Stelmo line gas spray cooling device and method for high-speed wire rod mill

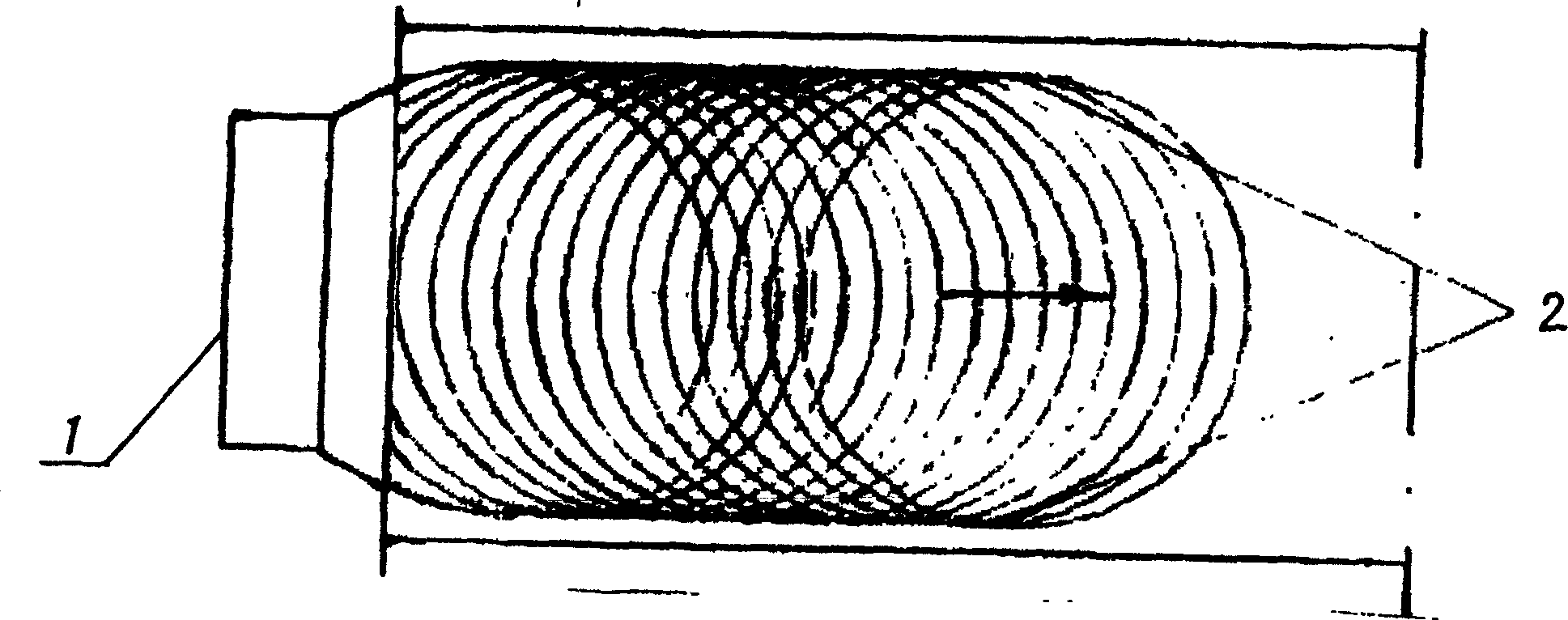

An aerosol cooling, high-speed wire rod technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of uneven performance, reduce iron oxide scale, reduce acid consumption, and improve the operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

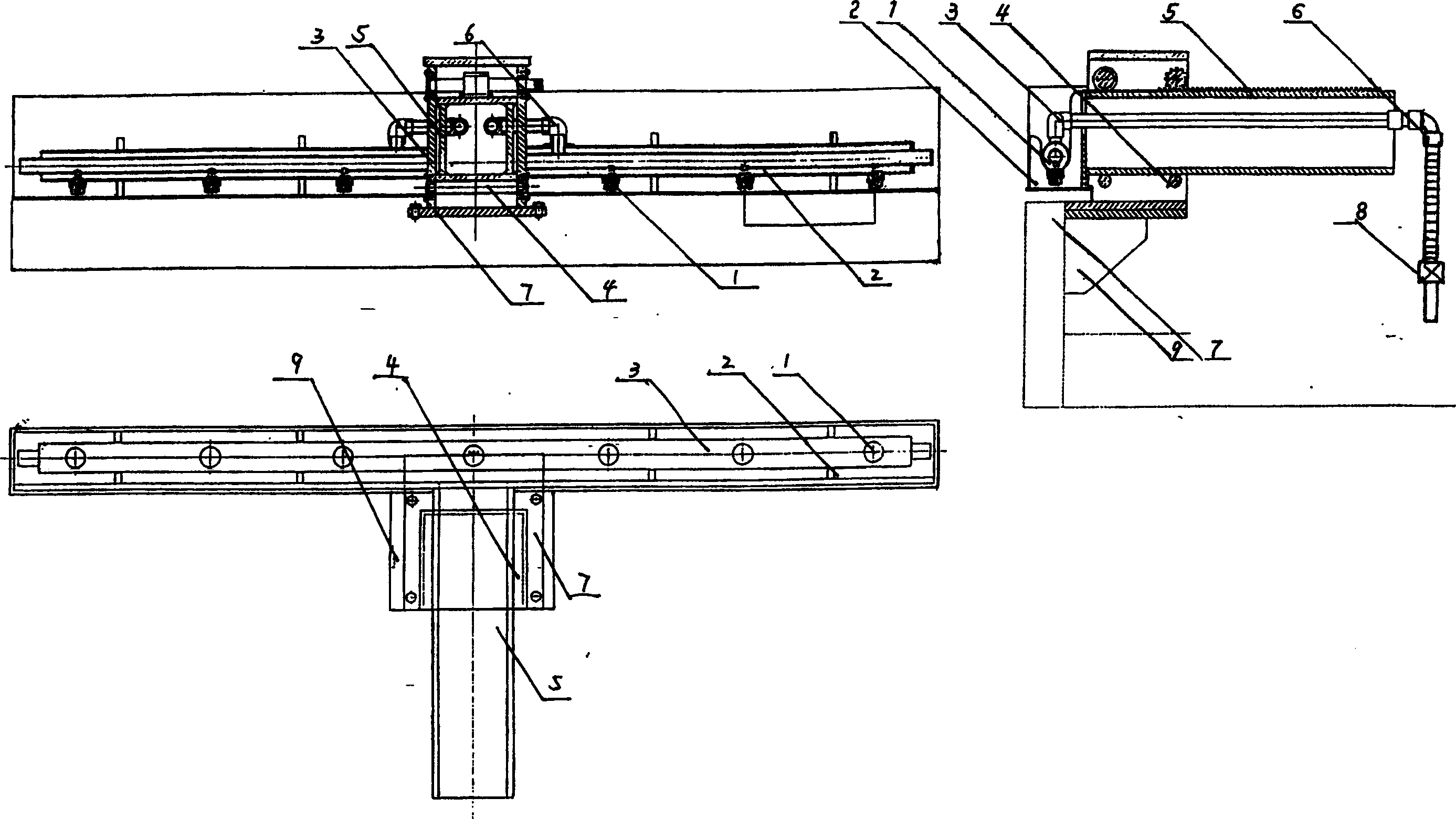

[0021] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

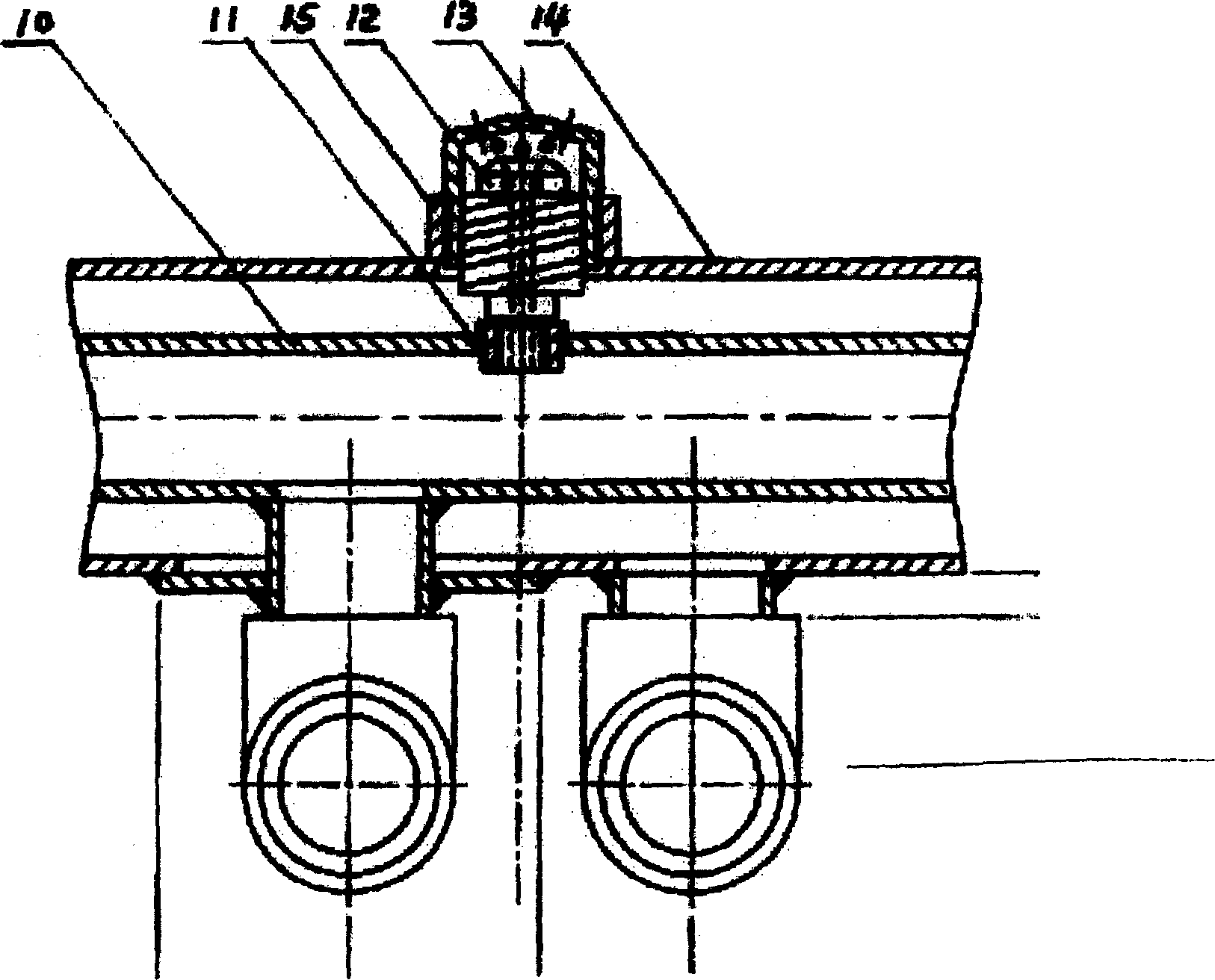

[0022] like figure 2 As shown, the gas mist cooling device uses a set of two gas mist coolers, which are symmetrically arranged on both sides of the Stelmore roller table. The gas mist cooler consists of nozzle 1, U-shaped support 2, spray sleeve 3, rolling support 4, mobile support 5, elbow and metal hose 6, fixed support 7, pipelines and valves 8, water connection Disc 9 composition. Nozzles, spray sleeves, elbows, metal hoses, pipelines and valves are connected. The U-shaped support supports the spray sleeve and is connected to the mobile bracket to control it to rotate around the axis at an angle of 20 to 30 degrees. The rolling support is in the The periphery of the mobile support supports the mobile support, the fixed support fixes the entire air mist cooling device at the bottom, and the water receiving tray is installed under the Stelmor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com