Radio-frequency discharge ionization device enhanced by using photoelectric effect

A technology of radio frequency discharge and photoelectric effect, applied in discharge tubes, circuits, electrical components, etc., can solve the problems of unstable discharge, difficulty in starting radio frequency discharge, narrow working pressure range of radio frequency discharge, etc. The effect of increasing the working air pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

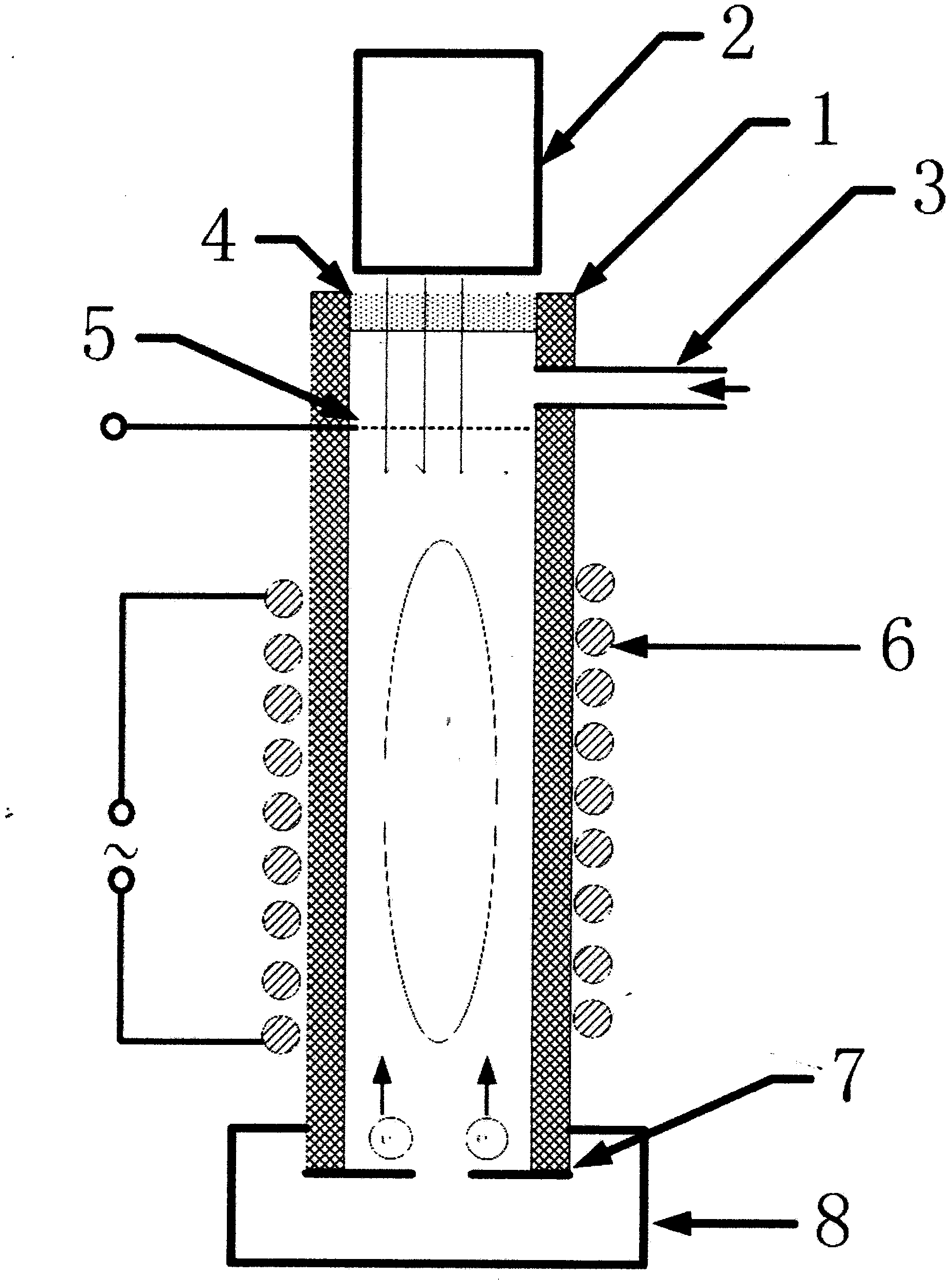

[0019] Example 1, see figure 1 Shown:

[0020] The present invention is a radio frequency discharge ionization device enhanced by the photoelectric effect, comprising an insulating medium cavity 1, an ultraviolet light source 2, a gas inlet 3, an optical lens 4, a grid 5, a radio frequency coil 6 and a photoelectric conversion electrode 7, the insulating medium cavity 1 Both ends are open, and the lower port is connected to the photoelectric conversion electrode 7; the optical lens 4 is installed at the upper port of the insulating medium cavity 1 and sealed; the radio frequency coil 6 is sleeved in the insulating medium cavity 1 Periphery of the middle part; the insulating medium cavity 1 is provided with the gas inlet 3 and the grid 5 in sequence between the optical lens 4 and the radio frequency coil 6; the ultraviolet light source 2 is arranged on the front of the optical lens 4 above.

[0021] The material of the insulating medium cavity 1 is quartz, the inner diameter ...

Embodiment 2

[0023] Example 2, see figure 1 Shown:

[0024] The structure of this embodiment is basically the same as that of Embodiment 1. The material of the insulating medium cavity 1 is glass, the inner diameter is 1mm, and the length is 20mm; the working gas is argon, and the gas flow rate is 1mL / min; the ultraviolet light source 2 is capable of emitting A light source with a wavelength less than 400nm; the aperture of the gas inlet 3 is 0.1 mm, 1 mm apart from the radio frequency coil and the optical lens; the material of the optical lens 4 is quartz, and its structural shape is a concave lens; The power supply applies a positive voltage, which is nickel material, and the hole density is 200 mesh; the radio frequency coil 6 is powered by a radio frequency power supply, the power frequency is 1MHz, the power is 0.05W, and it is cooled by air cooling or water cooling; the photoelectric conversion electrode 7 is a power The function is smaller than the photon energy in the ultraviolet ...

Embodiment 3

[0025] Example 3, see figure 1 Shown:

[0026] The structure of this embodiment is basically the same as that of Embodiment 1. The material of the insulating medium cavity 1 is ceramics, the inner diameter is 9mm, and the length is 200mm; the working gas is argon, and the gas flow rate is 50mL / min; the ultraviolet light source 2 is capable of emitting A light source with a wavelength less than 400nm; the aperture of the gas inlet 3 is 10mm, 3mm apart from the radio frequency coil and the optical lens; the material of the optical lens 4 is magnesium fluoride, and its structural shape is a plane mirror; The positive voltage is applied by an external power supply, which is made of gold or aluminum, and the hole density is 10 meshes; the radio frequency coil 6 is powered by a radio frequency power supply, the power frequency is 50MHz, the power is 50W, and it is cooled by air cooling or water cooling; the photoelectric conversion electrode 7 It is a stainless steel electrode with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com