Novel reciprocating type sleeve cylinder pump

A reciprocating, cylinder-infused technology, applied in multi-cylinder pumps, variable displacement pump components, pumps, etc., can solve the problems of low efficiency, poor suction, and high transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

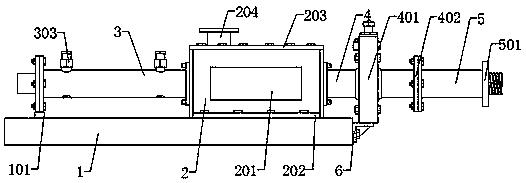

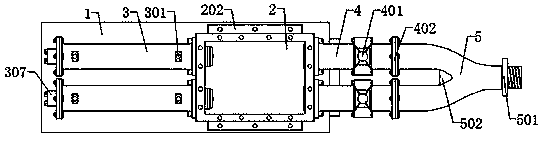

[0032] refer to Figure 1-5 , a new type of reciprocating casing pump, comprising a bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with a hopper 2, and materials are housed in the hopper 2;

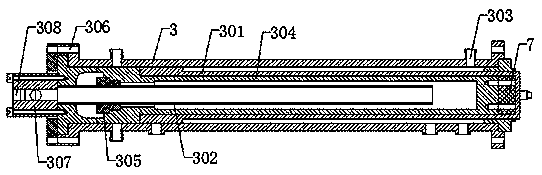

[0033] The outer wall of the hopper 2 is respectively connected with two conveying cylinders 3 through a flange, the inner walls of the two conveying cylinders 3 are fixedly connected with a plunger 302, the outer wall of the plunger 302 is slidingly connected with a pusher 304, and the pusher 304 is slidably connected On the inner wall of the delivery cylinder 3;

[0034] The outer wall of the pusher 304 is slidably connected with the sleeve body 301 , the sleeve body 301 is slidably connected to the inner wall of the conveying cylinder 3 , and the end of the sleeve body 301 away from the conveying cylinder 3 passes through the conveying cylinder 3 and is slidably connected to the hopper 2 Inside;

[0035] The outer wall of the end of the hopper 2 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com