Flat flame burner

A flat-flame burner and variable-section technology, applied in the field of furnaces and kilns, can solve the problems of reducing the recirculation zone, reducing the flat flame flame plate, and lowering the adjustment, so as to improve the combustion effect, improve the operation efficiency, and expand the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

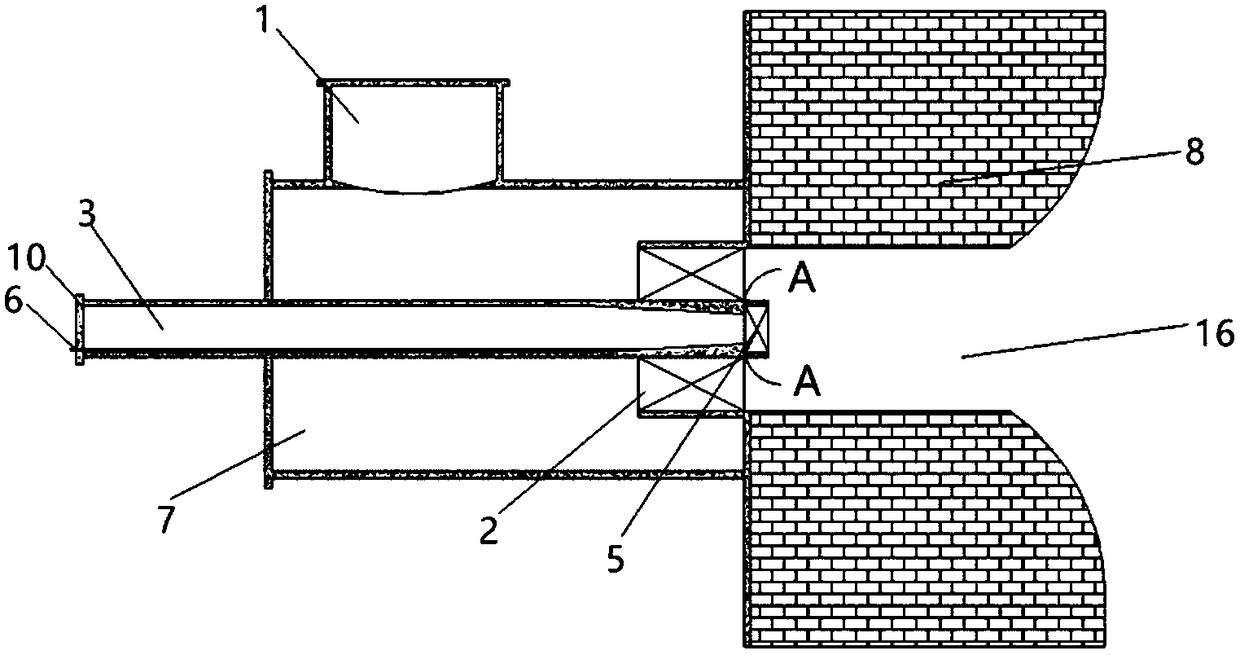

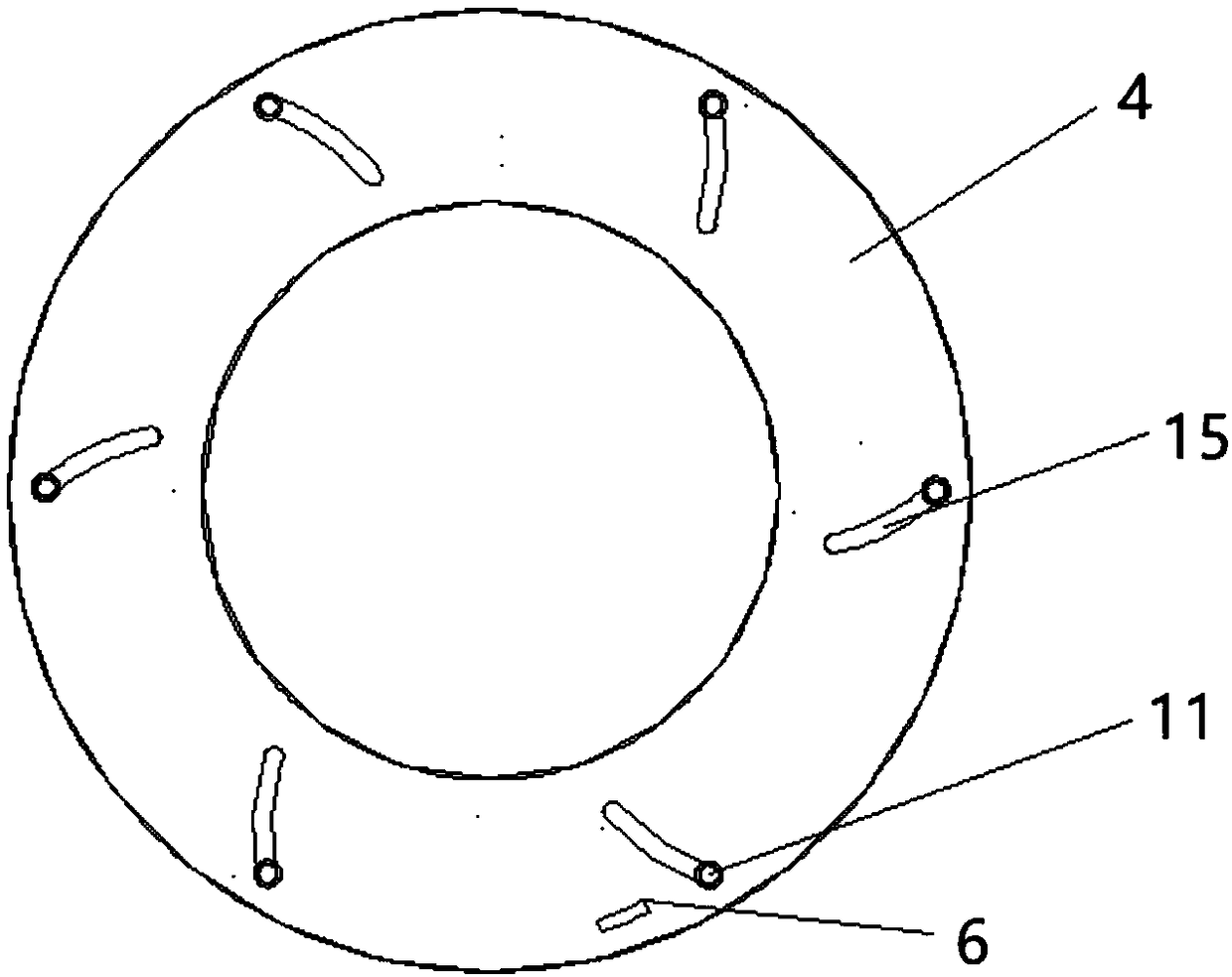

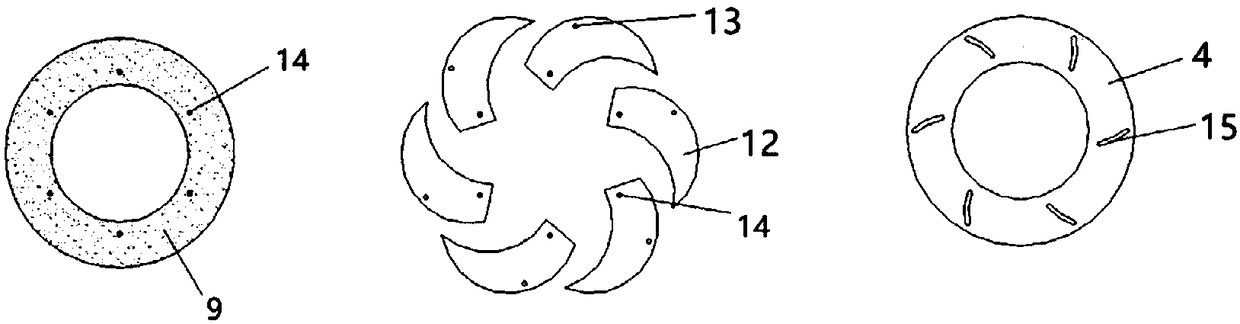

[0028] Such as Figure 1-9 As shown, the present invention discloses a flat flame burner, including: air intake pipe 1, gas intake pipe 3, swirler 2, burner housing 7, burner brick 8, variable section device 5, variable section control The rod 6 and the burner brick 8 form a combustion channel 16 with a gradually widening structure and communicate with the burner housing 7. The air intake pipe 1 is vertically arranged on the burner housing 7. The gas intake pipe 3 is a variable-section pipe and is sequentially arranged from the outside to the inside. The burner housing 7 and the swirler 2 extend into the combustion channel 16. The bottom of the gas inlet pipe 3 is provided with a variable-section device 5. The maximum cross-section of the variable-section device 5 is equal to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com