Biogas burner

A biogas and burner technology, which is applied to gas fuel burners, burners, combustion ignition and other directions, can solve the problems of low calorific value, insufficient combustion, and short service life of biogas, and achieve good combustion stability and use. The effect of long life and large adjustment ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

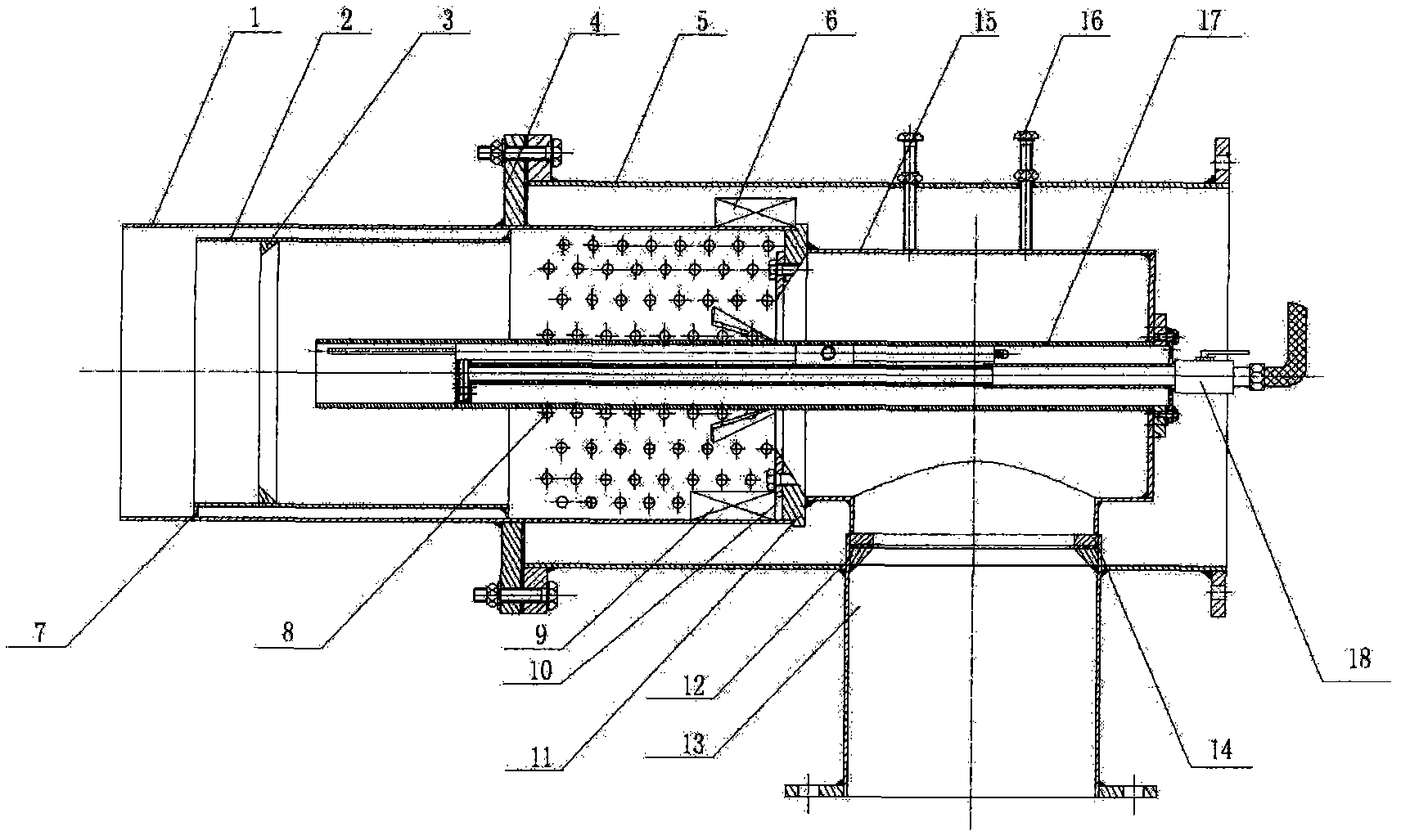

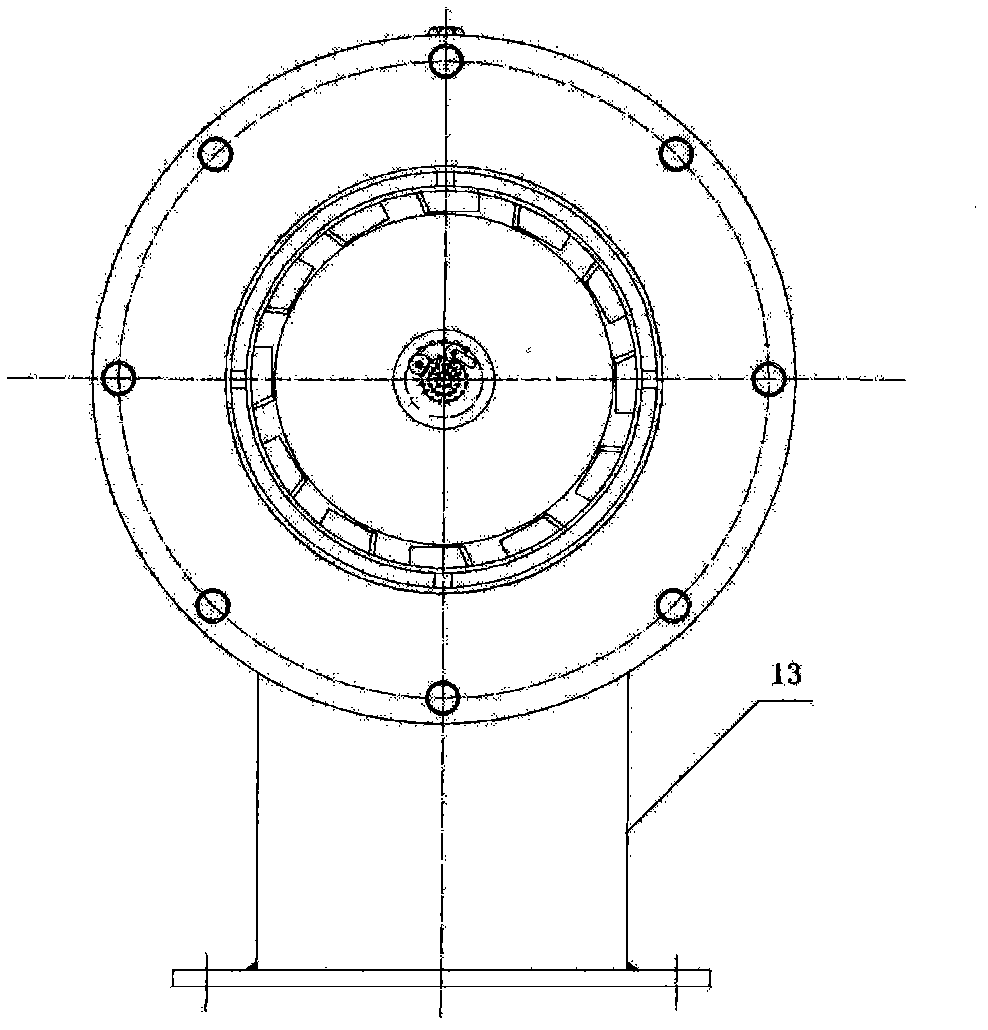

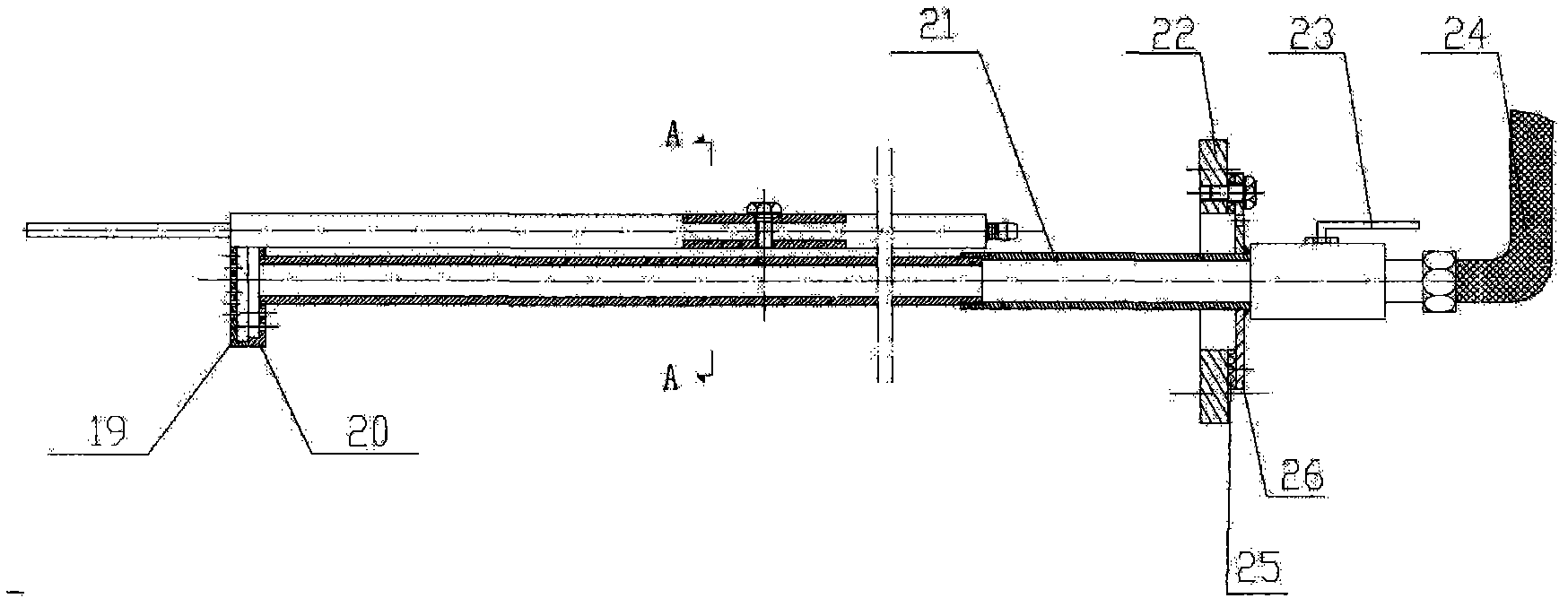

[0029] Such as Figure 1-9 As shown, the biogas burner includes the outer tube 1 of the combustion tube, the inner tube 2 of the combustion tube, the conical flame stabilization plate 3, the external air duct 5, the air outlet 8, the air swirl sheet 6, the gas swirl sheet 9, Conical port connector 11, defocusing conical port 12, air inlet device 13, conical port adapter flange 10, air intake outer tube 15, adjusting bolt 16, air inlet device 13 and defocusing conical port 12 is fixed on the detachable flange 14, and its function is to maintain and disassemble. The function of the decoking conical port 12 is to prevent tar from clogging in the pipeline, and to make a diffusion taper, so that the gas and tar are ejected and burned through the direction of the jet flow. out so the tar doesn't clog the burner. The detachable flange 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com