High-efficiency gas burning nozzle

A gas burner, high-efficiency technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of unfavorable bottom temperature, easy defire, gas diffusion, etc., to prevent residual gas diffusion, strong combustion , the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

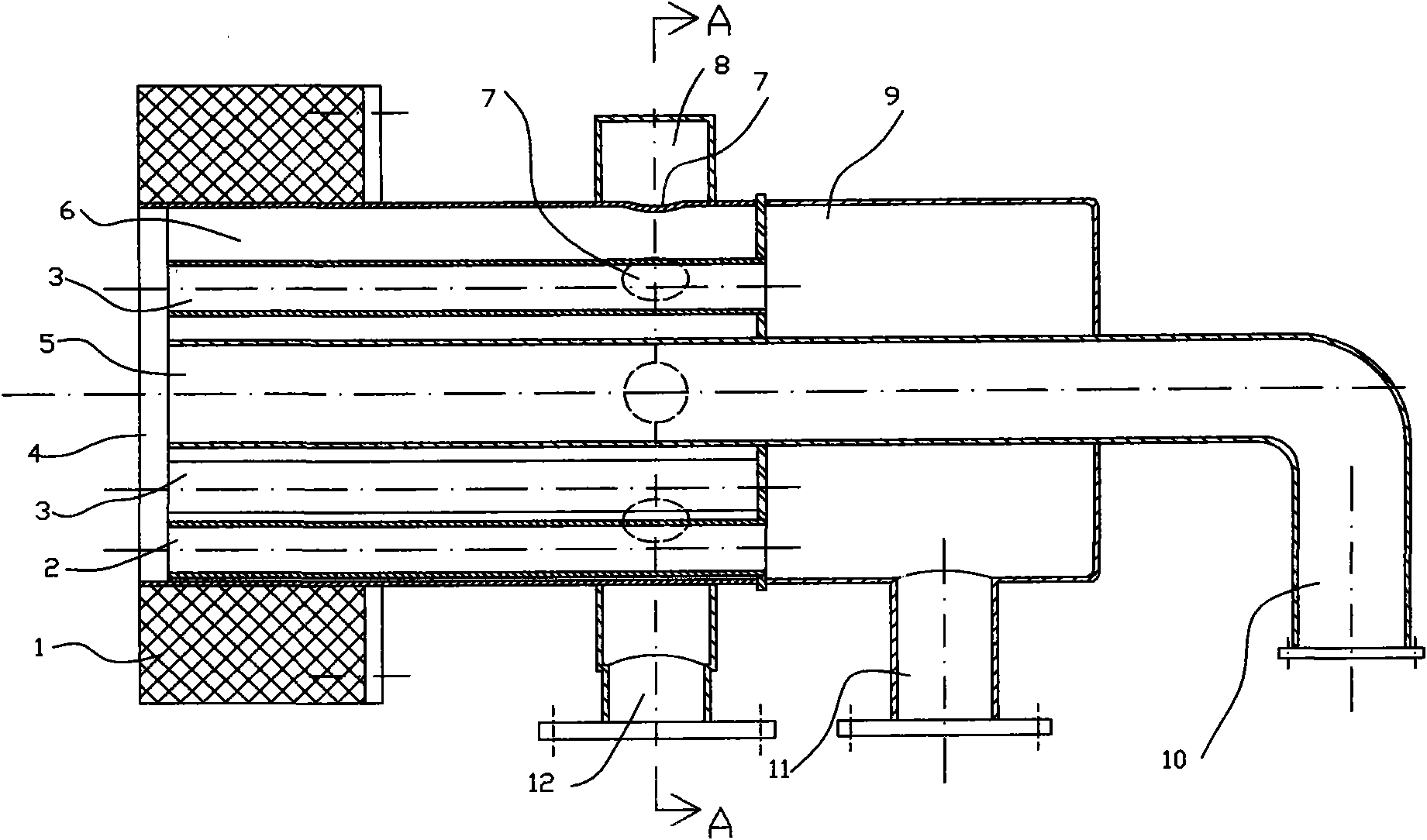

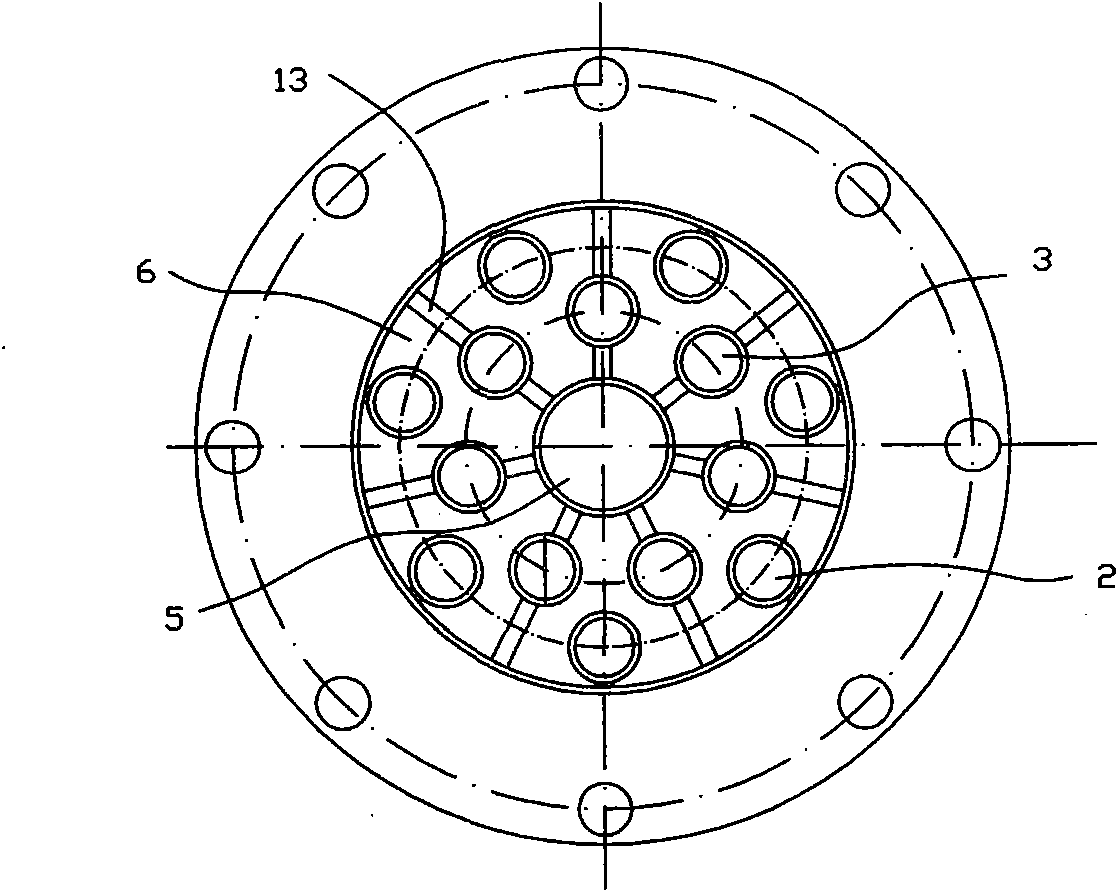

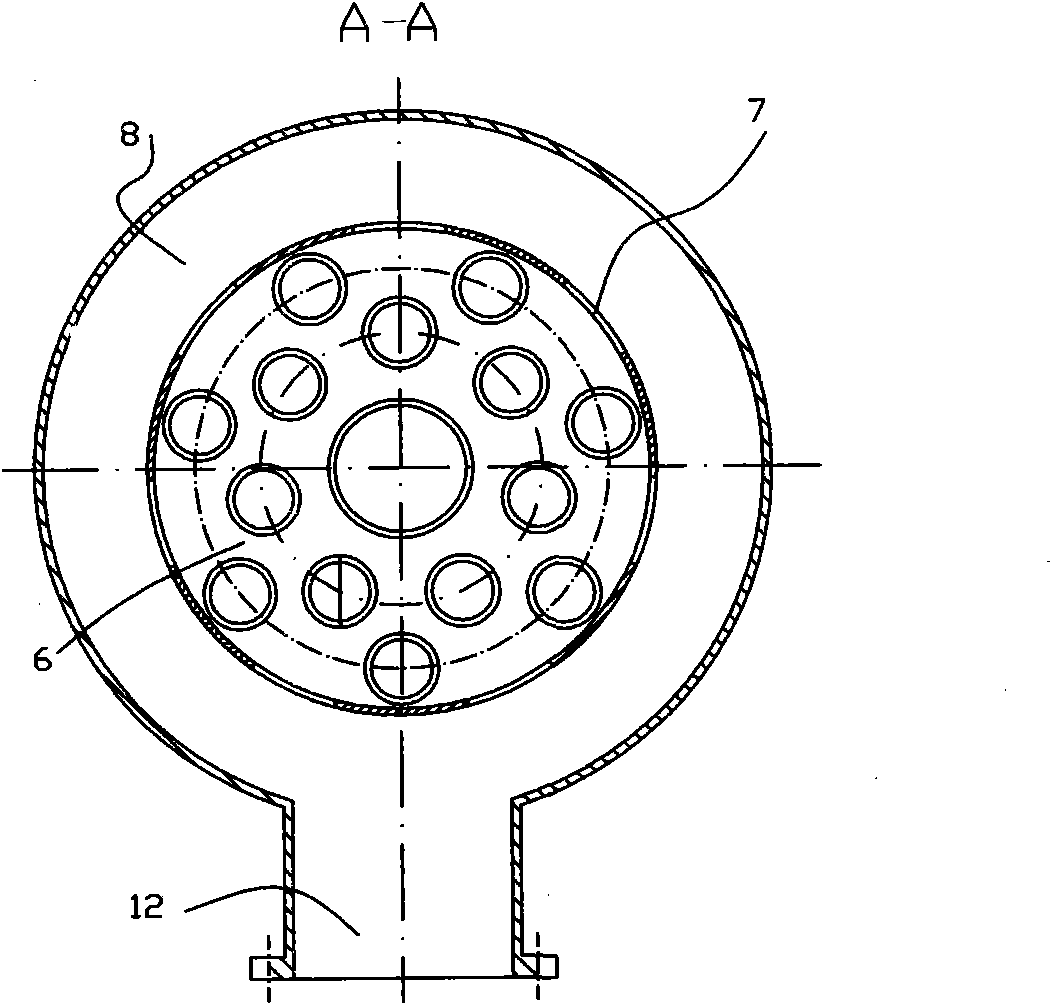

[0014] The present invention as Figure 1-3 As shown, it includes a cylindrical body 4, and a gas pipeline and an air pipeline arranged in the body 4, and the air pipeline includes a peripheral air channel 6 and a central air channel 5 coaxial with the body 4; A single number of inner-ring pipeline groups 3 are evenly distributed around the central airway 5, and outer-ring pipeline groups 2 equal in number to the inner-ring pipeline group 3 are evenly distributed around the inner-ring pipeline group 3; the body 4 The inner surface of the inner ring pipe group 3, the outer ring pipe group 2 and the outer surface of the central air channel 5, and the gap between them constitute the peripheral air channel 6.

[0015] It also has a peripheral airway inlet ring 8 , which is arranged outside the body 4 and communicates with the peripheral airway 6 through the through hole 7 opened on the body 4 .

[0016] The rear end of the body 4 is provided with a gas inlet chamber 9 , and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com