Aluminum-clad wood fire-resistant window

A fire-resistant window, aluminum-clad wood technology, applied in the field of doors and windows, can solve the problems of difficult to achieve fire protection standards, easy to shake and fall out of the window glass, and achieve the effect of being less susceptible to fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

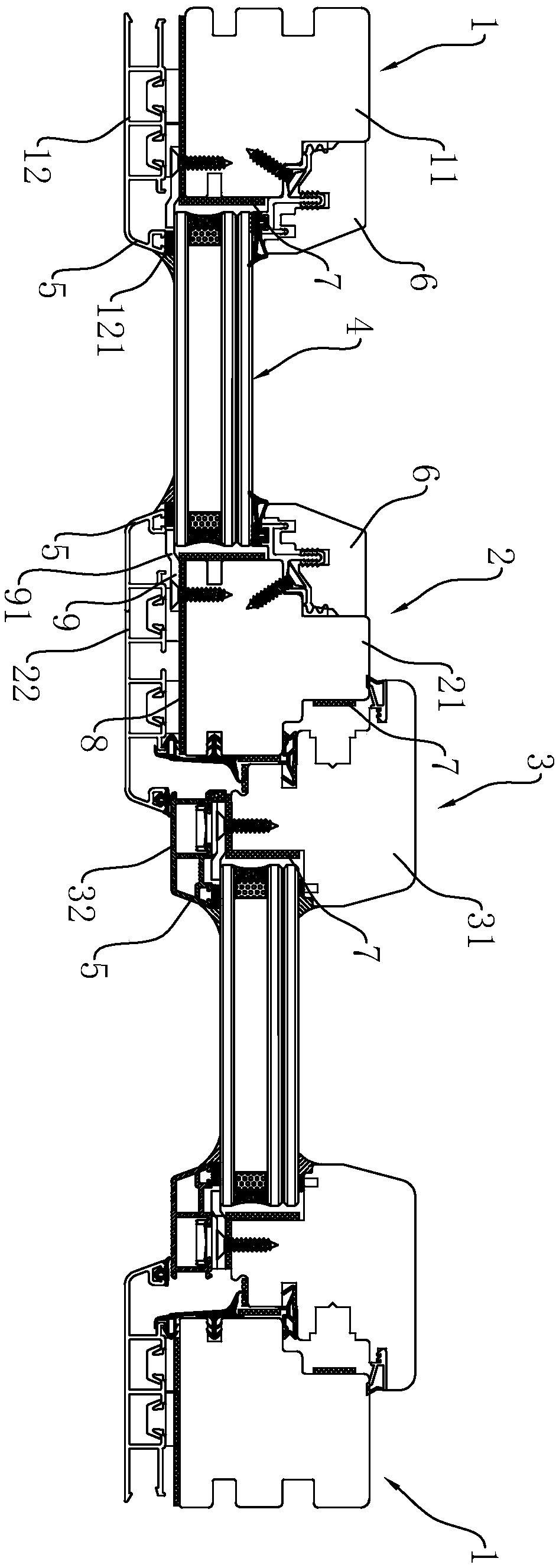

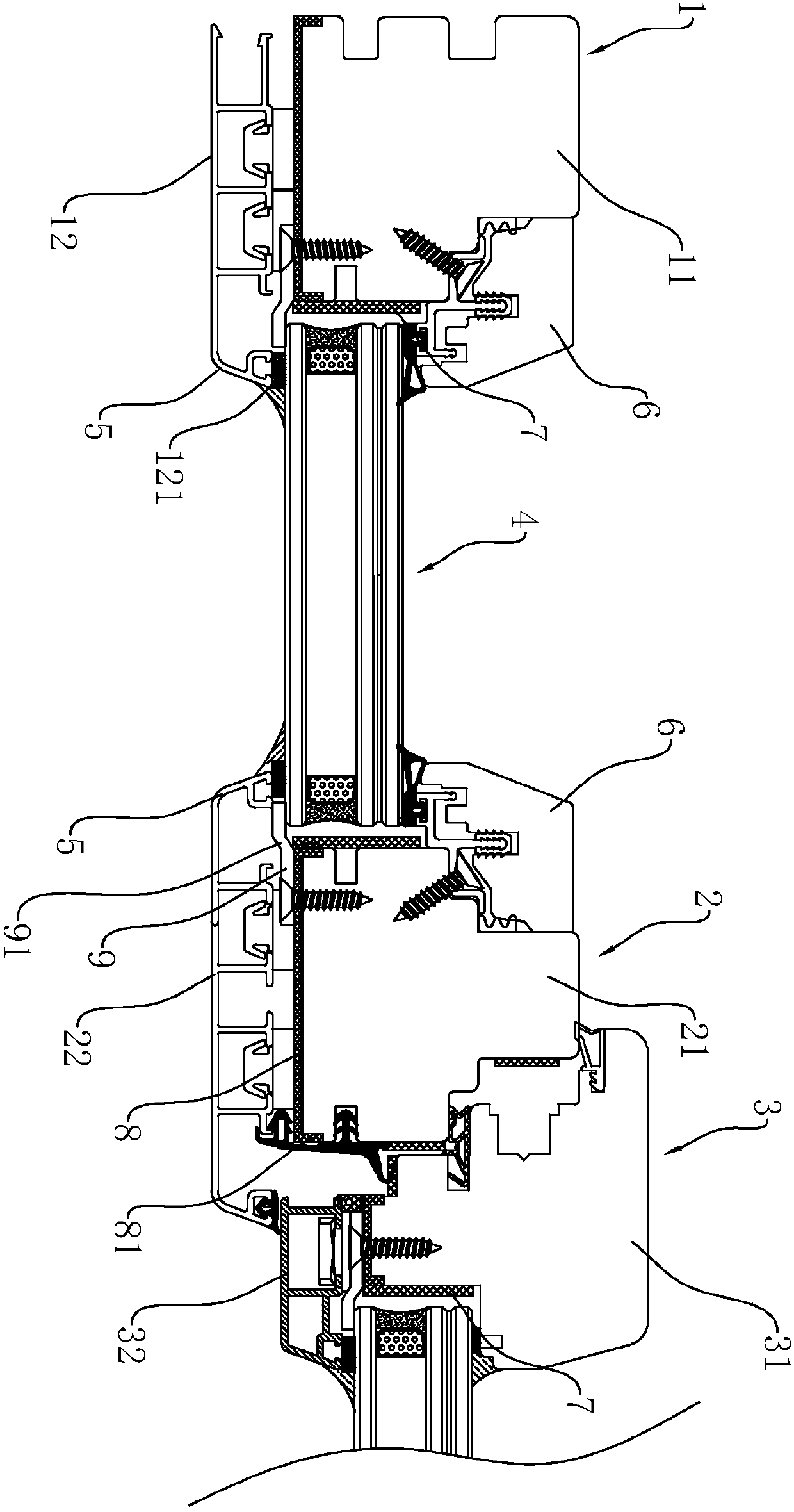

[0034] An aluminum-clad wood fire-resistant window, such as figure 1 As shown, it includes a window frame, a window sash 3 and a window glass 4 on the window frame and the window sash 3 installed respectively. The glass clip 9 on the edge, the glass clip 9 can be made of steel.

[0035] Frame 1 includes wood inner frame 11 and aluminum alloy outer frame 12, stile 2 includes wood inner stile 21 and aluminum alloy outer stile 22, window sash 3 includes wood inner sash 31 and aluminum alloy outer sash 32, wood inner frame 11, Timber inner stile 21 and timber inner sash 31 can be made of wood profiles, aluminum alloy outer frame 12, aluminum alloy outer stile 22 and aluminum alloy outer sash 32 can be made of aluminum alloy profiles, aluminum alloy outer frame 12 is close to the window One side of the glass 4, the side of the aluminum alloy outer stile 22 close to the window glass 4, and the side of the aluminum alloy outer sash 32 close to the window glass 4 all protrude to the ...

Embodiment 2

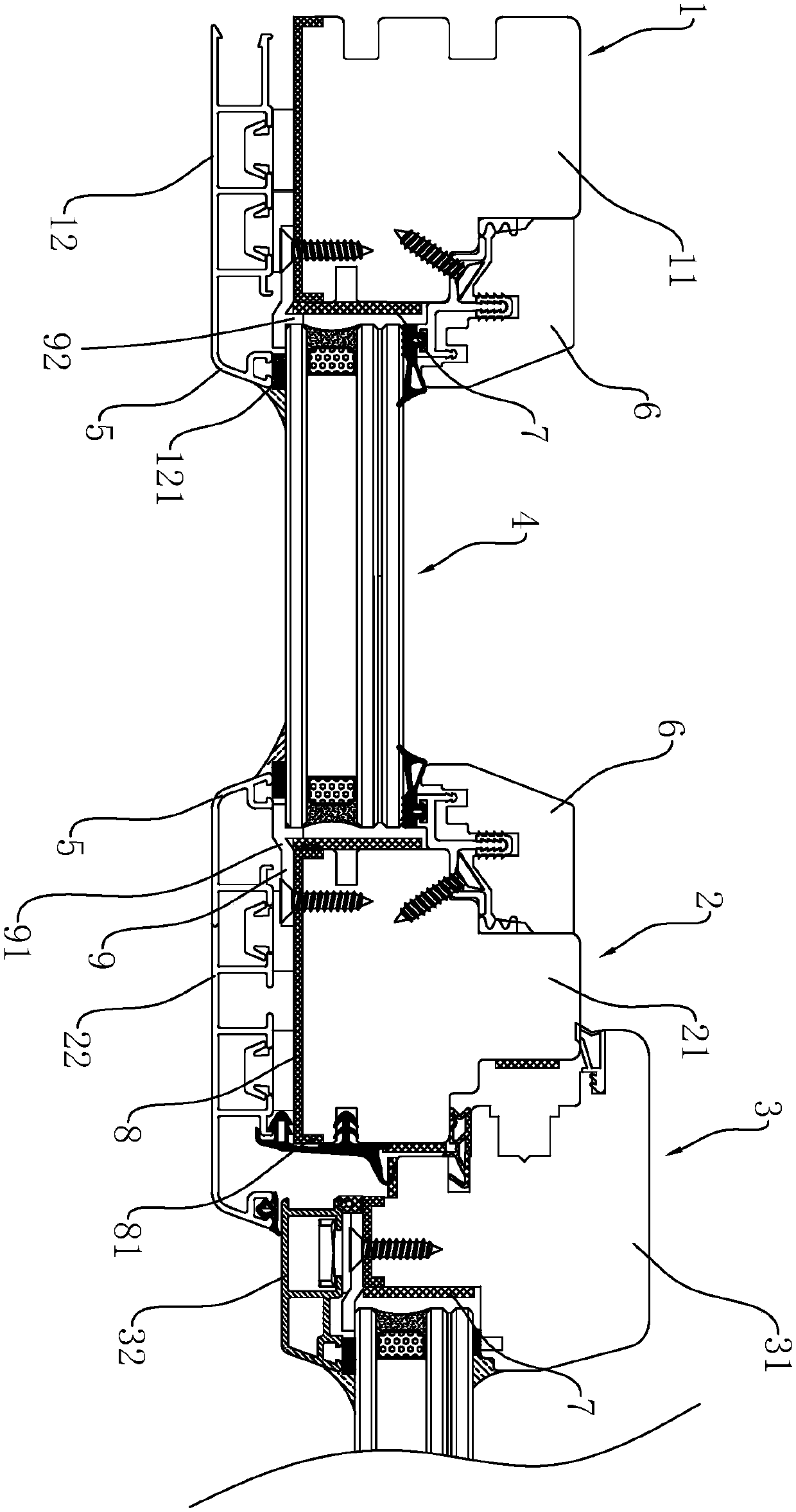

[0041] Such as image 3 As shown, the difference from Embodiment 1 is that the glass card 9 is formed with a positioning bar 92 that abuts against the side of the edge of the window glass 4, and the positioning bar 92 gives a supporting force to the side of the window glass 4, so that the window glass 4 does not Shakes easily.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com