Inverted full-premix condensing gas water heater

A gas-fired water heater, an inverted technology, which is applied in the directions of air heaters, fluid heaters, climate sustainability, etc., can solve the problems of insufficient uniform second mixing in the combustion mode, reduced thermal efficiency of gas-fired water heaters, and low combustion heat intensity, etc. To achieve the effect of short flame, preventing leakage of flue gas and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

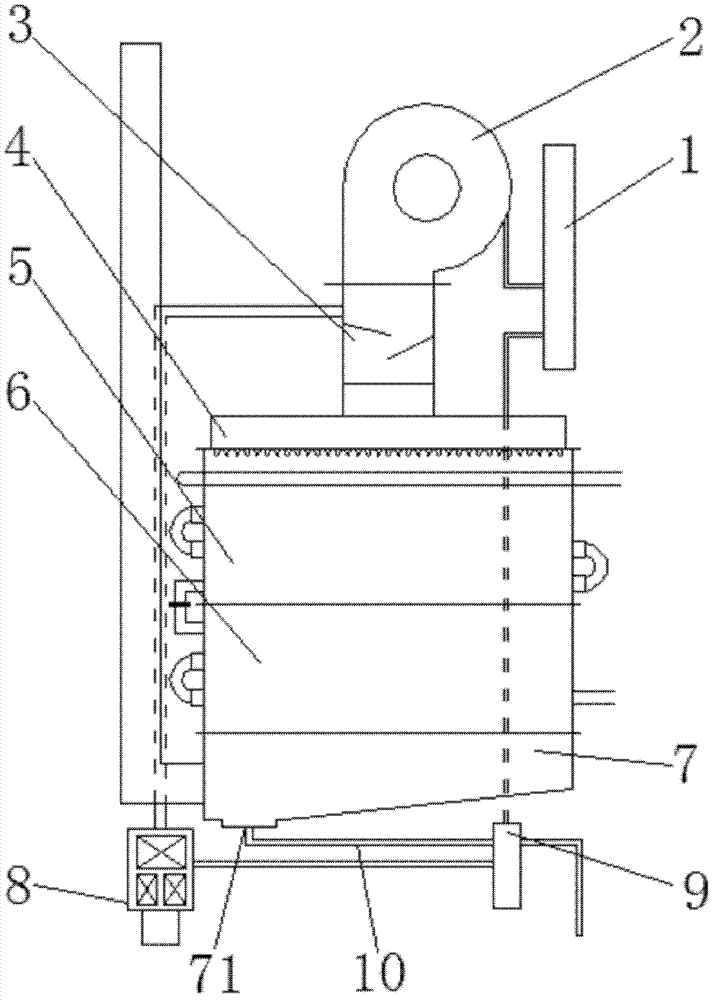

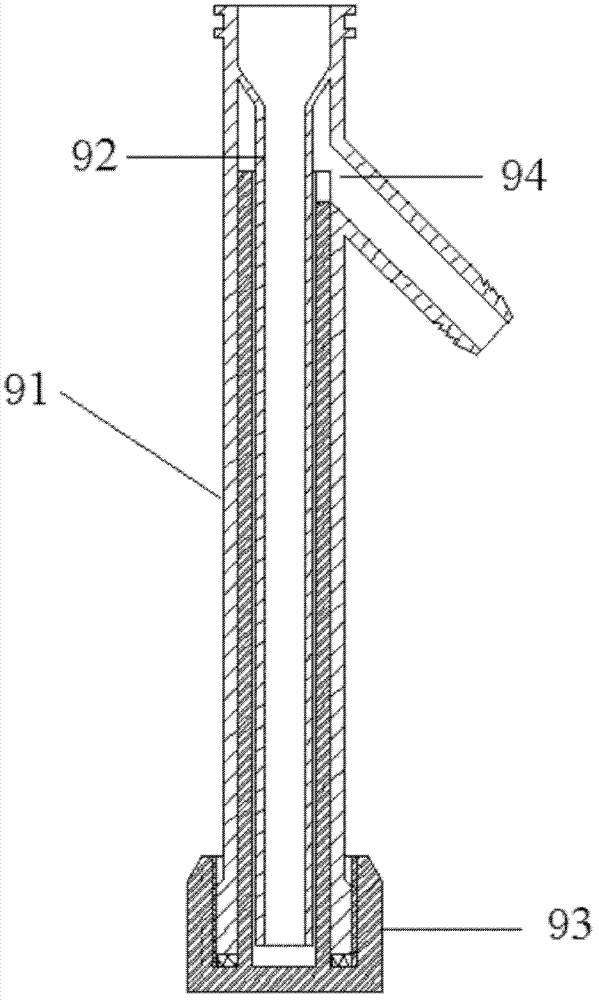

[0011] Embodiment: An inverted fully premixed condensing gas water heater, including a main controller 1, a fan 2, a gas valve assembly 8, a burner assembly 4, a primary heat exchanger 5, a secondary heat exchanger 6 and condensed water Collector 7, the main controller 1 controls the burner assembly 4, fan 2 and gas valve assembly 8, the primary heat exchanger 5 is connected below the burner assembly 4, and the primary heat exchange The secondary heat exchanger 6 is connected below the secondary heat exchanger 6, the condensed water collector 7 is connected below the secondary heat exchanger 6, the burner assembly 4 is an inverted metal fiber burner, and the primary The heat exchanger 5 and the secondary heat exchanger 6 are inverted, and a gas mixing device 3 is provided, the fan 2 communicates with the gas mixing device 3, and the gas valve assembly 8 is connected to the gas mixing device through a pipeline. Gas device 3 communicates. The main controller 1 controls the rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com