Method for double-effect molten salt low-temperature regeneration of waste lithium cobalt oxide positive electrode material

A cathode material, low-temperature regeneration technology, applied in chemical instruments and methods, cobalt compounds, battery electrodes, etc., can solve problems such as high energy consumption, high cost, non-compliance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for low-temperature regeneration of waste lithium cobaltate cathode material with double-effect molten salt, the specific steps are as follows:

[0028] (1) Preparation of a molten salt system: mixing three lithium salts lithium hydroxide, lithium nitrate and lithium acetate according to a mass ratio of 2:3:2.5 to obtain a molten salt system;

[0029] (2) Mix the molten salt system in step (1) with the positive electrode material of the waste lithium cobaltate battery according to the mass ratio of 2:1, manually grind the mixture for 20 minutes, and mix to obtain the mixture;

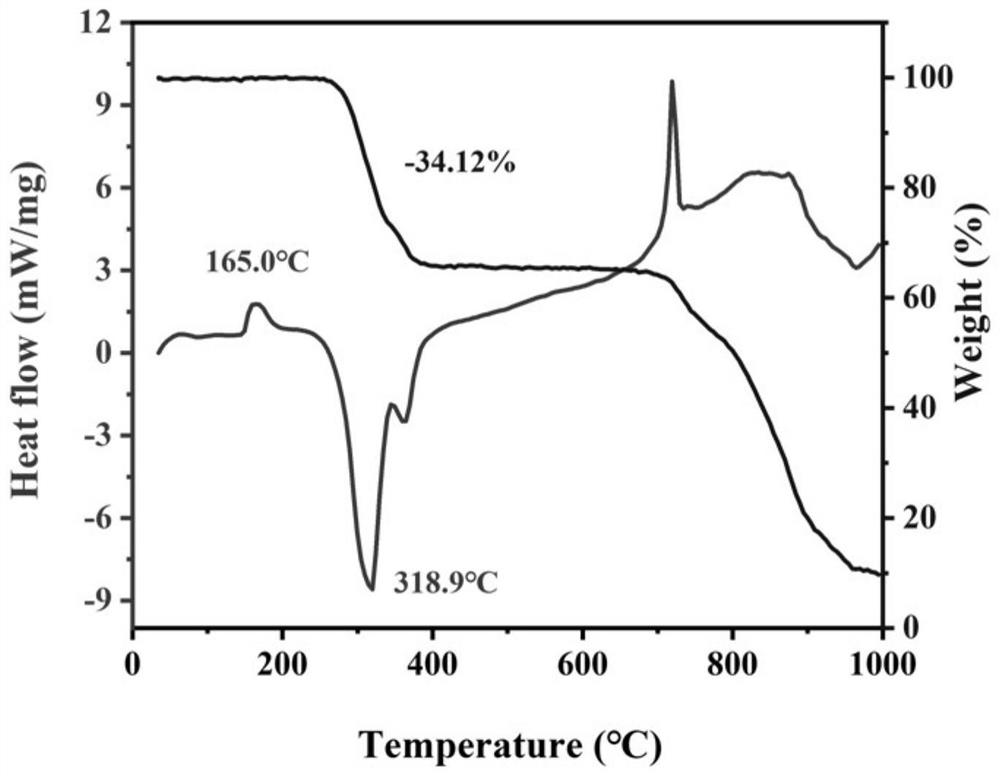

[0030] figure 1 It is the TG-DSC diagram of the molten salt system lithium hydroxide:lithium nitrate:lithium acetate=2:3:2.5 in this example. It can be seen from the figure that at 165°C, the lithium salt in the molten salt system is lithium ion In this embodiment, 165°C is selected as the regeneration temperature;

[0031] (3) Heat the mixture in step (2) to 165°C at 4°C / min and keep ...

Embodiment 2

[0033] A method for low-temperature regeneration of waste lithium cobaltate cathode material with double-effect molten salt, the specific steps are as follows:

[0034] (1) Preparation of molten salt system: three kinds of lithium salt lithium hydroxide, lithium nitrate and lithium acetate were mixed according to the mass ratio of 2:3:2.5 to obtain a molten salt system;

[0035] (2) Mix the molten salt system in step (1) with the positive electrode material of the waste lithium cobaltate battery according to the mass ratio of 2:1, manually grind the mixture for 20 minutes, and mix to obtain the mixture. The molten salt system is the same as that in Example 1. It can be observed from the DSC curve that the molten salt exists in a completely ionic state at 190°C. For a more complete reaction, 200°C is selected as the regeneration temperature in this example;

[0036] (3) Heat the mixture in step (2) to 200°C for 10 hours at 5°C / min in an air atmosphere. After the heat preservati...

Embodiment 3

[0042] A method for low-temperature regeneration of waste lithium cobaltate cathode material with double-effect molten salt, the specific steps are as follows:

[0043] (1) Preparation of a molten salt system: mixing three lithium salts lithium hydroxide, lithium nitrate and lithium acetate according to a mass ratio of 2:3:1 to obtain a molten salt system;

[0044](2) Mix the molten salt system in step (1) with the positive electrode material of the waste lithium cobaltate battery according to the mass ratio of 3:1, manually grind the mixture for 30 minutes, and mix to obtain the mixture;

[0045] Figure 6 It is the TG-DSC diagram of the molten salt system lithium hydroxide: lithium nitrate: lithium acetate=2:3:1 in this embodiment, it can be seen from the figure that the molten salt medium can reach the molten ionic state at 184.8°C, 184.8 °C can meet the reaction requirements, but it can be further observed from the DSC curve that the reaction ends at 208 °C. For a more co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com