Gas thrust vector control structure and method of hybrid rocket engine

A solid-liquid rocket, vector control technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of limited installation space, large thrust loss, constant loss, etc., and achieve a large thrust adjustment ratio, Easy and precise control, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

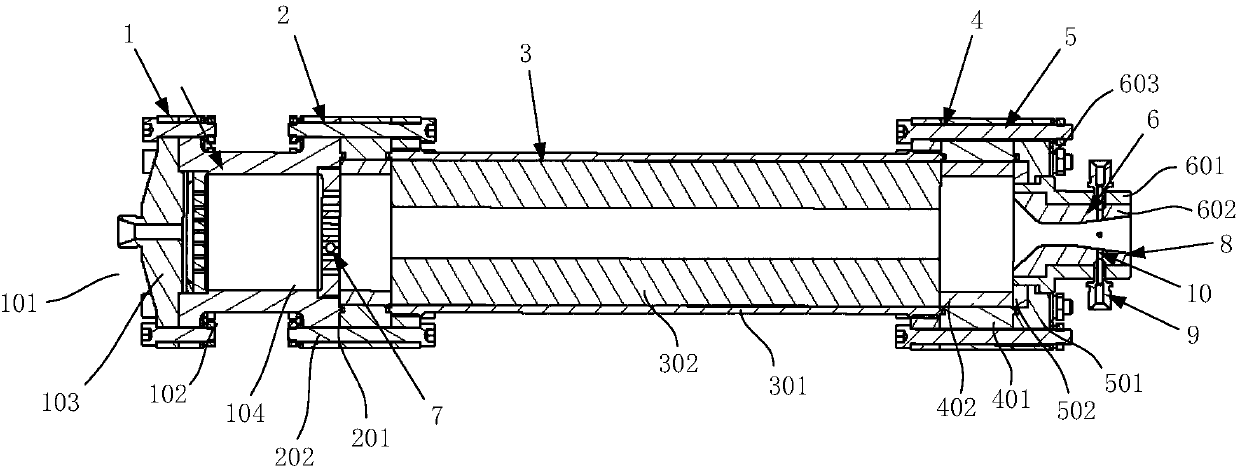

[0026] The solid-liquid rocket engine gas injection vector control method of the present invention, wherein the solid-liquid rocket engine comprises a catalytic bed assembly 1, a front combustion chamber assembly 2, a combustion chamber 3, a rear combustion chamber assembly 4, a rear head assembly 5 and a nozzle 6, such as figure 1 shown.

[0027] The catalytic bed assembly 1 includes an engine head 101, a catalytic bed shell 102, a liquid injection panel 103 and a gas injection panel 104, all made of 1Cr18Ni9Ti stainless steel. Wherein, a port is coaxially opened on the engine head 101 as the inlet of the liquid propellant. The catalytic bed shell 102 is filled with catalyst, and the catalytic bed shell 102 and the engine head 101 are coaxially fixed and installed by bolts and nuts, and an O-shaped rubber is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com