Upward air inlet burner and kitchen range using upward air inlet burner

A burner and injector technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of uneven gas pressure, increase the ejection resistance, and cannot be cleared, and achieve stable and uniform flame, The effect of reducing kinetic energy loss and improving suction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

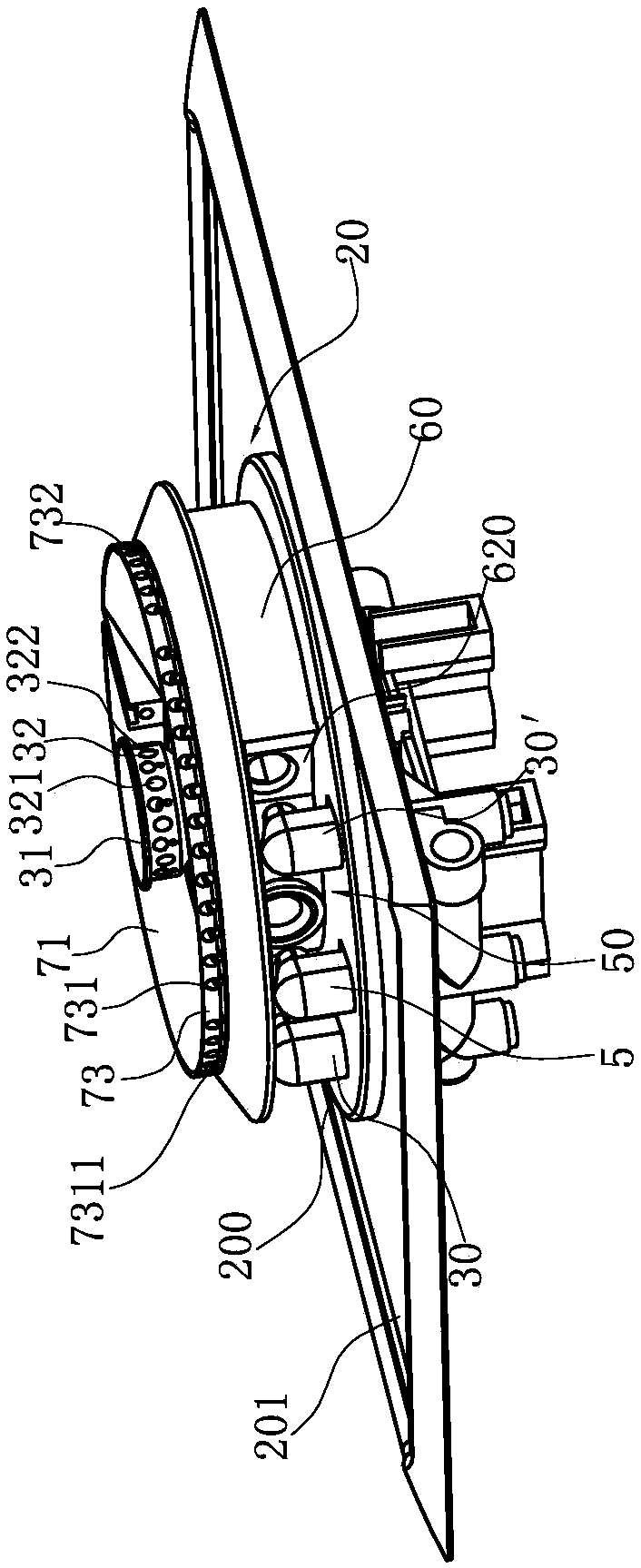

[0064] Such as Figure 1-9 Shown is the preferred embodiment of this embodiment. The upper air intake burner of this embodiment includes a first injection tube 2, a base 11 surrounding the tube wall of the first injection tube 2, and a base 11 surrounding the tube wall of the first injection tube 2. The buffer chamber 4 formed by the gap between the periphery of the tube wall of the shooter 2 and the base 11, and the first fire cover 3 arranged above the central position of the base 11, and a fire cover 3 is formed between the first fire cover 3 and the base 11 The first gas mixing chamber 1 located in the center, the gas outlet end 23 of the first injection tube 2 is in fluid communication with the first gas mixing chamber 1 through the buffer chamber 4, and the gas inlet end 24 of the first injection tube 2 is fitted with The first injector 5, the buffer chamber 4 effectively increases the length of the first injection pipe 2, and the setting of the buffer chamber 4 can mak...

Embodiment 2

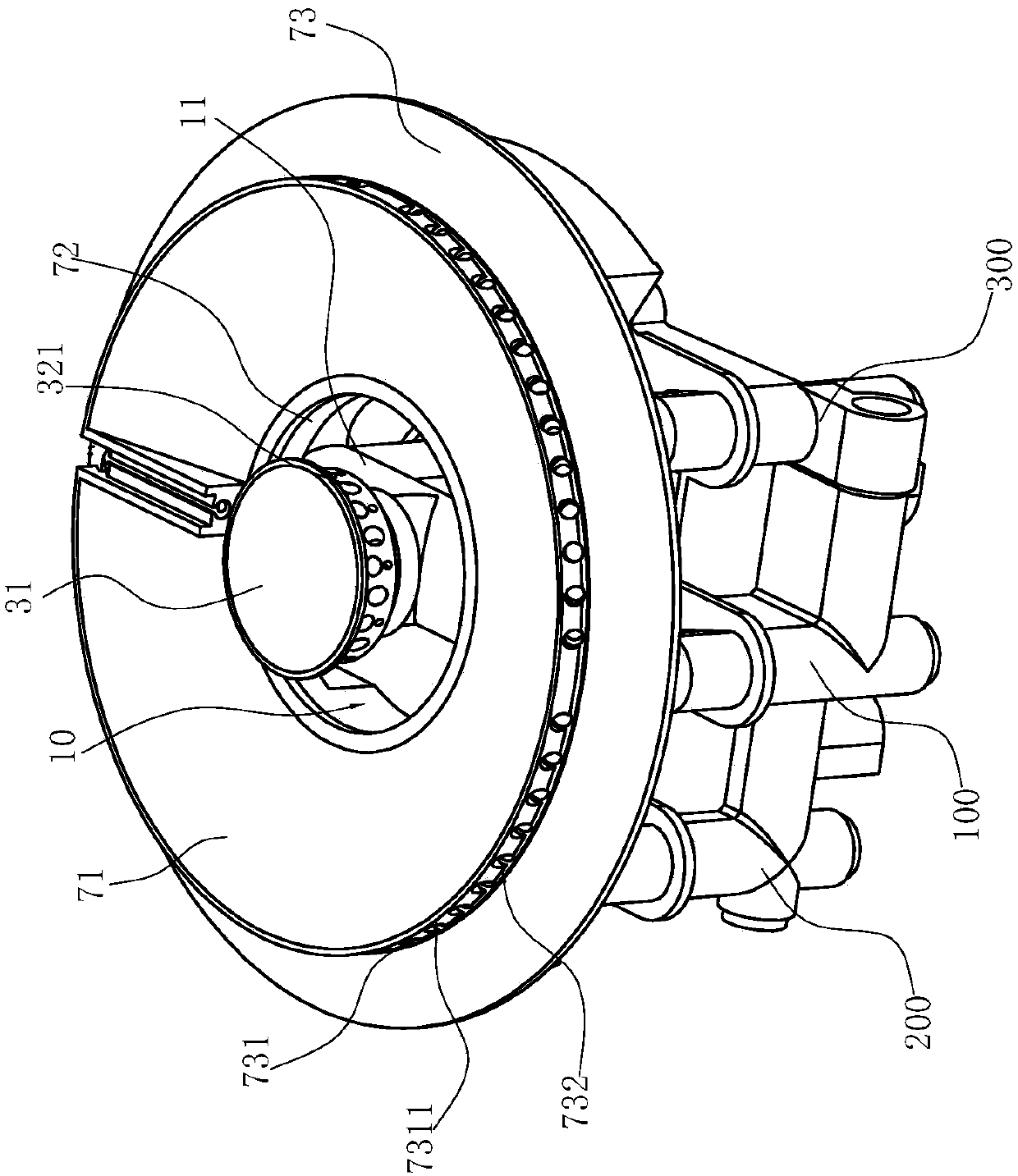

[0070] Such as Figure 10-20 As shown, the structure is basically the same as that of Embodiment 1, the only difference is that the base 11 is cross-shaped, including a transverse portion 111 and a vertical portion 112 connected to each other, and the transverse portion 111 of the base 11 surrounds the first ejector tube 2 Outside the tube wall; the vertical part 112 of the base 11 is divided into the upper vertical part 1111 above the horizontal part 111 of the base 11 and the upper vertical part 1111 below the horizontal part 111 of the base 11 by the tube wall of the first injection tube 2 The lower vertical part 1112, the lower vertical part 1112 is in communication with the upper vertical part 1111; since the first ejector tube 2 is completely enclosed in the transverse part 111 of the base 11, due to processing restrictions, the first ejector tube Shooting tube 2 can not be done too long, for this reason base 11 is cross-shaped and then can make up for the above-mentione...

Embodiment 3

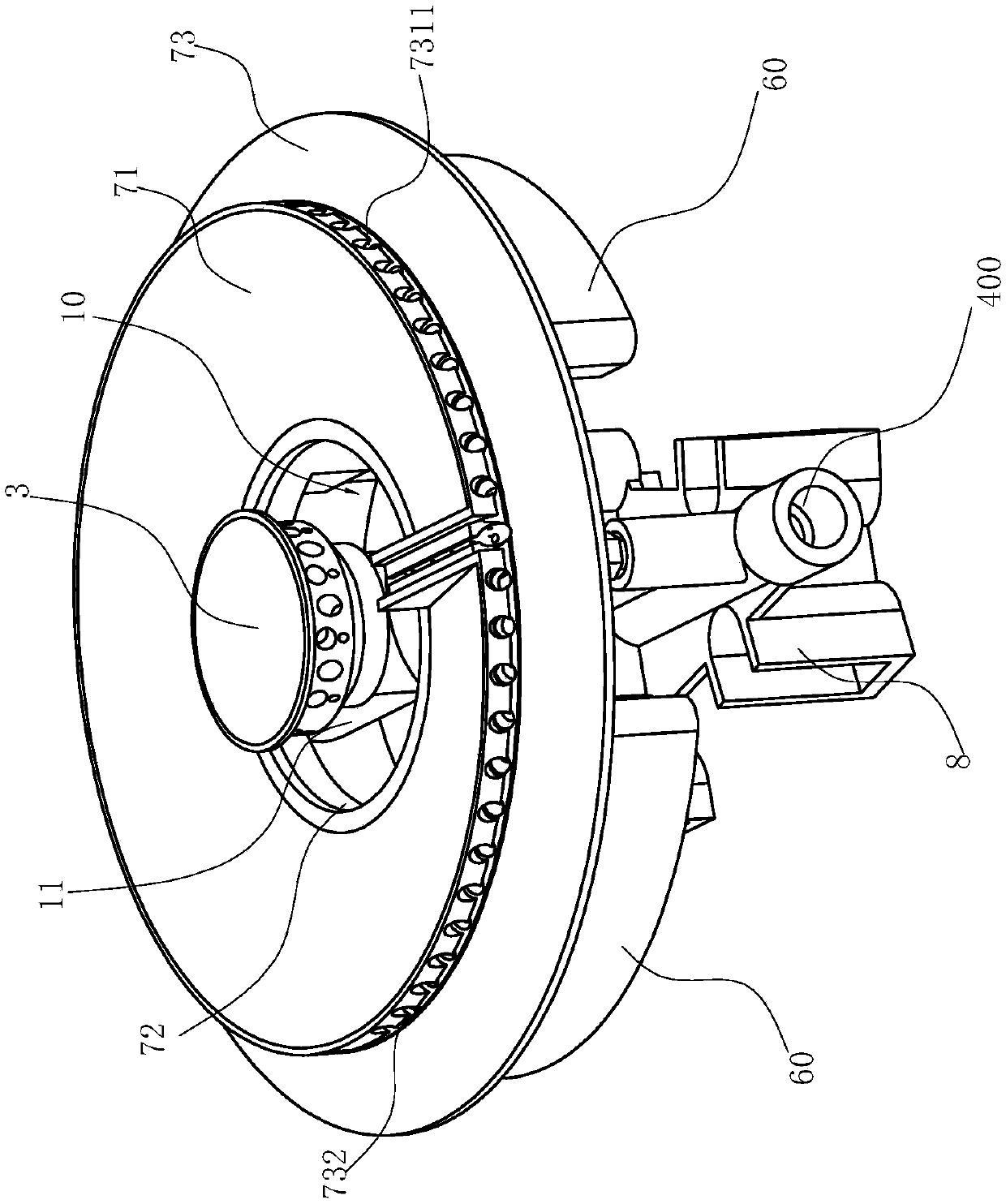

[0072] Such as Figures 21 to 30 As shown, the structure is basically the same as that of Embodiment 1, the only difference is that the base 11 is in an inverted T shape, has a horizontal tube 111 and a vertical tube 112 that communicate with each other, and the horizontal tube 111 surrounds the first injection tube 2 Outside the pipe wall, the inlet of the horizontal pipe 111 is the air inlet port 24, the end of the horizontal pipe 111 is a blind end, and the air outlet end 23 of the first ejector pipe 2 is close to the blind end; and the first fire cover 3 , covering the vertical pipe 112 to form the first air mixing chamber 1 in the center. Moreover, the inner wall of the horizontal tube 111 of the base 11 has a spiral rib 4″ and forms a spiral passage, the initial end 41 of the spiral passage communicates with the gas outlet end 23 of the first injection pipe 2, and the terminal end 42 of the spiral passage communicates with the first gas mixture. Chamber 1. Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com