Monitoring type full-automatic positive and negative pressure water discharge device

A fully automatic, positive and negative pressure technology, used in drainage, gas discharge, safety devices, etc., can solve problems such as pipeline blockage, large space occupied by floats, and prolonged extraction time to achieve standards, improve drainage efficiency, and improve drainage. Efficiency and easy fault location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

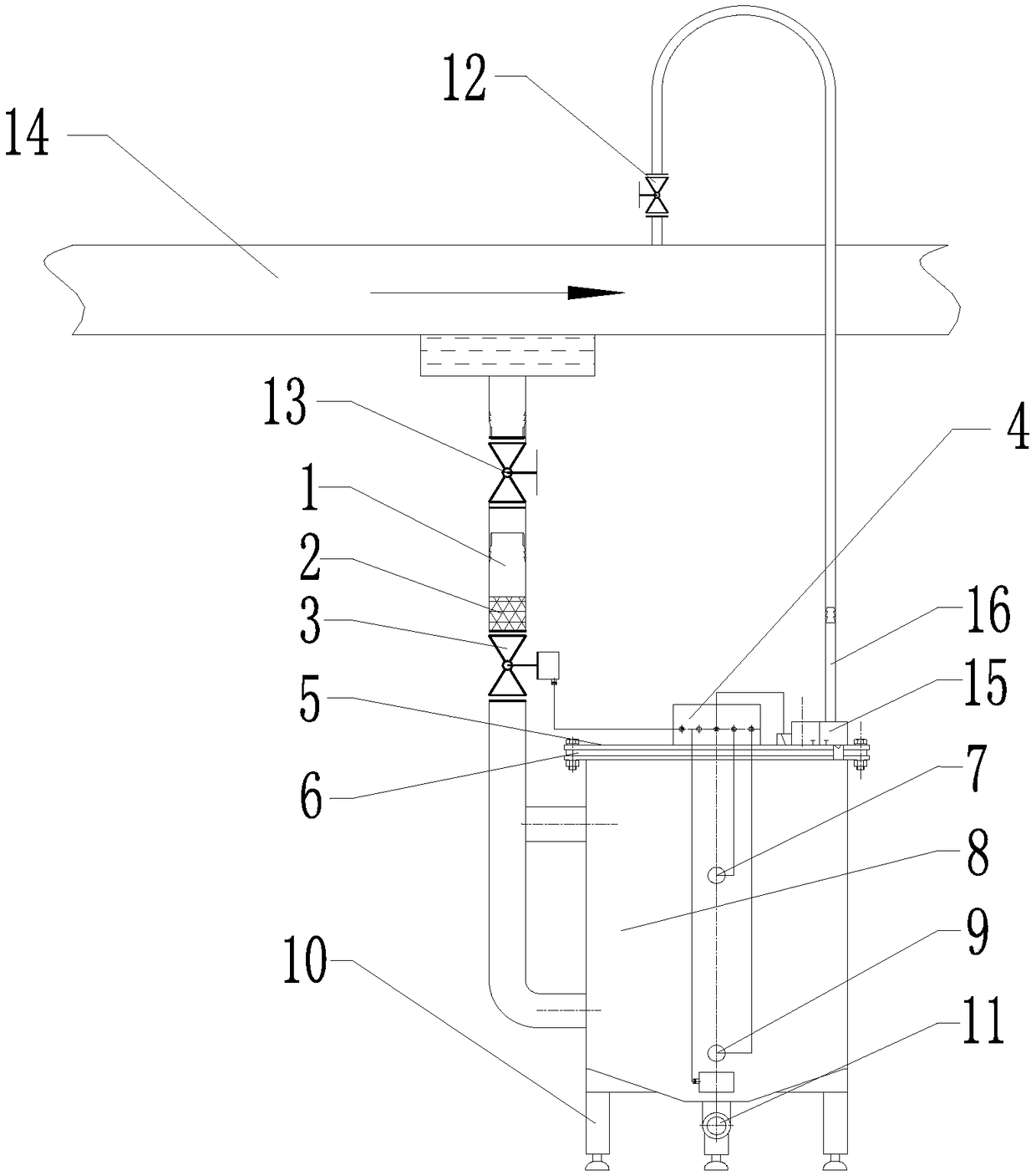

[0026] The above is the content of the technical scheme of the present invention, and the scheme of the present invention is described in detail as follows:

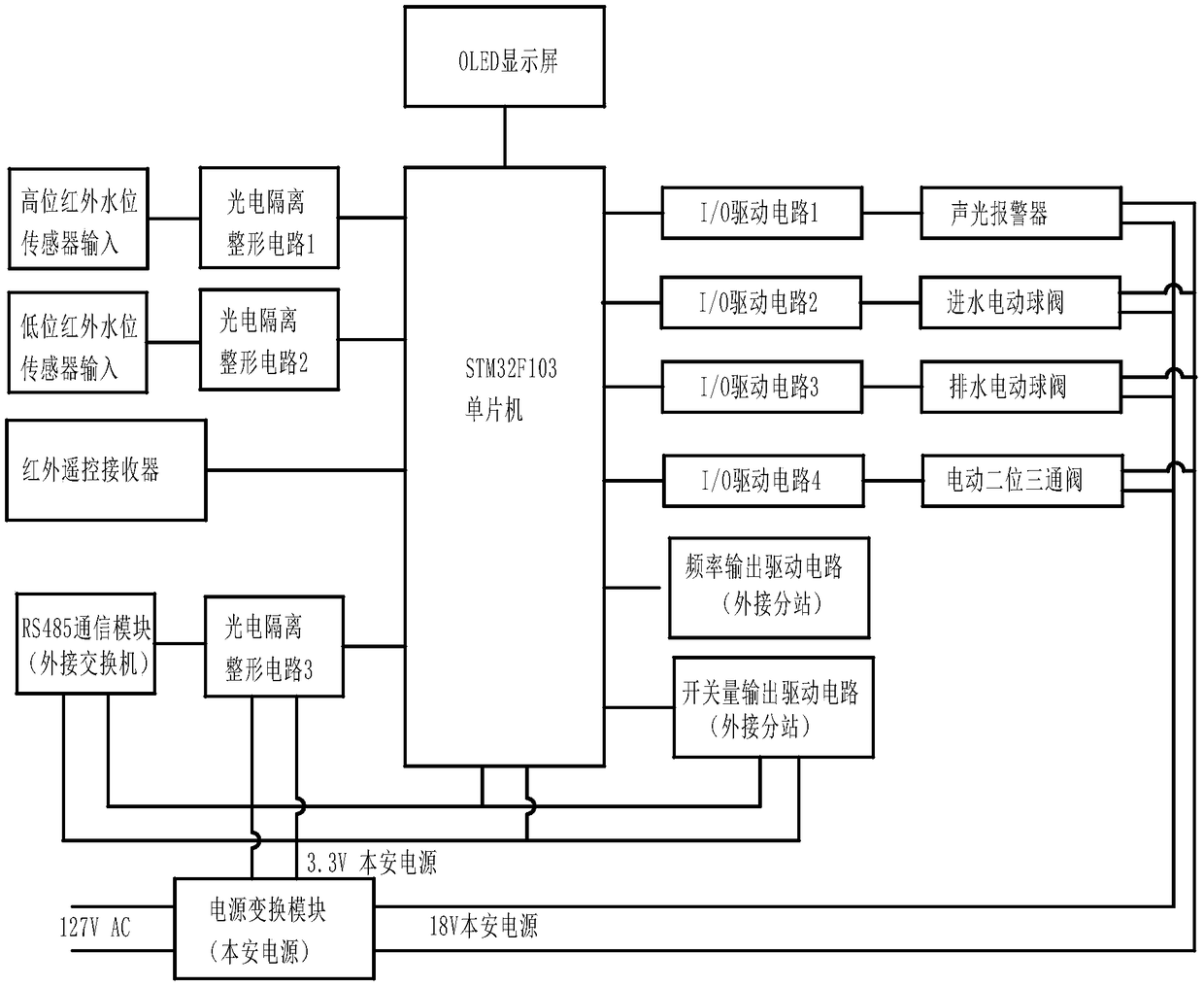

[0027] Combine figure 1 with figure 2 As shown, a monitoring type automatic positive and negative pressure water discharger disclosed by the present invention includes a water storage tank 8, a filter 2, an electric water inlet ball valve 3, a controller 4, a drainage electric ball valve 11 connected to the controller 4, and an electric Two-position three-way valve 15; the water storage tank 8 is provided with a low water level sensor 9 and a high water level sensor 7 connected to the controller 4, and the upper end of the water storage tank 8 is provided with a gasket 6, a flange 5, and an electric two-position three-way The valve 15 and the controller 4, the bottom of the water storage tank 8 is provided with an adjustable support seat; the filter 2 is connected to the gas pipeline 14 through the water inlet pipe 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com