Insulating skin fixed-length removing machine for wire processing

A technology for wire processing and insulation, which is applied in the field of fixed-length insulation removal machines for wire processing, which can solve problems such as low work efficiency, danger, and fire hazards, and achieve the effects of smooth wire movement, high work efficiency, and avoidance of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

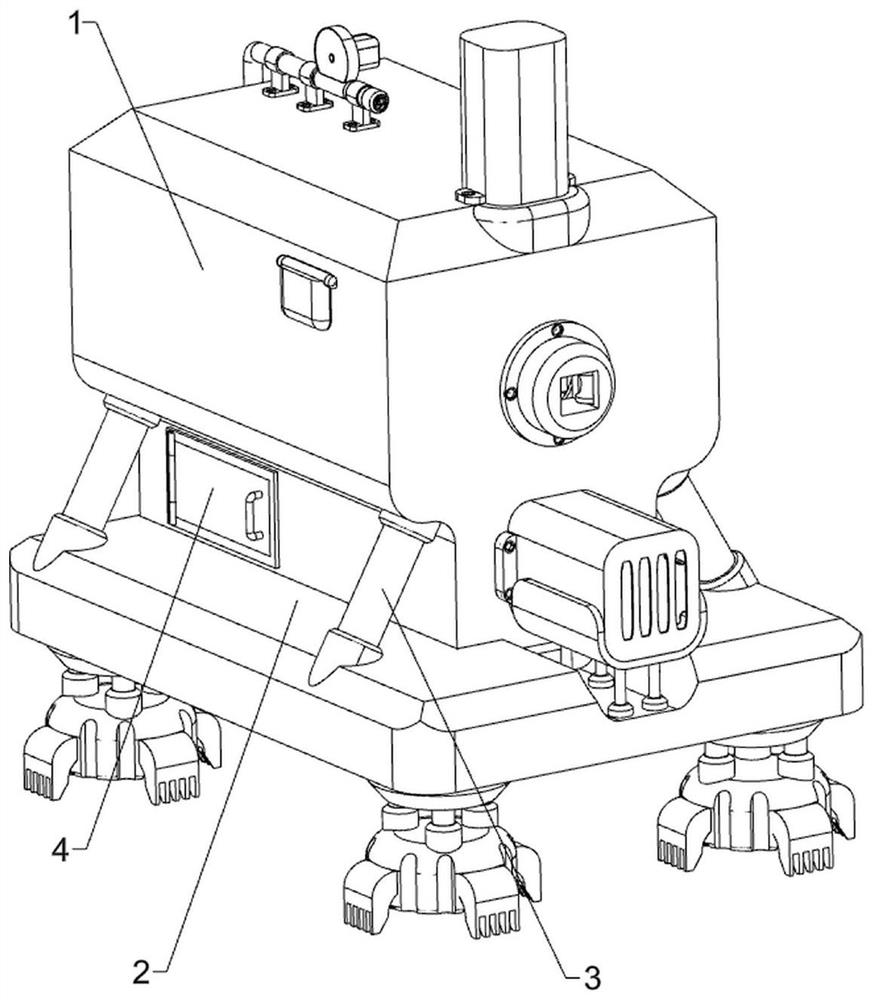

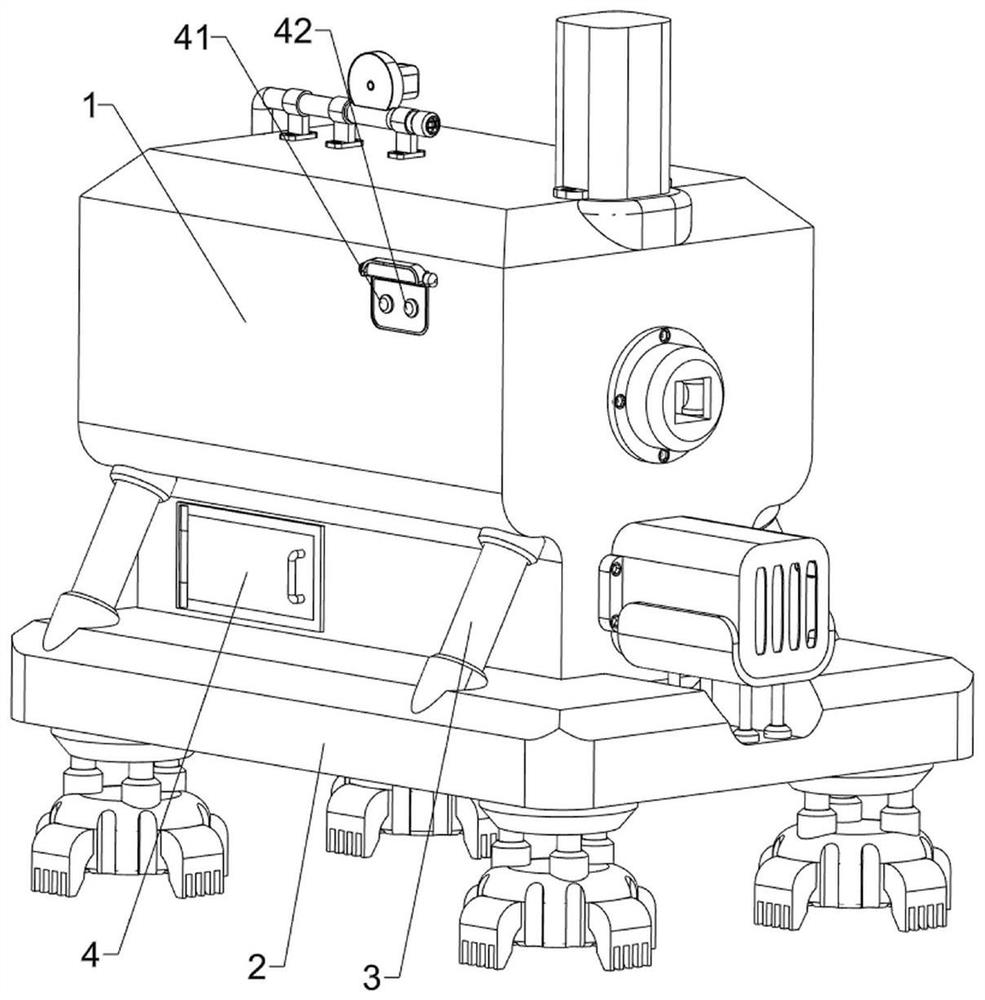

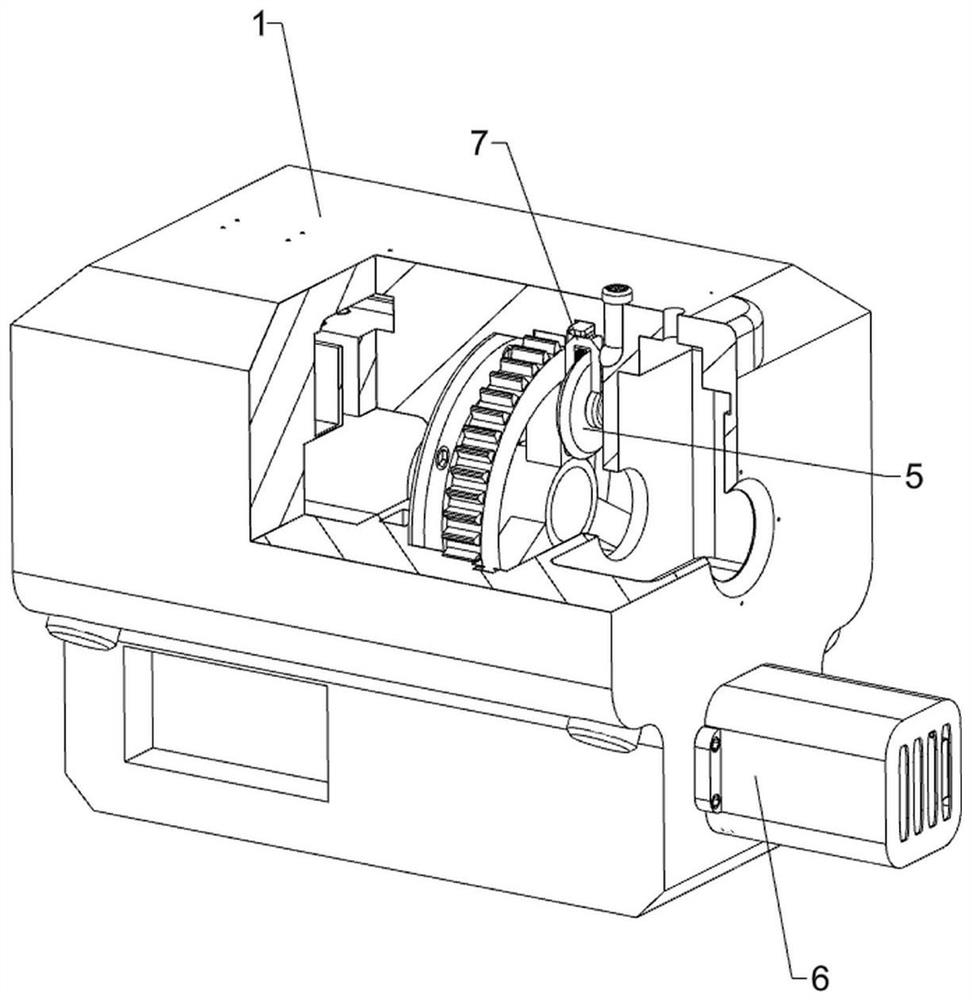

[0039] A kind of insulating skin fixed-length removing machine for electric wire processing, such as Figure 1-Figure 7 As shown, it includes a protective bottom box 1, a support base plate 2, a support column 3, a start button 41, a reset button 42, a separation cutter 5, a driving mechanism 6 and a cutting mechanism 7, and the bottom of the protective bottom box 1 is fixedly connected with a support base plate 2 , the top of the support base plate 2 is fixedly connected with four support columns 3 at intervals, the support columns 3 are connected with the protective bottom box 1, and the front part of the left side surface of the protective bottom box 1 is fixedly connected with a start button 41 and a reset button 42, and the reset button 42 is located at On the front side of the start button 41, the protective bottom box 1 is provided with a driving mechanism 6, and a cutting mechanism 7 is arranged between the driving mechanism 6 and the protective bottom box 1. The cuttin...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 7-Figure 13 As shown, a positioning mechanism 8 is also included, and the positioning mechanism 8 includes a second installation bottom box 81, an electric push rod 82, an arched connecting plate 83, a positioning plate 84, a positioning column 85, a rubber bottom block 86, a photoelectric sensor 87, The buffer bottom block 88, the second return spring 89 and the second pressure sensor 810, the second installation bottom box 81 is fixedly connected to the front middle side of the outer top of the protective bottom box 1, and the electric push rod 82 is fixedly connected to the inside of the second installation bottom box 81 , the electric push rod 82 telescopic rod passes through the protective bottom box 1, the electric push rod 82 telescopic rod is connected with an arched connecting plate 83, and the middle of the front part of the protective bottom box 1 is fixedly connected with a rubber bottom block 86, and the rubber bott...

Embodiment 3

[0049] On the basis of embodiment 1 and embodiment, as Figure 7 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, a blowing mechanism 10 is also included, and the blowing mechanism 10 includes a blanking ramp 101, an installation top block 102, an air intake pump 103, a telescopic duct 104, a limit top plate 105, a lifting installation plate 106, and a driving roller 107 , gas guide inclined pipe 108, positioning underframe 109, the fifth return spring 1010 and the third pressure sensor 1011, the middle part of the back side of the protective bottom box 1 is fixedly connected with a blanking ramp 101, and the rear side of the top of the protective bottom box 1 is separated by three A top block 102 is installed, and a telescopic conduit 104 is arranged between the tops of the three top blocks 102. The telescopic conduit 104 passes through the protective bottom box 1. The front portion of the telescopic conduit 104 is connected with an intake pump 103, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com