Double-aperture and direct-acting type water faucet

A direct-acting, faucet technology, applied in the field of faucets, can solve the problems of low pressure resistance, easy damage to the valve sleeve, difficult to control valve flow, etc. The effect of high pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

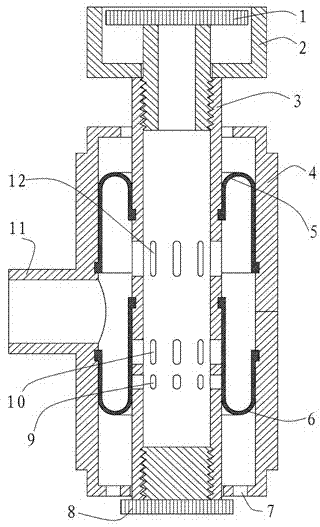

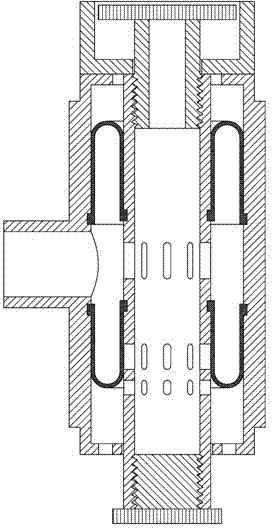

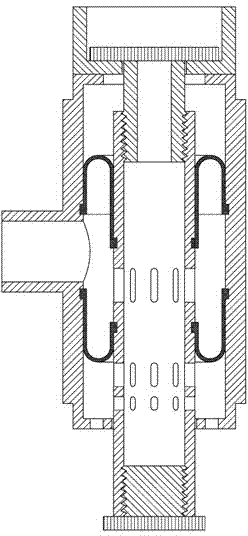

[0014] Such as figure 1 As shown, the present invention includes a valve body 4, a valve stem 3 and a water inlet interface 11; the valve stem 3 is a hollow body, and the valve stem is provided with a water inlet row hole 12 and upper and lower water outlet row holes 9, 10, and the upper water outlet row hole It is larger than the lower outlet hole. Upper and lower sealing valve sleeves 5 and 6 are arranged between the outer wall of the valve stem and the inner wall of the valve body, wherein the upper edge of the upper sealing valve sleeve 5 is fixed on the upper side of the water inlet column hole, and the lower edge of the upper sealing valve sleeve is fixed in the valve body The upper side of the water inlet interface 11 of the cavity, the upper edge of the lower sealing valve sleeve 6 is fixed between the water inlet and outlet holes of the valve stem and the upper water outlet row, and the lower edge of the lower sealing valve sleeve 6 is fixed on the water inlet interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com