Novel reciprocating type sleeve cylinder pump

A reciprocating, sleeved cylinder technology, applied in multi-cylinder pumps, variable capacity pump components, pumps, etc., can solve problems such as poor suction, high transportation costs, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

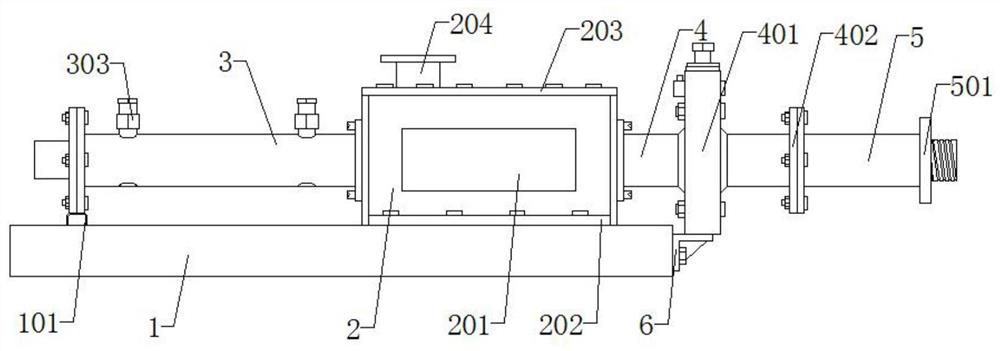

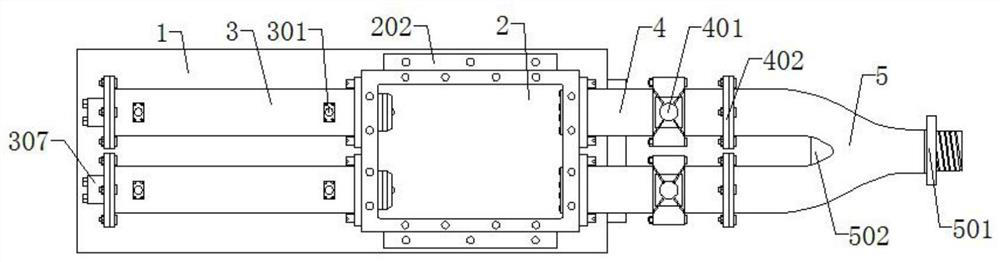

[0035] refer to Figure 1-5 , a new type of reciprocating cylinder pump, including a bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with a hopper 2, the hopper 2 is a square box, and materials are housed in the hopper 2;

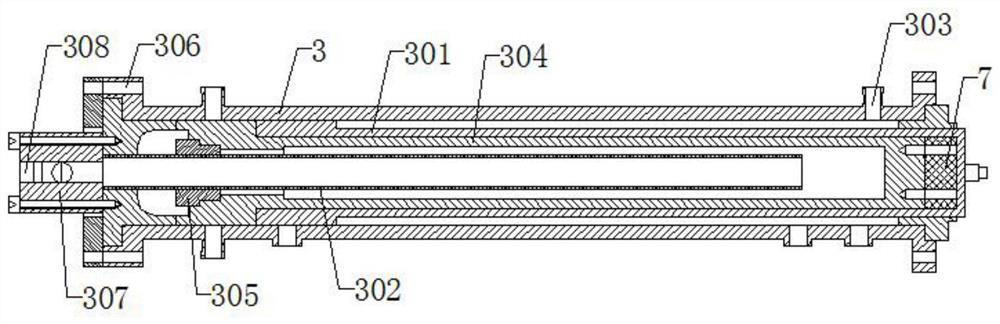

[0036] The outer wall of the hopper 2 is respectively connected with two conveying cylinders 3 through a flange, and the inner walls of the two conveying cylinders 3 are fixedly connected with a plunger 302, the plunger 302 is a circular tube structure, and the outer wall of the plunger 302 is slidingly connected with A pusher 304, the pusher 304 is slidably connected to the inner wall of the delivery cylinder 3;

[0037] The outer wall of the pusher 304 is slidably connected with the inner wall of the cylinder body 301, and the outer wall of the cylinder body 301 is slidably connected with the inner wall of the delivery cylinder 3, and the end (the left end in the figure) of the sleeve body 301 away from the delivery cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com