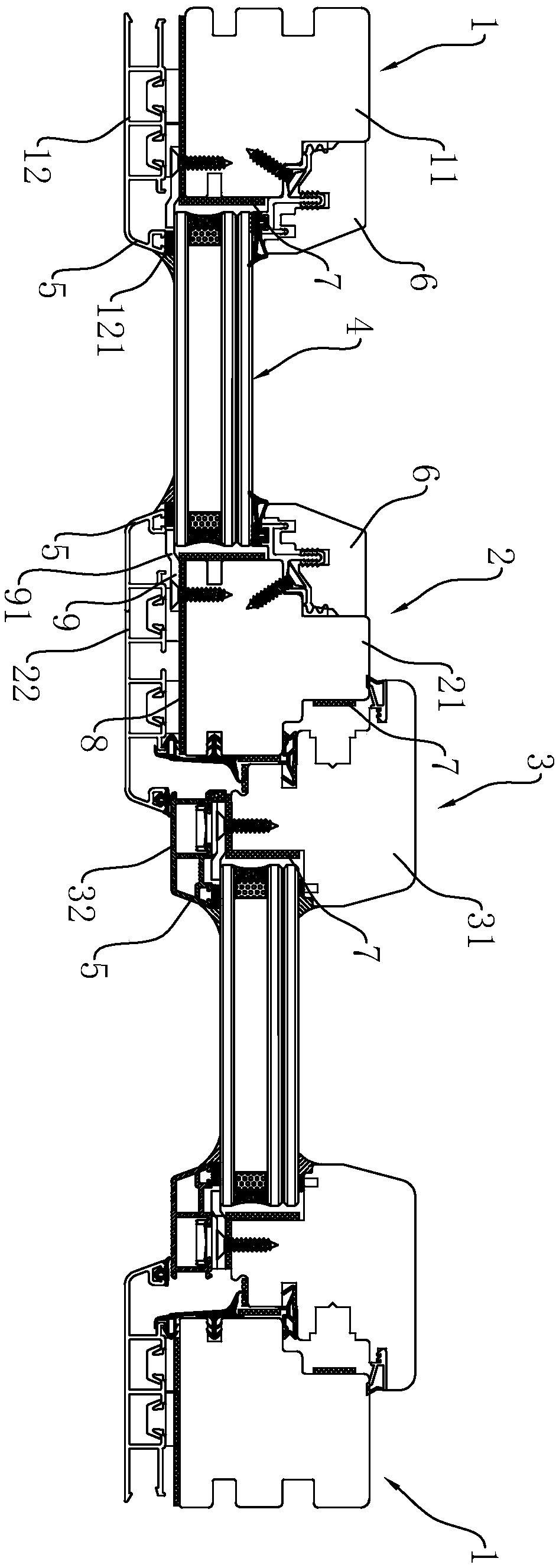

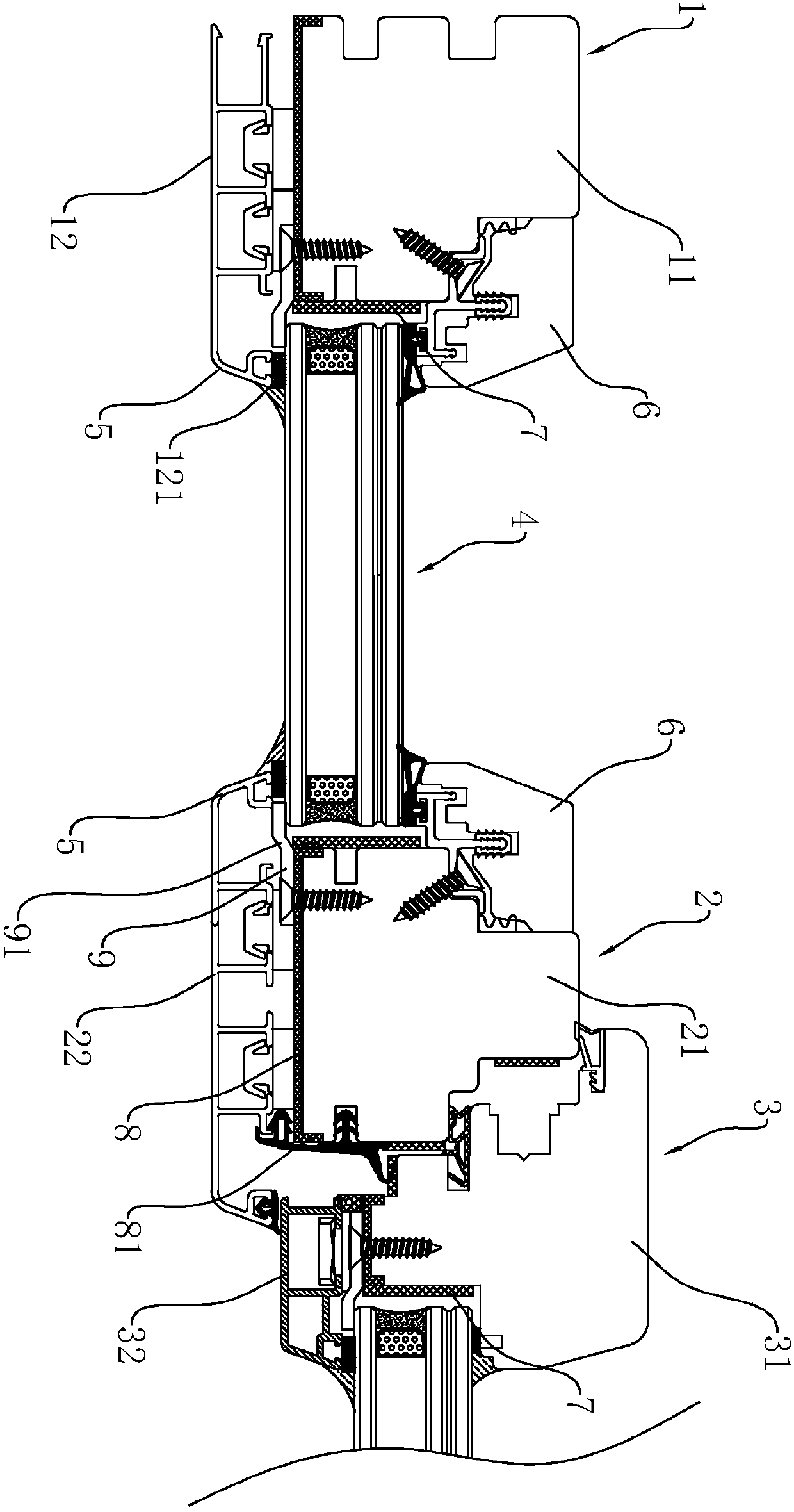

Aluminum alloy thermal-insulation and fire-resistant window

InactiveCN106320902AReasonable structureImprove fire integrityFireproof doorsWindow/door framesSash windowThermal insulation

The invention relates to an aluminum alloy thermal-insulation and fire-resistant window. The window comprises a window frame, a window sash, reinforcing supports and a glass protective frame, wherein the window frame is mounted on a wall, one side of the window sash is connected with the window frame through friction hinges, and a fire-resistant sealing rubber strip is arranged in the lap joint position of the other side and the window frame; the glass protective frame is fixedly connected with the window sash, a hollow cavity is formed in each of the window frame and the window sash, the reinforcing supports are arranged in the hollow cavities, and a fire-resistant and thermal-insulation filling material is injected in the hollow cavities. The window frame, the window sash, a mullion, the glass protective frame, the reinforcing supports and connectors are all fixedly linked, so that the whole window is connected into a whole and cannot be separated or fall off due to external factors such as wind power, fires and the like; the separation or falling resistance of glass is enhanced by the aid of the glass protective frame; the whole window is reasonable in structure and high in practicability, and the wind pressure resistance, whole window air tightness, water tightness and fire-resistant integrity are improved to a certain extent on the premise that the whole window material cost economy is fully considered.

Owner:青岛万和装饰门窗工程有限公司

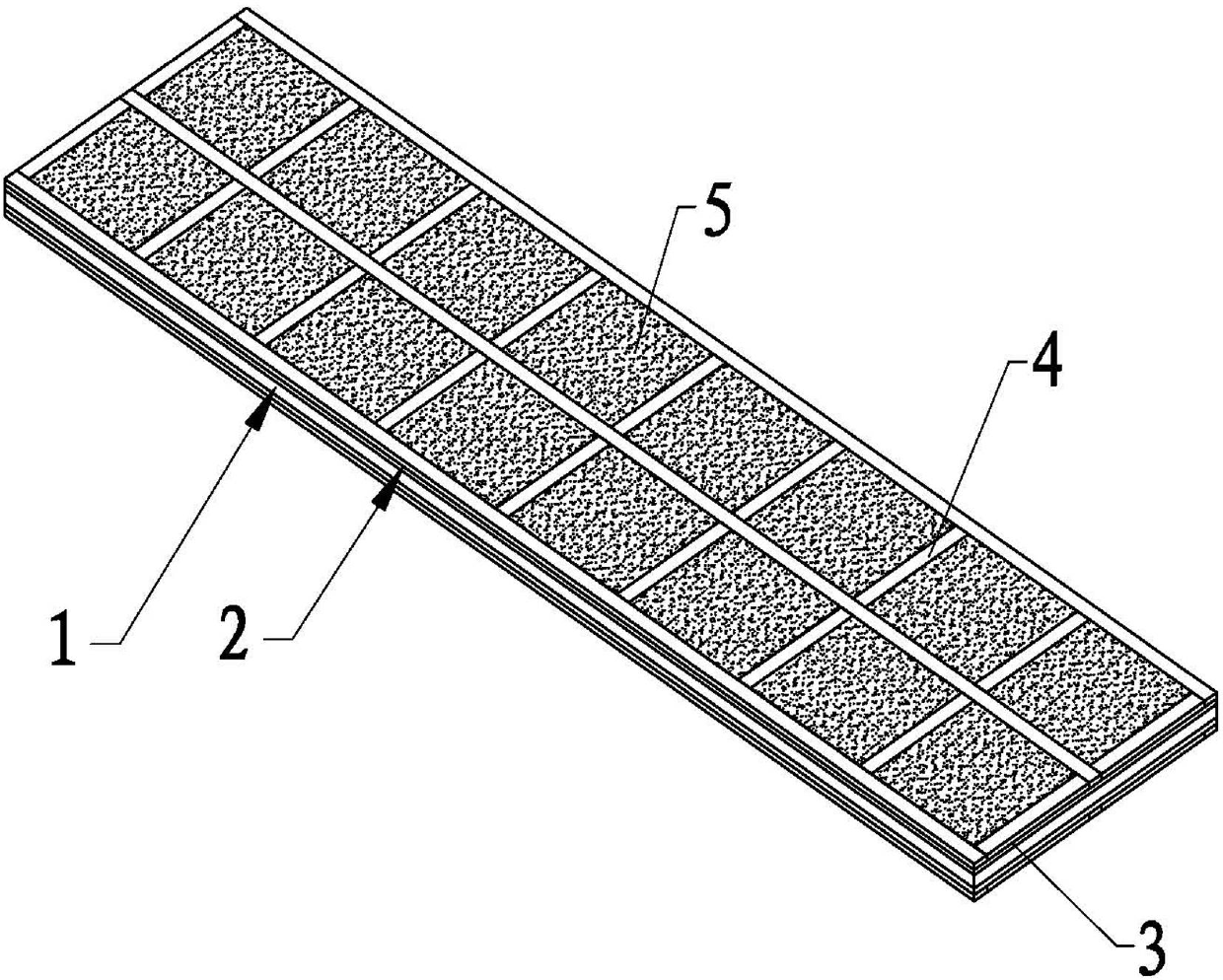

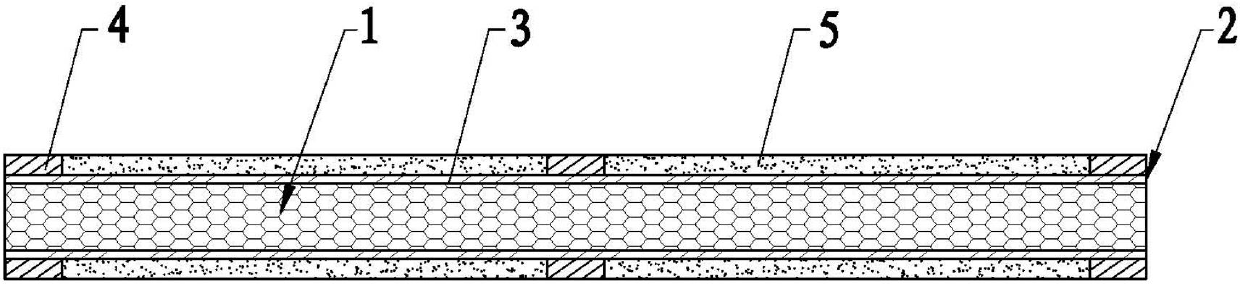

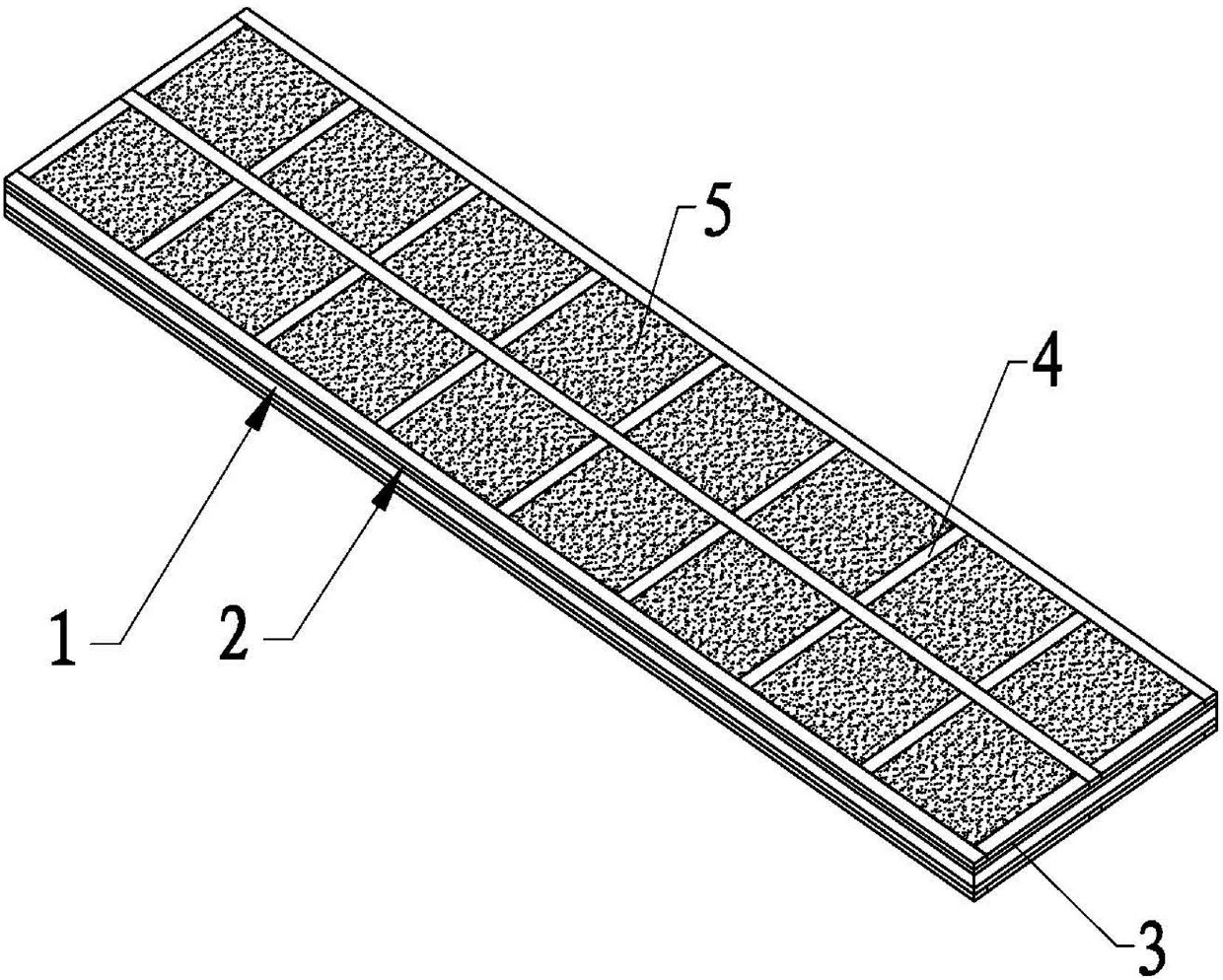

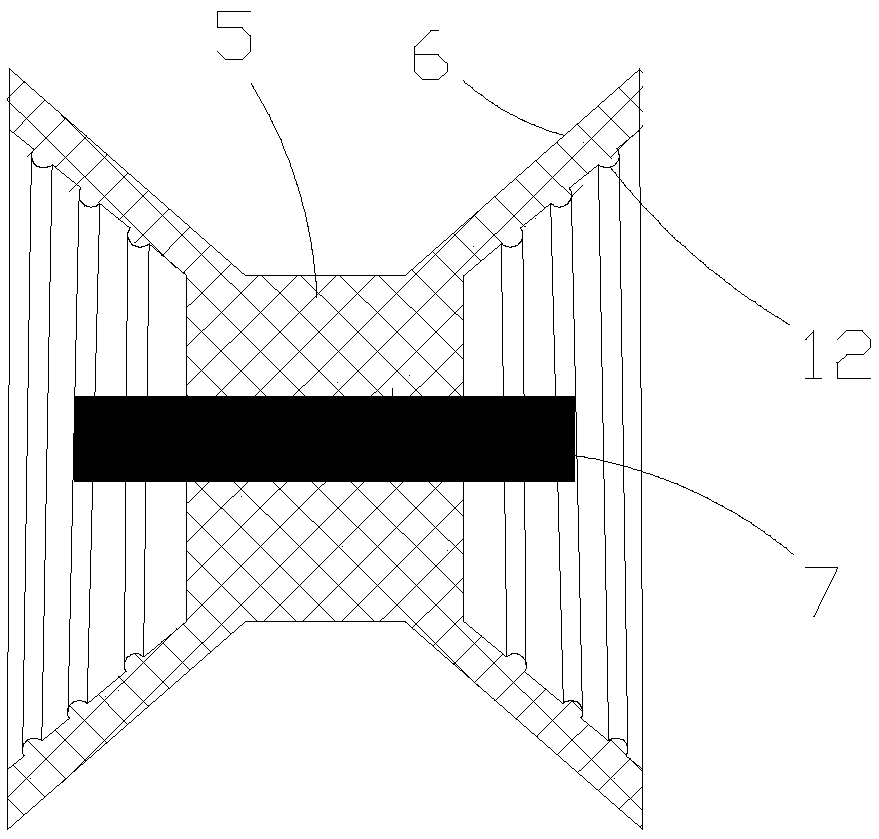

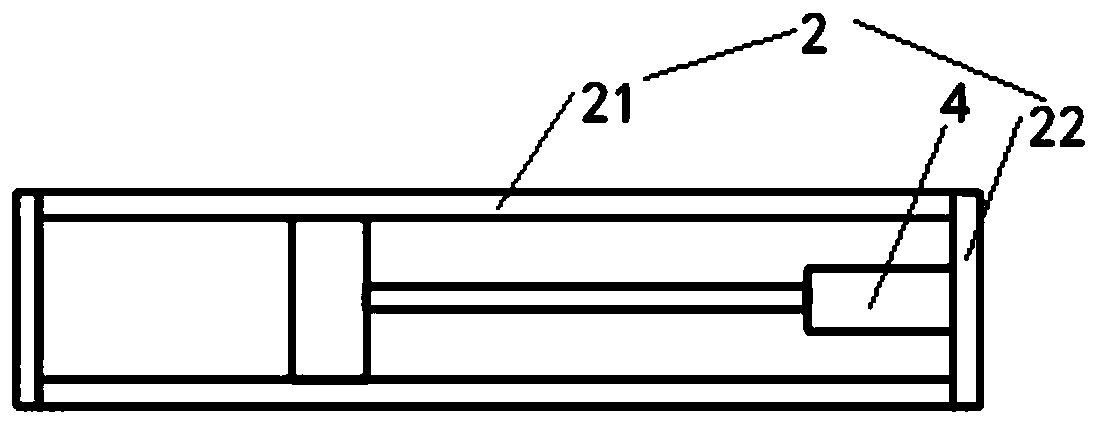

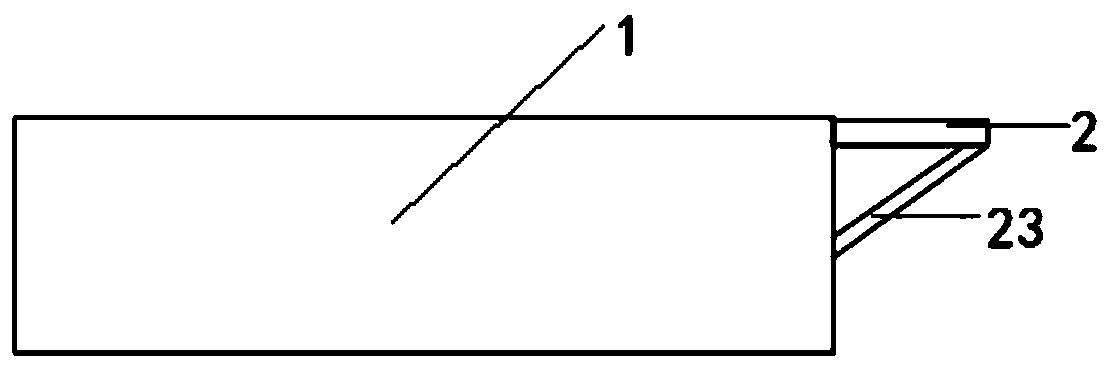

Novel composite partition wall board and production technology thereof

InactiveCN102433957AGive full play to the characteristicsReduce the burden onCeramic shaping apparatusShock proofingFiberEngineering

The invention discloses a novel composite partition wall board and a production technology of the novel composite partition wall board. The novel composite partition wall board comprises a core board (1) and side boards (2) arranged two sides of the core board (1), wherein the core board (1) is adhered to the side boards (2) by resins, each side board (2) comprises a lining board (3), a rib strip (4) and a fiber reinforced gypsum board (5), the rib strip (4) has a frame-shaped structure and is fixed on the outer side face of the lining board (3), and the fiber reinforced gypsum board (5) is arranged in the frame-shaped structure formed by the rib strip (4). The production technology of the novel composite partition wall board comprises the following steps of: firstly, machining a wood board into the lining board (3) and the rib strip (4), and combining the lining board (3) with the rib strip (4); secondly, producing the side boards (2) by the means that the fiber reinforced gypsum board (5) is cast in the rib strip (4); and finally, obtaining a finished product by the means that the gluing, the pre-pressing and the cold-pressing operations are preformed to the core board (1) and the side boards (2). The invention is applicable to the inner partition wall with a frame structure, has the characteristics of being light in weight, high in deformation capability and suspension capability, and good in vibration resistance and thermo-technical performance, and is convenient and fast to construct, thereby being suitable for popularization and use.

Owner:NANJING UNIV OF TECH

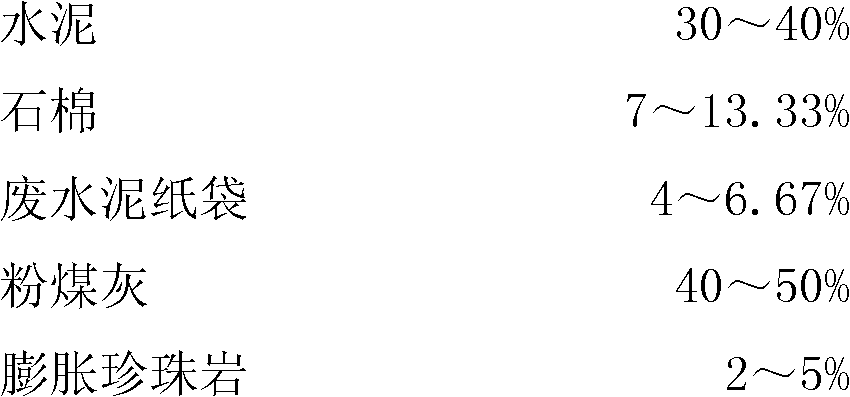

Fiber-reinforced fly ash pressure plate and manufacturing method

The invention relates to a fiber-reinforced fly ash pressure plate and its manufacturing method. Composed of cement, asbestos, waste cement paper bag, fly ash, and expanded perlite, the fly ash pressure plate is prepared by the processes of: pulping, releasing, beating, pulp storage, pulp discharge, pulp flow, vacuum pumping, molding, cold pressing pressurization, precuring, demoulding, autoclaving, drying, sanding, edging and chamfering. The invention provides the fiber-reinforced fly ash pressure plate with the advantages of rich raw material sources, low cost, environment friendliness, high density, great nail-holding power, good strength as well as good processability and its preparation method.

Owner:江苏康辉硅酸钙板有限公司

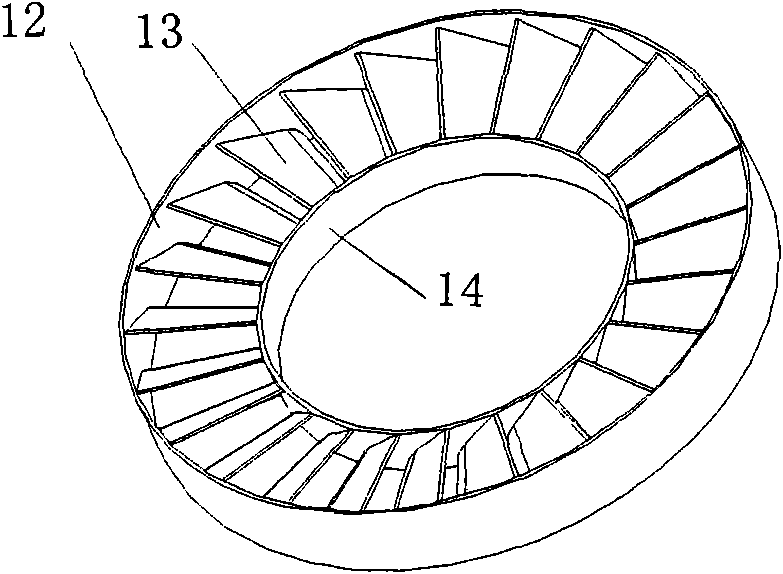

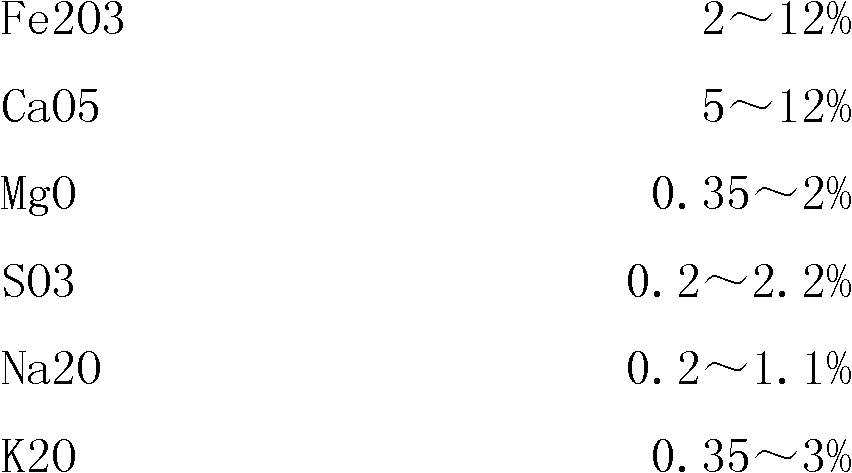

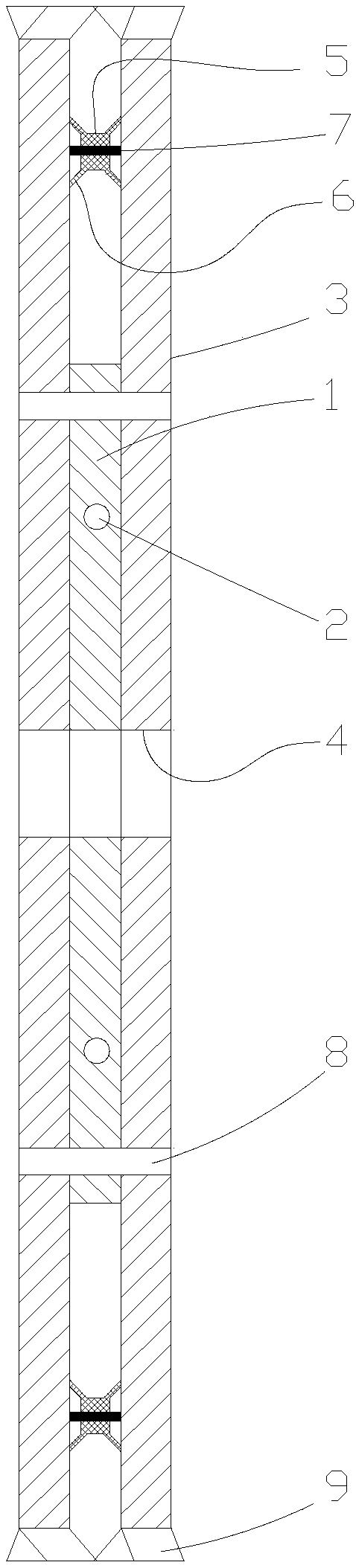

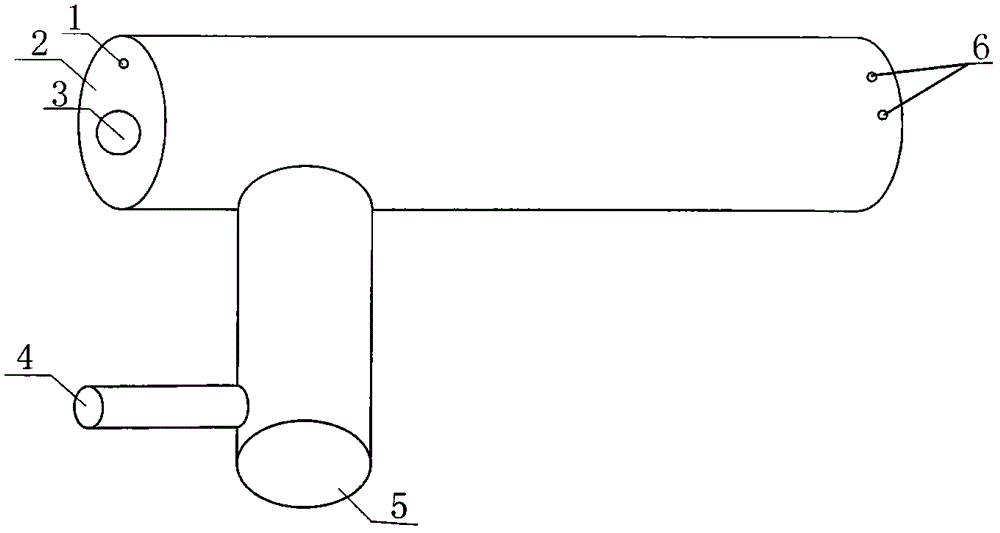

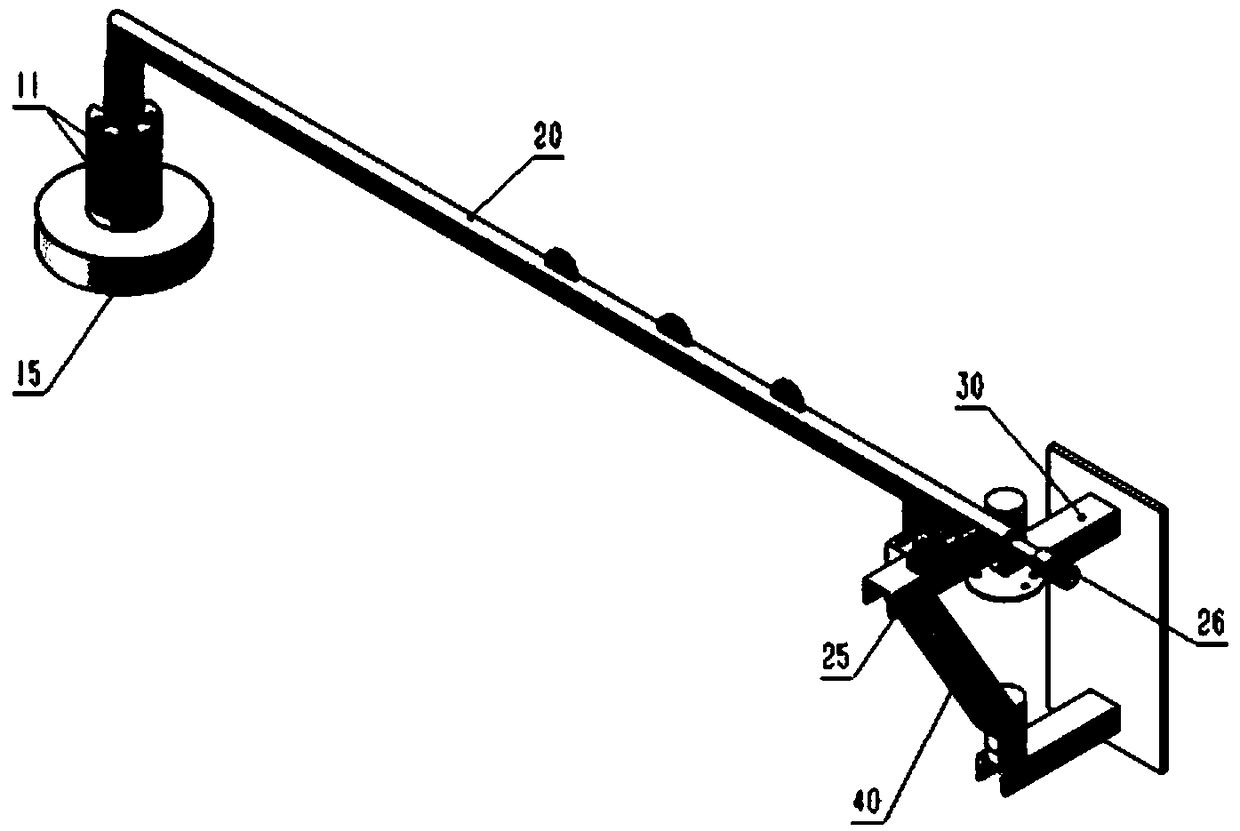

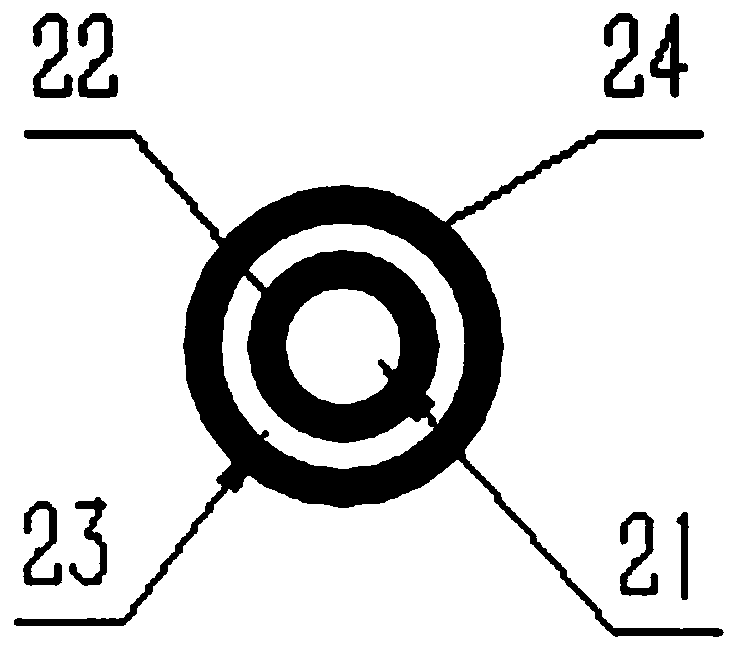

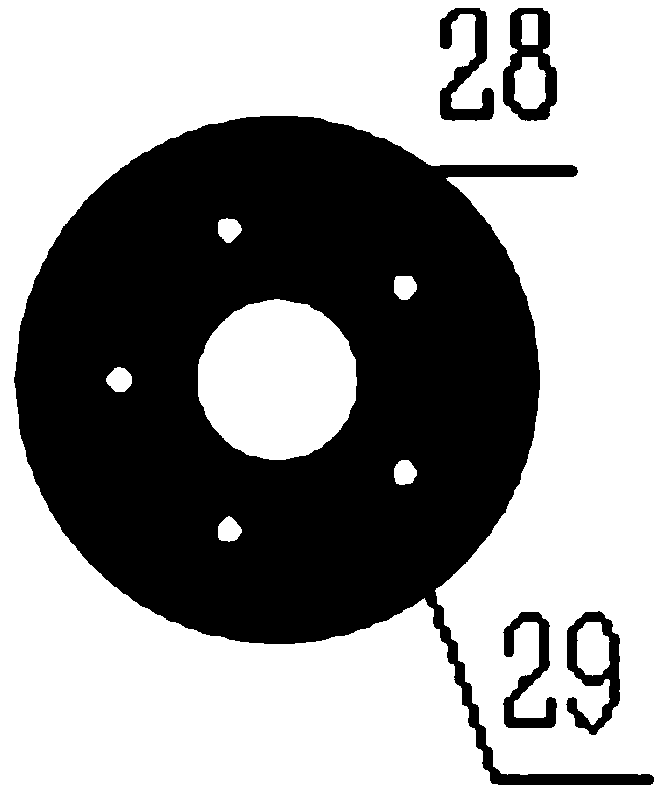

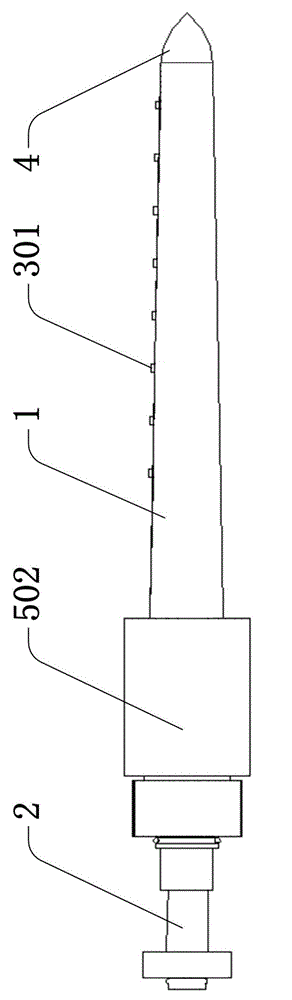

Roasting gun device

The invention discloses a roasting gun device. The roasting gun device comprises a support, a gun body and a gun head, wherein the middle part of the gun body is of a sleeve structure with an inner layer charged with fuel gas and an outer layer charged with compressed air, a bearing seat for allowing the gun body to rotate around the support is arranged on the rear part of the gun body, and a fuel gas connector and a compressed air connector are formed in the rear part of the gun body; a fuel gas-air mixing pipe and a secondary mixing and decompression pipe for supplementing air and balancing a gas pressure are arranged on the front part of the gun body; the support is used for installing and supporting the gun body and enabling the gun body to rotate and move around an axis in the horizontal direction; a main fire hole is formed in the middle of the gun head, and 18-28 auxiliary fire holes are distributed around the gun head; and the outer layer of the gun head is a heat-collecting cover. According to the roasting gun device disclosed by the invention, a fuel and air are uniformly mixed, air needed for combustion can be automatically balanced, and the temperature of the gun head can be lowered, so that the problems of poor roasting effect and unsafety of unshaped casting material products in scrap copper smelting, and anode copper casting dies are solved.

Owner:JIANGXI COPPER

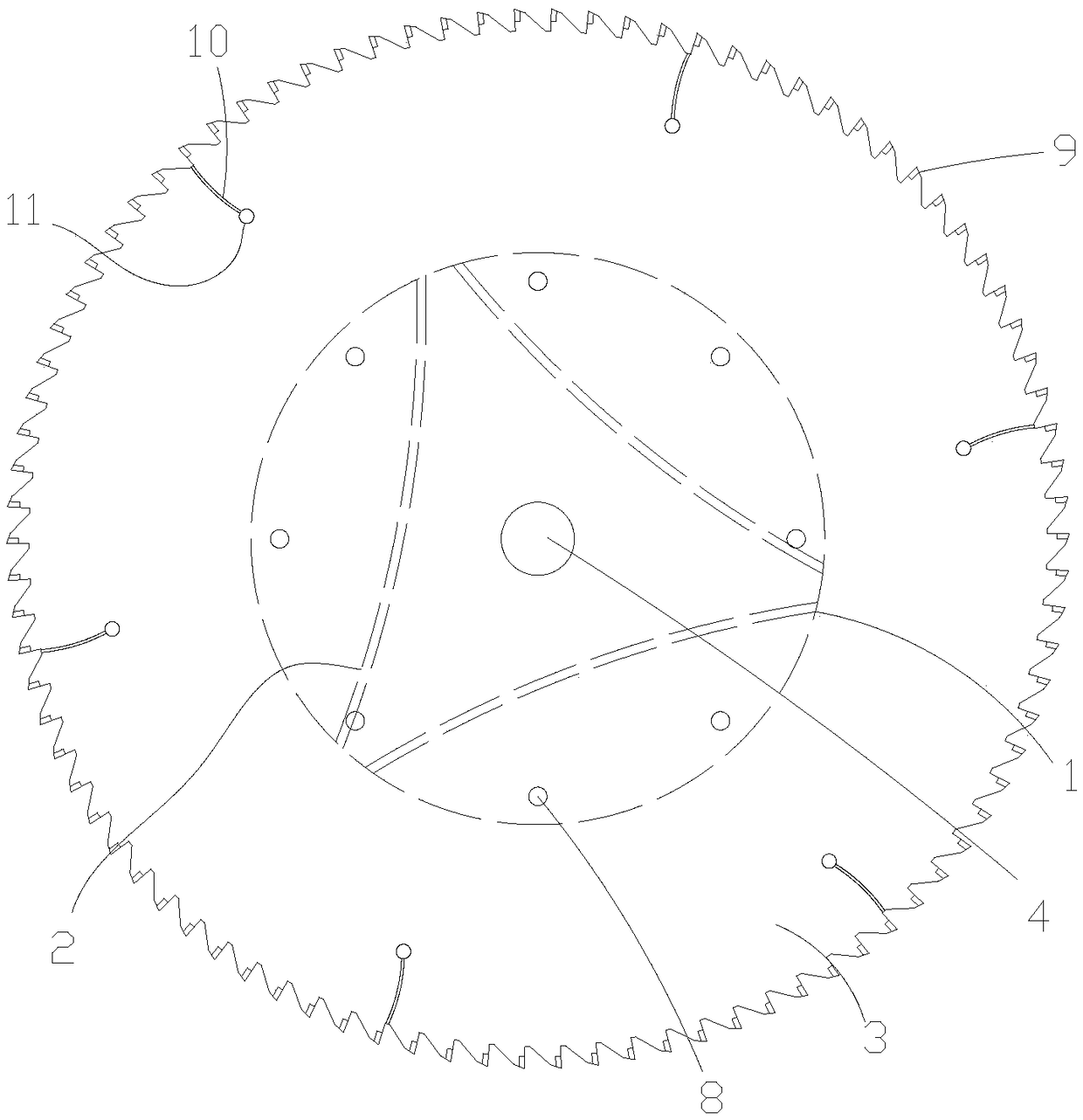

Noise-reducing saw blade for timber cutting

InactiveCN109093770ASaw blade life is not easy to shortenLess prone to fireCircular sawsSaw bladesEngineeringCopper

The invention discloses a noise-reducing saw blade for timber cutting. The noise-reducing saw blade comprises a copper core plate, a plurality of air holes are formed in the outer circumference of thecopper core plate, cutting disks are arranged on two sides of the copper core plate and provided with fixing holes penetrating the copper core plate, the outer edges of the cutting disks extend outwards to go beyond the outer edge of the copper core plate, a plurality of rubber posts surrounding the copper core plate are arranged between the two cutting disks, flared elastic bodies are arranged at two ends of the rubber posts, threaded rods are arranged in the rubber posts, the two cutting disks are fixed to two ends of the threaded rods and are connected with the copper core plate through pins penetrating a plurality of surrounding fixing holes, a plurality of saw teeth are arranged on the outer circumferential faces of the cutting disks, 10-15 saw teeth are designed in a group, an inwardly extending noise-reducing seam is formed in the root of one of each saw tooth group, and noise-reducing pillars are inlaid into the ends of the noise-reducing seams. The noise-reducing saw blade for timber cutting is not prone to being overheated and causing fire and long in service life without sharp noise.

Owner:湖州南浔登越家居有限公司

Environment-friendly and green building material

The invention discloses an environment-friendly and green building material. The environment-friendly and green building material is characterized by comprising following substances in parts by weight: 18-25 parts of alkyd resin, 19-26 parts of melamine resin, 16-21 parts of melamine-formaldehyde resin, 3-9 parts of color master batch, 9-11 parts of triethylamine, 5-12 parts of tartaric acid, 3-16 parts of methyl benzoate, 30-40 parts of sand, 0.5-3 parts of a wetting agent, 3-8 parts of trumpet shell powder, 4-9 parts of clam shell powder, 5-10 parts of carbon black, 3-9 parts of modified attapulgite and 3-7 parts of azodicarbonamide. The environment-friendly and green building material has the beneficial effects that the environment-friendly and green building material is not easy to age, is waterproof, fireproof, heat-insulation and sound-insulation, and is applicable to heat preservation of light separation walls and pipelines of high-rise buildings.

Owner:QINGDAO UWELL INFORMATION TECH

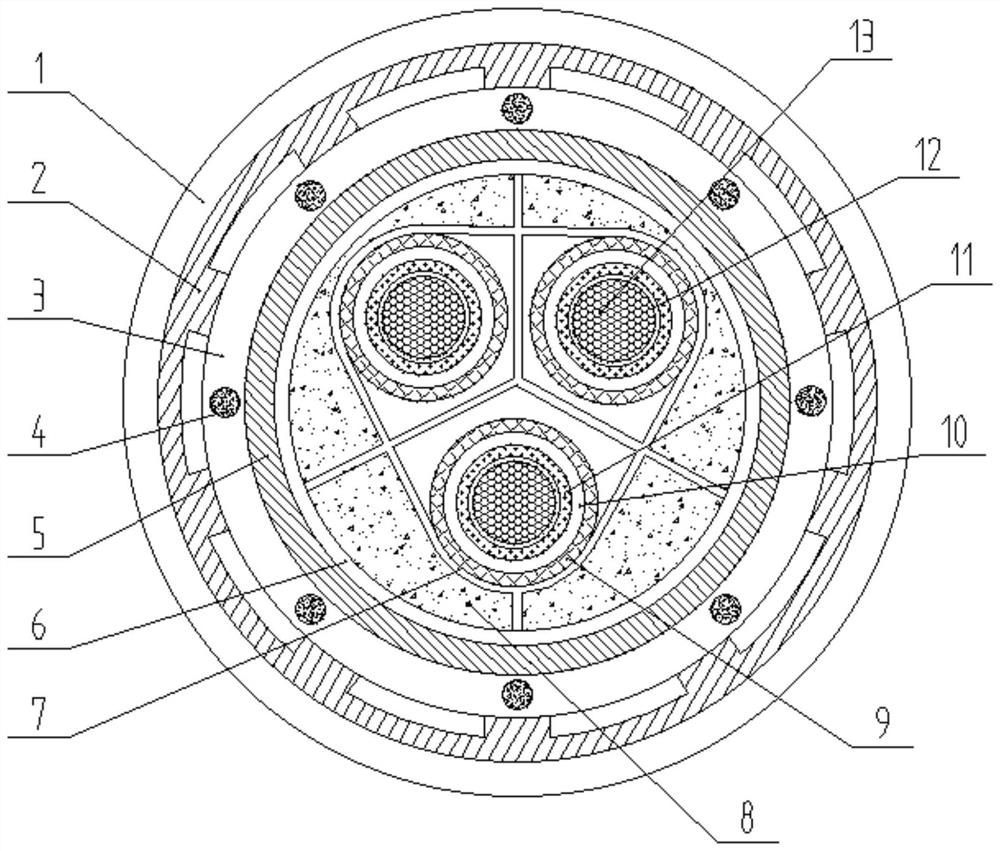

Fireproof and damp-proof subway cable

InactiveCN111653393ASolve fire resistanceSolve moisture resistanceInsulated cablesInsulated conductorsEngineeringStructural engineering

The invention relates to the technical field of wires and cables, in particular to a fireproof and damp-proof subway cable. The fireproof and damp-proof subway cable comprises a plurality of cable cores. An insulating layer, a shielding layer, a protective layer and a fireproof layer are sequentially arranged on the outer side of each cable core, the cable core is arranged in a fire insulation bracket, the fire insulation bracket is fixed on a water blocking layer, a damp-proof layer, a flame-retardant layer, an elastic isolation layer and a wear-resistant layer are sequentially coated outsidethe water blocking layer, and the fire insulation bracket divides all cable cores into independent cavities respectively. In order to overcome defects, the invention provides the fireproof and damp-proof subway cable with reliable performance, problems of poor fireproof and damp-proof performance of the existing subway cable are solved, and the cable is good in strength and not easy to damage.

Owner:云南龙源电缆有限公司

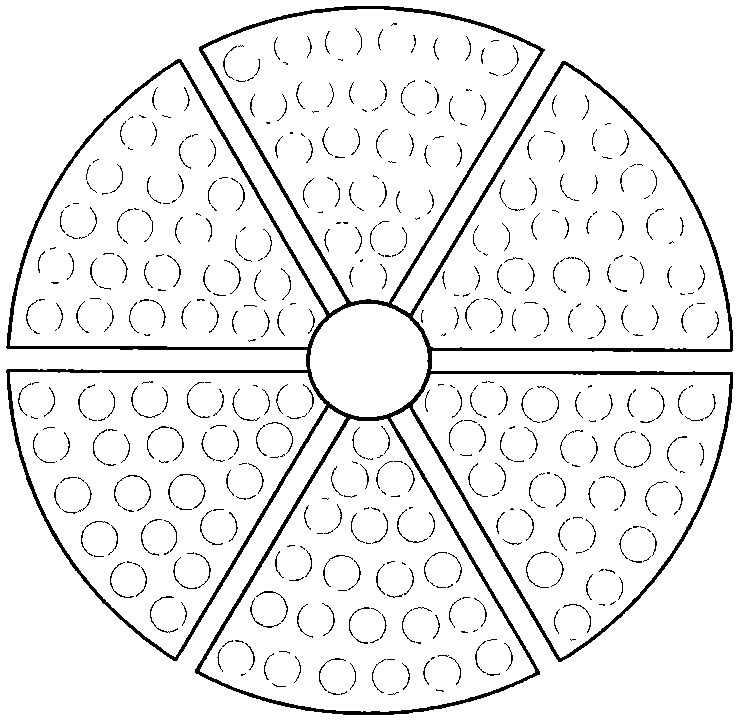

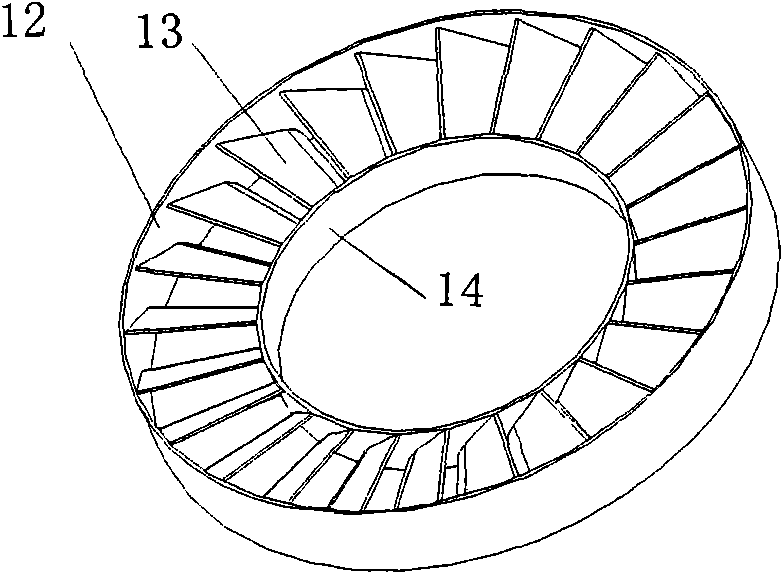

Gas premixed burner

The embodiment of the invention discloses a gas premixed burner. The gas premixed burner has a burning direction; an impeller-shaped mixer and a burner substrate are arranged in a burner main body; the impeller-shaped mixer is arranged on the upstream of the burner substrate, so that gas and air are uniformly mixed before burning; a main burning surface is arranged on the downstream of the burner substrate; the main burning surface and the burner substrate are tightly connected in a matching manner; an auxiliary flame burning surface and the main burning surface are tightly connected in the matching manner; a main flame of the main burning surface and an auxiliary flame of the auxiliary burning surface are positioned on the same plane; as the scale of the main flame is greater than that of the auxiliary flame and the air current speed of the main burning surface is greater than that of the auxiliary flame burning surface, the auxiliary flame realizes the effect of stabilizing the main flame; a burning chamber is arranged on the downstream of the main burning surface and the effect of further stabilizing the burning is realized. According to the gas premixed burner disclosed by the invention, a metal mesh is taken as the burning surface; with larger porosity, the metal mesh has low possibilities of being blocked by tiny dust in the air, tempering and floating flame; a fan has higher efficiency.

Owner:袁树月

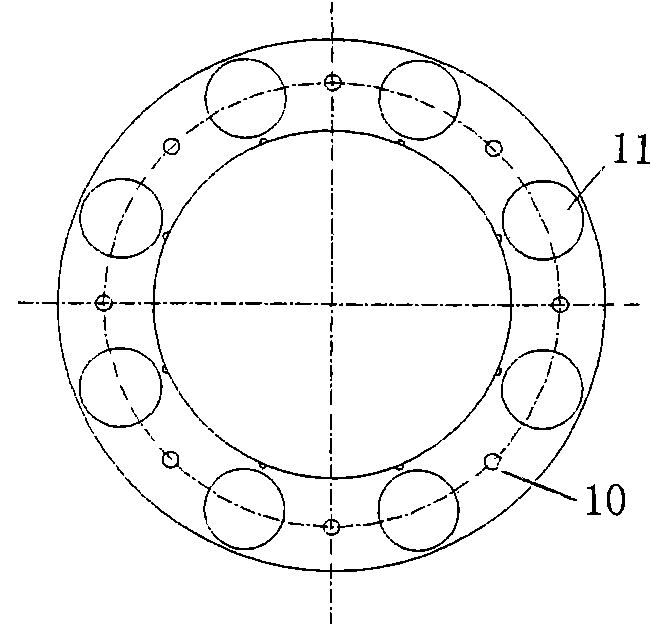

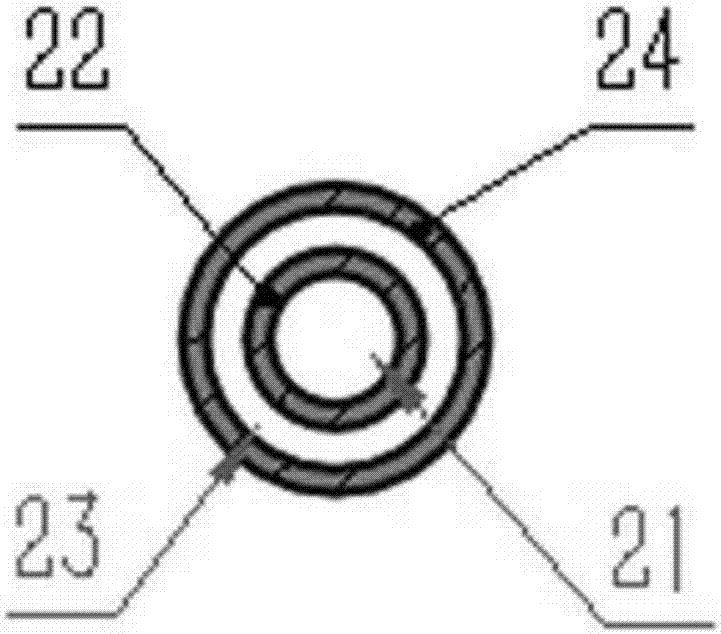

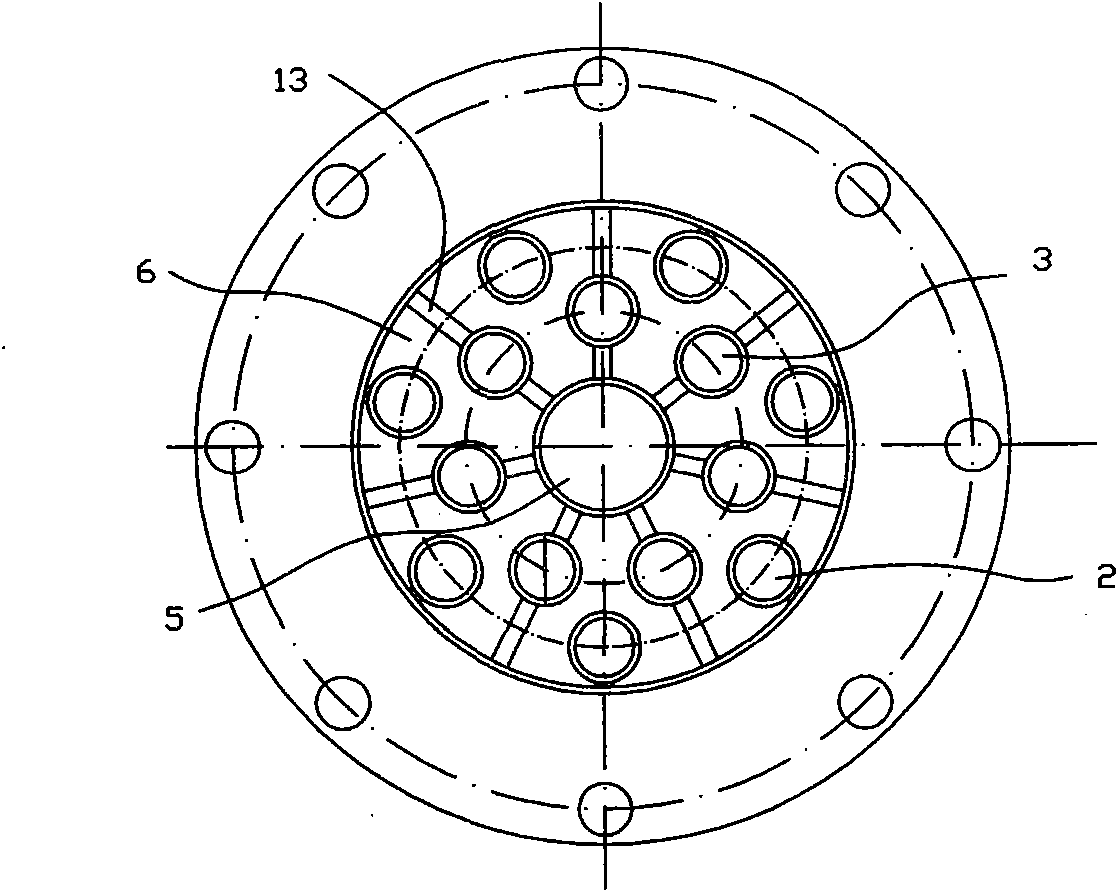

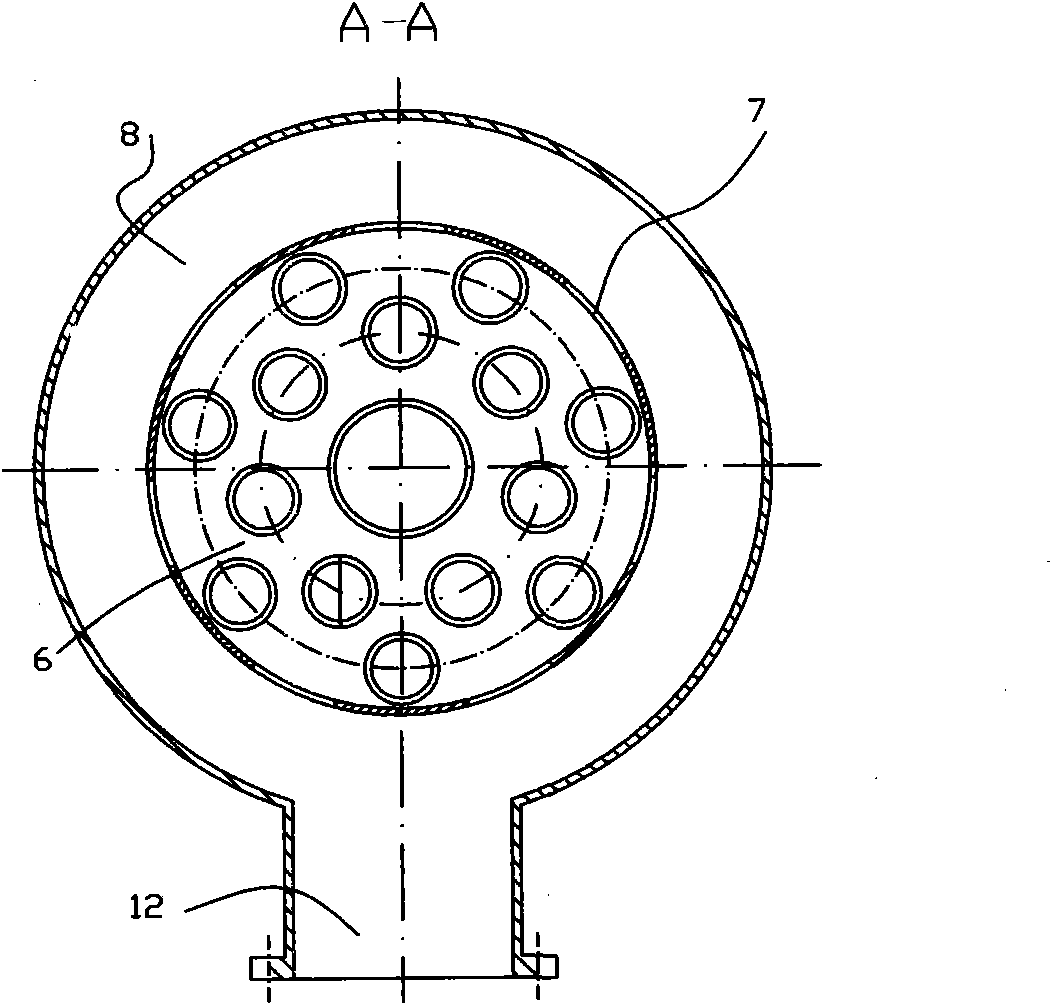

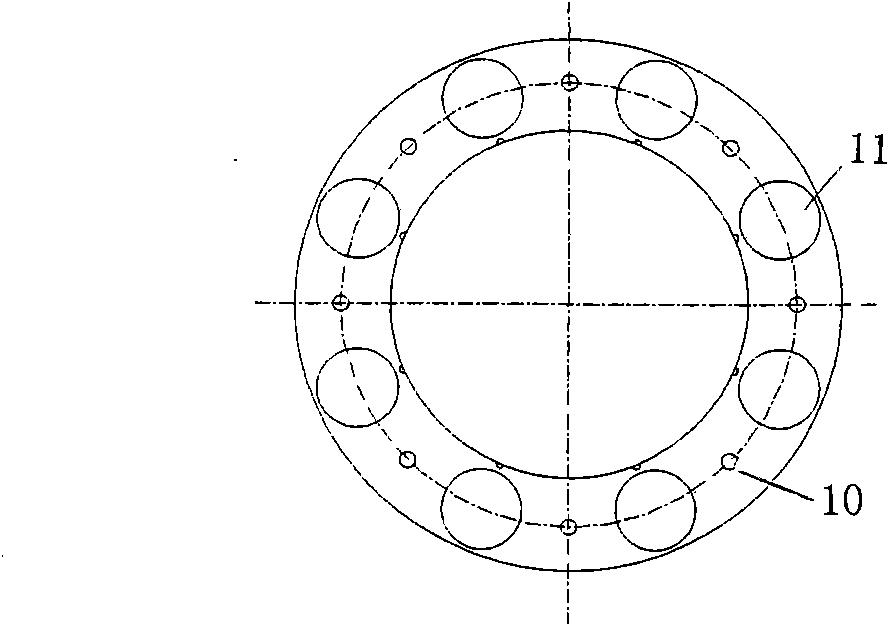

High-efficiency gas burning nozzle

InactiveCN102401378AImprove combustion efficiencyPrevent proliferationGaseous fuel burnerEngineeringGas burner

The invention discloses a high-efficiency gas burning nozzle and relates to an improvement on the structure of the burning nozzle of a gas burner. The high-efficiency gas burning nozzle can lead gas to be burnt fully, thus improving the burning efficiency of the gas. The high-efficiency gas burning nozzle comprises a barrel-shaped body, gas pipelines and an air pipeline, wherein the gas pipelines and the air pipeline are arranged in the body; the air pipeline comprises a peripheral gas channel and a central gas channel which is coaxial to the body; single-quantity inner-circle pipeline groups are uniformly distributed on the gas pipelines around the central gas channel, and outer-circle pipeline groups which have equal quantity with the inner-circle pipeline groups are also uniformly distributed around the inner-circle pipeline groups; and gaps among the inner surface of the body, the inner-circle pipeline groups, outer-circle pipeline groups and the outer surface of the central gas channel form the peripheral gas channel. In the high-efficiency gas burning nozzle, two circles of gas pipelines are arranged and include an inner circle and an outer circle, and the air pipeline covers the gas pipelines of the inner ring and the outer ring, so that the gas is fully contacted with the air, and further the burning efficiency of the gas is improved. In the high-efficiency gas burning nozzle, the flame lifting is not easy, the diffusion of residual gas is basically avoided, the burning flame is long, the burning is strong and the toasting time is shortened by 1.5-2 hours.

Owner:扬州博泰冶金设备制造有限公司

High-hardness biological building material

The invention discloses a high-hardness biological building material which comprises 11-13 parts by weight of isoprene rubber, 9-12 parts by weight of polyisoprene rubber, 3-5 parts by weight of halogen-free intumescent flame retardant, 14-18 parts by weight of tuber straw powder, 15-20 parts by weight of highland barley straw powder, 9-13 parts by weight of broad bean straw powder, 3-6 parts by weight of wood fibers, 9-14 parts by weight of silver birch saw dust, 3-8 parts by weight of oak tree saw dust, 1-2 parts by weight of bird cherry saw dust, 3-6 parts by weight of calcium carbonate, 5-8 parts by weight of potassium dichromate, 1-2 parts by weight of titanium dioxide and 3-6 parts by weight of kieselguhr. The high-hardness biological building material is high in hardness, not easy to age, waterproof, fireproof, heat-insulating and soundproof, and applicable to light partition walls of high-rise buildings and piping insulation.

Owner:QINGDAO UWELL INFORMATION TECH

Environmental-protection energy-saving building material

The invention discloses an environmental-protection energy-saving building material which comprises the following substances in parts by weight: 30-40 parts of a 108 solution, 20-30 parts of perlite, 1-6 parts of diatomite, 1-2 parts of hollow glass microbeads, 0.5-1.5 parts of a graphite powder, 1.5-3 parts of open-cell expanded perlite (14-120 mesh), 1.5-4 parts of hollow glass microbeads (120-200 mesh), 2-9 parts of polypropylene, 3-9 parts of bisphenol A type polycarbonate, 0.1-0.6 part of nano calcium carbonate, 3-8 parts of stearic acid, 5-8 parts of a talcum powder, 5-10 parts of carbon black, 3-9 parts of modified attapulgite clay, and 3-7 parts of azodicarbonamide. The environmental-protection energy-saving building material has the beneficial effects that the material is not easy to age, has the advantages of water resistance, fire resistance, heat insulation and sound insulation, and is suitable for thermal insulation of high-rise building lightweight partition walls and pipelines.

Owner:QINGDAO JIZHI ENERGY SAVING ENVIRONMENTAL PROTECTION

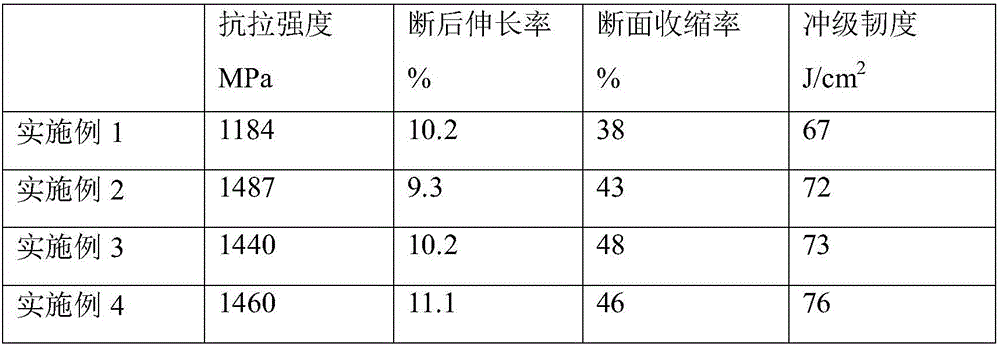

Special quenching agent for low-carbon alloy steel

The invention discloses a special quenching agent for low-carbon alloy steel. The special quenching agent comprises the following components in parts by mass: 2-5 parts of sodium sulfate, 4-6 parts of sodium hydroxide, 1-2 parts of starch, 5-7 parts of sodium bicarbonate, 6-8 parts of sodium phenylacetate, 5-8 parts of alums and 60-70 parts of white oil. A method for preparing the special quenching agent for low-carbon alloy steel comprises the following steps: dissolving sodium sulfate, sodium hydroxide, starch, sodium bicarbonate, sodium phenylacetate and alums into white oil of 55-60 DEG C according to proportions, and uniformly mixing. The special quenching agent for the low-carbon alloy steel, which is disclosed by the invention, is low in cost, safe and free of pollution, unlikely to cause fire hazard and convenient to use, and does not need to be prepared temporarily when being used.

Owner:江苏金基特钢有限公司

Flame-retardant energy-saving wall coating material

The invention discloses a flame-retardant energy-saving wall coating material which comprises the following components in parts by weight: 30-40 parts of 108 solution, 20-30 parts of perlite, 1-6 parts of kieselguhr, 15-30 parts of antiaging agent, 1-6 parts of compatiblizing agent, 3-9 parts of color master batch, 3-6 parts of light aggregate, 1-9 parts of coagulant, 30-40 parts of sand, 0.5-3 parts of wetting agent, 0.1-1 part of dispersant, 0.3-0.6 part of mold preventive, 0.3-0.5 part of preservative, 0.1-0.8 part of defoamer, 1-3 parts of film-forming assistant, 3-8 parts of stearic acid, 5-8 parts of talcum powder, 5-10 parts of carbon black, 3-9 parts of modified attapulgite and 3-7 parts of azobisformamide. The invention has the advantages of low aging tendency, water resistance, fire resistance, heat insulation and sound insulation, and is suitable for thermal insulation of light partition walls and pipelines of high-rise buildings.

Owner:QINGDAO JIZHI ENERGY SAVING ENVIRONMENTAL PROTECTION

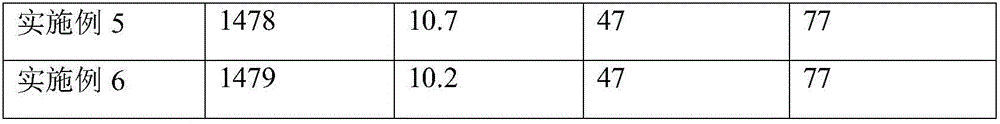

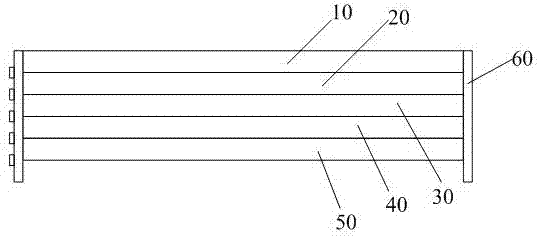

Double-glass solar cell module and system

InactiveCN106898659AAchieve fixationAchieve electrical connectionPhotovoltaicsPhotovoltaic energy generationEngineeringSolar cell

The invention discloses a double-glass solar cell module, which comprises a front tempered glass, a first bonding layer, a solar battery group, a second bonding layer and a back tempered glass which are sequentially stacked from top to bottom; the double-glass solar cell A fixed frame is arranged around the battery assembly, and the fixed frame includes a first bracket and a second bracket that are oppositely arranged, and the inner side of the first bracket and the second bracket is provided with a card slot, and the card slot is used to fix the double glass For the solar battery module, grooves are provided on the outside of the first support, protrusions are provided on the outside of the second support, and the grooves are adapted to the protrusions; the first support and / or the second support The second bracket is provided with a through hole for leading out the positive and negative poles of the double-glass solar cell module. Correspondingly, the present invention also discloses a system using the above-mentioned double-glass solar cell module. By adopting the invention, the assembly is very convenient and simple, the assembly quality can be unified, the yield rate is high, and the component reliability is high.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

Building decoration material for floor

The invention provides a building decoration material for a floor. The building decoration material for the floor is characterized by comprising the following raw materials in parts by weight: 20-60 parts of dolomite, 20-60 parts of calcite, 15-40 parts of PVC, 2-5 parts of calcium chloride, 2-5 parts of paraffin, 3-8 parts of stabilizer and 3-8 parts of antioxidant. When the material is used for producing an artificial floor, the middle of the floor is drilled during extrusion molding, so that the floor has the advantages of weight reduction and material saving; two ends are blocked by using a substrate, thus, it is convenient to form wedged holes in two ends of the artificial floor, and the mounting convenience of the floor cannot be affected; a paint surface on a surface layer is subjected to ultraviolet-curable paint baking, thus, not only can the paint surface be prevented from dropping, but also scratching can be avoided, and the wear resistance can be improved.

Owner:ANHUI ZHENXIN PAINT

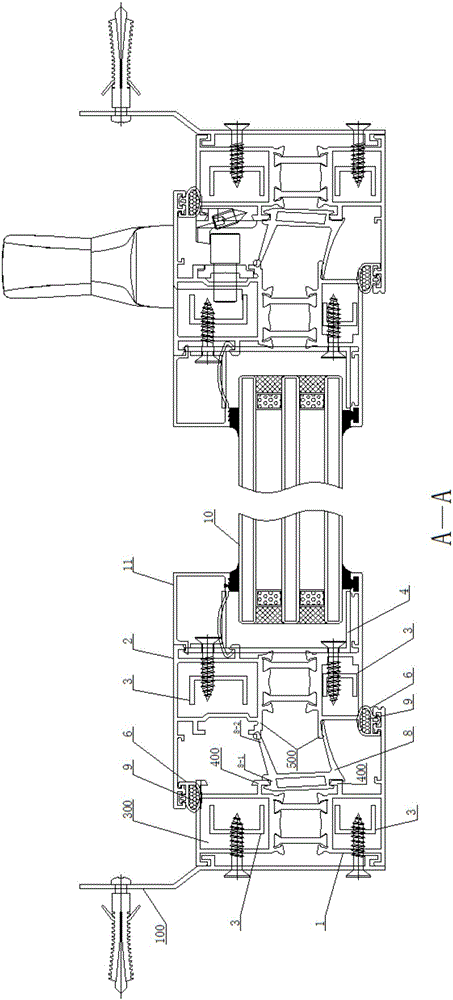

Aluminum alloy heat insulation fireproof window

InactiveCN111305725AReasonable structureImprove fire integrityFireproof doorsWindow/door framesSash windowEngineering

The invention relates to an aluminum alloy heat insulation fireproof window. The aluminum alloy heat insulation fireproof window comprises a window frame, a window sash, reinforcing supports and a glass protection frame, wherein the window frame is fixedly installed on a wall through a clamping type fixing piece, hollow cavities are formed in the window frame and the window sash, the reinforcing supports are arranged in the middles of the hollow cavities, and the hollow cavities are filled with a fire-resistant and heat-insulating filling material. The fireproof window further comprises a mullion used for fixing glass and supporting the window frame. The window frame, the window sash, the mullion, the glass protective frame, the reinforcing supports and corner connectors are fixedly linkedwith each other, it is guaranteed that the whole window is connected into a whole, and it is guaranteed that the window cannot be split or disengaged due to wind power, fire and other external factors; the split or falling resistance of the glass is enhanced through the glass protection frame; and the whole window is reasonable in structure, the wind pressure resistance, the air tightness, the water tightness and the fire resistance integrity of the whole window are improved to a certain extent on the premise that the material cost economy of the whole window is fully considered, and the practicability is high.

Owner:青岛万和装饰门窗工程有限公司

A roasting gun device

The invention discloses a roasting gun device. The roasting gun device comprises a support, a gun body and a gun head, wherein the middle part of the gun body is of a sleeve structure with an inner layer charged with fuel gas and an outer layer charged with compressed air, a bearing seat for allowing the gun body to rotate around the support is arranged on the rear part of the gun body, and a fuel gas connector and a compressed air connector are formed in the rear part of the gun body; a fuel gas-air mixing pipe and a secondary mixing and decompression pipe for supplementing air and balancing a gas pressure are arranged on the front part of the gun body; the support is used for installing and supporting the gun body and enabling the gun body to rotate and move around an axis in the horizontal direction; a main fire hole is formed in the middle of the gun head, and 18-28 auxiliary fire holes are distributed around the gun head; and the outer layer of the gun head is a heat-collecting cover. According to the roasting gun device disclosed by the invention, a fuel and air are uniformly mixed, air needed for combustion can be automatically balanced, and the temperature of the gun head can be lowered, so that the problems of poor roasting effect and unsafety of unshaped casting material products in scrap copper smelting, and anode copper casting dies are solved.

Owner:JIANGXI COPPER

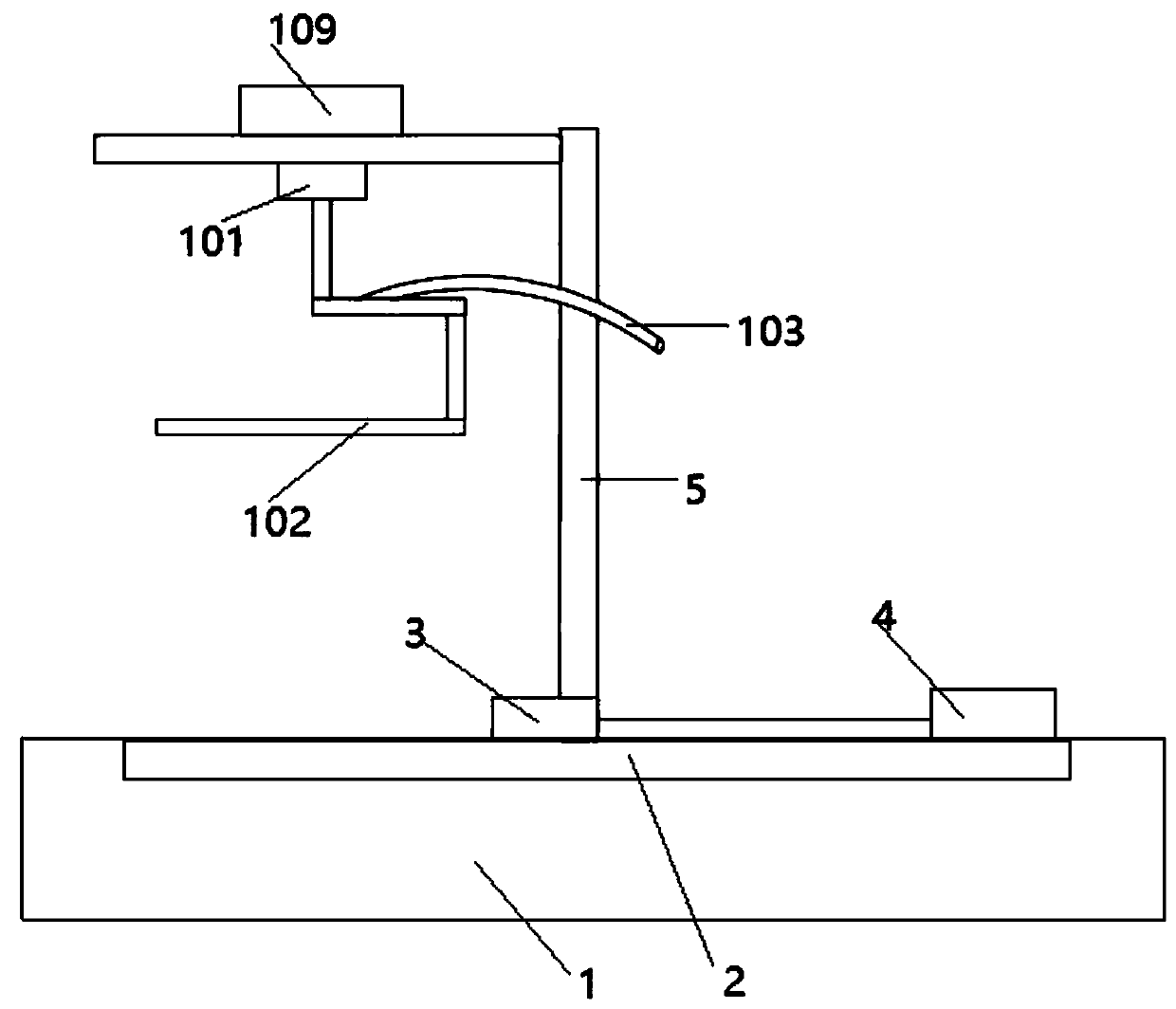

Gas stove system and method capable of preventing dry burning

ActiveCN108980909BAvoid dangerAvoid fireDomestic stoves or rangesLighting and heating apparatusMagnetic valveProcess engineering

The invention discloses a gas cooker system and method capable of preventing dry burning. The gas cooker system comprises a gas cooker, a transverse guide rail disposed on the gas cooker, a support plate and a first cylinder for driving the support plate to move transversely which are disposed on the transverse guide rail, a support column disposed on the support plate, a detection plate disposedat an upper end of the support column, and a temperature and humidity sensor disposed on a lower surface of the detection plate; the gas cooker system further comprises a controller and an alarm; thegas cooker is connected with a gas inlet pipe; the gas inlet pipe is provided with a pressure sensor and a first electromagnetic valve; the lower surface of the detection plate is provided with a second cylinder; and an expansion link is connected with a water pipe with two closed ends. The gas cooker system has the characteristics that the safety is good and dry burning of a pan is effectively prevented.

Owner:李广

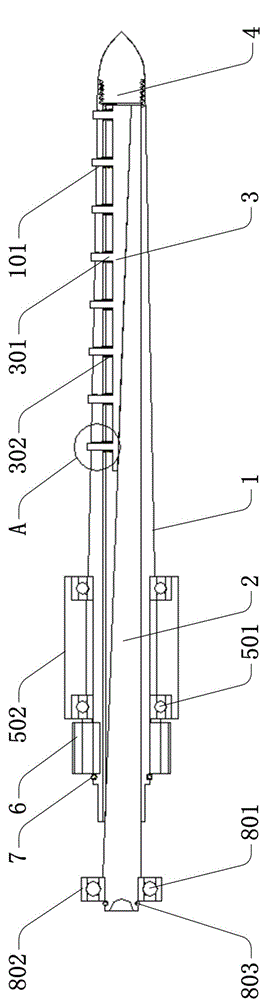

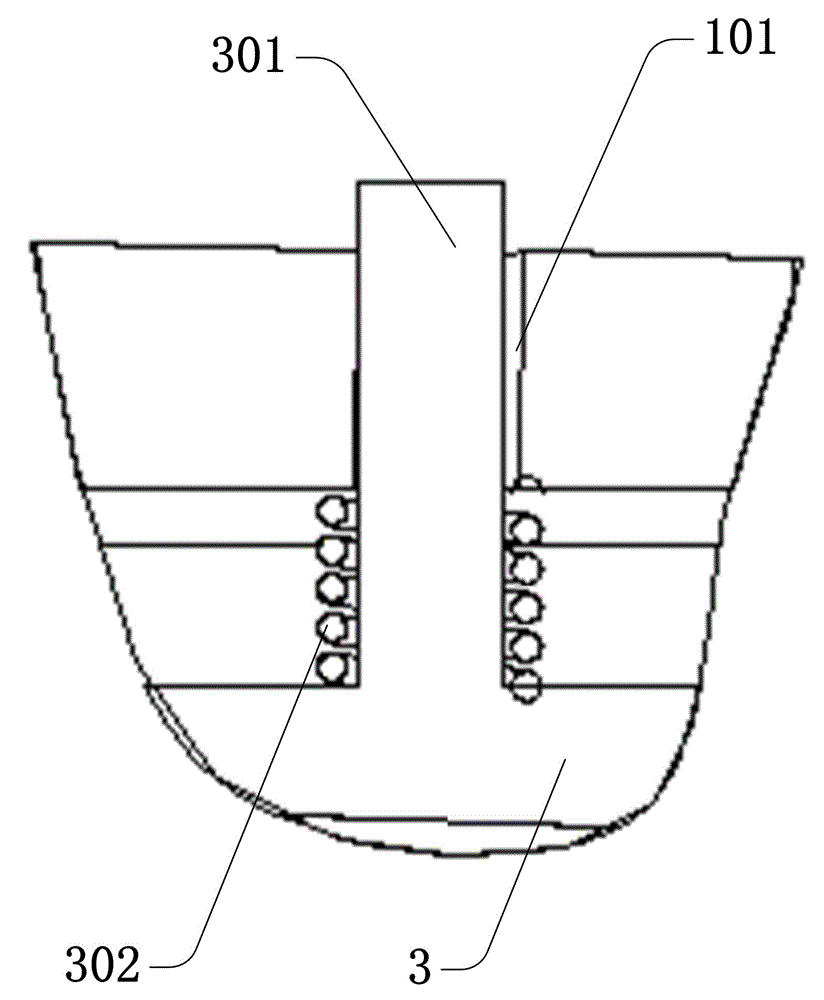

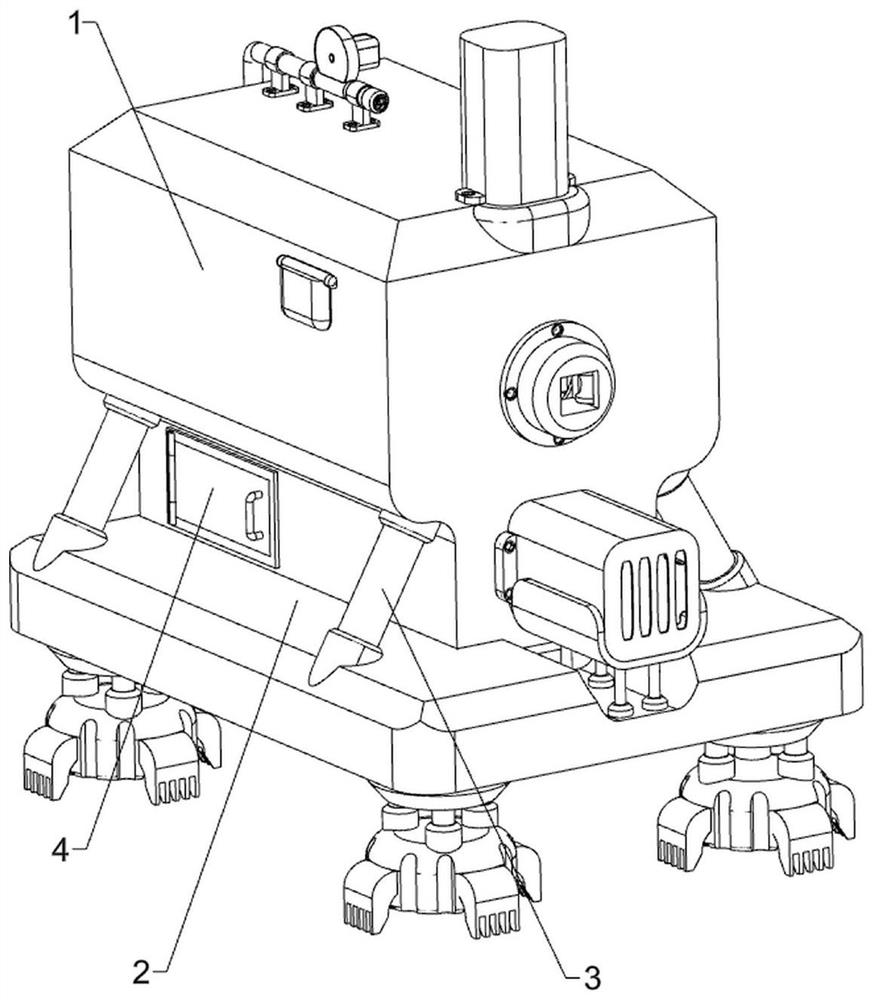

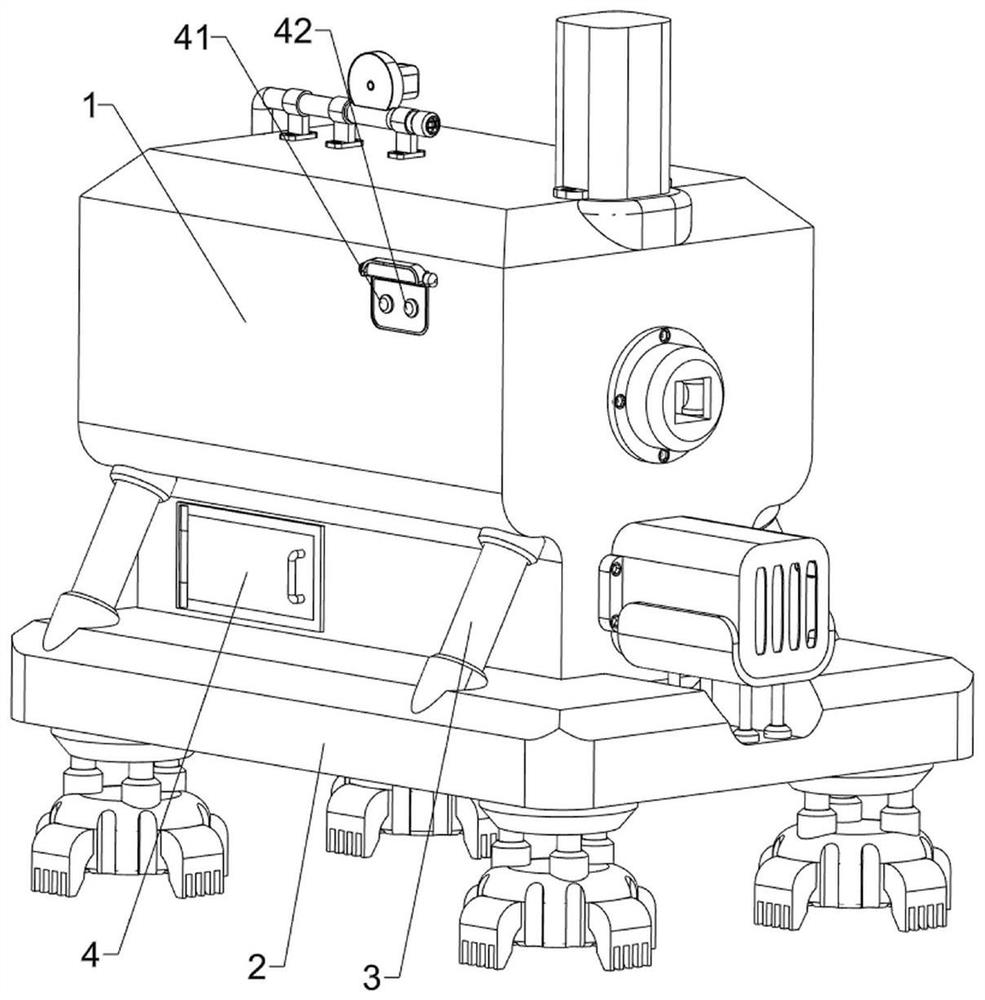

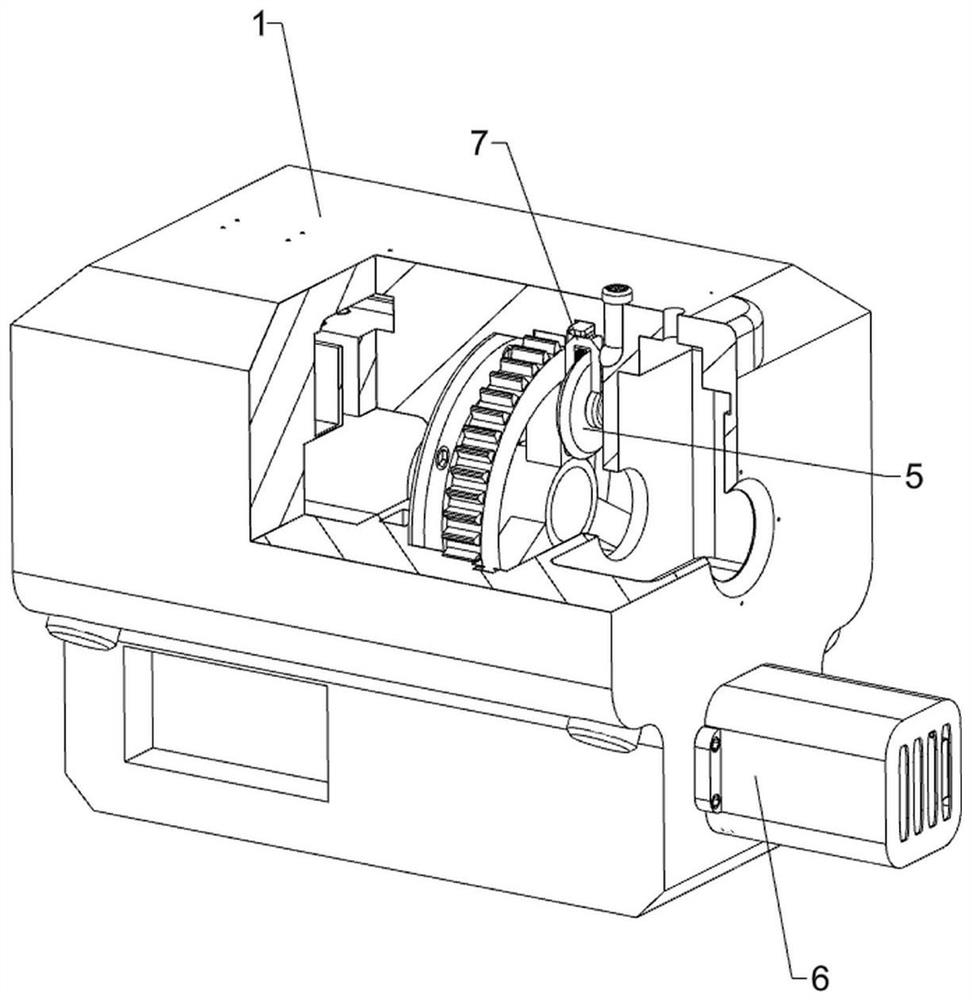

A kind of picking head for automatic cotton picker

The invention provides a picking head of a fully-automatic cotton picker, which comprises a jacket, a cotton picking finger, a needle base and a telescopic rod, wherein the jacket is a cavity cylinder with openings in two ends, the radius of the tail end of the cavity cylinder is more than that of the head end of the cavity cylinder, a plurality of needle holes in the same straight line are arranged in the head end of the cavity cylinder, the cotton picking finger is fixedly connected to the head end of the jacket, an opening of the head end of the jacket is sealed, the needle seat is shaped as a strip plate and is positioned in the jacket cavity, a plurality of cotton picking needles corresponding to the needle holes are arranged on the needle seat, the upper ends of the cotton picking needles can penetrate through the needle holes to be exposed out of the jacket, the lower ends of the cotton picking needles are fixedly connected to the upper surface of the needle base, an elastic part is arranged in a space enclosed by the upper surface and the inner wall of the jacket, the telescopic rod is arranged in the jacket, the head end of the telescopic rod is positioned in a space enclosed by the lower surface of the needle base and the inner wall of the jacket, one surface of the head end of the telescopic rod is jointed with the lower surface of the needle base, and the tail end of the telescopic rod is exposed out of the tail end of the jacket. The picking head has the advantages of good safety and good quality of picked cotton.

Owner:SHANGHAI JUCHENG MACHINERY TECH CO LTD

Insulating skin fixed-length removing machine for wire processing

PendingCN114039308AImprove work efficiencyNot easy to fireFilament handlingApparatus for removing/armouring cablesFire hazardStructural engineering

The invention relates to a removing machine, in particular to an insulating skin fixed-length removing machine for wire processing. The insulating skin fixed-length removing machine for wire processing is convenient for people to remove the insulating skin of each wire, time-saving, labor-saving, high in working efficiency and not easy to cause fire hazards. The insulating skin fixed-length removing machine for wire processing comprises a protective bottom box, a supporting bottom plate and supporting columns, wherein the supporting bottom plate is fixedly connected to the bottom of the protective bottom box, the four supporting columns are fixedly connected to the top of the supporting bottom plate at intervals, and the supporting columns are connected with the protective bottom box. The wire is pulled to be inserted into the protective bottom box, a servo motor is started to rotate forwards to drive a driving shaft to rotate forwards, then, a separation cutter moves inwards to make contact with the surface of the wire, a heating module operates to transmit heat energy to the separation cutter, and the separation cutter rotates backwards and moves inwards to cut the insulating skin of the wire, so that people can conveniently remove the insulating skin of the wire, time and labor are saved, working efficiency is high, and fire disasters are not prone to being caused.

Owner:鹰潭申江科技有限公司

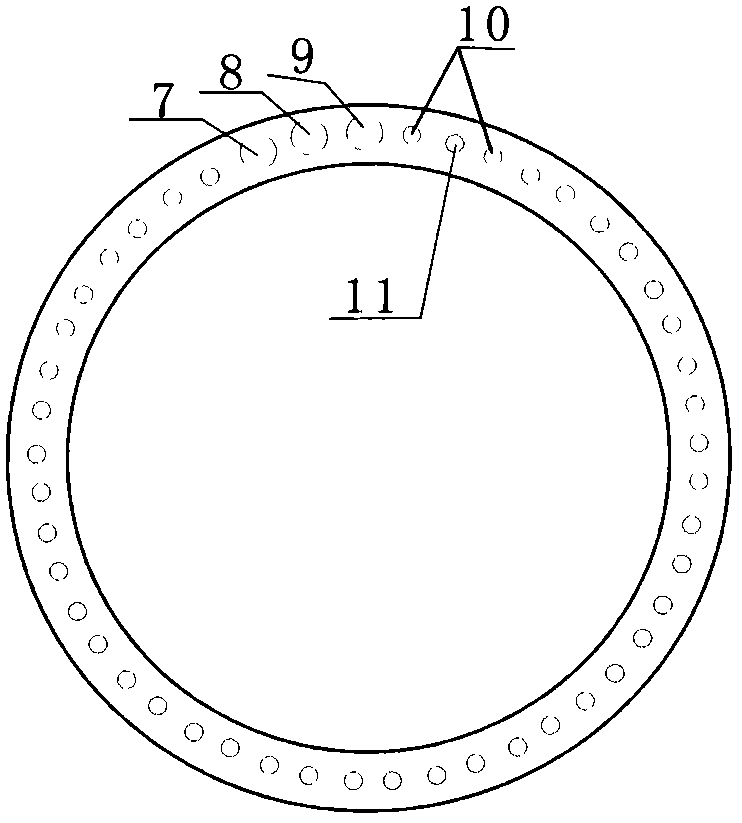

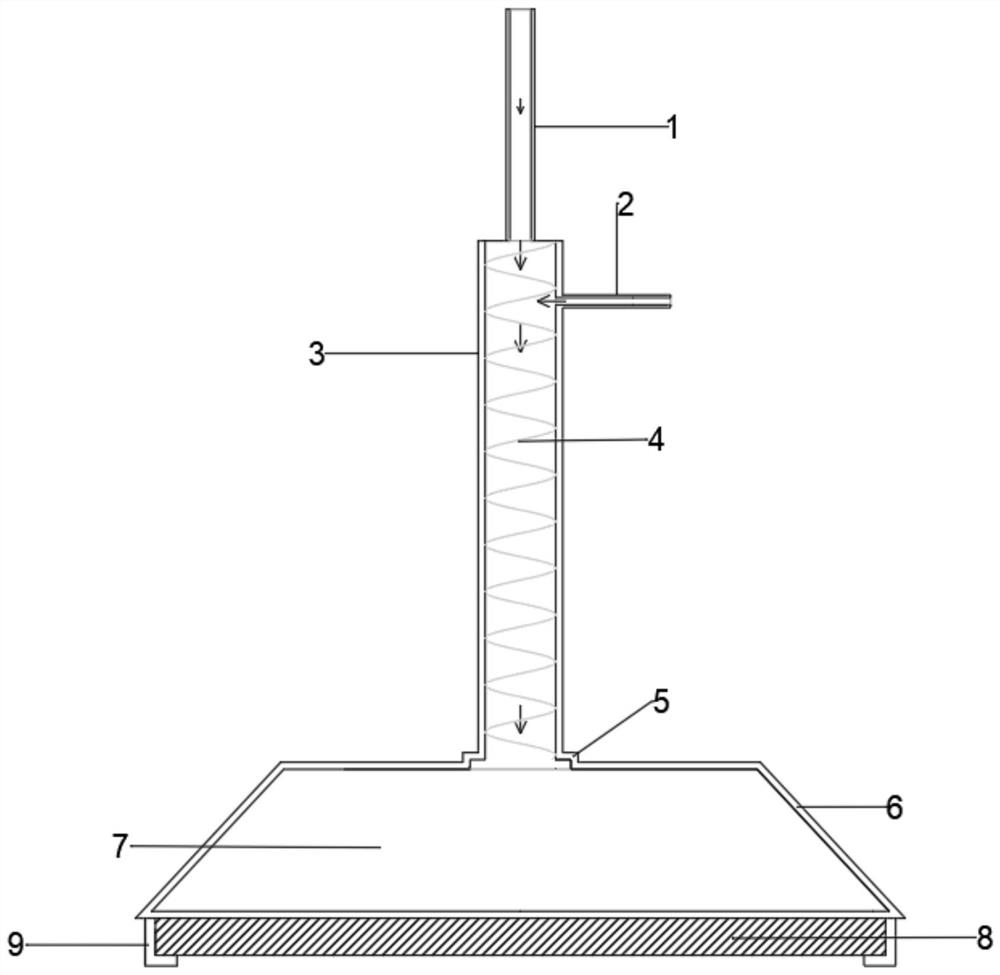

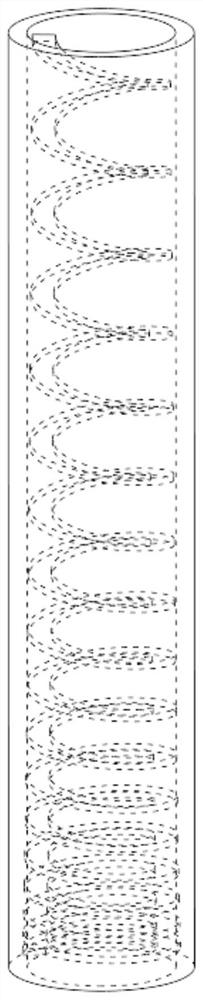

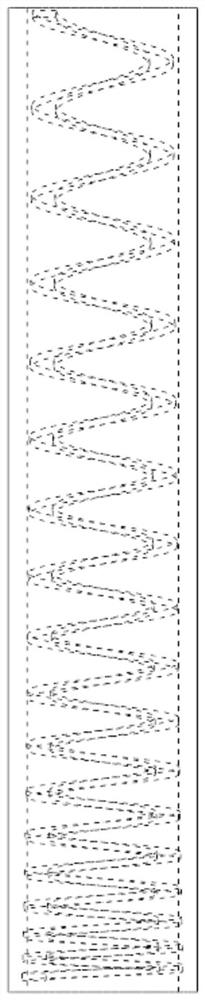

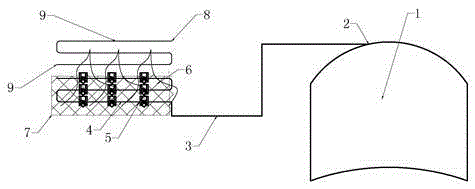

Single-layer porous medium burner

PendingCN114719255ANot easy to fireIncrease flow rateIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustion chamber

The invention provides a single-layer porous medium combustor. The single-layer porous medium combustor comprises an air inlet pipe, a fuel gas inlet pipe, a premixing chamber and a pre-combustion chamber. The air inlet pipe is arranged on the upper portion of the premixing chamber, the fuel gas inlet pipe is arranged on the side wall of the premixing chamber, and gas introduced into the air inlet pipe and gas introduced into the fuel gas inlet pipe are mixed in the premixing chamber; the pre-mixing chamber is fixedly connected with the pre-combustion chamber, and mixed gas in the pre-mixing chamber is introduced into the pre-combustion chamber.

Owner:SHANGHAI INST OF TECH

Water heater with liquid fuel as fuel

InactiveCN105299868AReduce consumptionControl alcohol flowBurnersWater heatersAlcoholAutomatic control

The invention discloses a water heater with liquid fuel as fuel. A combustion device comprises a fuel bottle containing the fuel, an ignition device, a flame-retardant pipeline, a pressurizing pump and heating pipes. The fuel bottle is connected with a pipe opening of the ignition device through the flame-retardant pipeline, a high-pressure atomizing device is arranged in the ignition device, the heating pipes are installed at the upper end of the high-pressure atomizing device, and a high-pressure pump is disposed in the fuel bottle and conveys alcohol to the high-pressure atomizing device. The high-pressure alcohol is atomized through the high-pressure atomizing device and is mixed with air to be ignited and combusted. According to the novel water heater, the fuel bottle is separated from the ignition device, the alcohol is pressured through pressurization of the fuel bottle or the pressurizing pump, and the alcohol is directly atomized, sprayed out, mixed with air and combusted; a furnace and the fuel bottle are connected through the flame-retardant pipeline, an electromagnetic valve is arranged in a spraying device, the spraying amount of the fuel is controlled according to start time, the electromagnetic valve is used for automatically controlling the supply amount of the fuel, combustion temperature can be conveniently adjusted and higher than that of a common alcohol furnace, the heat conversion rate can be increased, fuel consumption is reduced to the largest extent, fires are not likely to be caused, and fuel is non-toxic and harmless to human bodies.

Owner:黄维斌

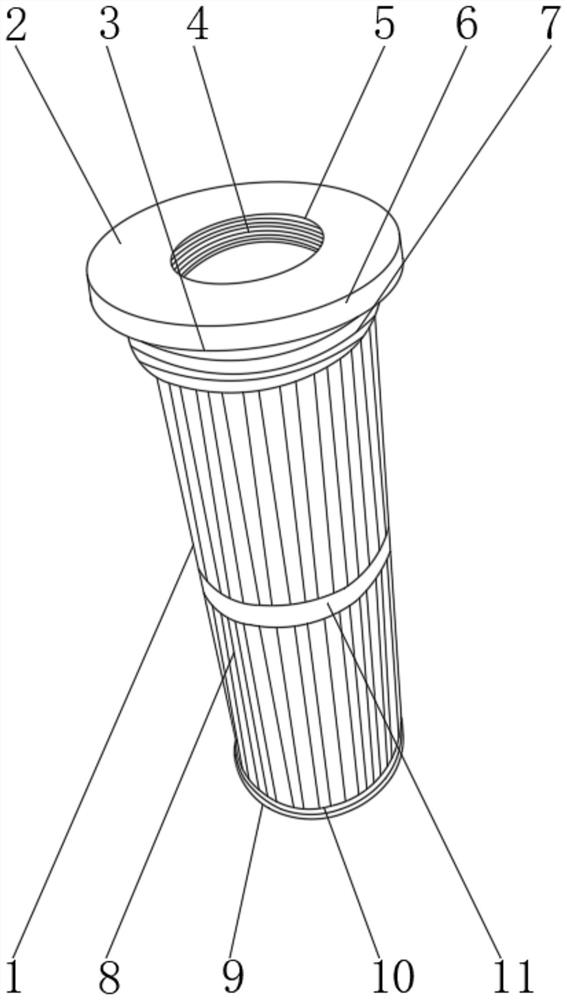

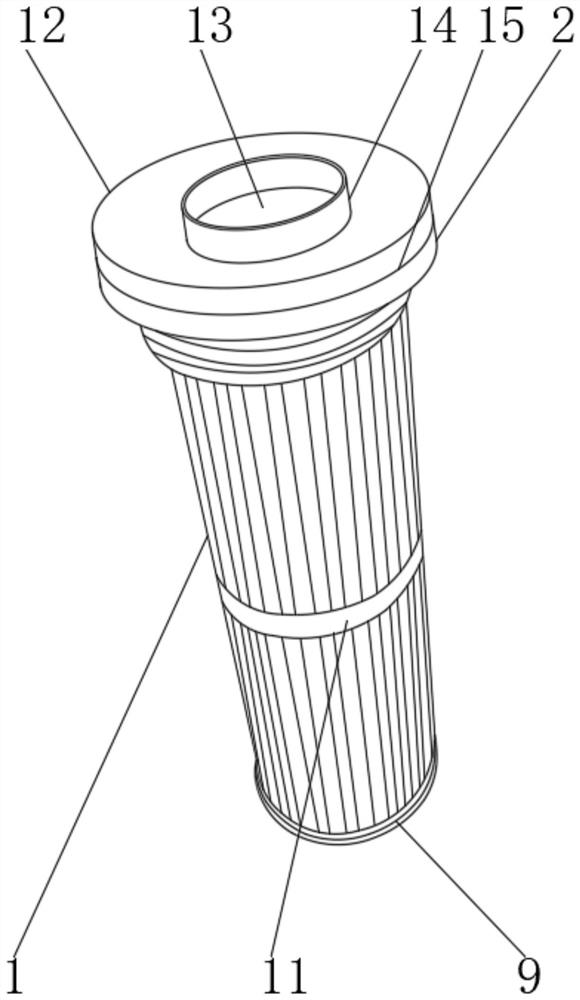

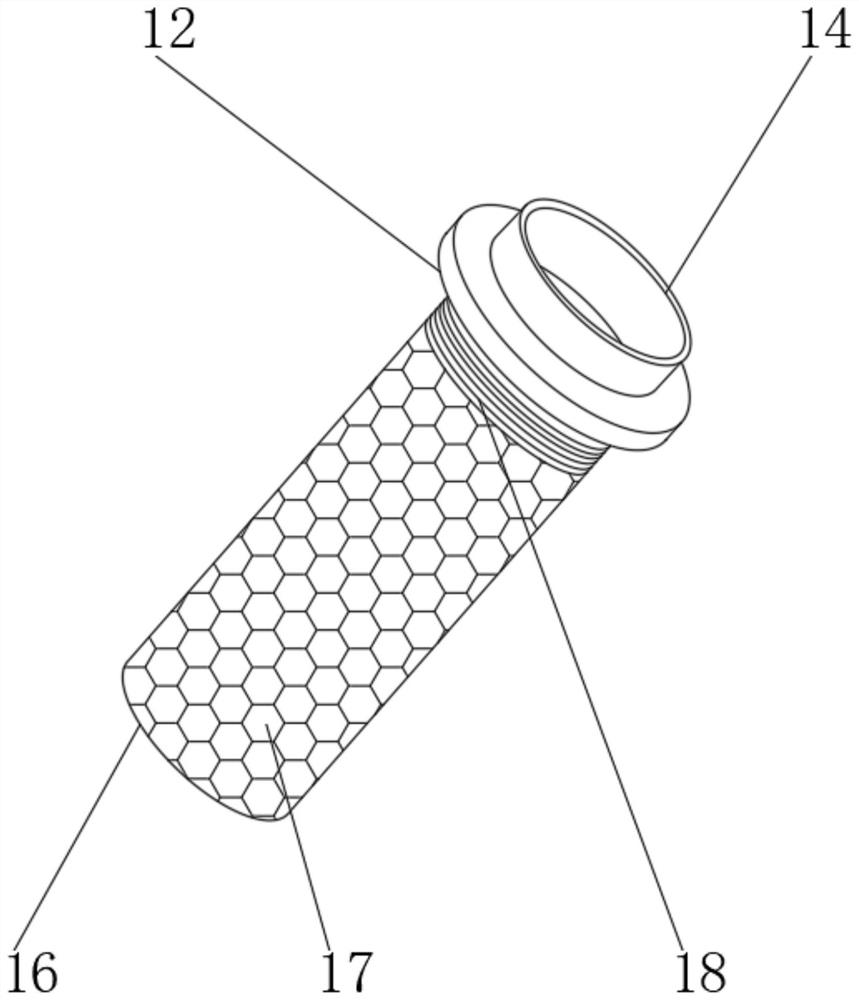

Cloth bag type folded slender dust-removing filter cartridge

InactiveCN113577943AImprove filtering effectEasy to assemble and disassembleDispersed particle filtrationMembrane filtersDust controlEngineering

The invention discloses a cloth bag type folded slender dust-removing filter cartridge. The cloth bag type folded slender dust-removing filter cartridge comprises a dust-removing filter cartridge main body, wherein one end of the dust-removing filter cartridge main body is provided with a tubesheet hole mounting seat, one end of the tubesheet hole mounting seat is provided with an upper-layer mounting retainer ring, the other end of the dust-removing filter cartridge main body is provided with a bottom-layer mounting retainer ring, a connecting support is installed between the bottom-layer mounting retainer ring and the dust-removing filter cartridge main body, and cloth bag type folds are installed on the outer side of the dust-removing filter cartridge main body. According to the cloth bag type folded slender dust-removing filter cartridge, a detachable inner filter ring, a honeycomb filter screen and a reinforced folded cloth bag are arranged, so the filter cartridge can be conveniently and better filtered, disassembled and assembled, t filtering effect is more excellent, use performance is improved, and dust can be conveniently and better filtered; and since a honeycomb structure is adopted, the filter cartridge is high in rigidity, not prone to deformation, light in weight, capable of insulating sound, heat and fire, the use performance of the filter screen is improved, and better use prospects are brought.

Owner:ZHANGJIAGANG ZEF IND FILTER

Aluminum-clad wood fire-resistant window

InactiveCN107664000ANot easy to shakeThose who are not easy fallFireproof doorsGlass pane fixingSash windowFlange

The invention discloses an aluminum-clad wood refractory window. The key points of the technical scheme are that it comprises a window frame, a window sash and a window glass, an aluminum alloy outer frame near the window glass, an aluminum alloy outer mullion near the window glass, and an aluminum alloy outer frame. The side of the window sash close to the window glass is formed with ribs, the side of the wood inner frame close to the window glass, the side of the wood inner mullion close to the window glass and the side of the wood inner sash are all provided with buckles, and the edge of the window glass is clamped on the side of the rib There are steel glass clips between the inner frame of the wood and the outer frame of the aluminum alloy, between the inner frame of the wood and the outer frame of the aluminum alloy, and between the inner sash of the wood and the outer sash of the aluminum alloy. One end of the glass clip is respectively fixed to the wood inner frame, the wood mullion and the wood inner sash, and the other end is pressed to the edge of the window glass, so that the window glass is not easy to shake or fall when exposed to fire.

Owner:北京金诺迪迈幕墙装饰工程有限公司

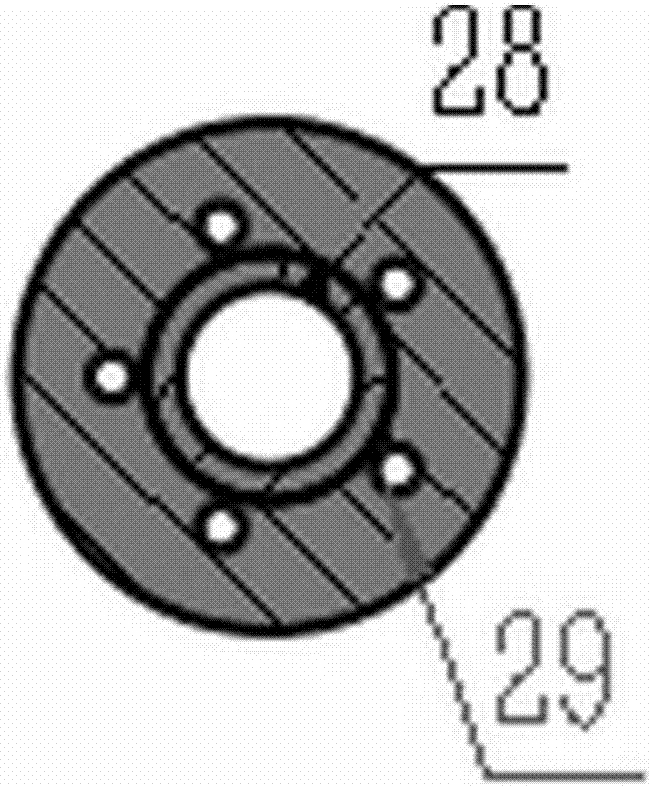

Novel cable reel

InactiveCN107512633AReasonable designSimple structureEmergency protective arrangements for automatic disconnectionFire - disastersEngineering

The invention discloses a novel cable reel. The novel cable reel comprises baffles (3), the two baffles (3) are connected through a bearing (2), the upper part of one baffle (3) is provided with a handle (1), and an overheat overload protector (4), an electromagnetic type leakage protector (8) and heat dissipation fans (9) are arranged on one face of one baffle (3) ; and a base (5) is arranged on the lower part of one baffle (3), pulleys (6) are arranged below the base (5), and a waterproof cover (7) is arranged outside the baffles (3). The novel cable reel has the beneficial effects of being reasonable in design and simple in structure; and the overheat overload protector is arranged to carry out automatic power cut to protect the cable reel when the temperature of the cable reel is too high, so that fire disasters can be prevented, cables can be protected against rain, dust and splashing; and construction operation is facilitated, and the safety hazard can be killed in the cradle.

Owner:JIANGYIN DONGREN MACHINERY

Material for building decoration and artificial floor manufactured by material for building decoration

InactiveCN102557522BEasy to prepareDoes not affect ease of installationCovering/liningsFlooringParaffin waxContinuous use

The invention discloses a material for building decoration. The material for building decoration is prepared by the following raw materials in parts by weight: 40-60 parts of calcite, 40-60 parts of PVC (Poly Vinyl Chloride), 1-2 parts of sodium chloride, 1-3 parts of paraffin wax and 1-2 parts of stabilizer. The main materials of the material for building decoration include the calcite and the PVC, and the specific weight of the calcite and the PVC accounts for above 93% of that of all the raw materials, and a base material prepared by the calcite and the PVC has the most direct advantages of being lighter than a ceramic tile and being non-deformed and difficultly corroded in a wet environment and the like; the decoration material prepared by the base material can be recovered, crushed, squeezed and granulated for continuous use after being used for a certain time, and has the advantages of energy saving and environmental friendliness, and a stone material is mixed with large amounts of PVC, so that the ice-cold feel of the decoration material can be reduced, and the insulation effect is enhanced; and the decoration material cannot be broken in case of collision, so that the base material can be squeezed to obtain a variety of decoration materials, such as floor tiles, wall tiles, ceilings and the like.

Owner:贵州中部能源集团安顺市西秀区博吉板业有限责任公司

Low emission high-power staged-combustion gas burner and gas collocation method thereof

ActiveCN102003710BReduce the temperatureReduce concentrationGaseous fuel burnerIndustrial gasLow speed

The invention belongs to the technical field of industrial gas burner and relates to a low emission high-power staged-combustion gas burner. The staged-combustion gas burner is characterized in that a swirling machine, a flame stabilizing plate, a central canister and a middle pipe are coaxially arranged in the throat of the burner main body from outer to inner, wherein the flame stabilizing plate is provided with a gas gun which is axially fixed and has same uniformly distributed radial lines. The gas collocation method comprises the following steps: (1) collocating no gas in a direct air channel, in which is low-speed central cooling air, (2) mixing the high-speed swirling air entered from a swirling air channel with the gas jetted from a small gas hole B on the gas gun along the radialdirection till reaching to the semi-premixed state before emerging from the throat of the gas burner, and (3) face-to-face jetting the gas from a big gas hole on the top of the gas gun, the high-speed swirling air and the high-speed peripheral axial air flow so as to form non-premixing diffusion combustion. Because of the air, the staged gas branch supply, the premixing combustion and the non-premixing diffusion combustion, the combustion is uniform and NOx is prevented from being generated. The discharge amount of NOx of the gas burner is 70% lower than that of the common burner in the priorart.

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

A kind of preparation method of photoinitiator bis (2,4,6-trimethylbenzoyl) phenyl phosphine oxide

The invention discloses a preparation method of a photoinitiator phenyl bis(2,4,6-trimethylbenzoyl)-phosphine oxide, comprising the steps of enabling diethyl benzylphosphonate and an excessive vitride solution to react in argon under the temperature of 60-70 DEG C, so as to generate phenyl phosphine, enabling the phenyl phosphine and 2,4,6-trimethylbenzoyl chloride to react, so as to obtain a methylbenzene solution of diphenyl(2,4,6-trimethylbenzoyl)phosphine, and oxidizing the diphenyl(2,4,6-trimethylbenzoyl)phosphine into 2 phenyl bis(2,4,6-trimethylbenzoyl)-phosphine oxide by hydrogen peroxide without separating. According to the process, dangerous metal sodium or potassium is not used, the process is advanced, the operation is simple and safe, the product yield is high, the quality is good, and large-scale production is easy.

Owner:YIDU YOUYUAN IND CO LTD

Flame-retardant building wall coating

The invention discloses a flame-retardant building wall coating which is characterized by containing the following substances, by weight, 30-40 parts of a 108 solution, 20-30 parts of perlite, 15-30 parts of an anti-aging agent, 1-6 parts of a compatilizer, 3-9 parts of color master batch, 3-6 parts of lightweight aggregate, 1-9 parts of a cementing material, 5-8 parts of calcium stearate, 6-10 parts of stearic acid, 9-16 parts of modified polypropylene, 3-15 parts of poly-4-methyl-1-pentene, 8-16 parts of active calcium, 30-50 parts of cement, 3-16 parts of a thickening agent, 1-2 parts of a wetting agent, 1-2 parts of a dispersant, 1-2 parts of a mildew inhibitor, 0.1-0.3 part of rutile type titanium dioxide and 0.3-0.8 parts of diatomite. The flame-retardant building wall coating is not easy to age, has waterproof, fireproof, heat-insulation and sound-insulation functions, and is suitable for heat insulation of lightweight baffle walls and pipelines of high-rise buildings.

Owner:黄艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com