Self-absorption rotational flow pneumatic atomization nozzle device

A pneumatic atomization and nozzle device technology, which is applied in combustion methods, lighting and heating equipment, continuous combustion chambers, etc., can solve the problems that the atomization fineness is greatly affected by hydraulic pressure, small flow nozzles are blocked by carbon deposits, and oil pumps are prone to wear and tear. and other problems, to achieve the effects of good fuel atomization quality, enhanced combustion, good ignition and combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

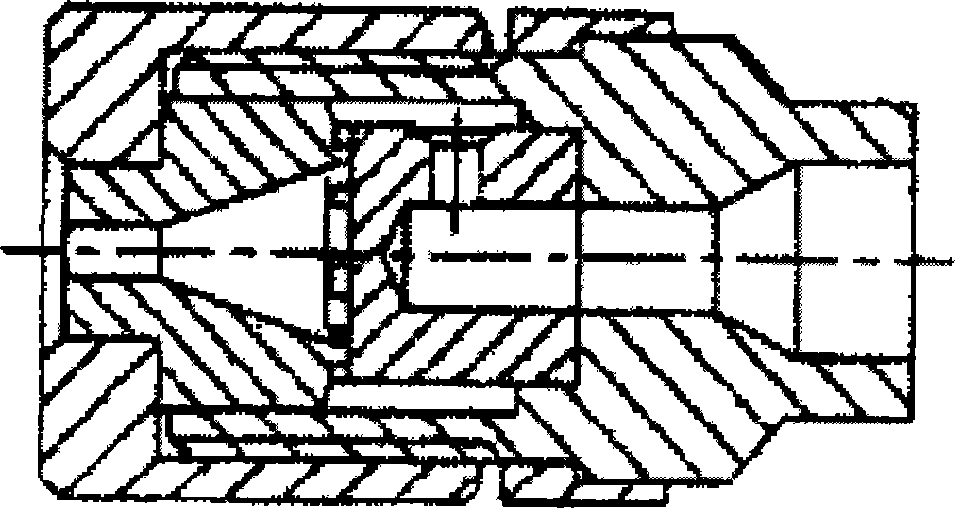

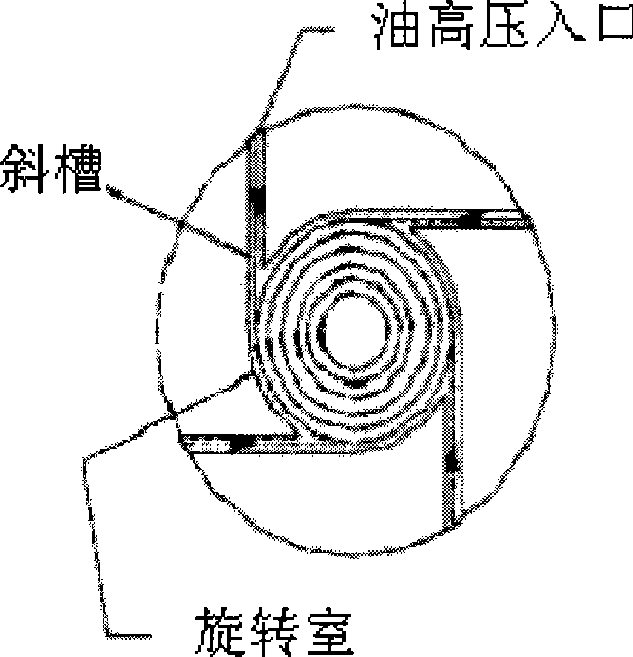

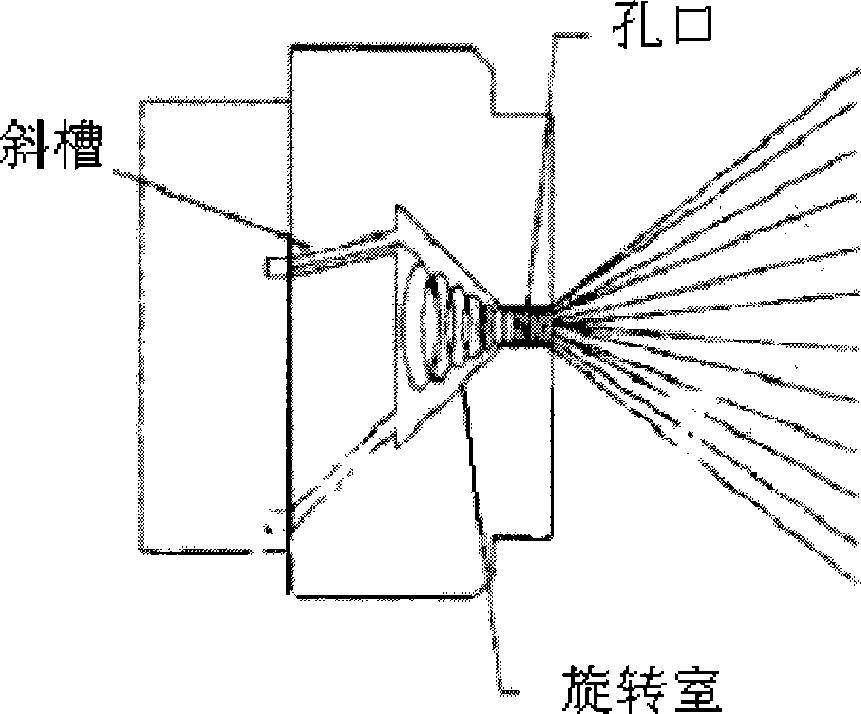

[0045] Embodiment 1: attached Figure 11 It is a schematic diagram of a self-priming swirling pneumatic atomizing nozzle device, which consists of a compression nut 1, an atomizing sheet 2, a swirling sheet 3, a guide sheet 4, a fixing piece 5, a sealing ring 6, a connecting piece 7, and an oil inlet hole 8. Air intake hole 9, air intake groove 10, tangential air hole 11, oil hole 12, swirl chamber 13, spray hole 14.

[0046] The compression nut 1 is connected with the connecting piece 7 and the fixing piece 5 through threads, and the atomizing piece 2, the swirl piece 3, and the guide piece 4 are compressed through the fixing piece 5; the outlet of the atomizing piece 2 is connected with the compression nut 1, The inlet is compressed with the swirl vane 3; the inlet of the swirl vane 3 is pressed with the guide vane 4, or the swirl vane 3 and the guide vane 4 are integrated, the middle is an oil hole, the outer side is an inclined groove, and the outlet is connected to the mi...

Embodiment 2

[0052] Self-priming swirl pneumatic atomizing nozzle device, including compression nut 1, atomizing sheet 2, swirl sheet 3, guide sheet 4, fixing piece 5, sealing ring 6, connecting piece 7, oil inlet hole 8, inlet Air hole 9, air inlet groove 10, tangential air hole 11, oil hole 12, swirl chamber 13, spray hole 14 are formed.

[0053] The compression nut 1 refers to a compression piece processed from copper, which is connected to the connecting piece 7 and the fixing piece 5 through threads, and the atomizing piece 2, the swirl piece 3, and the guide piece 4 are connected by the fixing piece 5 Compress to ensure that their centers are on the same axis; the atomizing sheet 2 refers to an inner cone processed with wear-resistant stainless steel, the rotating air flow accelerates the rotation at its inner edge, the outlet is compressed with the compression nut 1, and the inlet Compressed with the swirl sheet 3; the swirl sheet 3 refers to a cylindrical body processed by wear-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com