Fiber-reinforced fly ash pressure plate and manufacturing method

A technology of fiber reinforcement and fly ash, which is applied in the field of building materials, can solve the problems of insufficient strength of calcium silicate board, easy deformation of the board, poor nail holding force, etc., and achieves great environmental protection and economic significance, good moisture resistance, and nail holding Lego effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

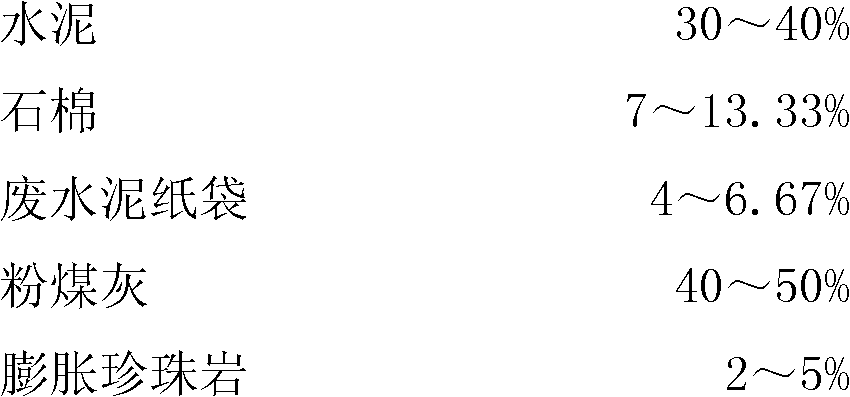

[0029] Embodiment 1: the formula of each component is: cement (common 32.5#) 271kg, accounting for 31.8%, asbestos 103kg, accounting for 12.1%, waste cement paper bag 52kg, accounting for 6.1%, fly ash 387kg, accounting for 45.4% %, expanded perlite 39kg, accounting for 4.6%; prepare raw materials according to the above-mentioned components and their mass percentages; pulp waste cement paper bags, add water to dilute, stir until the mass percentage concentration is 10%, sieve, add water to dilute, adjust to Use a slurry with a concentration of about 3%; loosen the asbestos, add water to dilute, stir, and loosen for 0.3h. The mass ratio of the added water to asbestos is 30:1, and then add the cement, fly ash, Expanded perlite and waste cement paper bag slurry are stirred and mixed to make a slurry; the slurry is passed through the headbox cloth to the wool cloth, vacuum dehydrated to a concentration of 70% by mass, and is pressed and formed by a roller stacked forming cylinder. ...

Embodiment 2

[0030] Embodiment 2, the formula of each component is: cement (common 32.5#) 310kg, accounting for 38.9%, asbestos 93kg, accounting for 11.7%, waste cement paper bag 47kg, accounting for 5.9%, fly ash 310kg, expanded perlite 35kg; Prepare raw materials according to the above components and their mass percentages; pulp waste cement paper bags, add water to dilute, stir until the mass percentage concentration is 11%, sieve, add water to dilute, and adjust to a slurry with a concentration of about 3%; The asbestos is loosened, diluted with water, stirred, and loosened for 0.3h. The mass ratio of the added water to asbestos is 35:1, and then the cement, fly ash, expanded perlite, and waste cement paper bag slurry are added, After stirring and mixing, the slurry is made; the slurry is passed through the headbox cloth to the wool cloth, vacuum dehydrated to a concentration of 72% by mass, and pressed by a roller stacked forming cylinder. The pressure of the forming cylinder is 2.5 MP...

Embodiment 3

[0031] Embodiment 3, the formula of each component is: cement (common 32.5#) 248kg, asbestos 78kg, waste cement paper bag 50kg, fly ash 271kg, expanded perlite 38kg; Prepare raw material according to above-mentioned component and mass percentage thereof; Pulping cement paper bags, adding water to dilute, stirring until the mass percentage concentration is 12%, sieving, adding water to dilute, and adjusting to a slurry with a concentration of about 3%; loosen the asbestos, add water to dilute, stir, and loosen 0.3% h, the mass ratio of the added water and asbestos is 40:1, then add the cement, fly ash, expanded perlite, waste cement paper bag slurry, stir and mix to make slurry; Pulp box cloth to felt cloth, vacuum dehydration to a mass percentage concentration of 75%, pressed by a roller laminated forming cylinder, the pressure of the forming cylinder is 3 MPa, and formed by longitudinal and transverse cutting to obtain a fiber-reinforced fly ash pressure plate slab ; Place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com