Regulation valve with accurately positioned valve core

A technology for precise positioning and regulating valves, applied in valve details, valve operation/release devices, valve lifts, etc., can solve problems such as large driving energy, difficult precise positioning, and no precise intermediate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

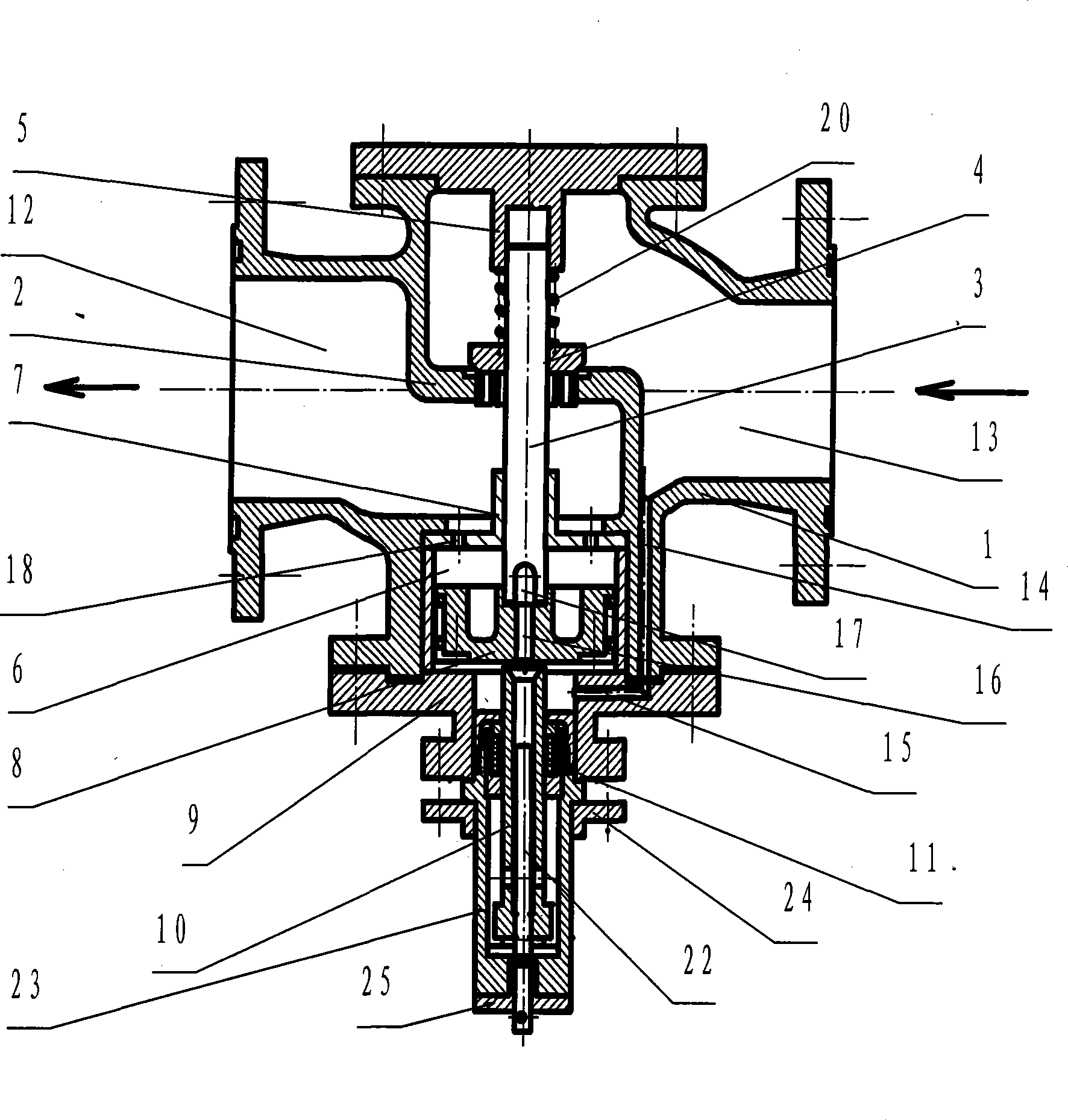

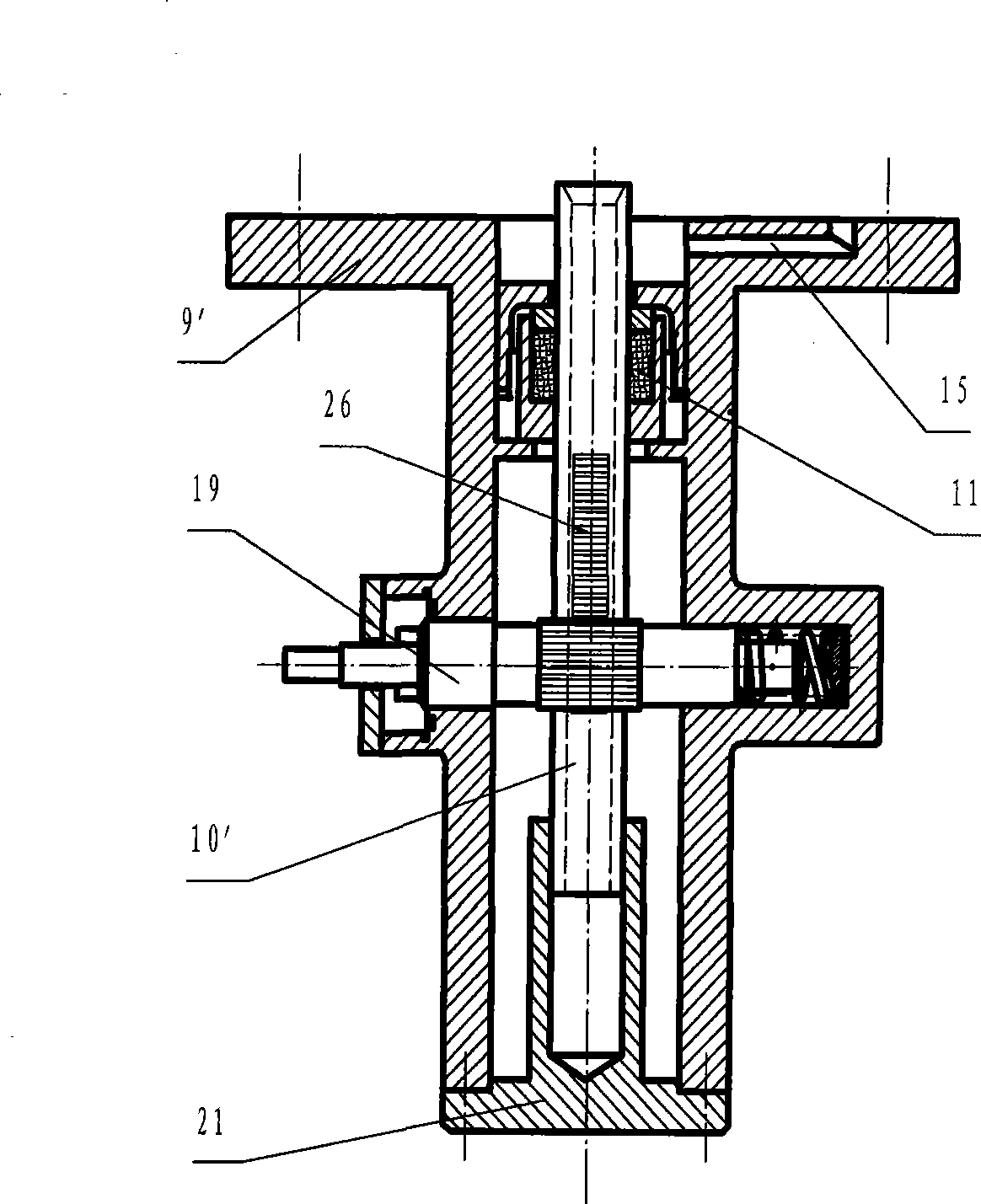

[0017] Preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the regulating valve for precisely positioning the spool includes three parts: the valve body, the driving mechanism and the servo mechanism. The driving mechanism includes the driving cylinder 6, the piston 8 and the valve stem 3 with the spool 4; 9. Servo tube 10, adjusting rod 22, guide sleeve 23, sealing assembly 11 and guide sleeve cover 25; valve body 1 is a combination of a valve body with a conventional stop valve structure and a drive cylinder 6, and processed to guide and control Fluid through passage.

[0019] Four openings with flanges on the outer edge are processed on the valve body 1, that is, the controlled fluid inlet and outlet of the coaxial line, the drive cylinder port and the stem seat installation port of the coaxial line, and the two axes are orthogonal The three-section bending partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com