Upper air inlet combustor

A technology of burners and injectors, which is applied in the direction of burners, gas fuel burners, and the combination of multiple burners. It can solve problems such as uneven gas pressure, large channel resistance, and small heat load, and reduce kinetic energy. Loss, increase the suction rate, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

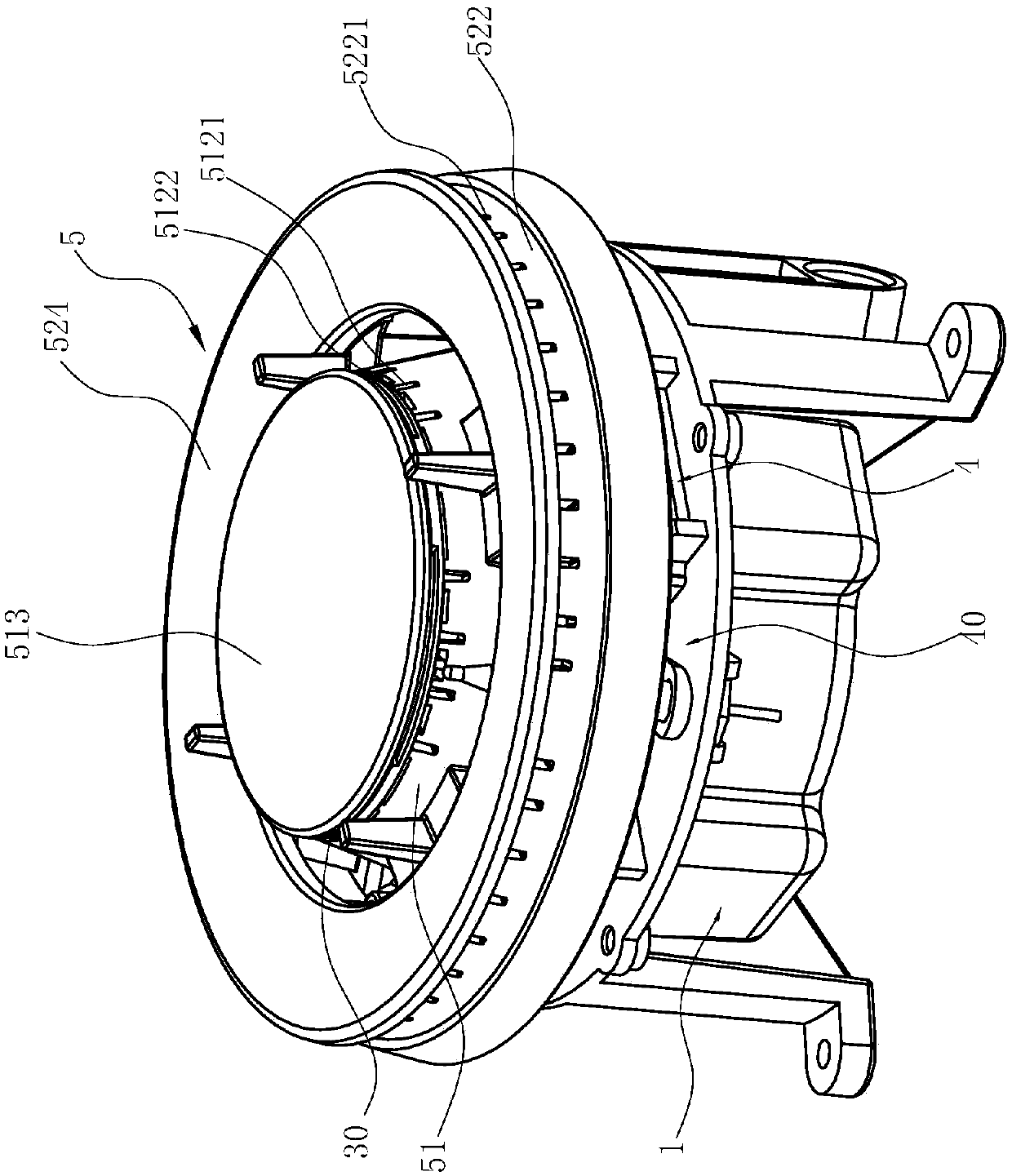

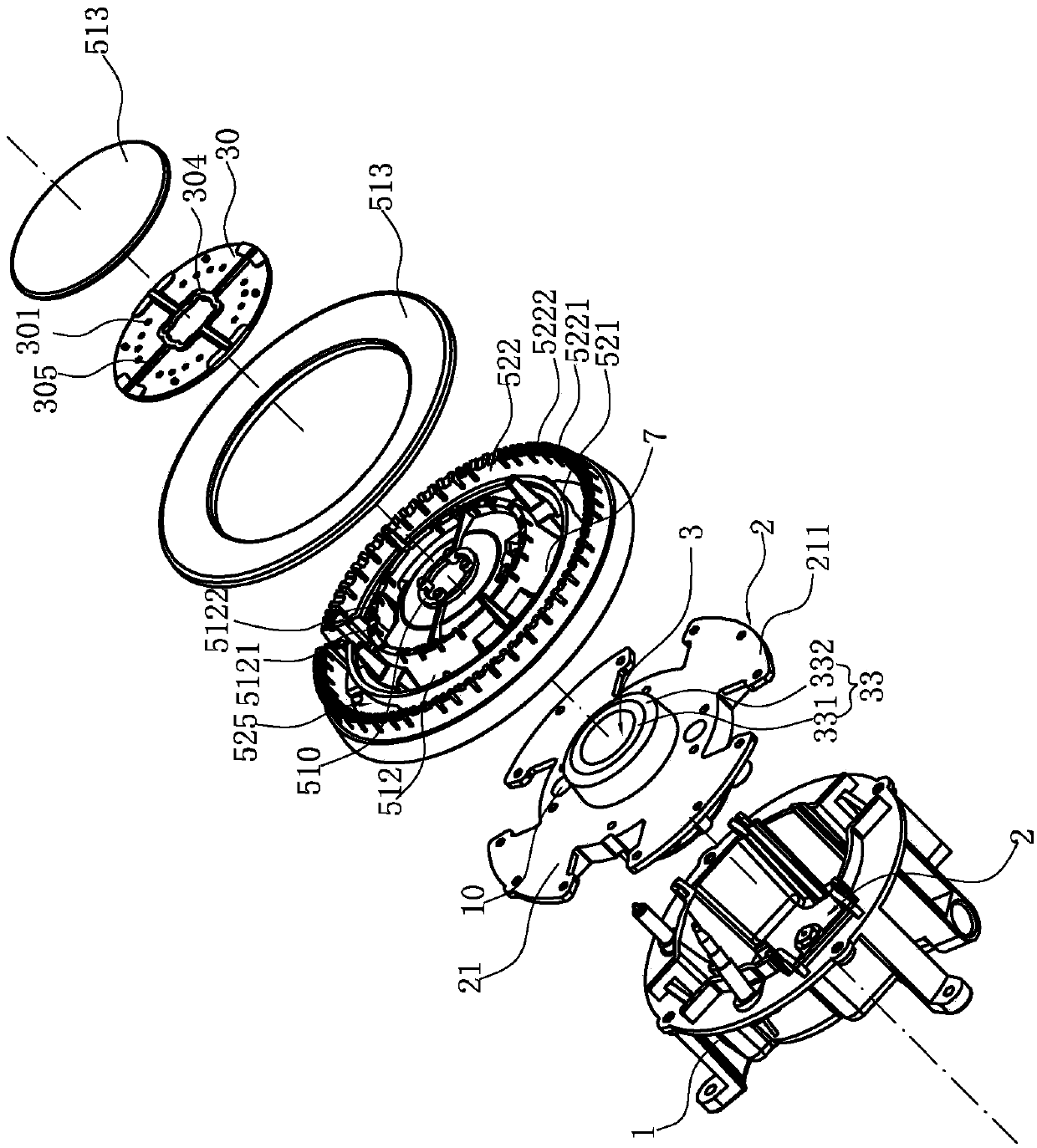

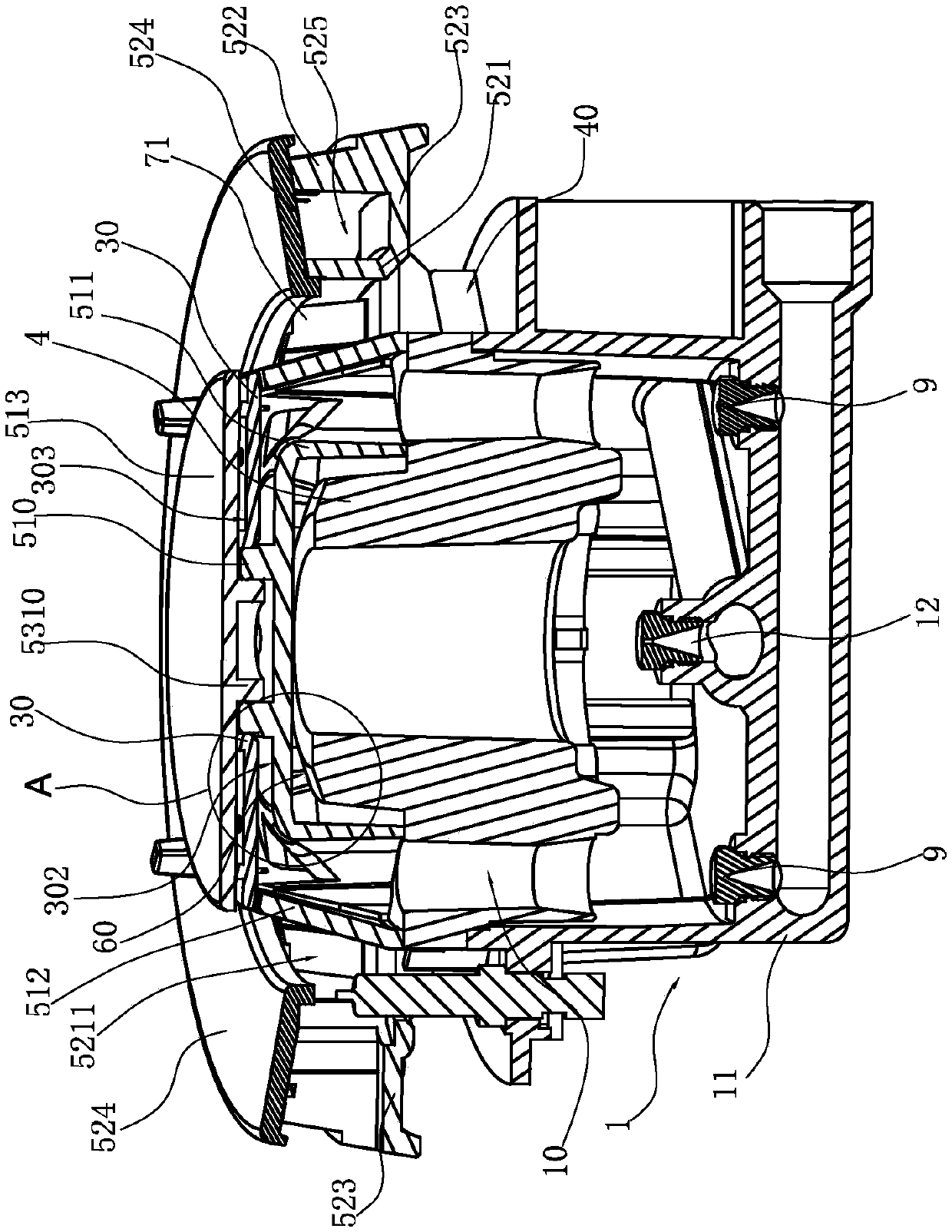

[0044] Such as Figure 1-8 As shown, it is the best embodiment of the present invention. This stove burner can be applied to the traditional upward air intake burner and can also be applied to the Italian Sabaf burner such as Europe. The central position of the concave cavity 11 is provided with a first injector 12, and the connecting body 2 provided on the base 1 includes a plate body 21, and the central position of the plate body 21 has a vertical first injection channel 3, The outer peripheral edge 211 of the plate body 21 extends in the horizontal direction and can cover the cavity 11; and is arranged at intervals along the circumference of the connecting body 2 for communicating the cavity 11 with the outside world so as to introduce primary air from the outside into the base The primary air channel 4 in the concave cavity 11 of the seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com