Patents

Literature

57results about How to "Large adjustment ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

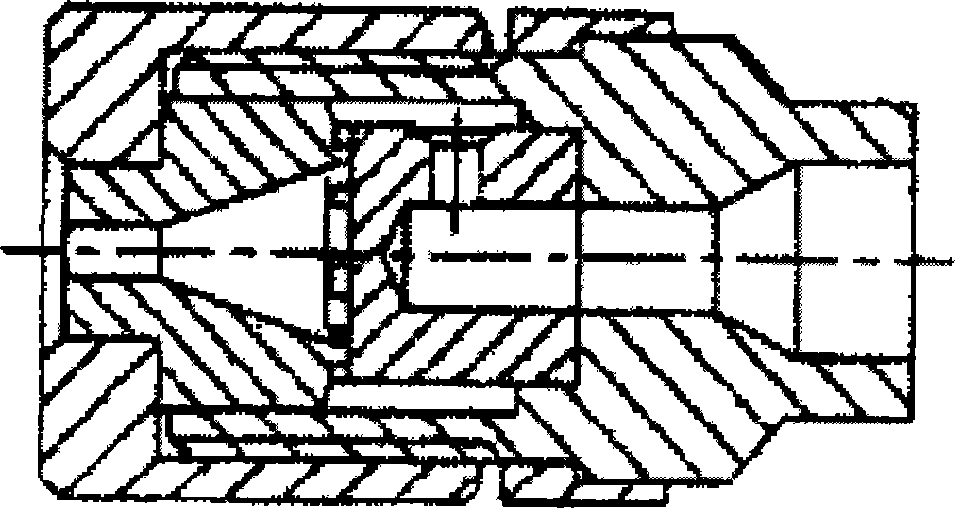

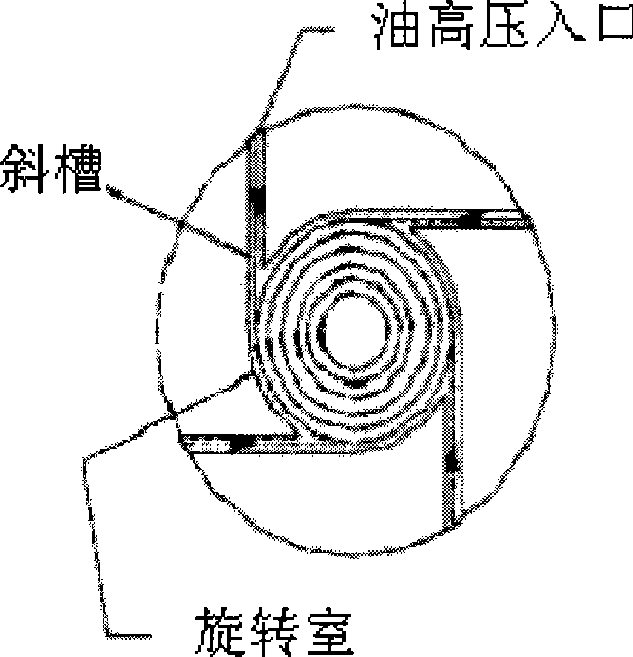

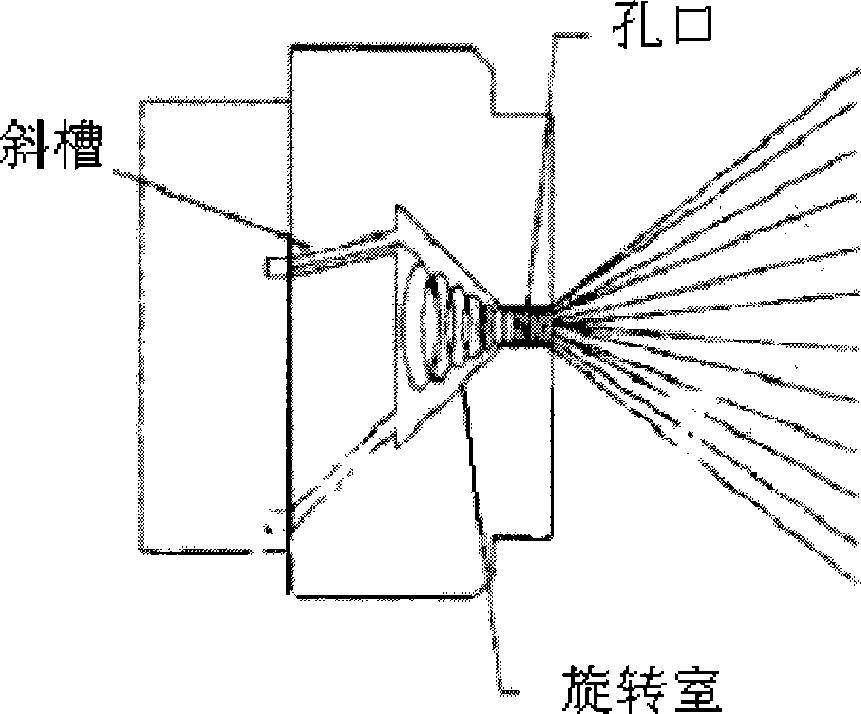

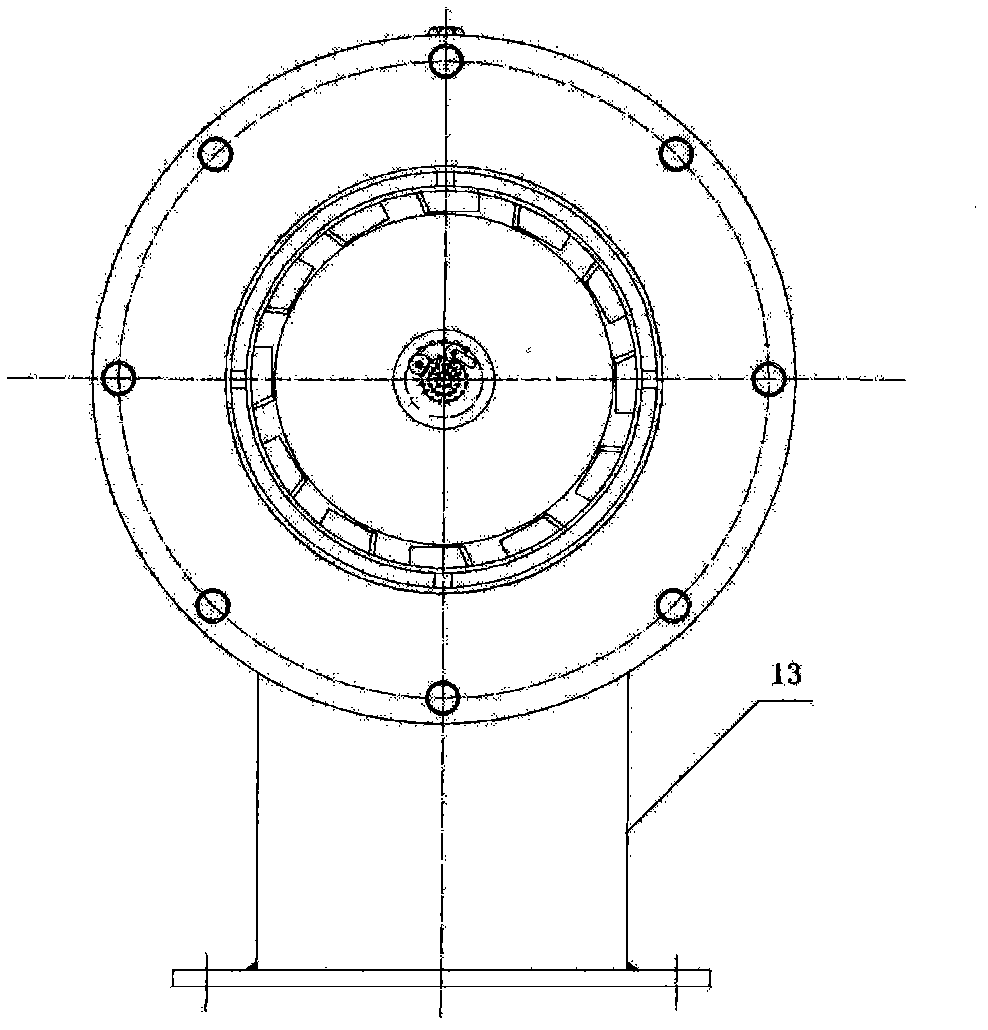

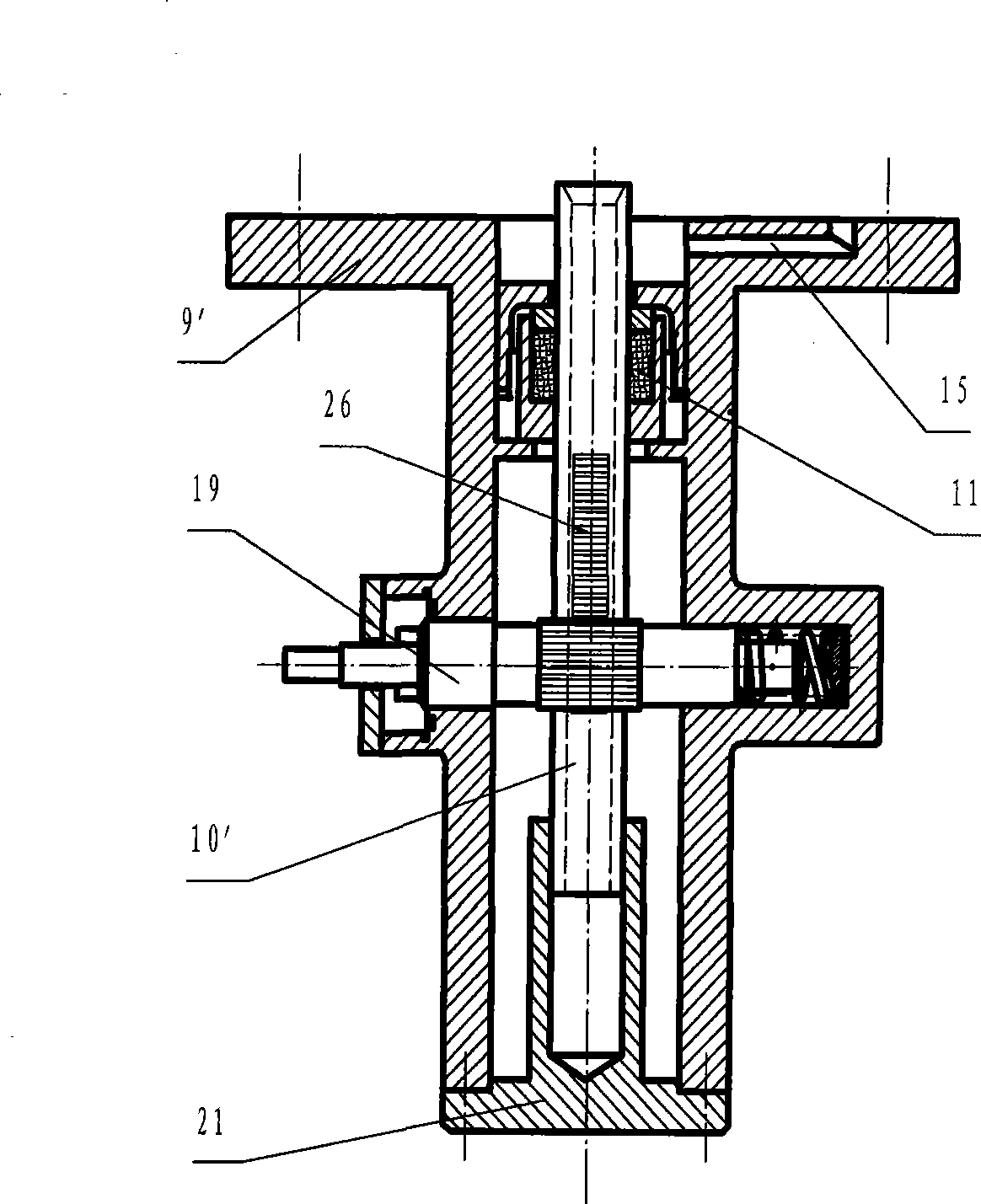

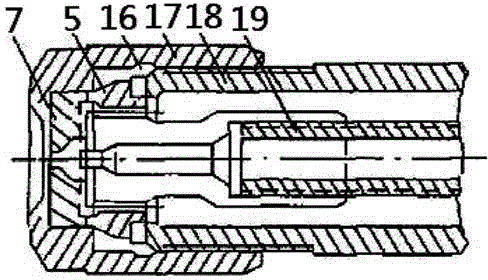

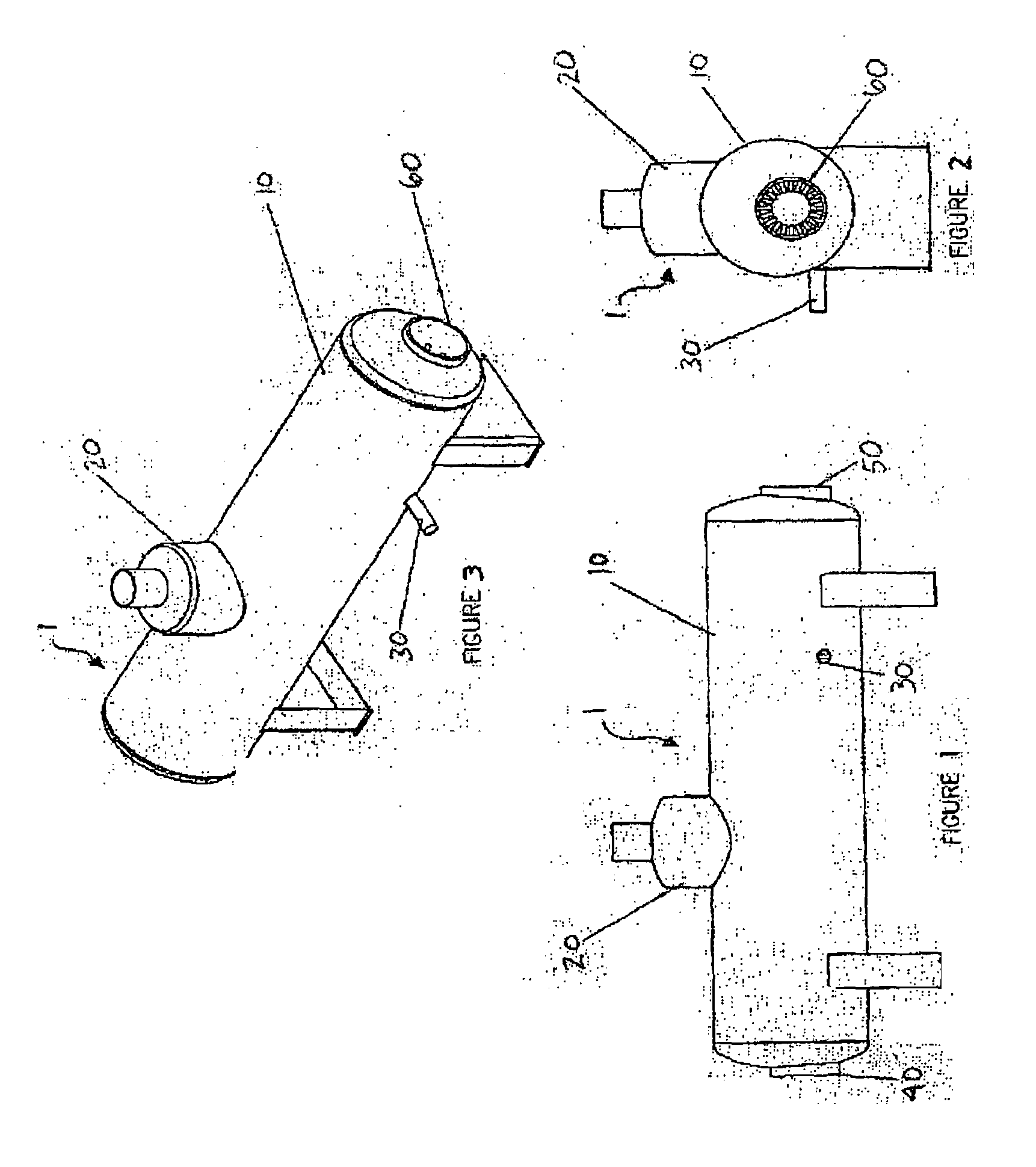

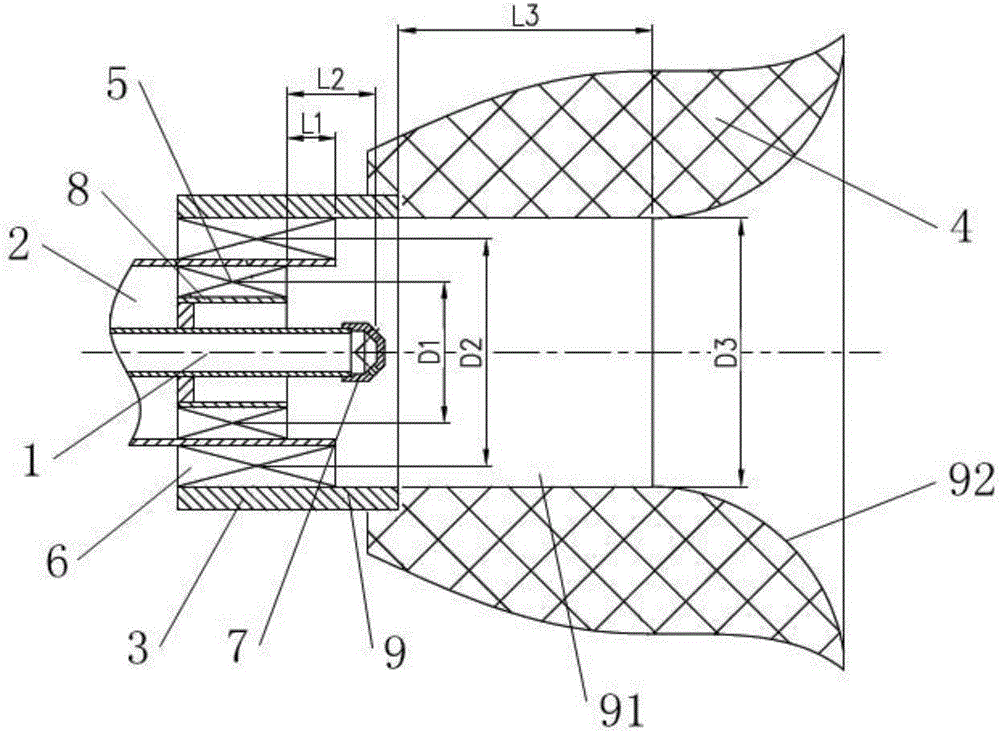

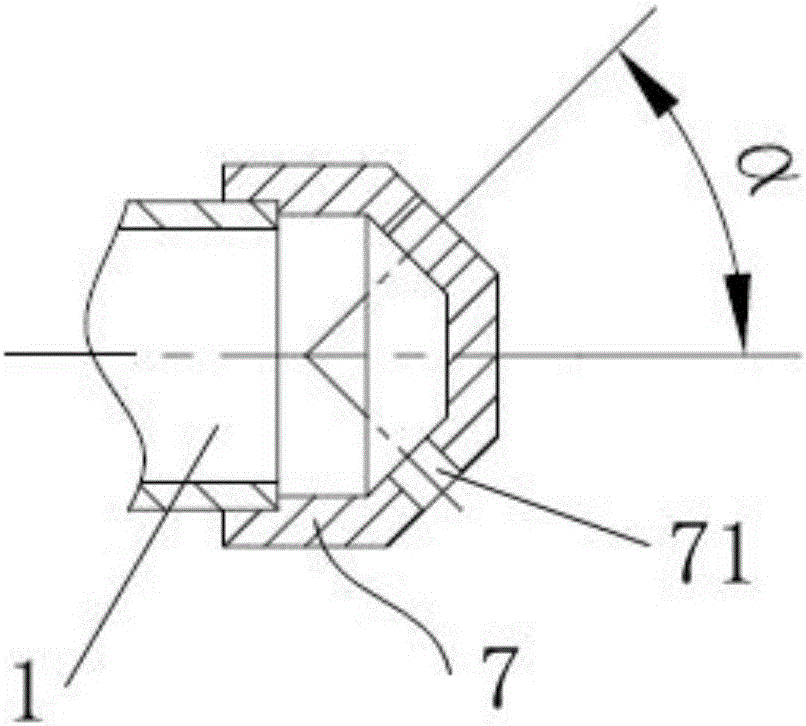

Self-absorption rotational flow pneumatic atomization nozzle device

InactiveCN101398186AGood fuel atomization qualityReasonable spatial distributionContinuous combustion chamberCombustion systemCombustion

The invention discloses a self-sucking swirl pneumatic atomizing nozzle device relating to a fuel atomizing evaporation mixing nozzle used for a full-automatic combustion engine and belongs to the field of industrial combustion systems. An atomizing sheet 2, a swirl sheet 3 and a stream guidance sheet 4 are compressed closely by a compression nut 1 and a fixing piece 5; the atomizing sheet 2 is an internal cone and the outlet of the atomizing sheet 2 is a spout 14; the swirl sheet 3 is provided with a tangential air hole 11; the outlet hole of the stream guidance sheet 4 is an oil hole 12 and the outlet of the stream guidance sheet 4 is a swirl chamber; the compression nut 1 is connected with the fixing piece 5 and a connecting piece 7; the outer surface of the upstream of the fixing piece 5 is provided with a seal ring 6; an oil inlet hole 8 is the inner hole of the connecting piece 7; an air inlet hole 9 is the connection hole of the connecting piece 7 along the radical and coaxial direction; compared with the existing centrifugal nozzle or pneumatic atomizing nozzle, the self-sucking swirl pneumatic atomizing nozzle device does not need an oil pump; has the advantages of improving the fuel atomizing evaporation mixing characteristic and the distribution uniformity of oil-gas space, improving the combustion performance, reducing contamination discharge, having no coking and plugging, and is an ideal nozzle for combusting the heavy oil and waste oil by the full-automatic combustion engine.

Owner:PEKING UNIV +1

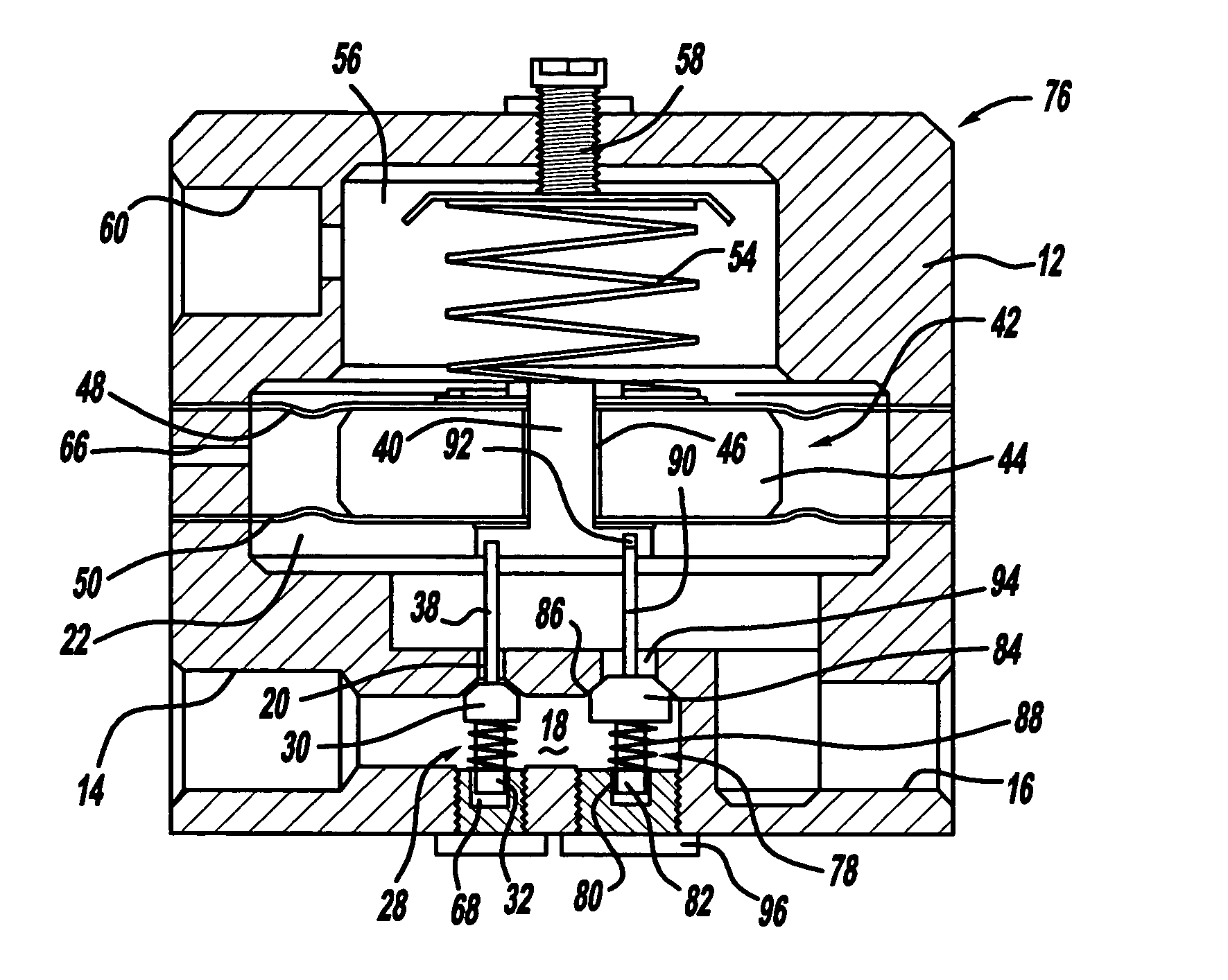

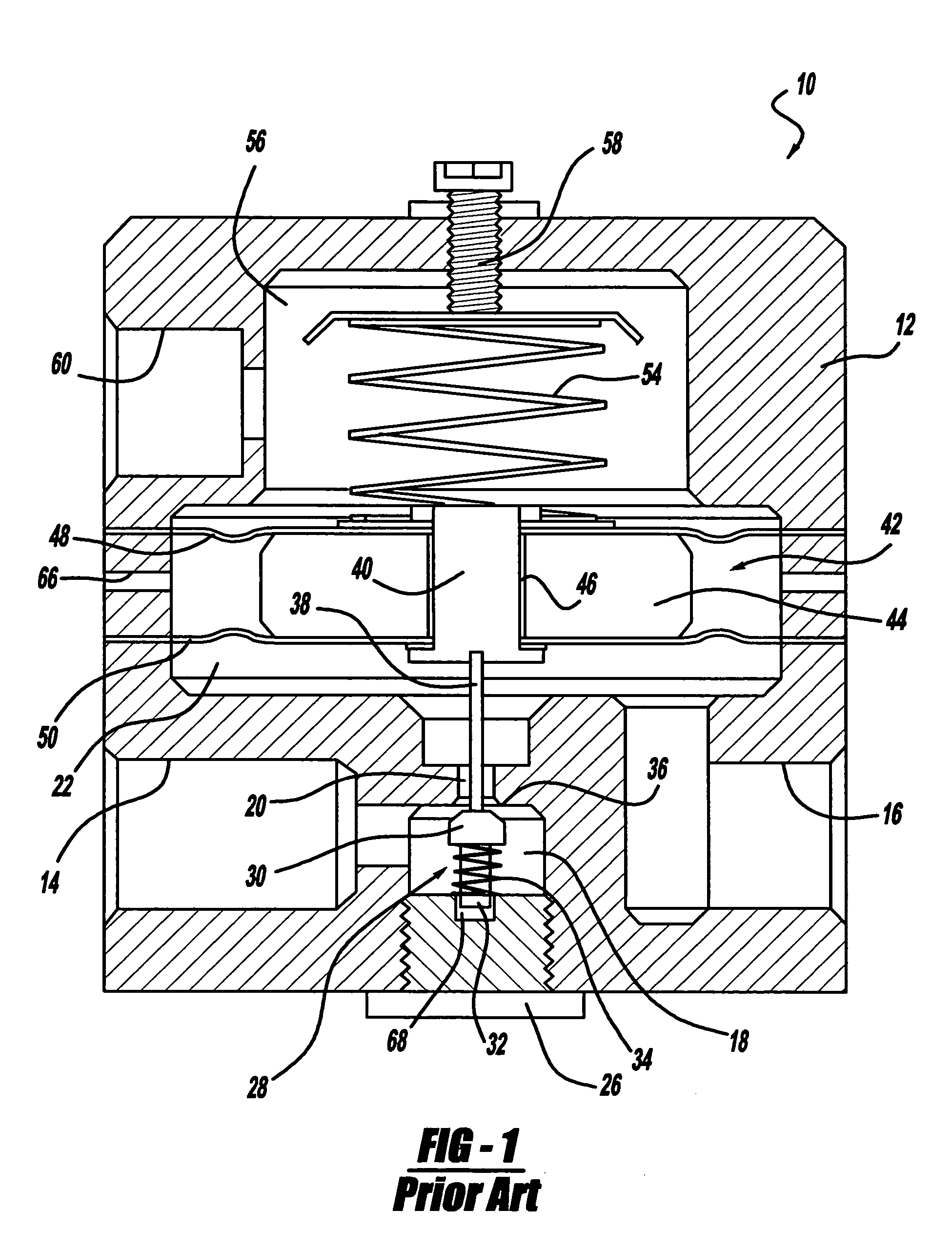

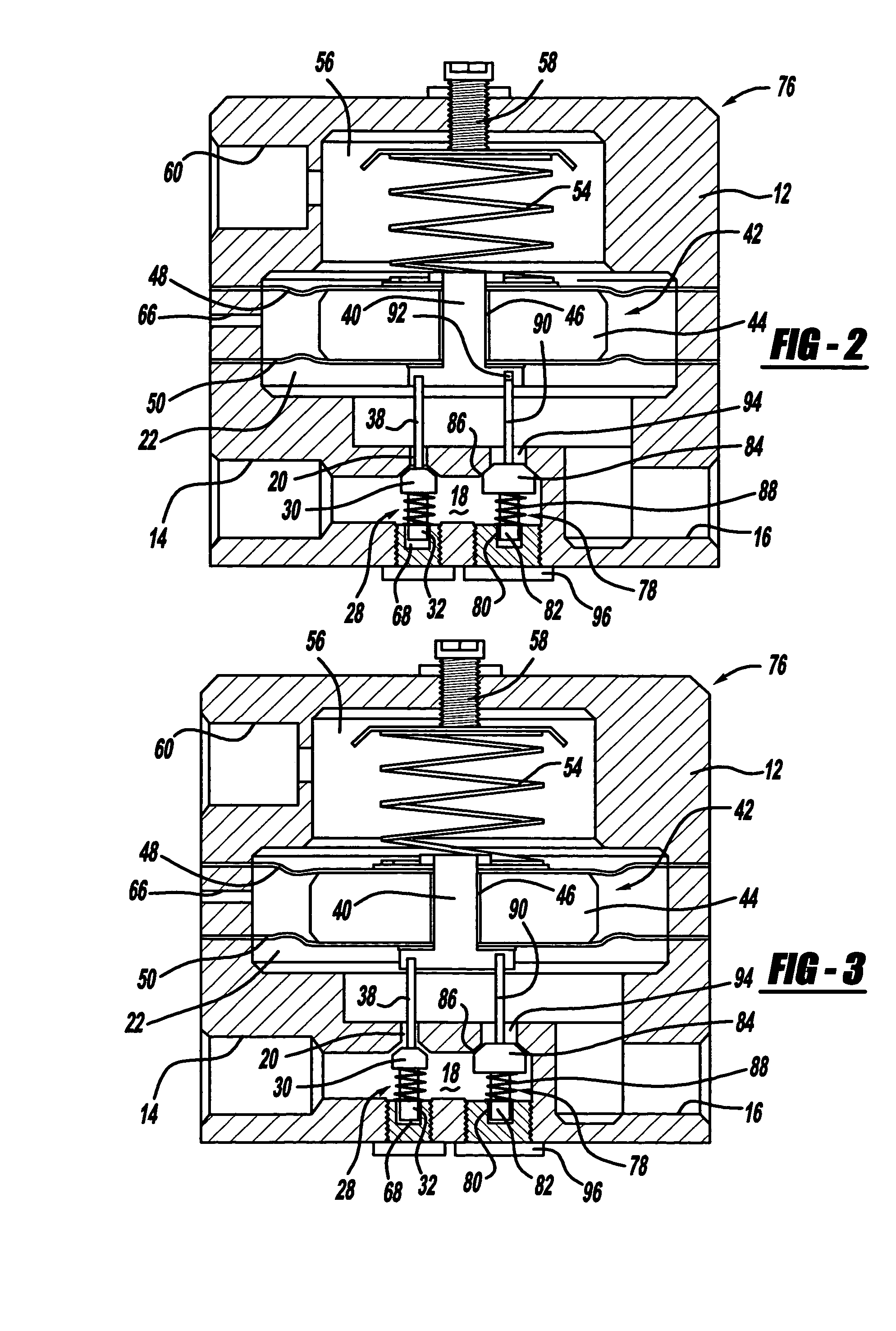

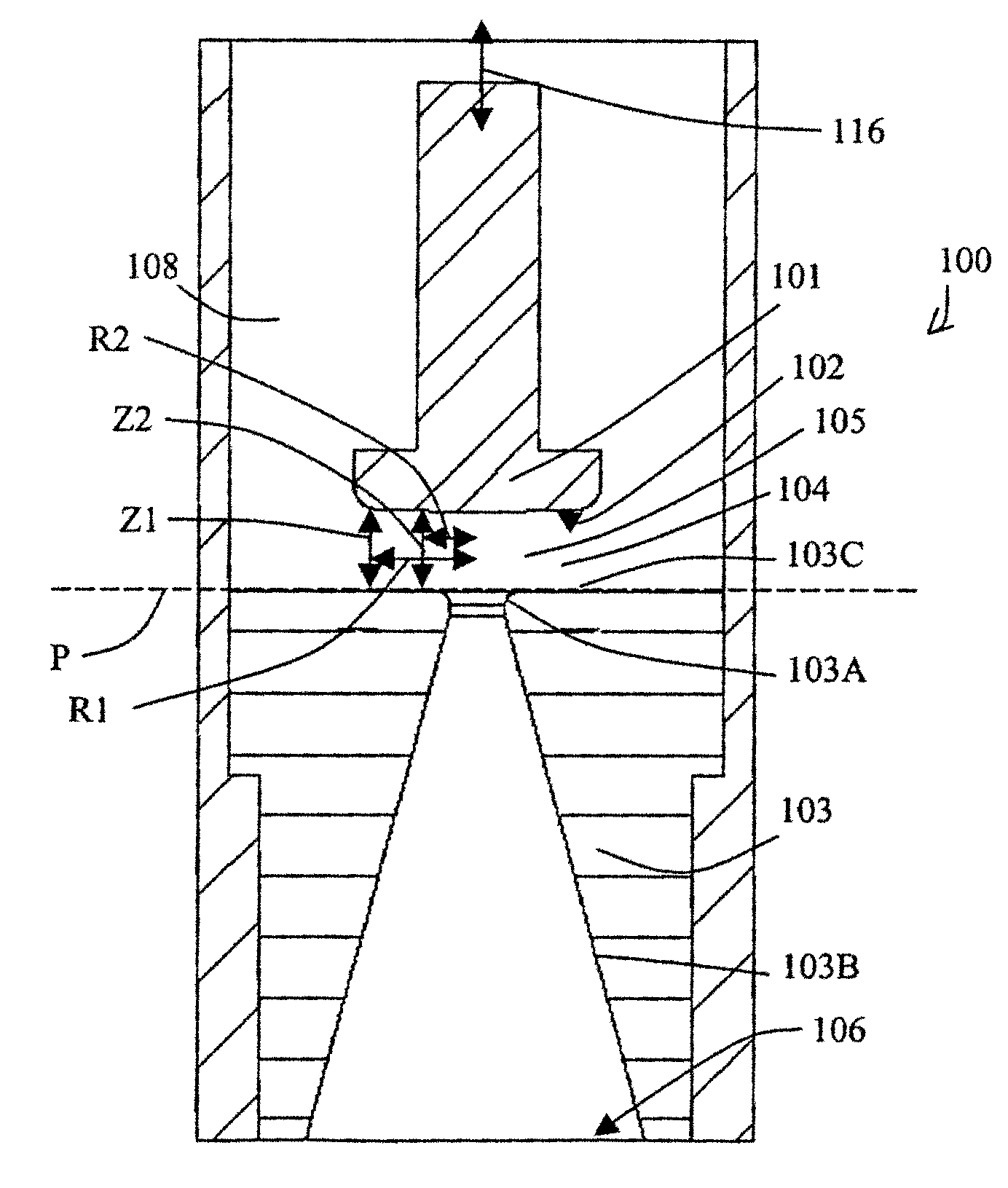

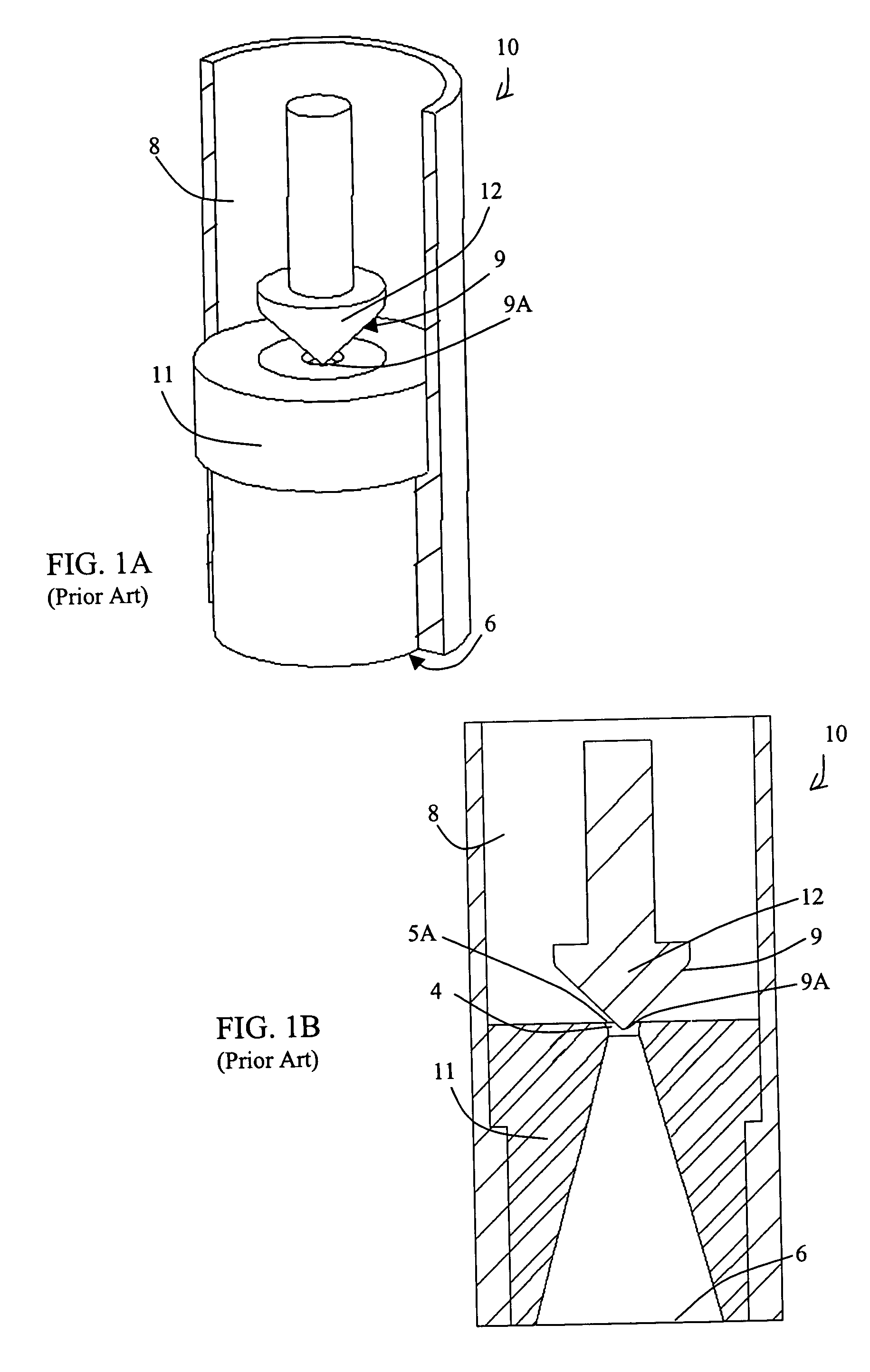

Multi-stage pressure regulator

ActiveUS20060260692A1Large adjustment ratioReduce flow rateOperating means/releasing devices for valvesMultiple way valvesFuel cellsEngineering

A pressure regulator that has particular application for an anode input side of a fuel cell system to provide the desired large turn-down ratio. The pressure regulator includes at least two valves positioned in parallel where the first valve is smaller than the second valve. The first valve is opened and closed and the second valve is maintained closed at low flow rates. Once the flow rate is high enough, the first valve is maintained completely open, and the second valve is opened and closed to control the flow at high flow rates.

Owner:GM GLOBAL TECH OPERATIONS LLC

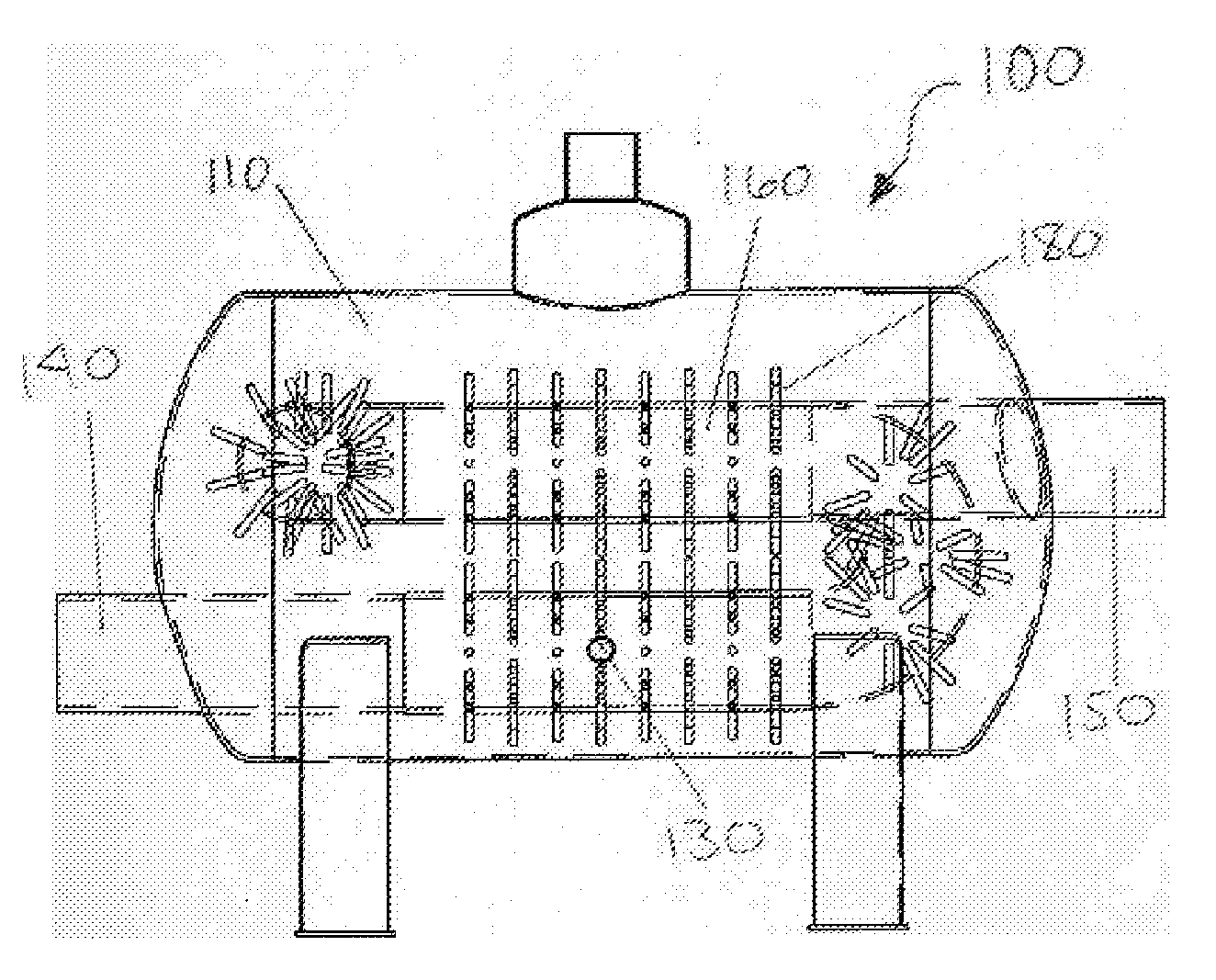

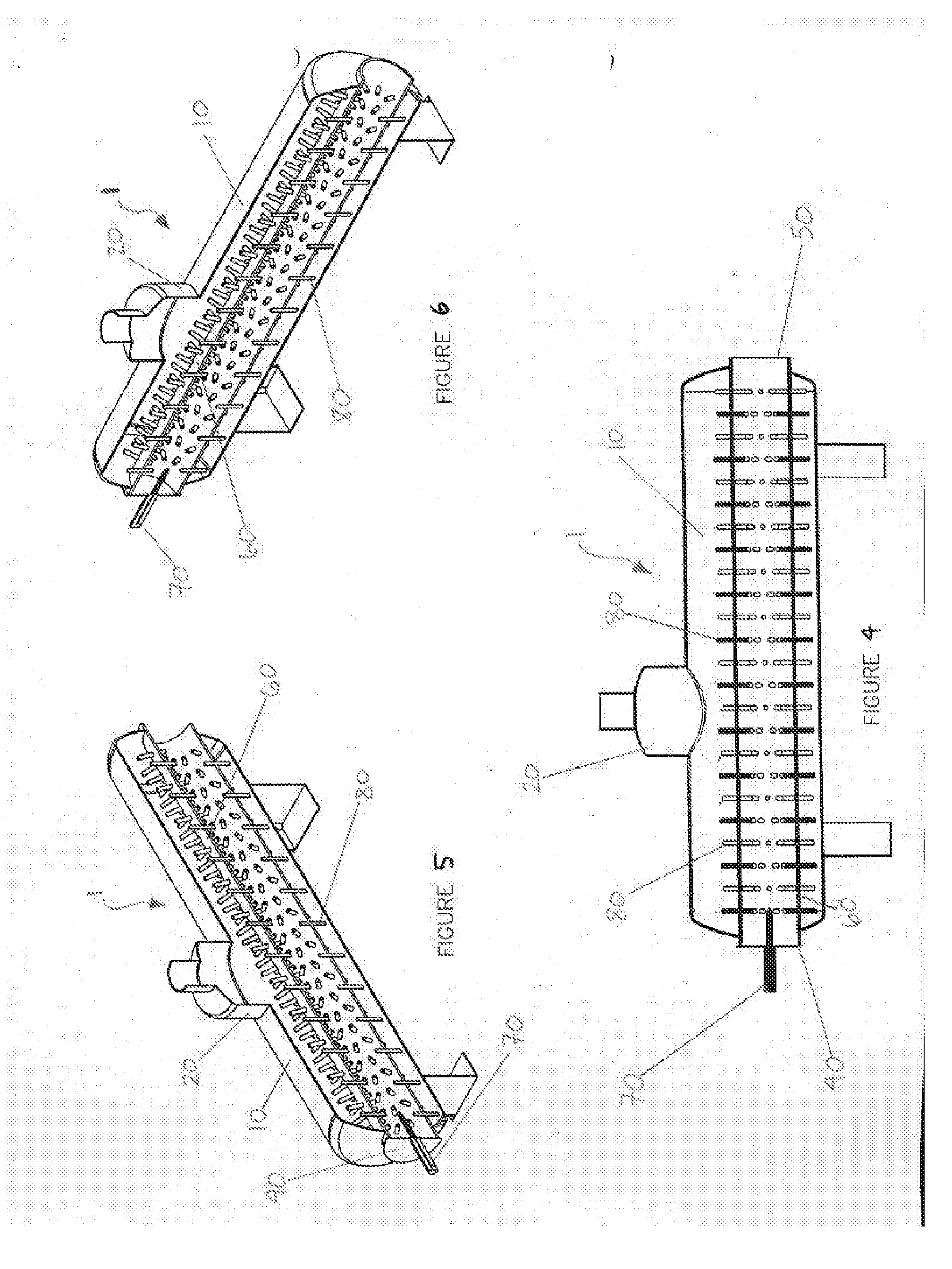

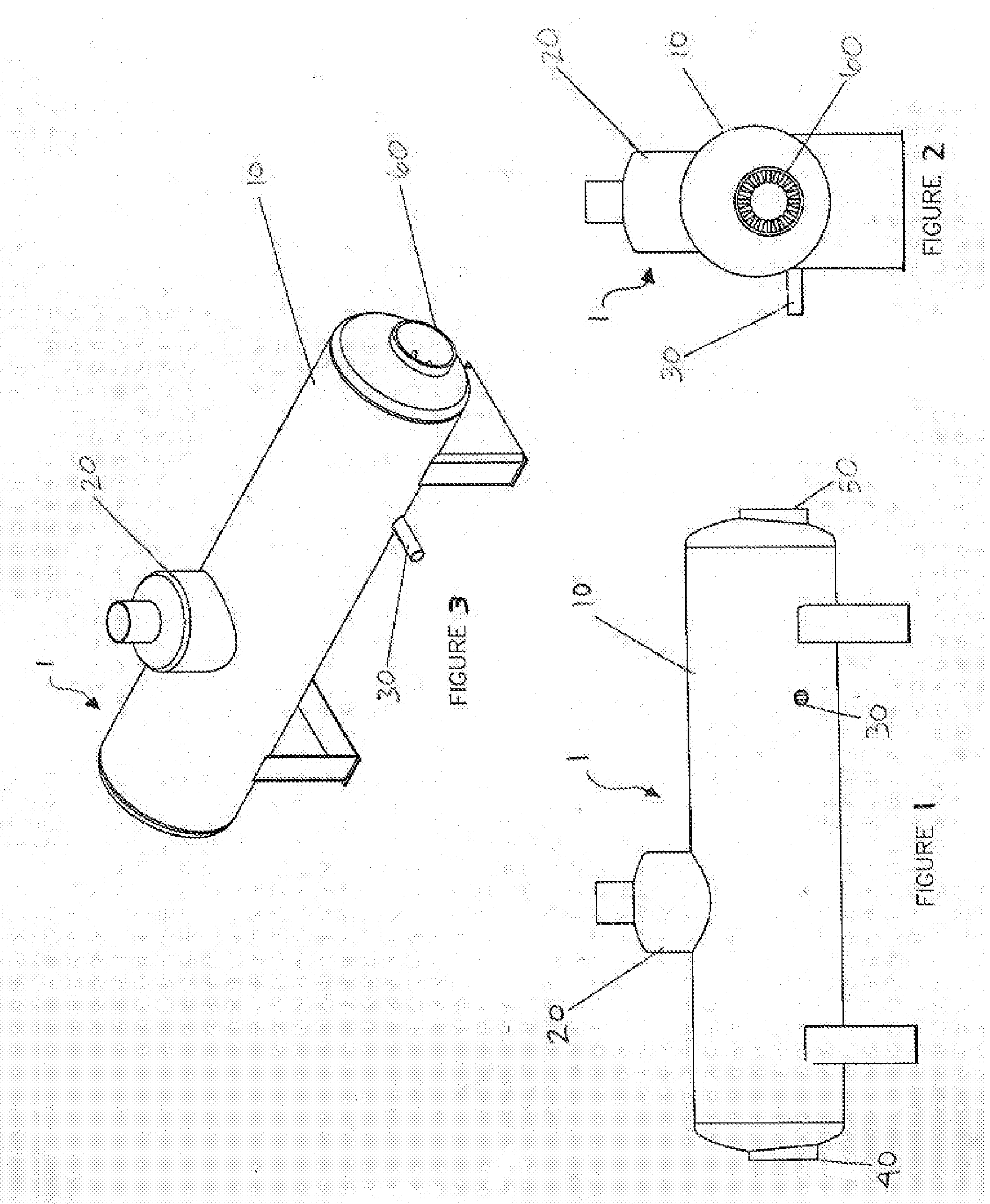

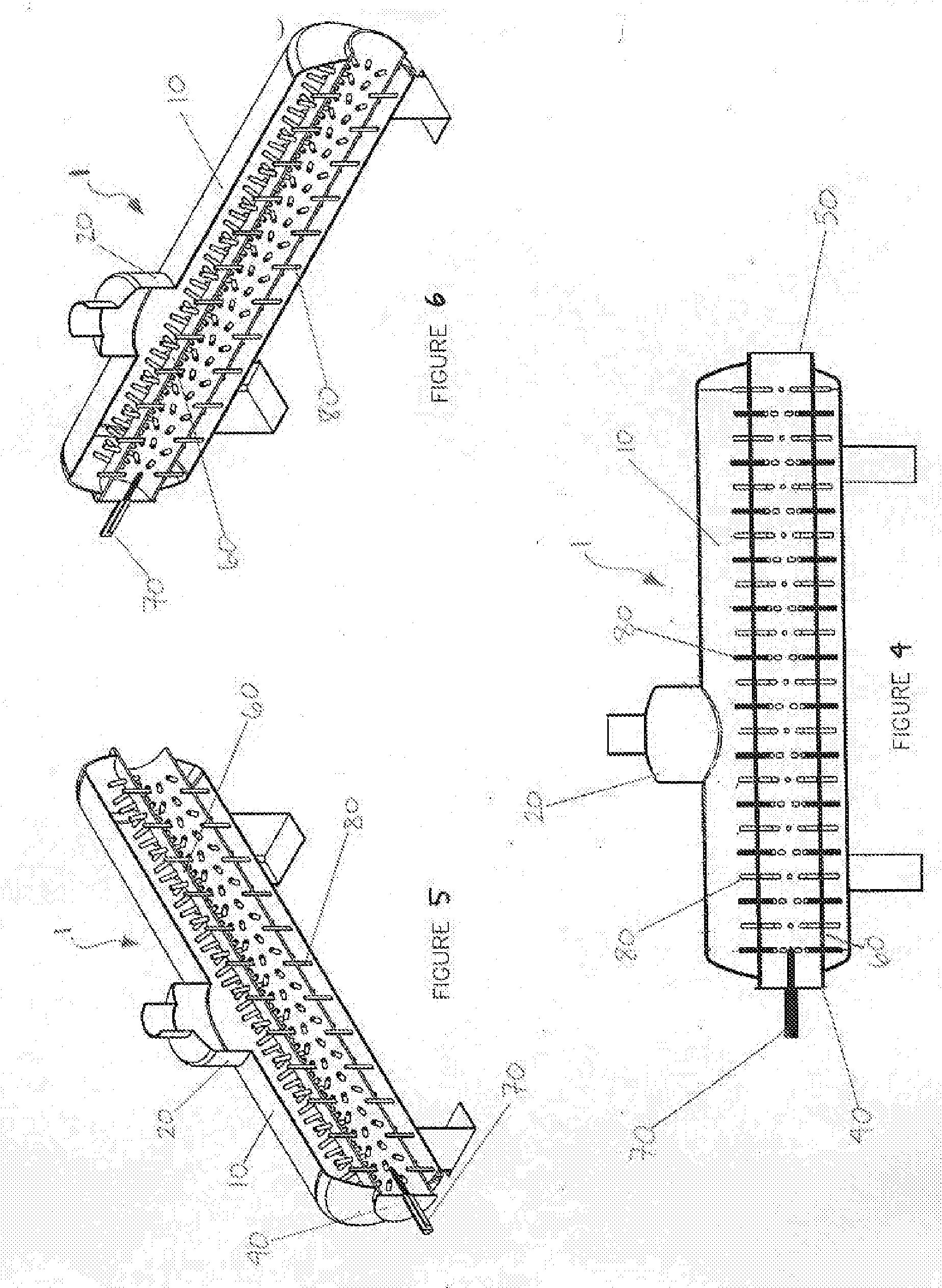

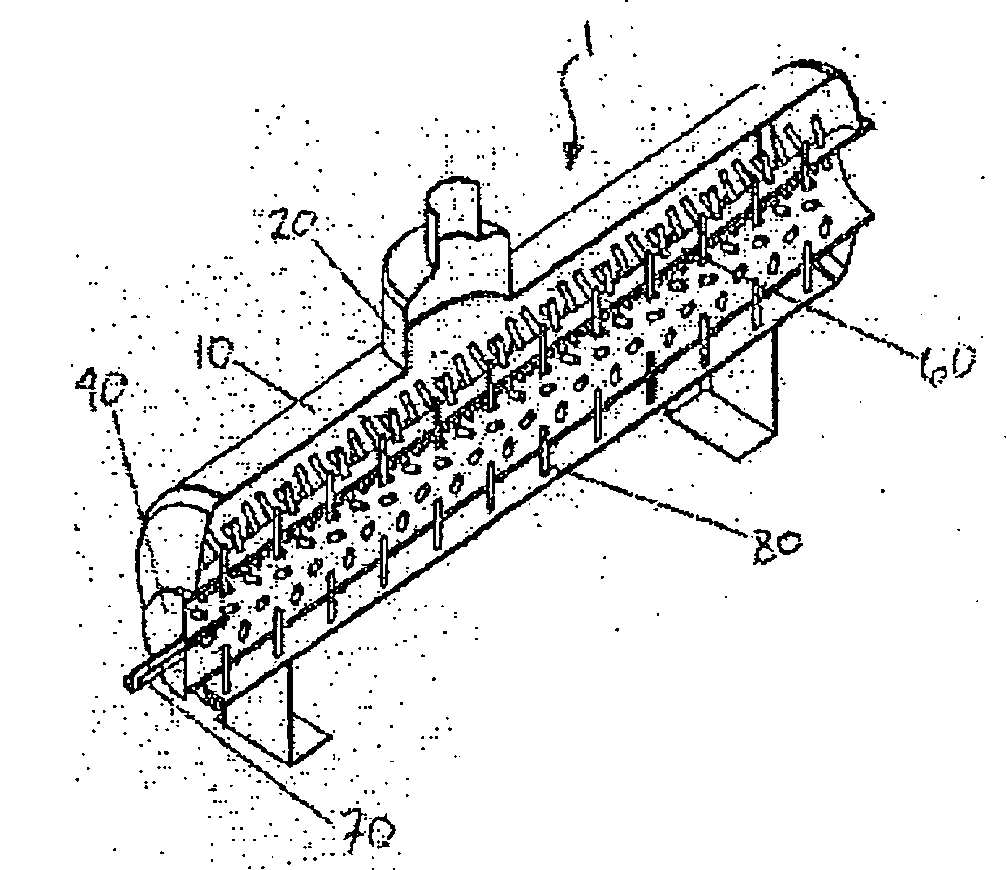

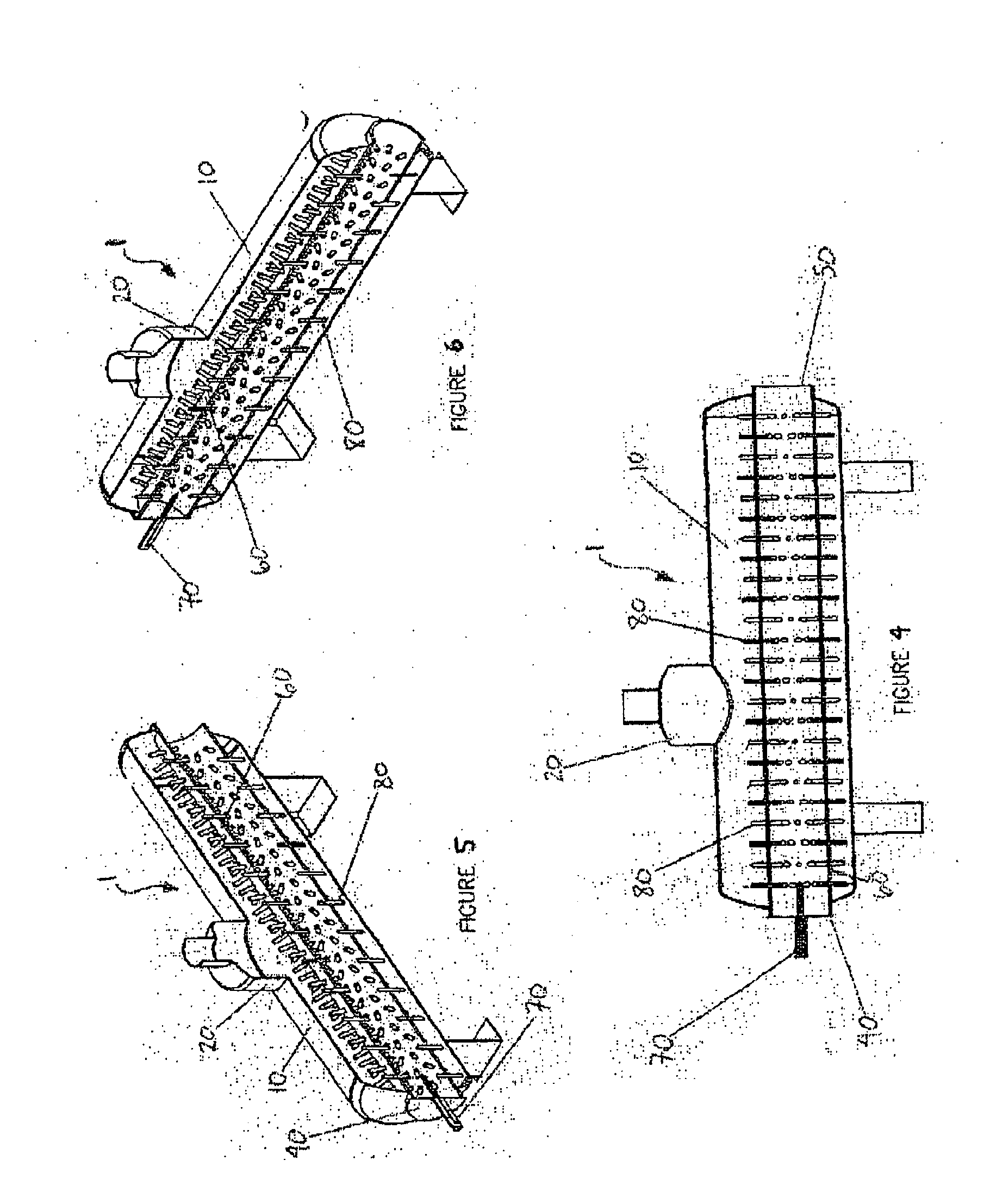

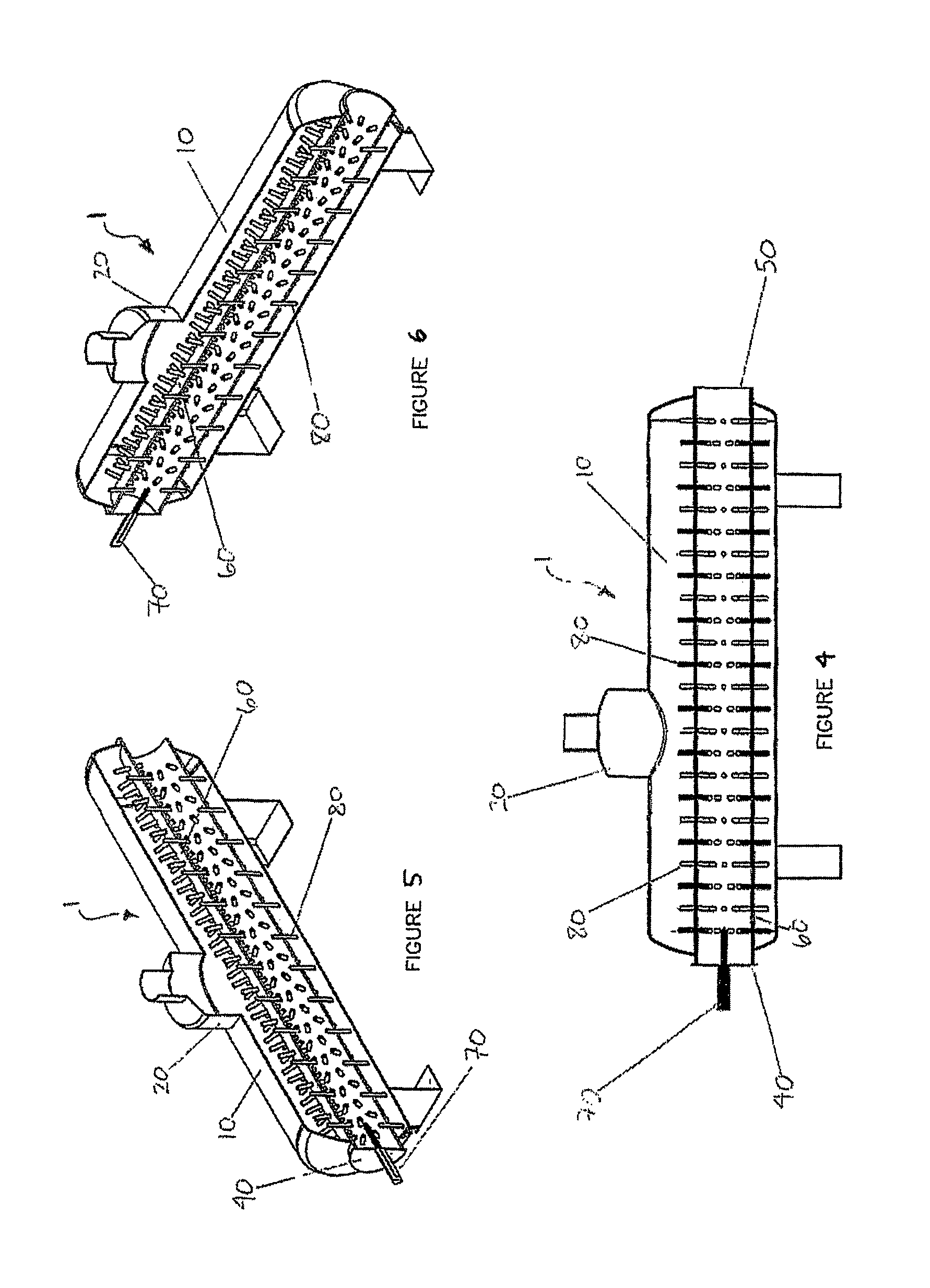

High-efficiency enhanced boiler

ActiveUS20070199688A1Increase surface areaEnhancing convection/conduction coupleStationary tubular conduit assembliesFire-tube steam boilersEngineeringConvection

In devices known in the art, “conventional firetube” and “waste heat recovery” boilers each require many small tubes making successive passes within the boiler. In one embodiment of the invention, however, an enhanced conduit replaces numerous conventional small tubes. In some embodiments, the enhanced conduit incorporates a plurality of fins, each of which extends through a wall of the conduit. In other embodiments, the enhanced conduit incorporates a plurality of tubes along its outer surface, through which a heat transfer medium flows. Both designs enhance the heat transfer relationship between the hot fluid and the heat transfer medium by providing a continuous heat transfer relationship with the heat transfer medium, increasing the surface area involved in the heat transfer relationship and enhancing convection / conduction couples. For some applications, all of the tube banks of other devices in the art can be replaced by one continuous enhanced conduit.

Owner:OKONSKI SR JOHN E +1

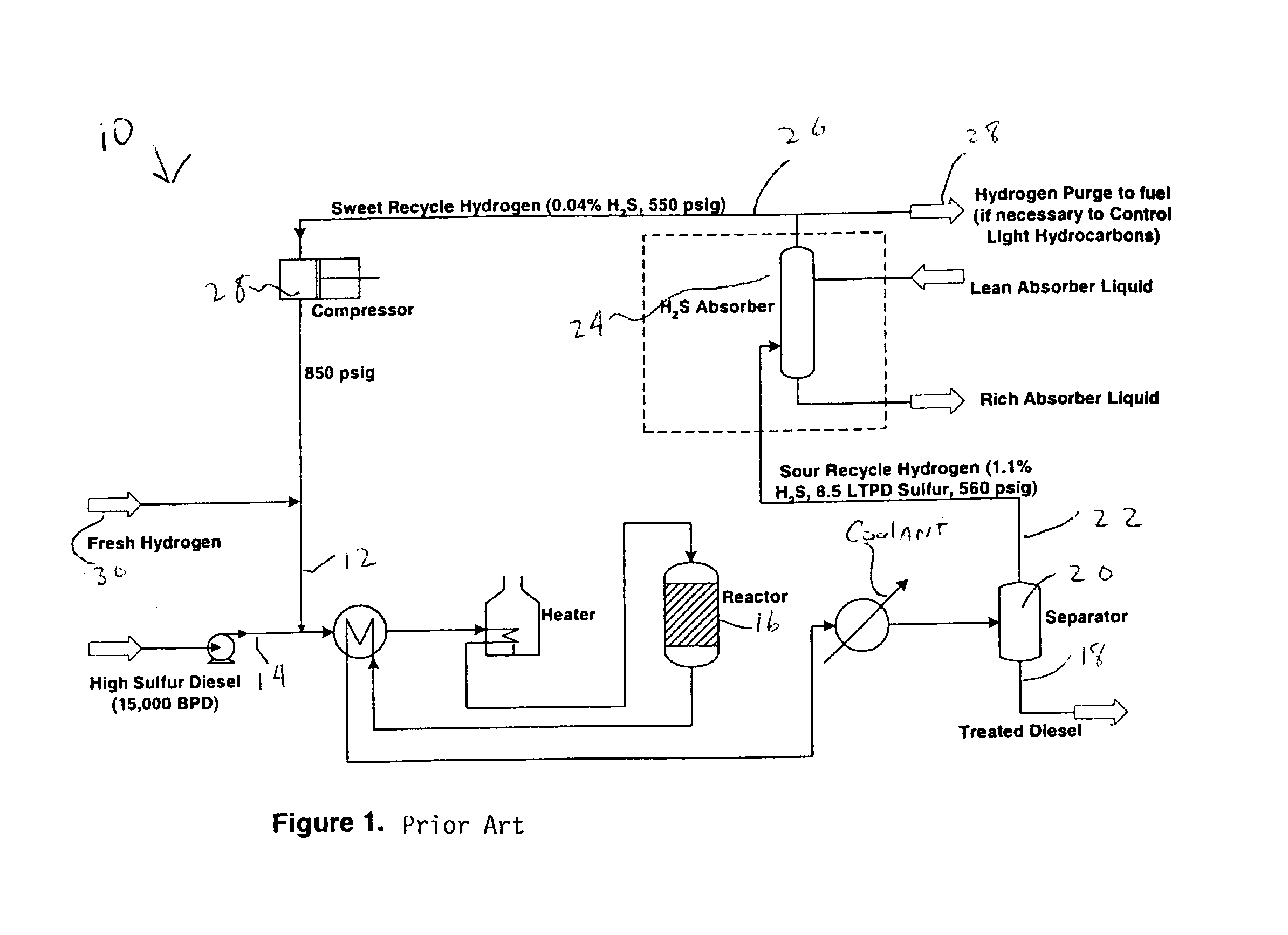

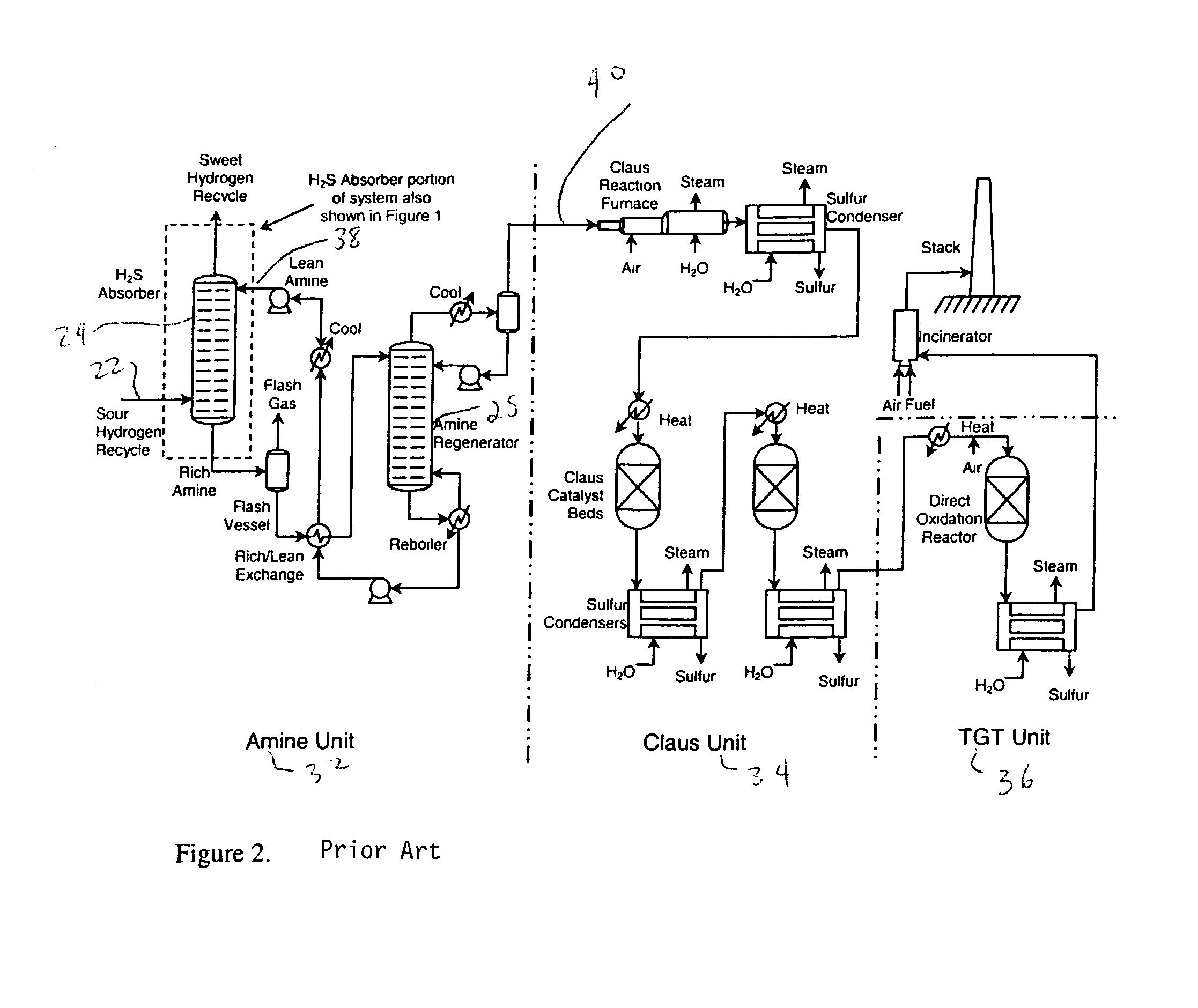

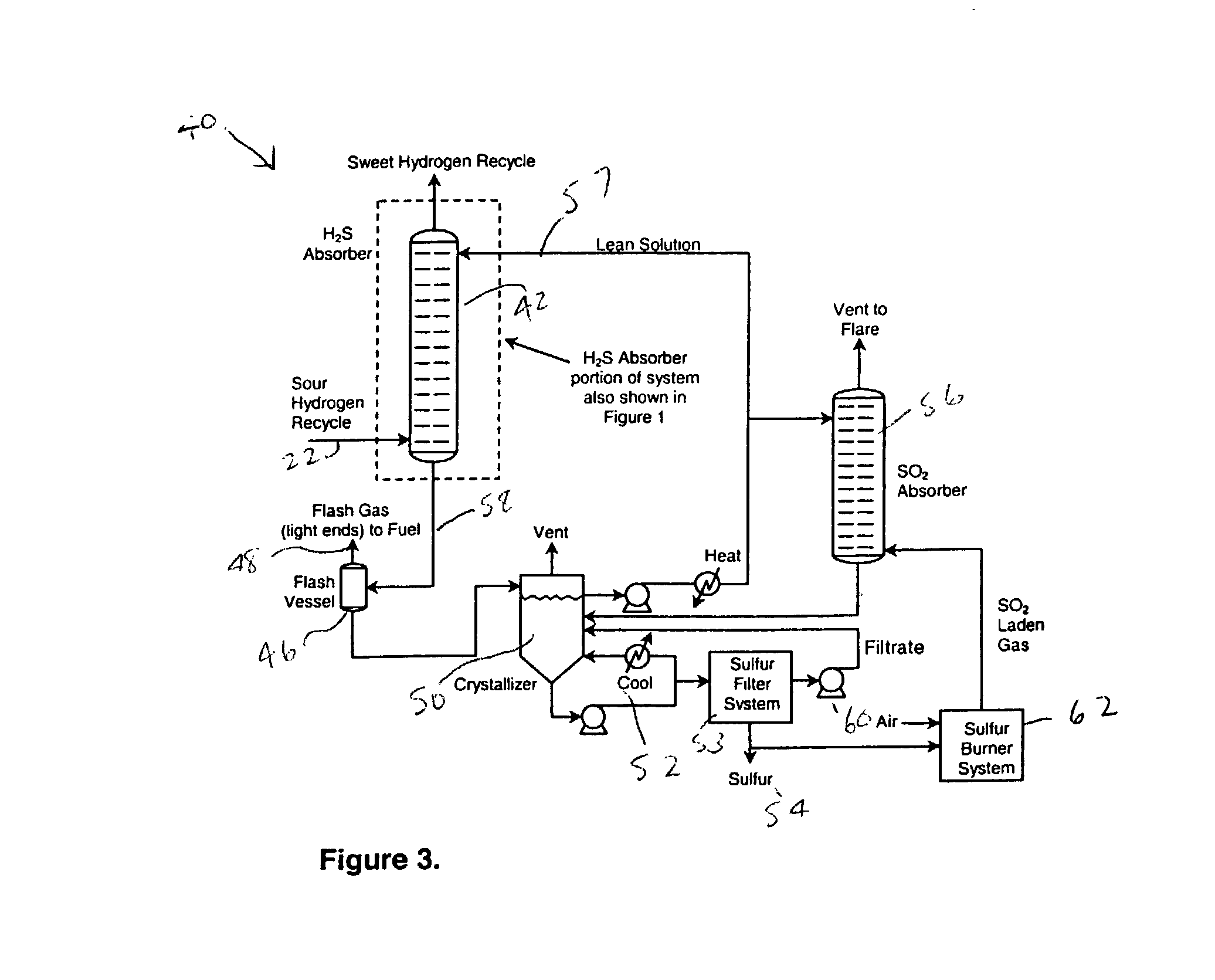

Process for recovering sulfur while sponging light hydrocarbons from hydrodesulfurization hydrogen recycle streams

InactiveUS20030057136A1Significant comprehensive benefitsReduce capacityDispersed particle separationGaseous fuelsHydrogenHydrodesulfurization

In a conventional hydrodesulfurization process sulfur is removed from liquid hydrocarbons by reacting the sulfur in the liquid hydrocarbons with hydrogen to form H2S. A sour hydrogen gas stream consisting of unreacted hydrogen, H2S, and undesired light hydrocarbons is then separated from the liquid hydrocarbons, and the H2S is removed to sweeten the hydrogen stream for recycling. Some of the undesired light hydrocarbons resulting from the reaction may be separated by the purging method discussed. In the present invention efficient separation of the light hydrocarbons is enabled without substantial loss of recyclable hydrogen. Both the H2S and light hydrocarbons are separated from the sour hydrogen gas stream by passing the stream through an absorber where it is reacted with a nonaqueous liquor. The light hydrocarbons are absorbed in the liquor, from which they are subsequently separated.

Owner:URS

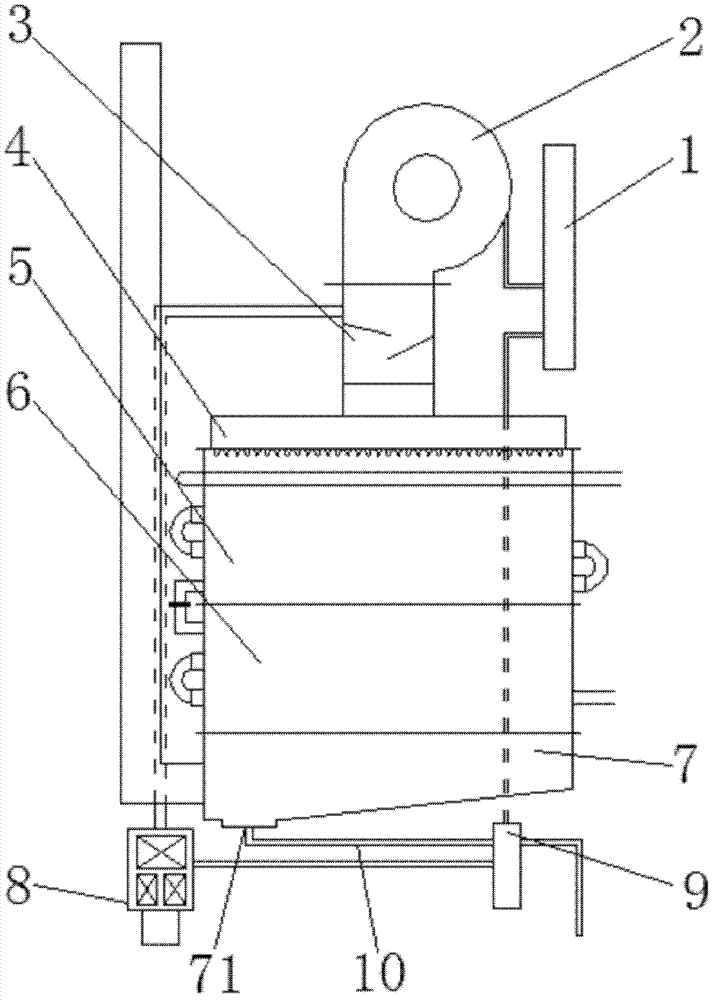

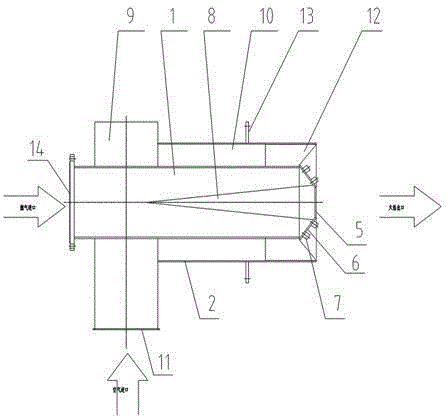

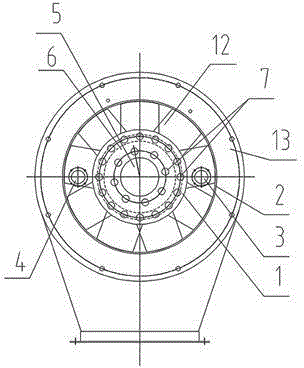

Biogas burner

InactiveCN103104914ALarge adjustment ratioNot easy to blockCombustion ignitionGaseous fuel burnerBiogasEngineering

The invention discloses a biogas burner which comprises a combustor drum outer pipe, a combustor drum inner pipe, a conical flame stabilizing disc, an outer air pipe, an air-outlet hole, an air spinning sheet, a gas spinning sheet, a decoking conical port, an air-inlet device, an air-inlet outer pipe and an adjusting bolt. The air-inlet outer pipe is welded on a conical port connector, a detachable flange is further fixed on the air-inlet outer pipe, the air-inlet device and the decoking conical port are fixed on the detachable flange, a conical port adapting flange is fixedly connected onto the conical port connector, the adjusting bolt is locked on the outer air pipe and butts against the air inlet outer pipe, the combustor drum inner pipe is sleeved on the combustor drum outer pipe, a support plate is further arranged on the combustor drum inner pipe, and the conical flame-stabilizing disc is fixedly connected onto the combustor drum inner pipe. The biogas burner enables fuel to be sufficiently combusted, cannot pollute environment, is not prone to be blocked, and is free of tempering blowing-off, long in service life and good in stability.

Owner:福建正泽新能源有限公司

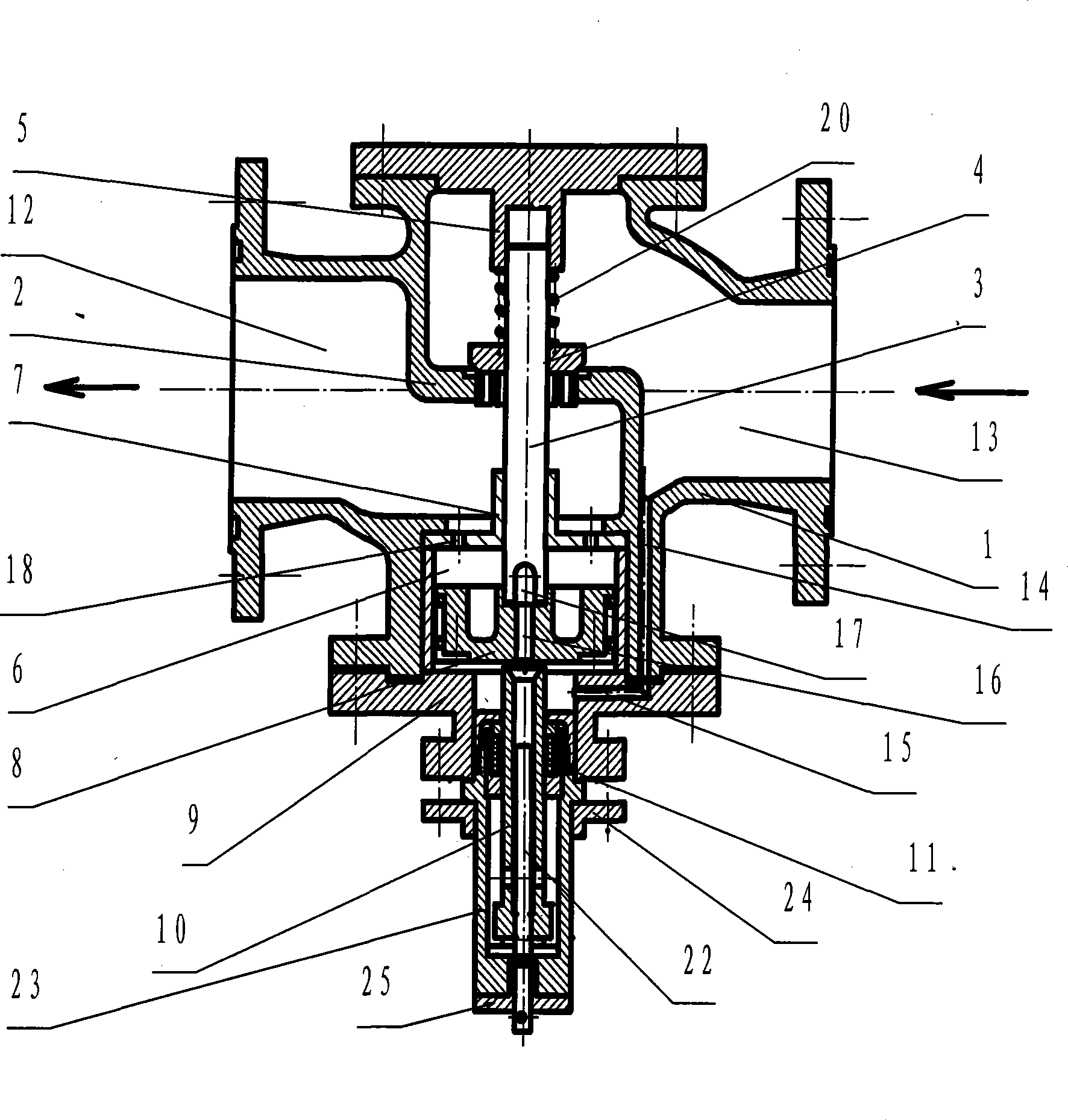

Regulation valve with accurately positioned valve core

ActiveCN101430023AHigh degree of intelligenceEasy to combineOperating means/releasing devices for valvesLift valveFluid pressureFluid control

A regulating valve used for accurately positioning a valve plug and regulating pressure or flow rate of fluid in a fluid transportation pipeline is especially suitable for power station, petroleum and chemical department, belonging to the field of engineering elements or parts. The regulating valve comprises three parts which are a valve body, a driving cylinder and a servo mechanism, and the valve body having the conventional structure of a stop valve is combined with the driving cylinder that is internally provided with a piston into a whole; a channel used for drawing in the controlled fluid is also processed; the servo mechanism mainly includes a servo pipe and a screw gearing pair (or a pinion and rack gearing pair). The gap between the end surface of the servo pipe and the end surface of an axial aerial drainage hole in the center of the piston is regulated to change the differential pressure of the controlled fluid at the two sides of the piston, and the valve plug linked with the piston is further moved and is accurately balanced at the requested position. The regulating valve has the advantages that the mobile servo pipe has low power consumption (watt level), high positioning accuracy, large turndown ratio, high sensitivity, good stability and easy combination with a fluid control system having high intelligence.

Owner:哈尔滨工程大学海能科技有限责任公司

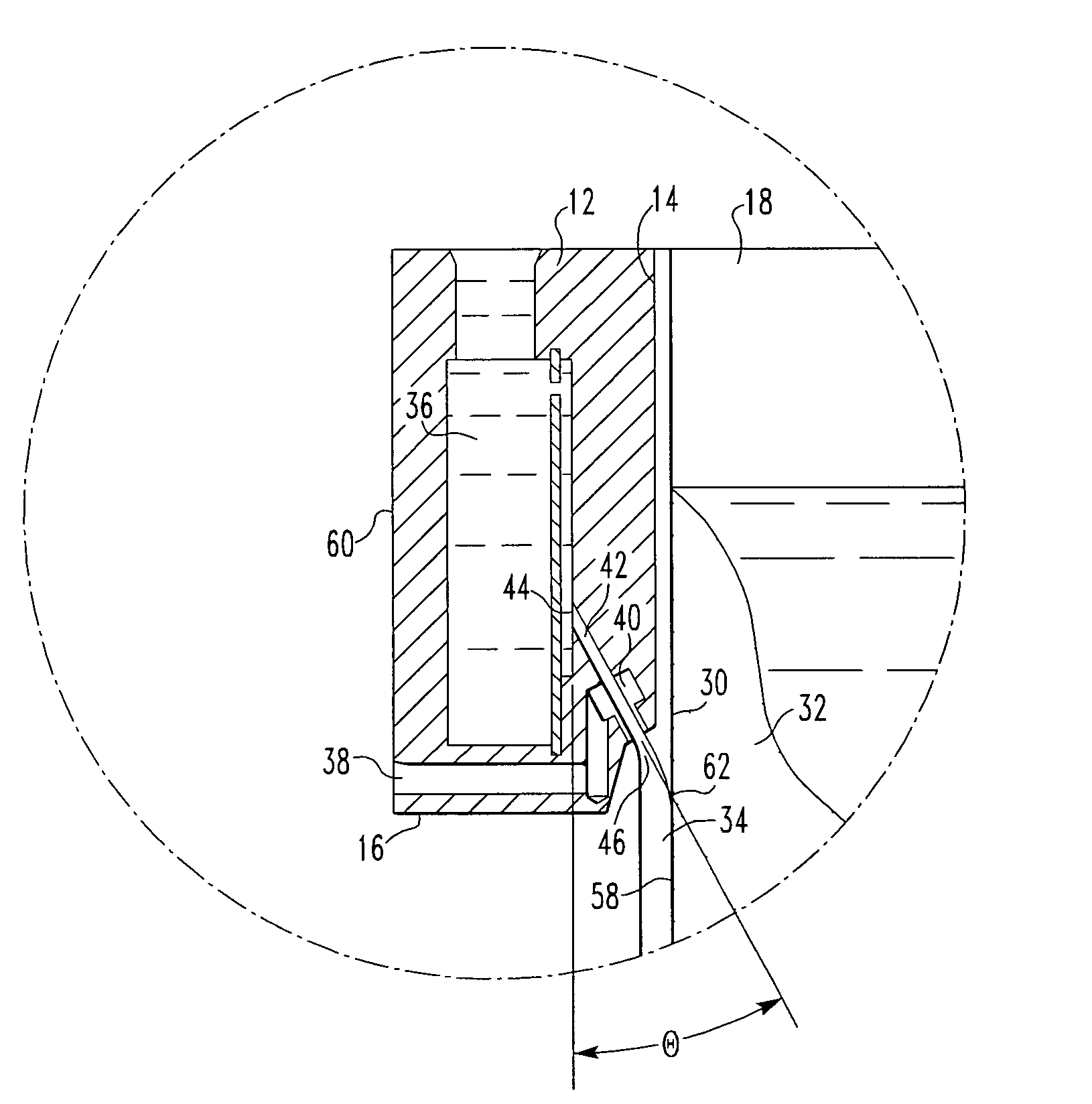

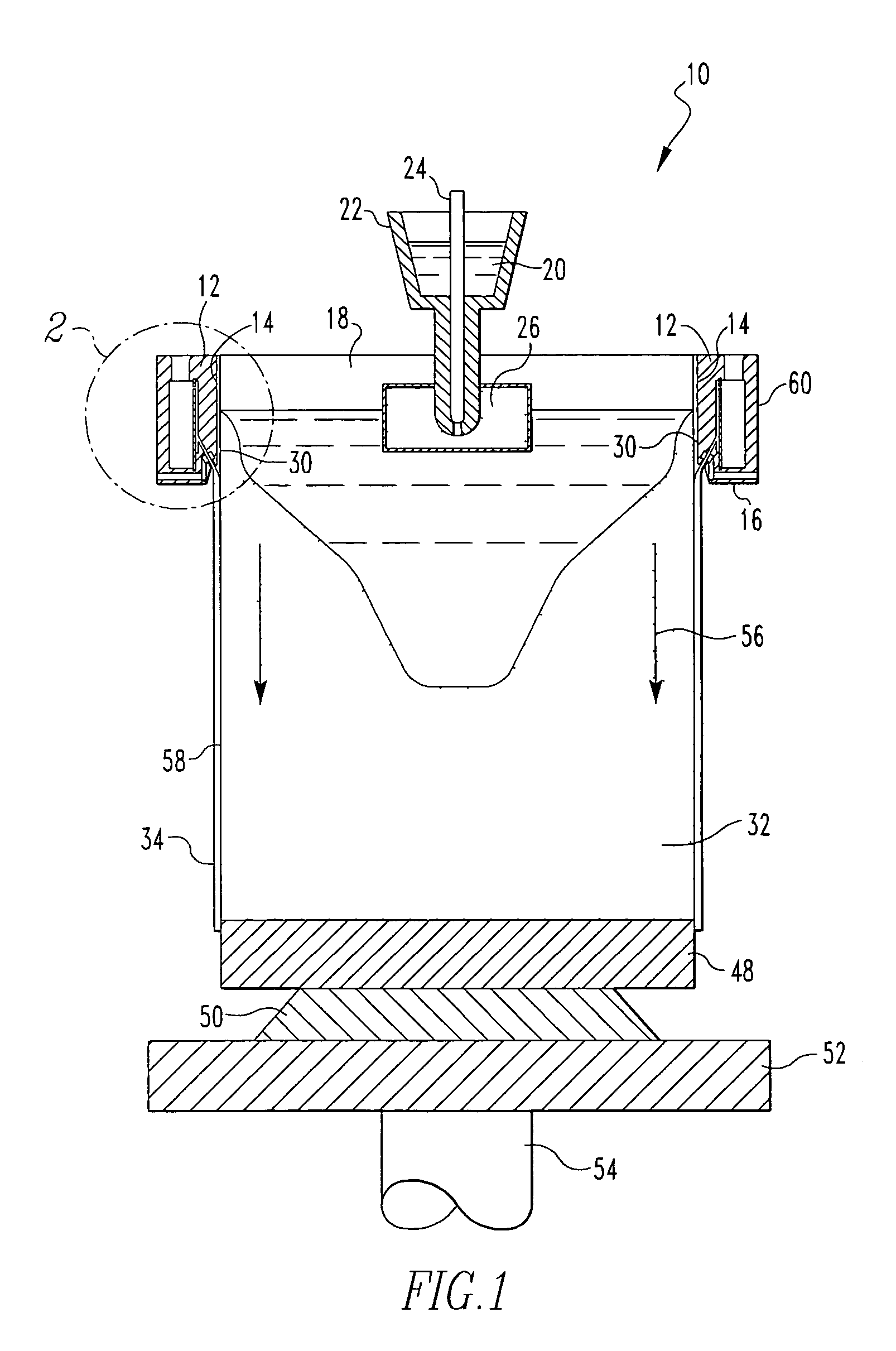

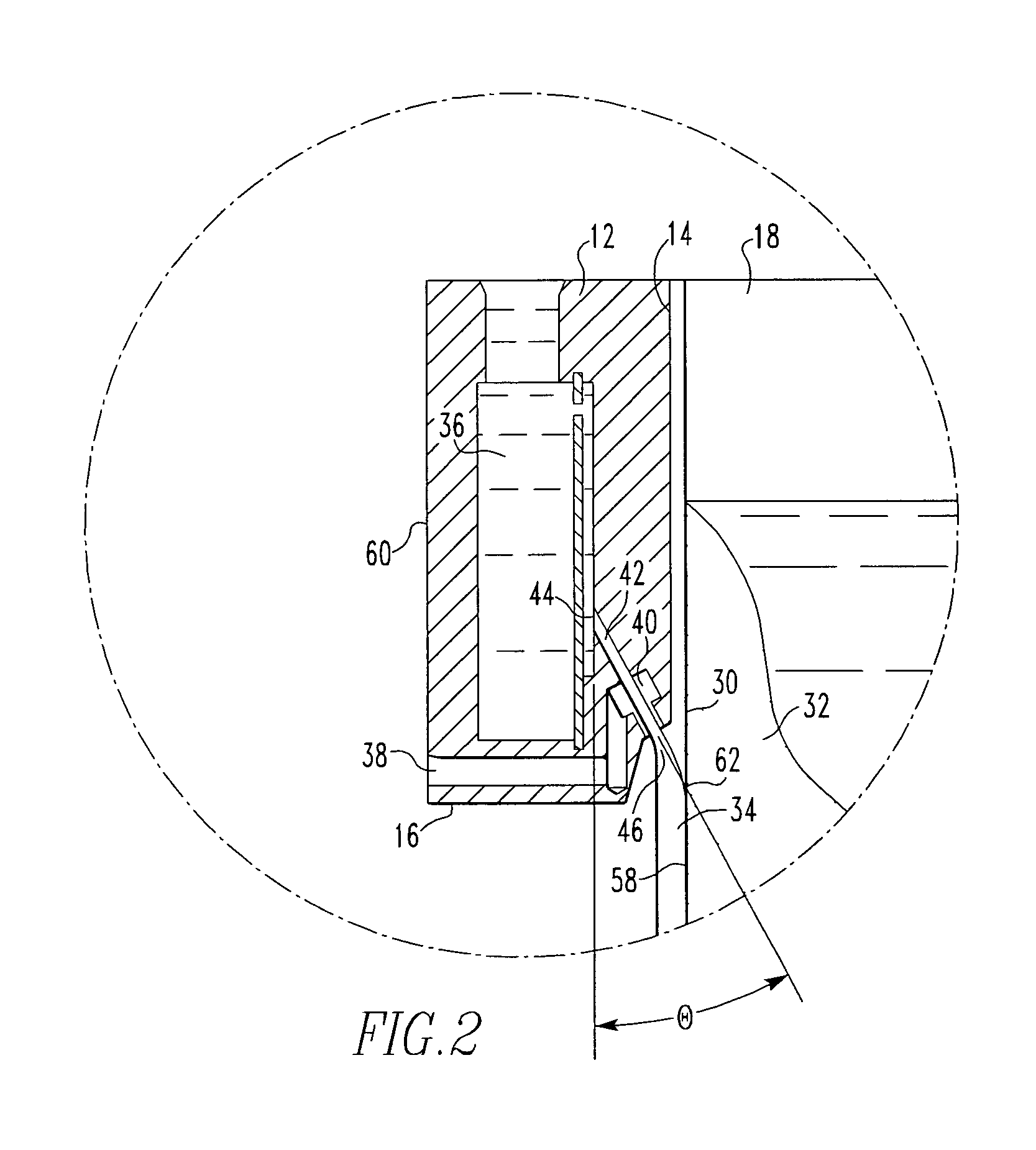

Gas enhanced controlled cooling ingot mold

InactiveUS7011140B1Minimum operation liquid flow rateConstant coolant impingement locationIngotProduct gas

A cooling mechanism for a casting apparatus having a mold that includes sides, a bottom, and a top defining a cavity. The cooling mechanism allows for simultaneous injection of liquid and gas onto a cast ingot therefore providing a lower minimum operation liquid flow rate, while maintaining a fairly constant coolant impingement location on the ingot surface. As a result, heat is extracted from the metal ingot at a much lower rate allowing the ingot to experience superior startup butt curl control, which substantially reduces the number of localized stresses that can lead to cracking of the ingot. Reducing the number of cracks in the ingot substantially reduces the number of wasted ingots, therefore improving efficiency and reducing costs. A method of casting is also disclosed.

Owner:ARCONIC INC

Inverted full-premix condensing gas water heater

ActiveCN103090541AWell mixedRaise emission levelsEnergy efficient heating/coolingAir heatersCombustorMaster controller

The invention discloses an inverted full-premix condensing gas water heater. An inverted metal fiber burner is used. A primary heat exchanger and a secondary heat exchanger are both inverted. Reasonable proportion of gas valve assemblies to fans is controlled via a master controller. Mixed gases enter a gas mixer and are mixed well by the gas mixer prior to entering a burner assembly, and uniformity of the gas mixture is guaranteed when the gas mixture enters the burner. Burning in the full-premix way need not air supply any more, the ratio of actual air to theoretical air is 1.3:1, burning efficiency is high, flames are short, temperature is low, and emission level is high. The metal fiber burner with wide regulating ratio range is used, and accordingly all fire power requirements can be met with no need of subsection control. In addition, the burner and the heat exchangers are inverted for the problem of proneness to blockage of the metal fiber burner, so that the problem that residue of the heat exchangers falls on the burner in long-term use is solved; condensate is discharged through a liquid sealing device, and smoke leakage is effectively prevented.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

Fluent control valve

InactiveUS6988705B1Eliminates thrust variationLow costValve members for absorbing fluid energyPipe elementsFluid controlEngineering

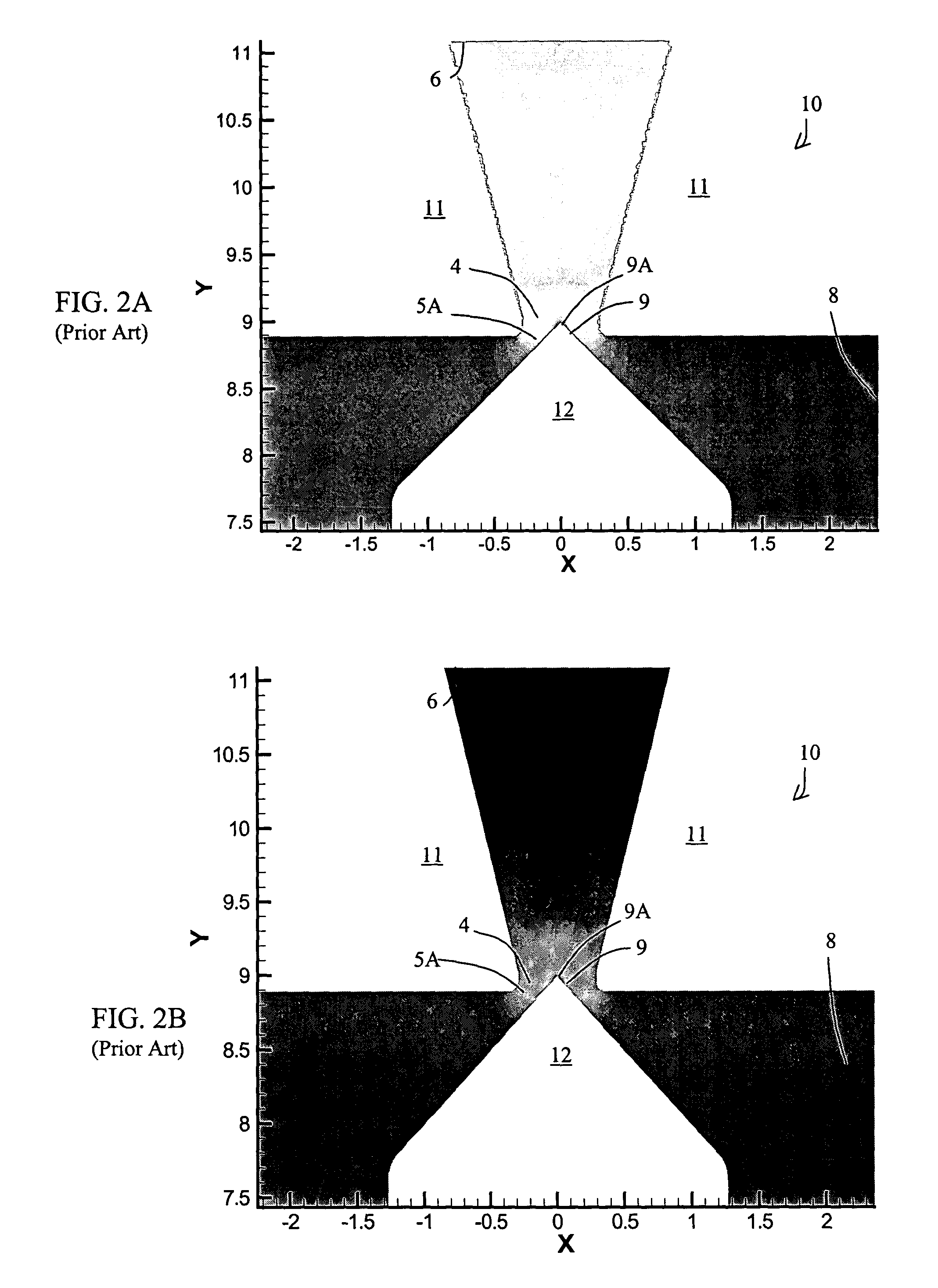

A continuously variable fluent control valve for controlling supersonic flow of gas. The valve has an upper plate with a very slightly angled physical control surface and a lower plate with a physical nozzle inlet. As the valve opens and closes during supersonic flow, a hydrodynamic pintle forms in the nozzle inlet just below the physical control surface. The hydrodynamic pintle provides a fluid control surface for redirecting flow from horizontal fllow to vertical flow through the nozzle and, depending on the expansion needs of the supersonic flow, the hydrodynamic pintle changes shape, expanding or shrinking in the axial direction of the valve. Because of the nearly flat physical control surface of the upper plate, matieral ablation is significantly reduced. The fluid-fluid boundary between the hydrodynamic pintle and the supersonic flow produces a flow through the nozzle with little or no recirculation.

Owner:HOOSE KARL V

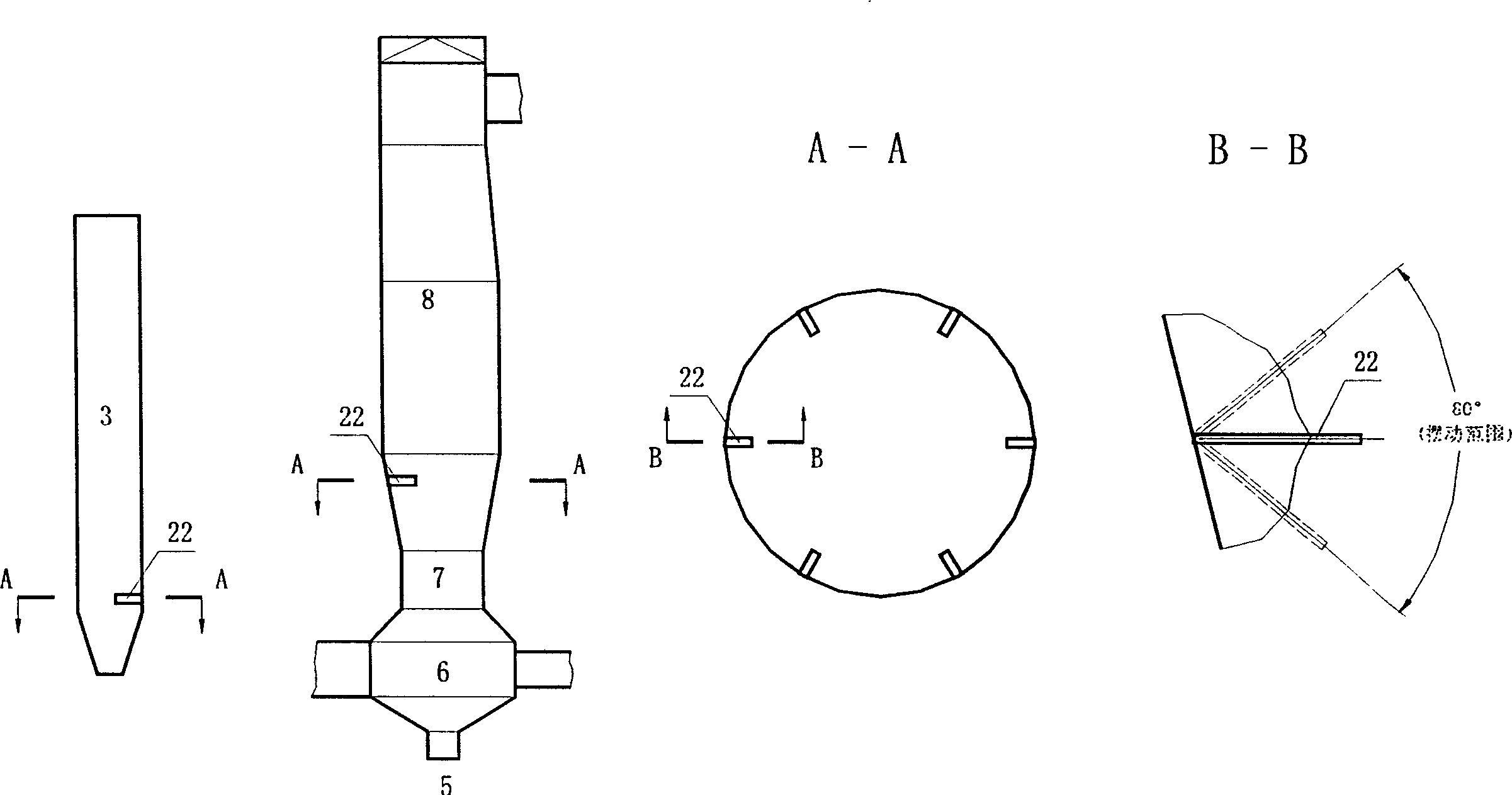

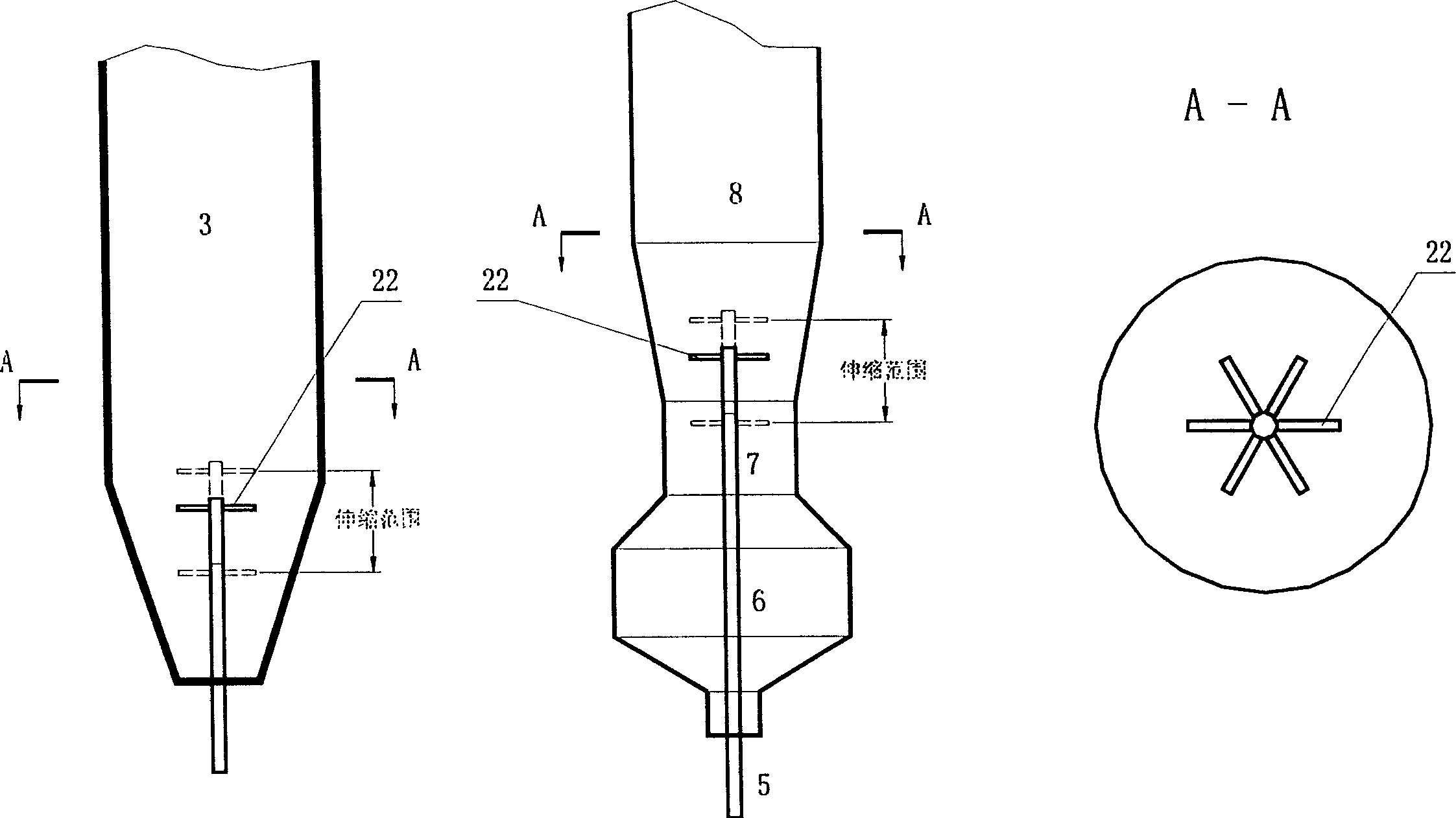

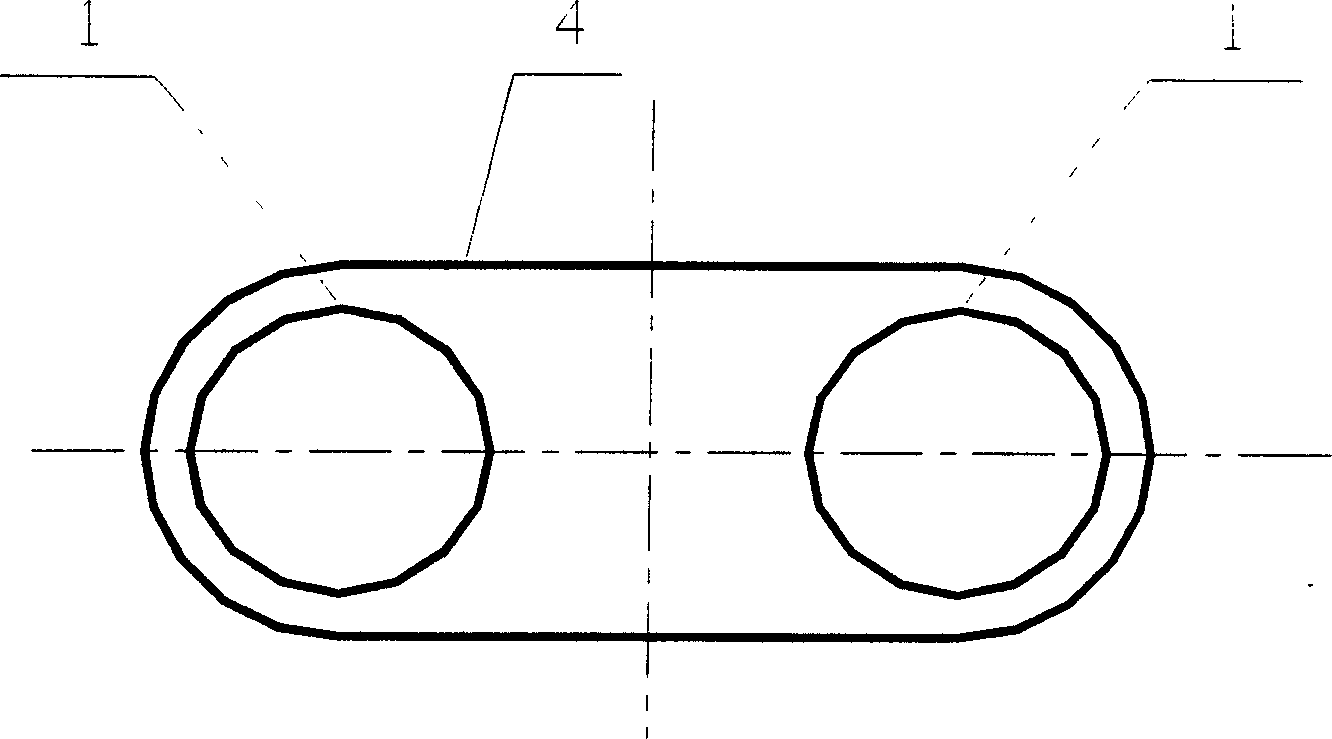

Dry-stack gas desulful-izing method using position regulatable water sprag atomization method

A fume desulfurizing process by dry method and using the position-adjustable water spraying and atomizing includes preparing and digesting the desulfurizing agent, internal desulfurizing reaction in tower, and external separation and recirculation of granular desulfurizing agent. It features that the water is sprayed into desulfurizing and digesting towers in such manner that its nozzle position can be adjusted in a certain range.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

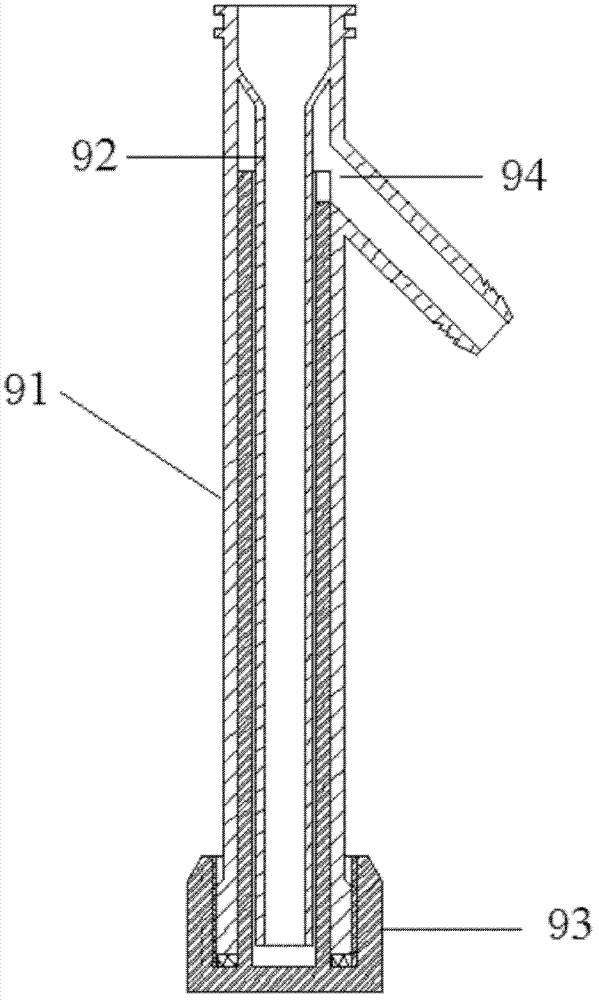

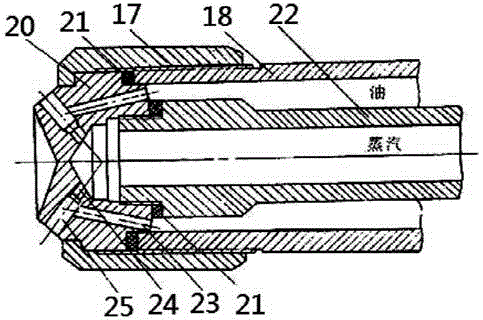

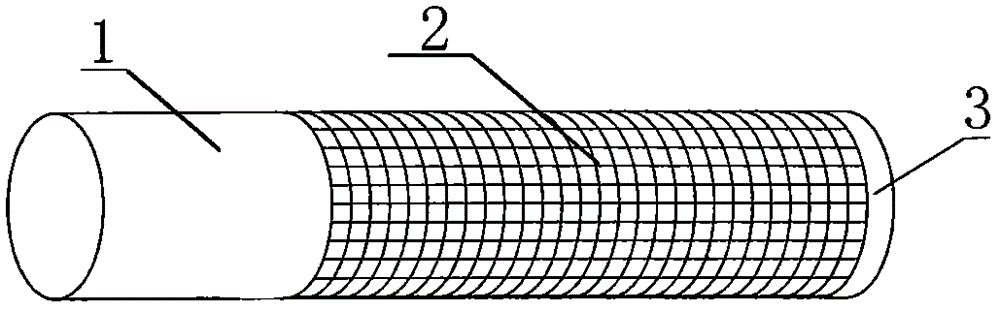

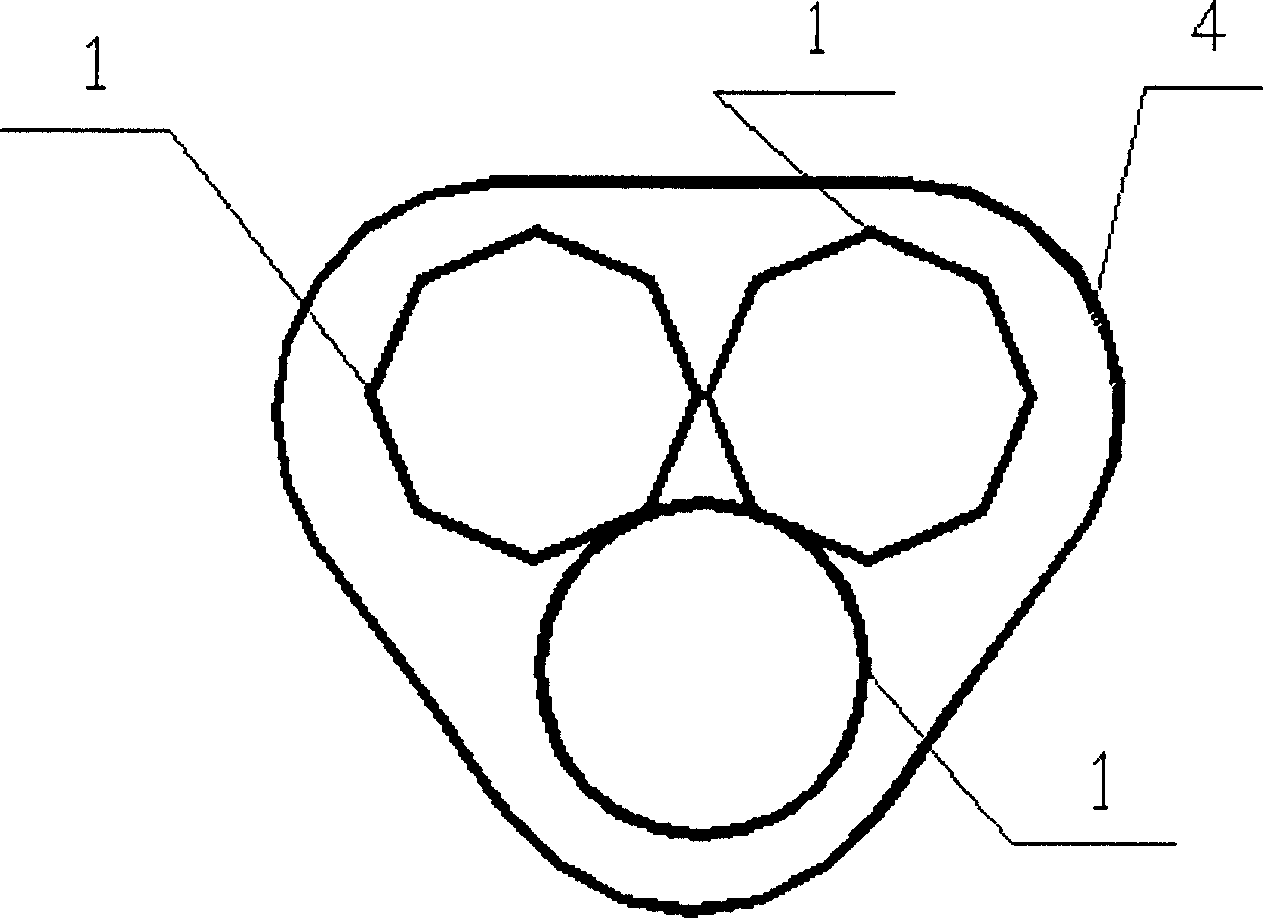

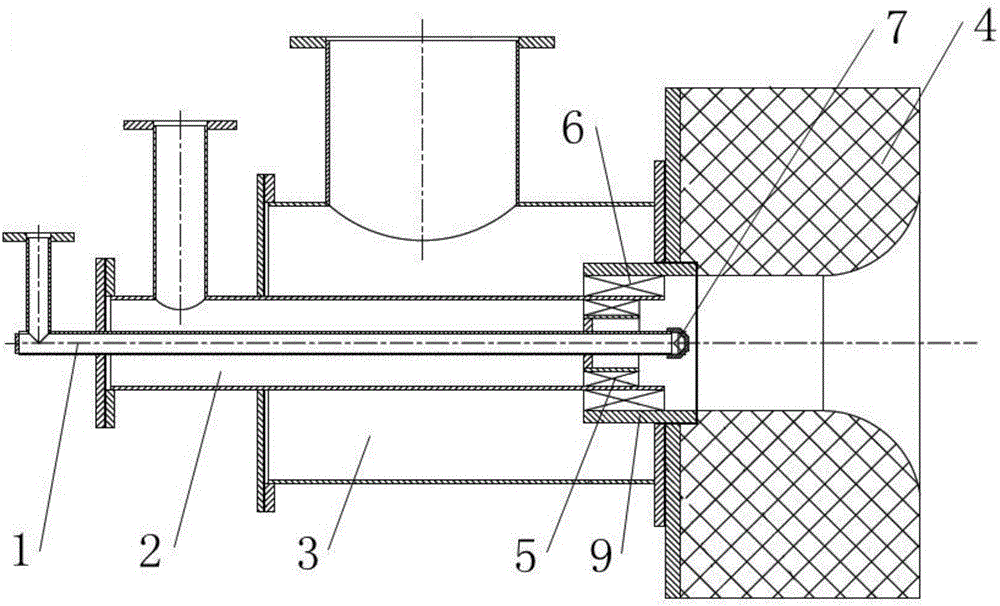

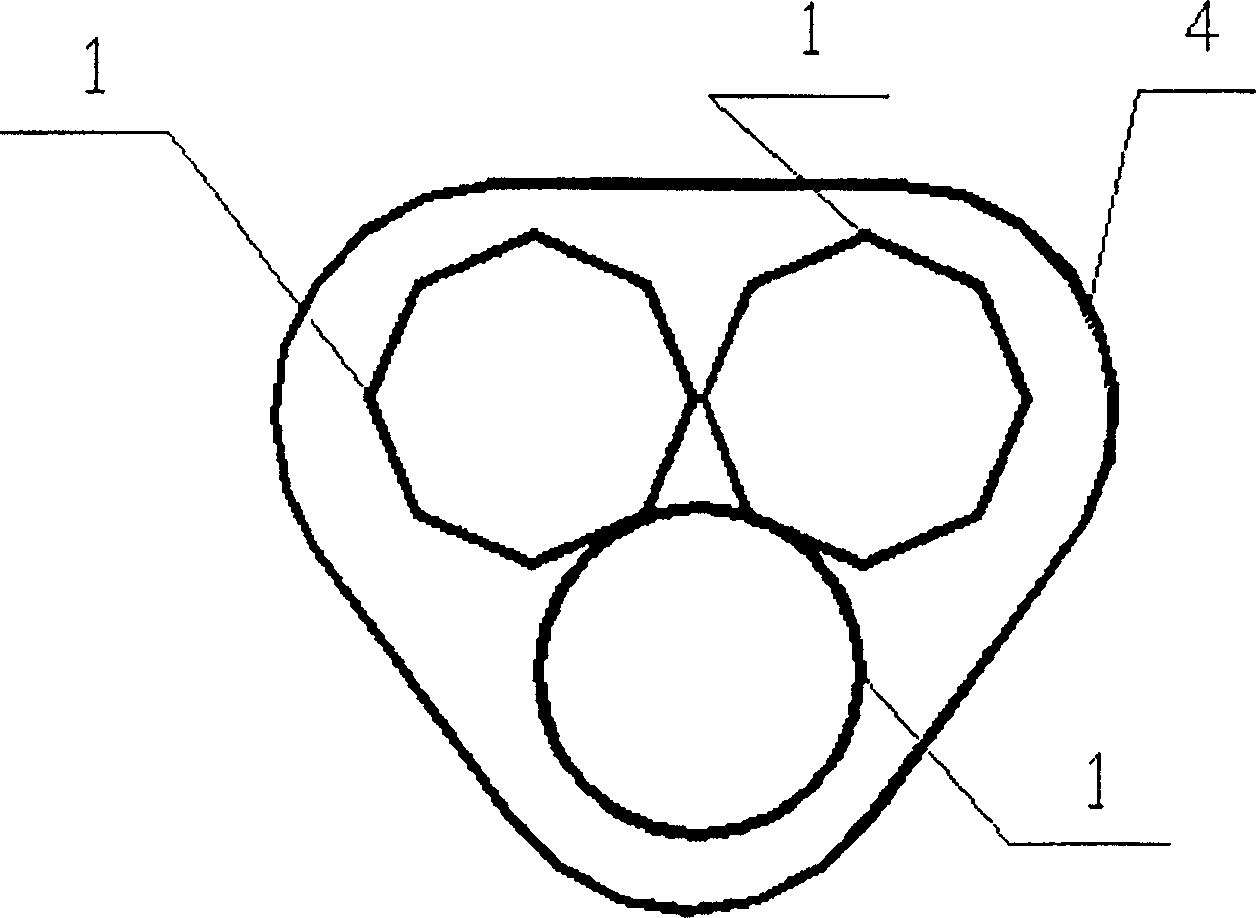

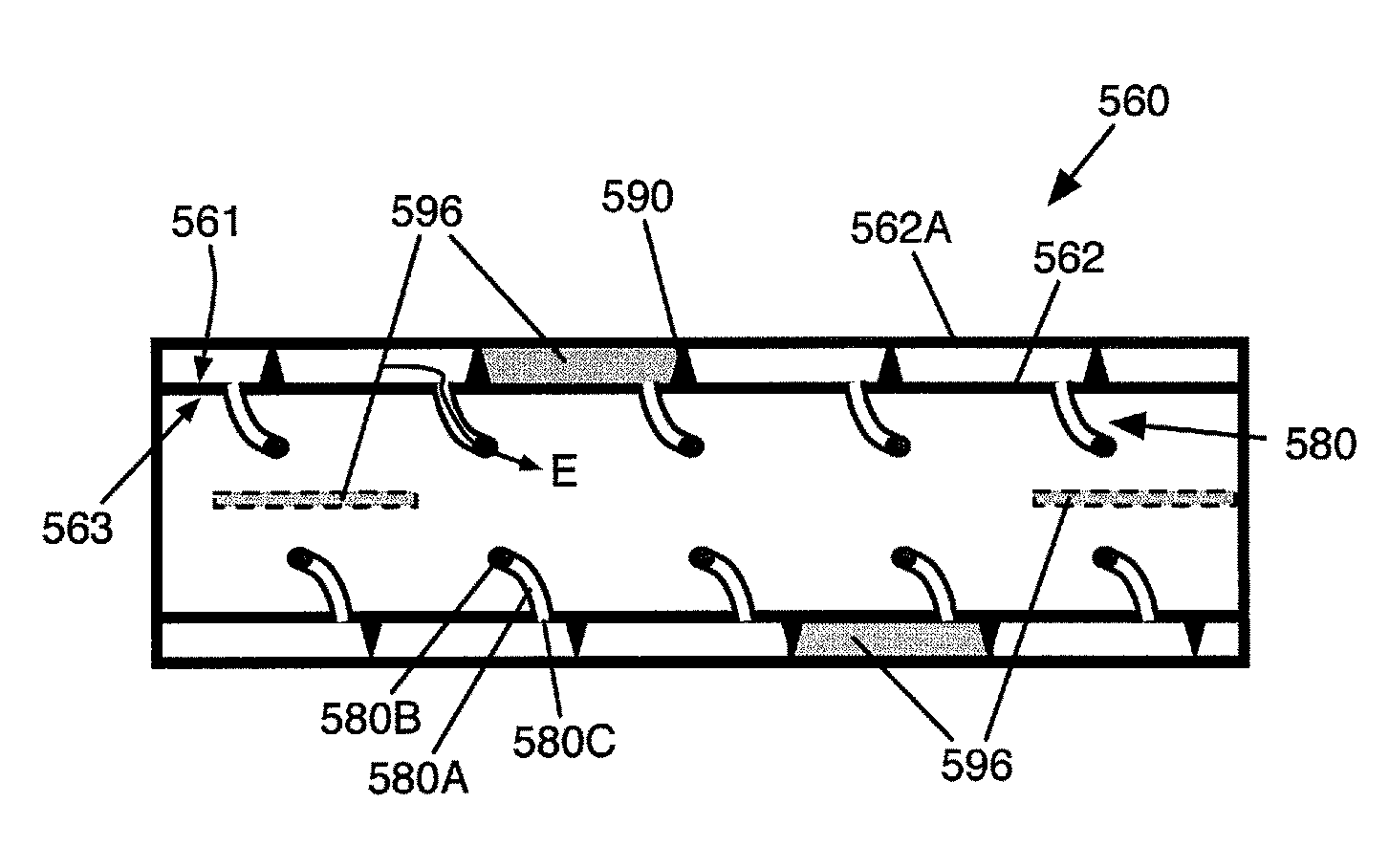

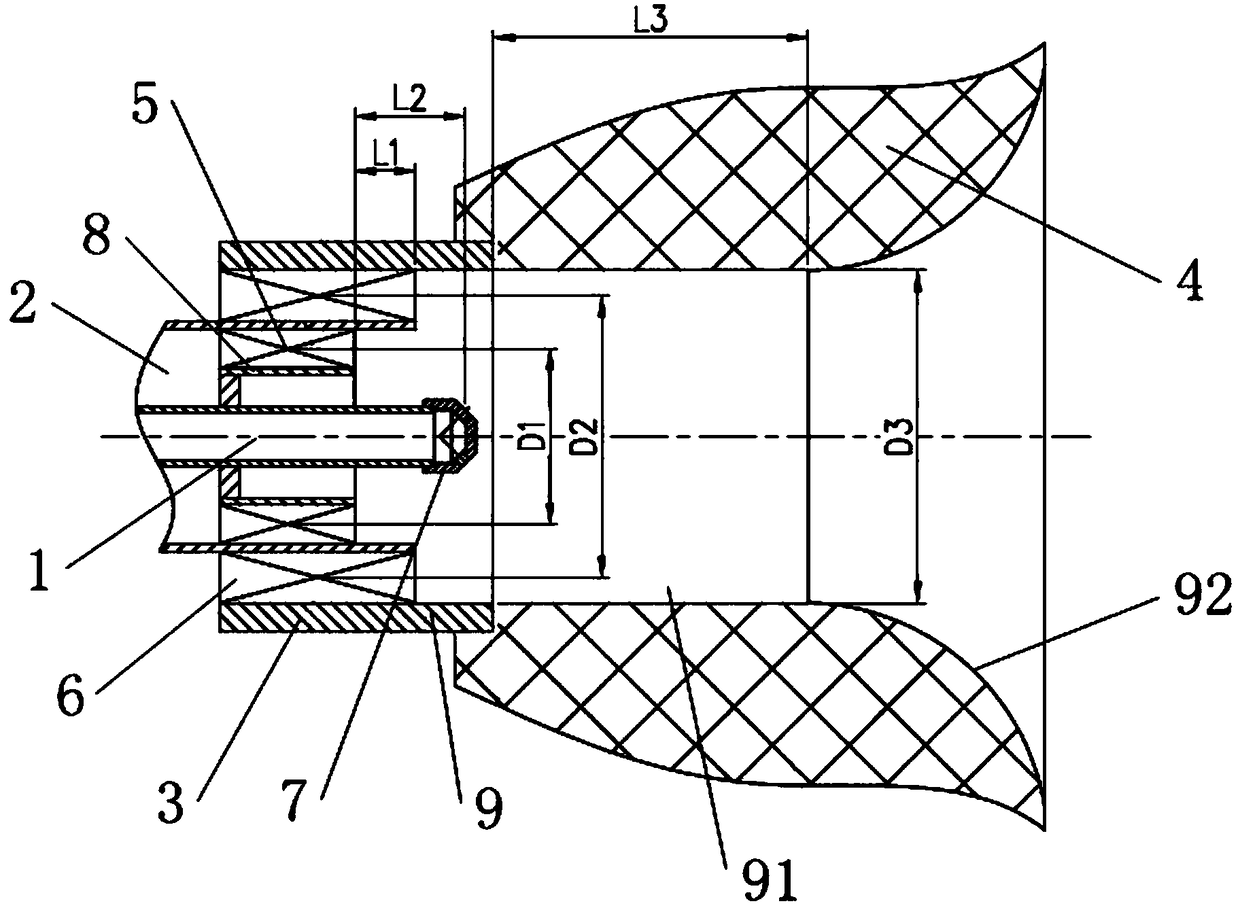

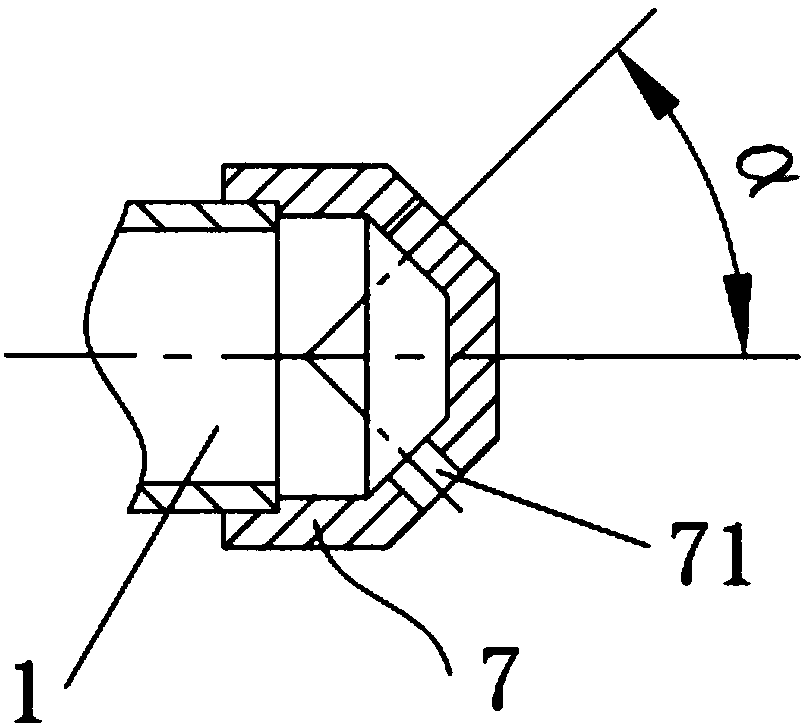

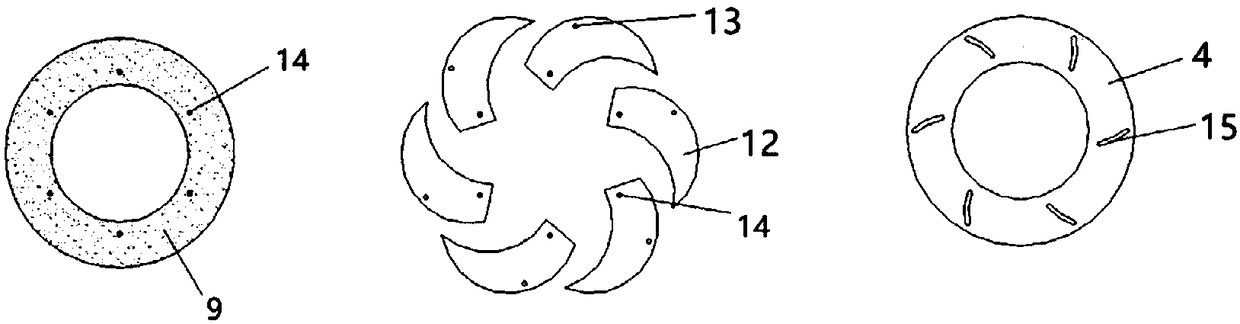

Multi-mechanism composite atomized fuel nozzle structure

InactiveCN104566363AAtomized particle size is smallSmall atomization energy consumptionLiquid fuel burnerLow noiseNozzle

The invention discloses a multi-mechanism composite atomized fuel nozzle structure. The atomized fuel nozzle structure comprises an inner pipe, an outer pipe, a mixer and a nozzle, wherein the inner pipe is communicated with a fuel inlet and is used as a fuel channel; the outer pipe is arranged on the inner pipe, an atomizing medium channel is formed between the outer pipe and the inner pipe, and an atomizing medium inlet communicated with the atomizing medium channel is formed in the pipe wall of the outer pipe; the mixer is arranged on the discharge port end of the atomizing medium channel and is communicated with the fuel channel and the atomizing medium channel; the nozzle arranged on one end of the outer pipe is arranged on the discharge port end of the mixer, and the front end of the nozzle is provided with a plurality of spraying holes; an atomizing structure for atomizing fuel is arranged between the mixer and the inner pipe. The atomized fuel nozzle structure has the advantages of simple structure, small fuel atomizing particle size, good atomizing particle size evenness, high regulating ratio, low atomizing agent consumption, low noise, good energy-saving effect and the like.

Owner:长沙恒威热能科技有限公司

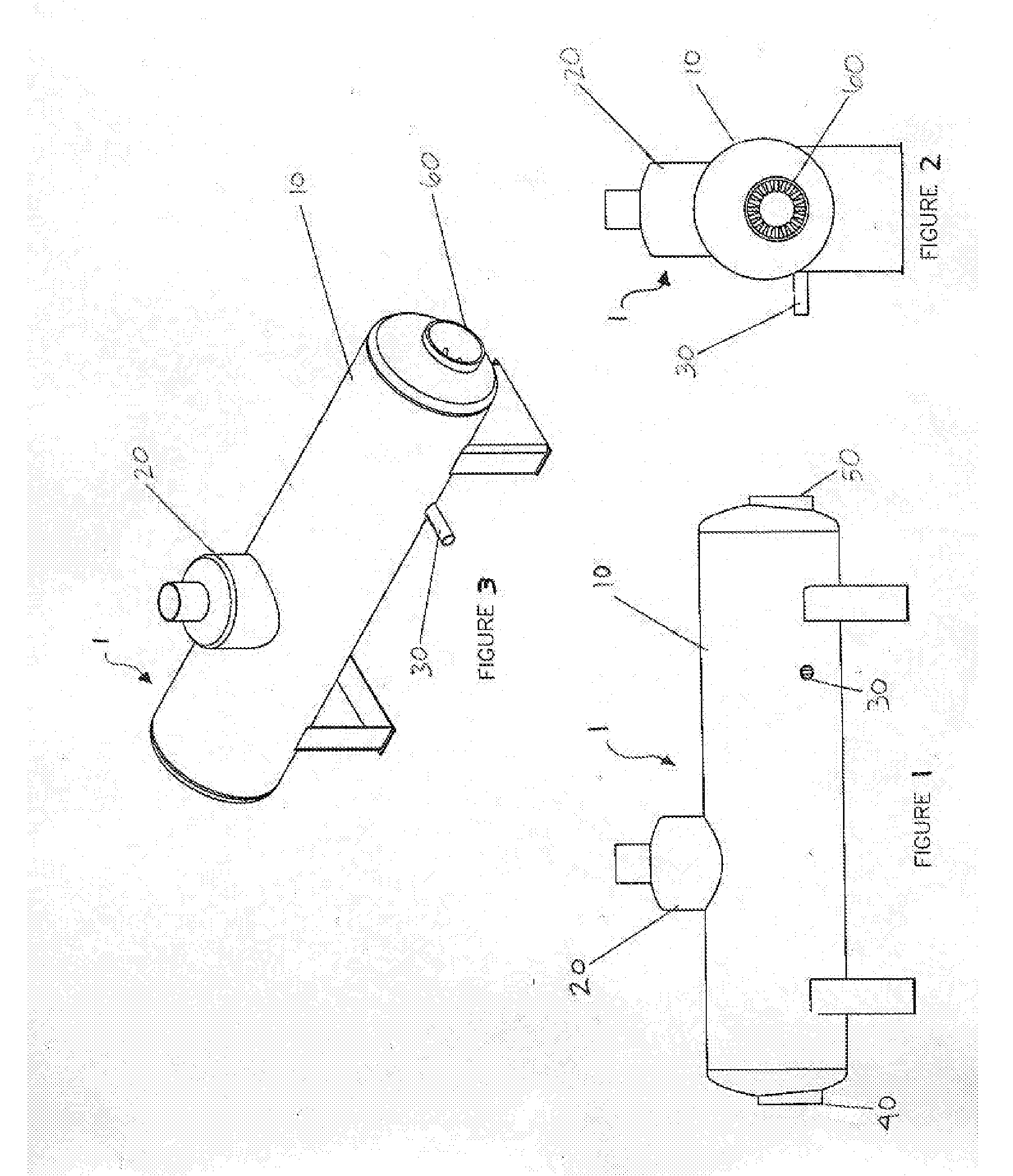

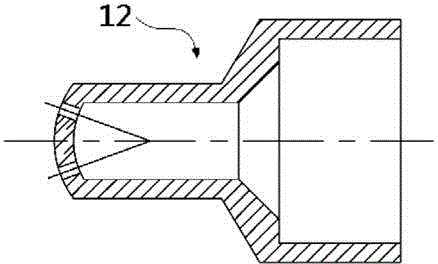

Biomass gas burner

The invention discloses a biomass gas burner. The biomass gas burner comprises a gas pipe (1) located at the axial center, an air pipe (2) arranged outside the gas pipe (1) in a sleeving mode, an ignition device (3) and a flame detection device (4), wherein a round sealing plate (5) with the front diameter smaller than the gas pipe (1) and a conical surface (6) connecting the front end edge of a pipe body with the round sealing plate (5) are arranged on the front end face of the gas pipe (1), and two circles of gas distribution nozzles (7) perpendicular to the conical surface (6) are arranged on the conical surface (6); a pressurization cylinder (8) is arranged in the gas pipe (1), and the ignition device (3) and the flame detection device (4) penetrate through the air pipe (2) and extend to the front end of the air pipe (2). The biomass gas burner has the beneficial effects that biomass gas is separated through the nozzles after being pressurized primarily, the pressure head of biogas gas is stable, flow balancing is achieved, and the diameter and length of a flame are guaranteed; burning is complete and sufficient, and heat efficiency is high.

Owner:广东宝杰环保科技有限公司

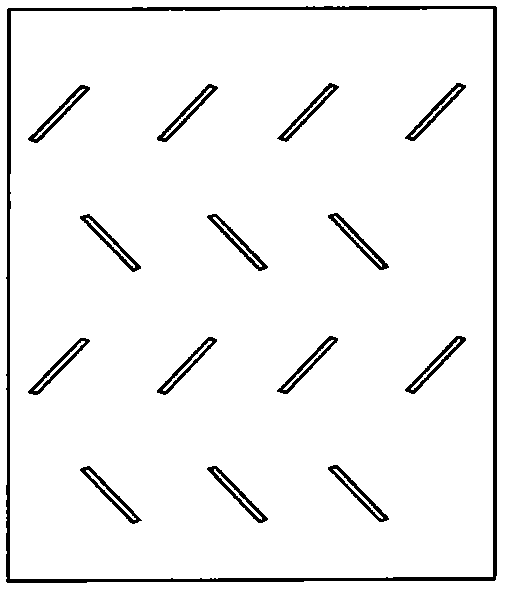

Fully-premixed metal net combustor

InactiveCN104791791AWell mixedUniform air distribution effectBurner material specificationsGaseous fuel burnerPorosityCombustor

The embodiment of the invention discloses a fully-premixed metal net combustor. A spiral flow type mixer is arranged on the upstream of a gas mixing and distributing device and arranged in a premixing cavity, the gas mixing and distributing device is arranged in a supporting element below the combustion surface, due to the fact that the spiral flow type mixer has the better gas and air mixing effect, the gas mixing and distributing device has the better uniform gas distributing effect, combustion is complete, and pollutants can be reduced. A high-temperature-resistant metal net serves as the combustion surface, the porosity of the metal net is large, air resistance is small, the mesh net is not likely to be blocked by tiny dust in air, and therefore the efficiency of a draught fan is high. Due to the adoption of the gas mixing and distributing device, the length-diameter ratio of the premixed combustor can be large, the premixed combustor with the high power can be manufactured, service life is long, and cost is low.

Owner:袁树月

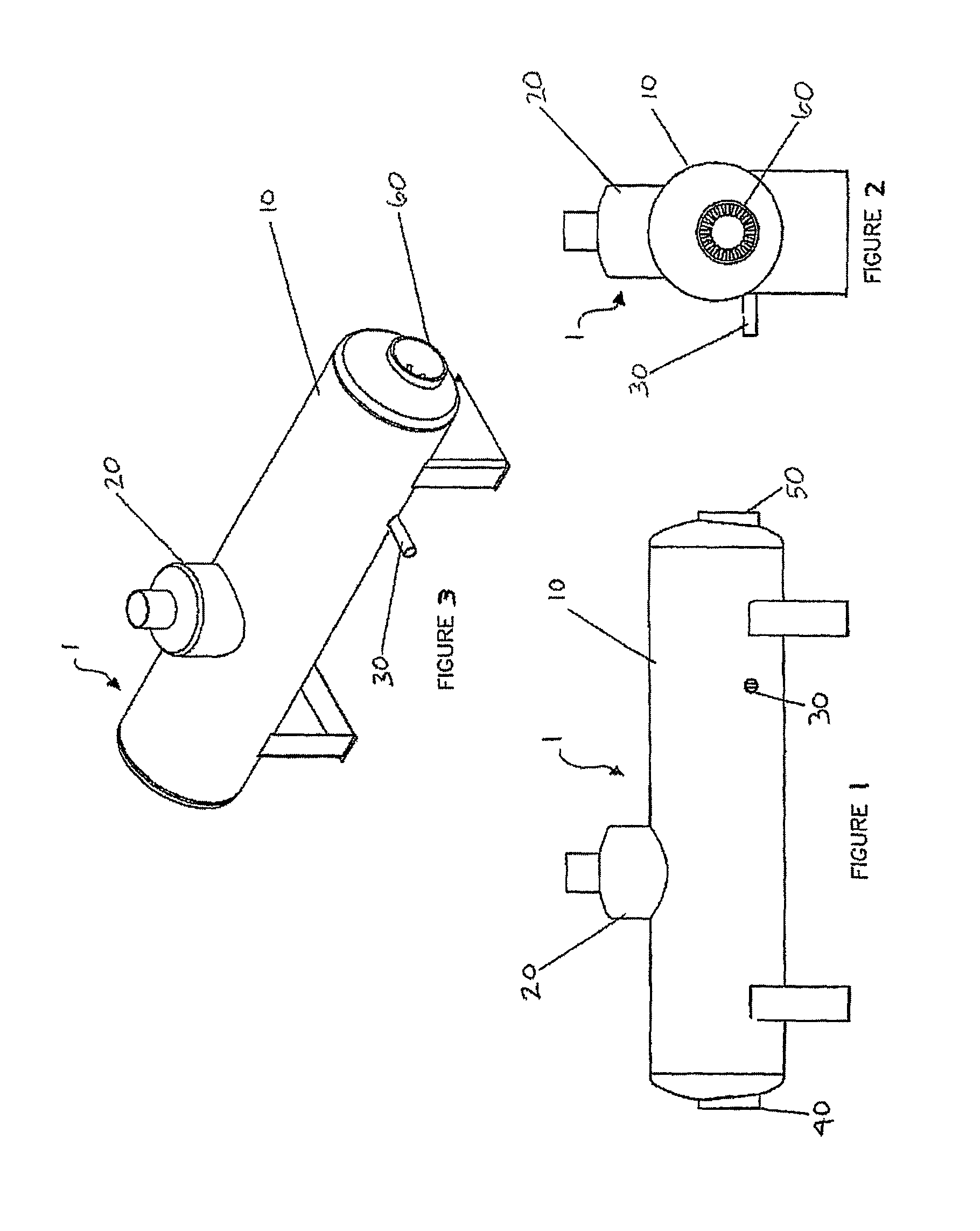

High-efficiency enhanced boiler

ActiveUS7413004B2Simple designOptimizationStationary tubular conduit assembliesFire-tube steam boilersEngineeringConvection

In devices known in the art, “conventional firetube” and “waste heat recovery” boilers each require many small tubes making successive passes within the boiler. In one embodiment of the invention, however, an enhanced conduit replaces numerous conventional small tubes. In some embodiments, the enhanced conduit incorporates a plurality of fins, each of which extends through a wall of the conduit. In other embodiments, the enhanced conduit incorporates a plurality of tubes along its outer surface, through which a heat transfer medium flows. Both designs enhance the heat transfer relationship between the hot fluid and the heat transfer medium by providing a continuous heat transfer relationship with the heat transfer medium, increasing the surface area involved in the heat transfer relationship and enhancing convection / conduction couples. For some applications, all of the tube banks of other devices in the art can be replaced by one continuous enhanced conduit.

Owner:OKONSKI SR JOHN E +1

High-efficiency enhanced boiler

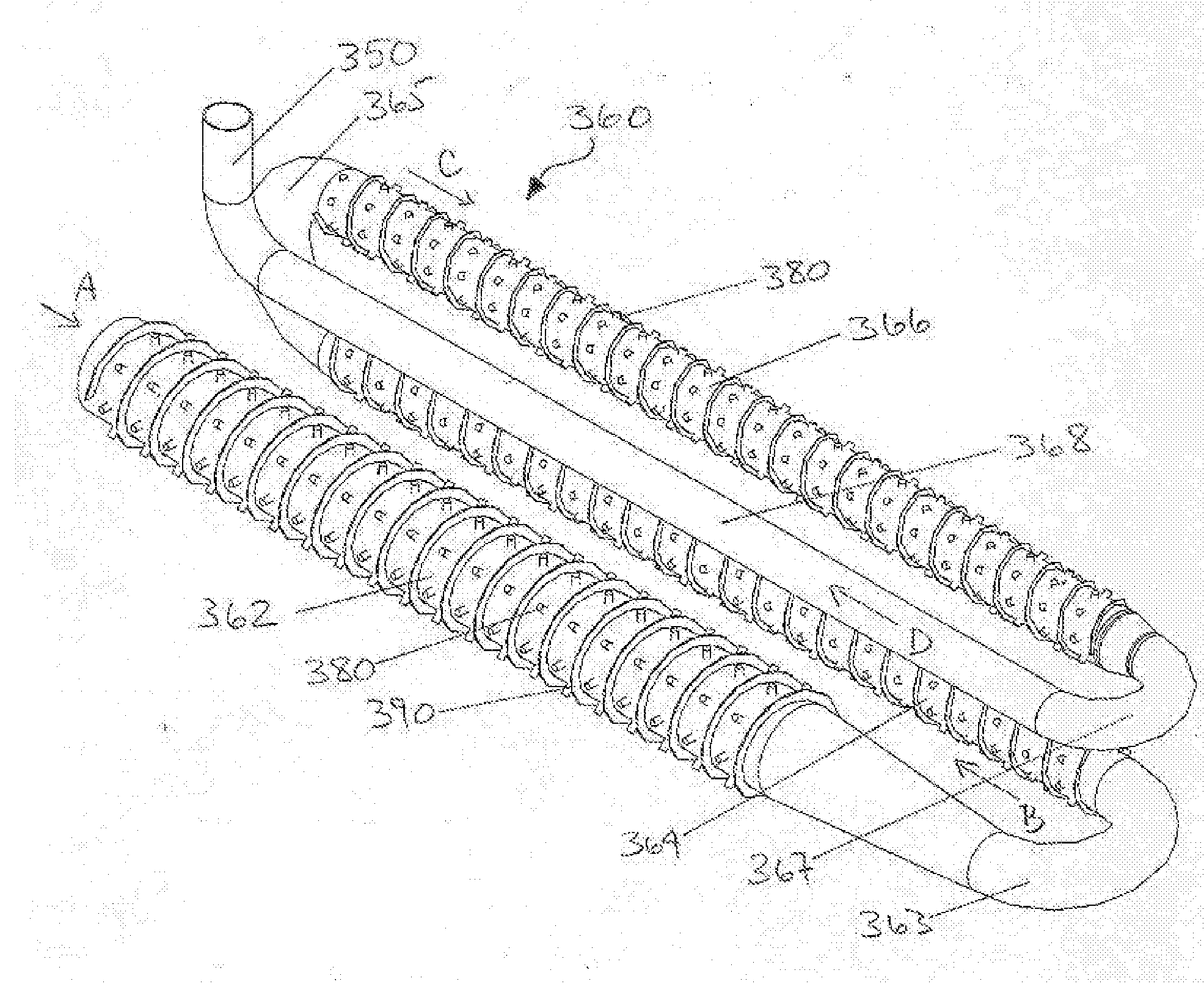

ActiveUS20110108238A1Increase surface areaEnhancing convection/conduction coupleAir heatersHeat exhanger finsEngineeringRADIUS

The invention provides high-efficiency heat transfer devices and apparatuses In one embodiment, the invention includes a vessel capable of containing the heat transfer medium, a conduit extending through a wall of the vessel, the conduit having a first surface for contacting the heat transfer medium and a second surface for contacting a fluid within the conduit, a helical member residing around and along a length of the first surface of the conduit capable of angularly directing a flow of the heat transfer medium along the first surface of the conduit; and a plurality of fins helically arranged adjacent the helical member, each fin extending through a wall of the conduit and being capable of directing at least a portion of the heat transfer medium to an area within a radius of the conduit.

Owner:OKONSKI JR JOHN E +1

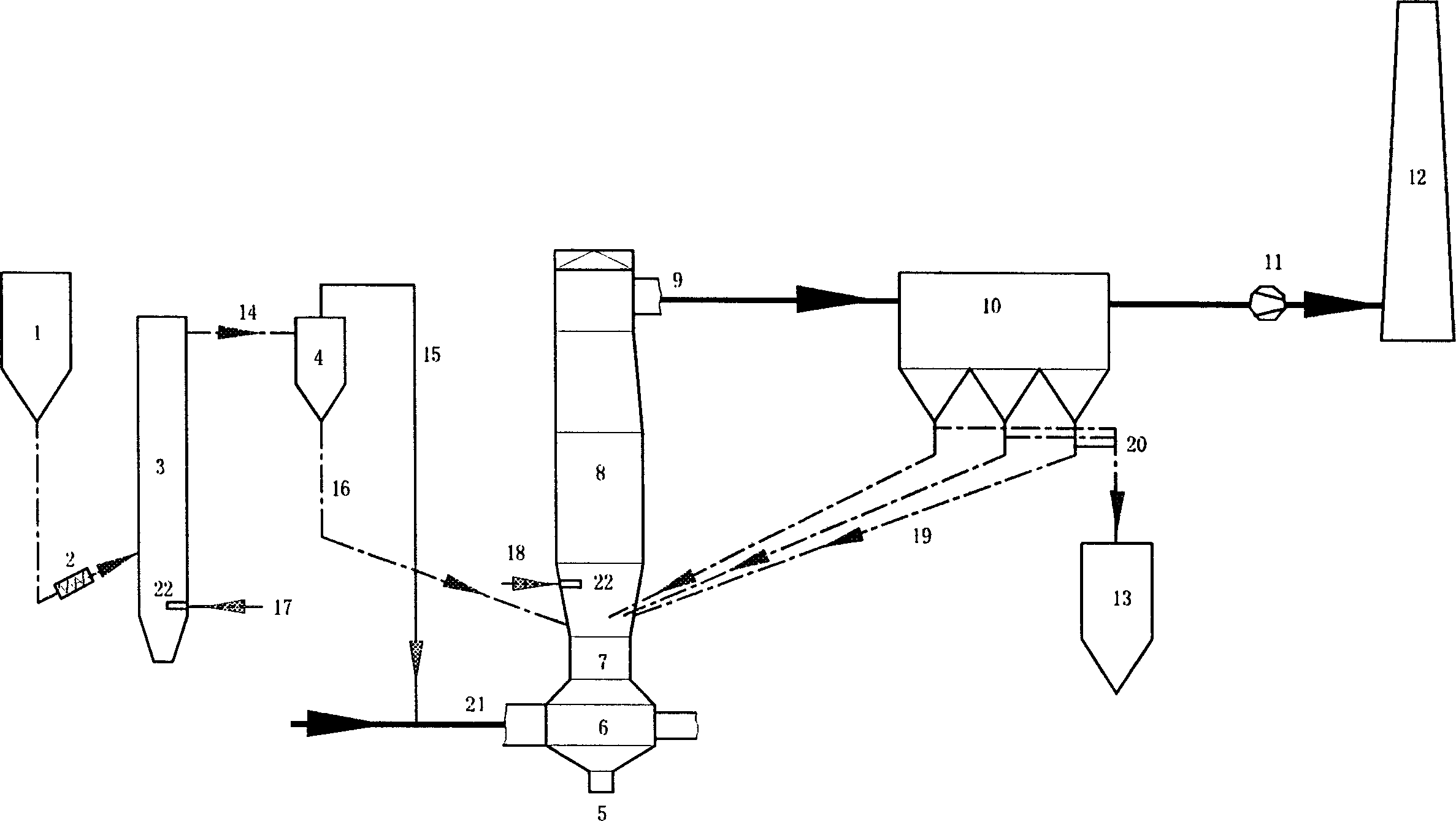

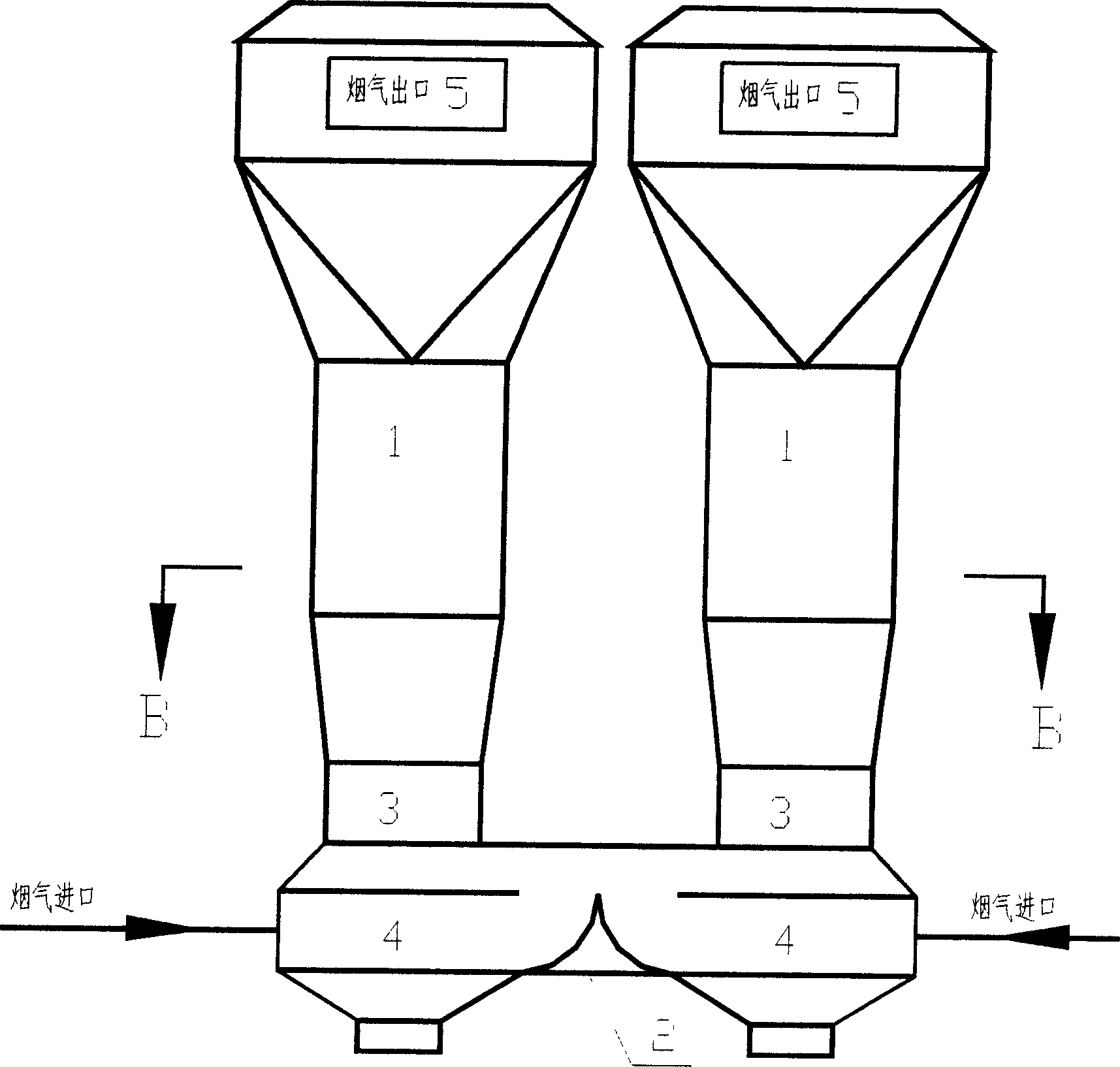

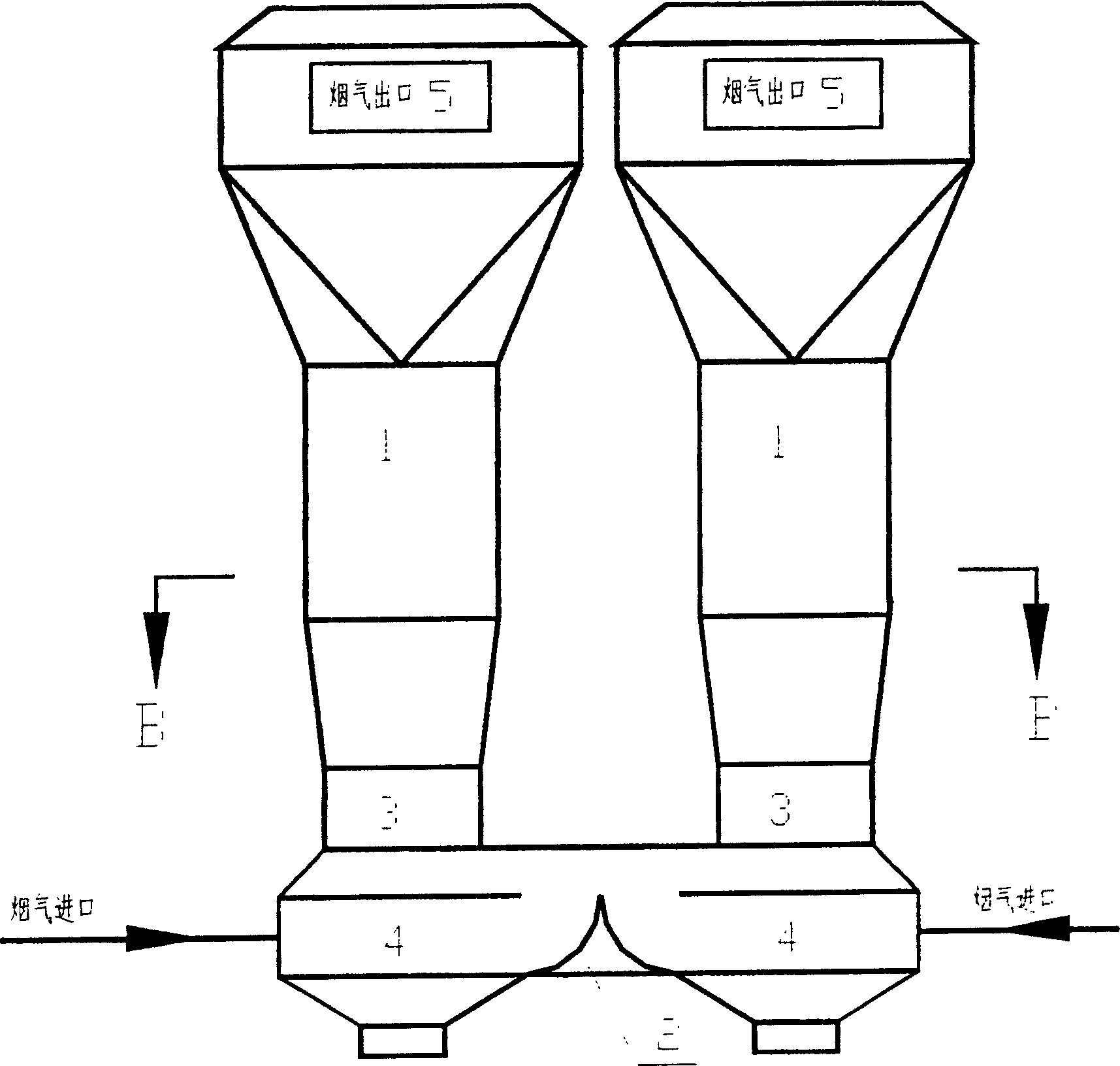

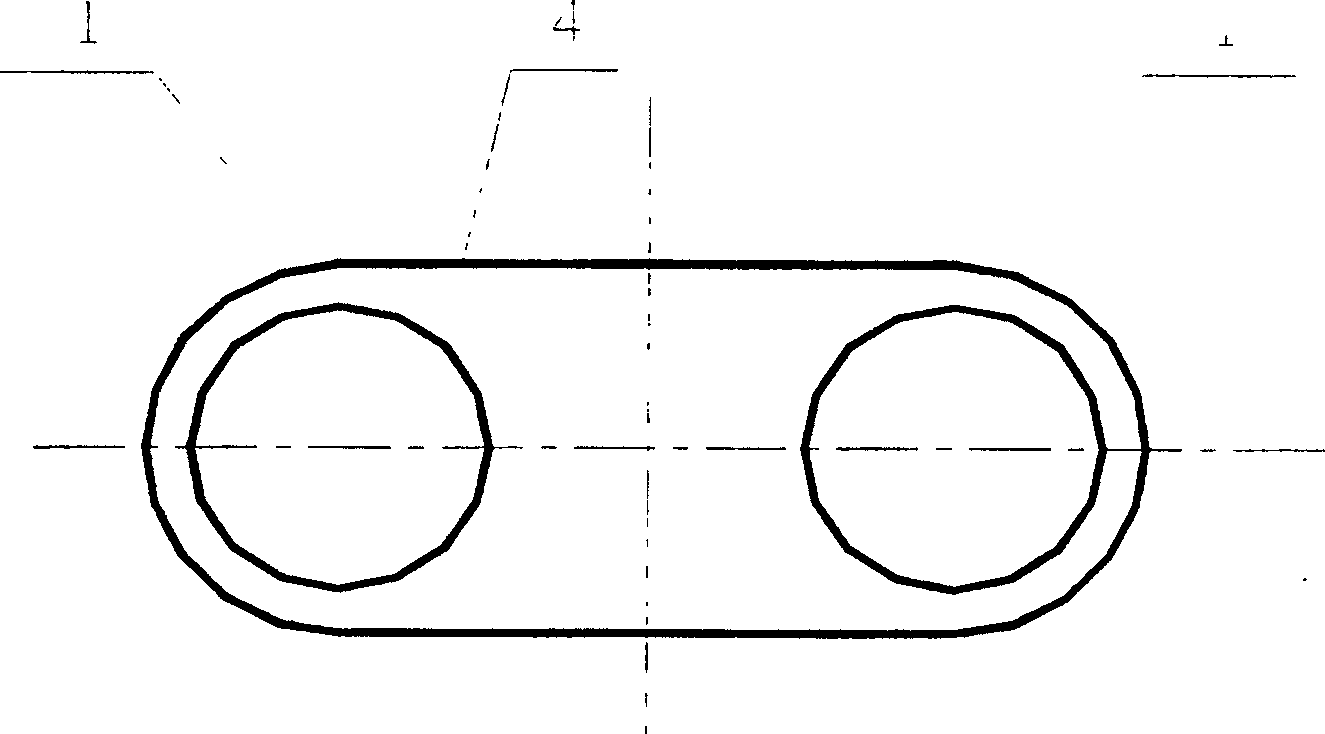

Dry process stack gas desulfur system using malti tower in parallel structure

InactiveCN1513585ASolve the fluidization problemSolve flow field organization problemsDispersed particle separationHigh intensityEngineering

A dry-method fume-desulfurizing system with parallel more towers features that its desulfurizing reaction tower is composed of 2 or more desulfurizing reaction subtowers, whose fume mixing chambers at their bottom are parallelly connected to form a large desulfurizing reaction system with wide regulation range. Said fume mixing chamber has the guide plate for uniformly distributing the fume to the fume jet accelerator in each substower. There is a composite fume jet in the middle of said subtower to form a strong turbulent mixing region.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Gas thrust vector control structure and method of hybrid rocket engine

InactiveCN107642436ALight weight designSolution to short lifeRocket engine plantsCombustion chamberControl vector

The invention discloses a hybrid rocket engine structure and method applicable to vector control. Secondary jet injection orifices are formed in the side wall of a front burning chamber of the hybridrocket engine; meanwhile second jet holes are evenly formed in the expansion segment of a spraying pipe in the circumference direction, and injectors are mounted in the secondary jet holes; the secondary jet injection orifices are communicated with the injectors through conveying pipes; the injectors are communicated with the interior of the spraying pipe through spraying and injecting passages formed in a thermal insulation layer of the spraying pipe; mixed gas in the front burning chamber is introduced to the expansion segment of the spraying pipe to conduct secondary spraying through the conveying pipes with the help of the secondary jet injection orifices. The mechanical mechanism is low in design mass, long in service life and suitable for long-time work; spraying gas is sprayed out from the spraying pipe, the engine performance is improved, and specific impulse loss caused by thrust adjustment is reduced.

Owner:BEIHANG UNIV

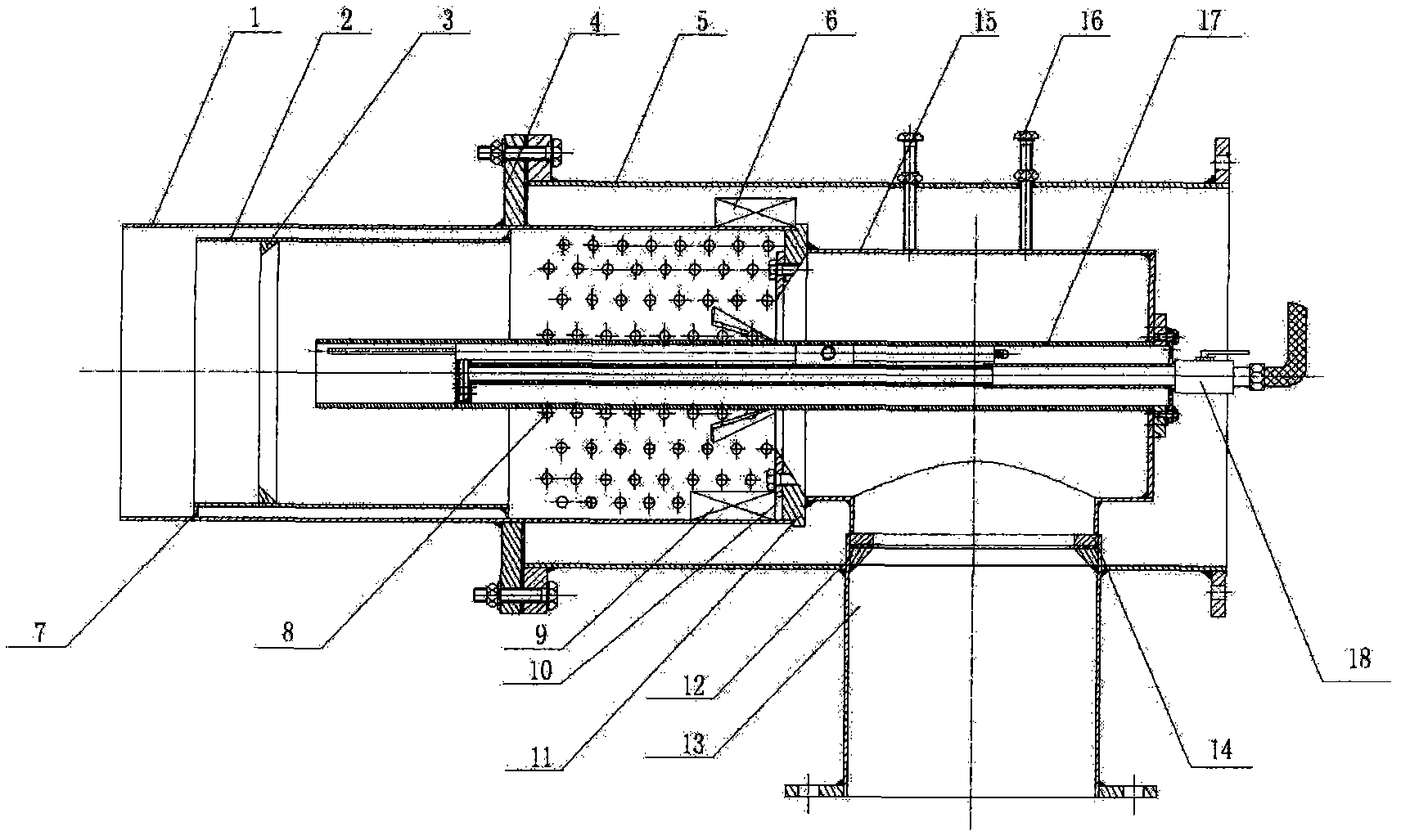

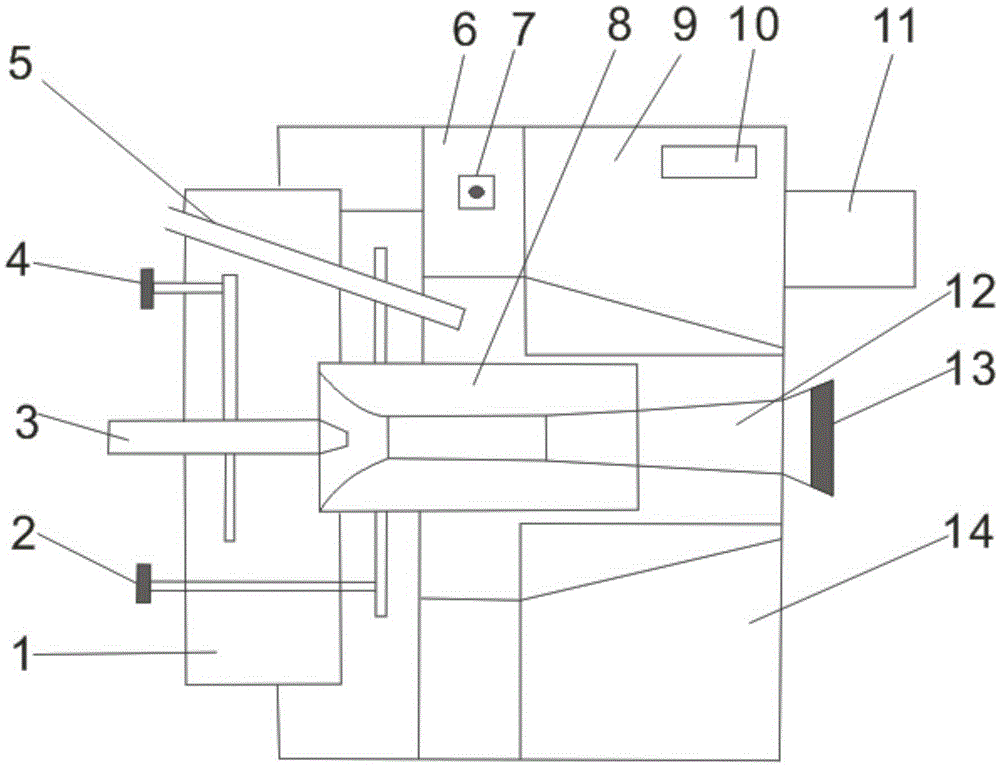

Novel energy-saving and environment-friendly combustion engine

InactiveCN105402731AReduce consumptionFast heatingFuel supply regulationIndirect carbon-dioxide mitigationBrickSprayer

The invention relates to the field of environmental protection technology and particularly relates to a novel energy-saving and environment-friendly combustion engine, which comprises a muffler, a primary air port, a secondary air port, a nozzle, an igniter, an injector, a sprayer, a plum blossom-type flue brick, a nameplate, a motor, a combustion cylinder, an air pressure switch, a control box and an ignition transformer. The injector and the sprayer are directly connected to form an integral structure. The nozzle and the motor are directly connected and are positioned right in front of the muffler. The nameplate is arranged on the left upper part of an instrument. The igniter is arranged in front of the muffler. The combustion cylinder is directly connected with the ignition transformer and is right above the sprayer. According to the technical scheme of the invention, through reasonably organizing the combustion process, the above combustion engine is more energy-saving, more environment-friendly, higher in combustion efficiency, stable in combustion, good in flame performance, strong in radiation capability, high in heat recovery capability, small in noise, less in amount of noxious gas and smoke, convenient to use, simple in design, low in cost and worth to popularize and use widely during the working process.

Owner:TIANJN TAIFENG XINGYE TECH CO LTD

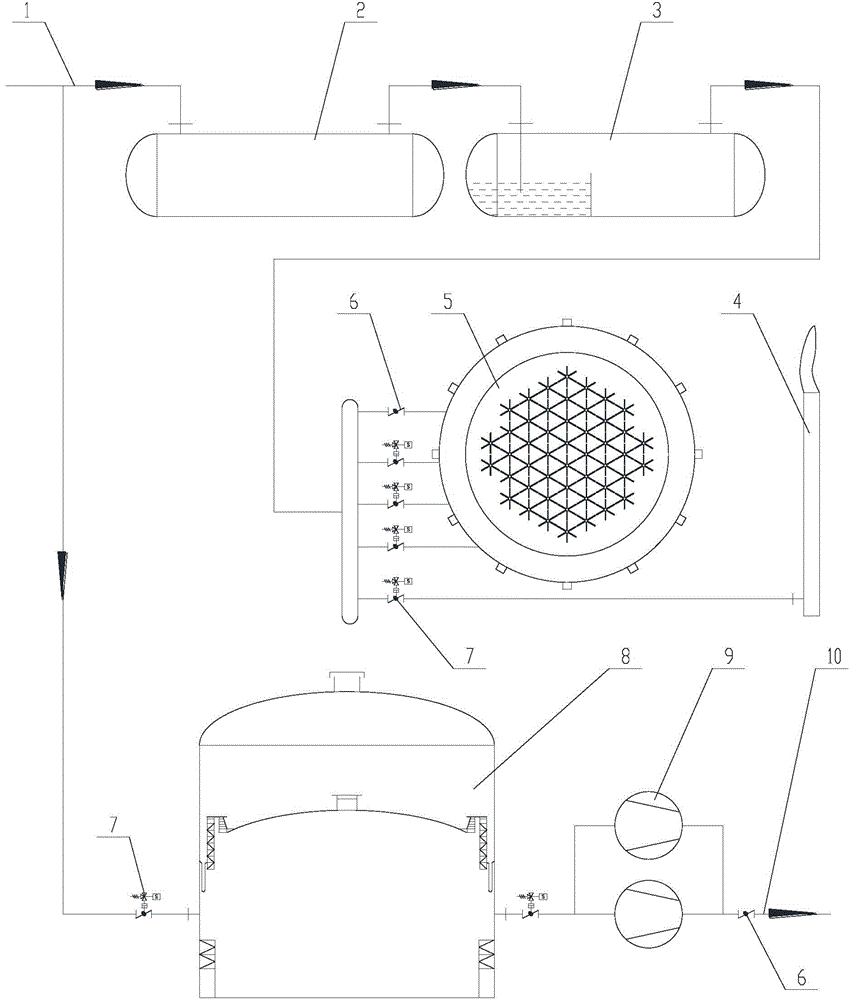

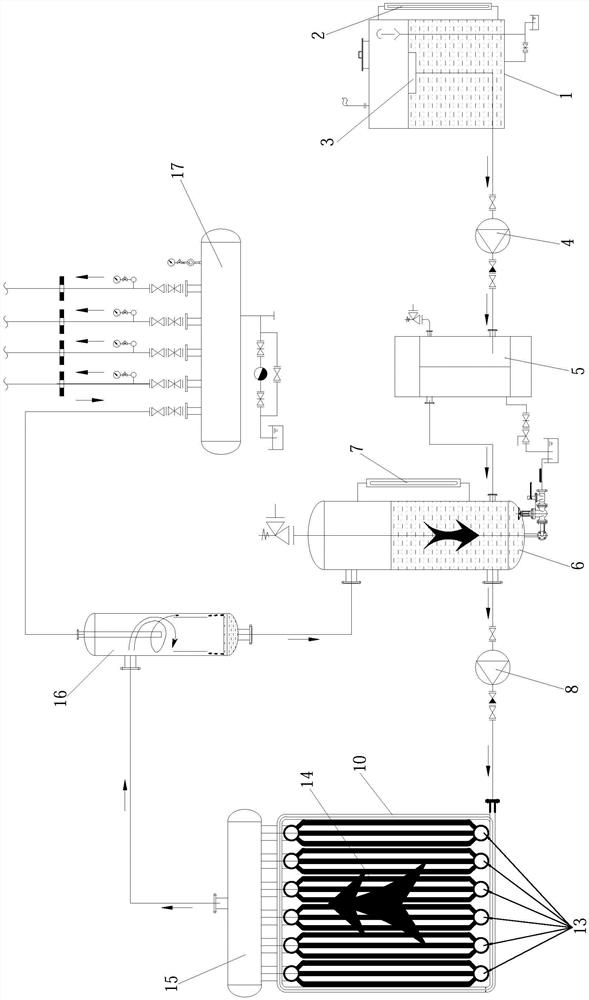

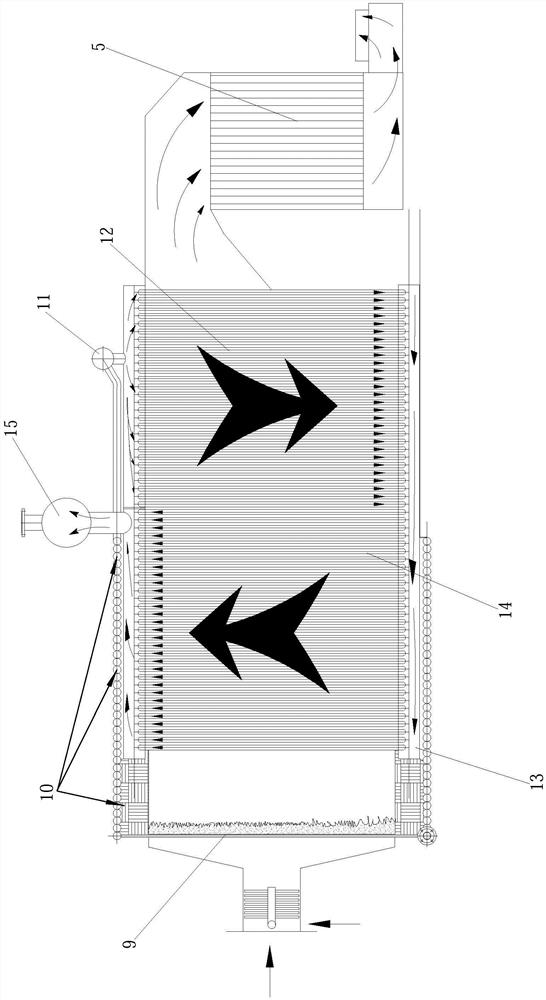

Direct recovery method and device applicable to industrial high-flow large-regulation-ratio flare gas

ActiveCN104964291AMeet Direct RecyclingIncrease the turndown ratioIncinerator apparatusRecovery methodEmergency treatment

The invention provides a direct recovery method and device applicable to industrial high-flow large-regulation-ratio flare gas. The flare gas sent from a flare gas pipe network is divided into two ways, wherein one way of flare gas can be conveyed to a gas cabinet, boosted through a compressor unit and then conveyed to a fuel gas pipe network; the other way of flare gas can pass through a liquid separation tank and arrive at a water sealed tank; when the pressure of the flare gas is higher than the height of a water seal of the water sealed tank, the flare gas enters a ground torch or an elevated torch to be incinerated; on a normal operating condition, the flare gas is conveyed to the fuel gas pipe network, and the ground torch and the elevated torch are put out; on a small accident condition, the flare gas is discharged into the ground torch to be incinerated, the gas cabinet operates normally, and the elevator torch is put out; on an emergent and large accident condition, the ground torch, the elevated torch and the gas cabinet conduct emergency treatment. Through the method and device, the disposal capacity is high, the flare gas with the discharge amount being 2000 tons per hour or more can be incinerated and treated through combined utilization of the ground torch and the elevated torch, and the requirement for safety discharge is met. The direct recovery method and device have the advantages that safety and reliability are achieved, and configuration is reasonable.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

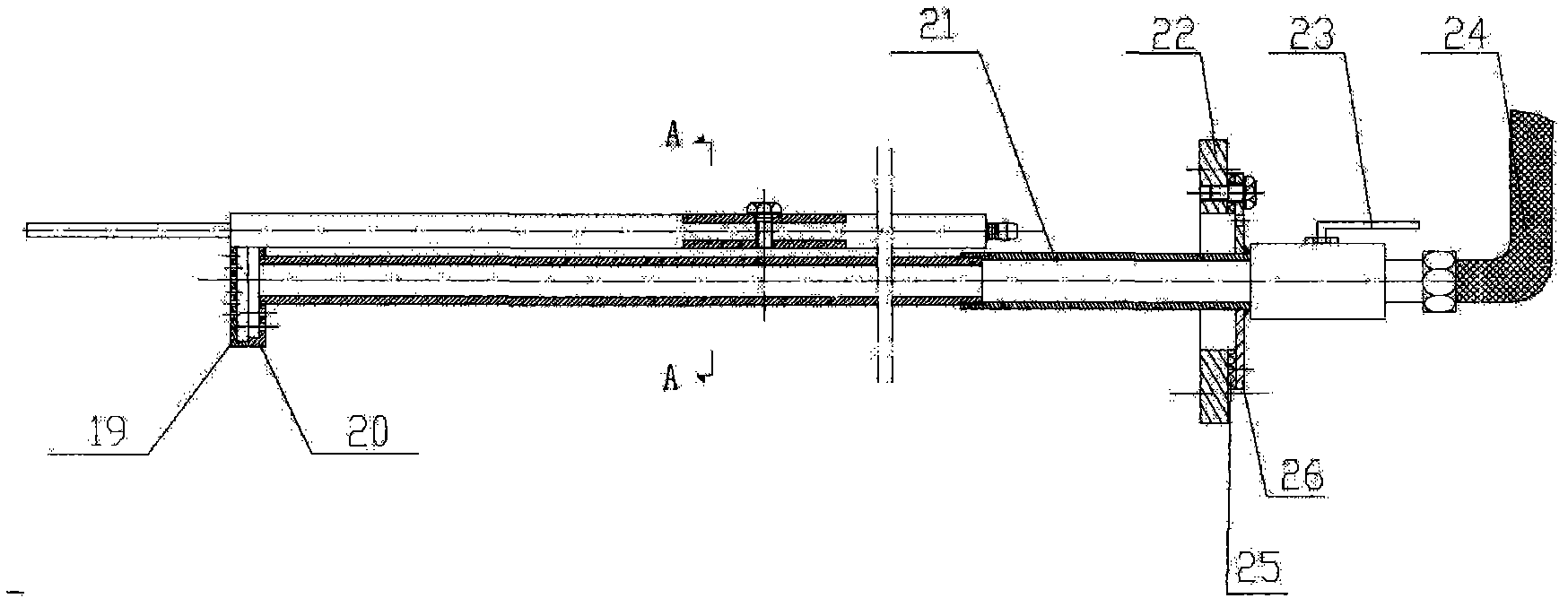

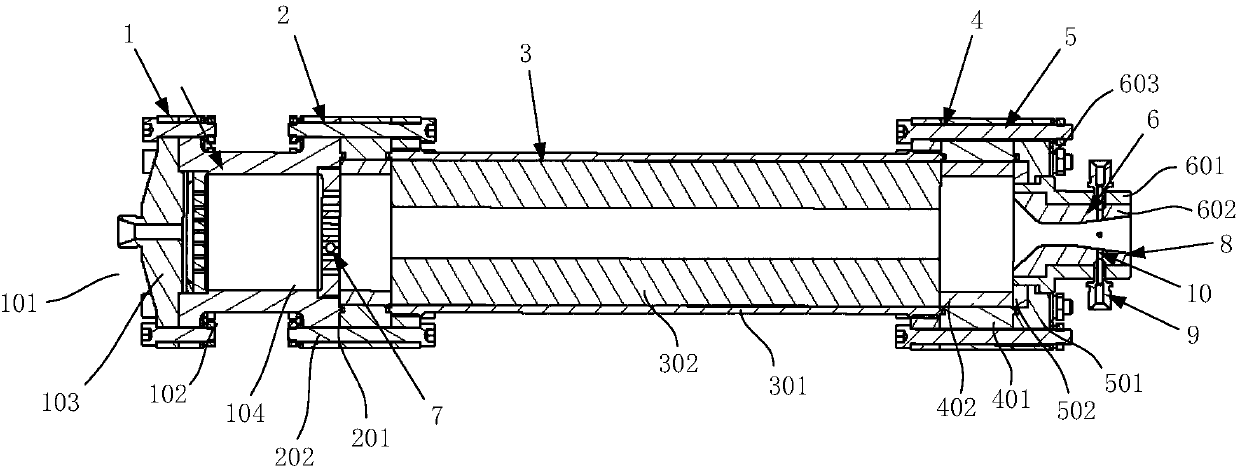

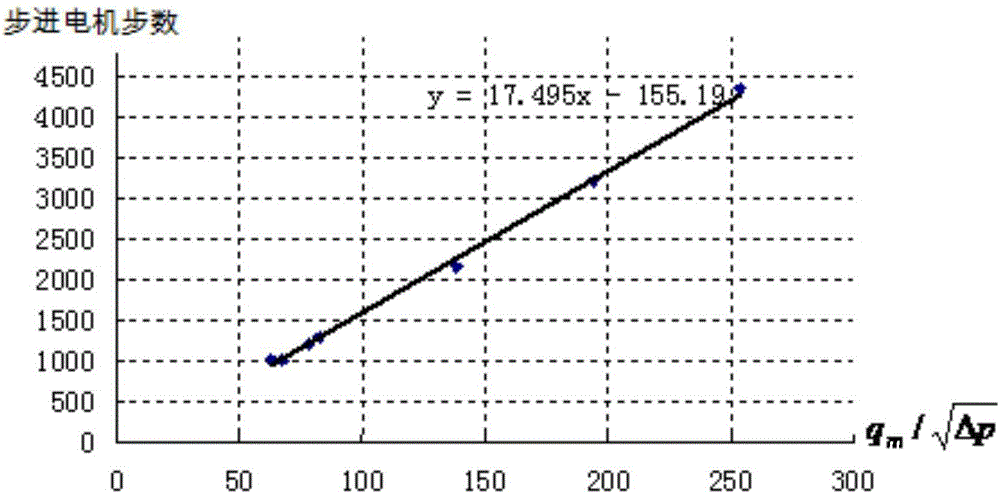

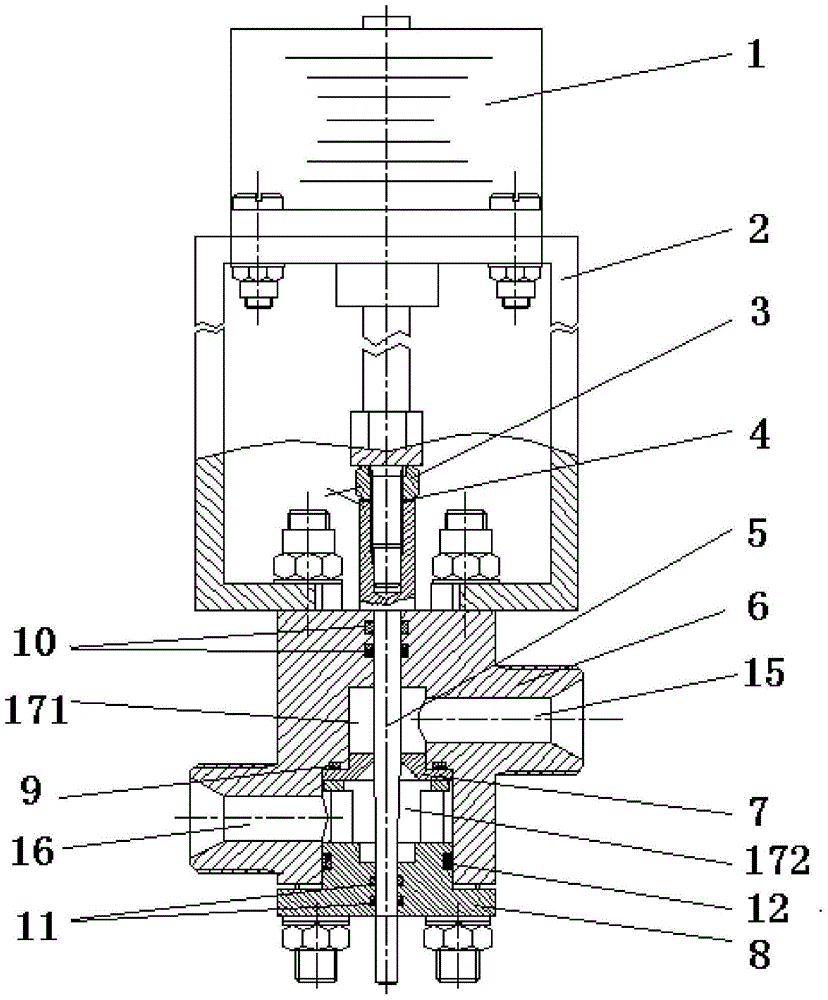

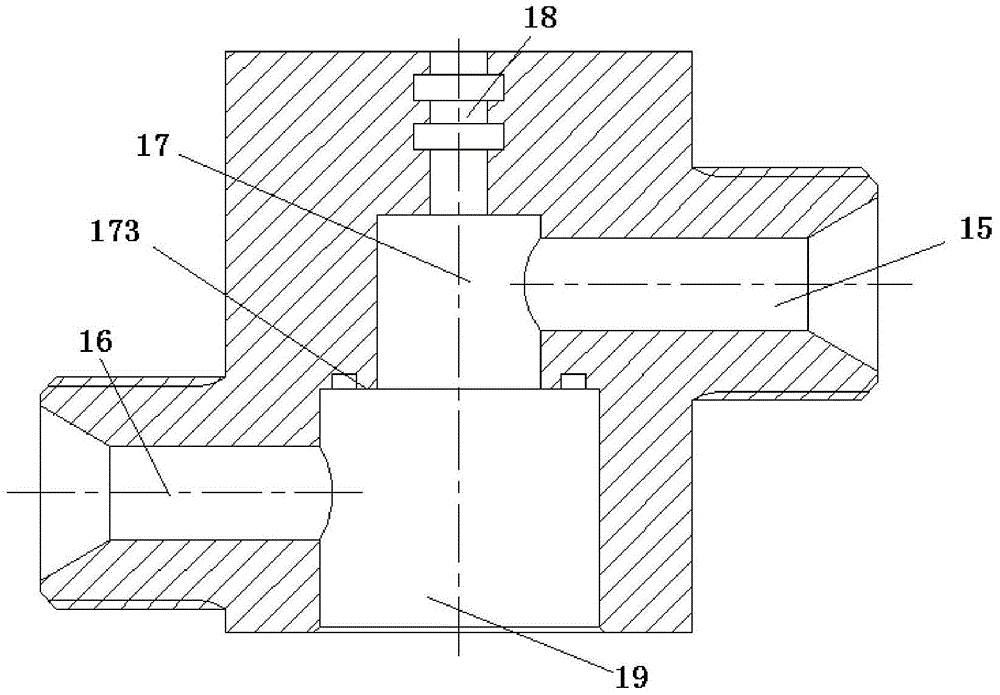

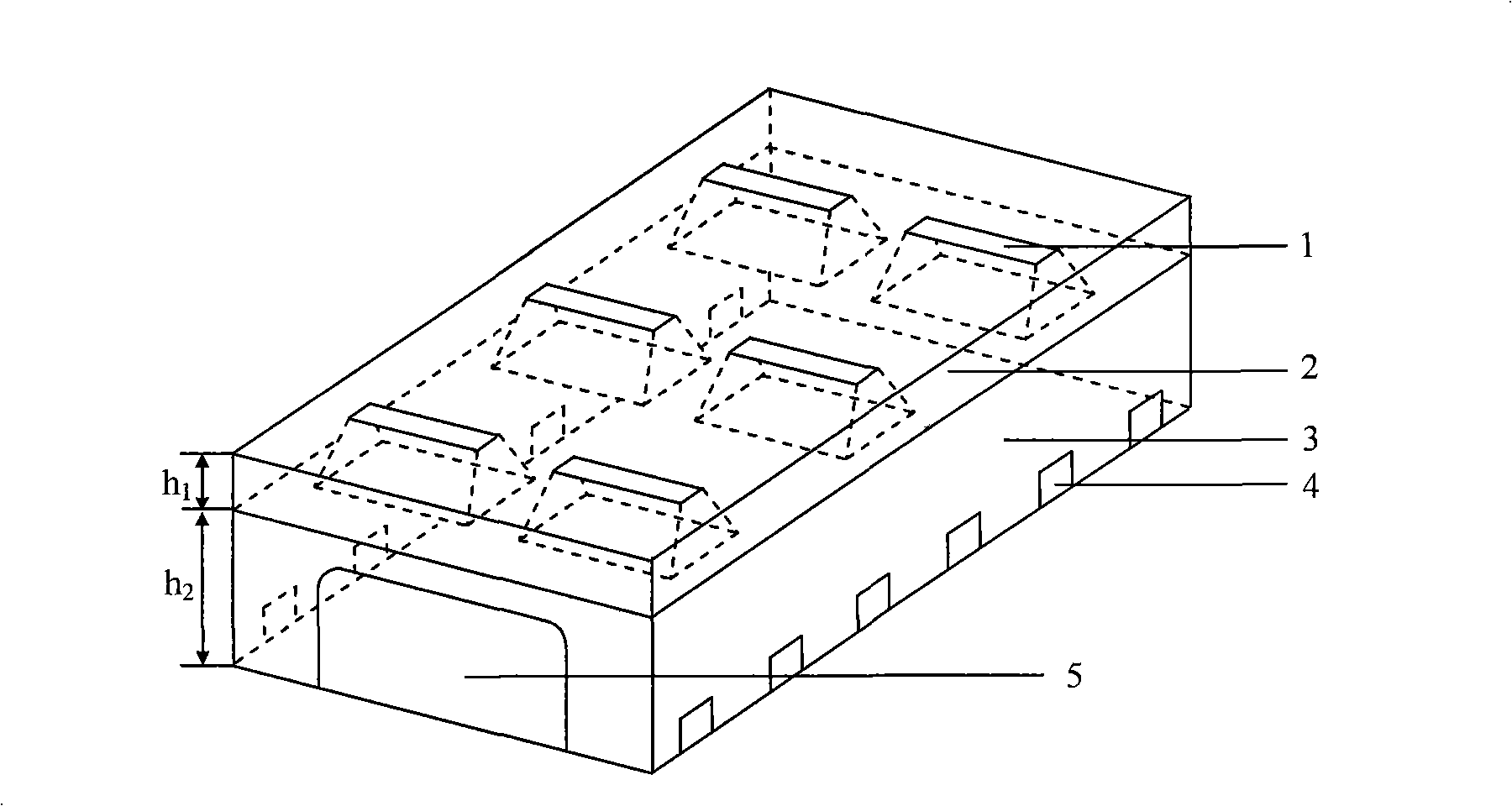

A high pressure and large ratio flow regulating valve

ActiveCN105386894BGuaranteed reliabilityHigh control precisionOperating means/releasing devices for valvesLift valveRubber ringMotor drive

The invention relates to a high-pressure large-transformation-ratio flow regulating valve which is composed of a linear stepping motor, a regulating rod, a machine frame, a throttling pore plate, a saddle-shaped gasket, a lock nut, a shell, a pressing plate and the like. A driving mechanism comprises the linear stepping motor. A regulation part is composed of the regulating rod and the throttling pore plate. The linear stepping motor is connected with the shell through the machine frame. A shaft of the linear stepping motor and the regulating rod are connected together and locked tightly through the saddle-shaped gasket and the lock nut. The throttling pore plate is installed inside the shell in a pressed mode through the pressing plate. The throttling pore plates with different pore diameters can be replaced according to different flow regulation ranges. In order to guarantee the sealing performance under high pressure, motive seal positions of external leakage are sealed through two O-shaped rubber rings. In the flow regulation process, a control signal is input to the linear stepping motor, the linear stepping motor drives a regulation element to move upwards and downwards, the flow area of the throttling pore plate is changed, and accordingly flow regulation is achieved.

Owner:XIAN AEROSPACE PROPULSION INST

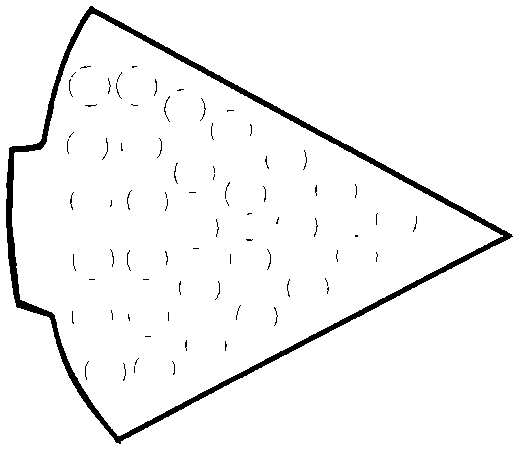

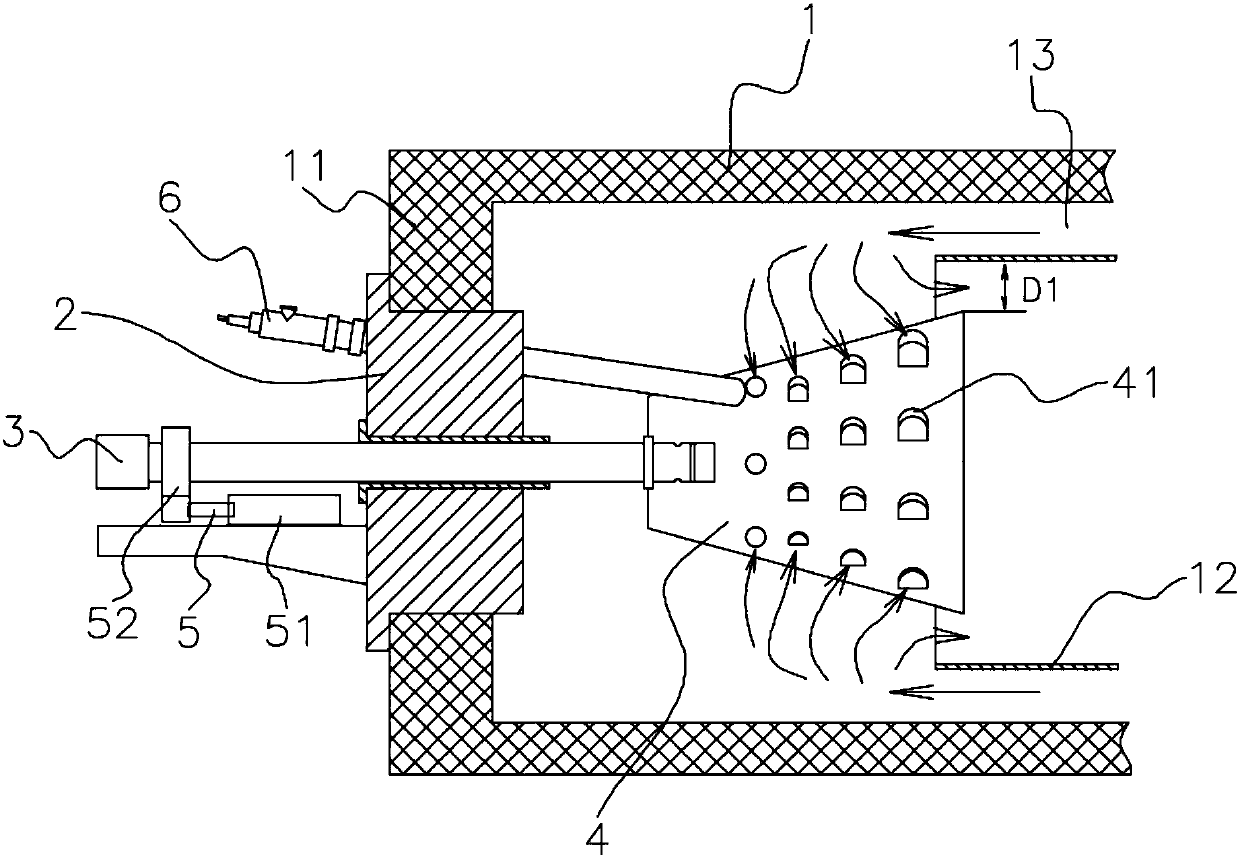

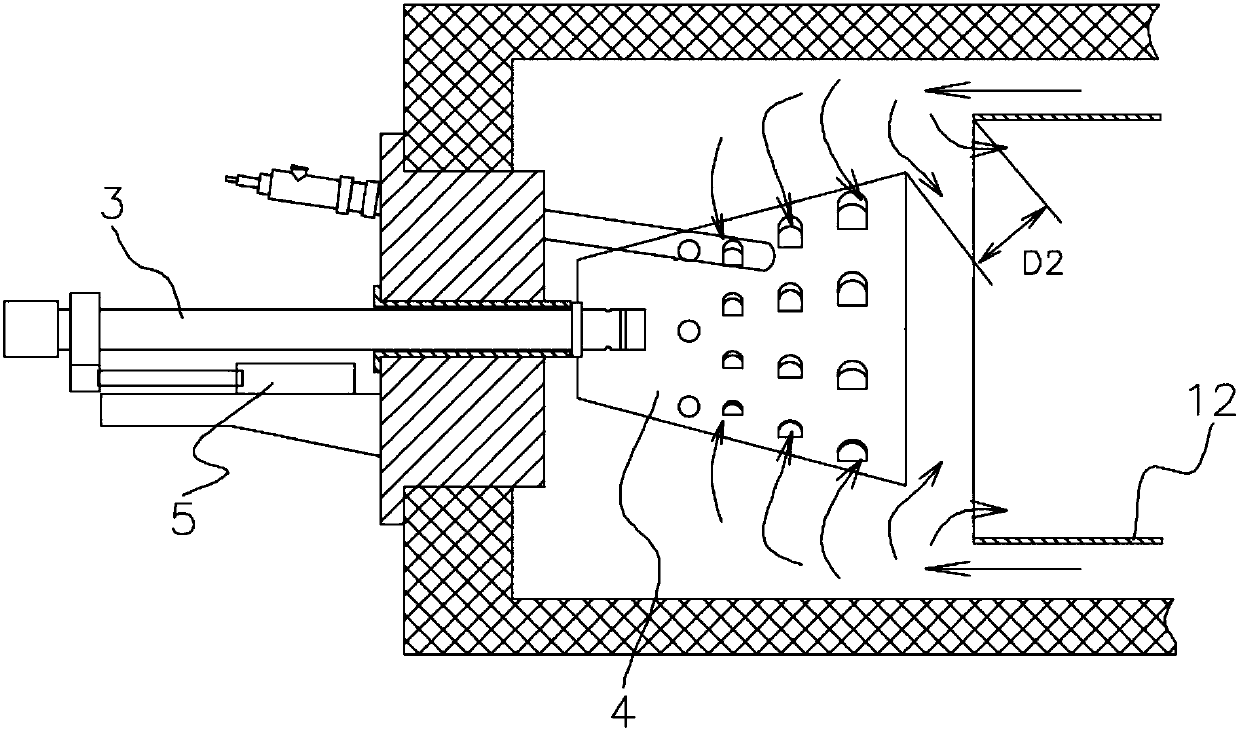

Double-rotational-flow flat flame burner

ActiveCN106122946ALarge adjustment ratioGuaranteed uptimeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelRotational flowAir–fuel ratio

The invention discloses a double-rotational-flow flat flame burner. The double-rotational-flow flat flame burner comprises a center air duct, a gas pipe, a main air pipe and a burner body, wherein a combustion channel is arranged on the burner body; the center air duct, the gas pipe and the main air pipe are sequentially and coaxially arranged from inside to outside; the burner body is arranged at an air outlet of the main air pipe; the combustion channel coaxially communicates with the air outlet of the main air pipe; a gas hydrocyclone and a main air hydrocyclone are arranged at the positions, located at the air outlet, of the gas pipe and the main air pipe correspondingly; the gas hydrocyclone is arranged between the center air duct and the gas pipe; the main air hydrocyclone is arranged between the gas pipe and the main air pipe; and an air outlet of the center air duct and the air outlet of the main air pipe are located in front of an outlet of the gas pipe. By means of the structure, air flow can be better attached to the wall to be spread to burn, a stable fire plate is formed, the regulating ratio of the burner is improved, especially when the load of the burner is small, flat flame can still be formed, normal operation can be achieved under the working condition of the imbalance air-fuel ratio, and the adjustability, applicability and reliability of the flat flame burner are improved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Dry process stack gas desulfur system using multi tower in parallel structure

InactiveCN1217728CSolve the fluidization problemSolve flow field organization problemsDispersed particle separationEngineeringHigh intensity

A dry-method fume-desulfurizing system with parallel more towers features that its desulfurizing reaction tower is composed of 2 or more desulfurizing reaction subtowers, whose fume mixing chambers at their bottom are parallelly connected to form a large desulfurizing reaction system with wide regulation range. Said fume mixing chamber has the guide plate for uniformly distributing the fume to the fume jet accelerator in each substower. There is a composite fume jet in the middle of said subtower to form a strong turbulent mixing region.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

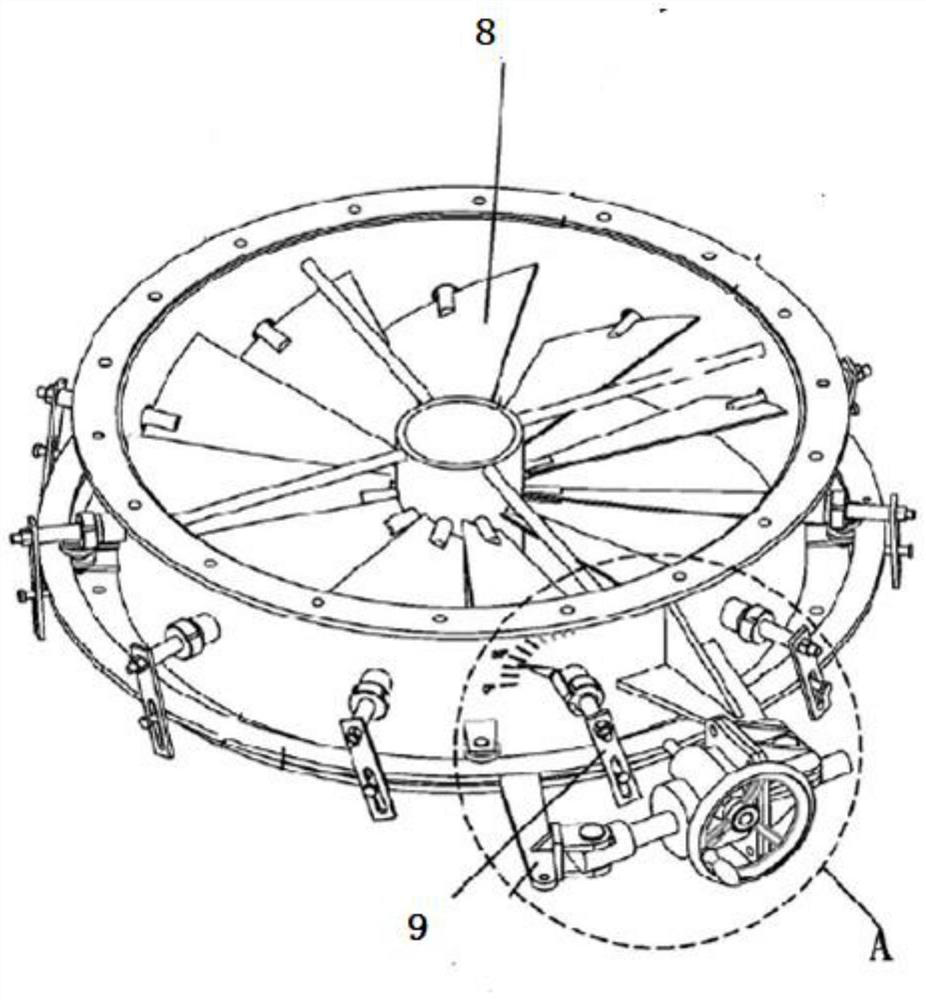

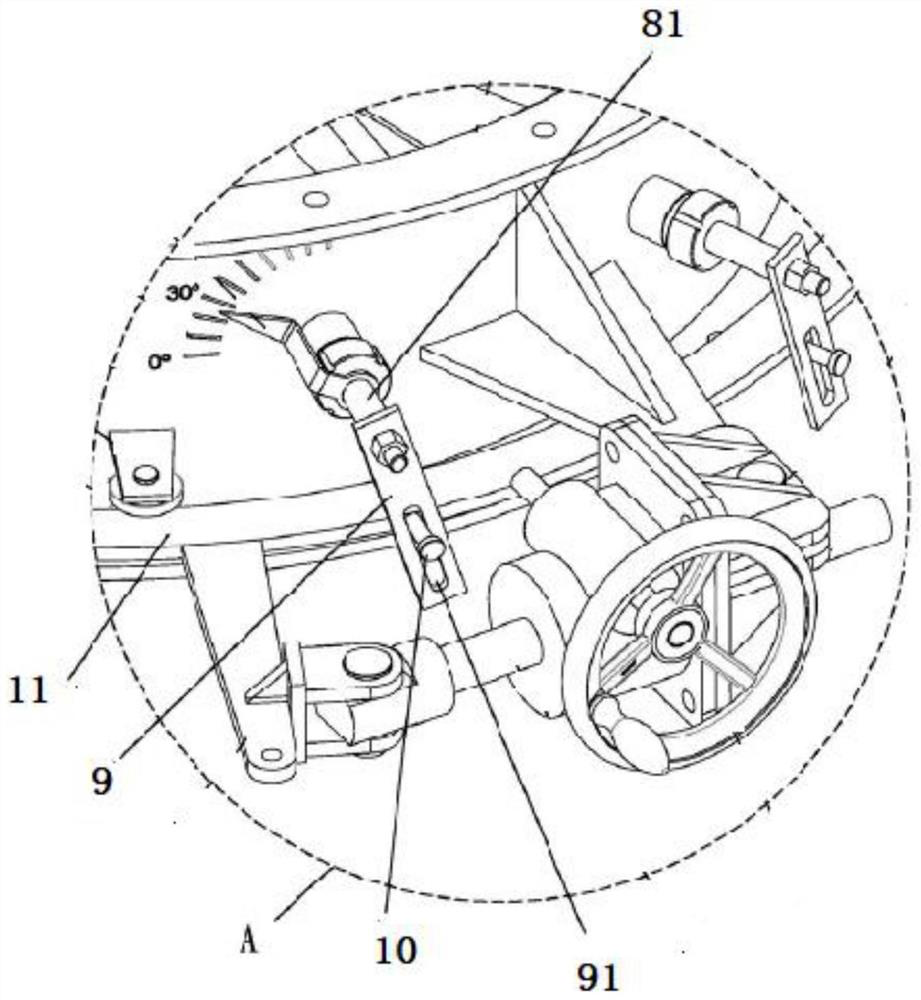

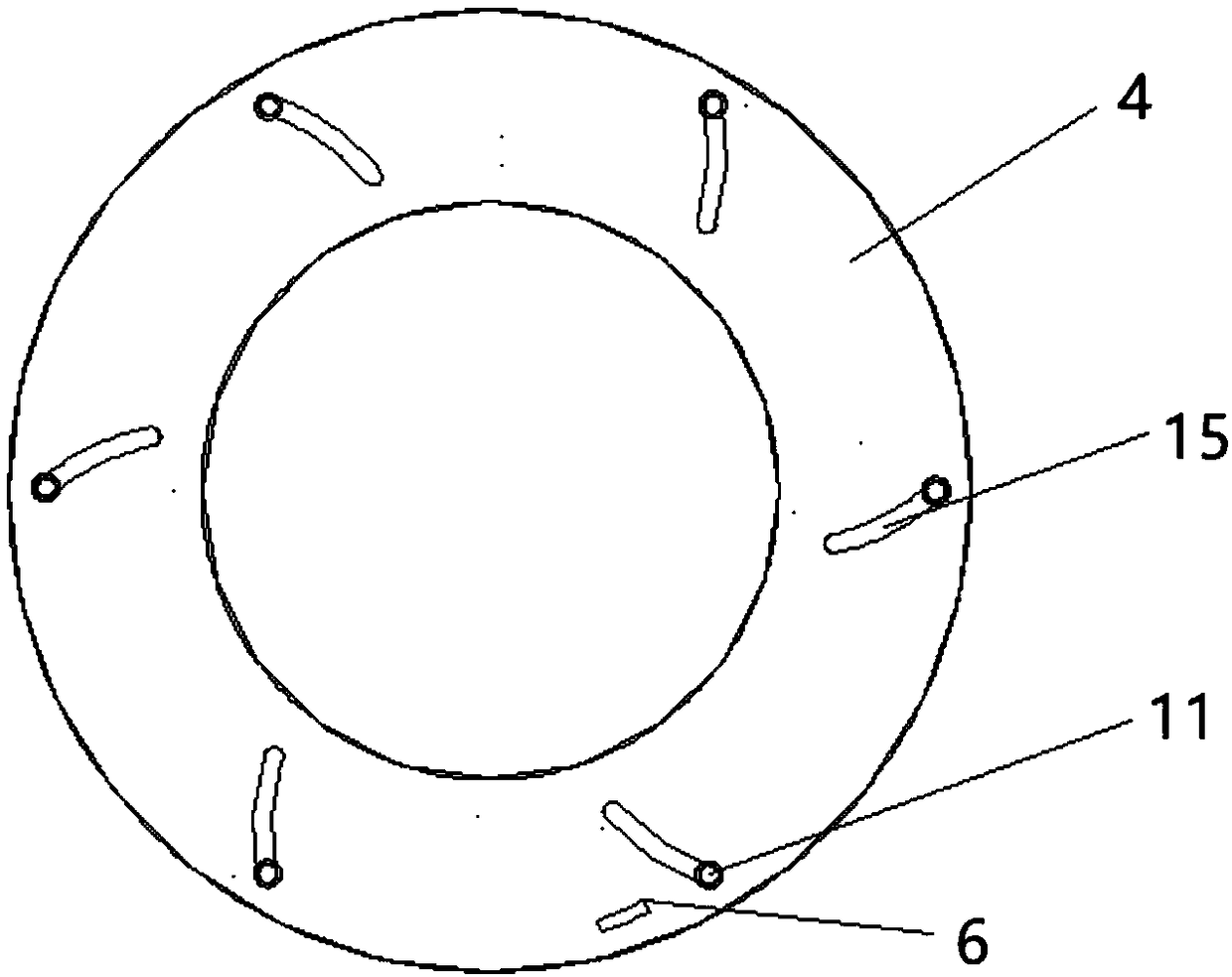

Adjustable swirl blade assembly and flat flame burner comprising same

ActiveCN113932220AEasy to adjustLarge adjustment ratioIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorCoaxial line

The invention relates to an adjustable swirl blade assembly and a flat flame burner comprising the same, and belongs to the technical field of combustion equipment. The adjustable swirl blade assembly comprises an adjustable swirl blade assembly body and a blade transmission device, and the body comprises a central rectification body, an outer cylinder, an inner cylinder and a plurality of rotatable blades which are coaxially arranged; the blade transmission device comprises a plurality of blade rotating shafts which are fixedly connected with the blades and are used for controlling the blades to rotate, transmission connecting rods which are fixedly connected with one ends of the blade rotating shafts in a one-to-one correspondence manner, a total connecting ring which is connected with the transmission connecting rods and surrounds the adjustable swirl blade assembly body, and an operating rod which is connected with the total connecting ring and is used for controlling the total connecting ring to move; and each transmission connecting rod is formed by rotationally connecting three rigid connecting rods, and two rotating pairs with non-coaxial lines and non-parallel rotating shafts are formed at the joint. The technical problem that in a traditional device, control over blades is not accurate is solved, a combustor can operate under the small-load working condition, the large air-fuel ratio working condition and the condition that the fuel heat value fluctuates violently, and stable flat flames are formed.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

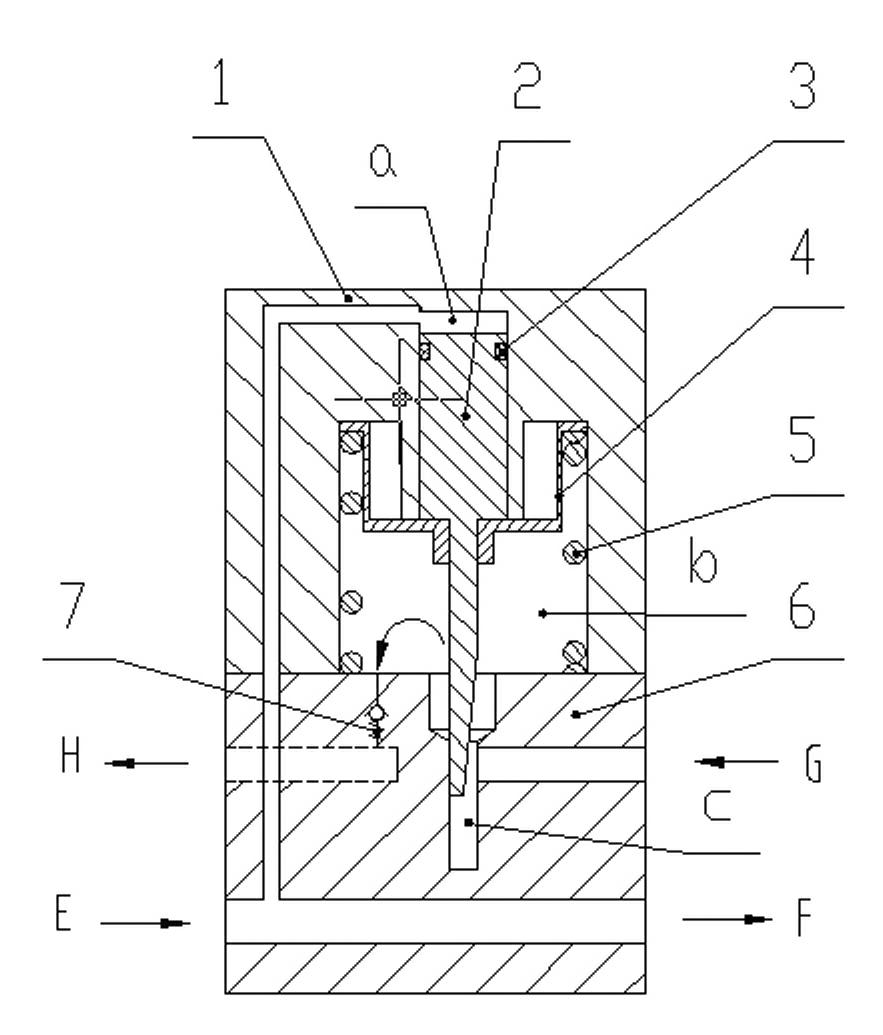

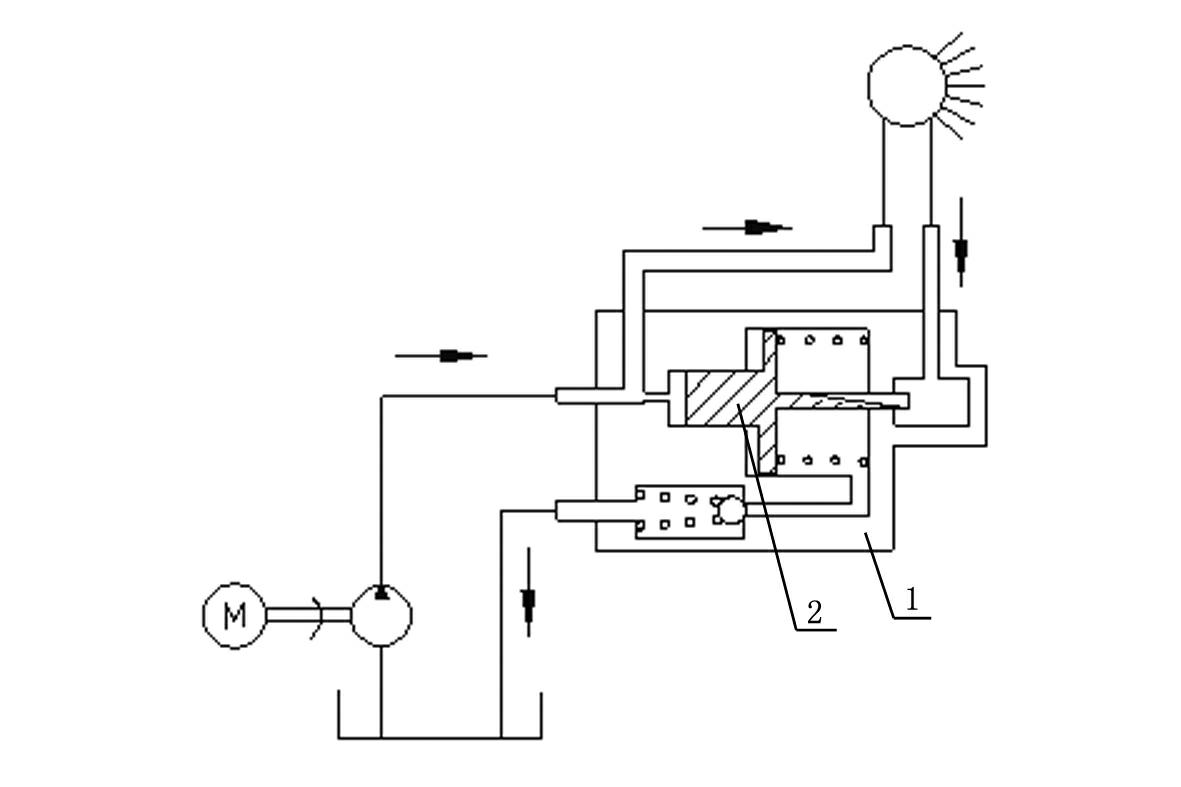

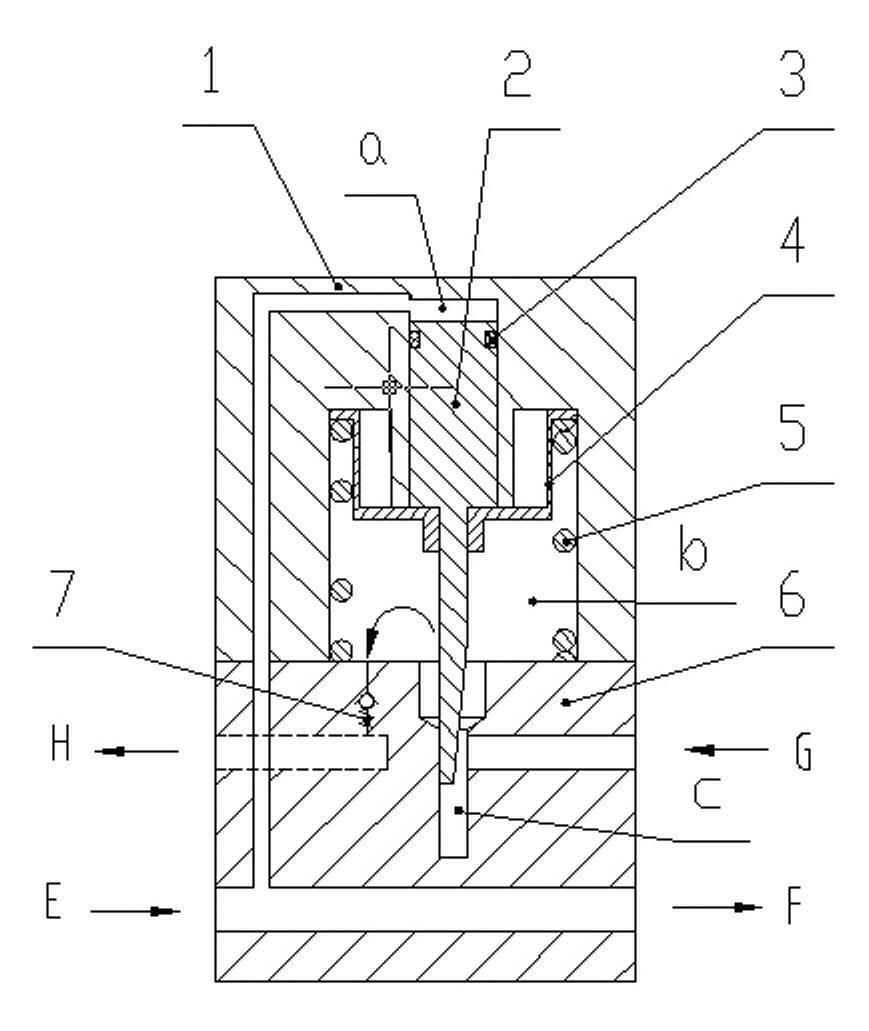

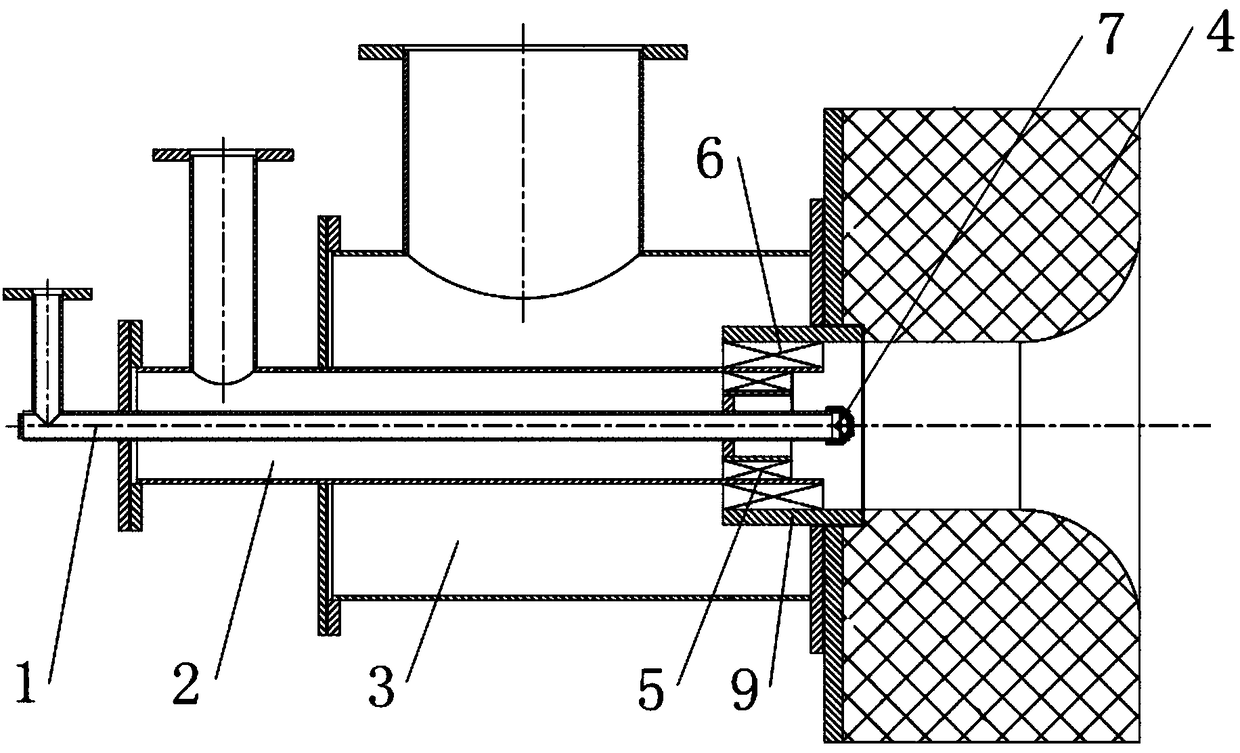

Small-sized fuel adjuster of turbojet engine

ActiveCN102493873AReduce designSmall turndown ratioTurbine/propulsion fuel controlInlet channelEngineering

The invention provides a small-sized fuel adjuster of a turbojet engine, which relates to a mechanical fuel adjusting device and is applicable to adjusting the flow of oil return type pressure atomizing nozzles. The small-sized fuel adjuster consists of a shell, an adjusting needle, an O-shaped sealing ring, a spring cover, a spring, an oil distributing block and a one-way valve, the oil distributing block is mounted in the shell, a cavity a, a cavity b and a cavity c are disposed on the oil distributing block, the spring is mounted in the cavity b of the oil distributing block, the spring cover is mounted on the spring and provided with an adjusting needle mounting hole, the upper portion of the adjusting needle is mounted in the cavity a, the lower portion of the adjusting needle is mounted in the cavity b and the cavity c, the O-shaped sealing ring is mounted on the upper portion of the adjusting needle, an oil inlet channel and an oil return channel are separated via the O-shaped sealing ring, and the one-way valve is mounted on the shell; and the cavity a is communicated with the oil inlet channel, pressure in the cavity a is equal to oil inlet pressure, an opening C is connected with a nozzle to realize oil return, one end of the one-way valve is connected with the cavity b, the other end of the one-way valve is connected with an opening H, an adjusting hole is arranged between the cavity b and the cavity c, and the adjusting needle is inserted in the adjusting hole.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

Heat treating furnace using porous medium combustor

InactiveCN101338356AEmission reductionSave energyMechanical apparatusFurnace componentsPorous mediumCordierite

A heat processing furnace which adopts a porous medium burner belongs to the technical field of heat processing furnace. The furnace includes a hearth body and burners. The burners adopt porous ceramics foam; the burners are arranged on the top part or the side wall of the furnace; the surrounding masonrys of the outlet sections of the burners are designed to be of a gradually expanded horn shape; the crossing line of the extending surface of the outlet sections of two neighboring burners or the crossing line between the extending surface of the outlet sections of the burners and the wall of the furnace wall is arranged above a workpiece to be heated; the heat loss of the wall of the furnace arranged in the mode is less; the radiation heat transmission share is large. The ceramics materials of the burners are cordierite, yttrium oxide-based zirconia, calcium oxide-based zirconia, silicon nitride, aluminum oxide or the ceramics particles bonded by a bonding agent. The burner is formed by one or a plurality of same burning units. The porous medium burner of the invention has the advantages of small size, low manufacture cost, low mounting difficulty, large adjusting ratio, high burning intensity and low contamination discharge. The heat processing furnace has the advantages of high burning efficiency, less heat loss and high heating quality.

Owner:NORTHEASTERN UNIV

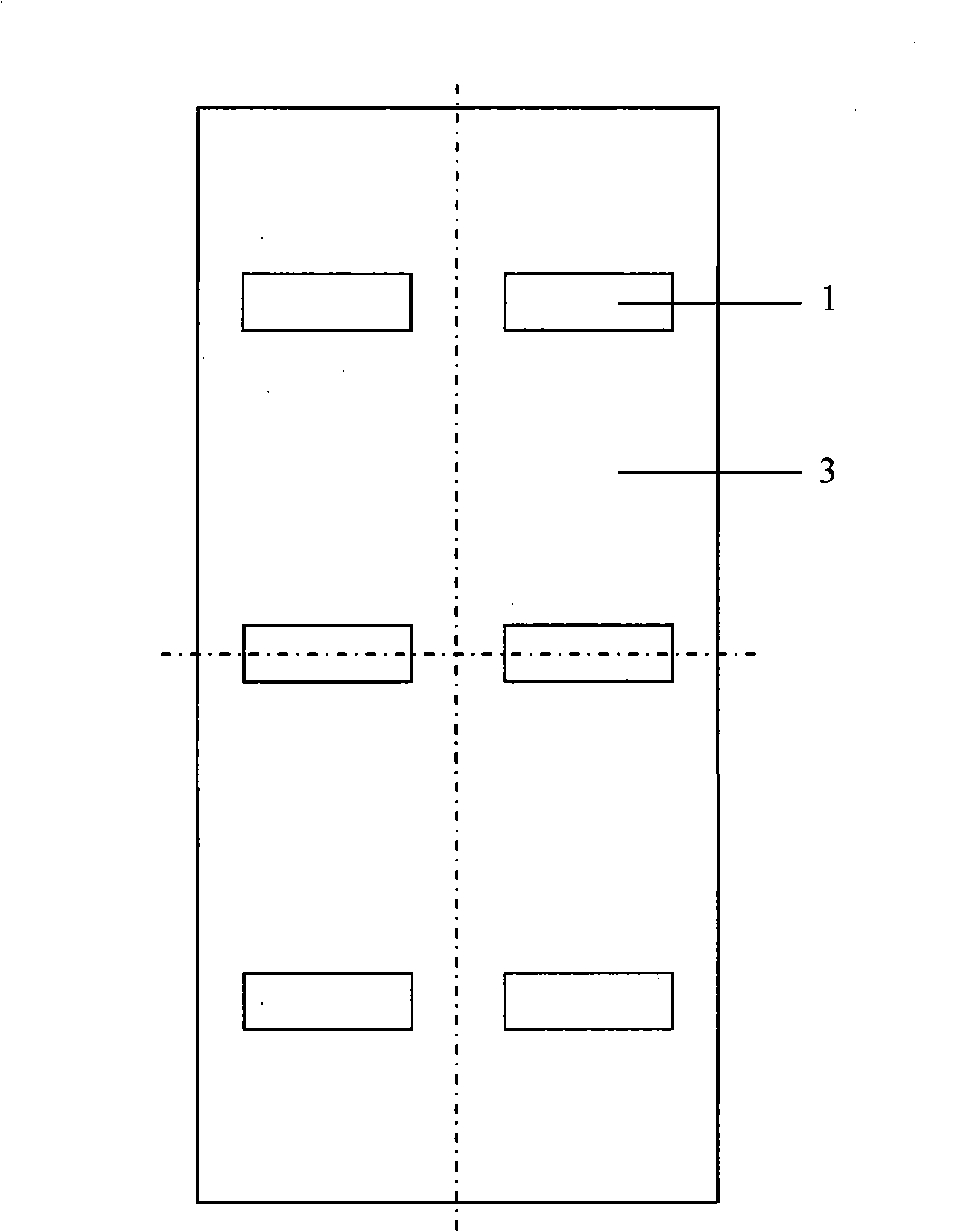

Forced recirculation water pipe steam boiler system and operating method thereof

ActiveCN111981455ASave on energy costsLarge adjustment ratioBoiler cleaning apparatusSteam separation arrangementsBoiler feedwater pumpCombustor

The invention provides a forced recirculation water pipe steam boiler system and an operating method thereof. A floater water carrier is arranged in a water tank, the floater water carrier is connected to a condenser through a boiler water supply pipeline, a boiler feed pump is connected in series to the boiler water supply pipeline, the condenser is connected to a buffer liquid control tank through a water feeding pipeline, the buffer liquid control tank is connected to a water inlet of a boiler body through a high-temperature water supply pipeline, a high-temperature circulation pump is connected in series on the high-temperature water supply pipeline, the water inlet of the boiler body communicates to a burner plate and a square coil pipe of a hearth, the square coil pipe of the hearthis connected to a tail gathering header, the tail gathering header is connected to a fin type downcomer economizer, the fin type downcomer economizer is connected to a bottom converging header, the bottom converging header is connected to a boiling ascension pipe of the hearth, the boiling ascension pipe of the hearth is connected to a top gathering header, a steam-water mixing outlet of the top gathering header is connected to a steam-water separator through a steam-water mixing pipeline, and a liquid outlet of the steam-water separator is connected to the buffer liquid control tank through areflow pipeline.

Owner:ZHEJIANG TUFF BOILER

High-efficiency enhanced boiler

ActiveUS9523538B2Improve relationshipIncrease surface areaBoiler water tubesAir heatersEngineeringRADIUS

The invention provides high-efficiency heat transfer devices and apparatuses. In one embodiment, the invention includes a vessel capable of containing the heat transfer medium, a conduit extending through a wall of the vessel, the conduit having a first surface for contacting the heat transfer medium and a second surface for contacting a fluid within the conduit, a helical member residing around and along a length of the first surface of the conduit capable of angularly directing a flow of the heat transfer medium along the first surface of the conduit; and a plurality of fins helically arranged adjacent the helical member, each fin extending through a wall of the conduit and being capable of directing at least a portion of the heat transfer medium to an area within a radius of the conduit.

Owner:OKONSKI JR JOHN E +1

A double swirl flat flame burner

ActiveCN106122946BLarge adjustment ratioGuaranteed uptimeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelRotational flowAir–fuel ratio

The invention discloses a double-rotational-flow flat flame burner. The double-rotational-flow flat flame burner comprises a center air duct, a gas pipe, a main air pipe and a burner body, wherein a combustion channel is arranged on the burner body; the center air duct, the gas pipe and the main air pipe are sequentially and coaxially arranged from inside to outside; the burner body is arranged at an air outlet of the main air pipe; the combustion channel coaxially communicates with the air outlet of the main air pipe; a gas hydrocyclone and a main air hydrocyclone are arranged at the positions, located at the air outlet, of the gas pipe and the main air pipe correspondingly; the gas hydrocyclone is arranged between the center air duct and the gas pipe; the main air hydrocyclone is arranged between the gas pipe and the main air pipe; and an air outlet of the center air duct and the air outlet of the main air pipe are located in front of an outlet of the gas pipe. By means of the structure, air flow can be better attached to the wall to be spread to burn, a stable fire plate is formed, the regulating ratio of the burner is improved, especially when the load of the burner is small, flat flame can still be formed, normal operation can be achieved under the working condition of the imbalance air-fuel ratio, and the adjustability, applicability and reliability of the flat flame burner are improved.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

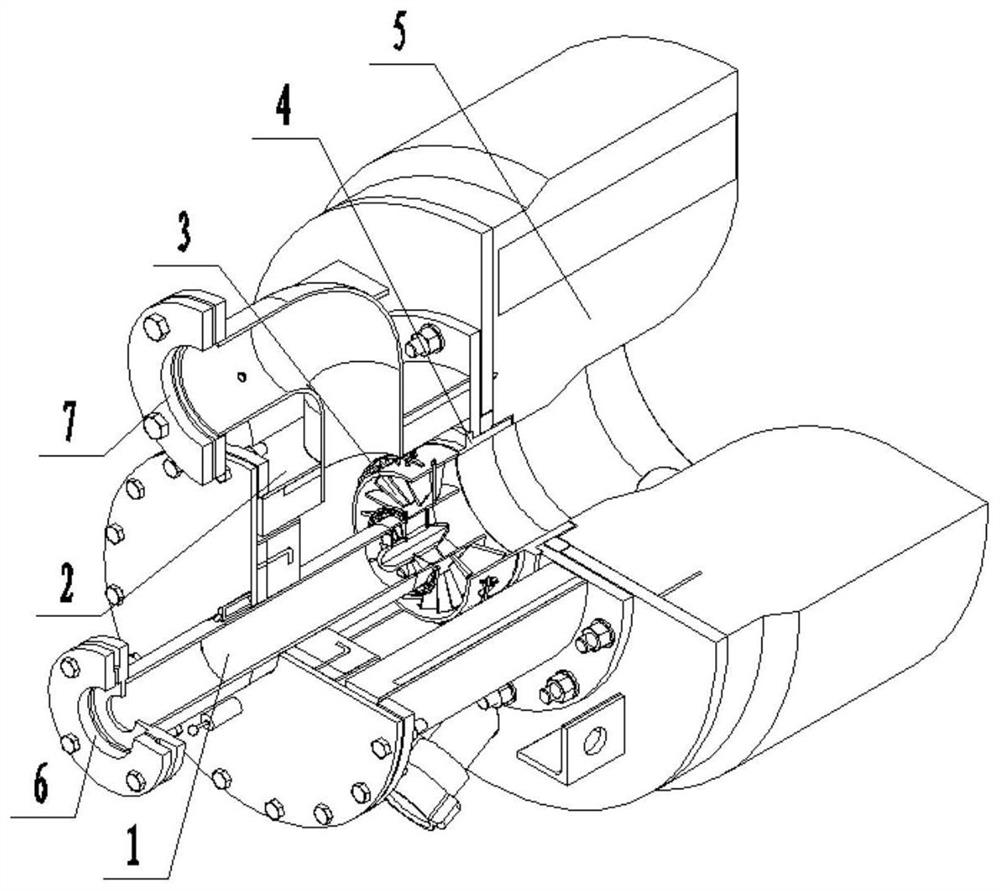

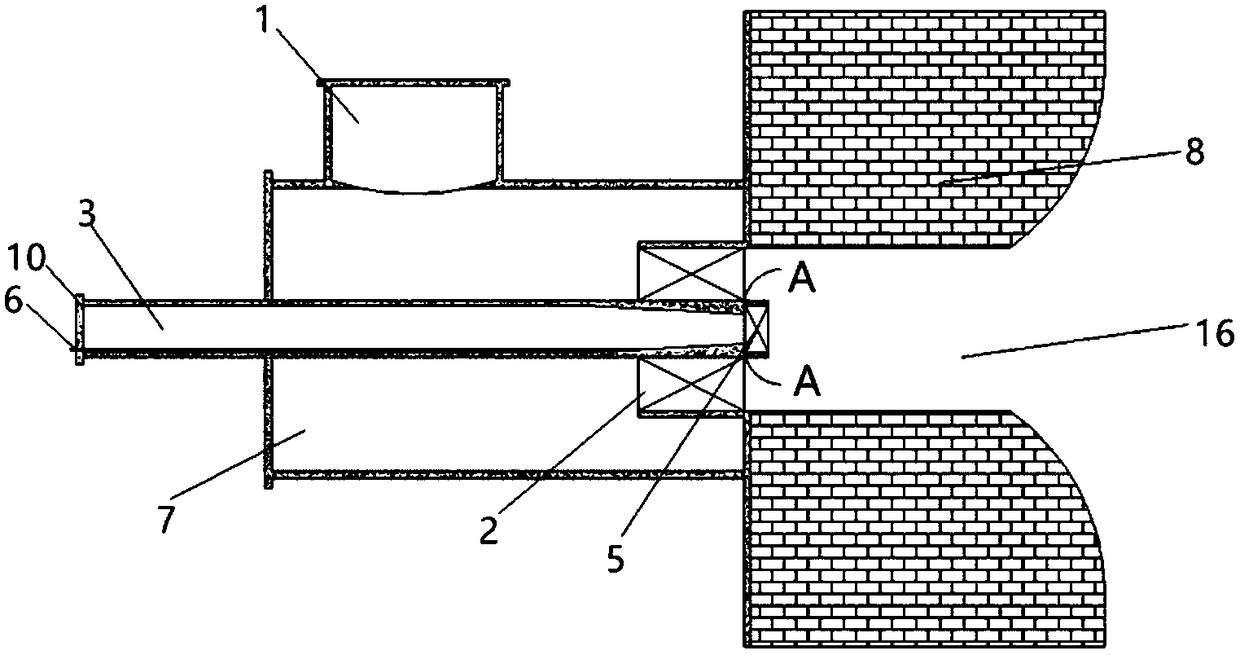

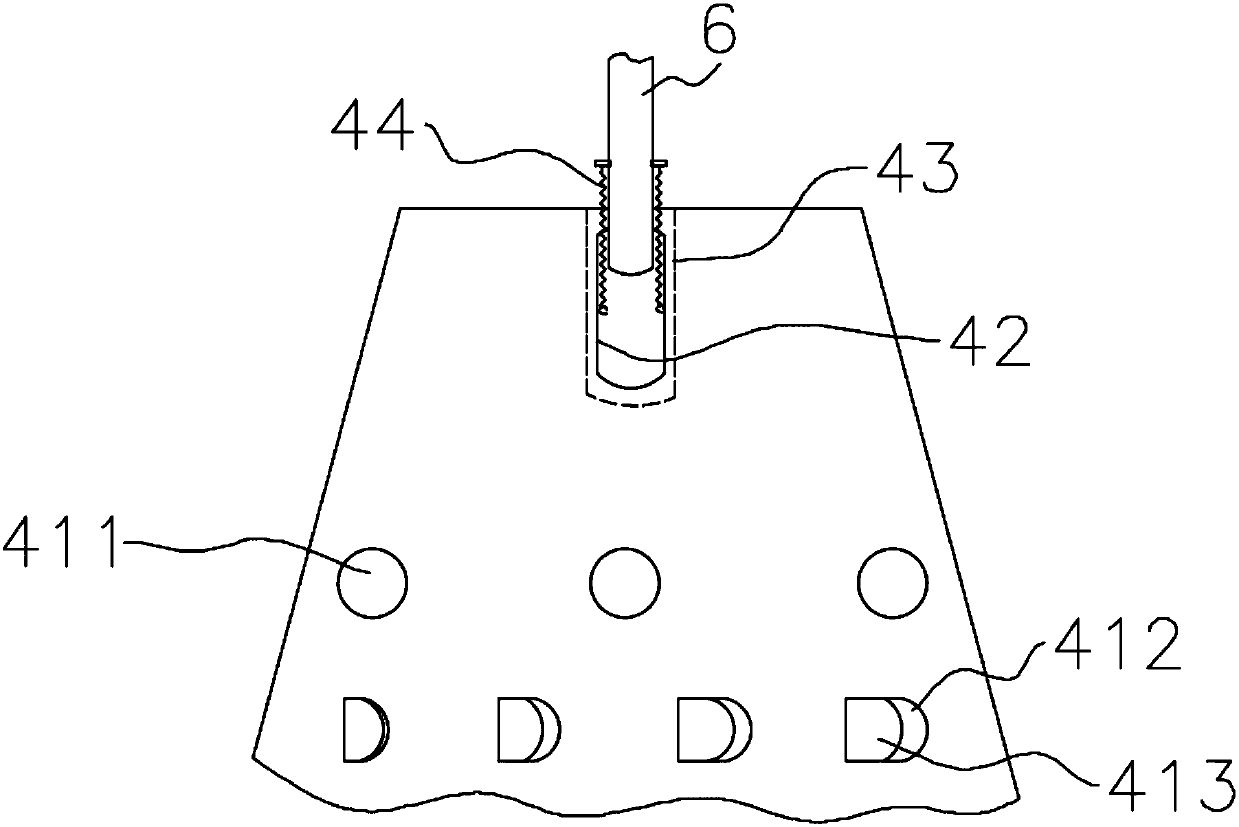

Flat flame burner

InactiveCN108826291ALittle resistance lossLarge adjustment ratioGaseous fuel burnerEngineeringFuel gas

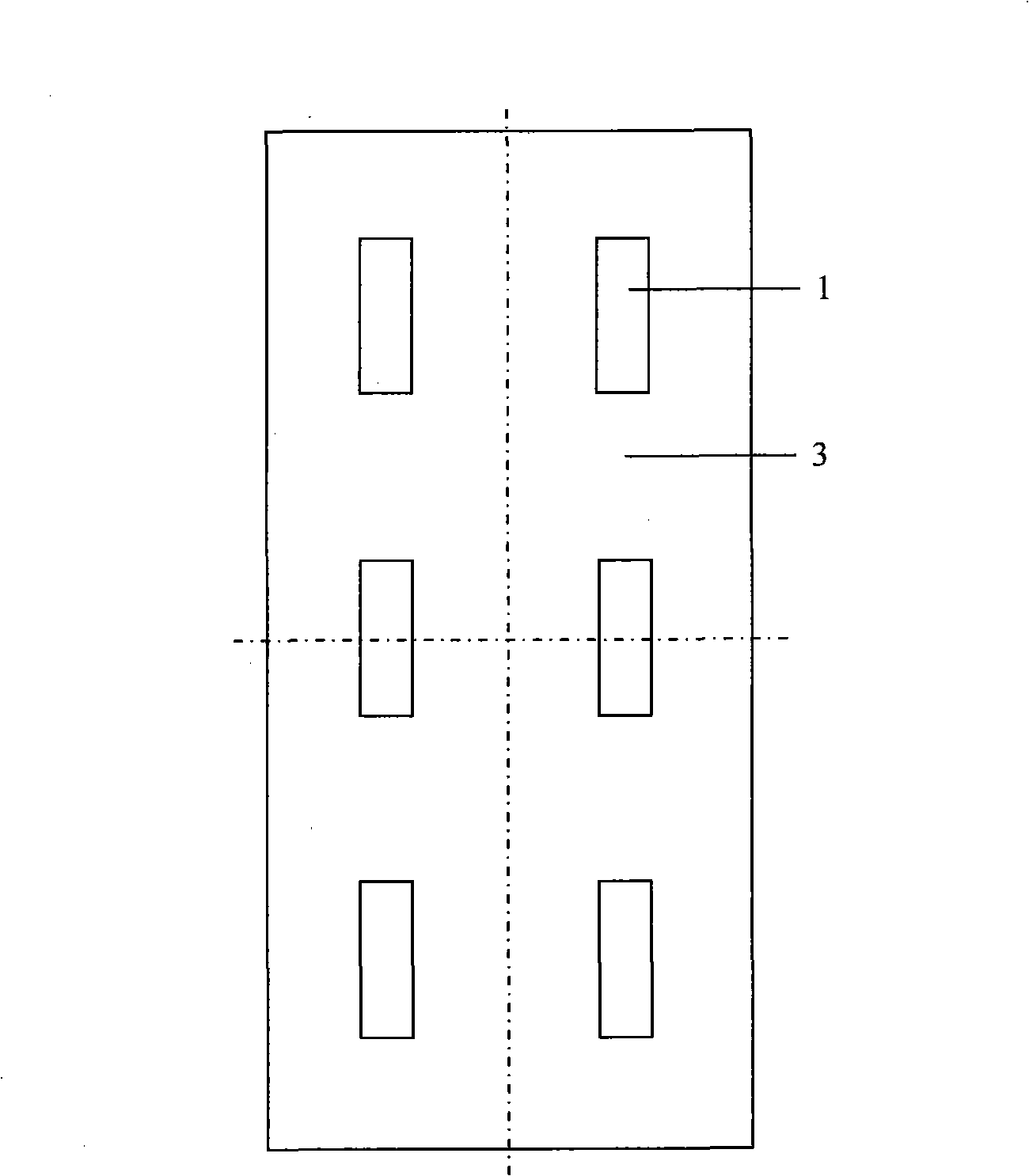

The invention discloses a flat flame burner. The flat flame burner comprises an air inlet pipe 1, an gas inlet pipe 3, a swirler 2, a burner shell 7, burner bricks 8, a variable cross section device 5and a variable cross section control rod 6, wherein the burner blocks 8 form a combustion channel 16 with a gradually-wide structure and communicates with the burner shell 7, the air inlet pipe 1 isvertically arranged on the burner shell 7, the gas inlet pipe 3 is a variable-cross-section pipe and sequentially passes through the burner shell 7 and the swirler 2 and extends into the combustion channel 16, the variable cross section device 5 is arranged at the bottom of the gas inlet pipe 3, the largest cross section of the variable cross section device 5 is equal to the cross section of the bottom of the gas inlet pipe 3, the gas inlet pipe 3 is arranged axial with the burner shell 7, the swirler 2, the variable-cross-section device 5 and the combustion channel 16, one end of the variable-section control rod 6 is connected with a blade driving ring 4 through a connecting rod, and the other end of the variable-section control rod 6 is arranged at the inlet of the gas inlet pipe 3, so that the variable-section control rod 6 is used for controlling the cross section area of the variable cross section device 5 to change the outlet of the bottom of the gas inlet pipe 3.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Combustor for exhaust gas incineration and adjustable in adjustment ratio

PendingCN110513705AStable combustionLarge adjustment ratioIncinerator apparatusEngineeringMechanical engineering

The invention provides a combustor for exhaust gas incineration and adjustable in adjustment ratio. The combustor for the exhaust gas incineration and adjustable in adjustment ratio comprises a bearing cover plate, a main fire gun, a taper spray head and a translation drive mechanism, wherein the translation drive mechanism can drive the main fire gun and the taper spray head to translate, therebychanging the size of an interval between the outer circumference of a big mouth end of the taper spray head and an opening of a hearth. Compared with the prior art, when the amount of process exhaustgas is obviously increased, the translation drive mechanism moves the main fire gun and the taper spray head back and enlarges the interval between the taper spray head and the hearth, a great amountof the exhaust gas can enter the hearth form the interval, differential pressure of the exhaust gas which passes through the taper spray head returns to a normal range, smooth combustion is ensured,the adjustment ratio of the combustor is increased, and the effective incineration of the exhaust gas is realized.

Owner:ANDERSON THERMAL SOLUTION SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com