A gearbox gear interlock structure

A technology of gearbox and lock structure, applied in the direction of components with teeth, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex structure and high production cost, and achieve simplified installation steps, simple manufacturing process and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

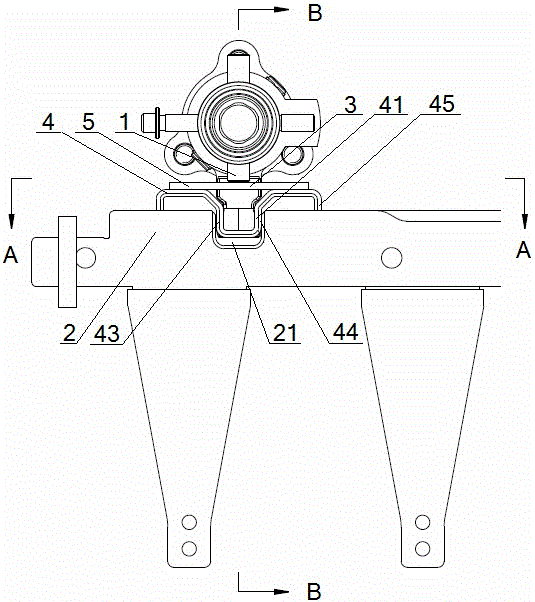

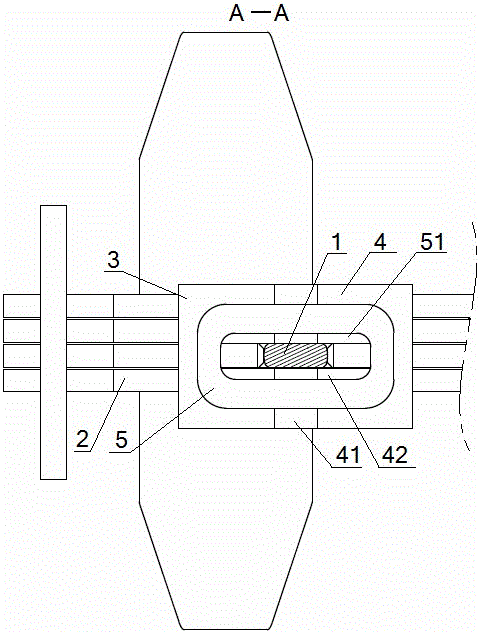

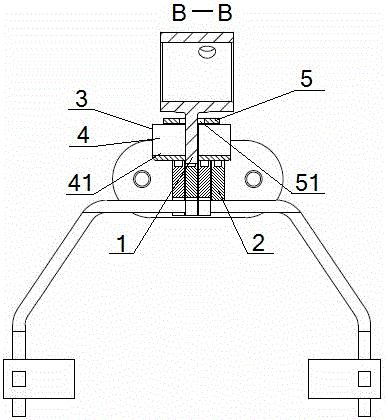

[0039] see Figure 1 to Figure 5, a gearbox gear interlocking structure, including a selector shift dial 1 and a plurality of shift pull plates 2 arranged in parallel, the tops of the plurality of shift pull plates 2 are provided with the same shift select groove 21, so The selector shift dial 1 is slidingly matched with the gear selection groove 21, and the selector shift dial 1 passes through the interlock seat 3 and then drives and cooperates with the shift pull plate 2; the interlock seat 3 includes a locking concave plate 4, The middle part of the locking recessed plate 4 is provided with a lower concave portion 41 that is slidingly matched with the gear selection groove 21, and the locking concave plate 4 is provided with a shift slide 42 perpendicular to the lower concave portion 41. The shifting head 1 passes through the shift sliding port 42 and cooperates with the shift pull plate 2 in transmission; the section of the lower concave portion 41 is a U-shaped structure,...

Embodiment 2

[0041] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0042] The interlock seat 3 also includes a guide plate 5 with a flat plate structure, the bottom surface of the guide plate 5 is fixedly connected to the top of the locking concave plate 4, and the middle part of the guide plate 5 is provided with a guide opening 51 corresponding to the shift slide 42 , the selector shift dial 1 sequentially passes through the guide port 51 and the shift slide 42 and then cooperates with the shift pull plate 2; the value range of the width of the shift slide 42 is d+0.5mm- d+1.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com