Direct recovery method and device applicable to industrial high-flow large-regulation-ratio flare gas

A technology of flare gas and large flow, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of low combustion efficiency of elevated flare, small operation adjustment ratio, low system capacity, etc., and achieve significant economic and environmental benefits, Reduce the frequency of use and configure the effect reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

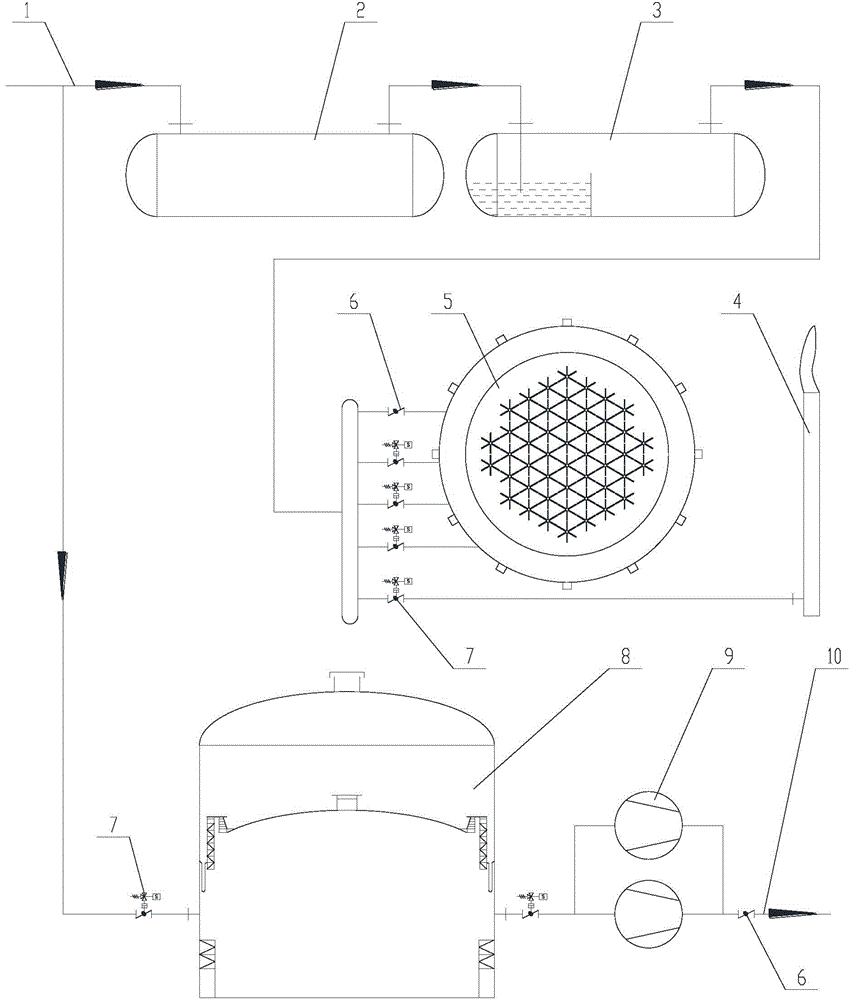

[0023] Such as figure 1 As shown, the present invention is applicable to a direct recovery device for industrial large flow rate and large adjustment ratio flare gas, which includes a flare gas pipeline network 1, and the flare gas sent from the flare gas pipeline network 1 is divided into two paths, and one path is connected to the gas The inlet of cabinet 8, and the other gas connection to the inlet of separator tank 2;

[0024] The outlet of the gas cabinet 8 is connected to the inlet of the compressor unit 9, and the outlet of the compressor unit 9 is connected to the fuel gas pipeline network 10; A self-control valve 7 is provided on the connection pipeline between the flare gas pipeline network 1 and the inlet of the gas cabinet 8 , an automatic control valve is provided on the connection pipeline between the outlet of the gas cabinet 8 and the compressor unit 9 , and a manual valve 6 is provided on the fuel gas pipeline network 10 .

[0025] The outlet of liquid separa...

Embodiment 2

[0028] Adopt a kind of device described in embodiment 1 to be applicable to the direct recovery method of industrial large flow, large adjustment ratio flare gas, specifically as follows:

[0029] The torch gas sent from the torch gas pipeline network 1 is divided into two paths, one path of gas can be transported to the gas cabinet 8, after being boosted by the compressor unit 9, it can be transported to the fuel gas pipeline network 10; the other path of gas can pass through the liquid separation tank 2 to the water seal tank 3. When the pressure of the flare gas is greater than the water seal height of the water seal tank 3, the flare gas enters the ground flare 5 or elevated flare 4 for incineration;

[0030] Under normal working conditions, the flare gas is delivered to the fuel gas pipeline network 10 and the ground flare 5 and the overhead flare 4 are extinguished. Under normal working conditions, the self-control valve 7 provided at the outlet and inlet of the gas cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com