Patents

Literature

100results about How to "Short flame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

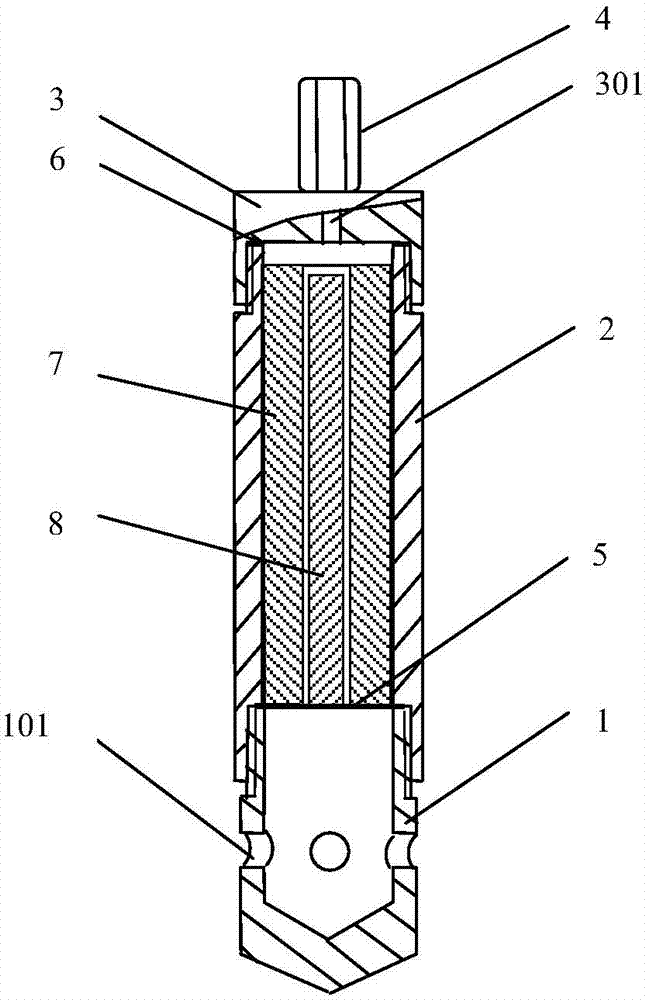

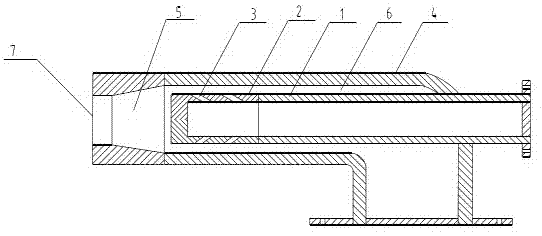

Gas circuit axial grading type dual-fuel nozzle

InactiveCN103175223AIncrease the circulation areaReduce radial sizeContinuous combustion chamberWater vaporEngineering

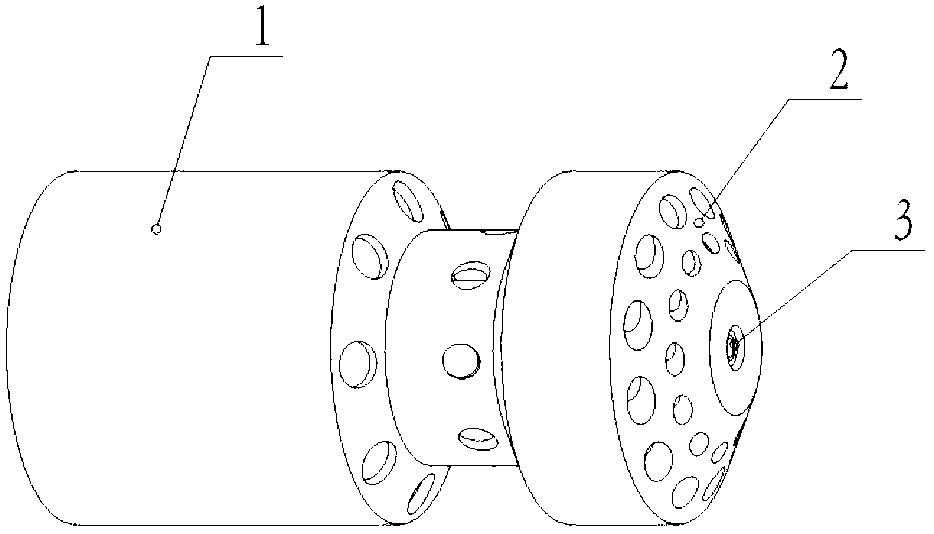

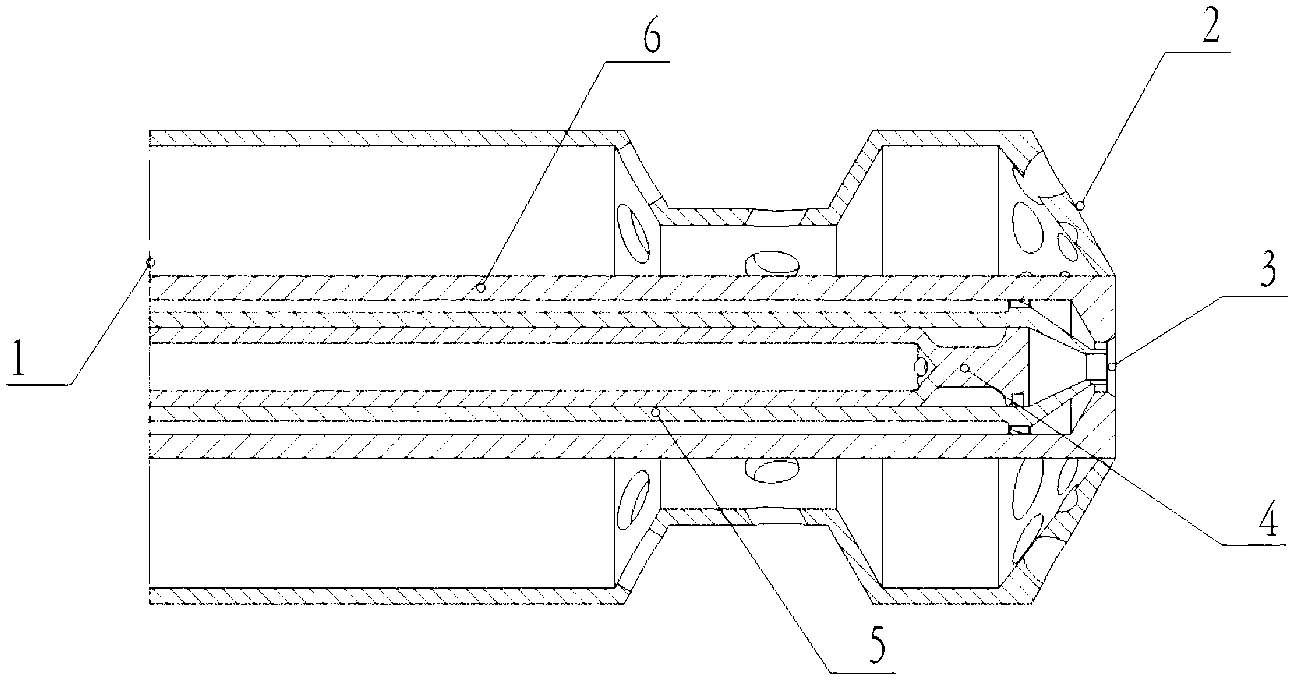

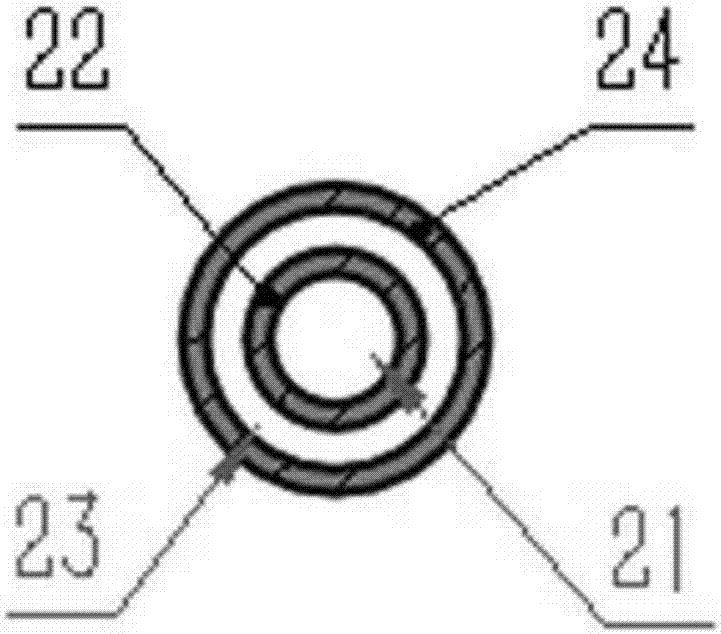

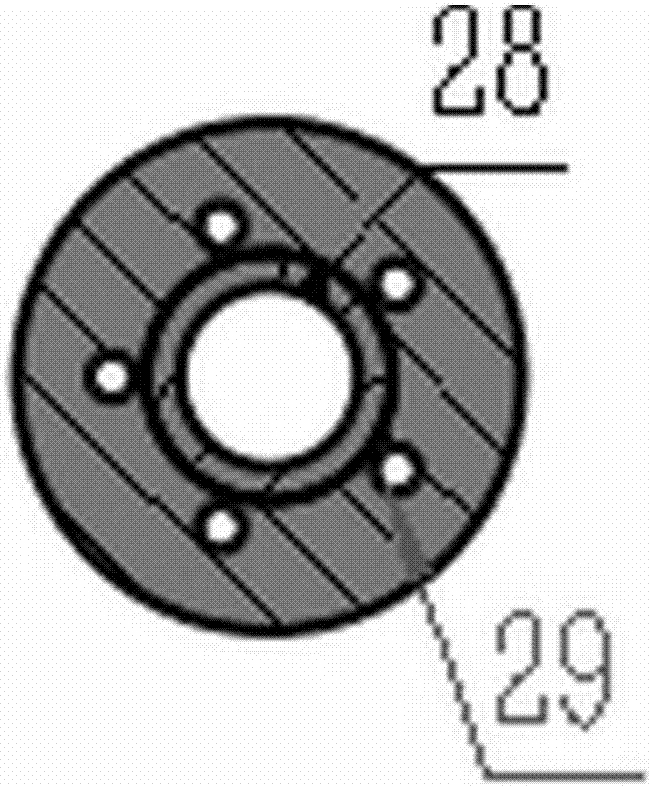

The invention aims to provide a gas circuit axial grading type dual-fuel nozzle which comprises a gas circuit outer wall and a main oil circuit wall arranged inside the gas circuit outer wall. An auxiliary oil circuit wall is arranged inside the main oil circuit wall. A main oil circuit channel is formed between the main oil circuit wall and the auxiliary oil circuit wall. An auxiliary oil circuit channel is formed inside the auxiliary oil circuit wall. A gas circuit is formed between the gas circuit outer wall and the main oil circuit wall. The gas circuit comprises a gas circuit front cavity, a gas circuit laryngeal and a gas circuit rear cavity in sequential communication. A first level gas circuit gas ejection hole is formed in a position, arranged on the gas circuit front cavity, of the gas circuit outer wall. A laryngeal gas ejection hole is formed in the gas circuit laryngeal. A second level gas circuit gas ejection hole is formed in the gas circuit rear cavity. Due to the fact that a gas circuit axial grading type structure is adopted, the gas circuit axial grading type dual-fuel nozzle has the advantages of reducing the radial size of the nozzle, simultaneously increasing gas circuit flow area, enhancing mixing of fuel and air, strengthening burning, shortening flame, and simultaneously not burning the wall surface of a flame tube. When liquid fuel is burned, water vapor reinjection is conducted by the gas circuit.

Owner:HARBIN ENG UNIV

Continuous casting crystallizer casting powder special for bar plate stainless steel containing titanium and manufacturing technique thereof

The invention relates to an auxiliary product for metallurgy used for continuous casting of titanium-containing stainless steel in the metallurgy field, which is mainly applied in the mould powder technique of pre-melted crystallization mould of continuous casting for high titanium containing stainless steel. The materials of the invention comprise: specific used pre-melted base materials containing boron, flux materials, carbonaceous materials and additives; wherein, the flux materials comprise Li2CO3, Na2CO3, NaF, etc. The invention is characterized by good performance of accommodating and adsorbing titanium inclusion under the condition of meeting requirements for adding no carbon and reducing regrinding of traditional stainless steel; besides, after absorption of inclusion, the viscosity properties and solidification properties of the mould powder can be kept relatively stable, and compared with the import slag, the invention has the advantages of lower caking bleeding rate, casting billet with less surface defect, high anterograde of processing. Besides, the production of the invention has little slag strip; reaction in the crystallization mould is active; spreading property is good.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

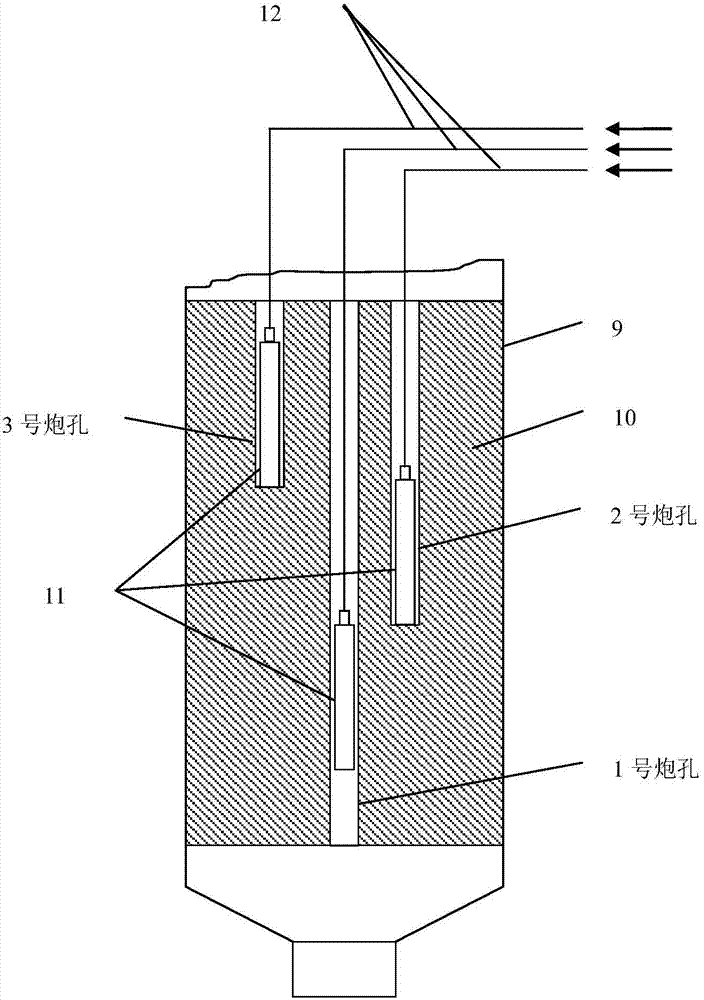

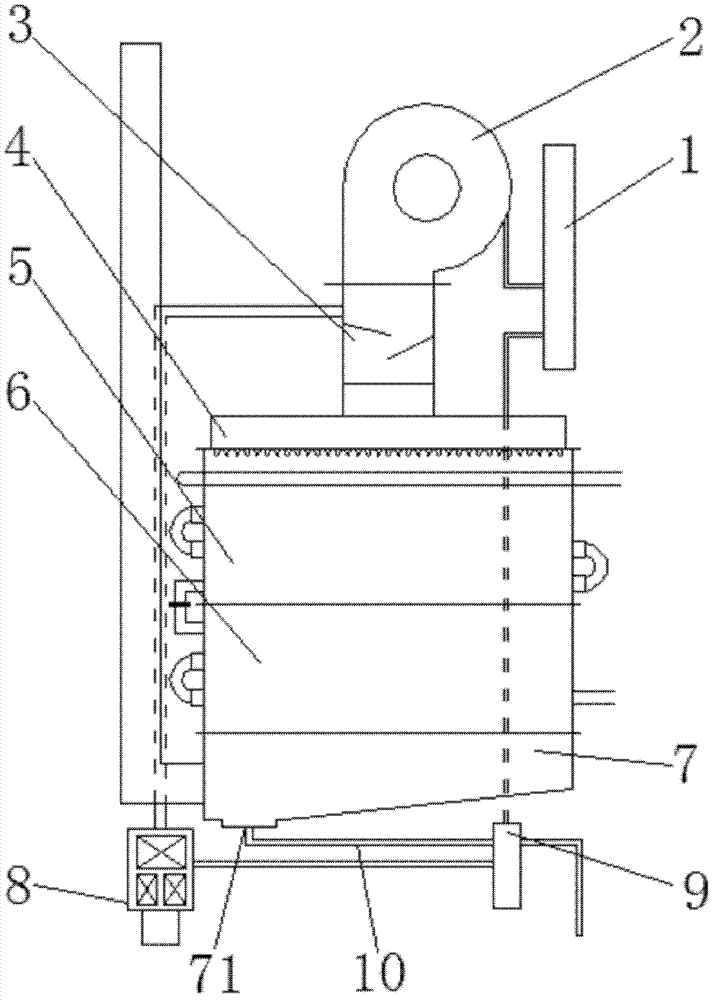

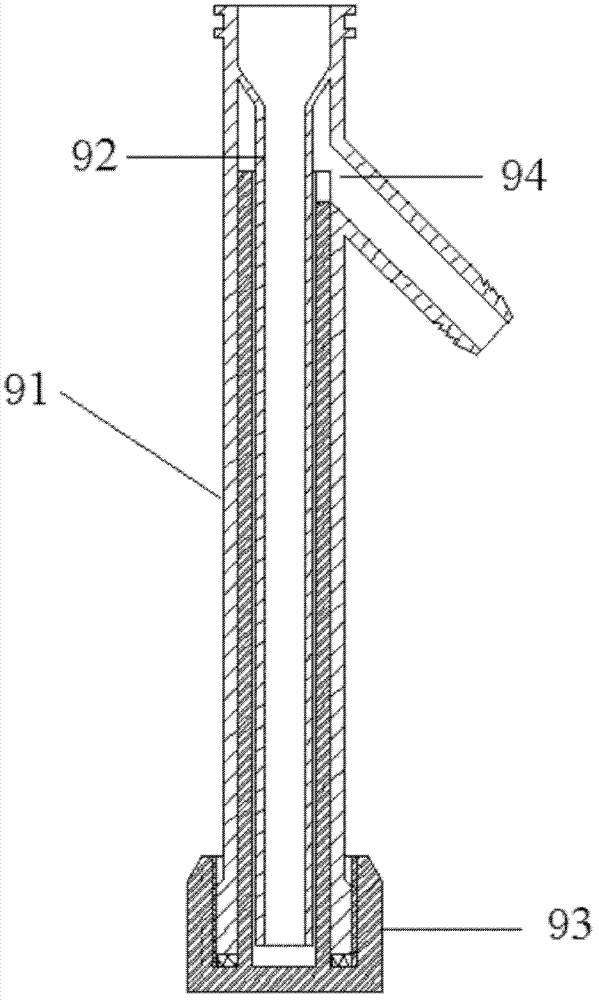

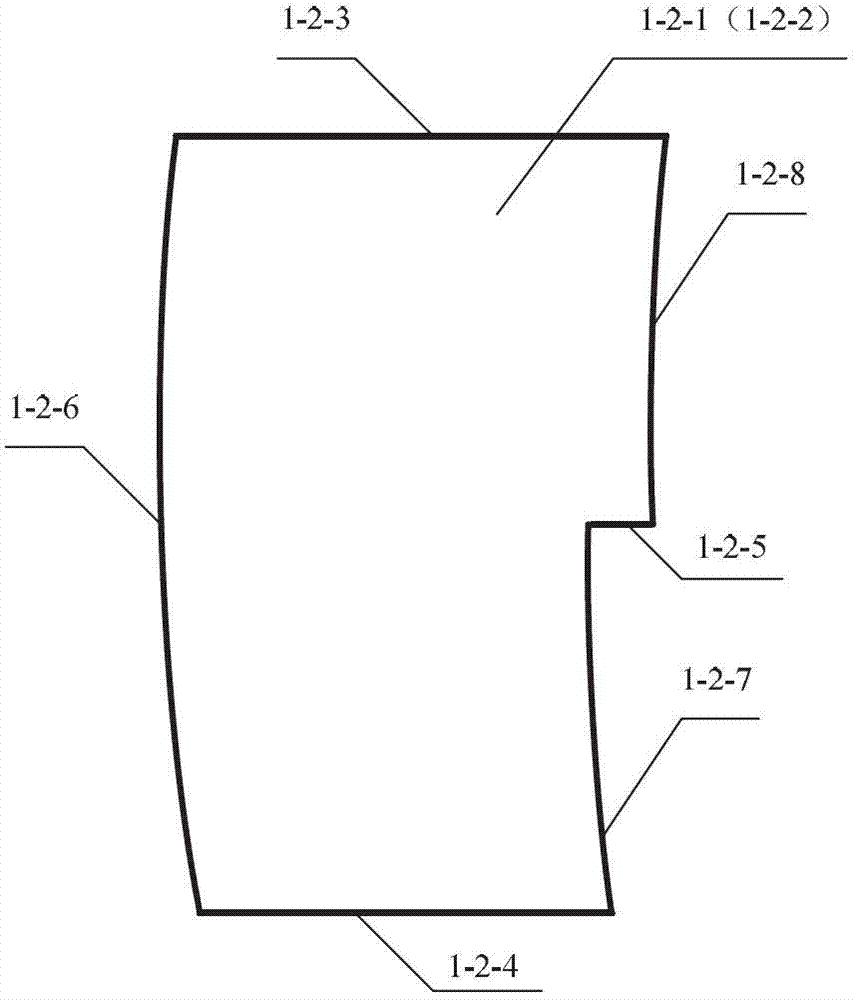

Dry ice blasting method and dry ice blasting device

InactiveCN104500068AOvercome potentially dangerous drawbacksWill not cause an explosionDisloding machinesUnderground miningToxic gasWater source

The invention relates to a dry ice blasting method and a dry ice blasting device, and belongs to the field of engineering blasting. The dry ice blasting device comprises a spray head, a cylinder body, a tail cover and a one-way valve, wherein the spray head is provided with an exhaust hole; the tail cover is provided with a water inlet hole; a sealing gasket is arranged between the cylinder body and the tail cover; a blasting sheet is arranged between the cylinder body and the spray head; and the tail cover is communicated with the one-way valve through the water inlet hole. The dry ice blasting method comprises the following steps: drilling in a coal bed; assembling the dry ice blasting device, and filling the dry ice blasting device with dry ice and a heating bag; connecting the dry ice blasting device with a water pipe, and placing into a blast hole; and communicating with a water source, and injecting water into the dry ice blasting device, wherein the heating bag inside the cylinder body fast releases heat when encountering water so as to urge the dry ice to be fast sublimated into carbon dioxide gas, when gas pressure exceeds the design pressure of the blasting sheet, the instant blasting of the blasting sheet is caused, and the carbon dioxide gas is fast discharged through the exhaust hole formed in the spray head to form impaction and expansion extrusion on the wall of the blast hole, so that the blasting is realized. The dry ice blasting method and the dry ice blasting device which are disclosed by the invention have the advantages of achieving the bursting at normal temperature, generating no flame or toxic gas and being suitable for a coal mine with gas and coal dust explosion risks.

Owner:CHINA UNIV OF MINING & TECH

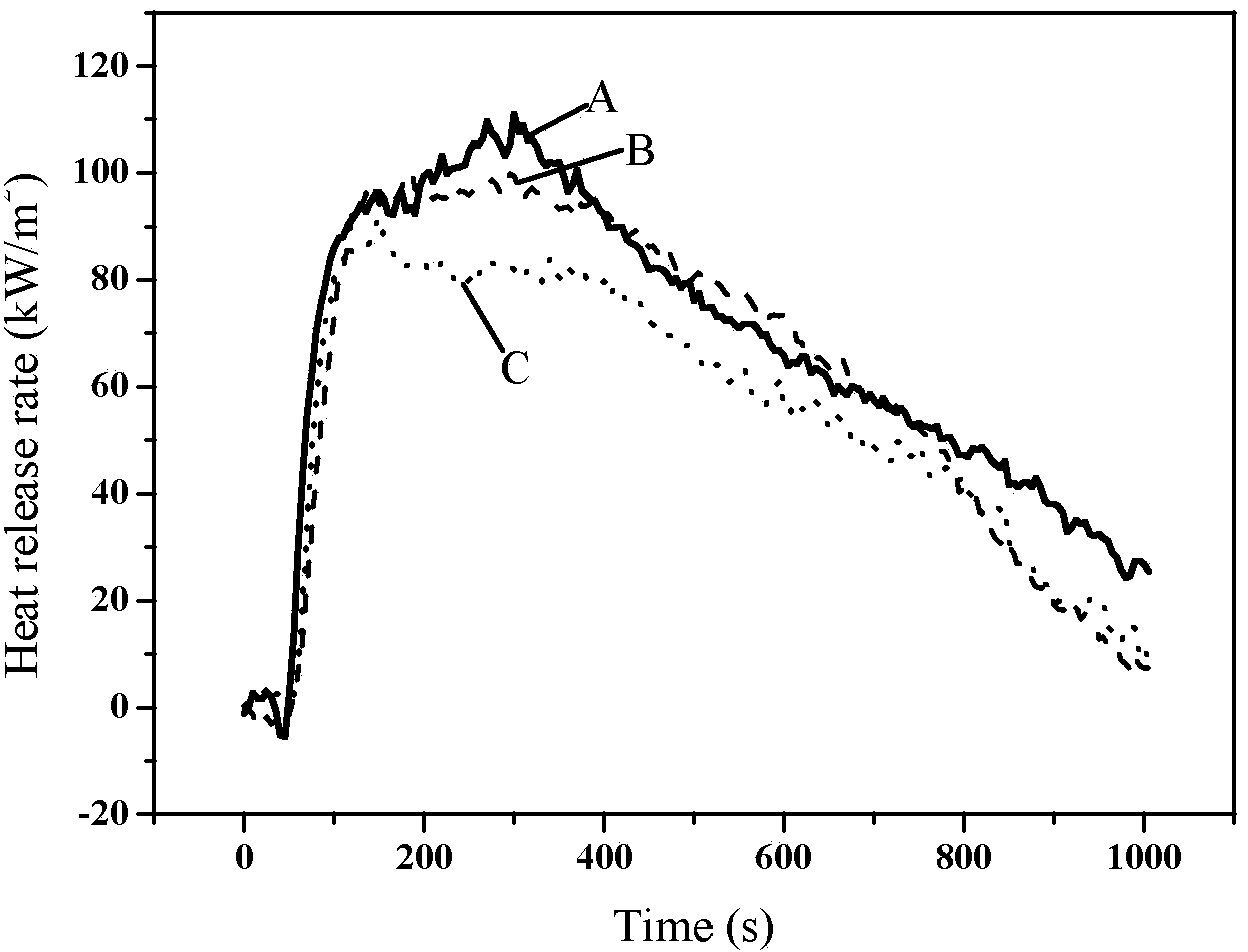

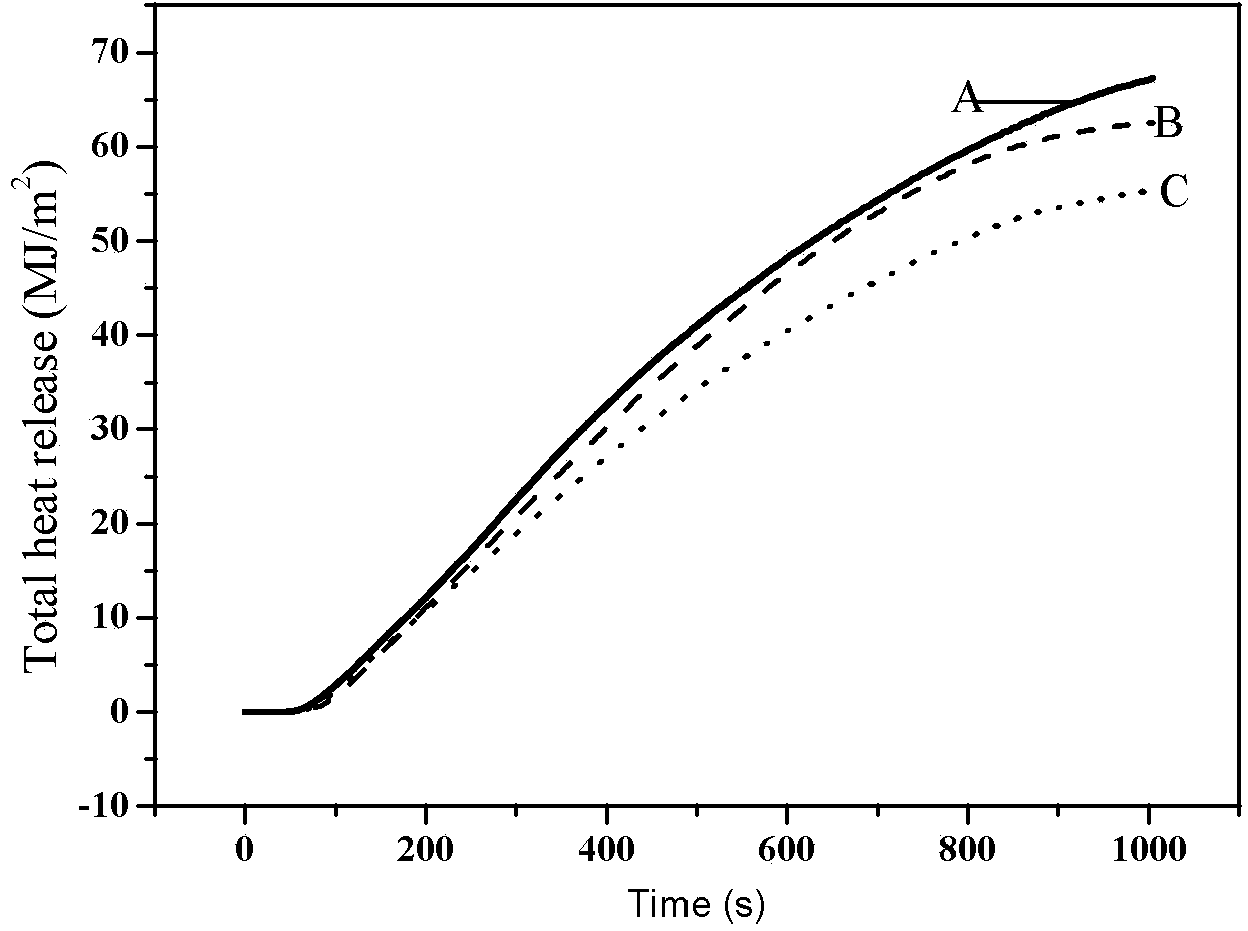

Preparation method of halogen-free composite flame retardant polypropylene/thermoplastic polyurethane elastomer composite material

The invention discloses a preparation method of a halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The method mainly consists of: A. mixing 80 parts by weight of polypropylene, 20 parts by weight of a thermoplastic polyurethane elastomer, 3 parts by weight of dry polypropylene grafted maleic anhydride and 0.2 part by weight of an antioxidant fully, then employing a double-screw extruder to perform mixing and granulating, and conducting drying to obtain a modified polypropylene masterbatch; B. then fully mixing 100 parts by weight of modified polypropylene masterbatches, 6.7-15 parts by weight of modified expandable graphite, and 4-13.3 parts by weight of red phosphorus flame retardant masterbatches to obtain a mixture; and then subjecting the mixture to mixing and granulating by the double-screw extruder, drying the extruded granules, and then carrying out injection molding by an injection molding machine, thus obtaining the halogen-free composite flame retardant polypropylene / thermoplastic polyurethane elastomer composite material. The flame retardant polypropylene / thermoplastic polyurethane elastomer composite material prepared by the method has good flame retardance, and the flame retardant level can reach vertical burning UL-94V-0.

Owner:SOUTHWEST JIAOTONG UNIV

Speical superthin slab continuous cast crystallizer protecing slay and production process thereof

The invention relates to an ultrathin-slab special continuous-casting crystallizer protective residue as well as its producing technique. It is composed of premelting matiral (substrate), flux material and carbonaceous material, where the flux material includes Li2CO3, K2CO3, MnCO3, MgCO3, etc; its producing technique: gasifying all the materials into the storage bin, then making microcomputer batching 6T per work according to specific project, then blending in blender, detecting semi-finished products, when up to standard, dry-milling in ball mill, finely milling in water mill and slurrying, drawing to spray to make particles and then packaging the qualified products and put them in storage. It has a few residue bars and active reaction in the crystallizer.

Owner:HENAN LONGCHENG GROUP CO LTD

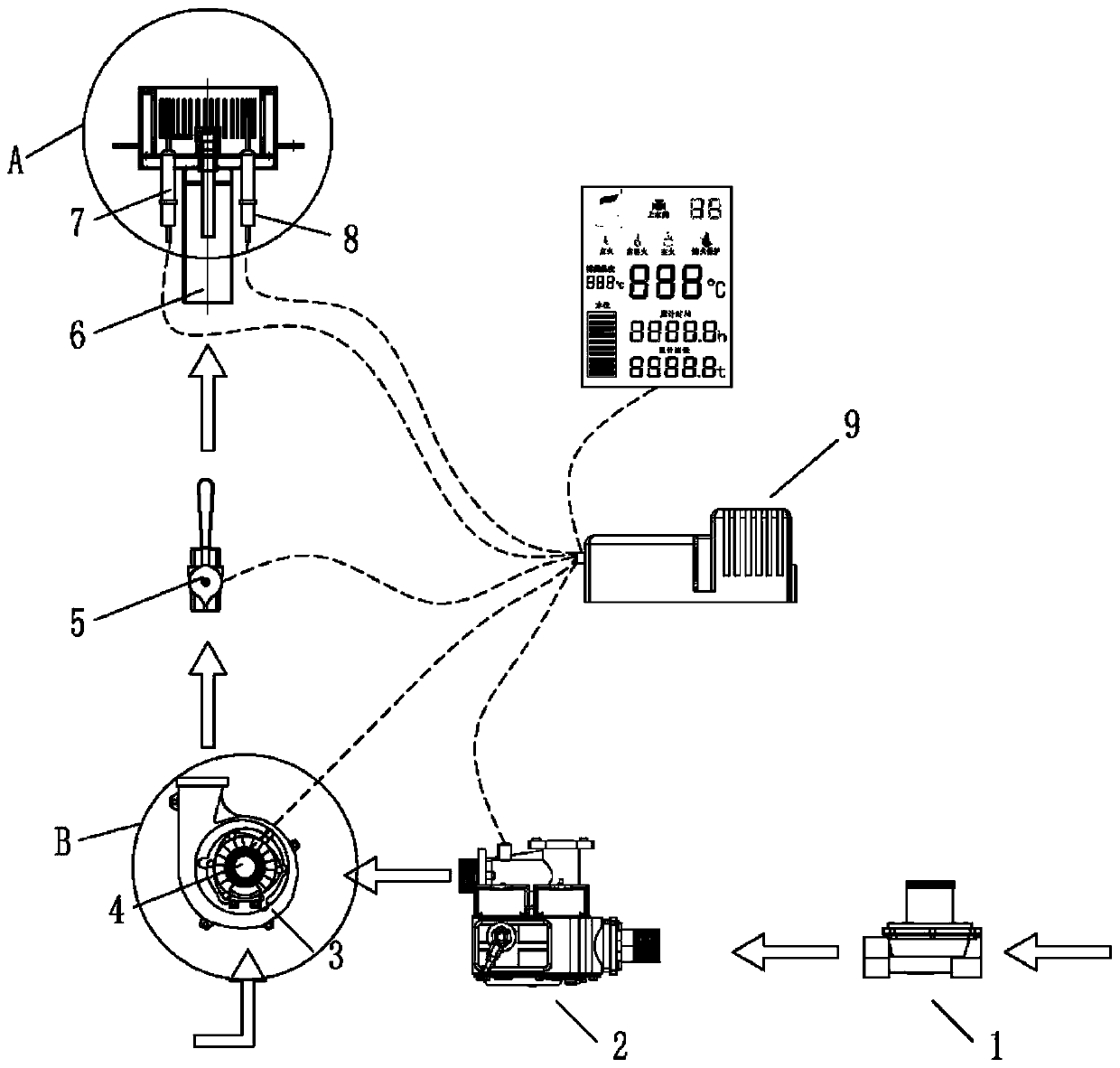

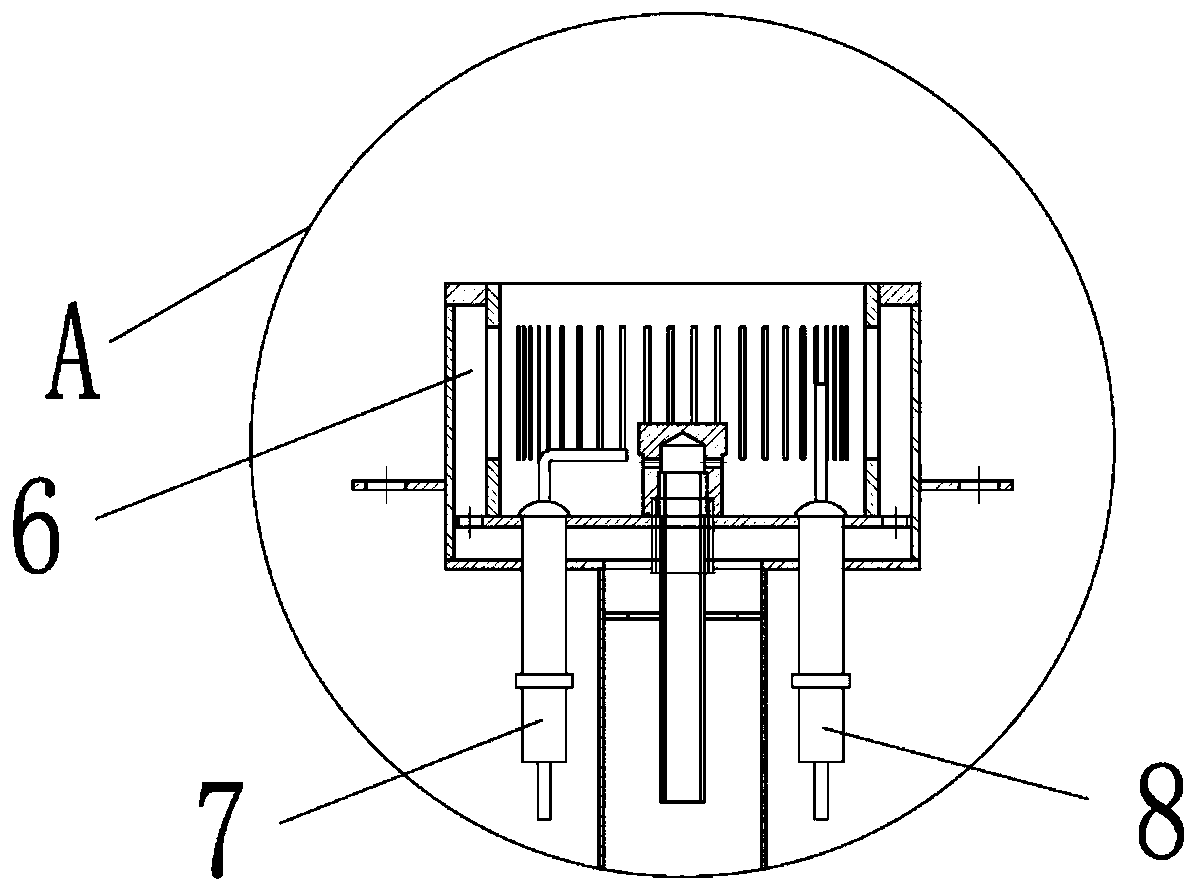

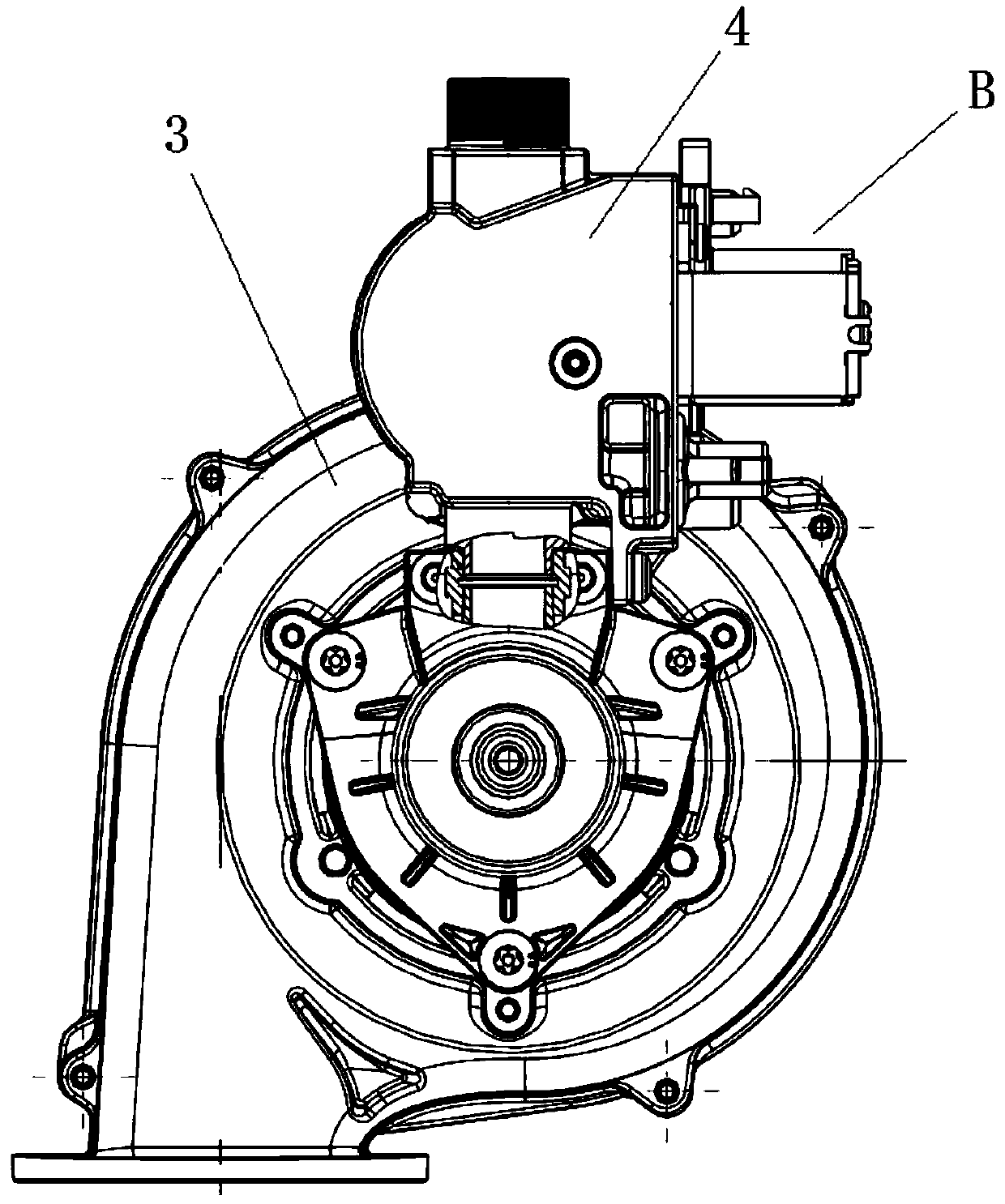

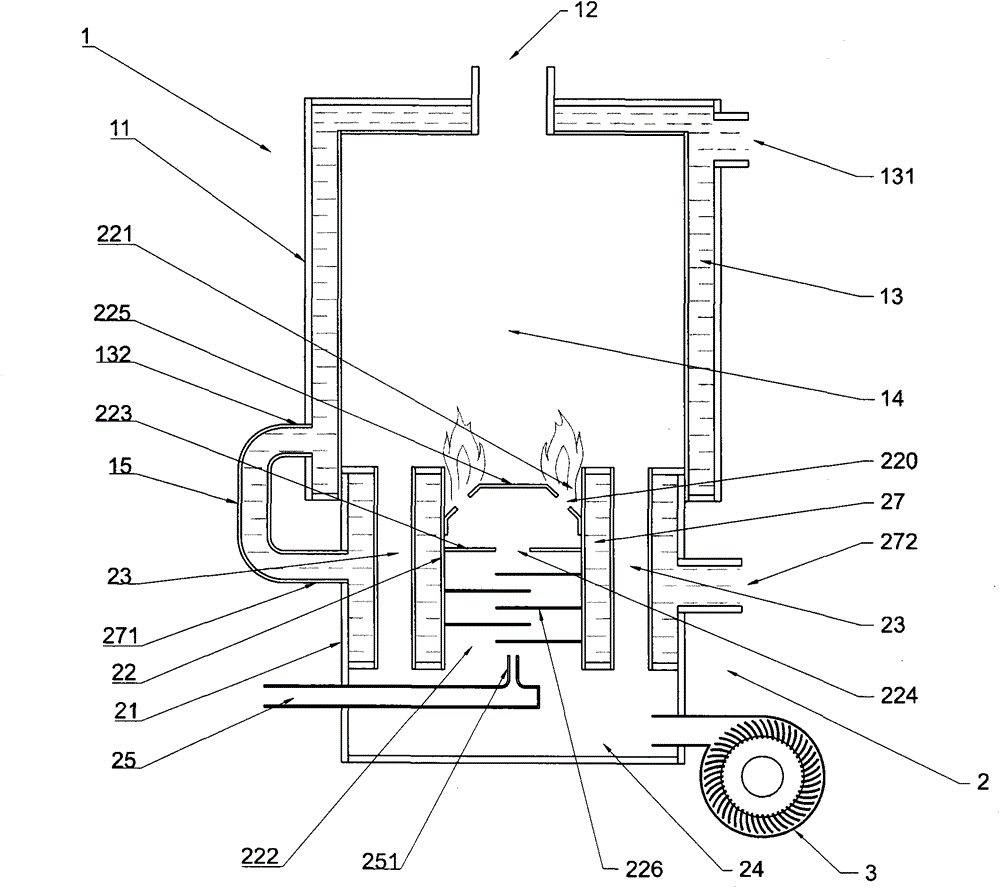

Inverted full-premix condensing gas water heater

ActiveCN103090541AWell mixedRaise emission levelsEnergy efficient heating/coolingAir heatersCombustorMaster controller

The invention discloses an inverted full-premix condensing gas water heater. An inverted metal fiber burner is used. A primary heat exchanger and a secondary heat exchanger are both inverted. Reasonable proportion of gas valve assemblies to fans is controlled via a master controller. Mixed gases enter a gas mixer and are mixed well by the gas mixer prior to entering a burner assembly, and uniformity of the gas mixture is guaranteed when the gas mixture enters the burner. Burning in the full-premix way need not air supply any more, the ratio of actual air to theoretical air is 1.3:1, burning efficiency is high, flames are short, temperature is low, and emission level is high. The metal fiber burner with wide regulating ratio range is used, and accordingly all fire power requirements can be met with no need of subsection control. In addition, the burner and the heat exchangers are inverted for the problem of proneness to blockage of the metal fiber burner, so that the problem that residue of the heat exchangers falls on the burner in long-term use is solved; condensate is discharged through a liquid sealing device, and smoke leakage is effectively prevented.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

Halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke

InactiveCN104479210AReduce migration speedReduce dosagePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideLead phosphate

The invention discloses a halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke. The insulating material is prepared from the following raw materials in parts by weight: 80-150 parts of cross-linked polyethylene, 10-30 parts of magnesium hydroxide, 5-9 parts of aluminium hydroxide, 1-2 parts of lead sulfate tribasic, 0.5-0.9 part of dibasic lead phosphate, 0.3-0.7 part of paraffin, 20-50 parts of phthalate and 5-15 parts of nano-montmorillonite. The insulating material provided by the invention has the advantages of being light in weight, good in toughness, small in flame and low in burning speed, having no molten drop and less smoke, being anti-migration, good in char forming characteristics, easy in processing and the like.

Owner:GUIZHOU MINGHCOO WIRE & CABLE CO LTD

Swirling flow premixing type burner

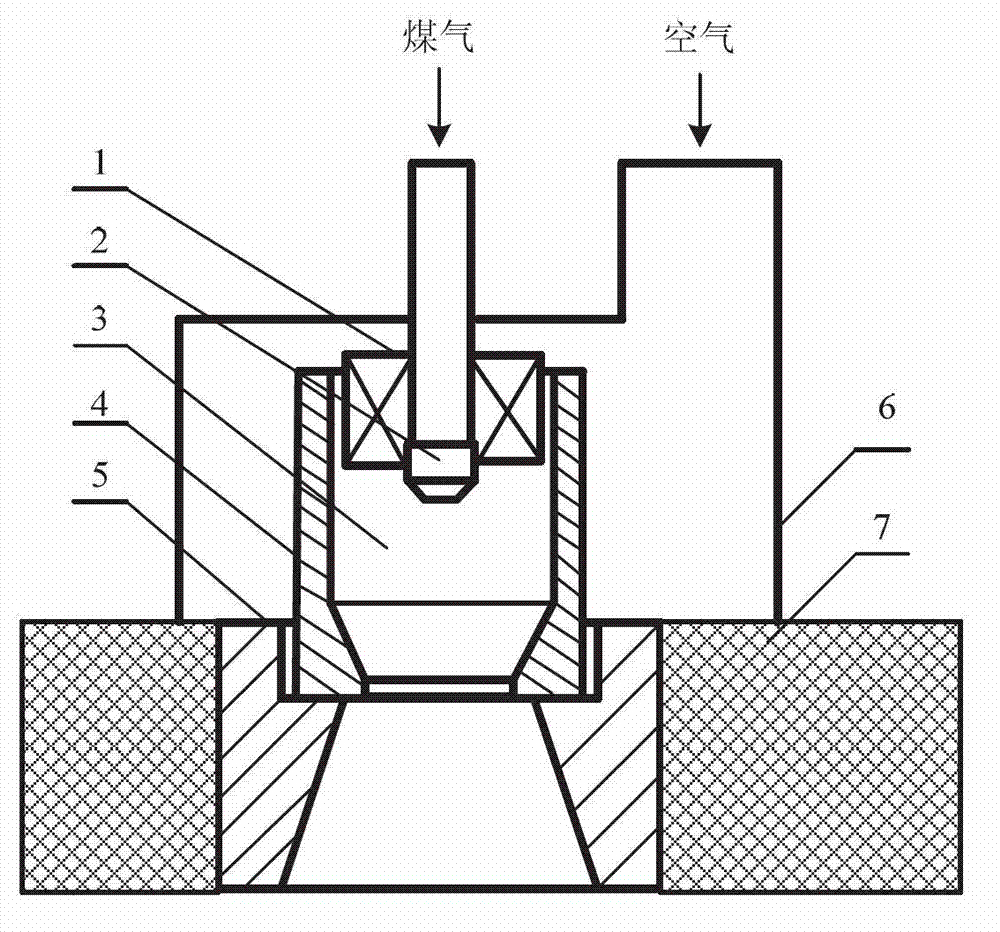

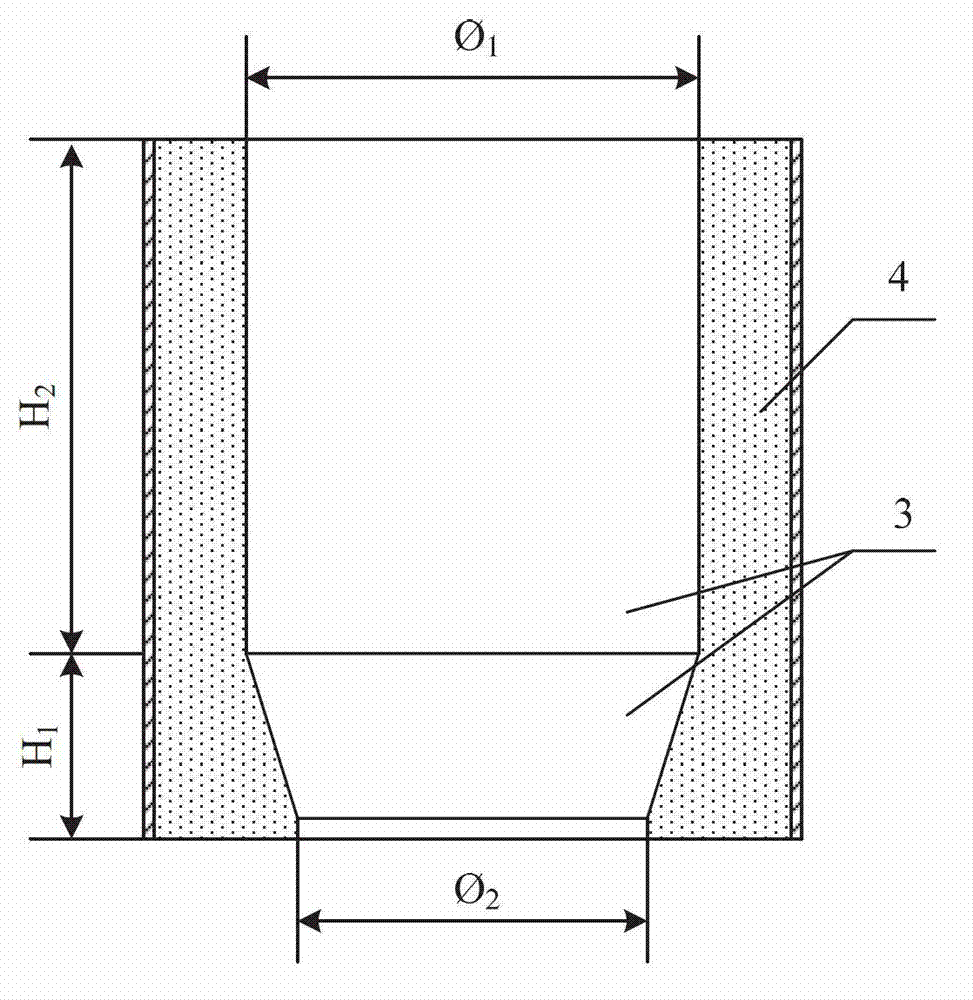

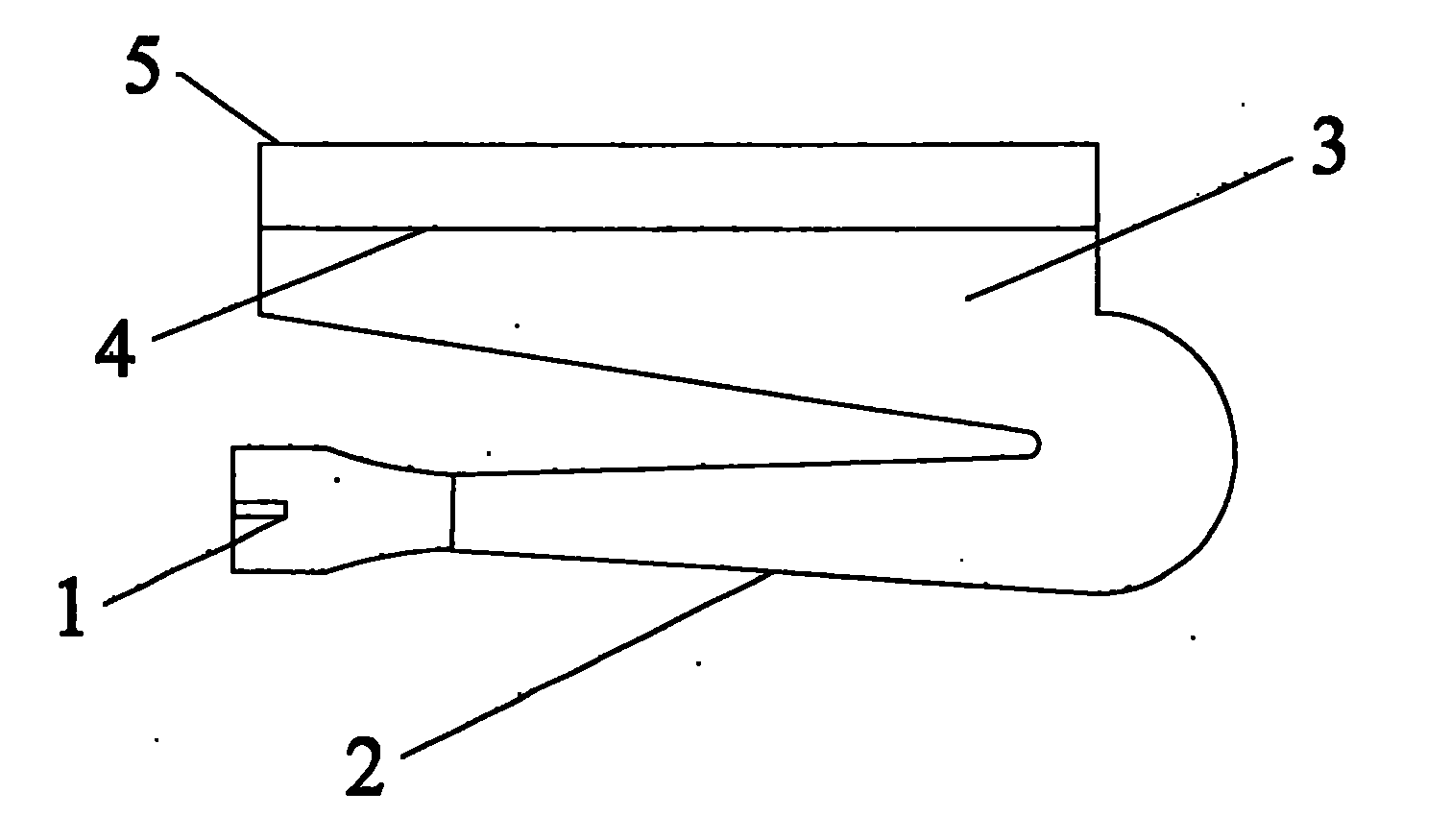

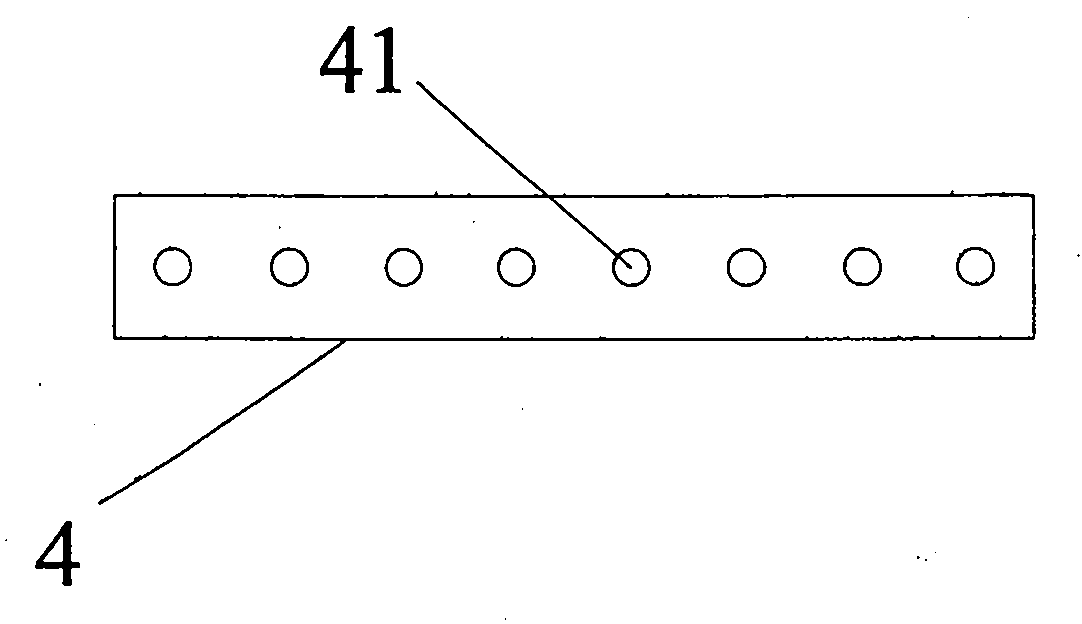

The invention discloses a swirling flow premixing type burner. The swirling flow premixing type burner comprises a first burner brick, a second burner brick, a burning-supporting air chamber, an air swirler and a fuel gas nozzle, wherein a central hole is formed in the first burner brick; an upper section of the central hole is matched with the shape of the exterior outline and the dimension of the second burner brick; a lower section of the central hole is a cone-shaped hole with a large upper end aperture and small lower end aperture; a premixing chamber is arranged in a central part of the second burner brick; the fuel gas nozzle is a swirling flow nozzle and consists of a nozzle body and a gas inlet pipe which is connected with the nozzle body; the first burner brick is arranged on a furnace body; the second burner brick is arranged in the first burner brick; the air swirler is positioned at the inlet of the premixing chamber arranged in the second burner brick; the fuel gas nozzle is combined with the air swirler; the nozzle body of the fuel gas nozzle is positioned below the air swirler; and the burning-supporting air chamber is arranged on the furnace body.

Owner:SICHUAN UNIV

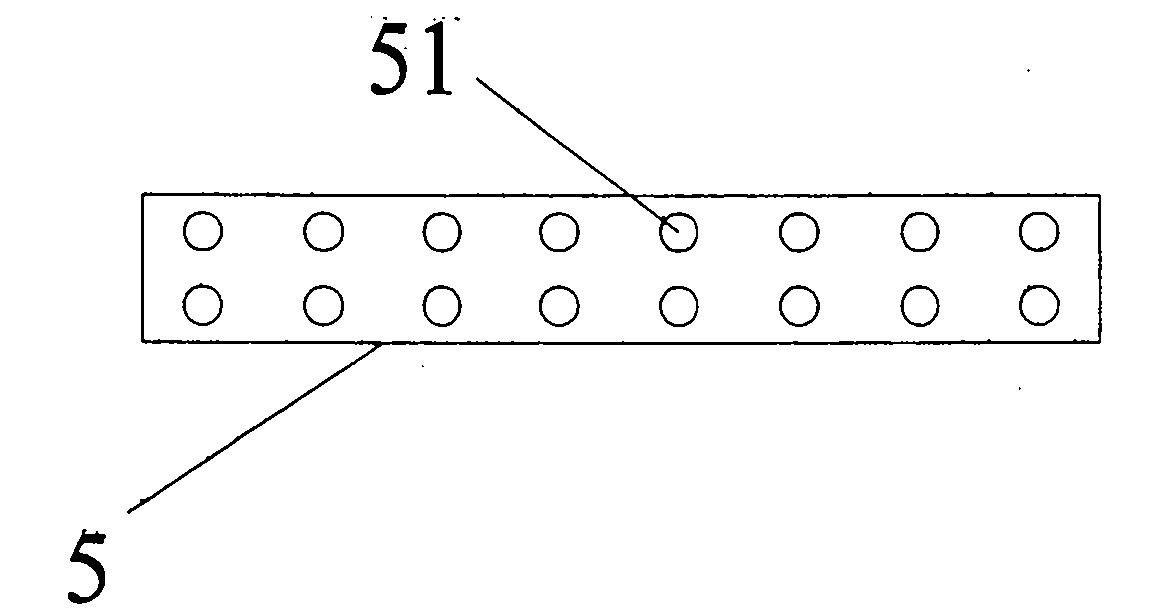

Completely-premixed gas burner

The invention relates to a completely-premixed gas burner, which comprises a nozzle, an ejector, a distribution chamber, a shunting plate and a burning fire-hole plate, wherein the nozzle is arranged on one end of the ejector, and the other end of the ejector is connected with the distribution chamber; the shunting plate is arranged on the distribution chamber; the burning fire-hole plate is arranged above the shunting plate; gas is injected into the ejector via the nozzle and is evenly mixed with air ejected and boosted by the ejector in the distribution chamber; and the mixture flows into the burning fire-hole plate after being shunted by the shunting plate. Compared with the prior art, the completely-premixed gas burner has the advantages of complete burning, low pollutant discharge amount in smoke and the like.

Owner:SHANGHAI HESEN ELECTRO MACHINERY

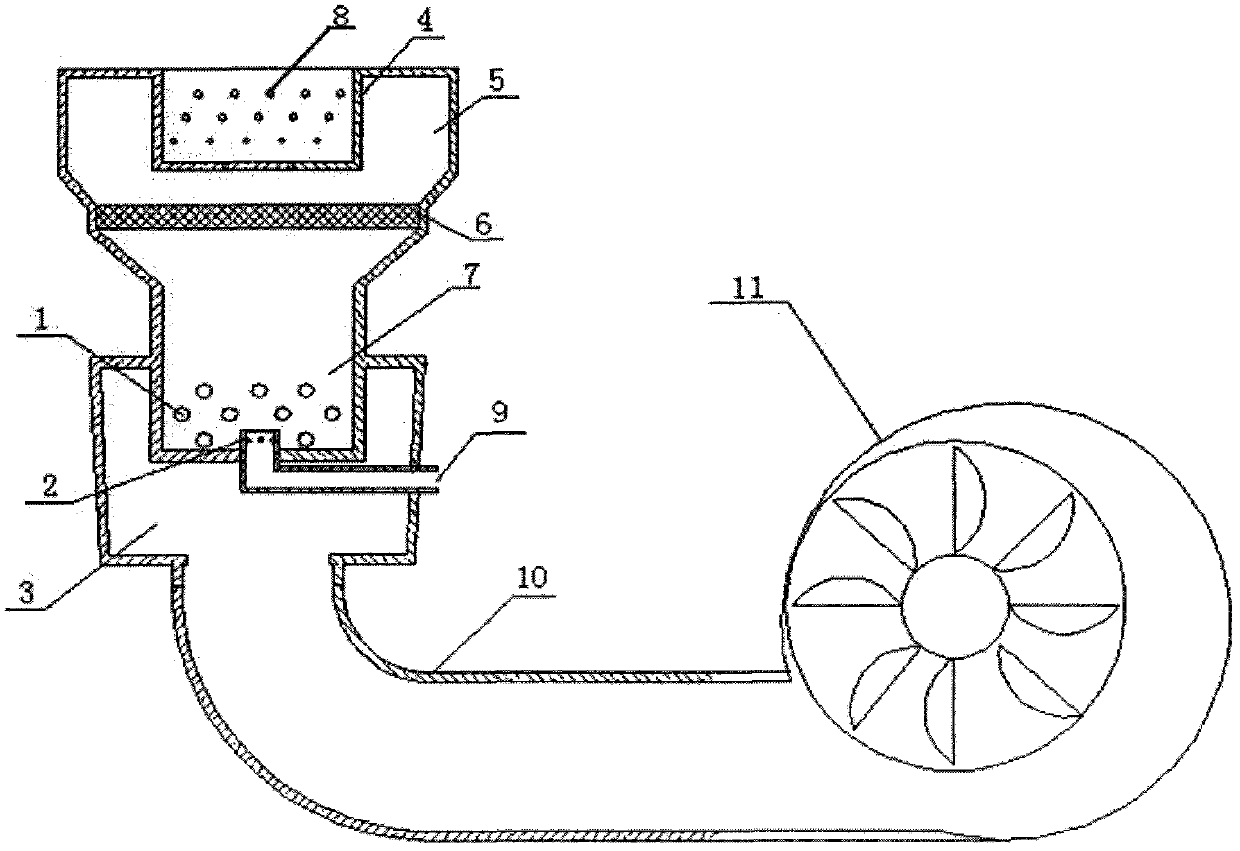

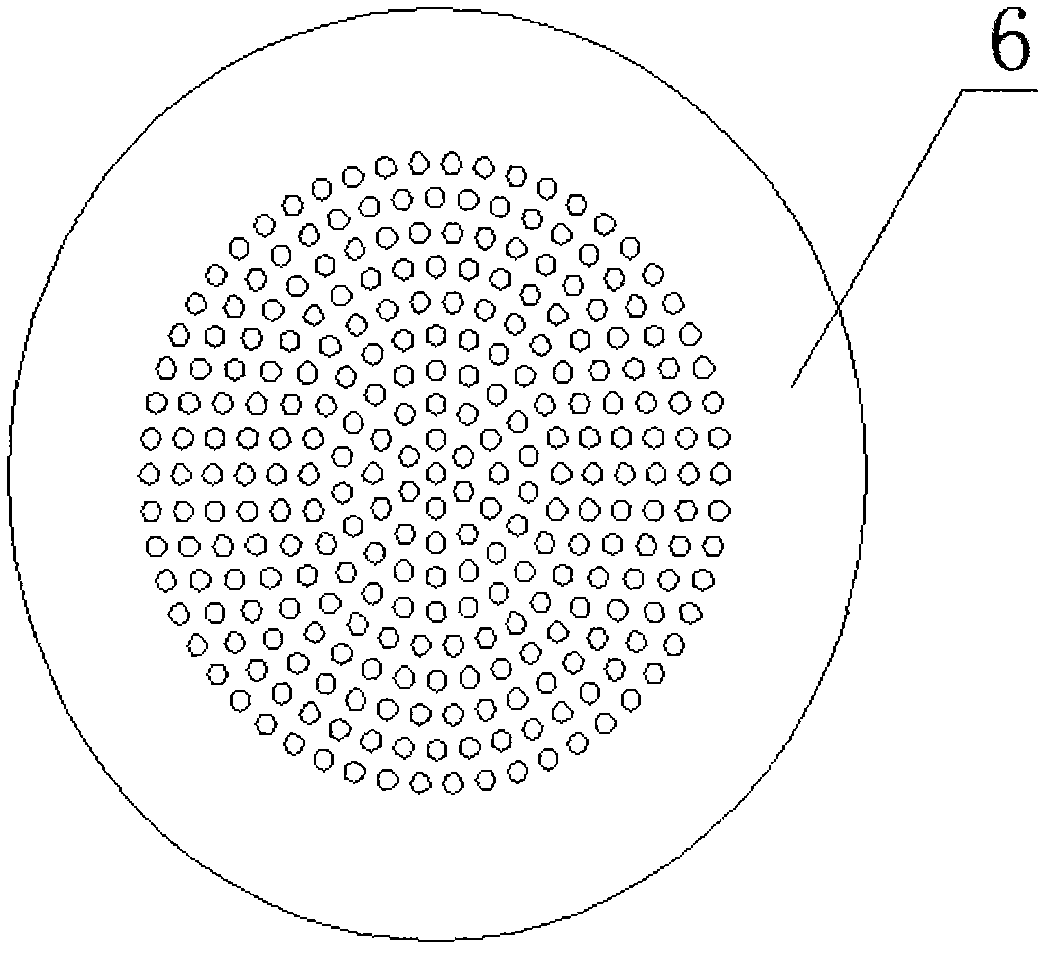

Premixed type blast combustion device

InactiveCN103292324AHigh thermal efficiencyBurn fullyGaseous fuel burnerCombustion chamberHigh energy

The invention belongs to the field of fuel devices, and particularly relates to a premixed type blast combustion device. The premixed type blast combustion device comprises an air chamber, a combustion chamber, a diffusion chamber, a steady flow plate, a gas mixing chamber, an air duct and an air blower, and is characterized in that the gas mixing chamber is wrapped with the air chamber; the diffusion chamber is arranged on the gas mixing chamber; the combustion chamber is arranged in the diffusion chamber; flaming holes are formed in the inner walls of the combustion chamber and the diffusion chamber; the steady flow plate is arranged between the gas mixing chamber and the diffusion chamber; a gas nozzle is located in the center position of the gas mixing chamber; a gas inlet is formed in the gas nozzle, and the gas nozzle stretches out of the air chamber; the air duct is arranged at the lower end of the air chamber; and the air blower is arranged at the rear end of the air duct. With the adoption of premixed type combustion, the fuel can be combusted more rapidly and fully, the flame is short, the flame temperature and the heat efficiency of a combustor are improved, the emission of nitrogen oxides and carbon monoxide is reduced, and problems of insufficient combustion of the fuel, low heat efficiency, high energy consumption and relatively higher emission of the nitrogen oxides and the carbon monoxide due to low local temperatures are solved.

Owner:马清飞

Gas burner for premixing automatically-sucked air

The invention discloses a gas burner for premixing automatically-sucked air, which comprises a gas-gun pipe and an air pipe, wherein the gas-gun pipe is positioned at the center in the air pipe, the front end of the gas-gun pipe is provided with a gas-spraying head, the circumferential direction on the lateral surface of the gas-spraying head is provided with spraying holes, the annular cavities of the gas-gun pipe and the air pipe are air passages, the front end of the air pipe is provided with a spraying opening, the inner side at the front end of the air pipe is conical, the rear end of the air pipe is provided with a 90-degree right-angle bend, and a premixing chamber is arranged between the spraying holes at the front end of the gas-gun pipe and the air pipe. In the invention, gas after being sprayed out from the gas-gun pipe is rapidly burnt within a short period of time after strengthened premixing is firstly carried out in the premixing chamber, and the gas burner has the advantages of high burning speed, short flame, high temperature, high thermal efficiency and small smoke-gas quantity; and natural wind is used in wind distribution, the gas and air enter by means of respective power, the other party is driven by the power of one party in the entering process, and auxiliary equipment for wind supply does not need to be additionally equipped for the driven party, thereby the production cost is lowered.

Owner:金艺

Fully premixed fuel gas burner

The invention discloses a fully premixed fuel gas burner which comprises a sealing plate. The fully premixed fuel gas burner further comprises a mixing cylinder, a fuel gas and air distribution cylinder and a fire hole cylinder which are sequentially arranged in a sleeved and spaced mode from the inner to the outer. The space between the mixing cylindrical and the fuel gas and air distribution cylinder forms a distribution chamber, the space between the fuel gas and air distribution cylinder and the fire hole cylinder forms a thermal insulation chamber, a plurality of ignition chambers are arranged in the mixing cylindrical by penetrating the mixing cylindrical, a plurality of distribution holes are formed in the fuel gas and air distribution cylinder, a plurality of fire holes are formed in the fire hole cylinder, the sealing plate is connected with an air intake pipe, a fuel gas inlet pipe penetrates the wall surface of the air intake pipe to be communicated with an air inlet on a fuel gas distribution chamber which is arranged in an air outlet of the air intake pipe, and a plurality of gas outlets communicated with fuel gas nozzles which are arranged in correspondence with the ignition chambers are arranged on the fuel gas distribution chamber. According to the fully premixed fuel gas burner, the emission load of pollutants in flue gas is low, and the proportion of fuel gas and air can be controlled easily.

Owner:HEBEI CHUNFENG HEATING EQUIP

Front pre-mixing combustor used for commercial fuel gas stove

The invention discloses a front pre-mixing combustor used for a commercial fuel gas stove. The front pre-mixing combustor comprises a stove head, an ignition needle, an ion needle, a fuel gas valve, aPWM fan, a Venturi pre-mixer, a zero-pressure header tube fuel gas solenoid valve, a pressure stabilizing vale, a commercial fuel gas stove front pre-mixing controller. The front pre-mixing combustoradopts a front pre-mixing type technology for completely mixing fuels with air before the fuels and the air enter a spray nozzle of a stove head combustion chamber, so that gas molecules are sufficiently stirred and mixed, and therefore, mixing is more complete, combustion speed is not limited by physical conditions such as gas diffusion velocity, combustion speed is higher, efficiency is higher,and emission of harmful CO in smoke gas is reduced. And meanwhile, an automatic pre-mixing technology is applied, so that mixing is guaranteed to be relatively precise. The front pre-mixing combustorguarantees working safety, and is free of phenomena such as flame-lifting, flame-floating and tempering.

Owner:合肥中科顺昌余热利用科技有限公司

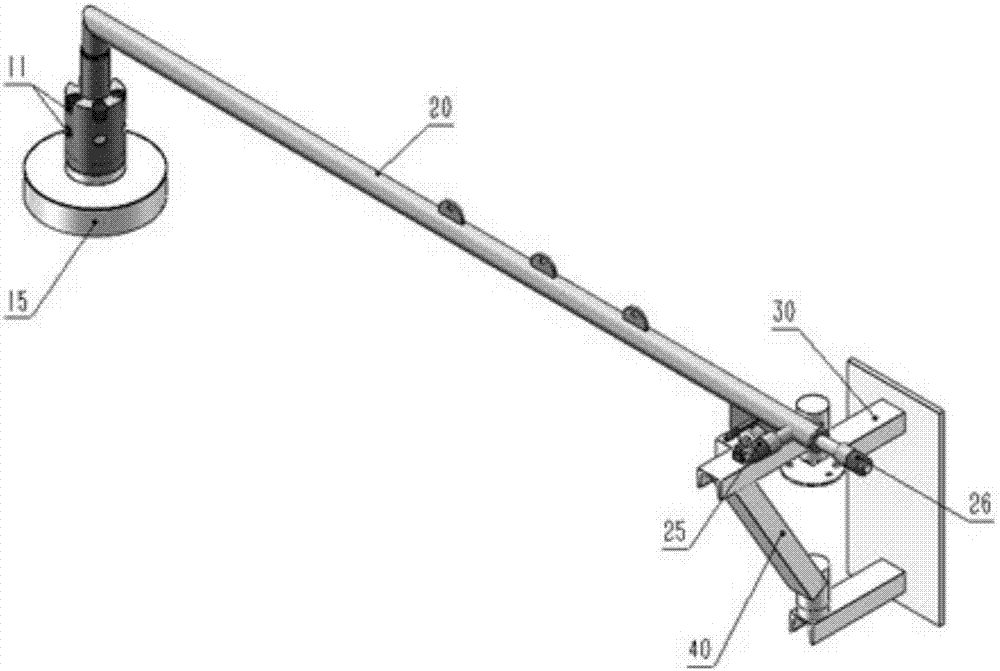

Roasting gun device

The invention discloses a roasting gun device. The roasting gun device comprises a support, a gun body and a gun head, wherein the middle part of the gun body is of a sleeve structure with an inner layer charged with fuel gas and an outer layer charged with compressed air, a bearing seat for allowing the gun body to rotate around the support is arranged on the rear part of the gun body, and a fuel gas connector and a compressed air connector are formed in the rear part of the gun body; a fuel gas-air mixing pipe and a secondary mixing and decompression pipe for supplementing air and balancing a gas pressure are arranged on the front part of the gun body; the support is used for installing and supporting the gun body and enabling the gun body to rotate and move around an axis in the horizontal direction; a main fire hole is formed in the middle of the gun head, and 18-28 auxiliary fire holes are distributed around the gun head; and the outer layer of the gun head is a heat-collecting cover. According to the roasting gun device disclosed by the invention, a fuel and air are uniformly mixed, air needed for combustion can be automatically balanced, and the temperature of the gun head can be lowered, so that the problems of poor roasting effect and unsafety of unshaped casting material products in scrap copper smelting, and anode copper casting dies are solved.

Owner:JIANGXI COPPER

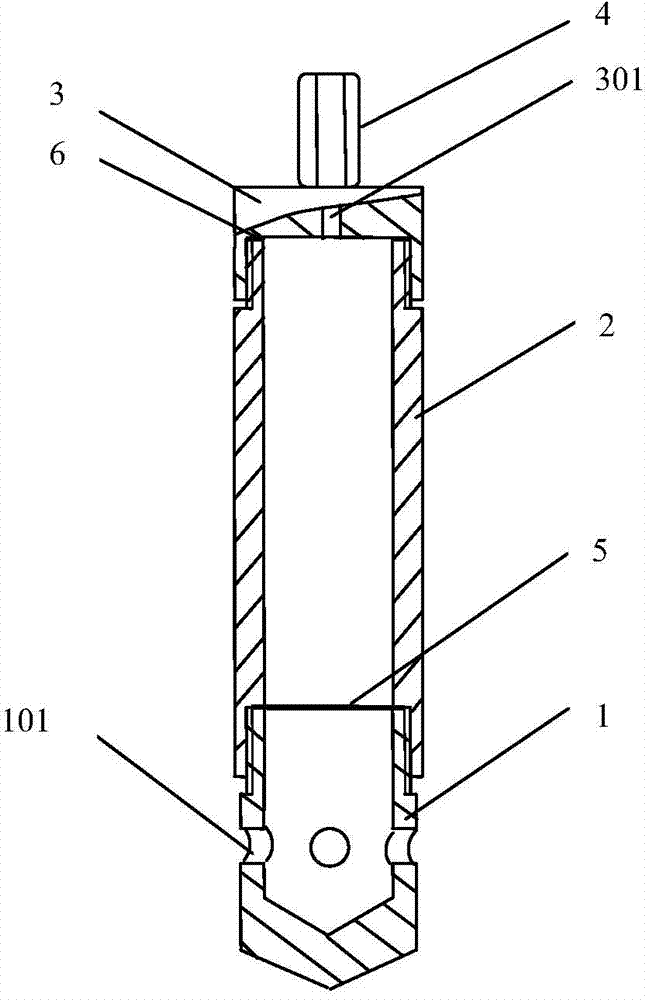

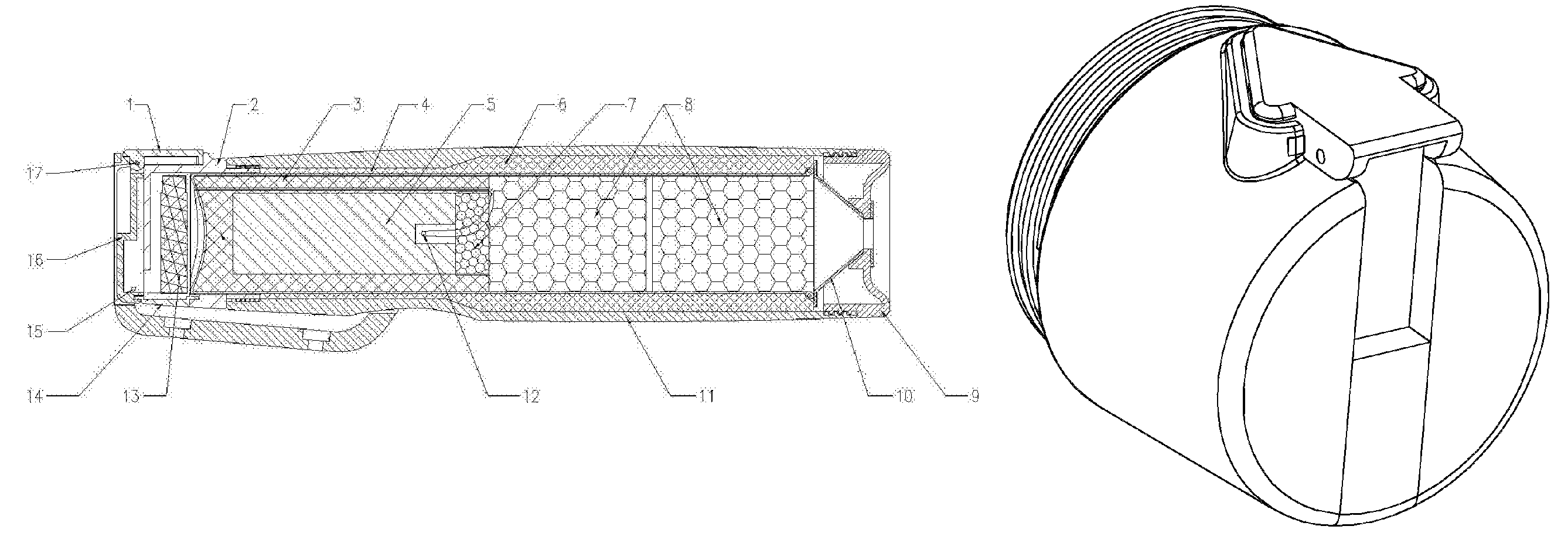

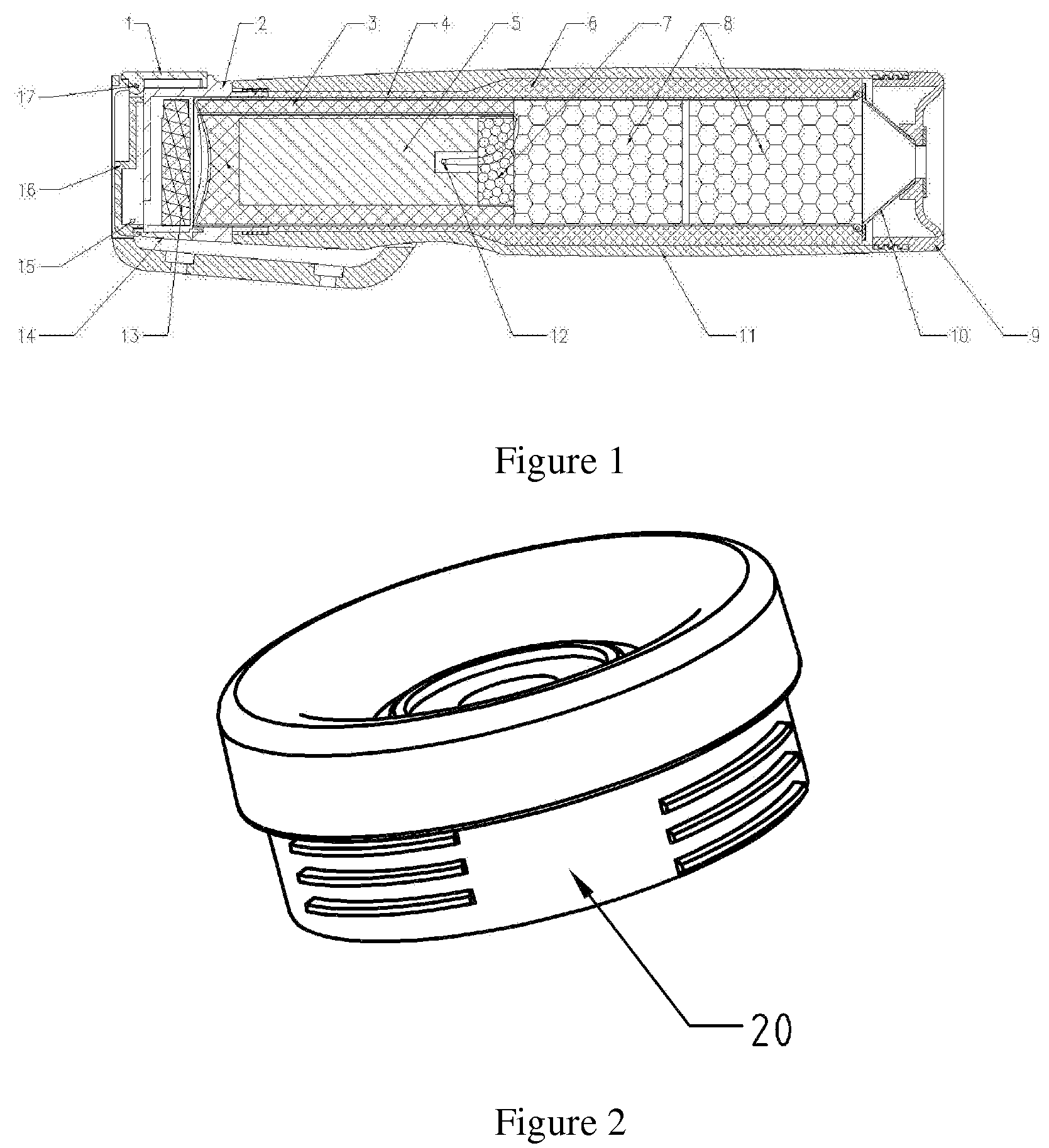

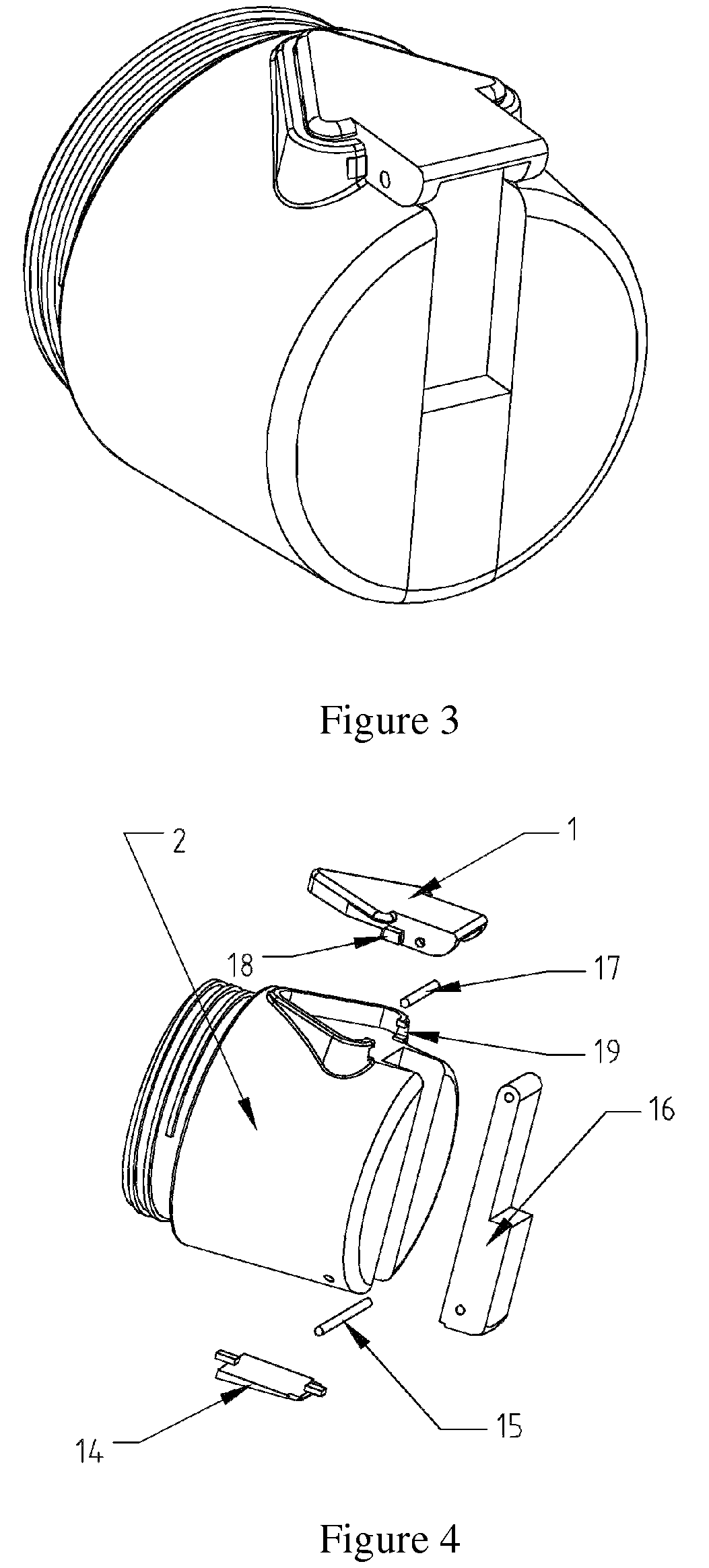

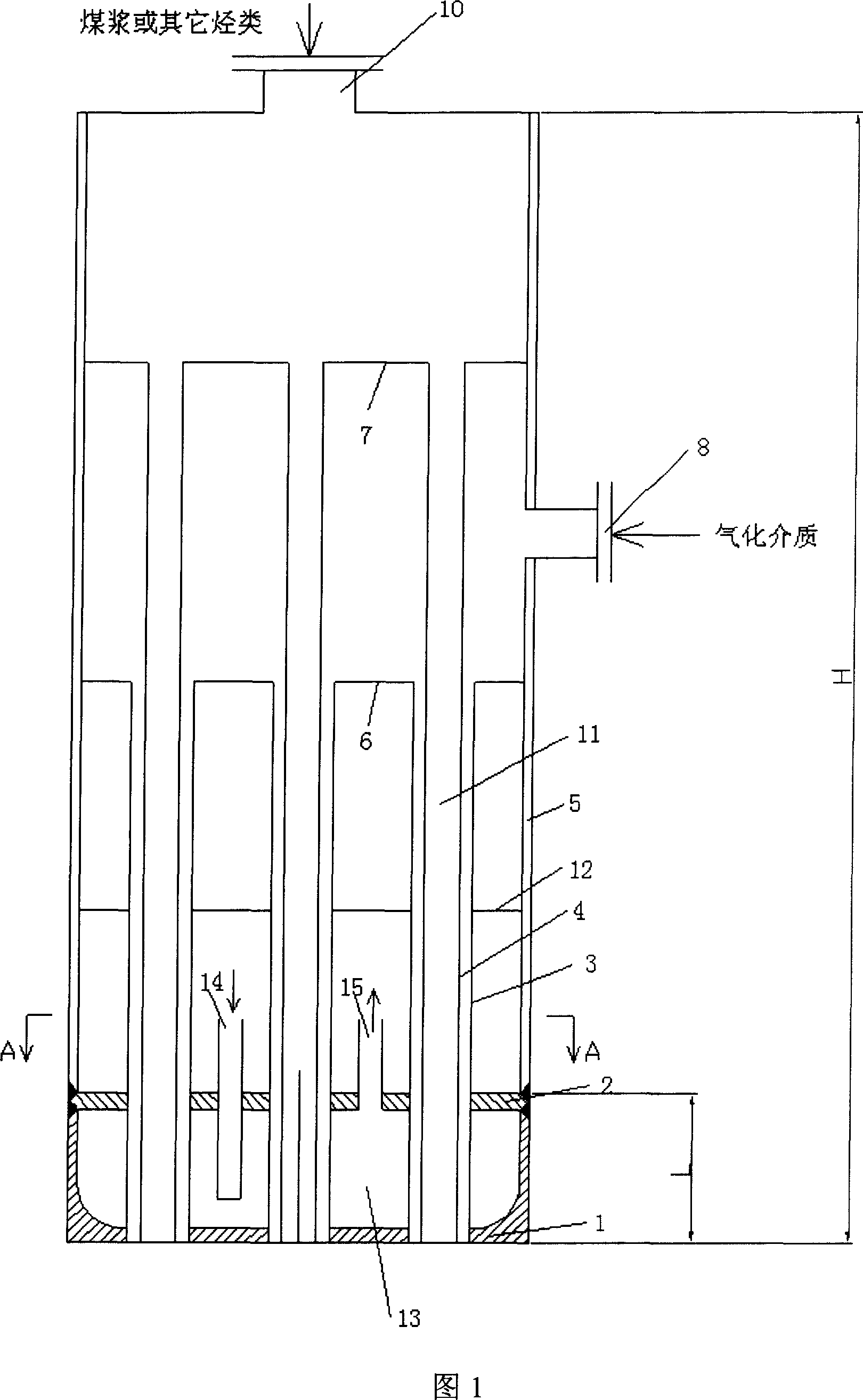

Hand-held aerosol fire suppression apparatus

The present invention relates to a novel hand-held aerosol fire suppression apparatus, comprising thermal insulating layer (3), inner cylinder (4), aerosol generating agent (5), heat insulating material (6), jet nozzle (9), tapered jet orifice (10), enclosure (11), ignition head (12) and piezoelectric crystal assembly (13), wherein the thermal insulating layer (3) is arranged between the inner cylinder (4) and the aerosol generating agent (5), and the jet nozzle (9) is screwed to the enclosure (11) by means of a thread structure that comprises 3˜6 thread segments. Compared to that in the prior art, with the segment thread design for screwing the jet nozzle to the enclosure, the time required for removing the jet nozzle can be reduced significantly, and therefore the apparatus in the present invention has much better safety feature against accidents.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Flame retardant rubber

The invention discloses flame retardant rubber, and belongs to the rubber technical field, and the flame retardant rubber consists of the following raw materials by weight: 63-68 parts of styrene-butadiene rubber, 16-19 parts of natural rubber, 3-7 parts of magnesium chloride, 2-4 parts of stearic acid, 21-23 parts of carbon black, 12-14 parts of chlorinated paraffin, 3-5 parts of antimony trioxide, 1-3 parts of zinc borate, 2-5 parts of aluminum hydroxide and 3-8 parts of clay. The flame retardant rubber is added with the natural rubber, has the good performance of the natural rubber, and improves the shortcoming of single rubber; the flame retardant rubber uses the antimony trioxide, the aluminum hydroxide, the clay and the like as flame retardants, when the flame retardant rubber is heated, crystal water is released, heat is absorbed or thermal conductivity is improved, when in burning, the flame may be diminished, and the flame retardant rubber has good flame retardant performance.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

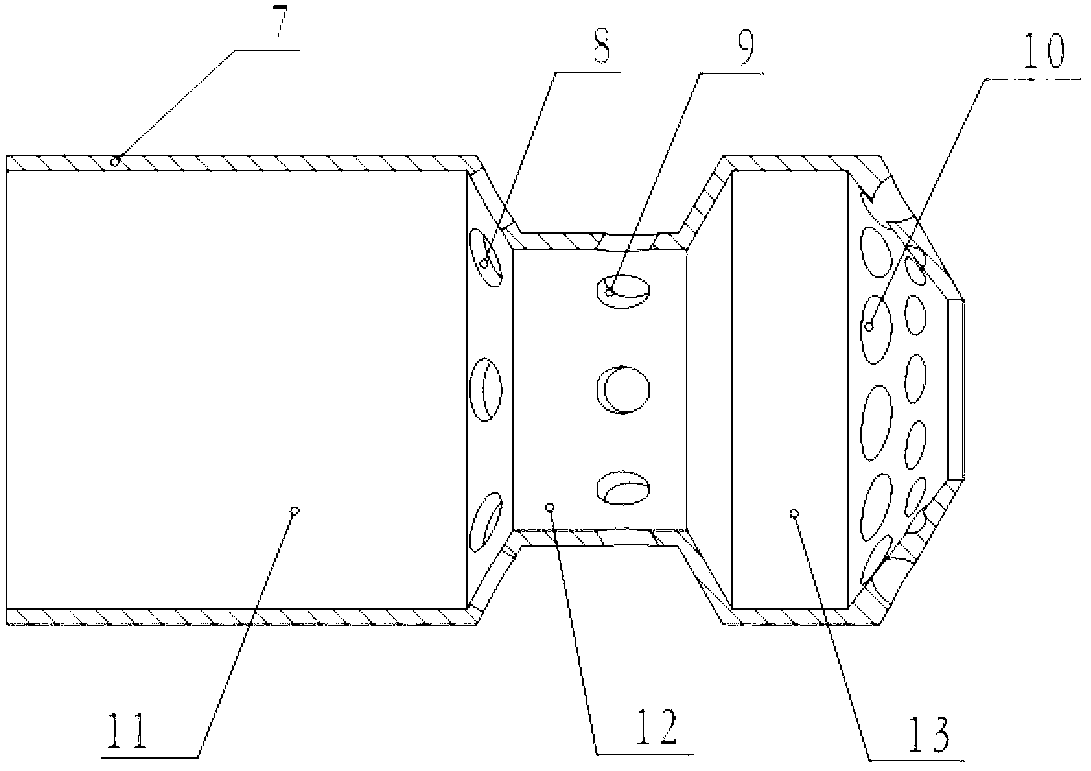

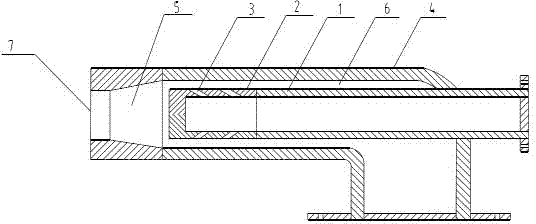

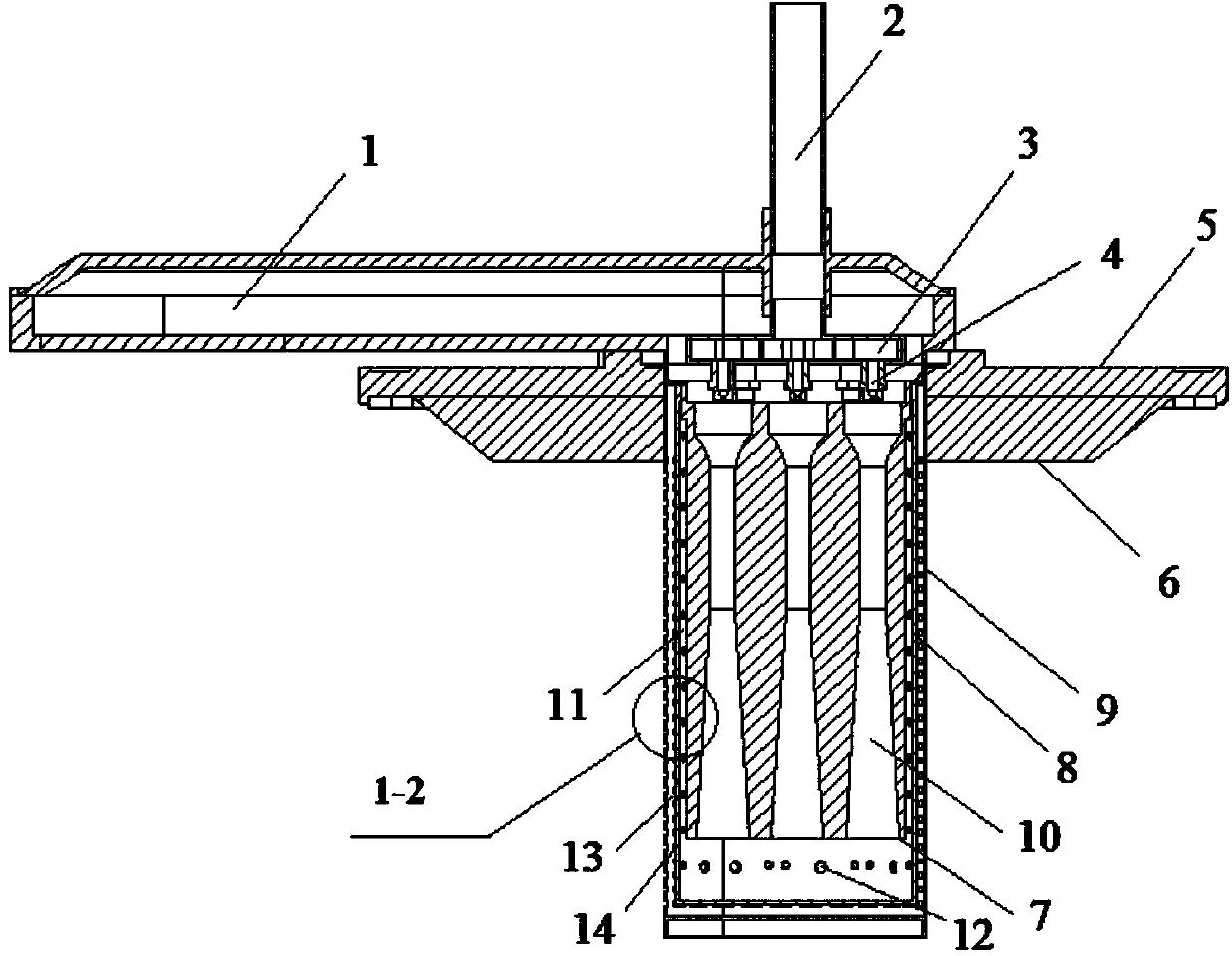

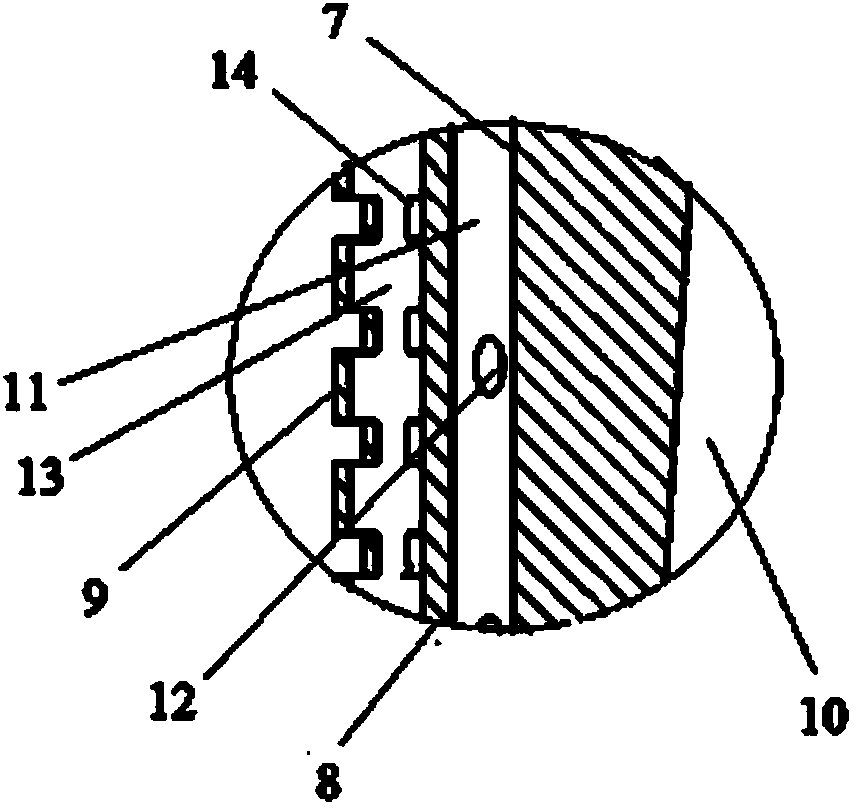

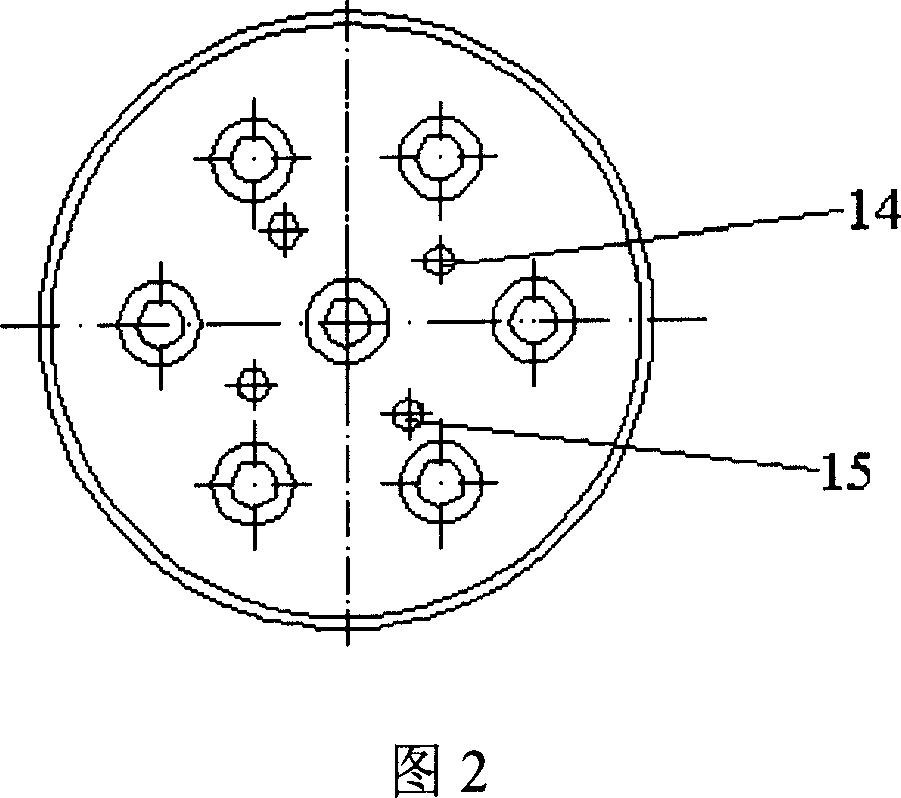

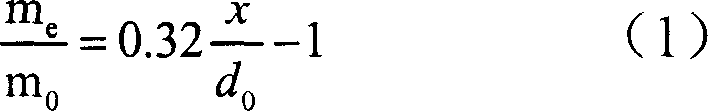

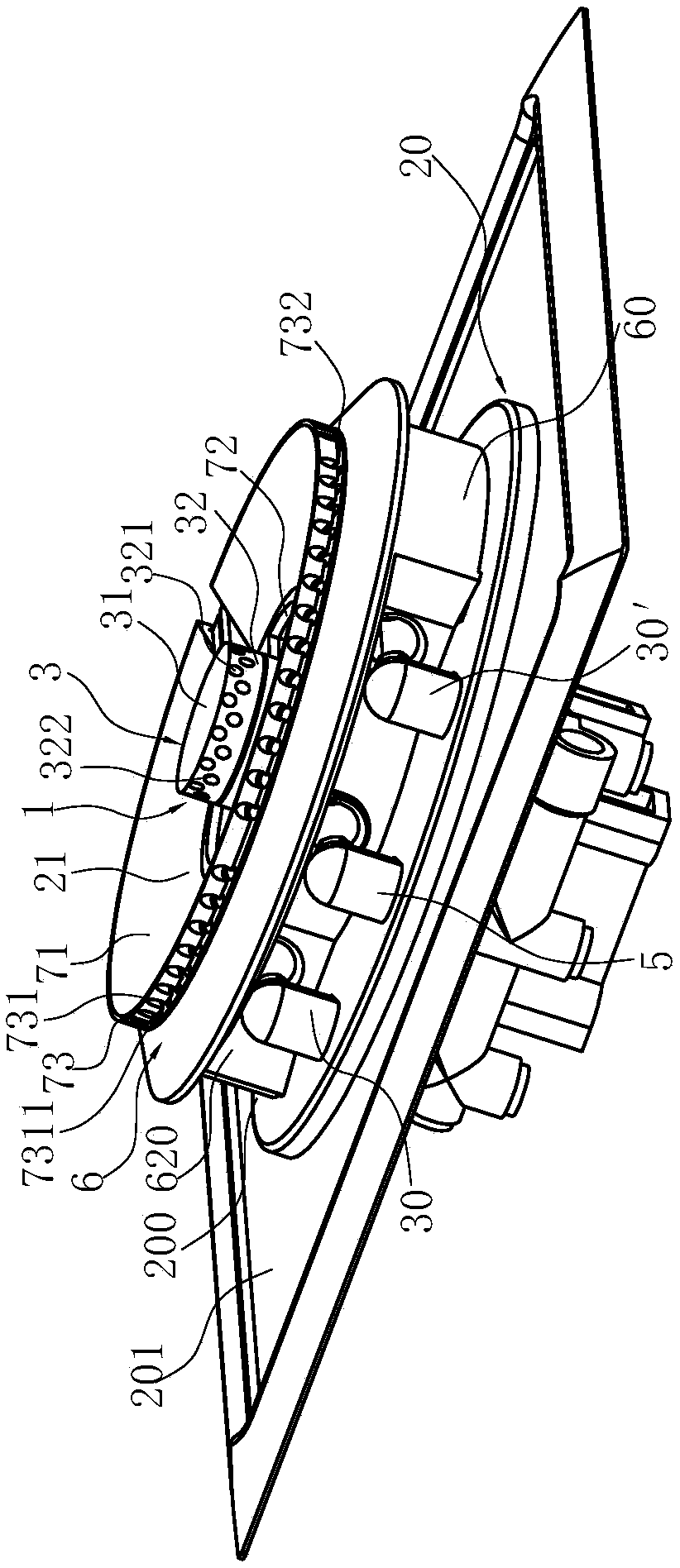

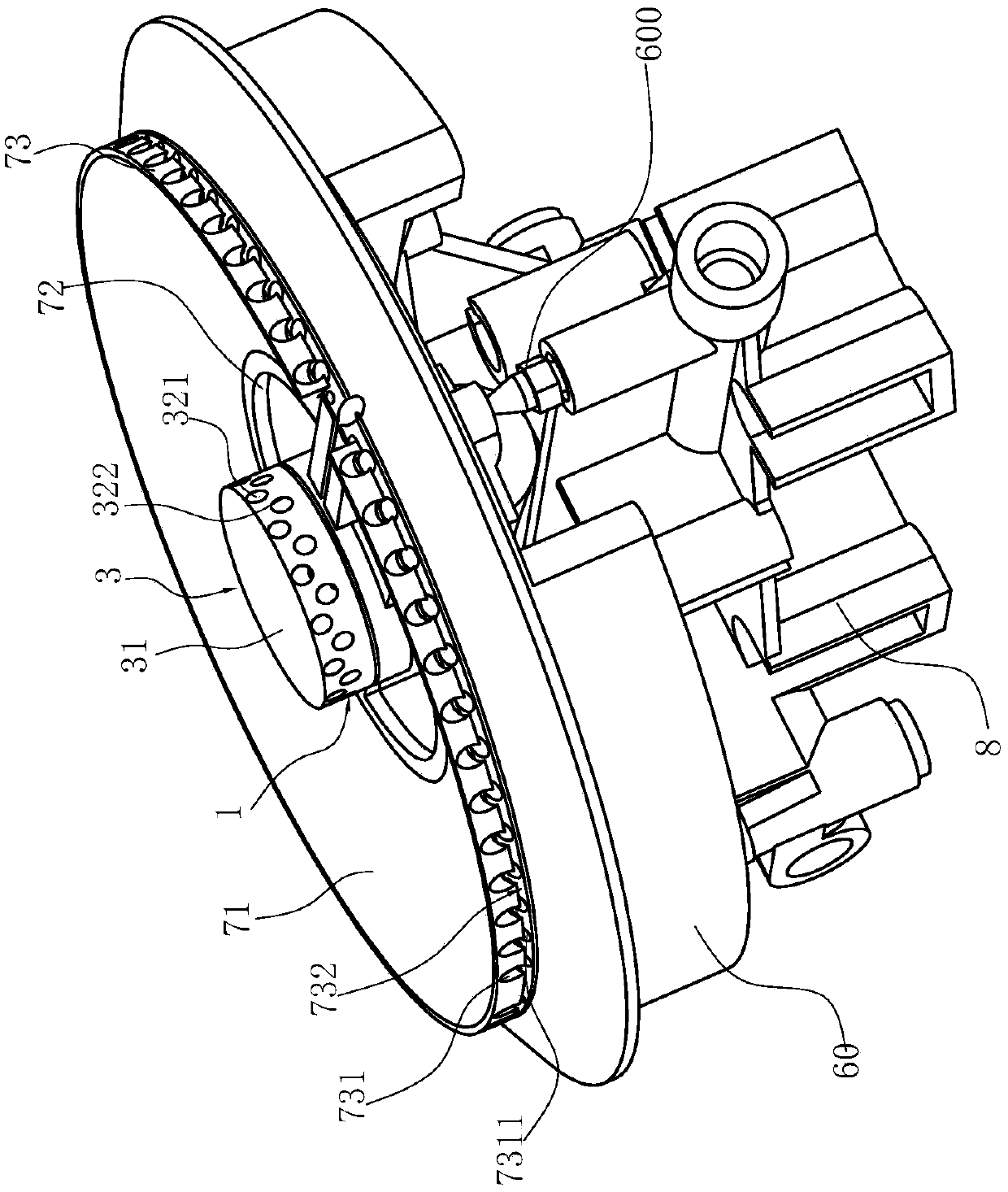

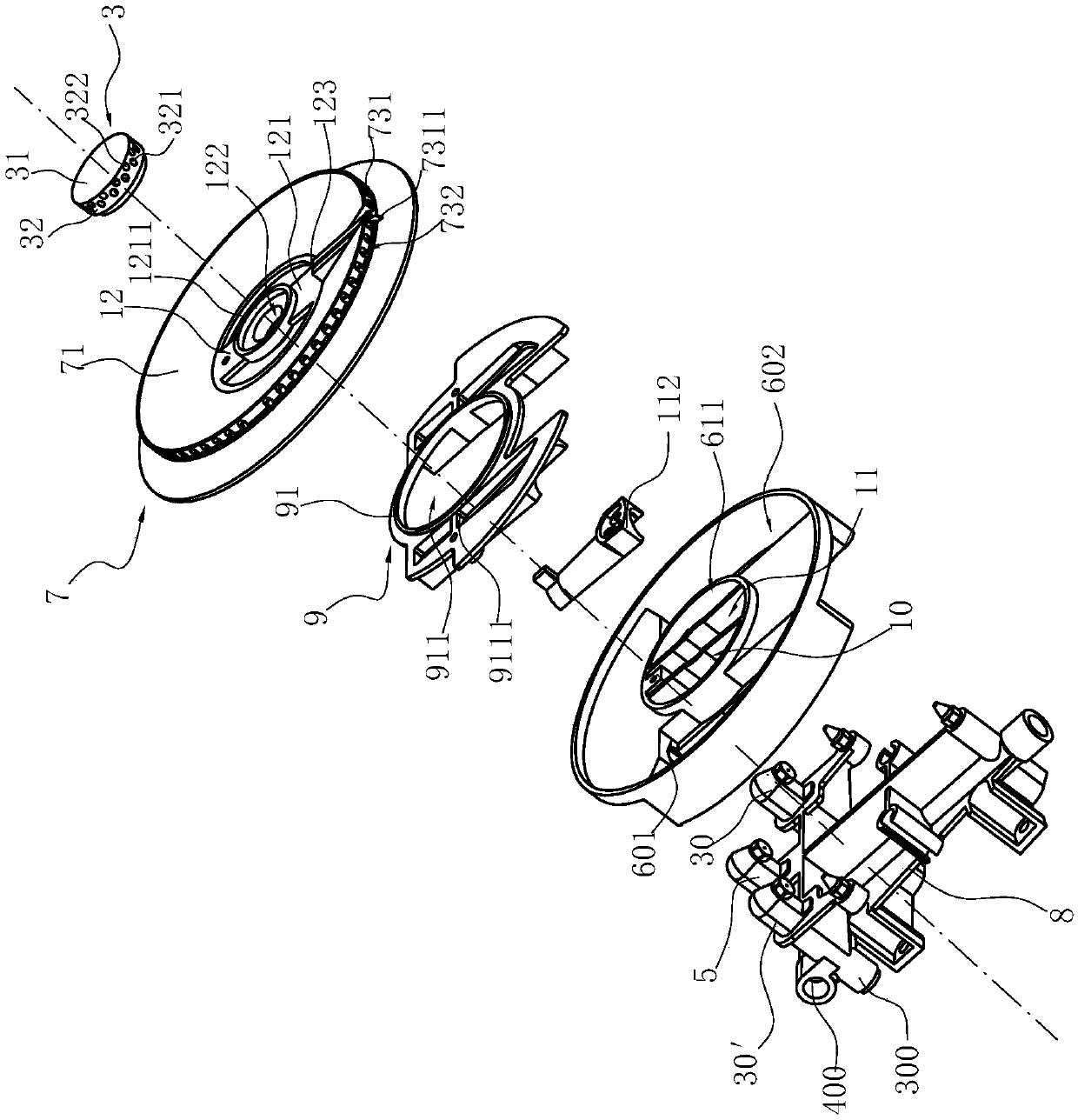

Beaming type gasification or combustion nozzle and its industrial use

InactiveCN1928431AExtended service lifeReasonable structureFluidized bed combustionCombustion using liquid and pulverulent fuelCombustionFire brick

The invention discloses a beaming gasifying or burner nozzle and the application in industry. It comprises shell (5) and N nozzles (11) set in shell (5), which comprises outer tube (3), inner tube (4) set in outer tube, lower tube plate (6), upper tube plate (7) and cooling room (13). Compared with conventional nozzle with concentric tubes (such as two-way, three-way and multiple way nozzle), it can protect anti-fire brick on the middle and lower part of gasifying boiler and prolong the service life because the flame is short and rectangle; improve conversion ratio of carbon because Residence time is scattered narrowly; and improve the service life of nozzle because of rational structure.

Owner:EAST CHINA UNIV OF SCI & TECH

gas boiler burner

The invention relates to the technical field of burners, in particular to a gas boiler burner. The gas boiler burner comprises a boiler body and a burner body. The boiler body comprises a boiler shell. A heating cavity is formed in the boiler shell. The boiler shell is provided with a discharge port. The discharge port is communicated with the heating cavity. The burner body comprises a burner shell. A cylinder is arranged on the upper portion in the burner shell. A first mixing chamber is formed on the lower portion in the burner shell. A combustion chamber is arranged on the upper portion in the cylinder. A second mixing chamber is arranged on the lower portion in the cylinder. The combustion chamber is communicated with the heating cavity. A combustion plate with a plurality of combustion holes is arranged in the combustion chamber. A plurality of air passages are arranged in the cylinder or on the periphery of the cylinder. The first mixing chamber is connected with a gas pipe and an air boosting device. The burner shell and the boiler shell are connected with each other. The gas boiler burner has the advantages of being reasonable in structural arrangement, long in service life, more sufficient in combustion and the like.

Owner:NINGBO DUOBEI MACHINERY IND

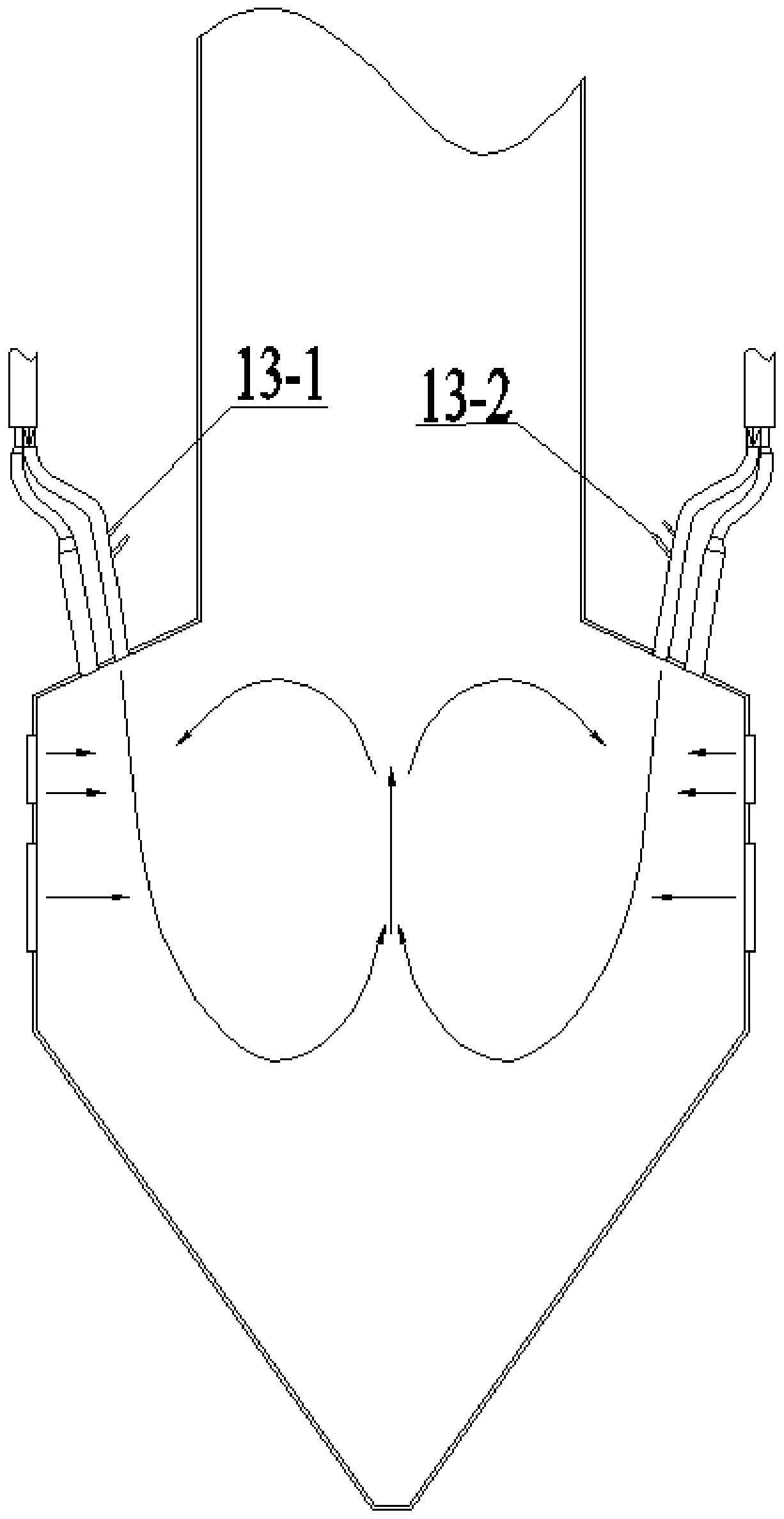

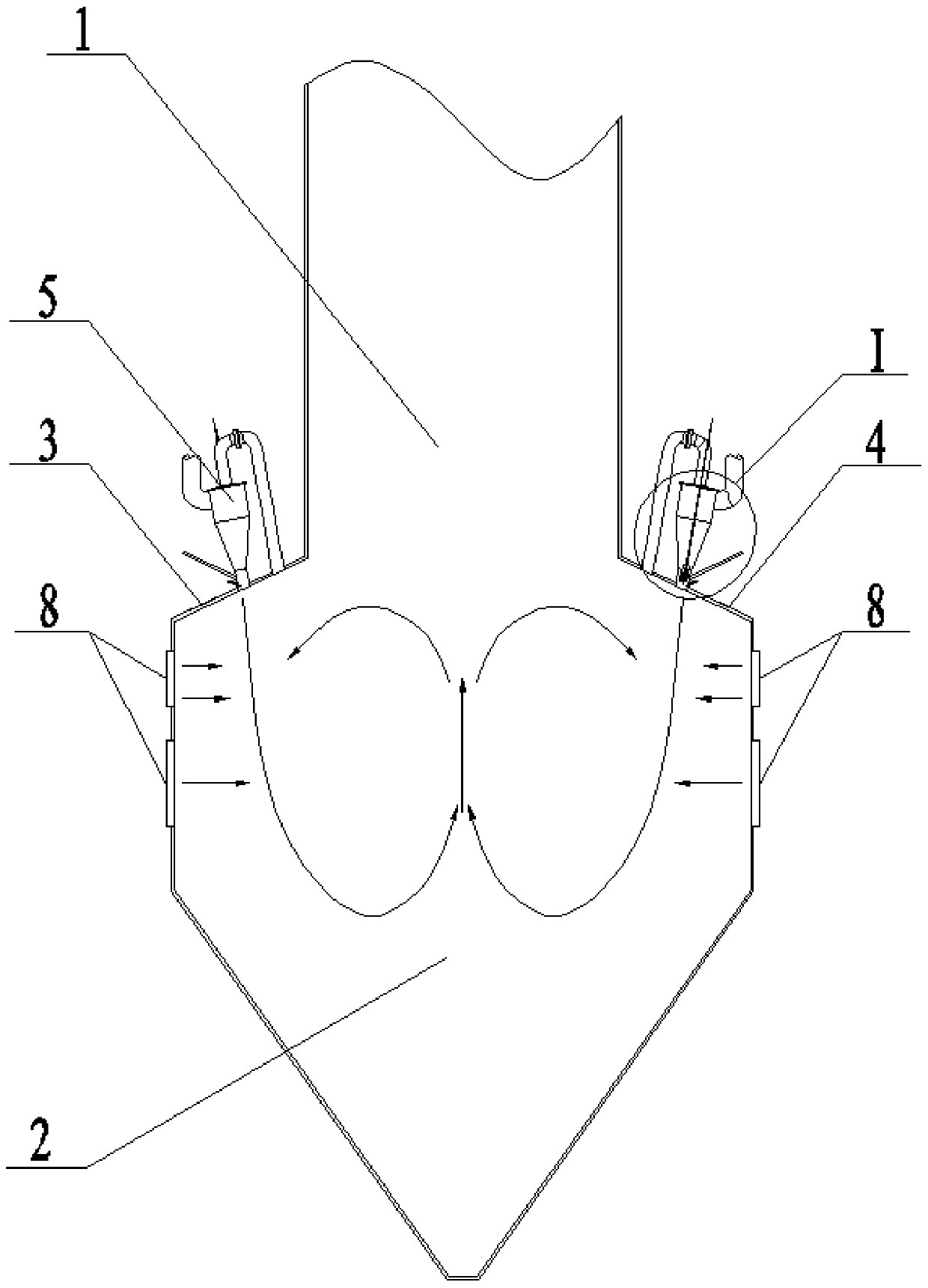

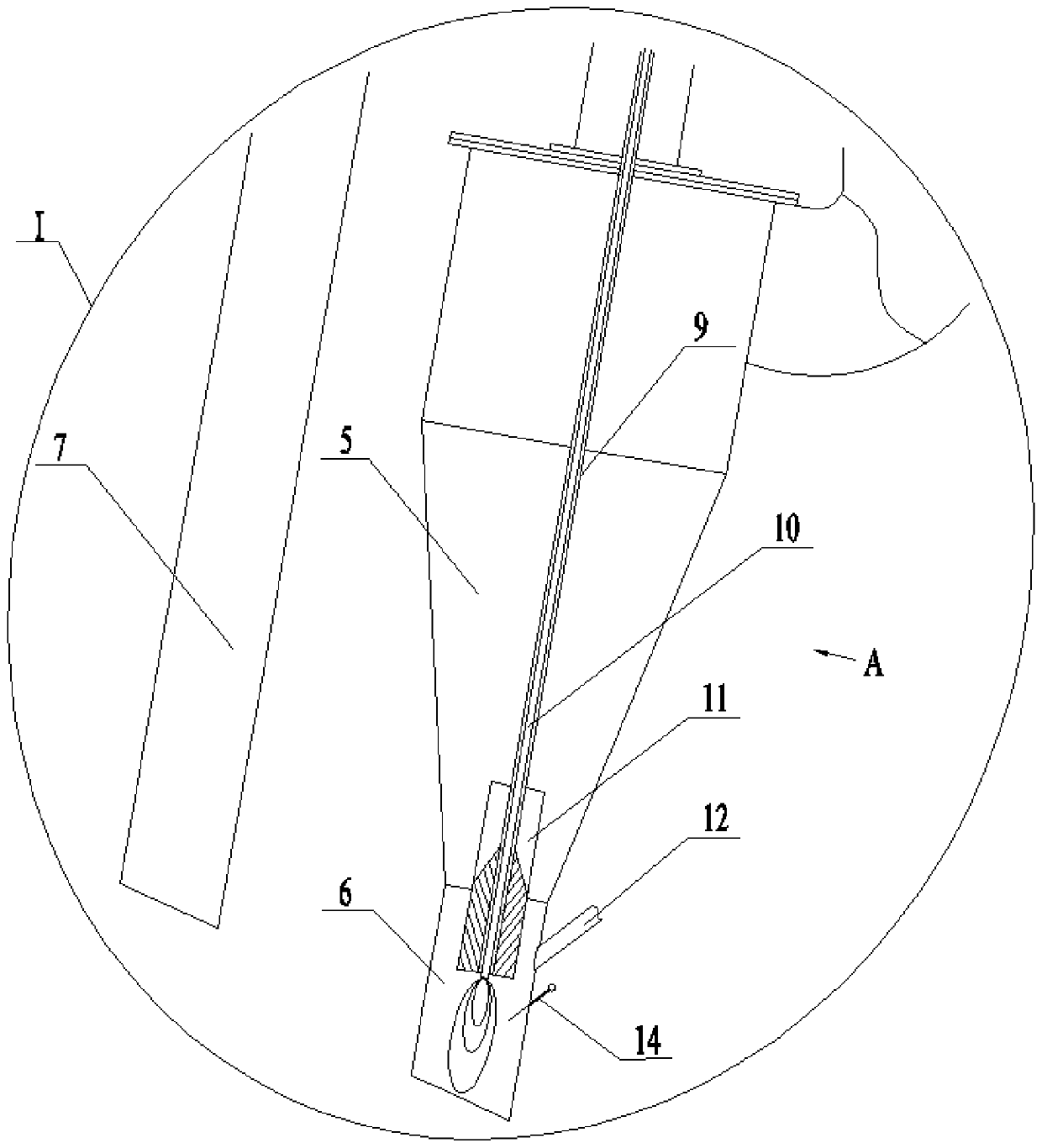

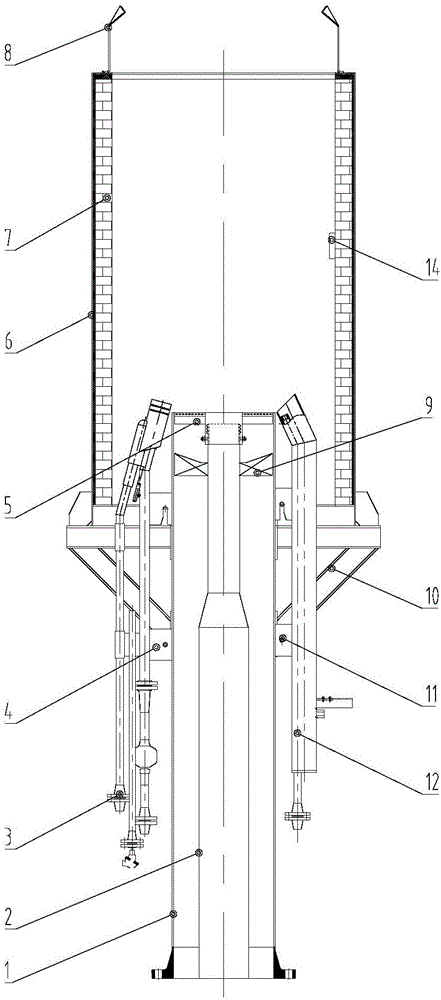

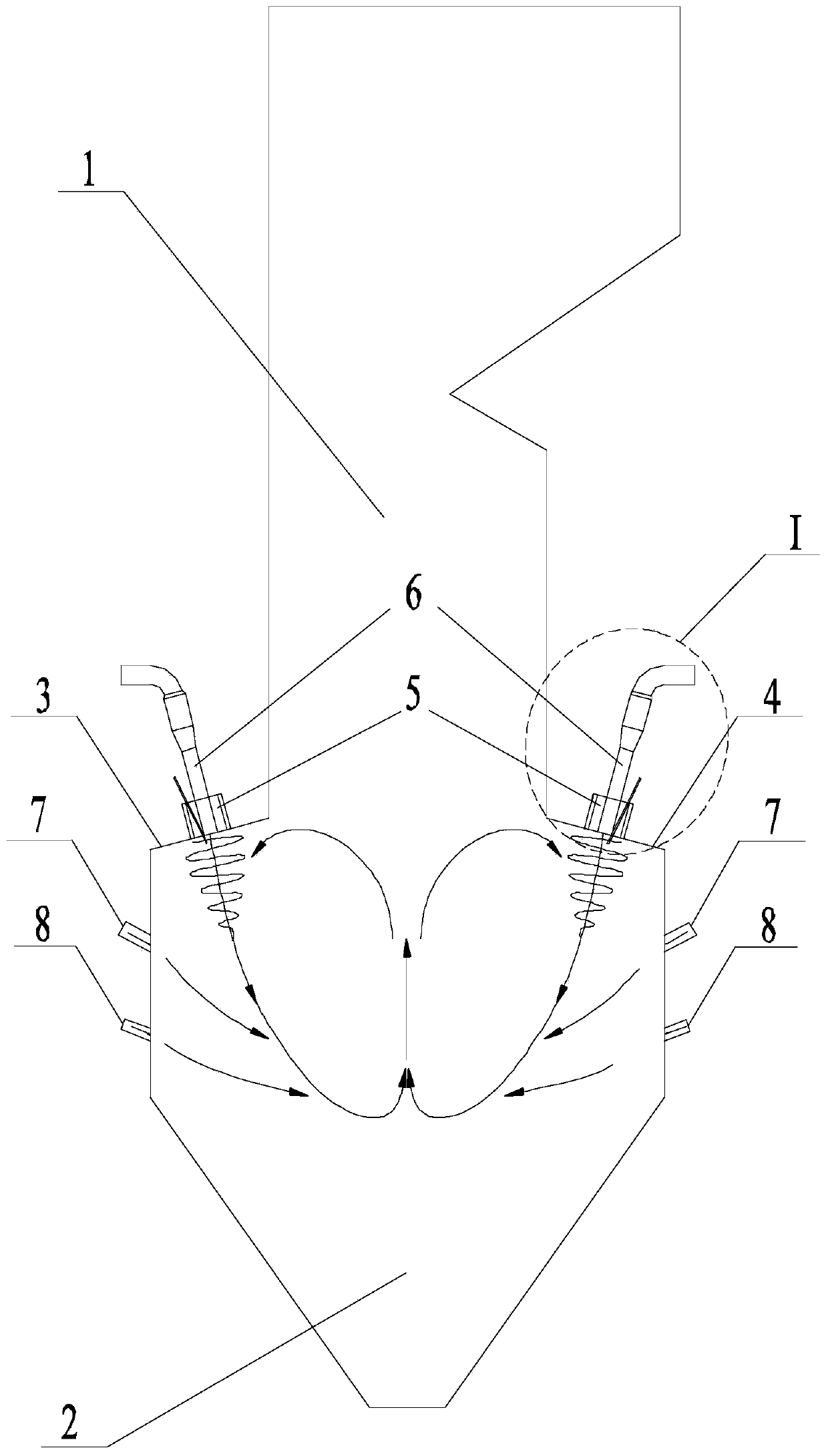

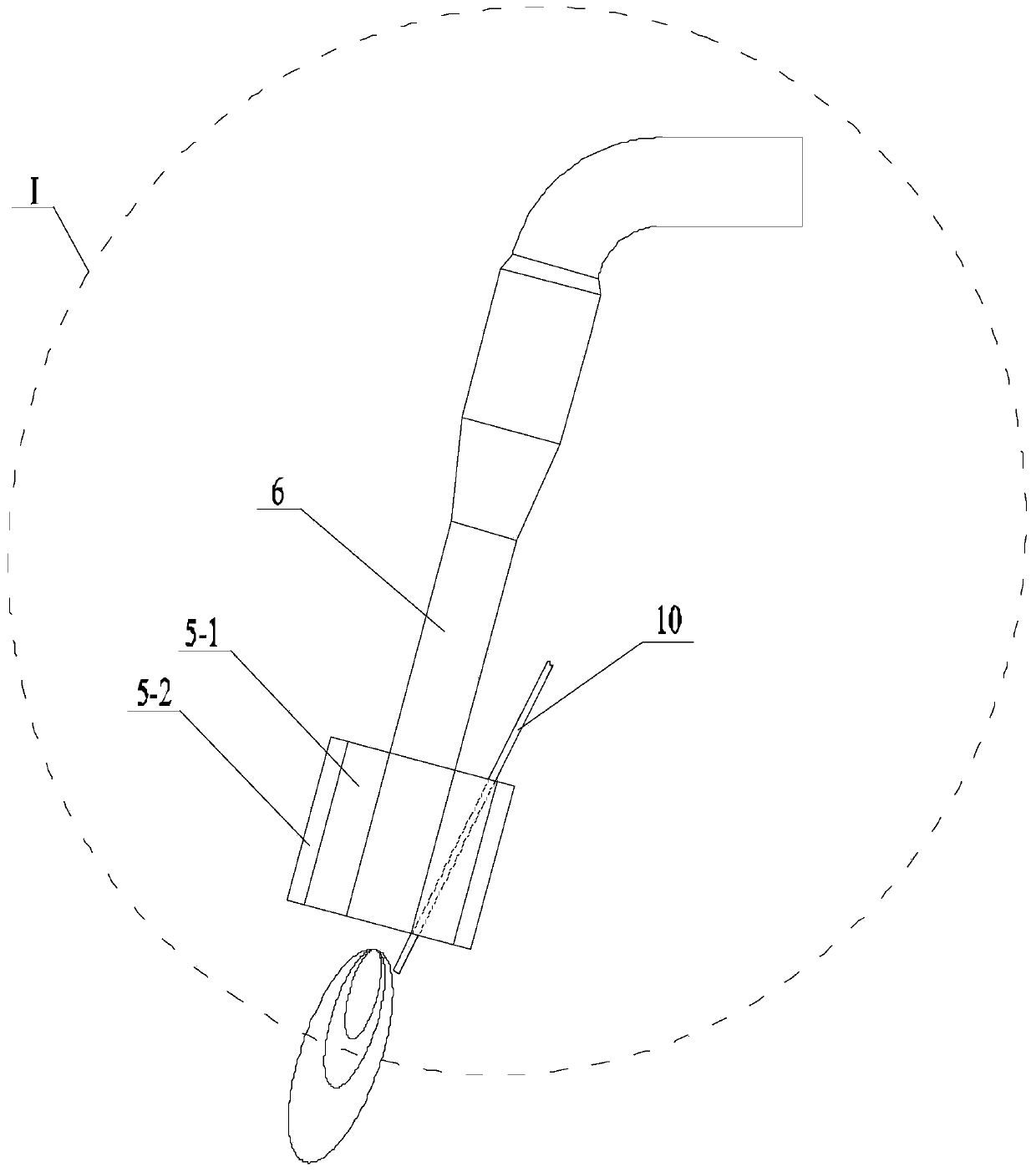

W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors

InactiveCN111023084APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorPower station

The invention provides a W flame boiler with double-cyclone-barrel thick and thin pulverized coal separation type combustors, and relates to a power station boiler which adopts the flexible peak regulation technology. The W flame boiler with the double-cyclone-barrel thick and thin pulverized coal separation type combustors is used for solving the problems that a W flame boiler is poor in ultralowload stable combustion and operation capacity, and the flexible peak regulation load cannot be 20%. The W flame boiler comprises an upper combustion chamber, a lower combustion chamber, a front boiler arch, a rear boiler arch, a front wall, a rear wall, the multiple double-cyclone-barrel thick and thin pulverized coal separation type combustors and multi-layer arch bottom secondary air nozzles. Each double-cyclone-barrel thick and thin pulverized coal separation type combustor comprises two thick pulverized coal airflow nozzles and two exhaust air nozzles. The upper combustion chamber, the front boiler arch, the front wall, the lower combustion chamber, the rear wall and the rear boiler arch are combined to form a boiler body. The multi-layer arch bottom secondary air nozzles are arrangedon the front wall and the rear wall in sequence from top to bottom. The double-cyclone-barrel thick and thin pulverized coal separation type combustors are installed on the front boiler arch and therear boiler arch in a linear mode, and the corresponding thick pulverized coal airflow nozzles and the corresponding exhaust air nozzles of each double-cyclone-barrel thick and thin pulverized coal separation type combustor communicate with the boiler body. The invention belongs to the field of boilers.

Owner:HARBIN INST OF TECH

Thermosensitive wire and preparation method thereof

InactiveCN111689824AImprove moisture resistanceImprove flammabilityFire rescueFuse manufacturePhysical chemistryMoisture resistance

The invention provides a thermosensitive wire and a preparation method thereof. The preparation method comprises the steps that a temperature-sensitive combustible agent, a stabilizing agent, a flameinhibitor, a performance modifier and a solvent are mixed and plasticized, the mixture is pressed into a medicine strip after being plasticized, and the medicine strip is cut and dried after being dried in the air. The thermosensitive wire prepared by the invention can be started in a rated temperature range; when the temperature of the surface of the thermosensitive wire reaches 170-180 DEG C andthe heating duration exceeds 10 seconds, the thermosensitive wire can be automatically started, the false touch rate is low under normal conditions, and the thermosensitive wire has excellent moisture resistance, small combustion smoke and small flame, belongs to an environment-friendly moisture-proof lead, and is simple and convenient in production process.

Owner:LUZHOU NORTH CHEM IND

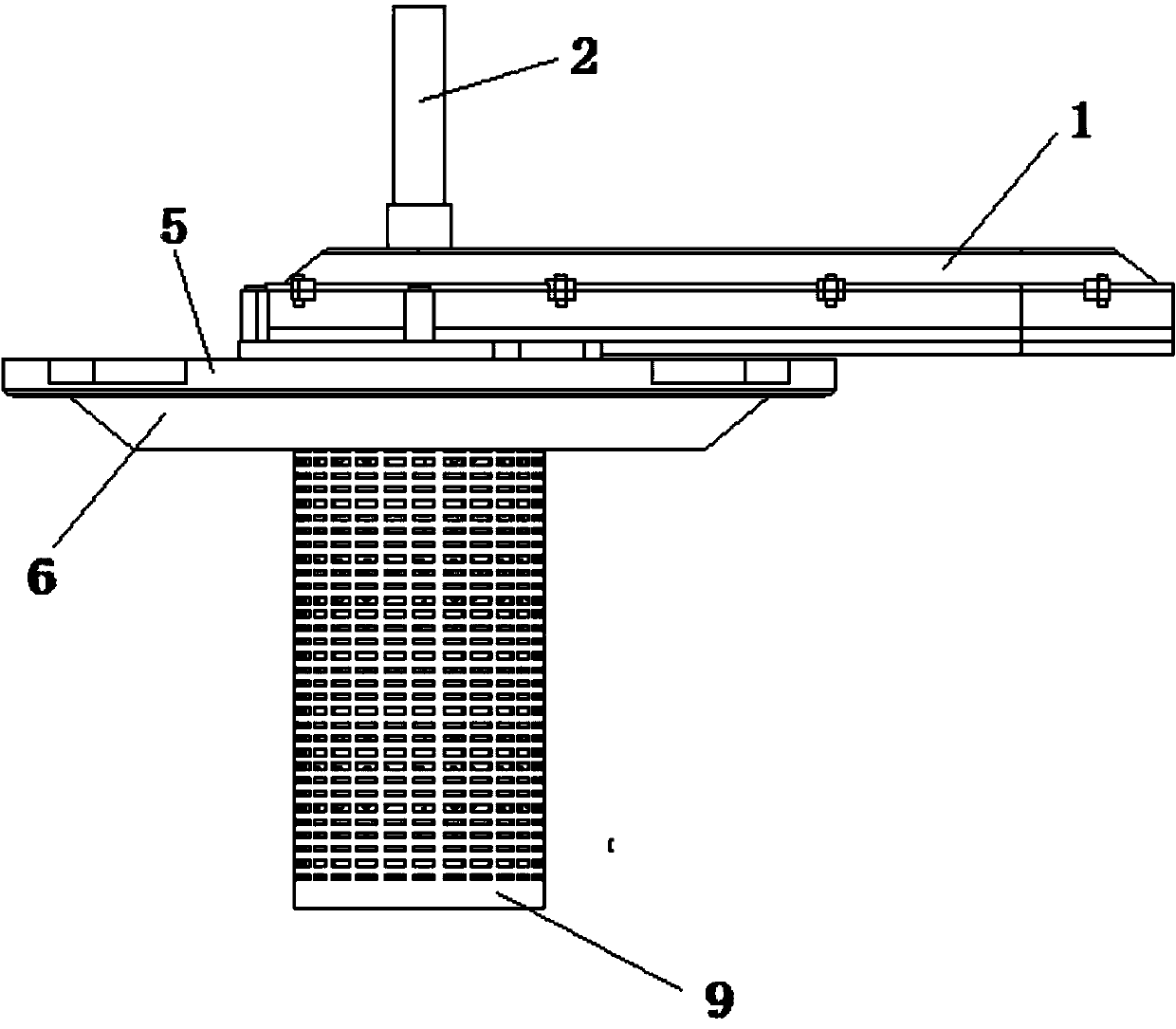

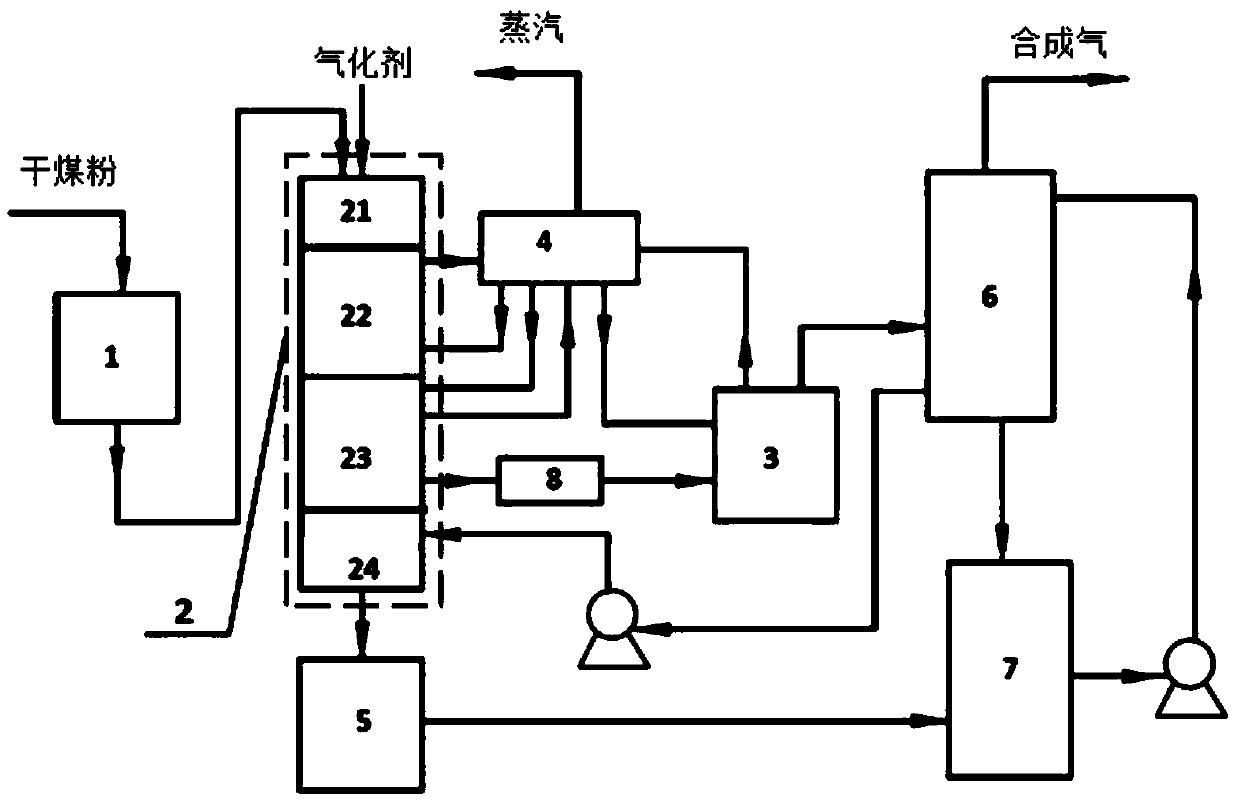

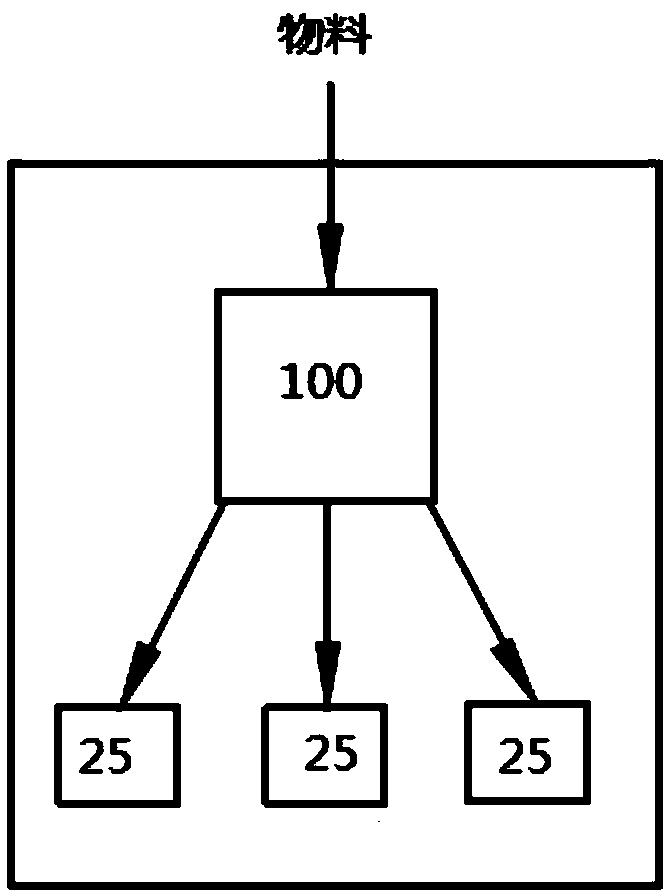

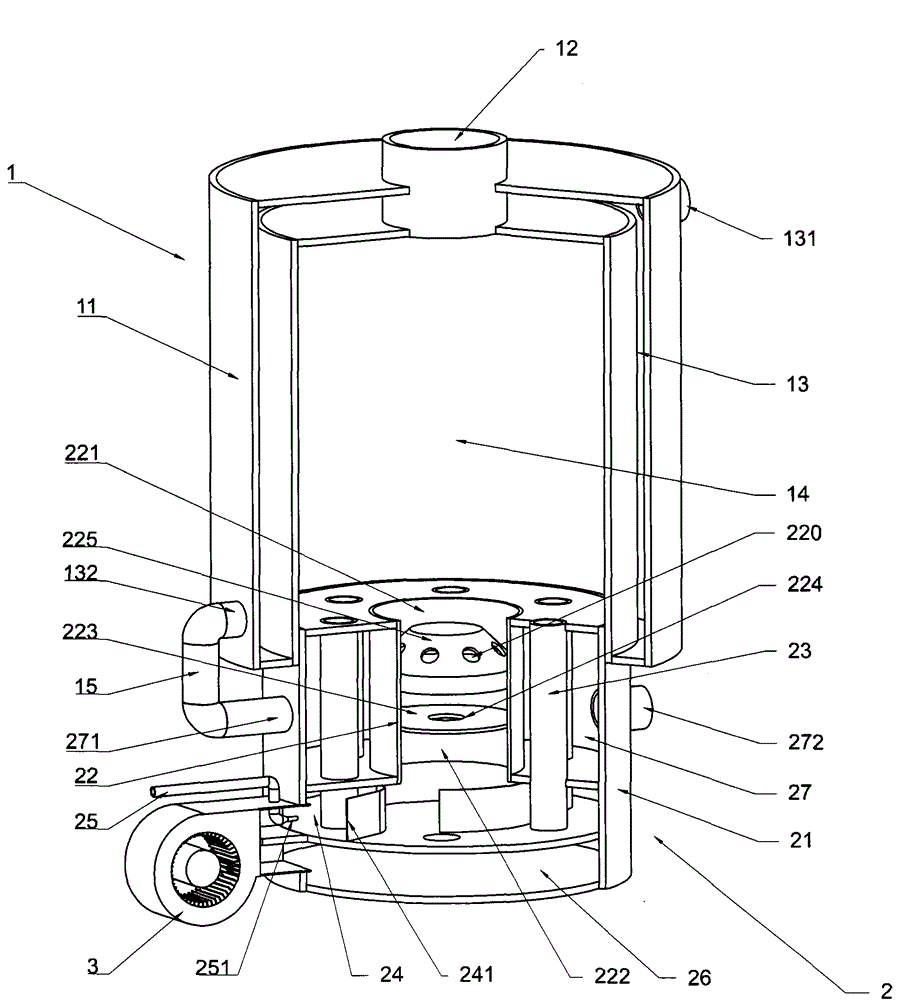

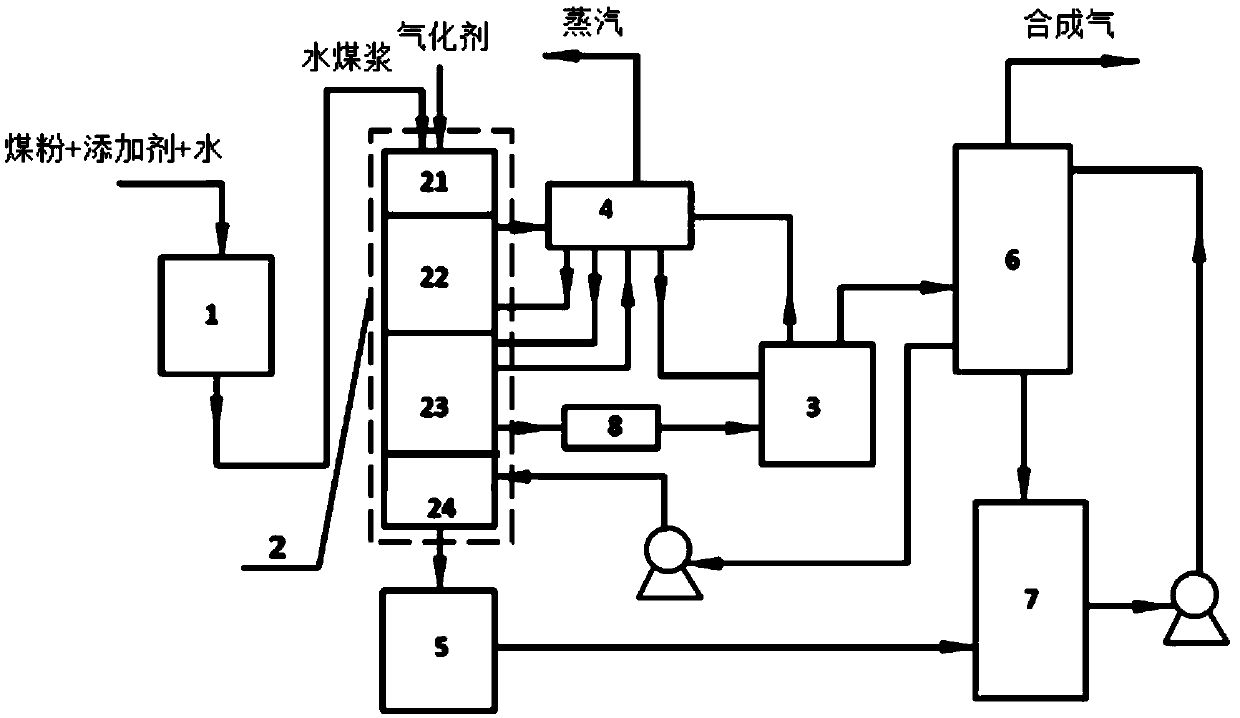

Entrained-flow bed gasification system and method for dry pulverized coal

ActiveCN111349464AGasification reaction space requirements are smallLow investment costGasifier feeding meansGasification processes detailsSlagProcess engineering

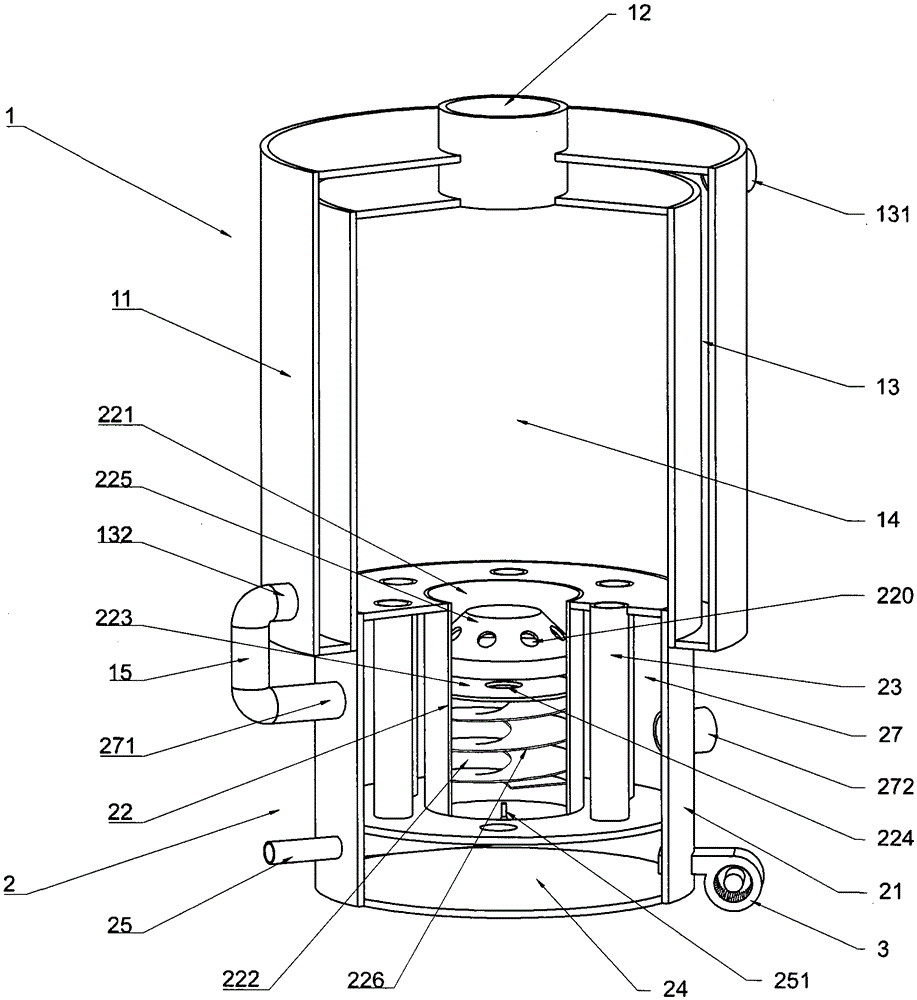

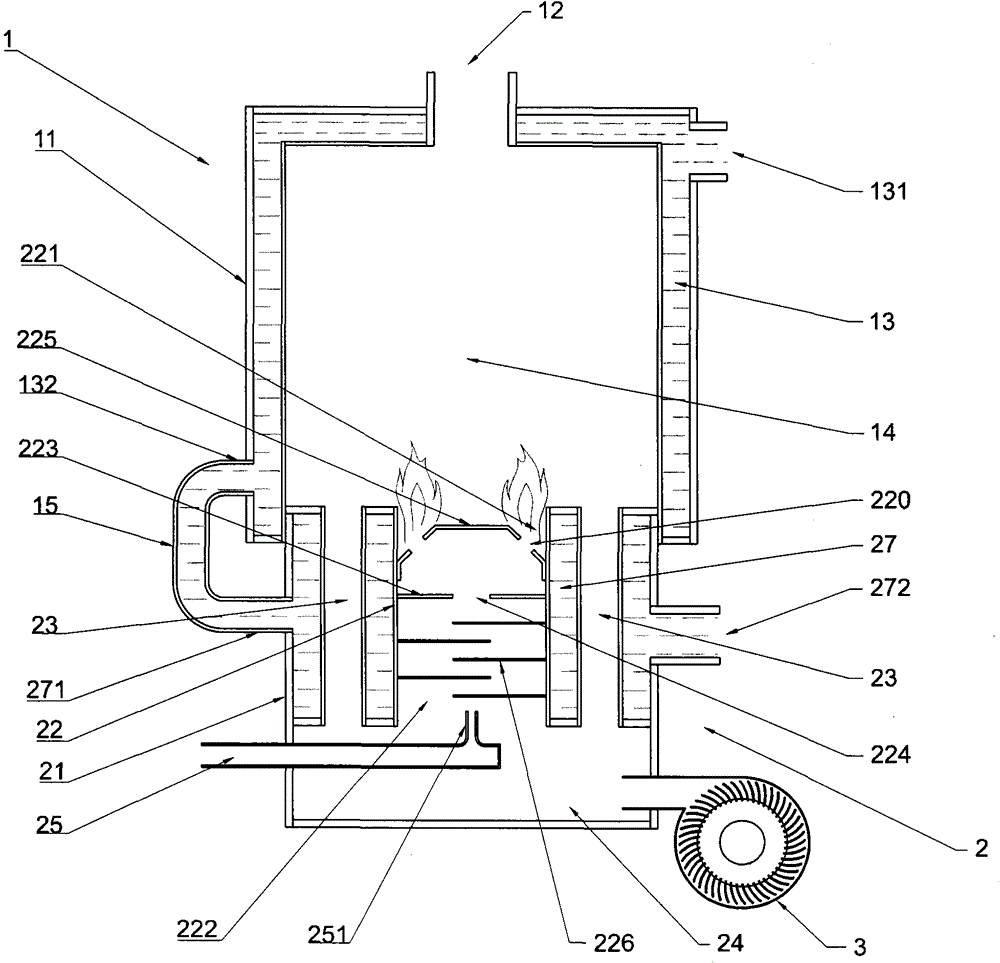

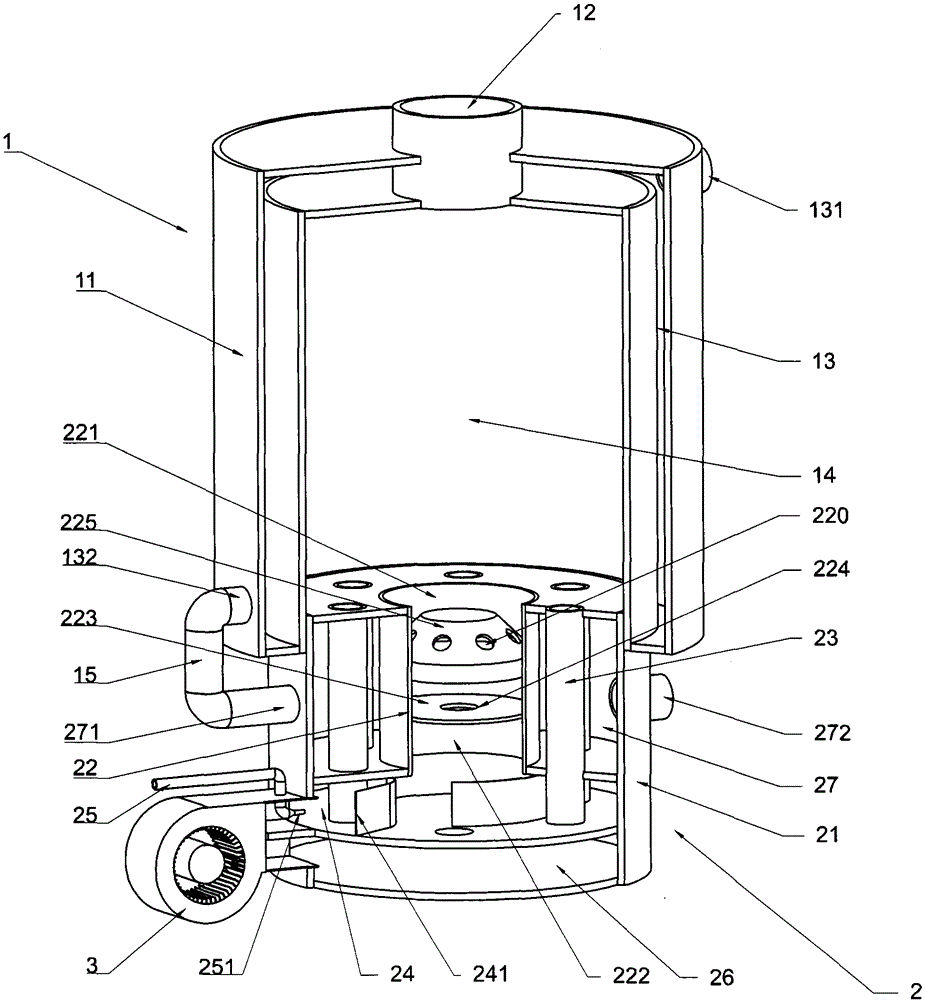

The invention relates to the technical field of coal gasification, and discloses an entrained-flow bed gasification system and a method for dry pulverized coal. The system comprises a material conveying unit (1), a gasification unit (2), a second heat exchange unit (3) and a steam unit (4), the gasification unit (2) comprises a flat flame type gasification burner (21), a gasification chamber (22),a first heat exchange unit (23) and a slag collecting chamber (24) which are sequentially communicated, and the first heat exchange unit (23) is communicated with the steam unit (4); wherein the flatflame type gasification burner (21) comprises burner units (25) arranged at the top of the gasification unit (2), the flat flame type gasification burner (21) can enable a gasification agent and drypulverized coal to collide in the gasification chamber (22) and be ignited to form flat flame, and the number of the burner units (25) is larger than or equal to 3. When the system is used for the entrained-flow bed gasification process of dry pulverized coal, the heat efficiency of the system can be remarkably improved, and meanwhile specific oxygen consumption and specific coal consumption are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Upper air inlet combustor and kitchen range with same

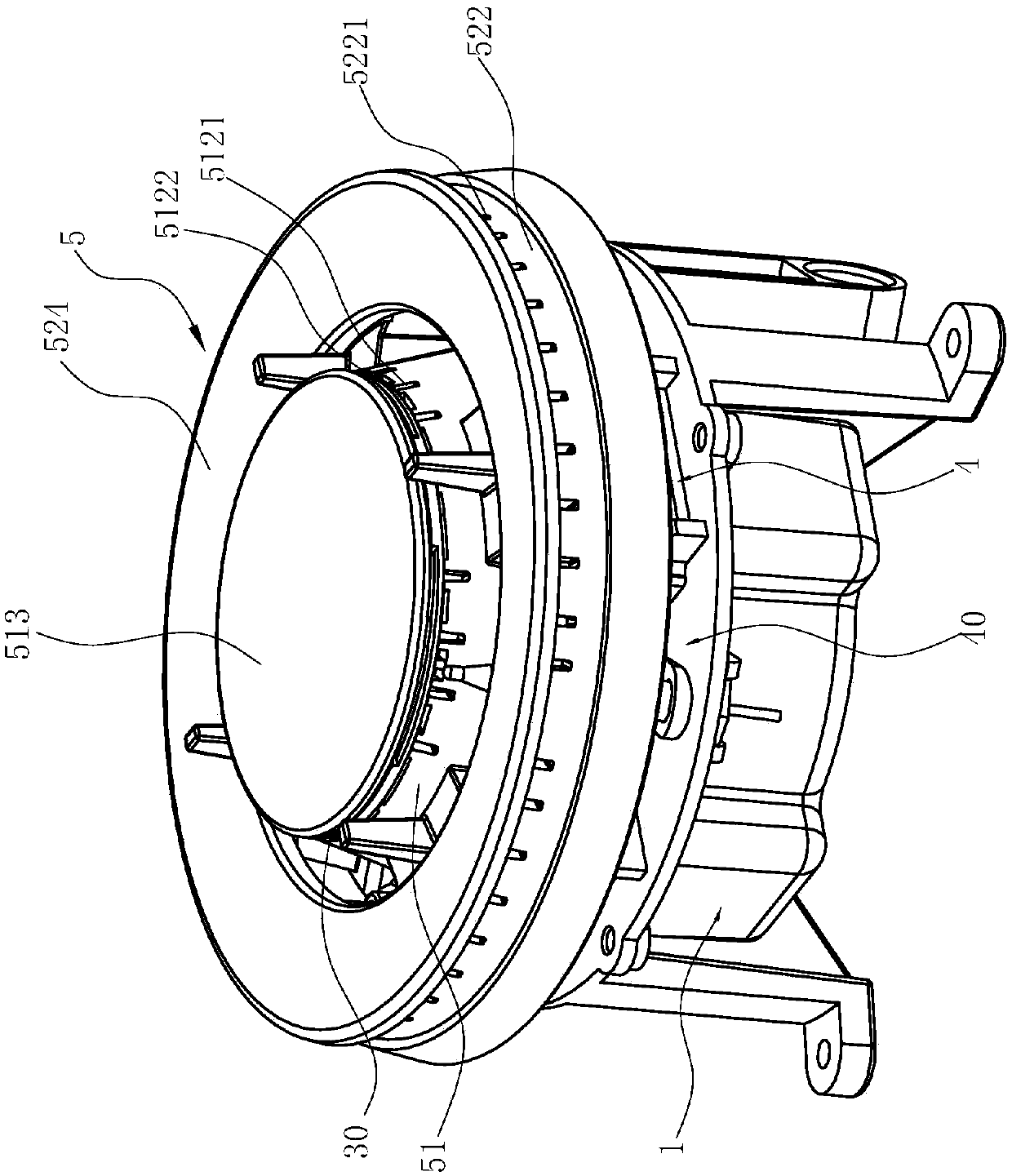

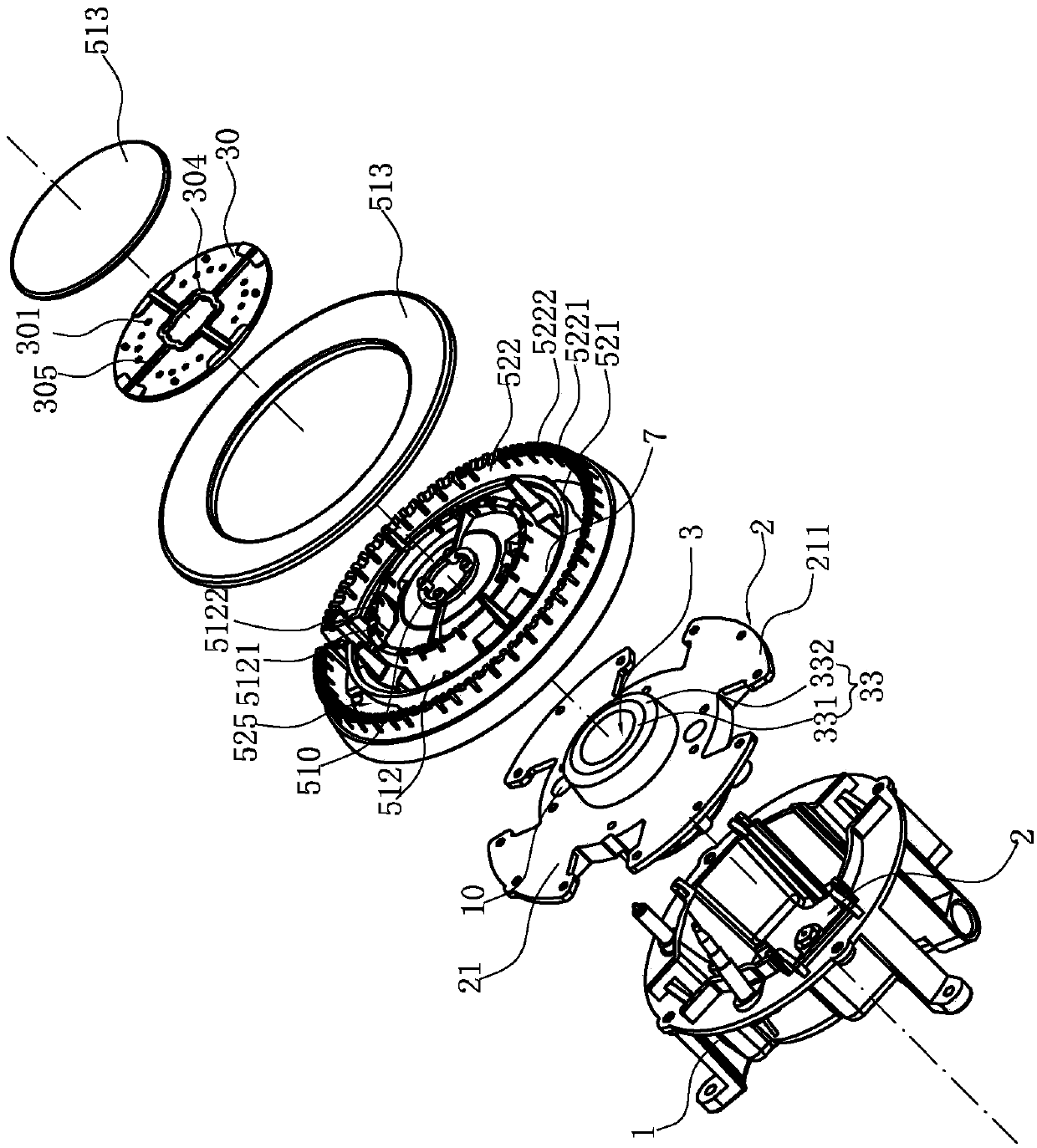

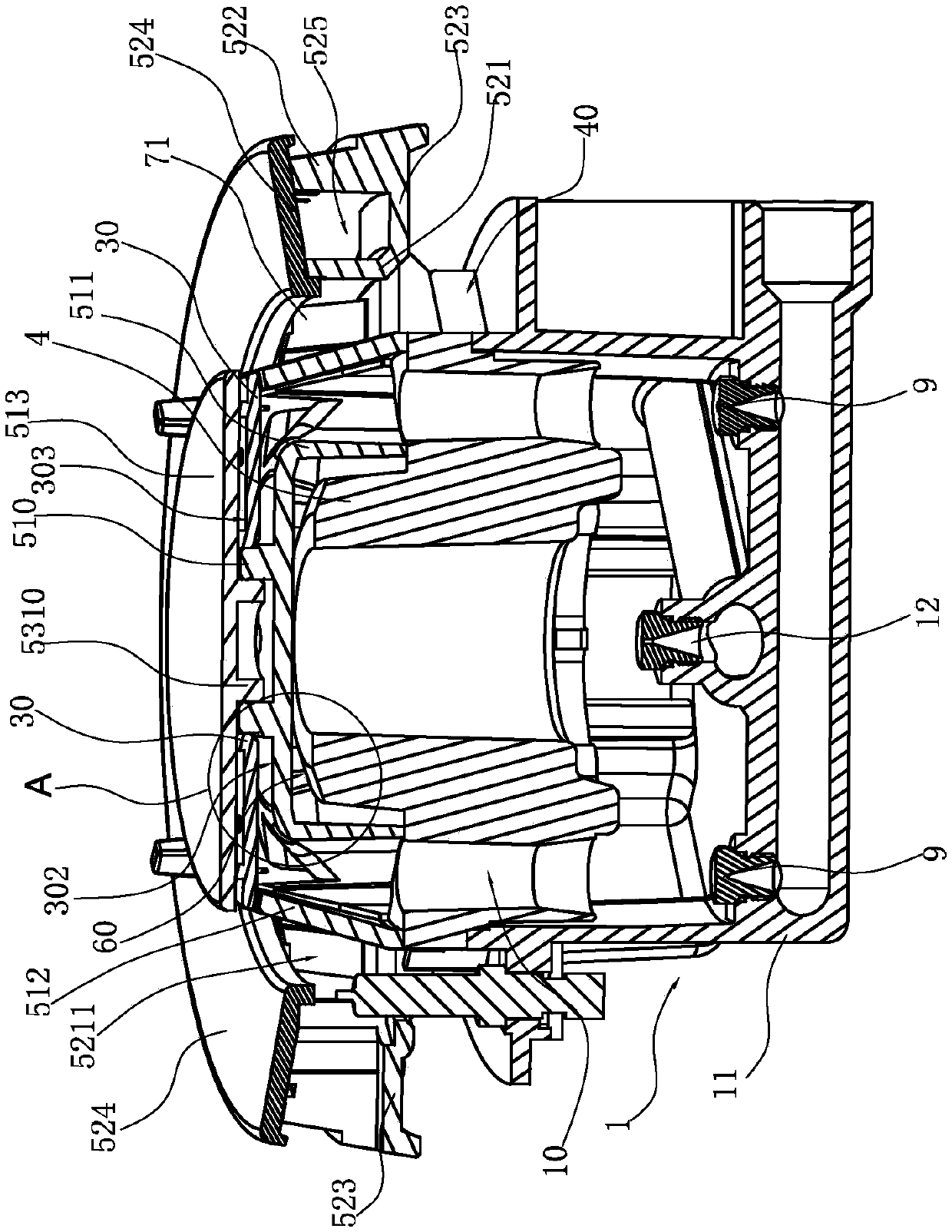

PendingCN111121035AStable and uniform flameShort flameNon-combustible gases/liquids supplyGaseous fuel burnerCombustorEngineering

The invention relates to an upper air inlet combustor. The combustor is characterized by comprising a first injection pipe, an inverted T-shaped base, and a first fire cover; the first injection pipecomprises an air outlet end and an air inlet end, and a first ejector is matched at the air inlet end; and the first fire cover overlies a vertical pipe to form a centrally located first air mixing chamber. Compared with the prior art, the combustor has the advantages that the first injection pipe is completely enclosed in a horizontal pipe of the base, and the first injection pipe cannot be madeto be too long due to processing limitation, therefore, a spiral channel formed by spiral ribs on the inner wall of the horizontal pipe in the base can drive gas and primary air to enter the first airmixing chamber after being uniformly mixed along the spiral channel, so that the flame of the upper air inlet combustor is short, uniform and powerful, and the defects of yellow flame, tempering andthe like are avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

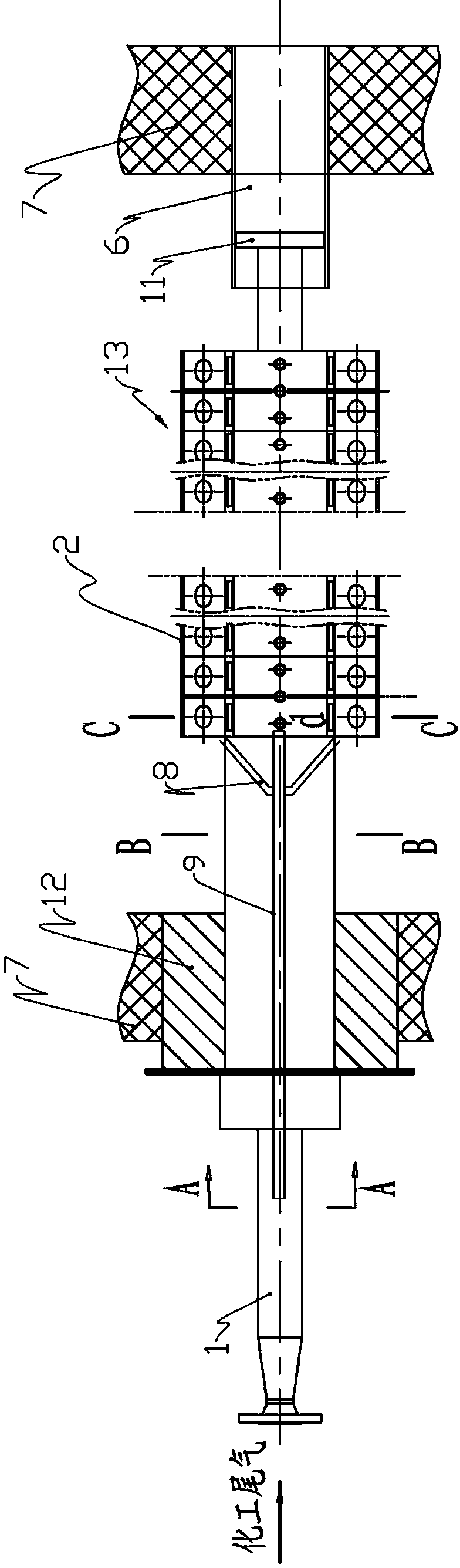

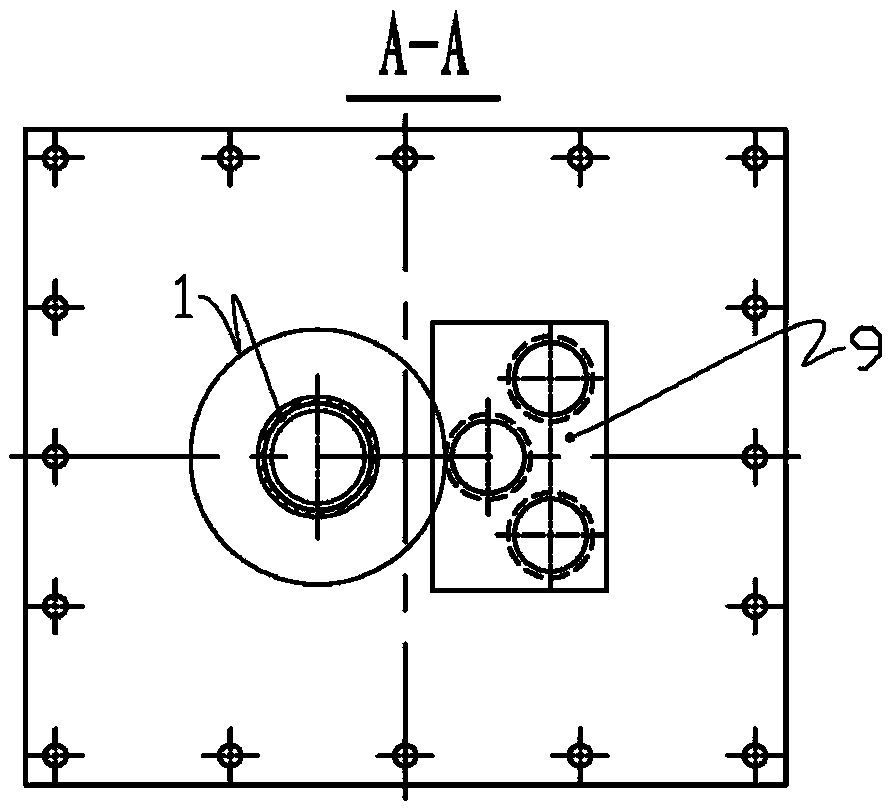

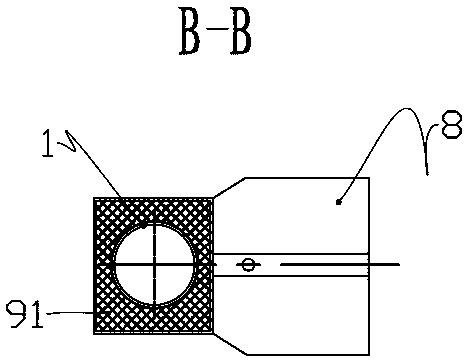

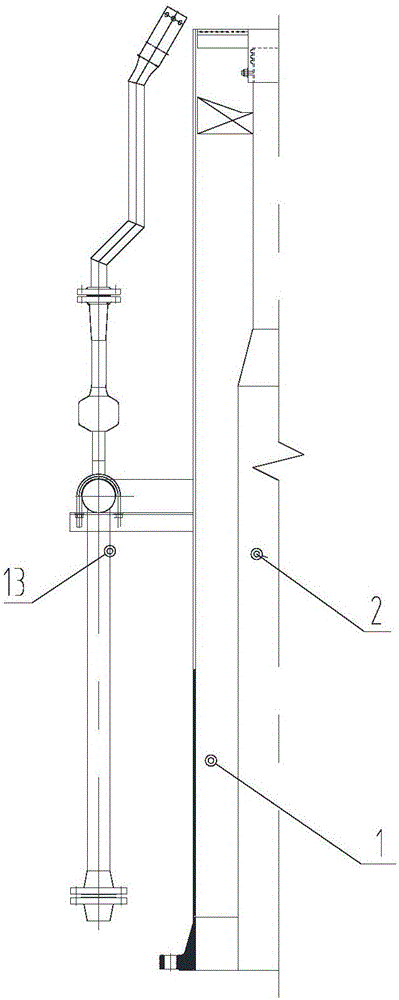

Afterburning burner for gas turbine waste heat boiler

ActiveCN103807850AMeet the requirements of combustionShort flameCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The invention discloses an afterburning burner for a gas turbine waste heat boiler. The afterburning burner for the gas turbine waste heat boiler comprises a chemical engineering tail gas pipe, an ignition device and a flame stabilizing component; one side of a burning part of the chemical engineering tail gas pipe is provided with a plurality of ranked spray holes; a spray pipe extends vertically outwards from the spray holes; the cross sectional area of a gas flow channel of the spray pipe is 10-20 times of the cross sectional areas of the spray holes; the flame stabilizing component comprises inner flame stabilizing covers and outer flame stabilizing covers, wherein the inner flame stabilizing covers and the outer flame stabilizing covers are of V-shaped structures; the inner flame stabilizing covers are formed integrally and are sequentially provided with V-shaped grooves, flat bases and oblique walls from the centers to two sides; each outer flame stabilizing cover is sequentially provided with a first through hole and a second through hole which are parallel to the spray pipe from inward to outward. The afterburning burner for the gas turbine waste heat boiler, which is provided by the invention, has the characteristics of being short in flames, complete in burning, high in flame intensity and reasonable in smoke distribution, and is suitable for waste heat boilers, so that high-temperature smoke and toxic chemical engineering tail gases in industry can be treated effectively in a combined mode by the waste heat boiler.

Owner:JINAN TORCH CREATION ENERGY SCI & TECH

Gas boiler burner

The invention relates to the technical field of burners, in particular to a gas boiler burner. The gas boiler burner comprises a boiler body and a burner body. The boiler body comprises a boiler shell. A heating cavity is formed in the boiler shell. The boiler shell is provided with a discharge port. The discharge port is communicated with the heating cavity. The burner body comprises a burner shell. A cylinder is arranged on the upper portion in the burner shell. A first mixing chamber is formed on the lower portion in the burner shell. A combustion chamber is arranged on the upper portion in the cylinder. A second mixing chamber is arranged on the lower portion in the cylinder. The combustion chamber is communicated with the heating cavity. A combustion plate with a plurality of combustion holes is arranged in the combustion chamber. A plurality of air passages are arranged in the cylinder or on the periphery of the cylinder. The first mixing chamber is connected with a gas pipe and an air boosting device. The burner shell and the boiler shell are connected with each other. The gas boiler burner has the advantages of being reasonable in structural arrangement, long in service life, more sufficient in combustion and the like.

Owner:NINGBO DUOBEI MACHINERY IND

Air premixed type flare combustor capable of treating poisonous gas

InactiveCN105927992AGuaranteed decompositionImprove burnout rateIncinerator apparatusGaseous fuel burnerToxic gasCombustor

The invention relates to an air premixed type flare combustor capable of treating poisonous gas. A flare gas cylinder body of the combustor is arranged inside an air clamping sleeve body for forming a clamping sleeve body structure, and swirling plates are arranged inside the clamping sleeve body structure; a flare gas nozzle is installed at the upper end of the flare gas cylinder body; a combustion chamber is connected to the outer wall of the upper part of the air clamping sleeve body through a supporting assembly, and the air clamping sleeve body extends into the combustion chamber; a temperature monitoring element is installed on the inner wall of the combustion chamber; the combustion chamber is of a cylindrical shape, and a gap is formed between the lower part of the combustion chamber and the air clamping sleeve body and accepts entry of secondary air; an ever-burning lamp, an igniter and a combustion-assisting device are arranged outside the air clamping sleeve body in the circumferential direction, are connected to the air clamping sleeve body and extend into the combustion chamber. According to the flare combustor, the air partial combustion-supporting mode is adopted, flames are short, combustion is stable, and the burn-off rate of the poisonous exhaust gas is greatly increased; the height and the manufacturing cost of a torch can be effectively lowered on the same exhaust condition.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Upper air inlet burner and cooker comprising same

PendingCN111121033AIncrease the lengthReduce lossesNon-combustible gases/liquids supplyGaseous fuel burnerCombustorMechanics

The invention relates to an upper air inlet burner. The upper air inlet burner comprises a base for accommodating a first injection pipe, a connector arranged on the base and a first burner cap connected to the connector, wherein the connector is provided with a vertical first gas channel and can cover the base; a first gas mixing chamber located at the center is formed between the first burner cap and the connector; and the first gas mixing chamber corresponds to the first gas channel. The upper air inlet burner is characterized in that the first injection pipe is transversely arranged in thebase; an inner cavity of the first injection pipe comprises a transition section and a horn section in sequence in the gas flow direction from a gas inlet to a gas outlet; and a buffer cavity is formed between the horn section and the lower surface of the first gas channel. Compared with the prior art, the upper air inlet burner has the advantages that the first injection pipe is arranged in thebase and provided with the buffer cavity; the length of the first injection pipe is effectively increased through the buffer cavity; and meanwhile, through arrangement of the buffer cavity, a primaryair / gas mixture injected from the gas outlet end of the first injection pipe can have a buffer space.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Upper air inlet combustor

PendingCN110529850AIncrease inhalation rateAvoid hitting each otherAir/fuel supply for combustionNon-combustible gases/liquids supplyCombustorTransmission channel

The invention relates to an upper air inlet combustor which comprises a base, wherein the base is provided with a concave cavity of which the opening is upwards and which is used for containing at least one first ejector; a first ejection channel which is arranged on the base and is in fluid connection with the base and the first ejector; a primary air channel which is arranged on the base; a burner cap and a transmission channel which are arranged on the base, and is characterized in that the first injection channel comprises a central cavity located in the center and a peripheral cavity surrounding the central cavity, an inlet of the central chamber is opposite to the first ejector, and the peripheral chamber is used for uniformly surrounding the primary air at the periphery of the central chamber. Compared with the prior art, the upper air inlet combustor has the advantages that by the sandwich structure design of the first injection channel, the gas in the center cavity can be better and more directly mixed with the primary air in the peripheral cavity, the uniformity of the primary air evenly distributed at the periphery of the center cavity is further improved, the primary air suction rate is increased, and meanwhile the phenomena of yellow flames and firepower weakness which are likely to occur during combustion are avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

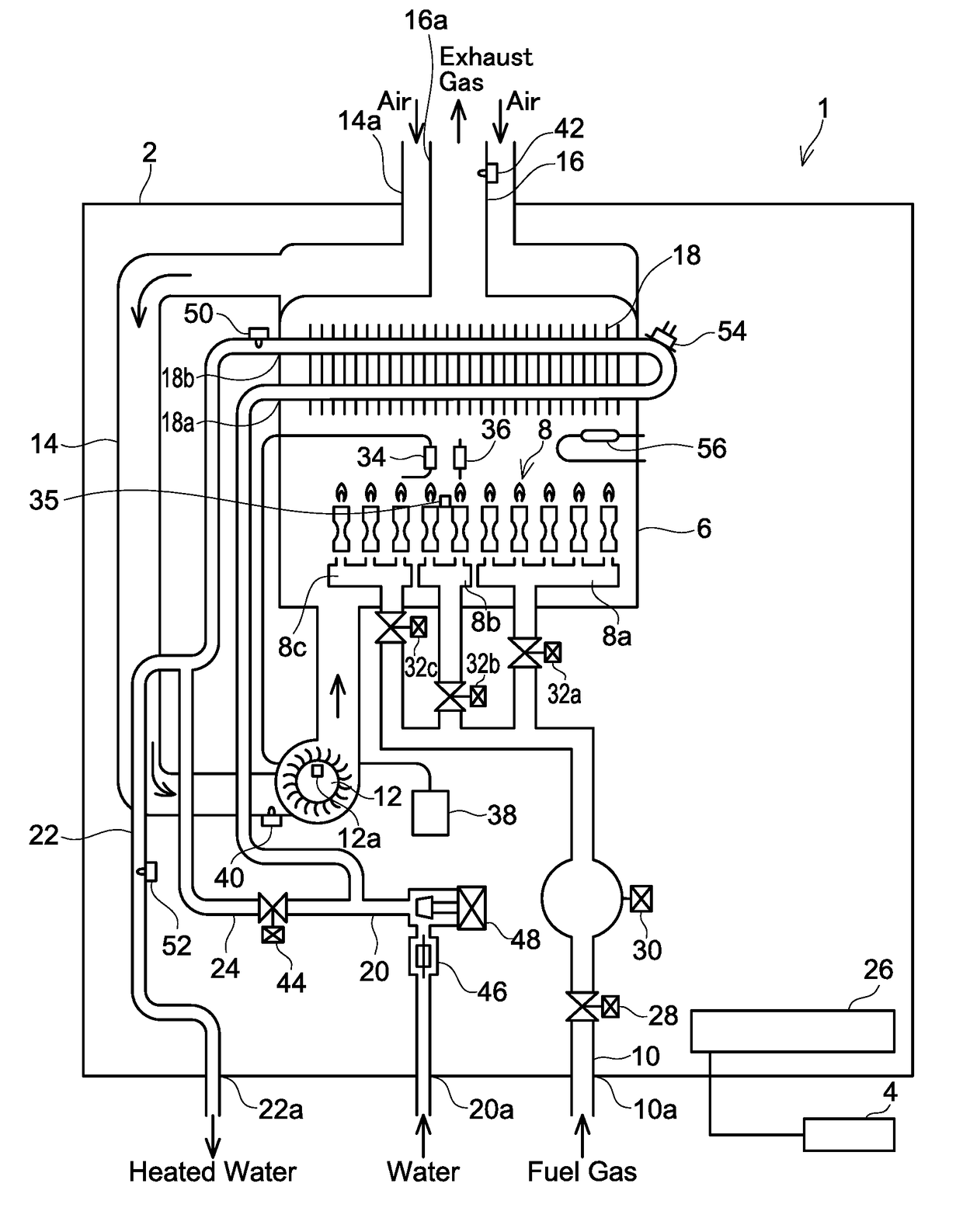

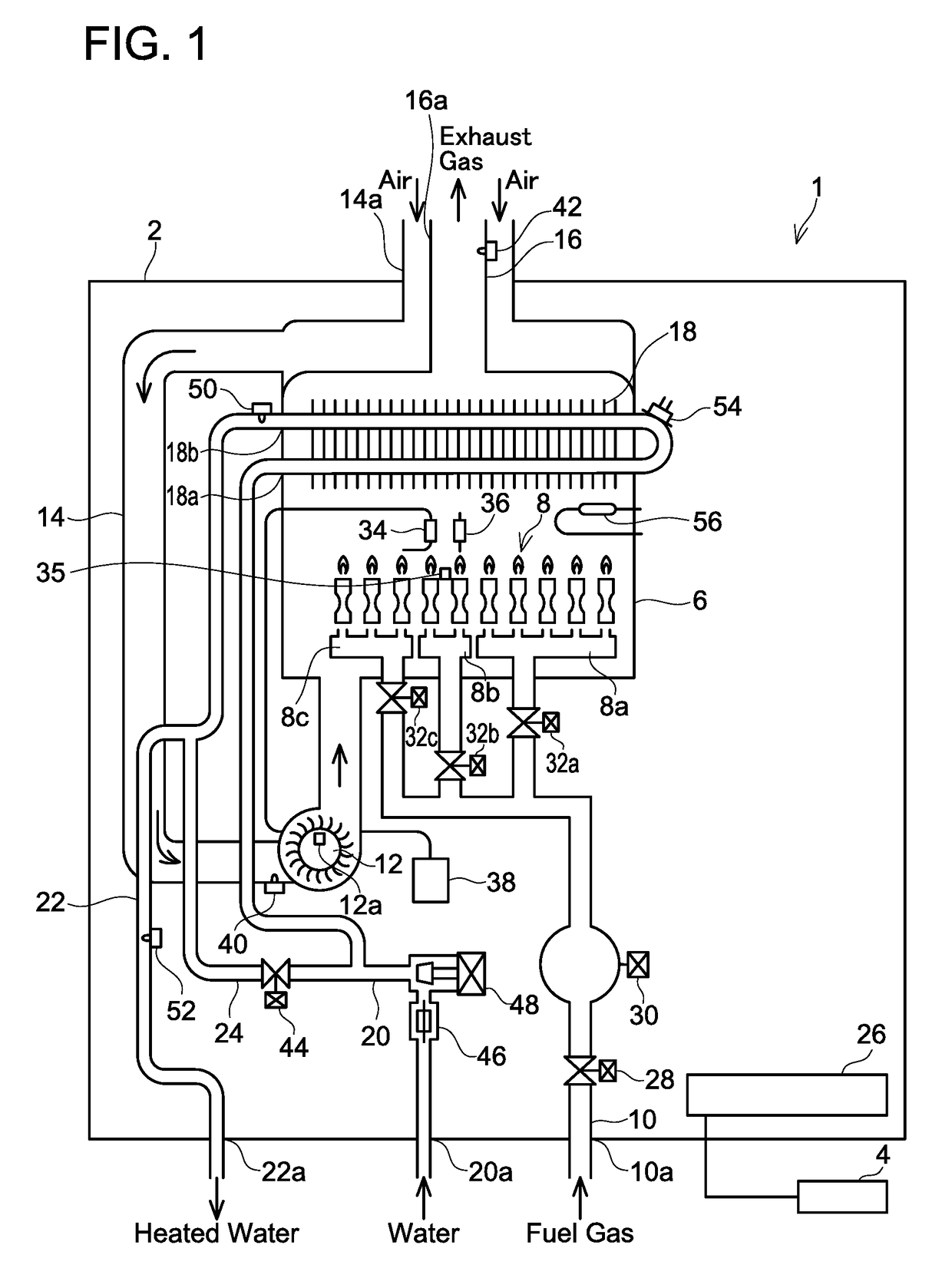

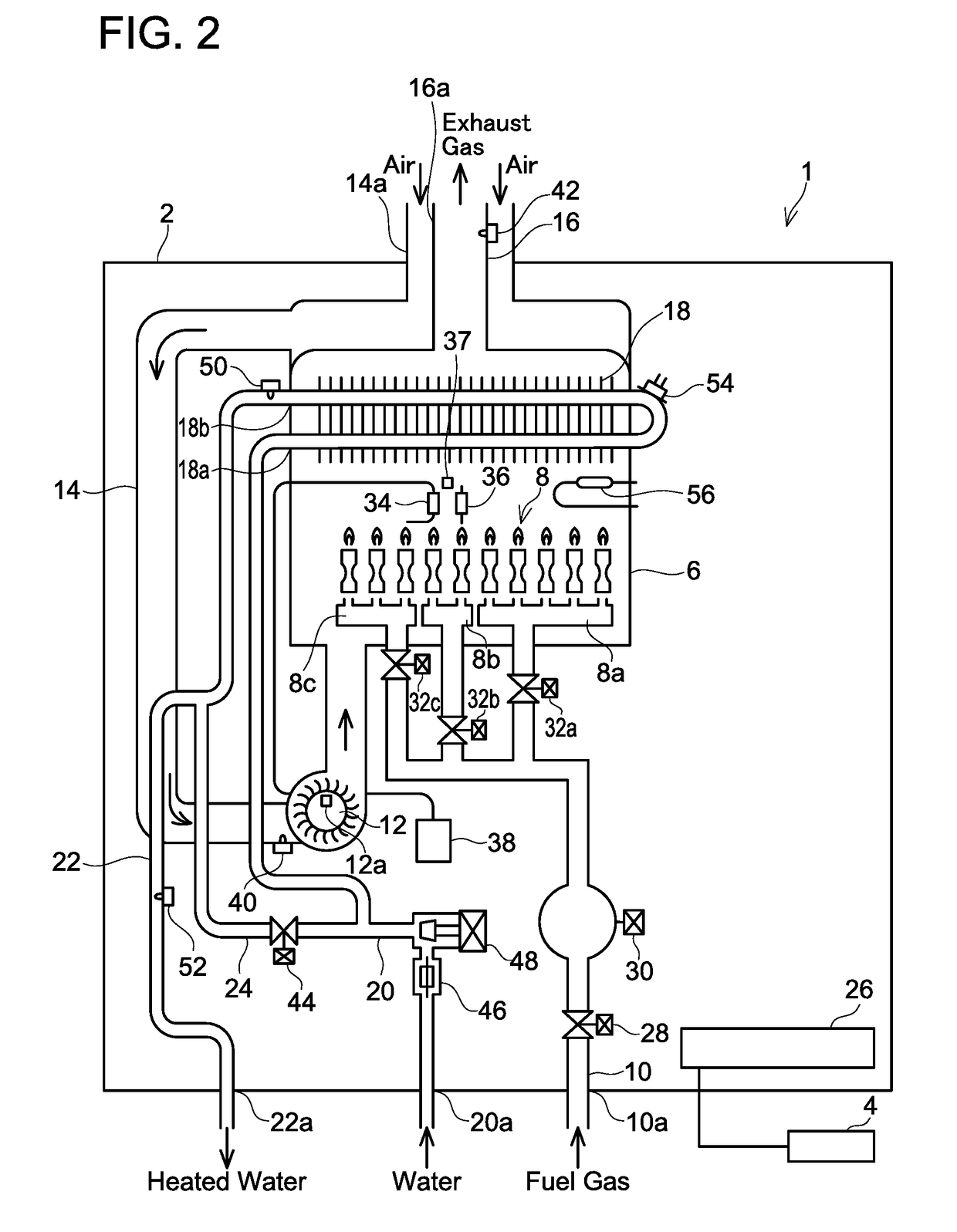

Combustion type water heater

ActiveUS10018376B2Ensure correct executionImprove performanceCleaning heat-transfer devicesRecuperative heat exchangersPlate heat exchangerCombustion

The present description discloses a combustion type water heater that heats water by burning fuel. The combustion type water heater includes: a burner that generates combustion gas by burning the fuel; a heat exchanger that exchanges heat between the water passing through on an inside of the heat exchanger and the combustion gas flowing on an outside of the heat exchanger, an exhaust pipe that discharges the combustion gas after the heat exchange in the heat exchanger as exhaust gas; an exhaust gas temperature detector that detects a temperature of the exhaust gas flowing in the exhaust pipe as an exhaust gas temperature; a clog degree detector that detects a degree of clog in the exhaust pipe; and a scale buildup determiner that determines whether or not scale has built up inside the heat exchanger based on the exhaust gas temperature and the degree of clog in the exhaust pipe.

Owner:RINNAI CORP

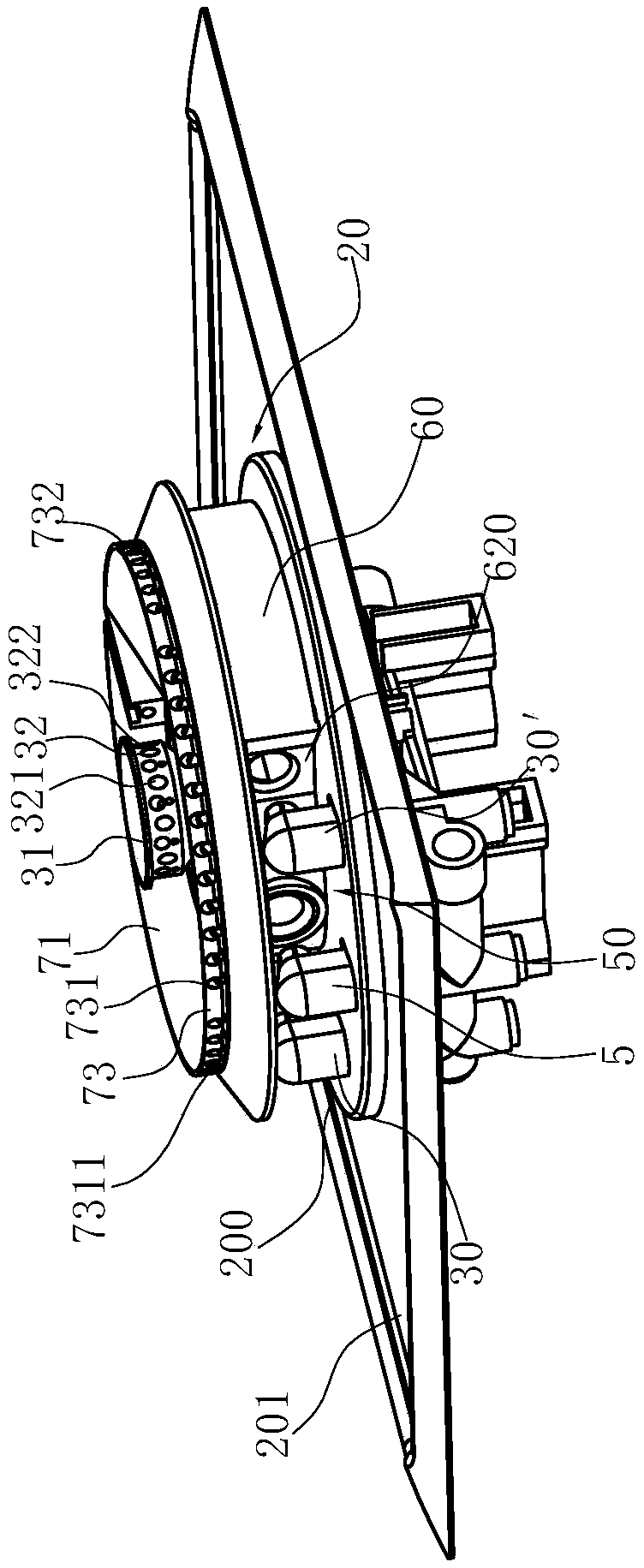

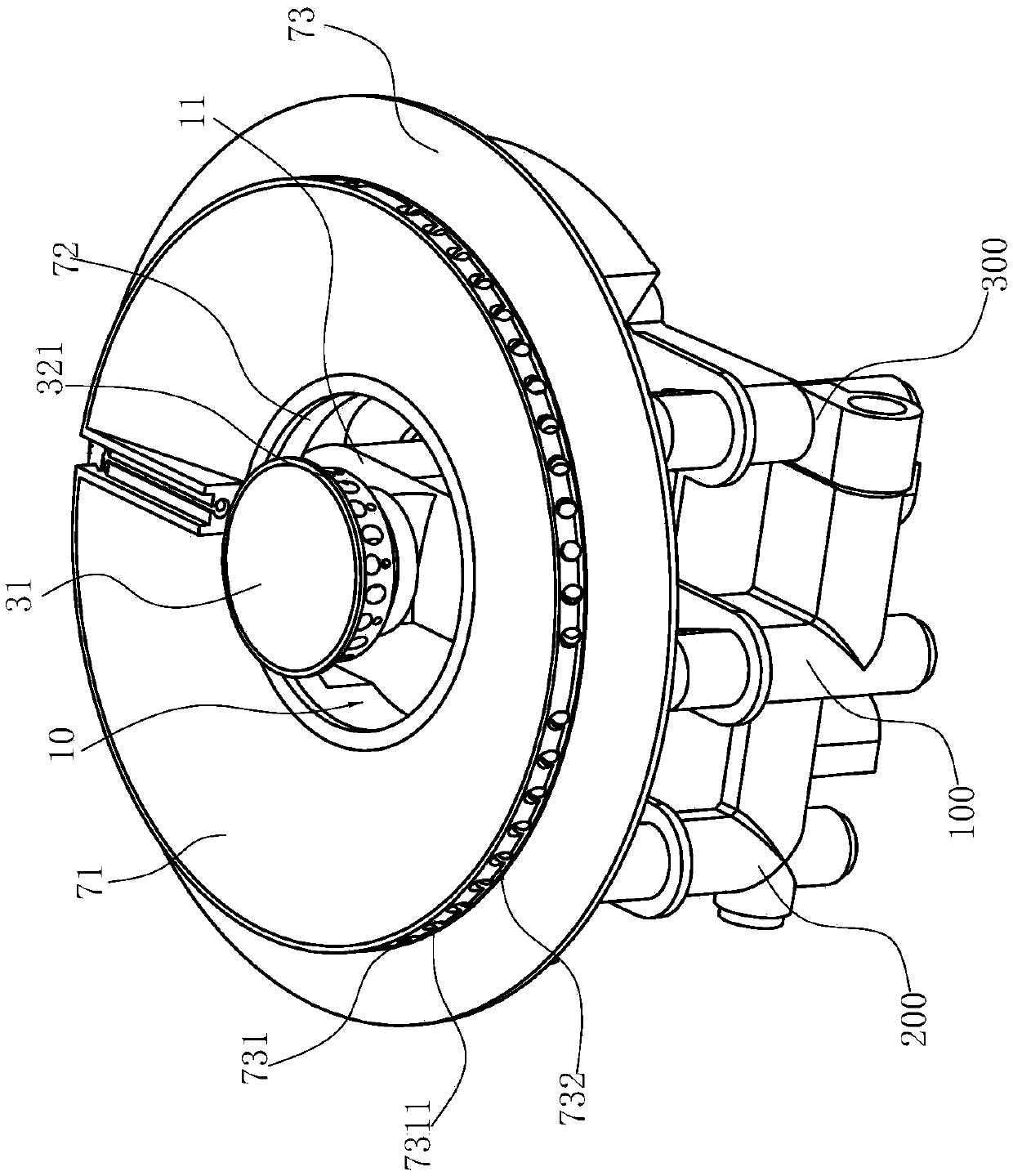

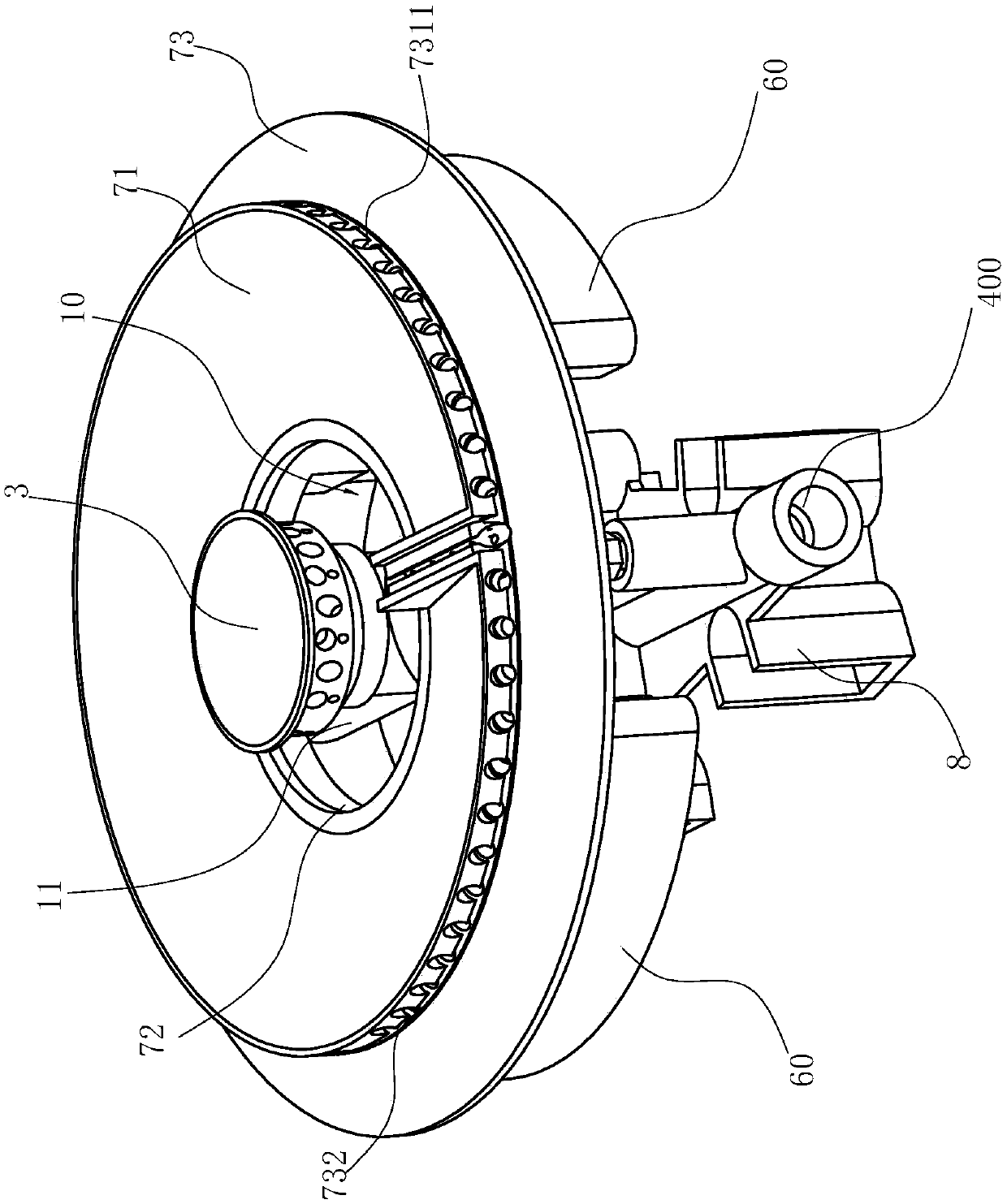

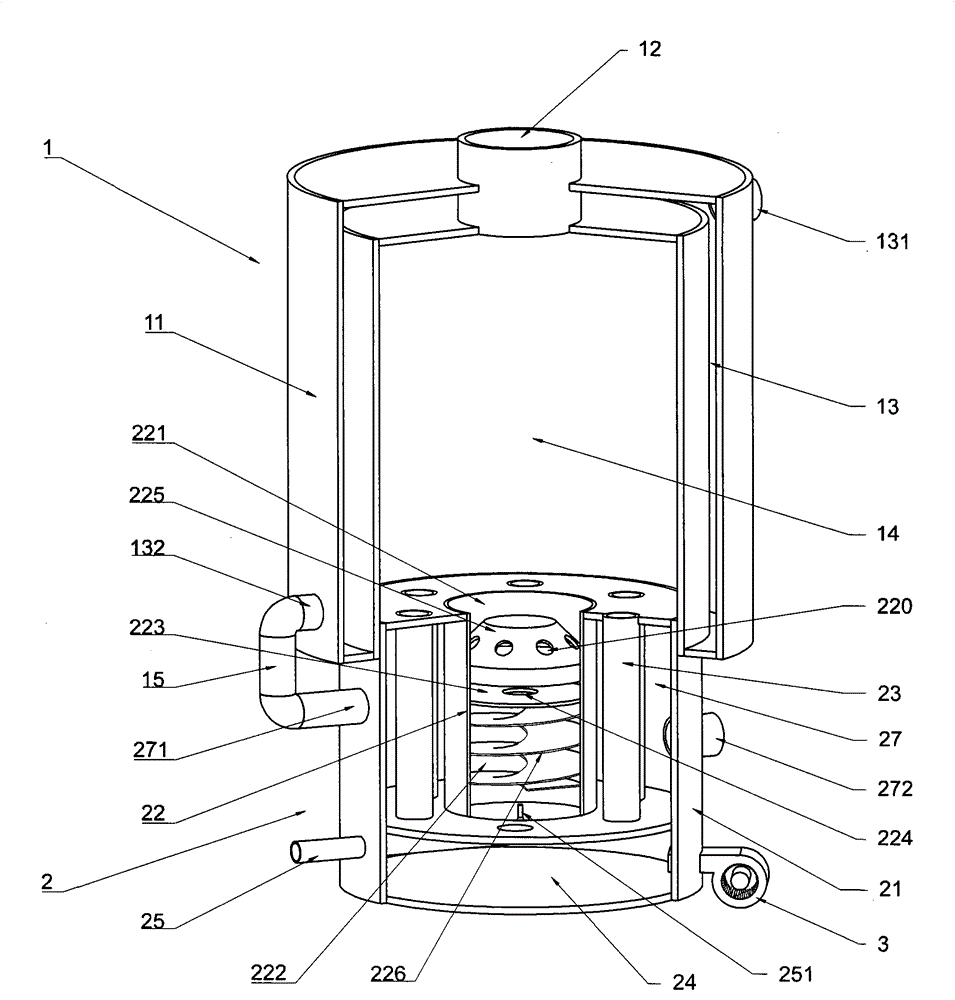

Entrained-flow bed gasification system and method for coal water slurry

ActiveCN111349462AFast gasification reactionShort flameGasification processes detailsGasification apparatus detailsCoal waterSlag

The invention relates to the technical field of coal gasification, and discloses an entrained-flow bed gasification system and method for coal water slurry. The system comprises a material conveying unit (1), a gasification unit (2), a second heat exchange unit (3) and a steam unit (4); the gasification unit (2) comprises a flat flame type gasification burner (21), a gasification chamber (22), a first heat exchange unit (23) and a slag collecting chamber (24) which are sequentially communicated, and the first heat exchange unit (23) is communicated with the steam unit (4); wherein the flat flame type gasification burner (21) comprises burner units (25) arranged at the top of the gasification unit (2), the flat flame type gasification burner (21) can enable a gasification agent and coal water slurry to collide in the gasification chamber (22) and be ignited to form flat flame, and the number of the burner units (25) is larger than or equal to 3. When the system is used for the entrained-flow bed gasification process of coal water slurry, the heat efficiency of the system can be remarkably improved, and meanwhile specific oxygen consumption and specific coal consumption are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

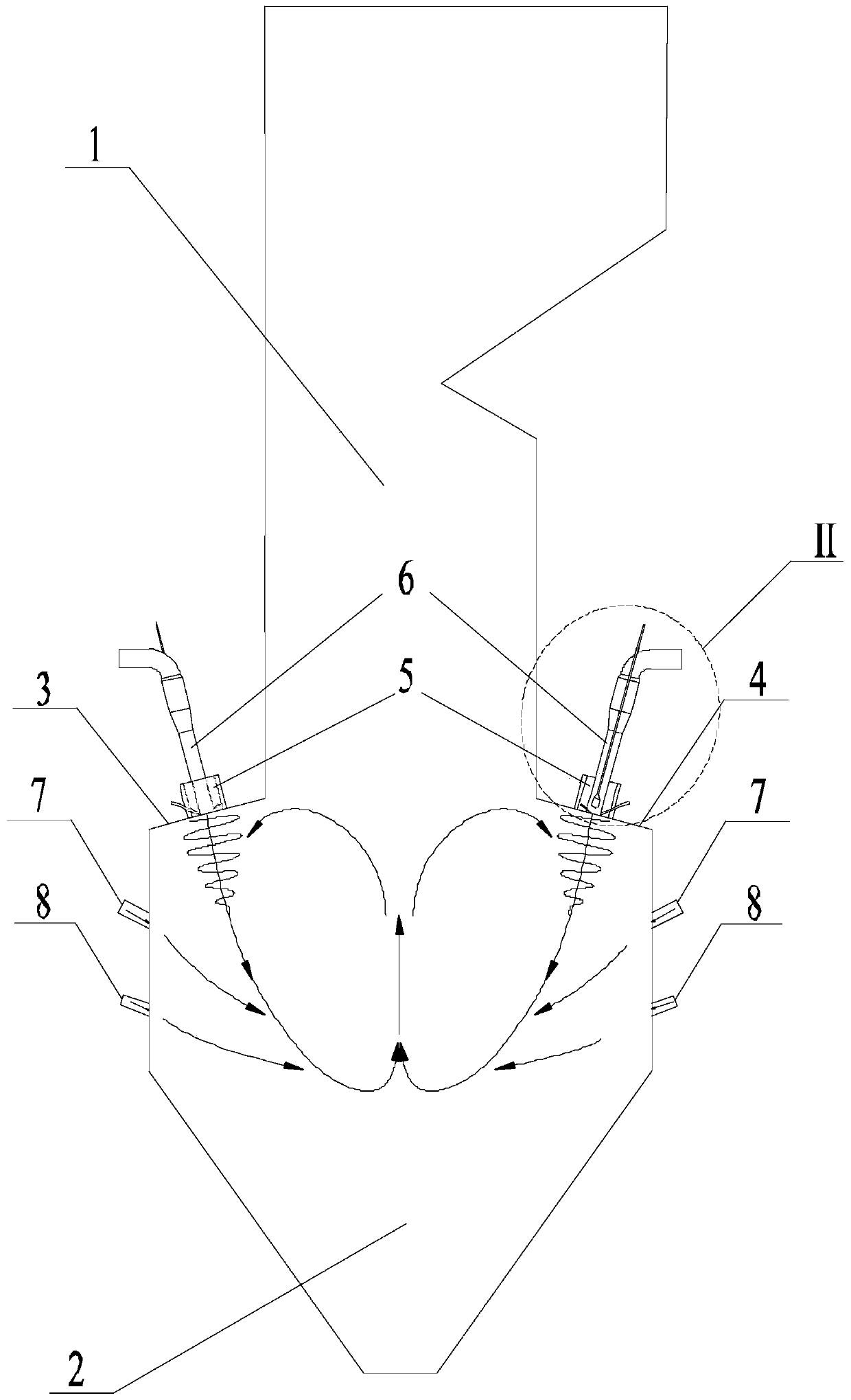

W flame boiler adopting turbulent burners

ActiveCN111023083APromote fireImprove featuresPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationPower stationCombustor

The invention discloses a W flame boiler adopting turbulent burners, relates to a power station boiler adopting a flexible peak shaving technology, and belongs to the field of boilers. The invention aims to solve the problem that the W flame boiler adopts the turbulent pulverized coal burners in the prior art, the maximum peak shaving capacity of a boiler with a common micro-oil ignition mode is about 50%, the requirement of the government on the flexible peak shaving capacity of the power station boiler cannot be met; the W flame boiler adopting the turbulent burners comprises an upper hearth, a lower hearth, a front furnace arch, a rear furnace arch, a front wall, a rear wall and a plurality of turbulent pulverized coal burners, each turbulent pulverized coal burner comprises an adjustable cone pulling rod, a micro oil ignition gun and a flow guide cone, wherein the micro oil ignition guns are installed in the adjustable cone pulling rods, the bottom ends of the adjustable cone pulling rods are fixedly installed in the flow guide cones, the adjustable cone pulling rods, the micro oil ignition guns and the flow guide cones are installed in shells of the turbulent pulverized coal burners, and the turbulent pulverized coal burners are installed on a front furnace arch water wall and a rear furnace arch water wall correspondingly.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com