Entrained-flow bed gasification system and method for dry pulverized coal

A technology of gasification system and dry coal powder, which is applied in the field of coal gasification, can solve the problems of poor adaptability of coal types, fast gasification reaction speed, short reaction residence time, etc. The effect of less demand and short reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

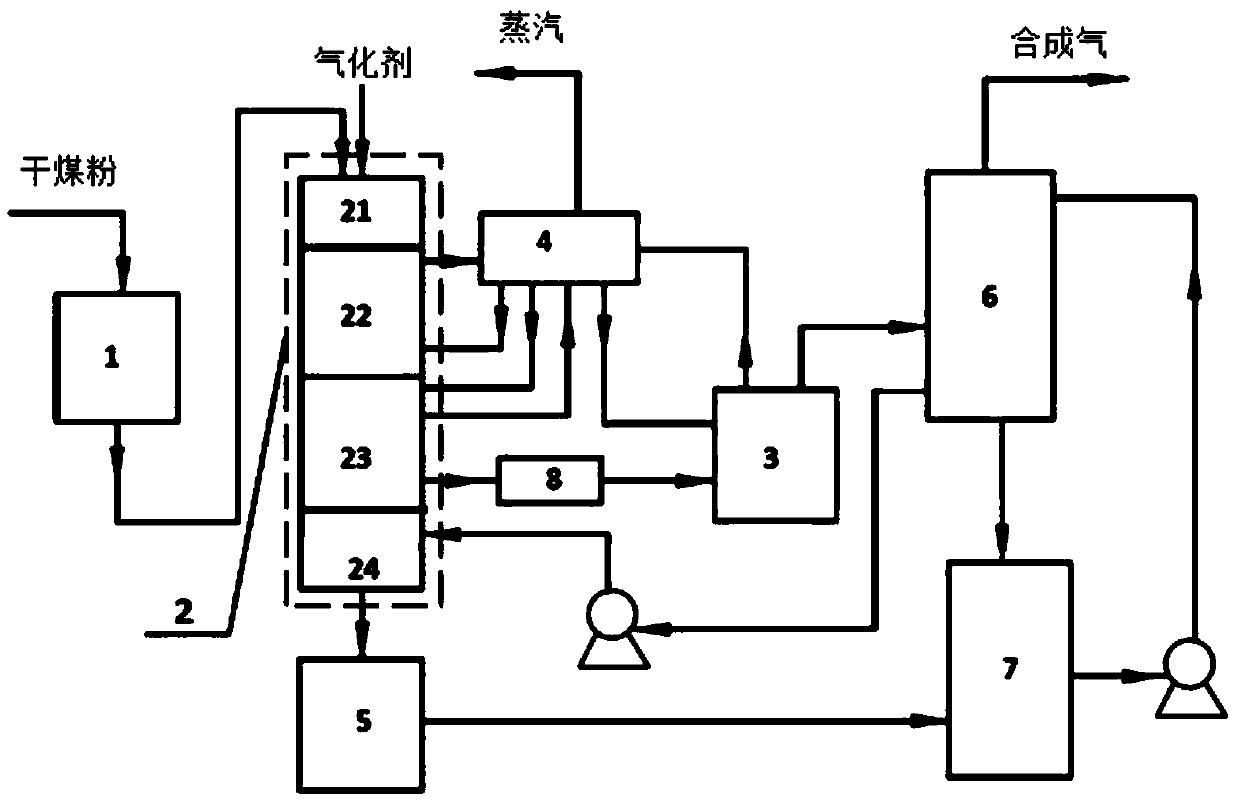

[0209] This embodiment combines figure 1 , Table 1 is the coal quality analysis data of the dry coal powder used in this embodiment.

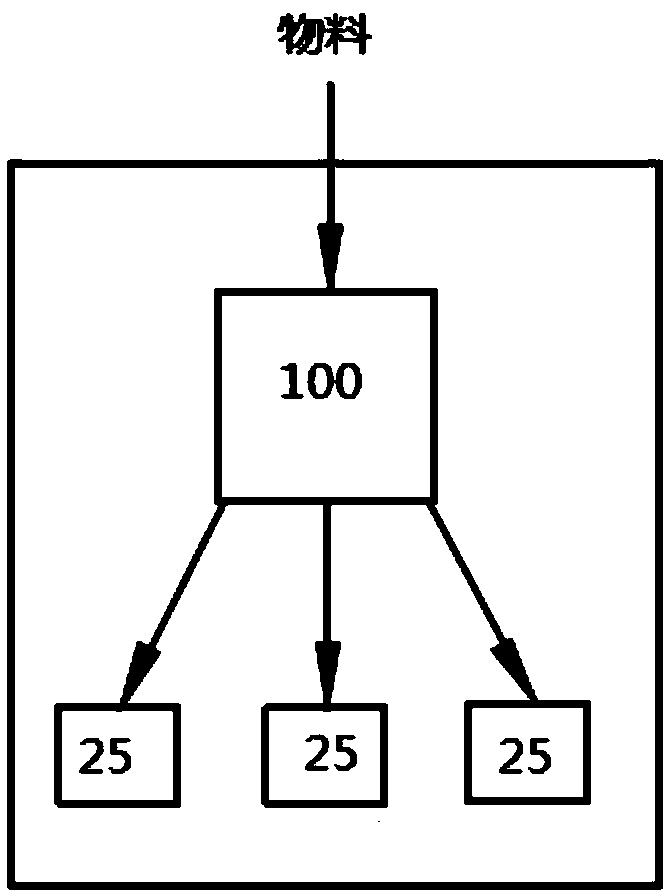

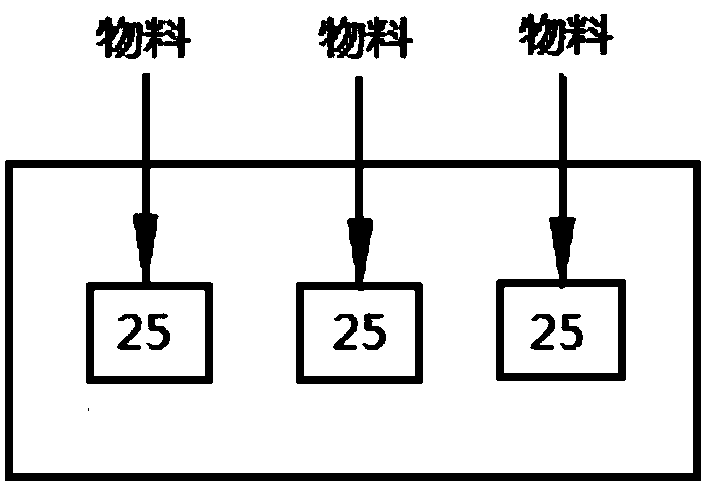

[0210] In this embodiment, the operating conditions of the gasification unit are: pressure 4.0MPa, reaction temperature 1400°C; the height-to-diameter ratio of the gasification chamber 22 is 2:1; the processing capacity of the gasification unit is 2000 tons / day; flat flame type The gasification burner includes three burner units evenly spaced along the circumference, and each burner unit has a dry coal powder channel in the center and 3 gasification agent channels around the dry coal powder channel; the impact point The distance CP from the end face of the flat-flame gasification burner 21 is 25.68 mm, the distance OC from the center of the burner gasification agent to the center of the dry coal powder outlet is 12.5 mm; the speed of the dry coal powder leaving the burner unit is 9 m / s , the velocity of the gasification agent when it leaves th...

Embodiment 2

[0221] The system and method of this embodiment are the same as those of Embodiment 1, but the aspect ratio of the gasification chamber is 0.5:1.

[0222] Table 1 is the coal quality analysis data of the dry coal powder used in this embodiment. After continuous and stable operation, the system was analyzed, and the results are shown in Table 2.

Embodiment 3

[0224] The system and method of this embodiment are the same as in Embodiment 1, but the number of burner units is ten.

[0225] Table 1 is the coal quality analysis data of the dry coal powder used in this embodiment. After continuous and stable operation, the system was analyzed, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com