Patents

Literature

55results about How to "Avoid frequent maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

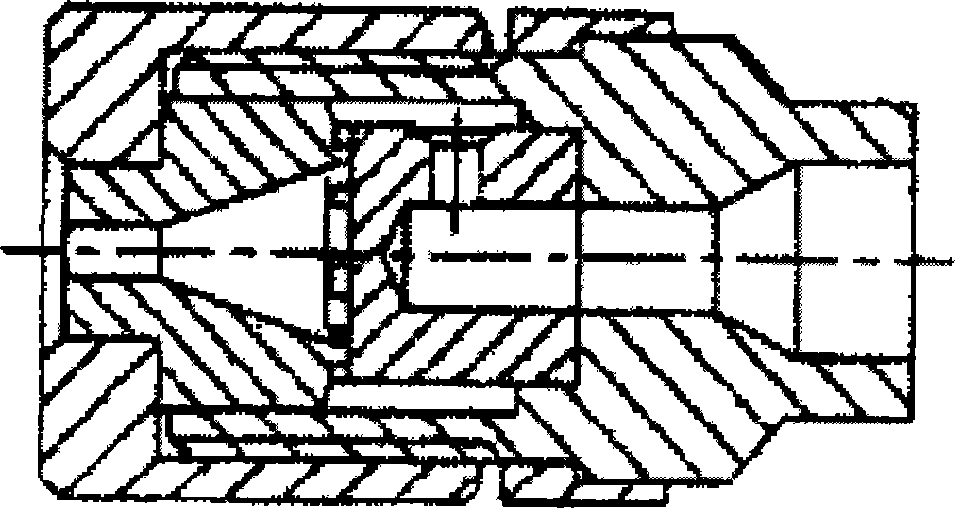

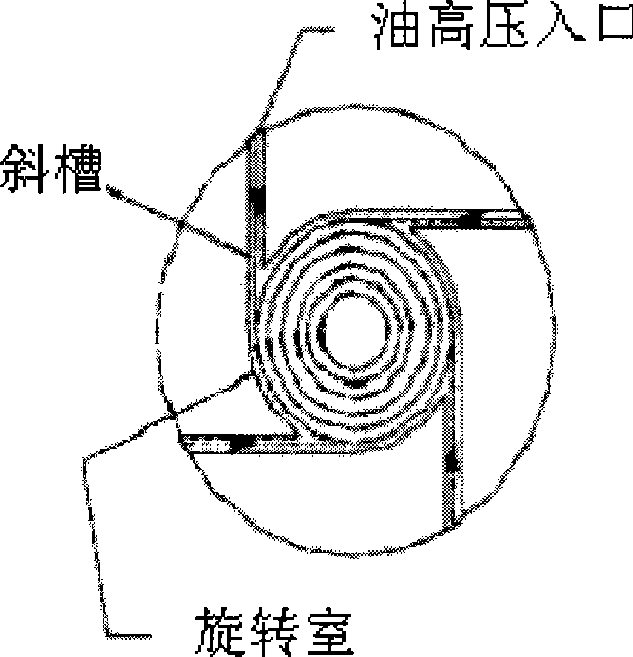

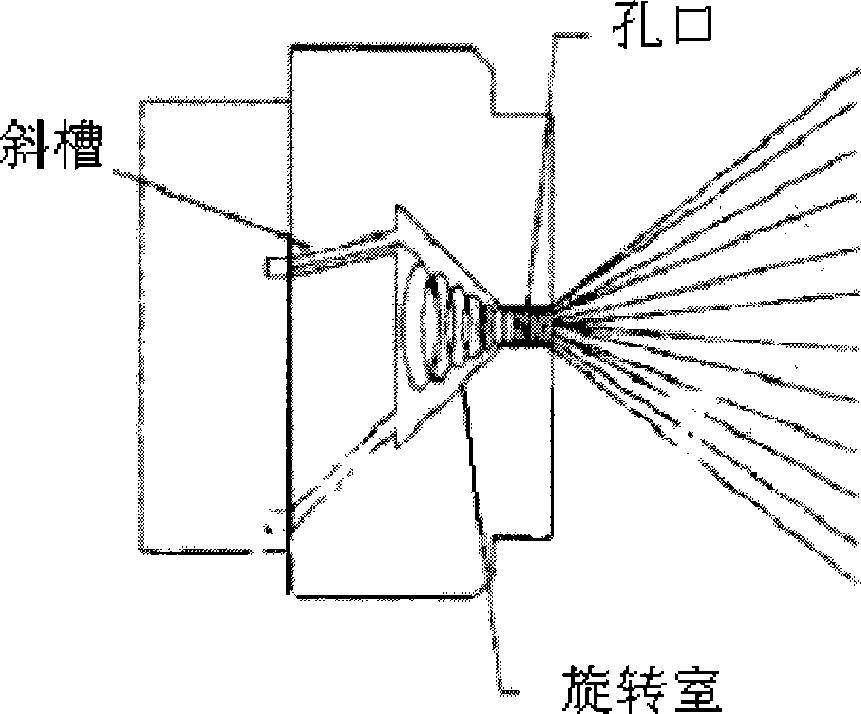

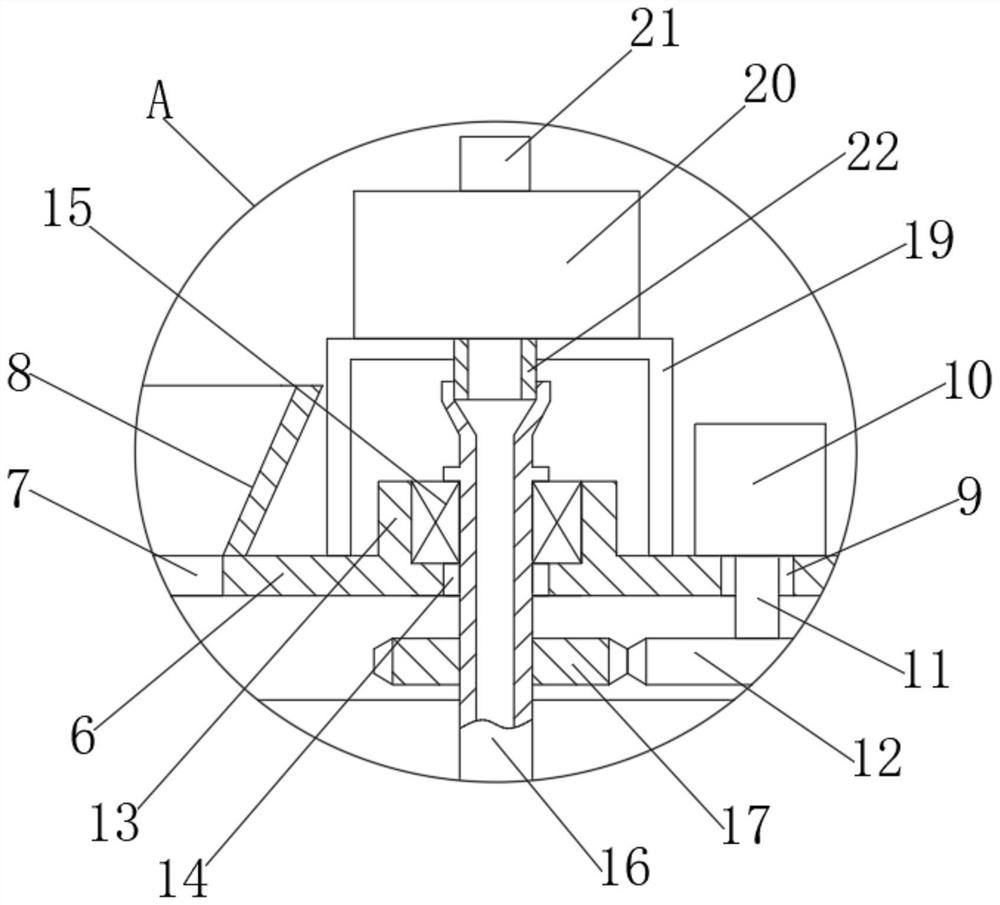

Self-absorption rotational flow pneumatic atomization nozzle device

InactiveCN101398186AGood fuel atomization qualityReasonable spatial distributionContinuous combustion chamberCombustion systemCombustion

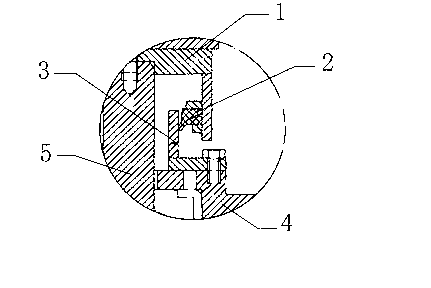

The invention discloses a self-sucking swirl pneumatic atomizing nozzle device relating to a fuel atomizing evaporation mixing nozzle used for a full-automatic combustion engine and belongs to the field of industrial combustion systems. An atomizing sheet 2, a swirl sheet 3 and a stream guidance sheet 4 are compressed closely by a compression nut 1 and a fixing piece 5; the atomizing sheet 2 is an internal cone and the outlet of the atomizing sheet 2 is a spout 14; the swirl sheet 3 is provided with a tangential air hole 11; the outlet hole of the stream guidance sheet 4 is an oil hole 12 and the outlet of the stream guidance sheet 4 is a swirl chamber; the compression nut 1 is connected with the fixing piece 5 and a connecting piece 7; the outer surface of the upstream of the fixing piece 5 is provided with a seal ring 6; an oil inlet hole 8 is the inner hole of the connecting piece 7; an air inlet hole 9 is the connection hole of the connecting piece 7 along the radical and coaxial direction; compared with the existing centrifugal nozzle or pneumatic atomizing nozzle, the self-sucking swirl pneumatic atomizing nozzle device does not need an oil pump; has the advantages of improving the fuel atomizing evaporation mixing characteristic and the distribution uniformity of oil-gas space, improving the combustion performance, reducing contamination discharge, having no coking and plugging, and is an ideal nozzle for combusting the heavy oil and waste oil by the full-automatic combustion engine.

Owner:PEKING UNIV +1

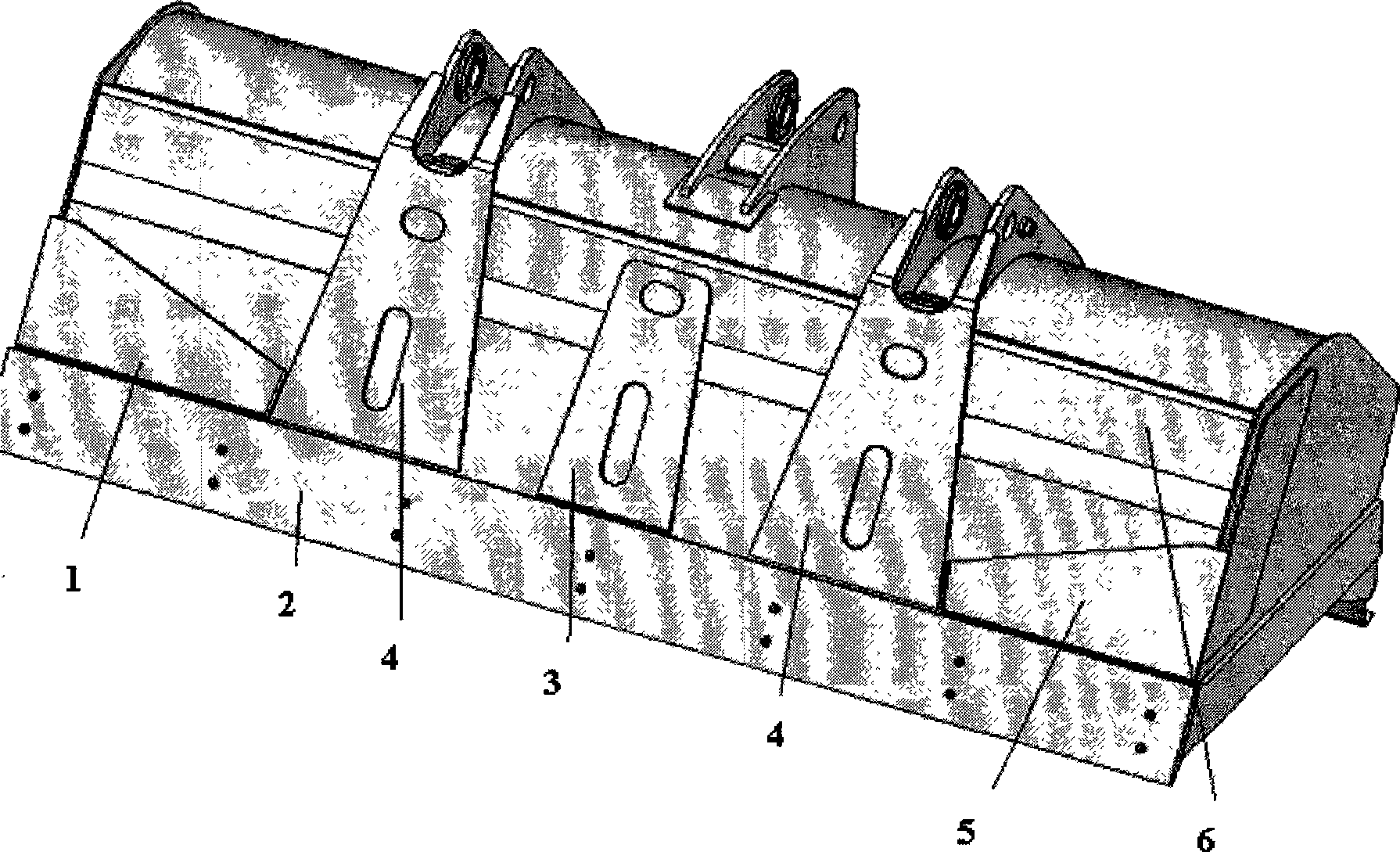

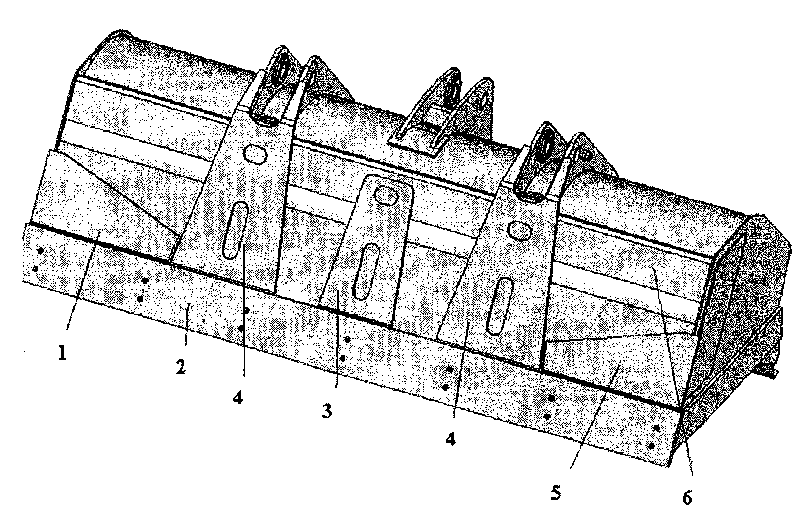

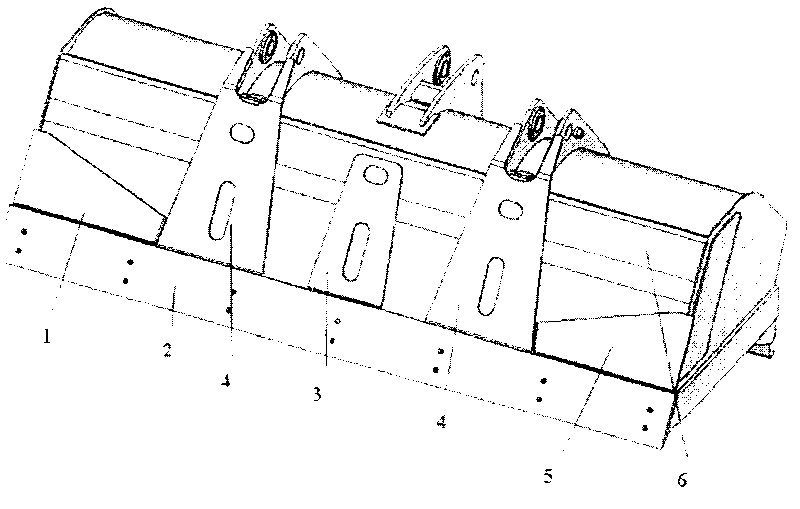

Method for realizing abrasion proof treatment to loader hopper and special welding wire thereof

InactiveCN101456123AImprove efficiencySuitable for mass productionArc welding apparatusWelding/cutting media/materialsIsosceles trapezoidSheet steel

The invention discloses a method for performing anti-wear treatment on a hopper of a loading machine, which comprises the following steps: using a low-carbon steel or low-alloy steel plate as a base plate, selecting a build-up welding flux-cored soldering wire of which the diameter is between 2.0 and 4.0 millimeters special for the hopper of the loading machine, and welding a wear-resisting layer of which the thickness is between 3.5 and 8.0 millimeters on the base plate by adopting a visible arc build-up welding or gas coverage build-up welding process to prepare a wear-resisting composite steel plate; by adopting a plasma cutting device, cutting out a left wear-resisting plate and a right wear-resisting plate in a right trapezoid shape respectively, a middle wear-resisting plate in an isosceles trapezoid shape, and two bottom plates in isosceles trapezoid shapes on the wear-resisting composite steel plate; leveling the plates; and putting the cut wear-resisting layers of the left wear-resisting plate, the middle wear-resisting plate, the two bottom plates and the right wear-resisting plate outwards, and welding the wear-resisting layers on the outside surface of the hopper bottom of the main cutting board side of the hopper respectively through gas shielded arc welding or welding rod arc welding so that the wear-resisting layers are integrated with the original hopper bottom into a whole. After the treatment by the method, the service life of the hopper is greatly improved, the frequent maintenances are avoided, the working efficiency of the loading machine is improved, and steel materials are saved.

Owner:SHANDONG LINGONG CONSTR MACHINERY

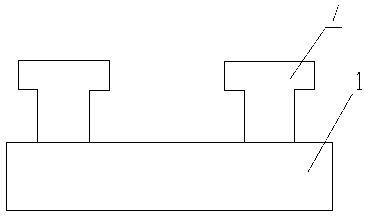

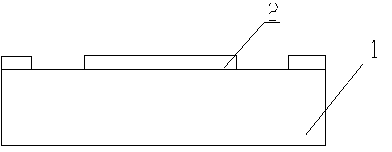

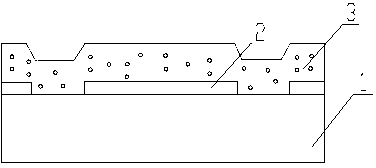

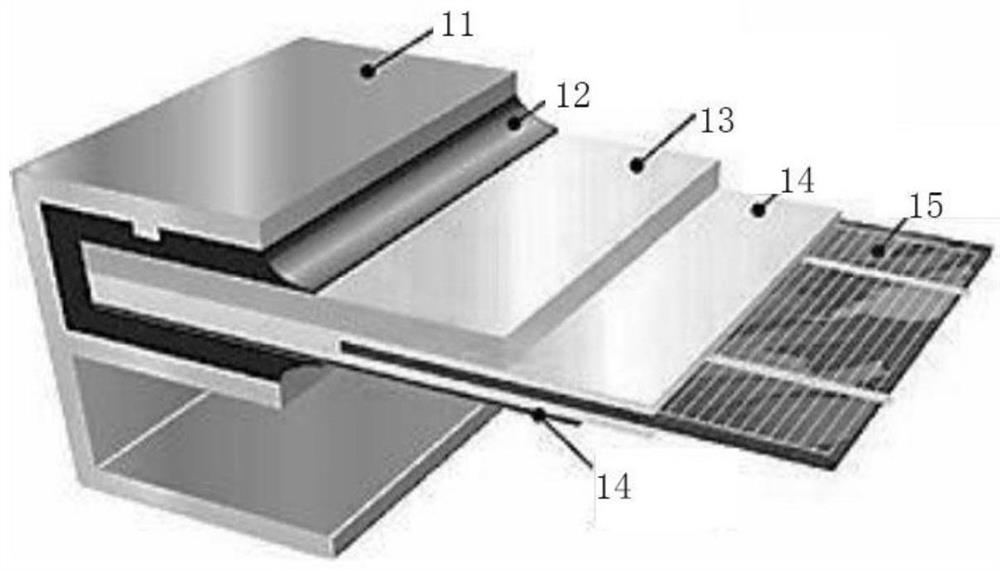

High-temperature-resistant MIM capacitor for microwave internal matching transistor and manufacturing method thereof

ActiveCN103219318AIncreased photolithography processAvoid stressSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMicrowave

The invention discloses a high-temperature-resistant MIM capacitor for a microwave internal matching transistor and a manufacturing method of the high-temperature-resistant MIM capacitor and relates to the technical field of integrated circuits and manufacturing methods of the integrated circuits. The high-temperature-resistant MIM capacitor comprises a substrate, a metal lower electrode, an insulating medium layer and a metal upper electrode, wherein the metal lower electrode is fixed on the upper surface of the substrate, the insulating medium layer wraps outside the metal lower electrode, a metal lower electrode extracting hole which penetrates through the insulating medium layer is formed in the insulating medium layer, a lower electrode extracting electrode which is fixedly connected with the metal lower electrode is arranged in the metal lower electrode extracting hole, and the metal upper electrode is fixed on the upper surface of the insulating medium layer. The manufacturing method of the high-temperature-resistant MIM capacitor for the microwave internal matching transistor can avoid that the insulating medium layer is influenced by stress. The high-temperature-resistant MIM capacitor for the microwave internal matching transistor has the advantages of being good in microwave characteristics and high-temperature operating characteristics, and easy to process.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

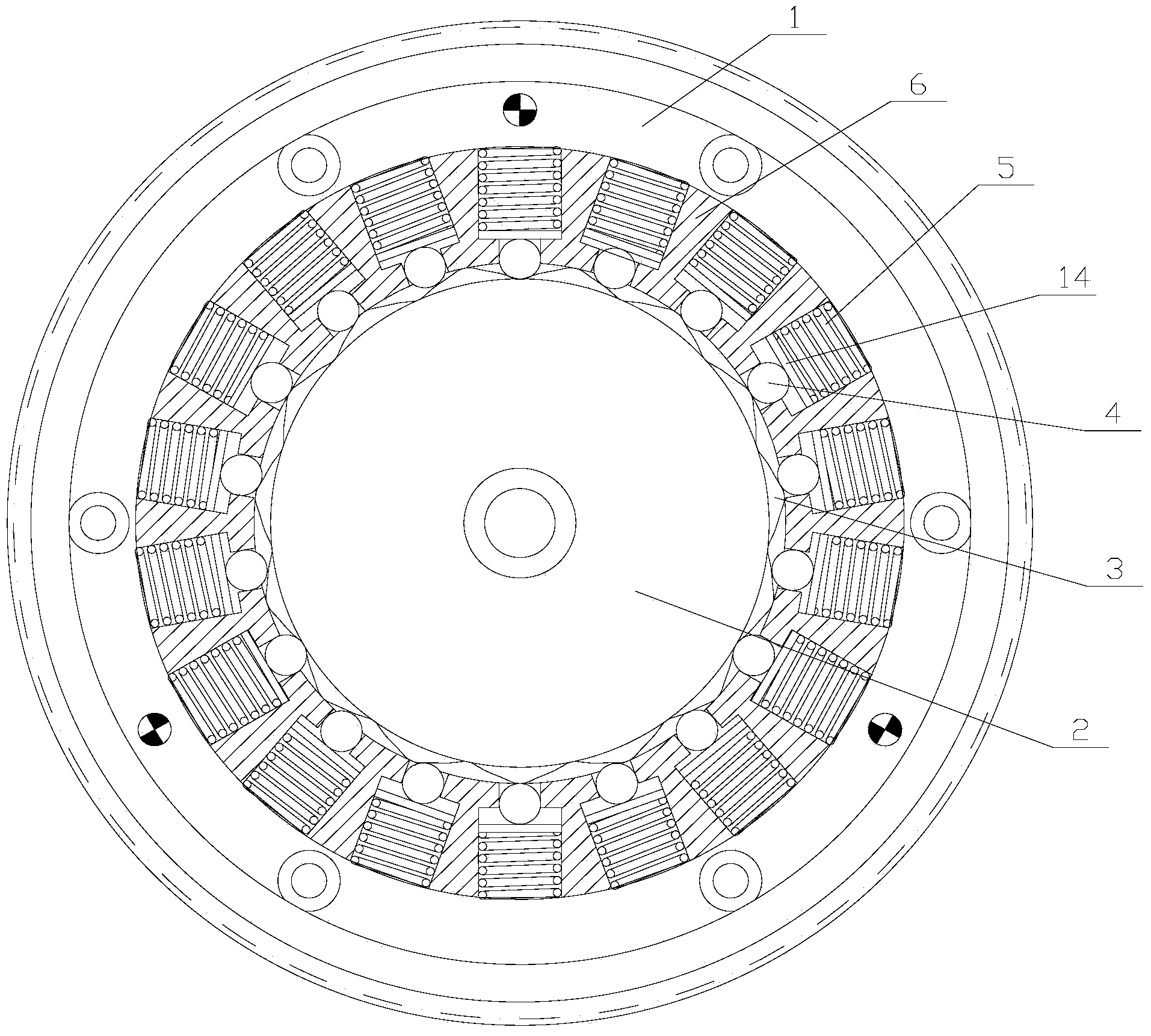

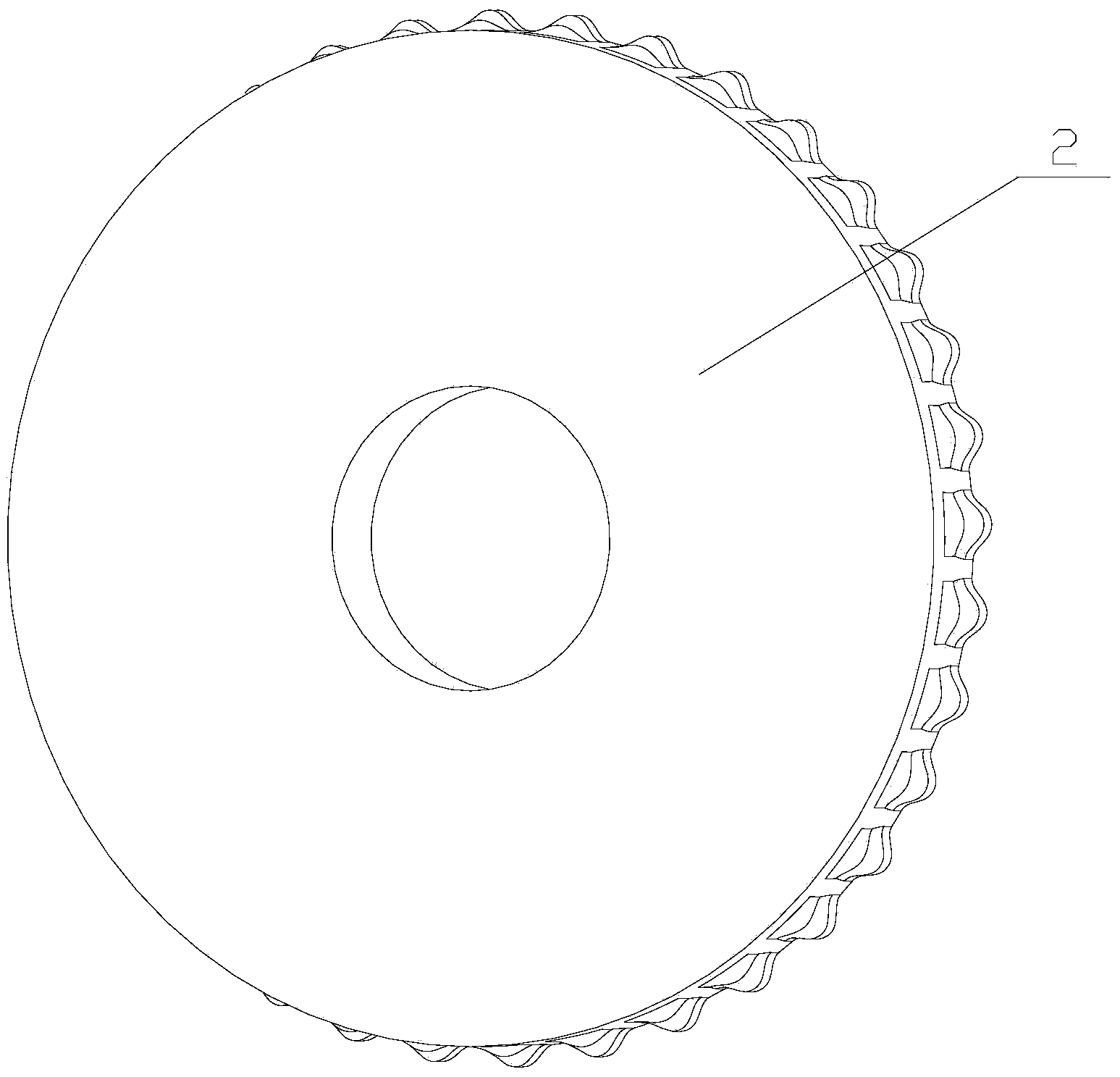

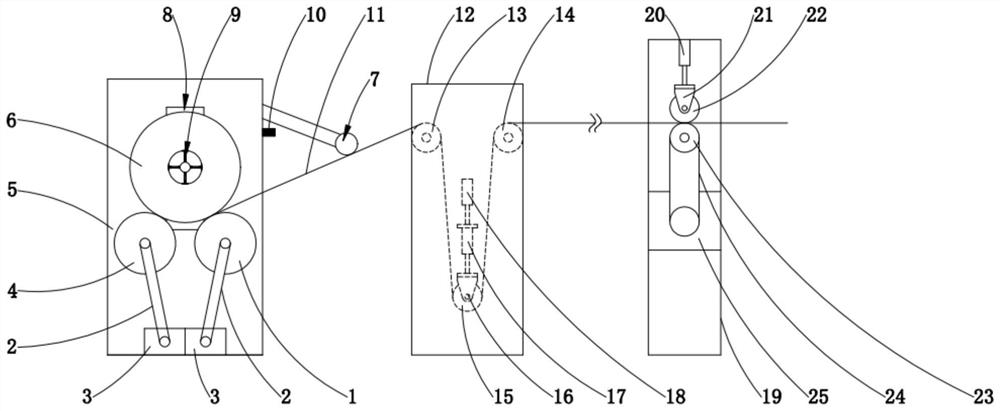

Non-friction clutch

ActiveCN103925308AStrong ability to transmit torqueImprove powerMechanical actuated clutchesGear toothContinuous variable

The invention discloses a non-friction clutch which comprises a driving part, a driven part and a transmission part. The driving part and the driven part are coaxially assembled together in a sleeved mode and matched with each other in a rotary mode, and the rotary matching face of the driven part is provided with gear teeth; the transmission part comprises a floating block which is radially arranged on the rotary matching face of the driving part in a floating mode and is in mesh transmission with the gear teeth; the tangential angle of the floating block and the action point of the gear teeth can be changed continuously; the transmission part is of a transmission structure where the floating block is matched with the gear teeth, and the tangential angle of the action point of the floating block and the gear teeth is made to be changed continuously with in a certain range to generate continuous variable joint force; when the tangential angle is relatively large, equal-torque output is achieved, torque transmission capacity is strong, dynamic performance is good, meanwhile, the floating block and the gear teeth are in non-friction match so that the problems that overhaul is frequent and service life is short due to abrasion of the parts can be avoided, and operation cost is lowered.

Owner:CHONGQING LONGWANG ELECTROMECHANICAL

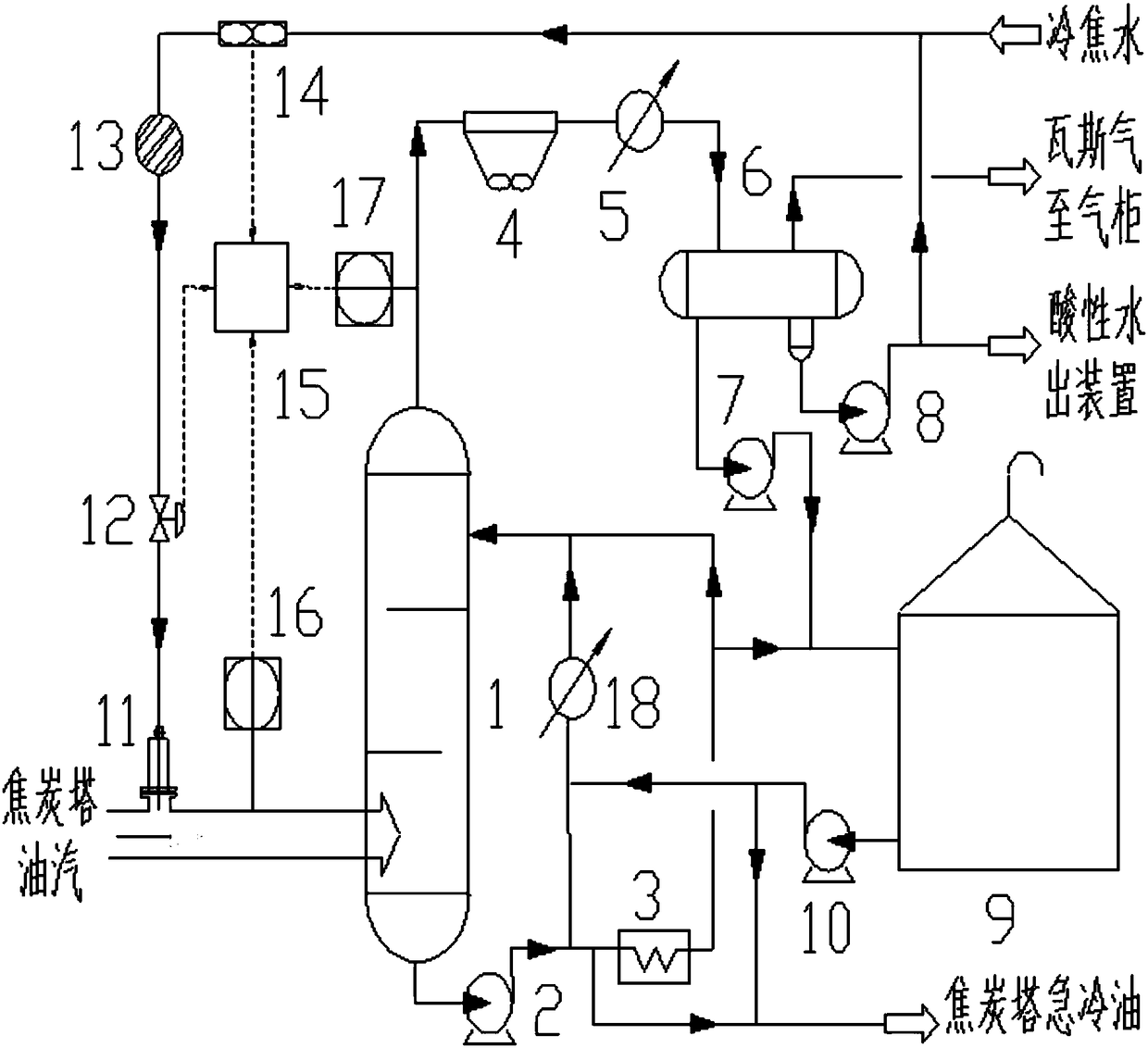

Delayed coking steam-blast emptying system

InactiveCN108264923AReduces the chance of falling off on impactReduce lossesThermal non-catalytic crackingGas purification by non-gaseous materials condensationGas compressorProcess engineering

The invention belongs to the field of petroleum refining, and particularly relates to a delayed coking steam-blast emptying system. A large amount of high-temperature oil gas and steam which are generated in the steam-blasting and water feed coke cooling process in an original coke tower does not directly enter a steam-blast emptying tower for washing, and reversely contact with atomized acidic water or coke cooling water reversely sprayed by an atomizing nozzle mounted on the feeding line of the steam-blast emptying tower, the obtained cooled and washed mixed gas enters the steam-blast emptying tower, and reverse atomizing spraying cooling washing reduces the impact of the large amount of the high-temperature mixed gas to a baffle plate in the steam-blast emptying tower, reduces pollutedoil and coke powder in gaseous heavy components from the top of the steam-blast emptying tower to avoid waxing obstruction of a heat exchanger, and also can reduce coke powder and water in emptied gasin order to avoid frequent maintenance of a gas holder gas compressor.

Owner:NORTH HUAJIN CHEM IND CO LTD

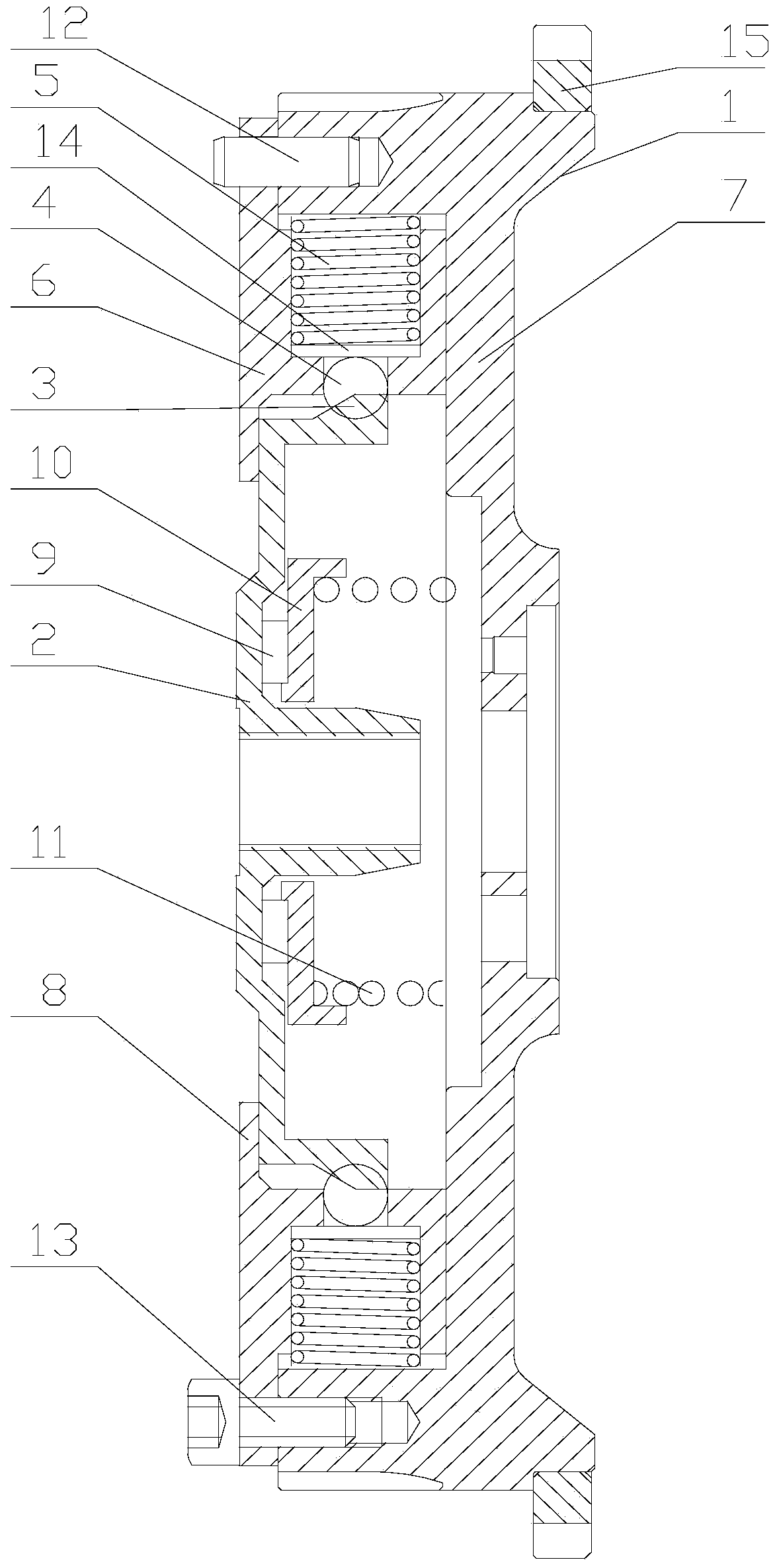

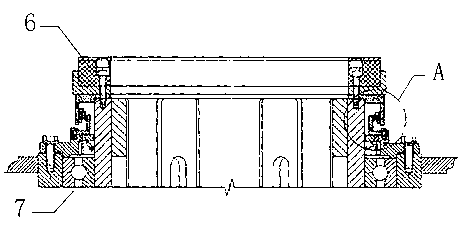

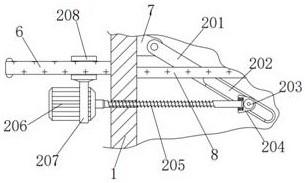

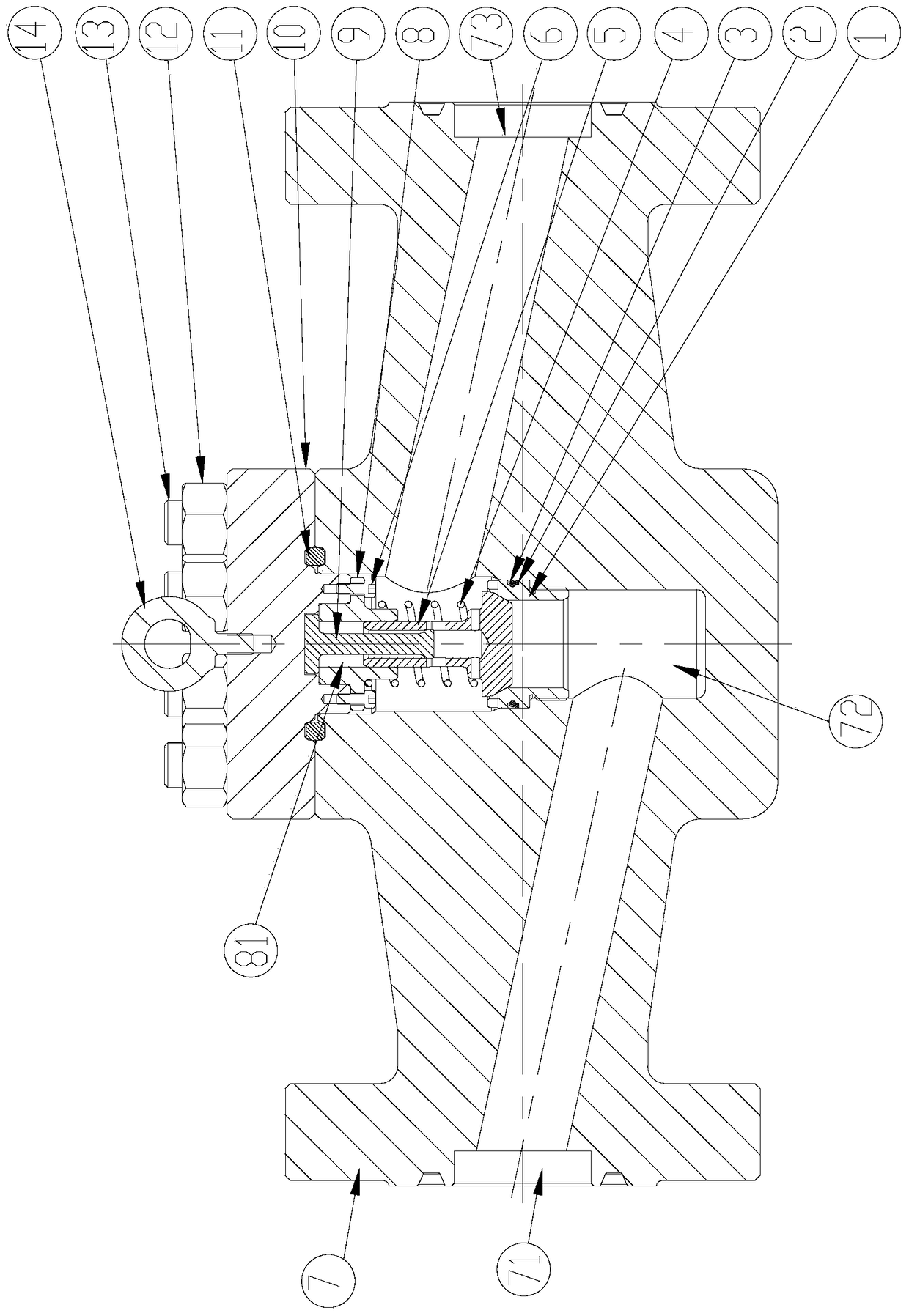

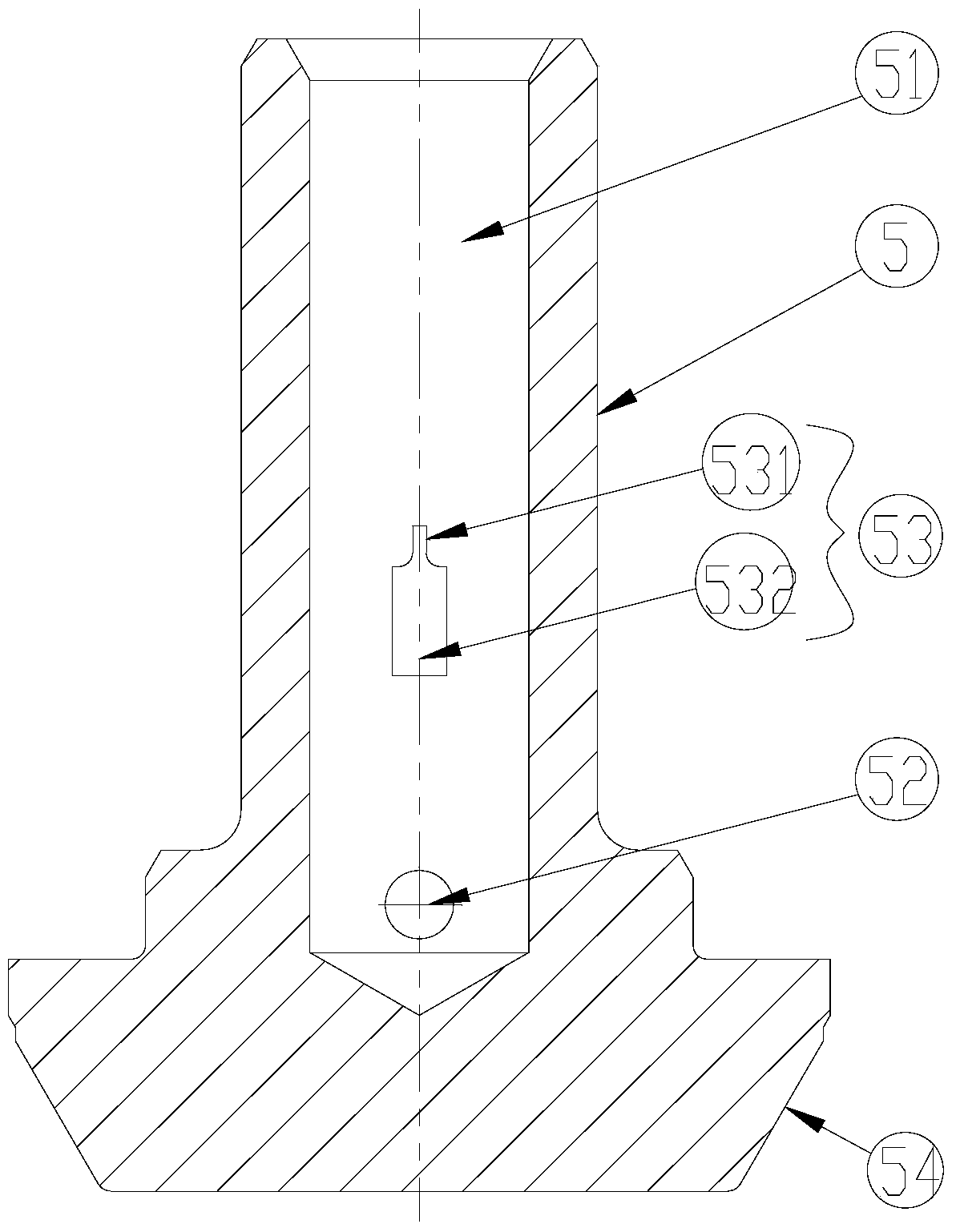

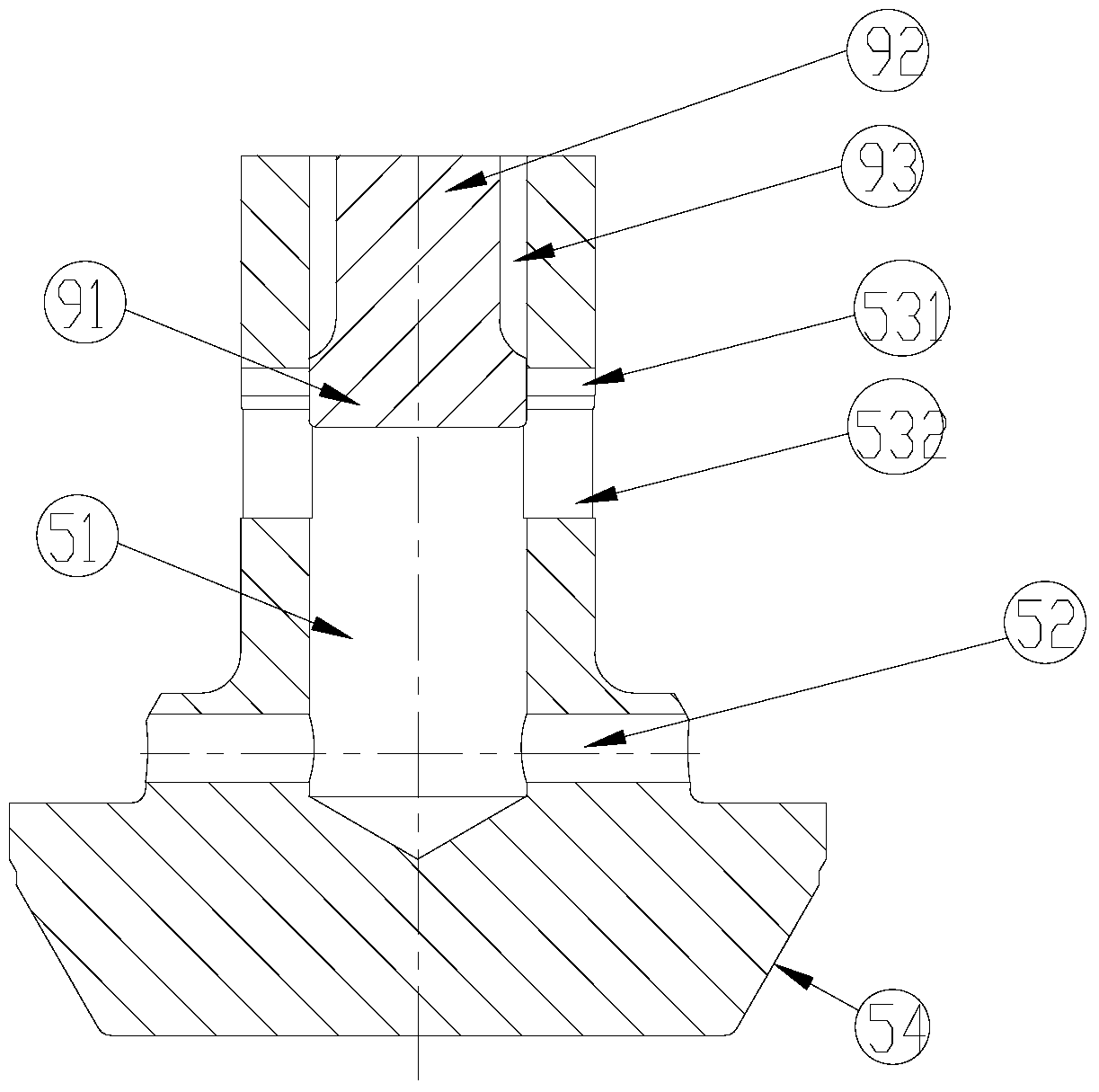

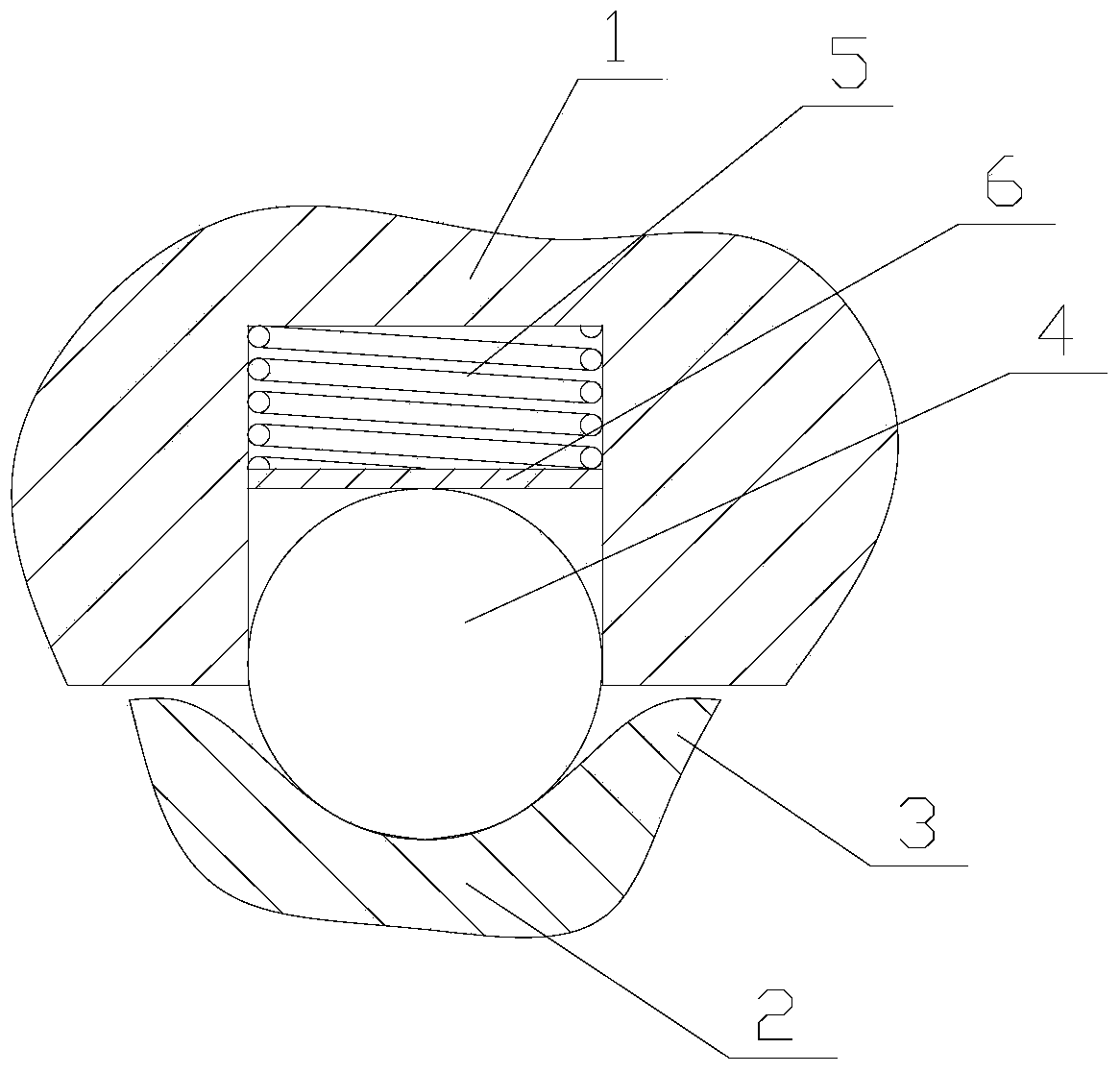

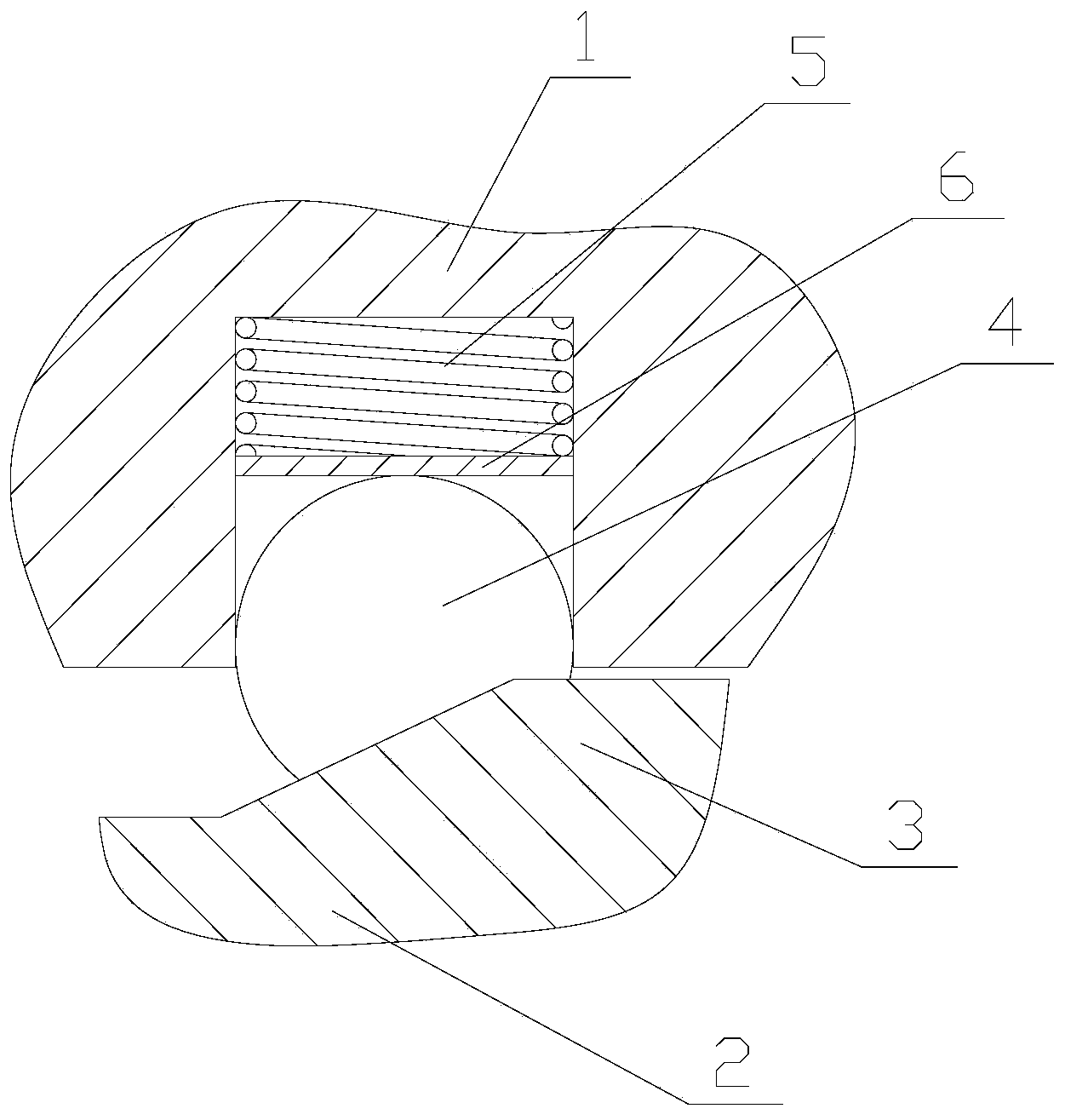

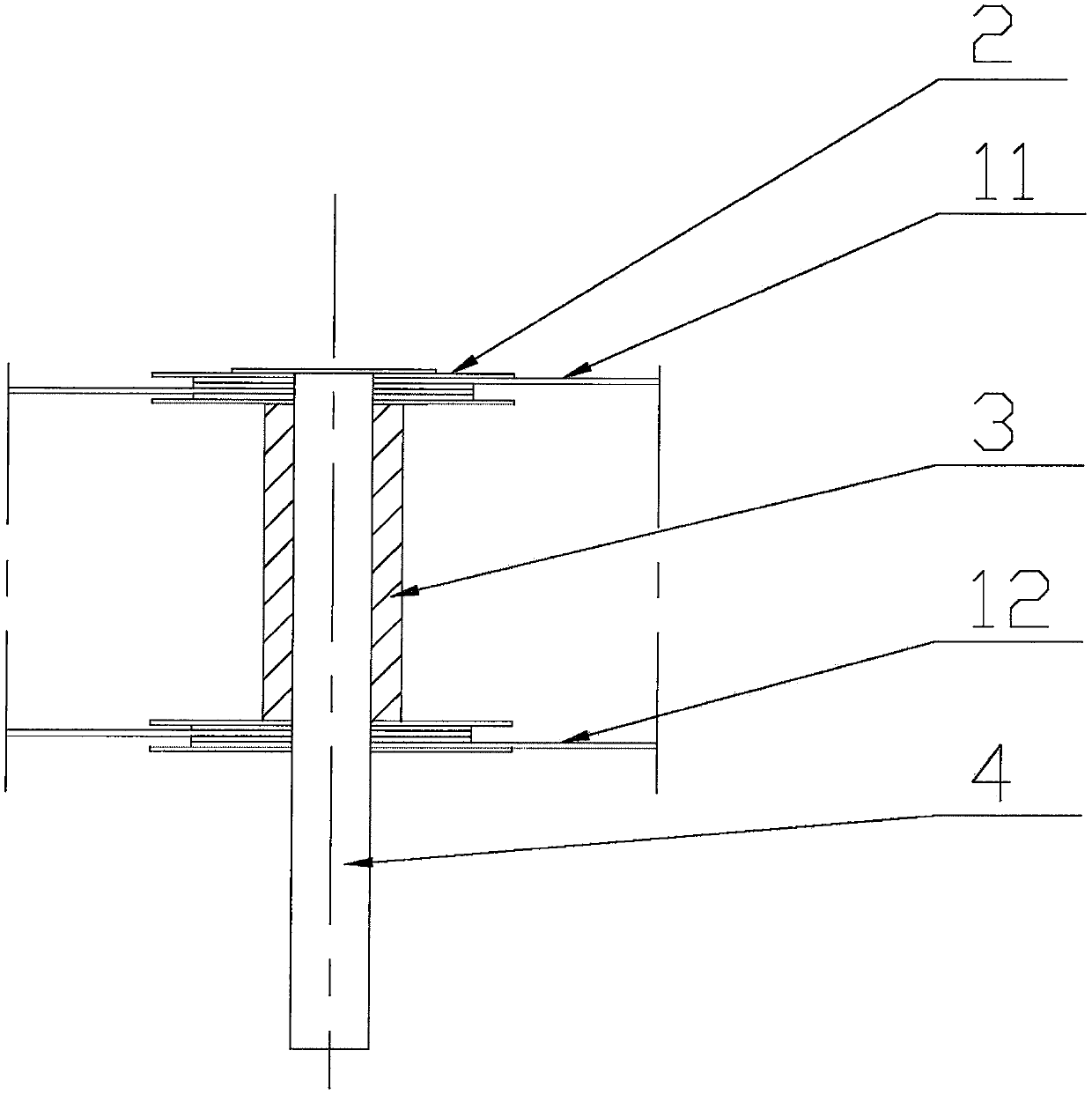

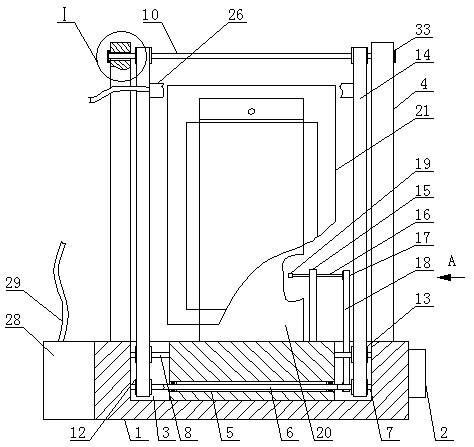

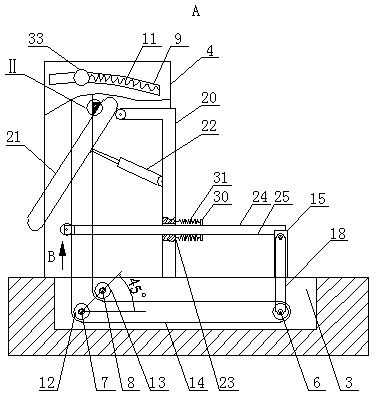

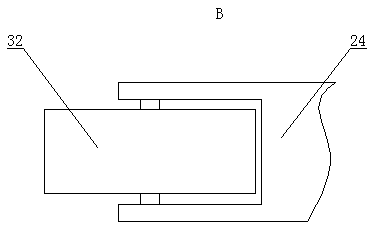

Mud-prevention sealing device of power head

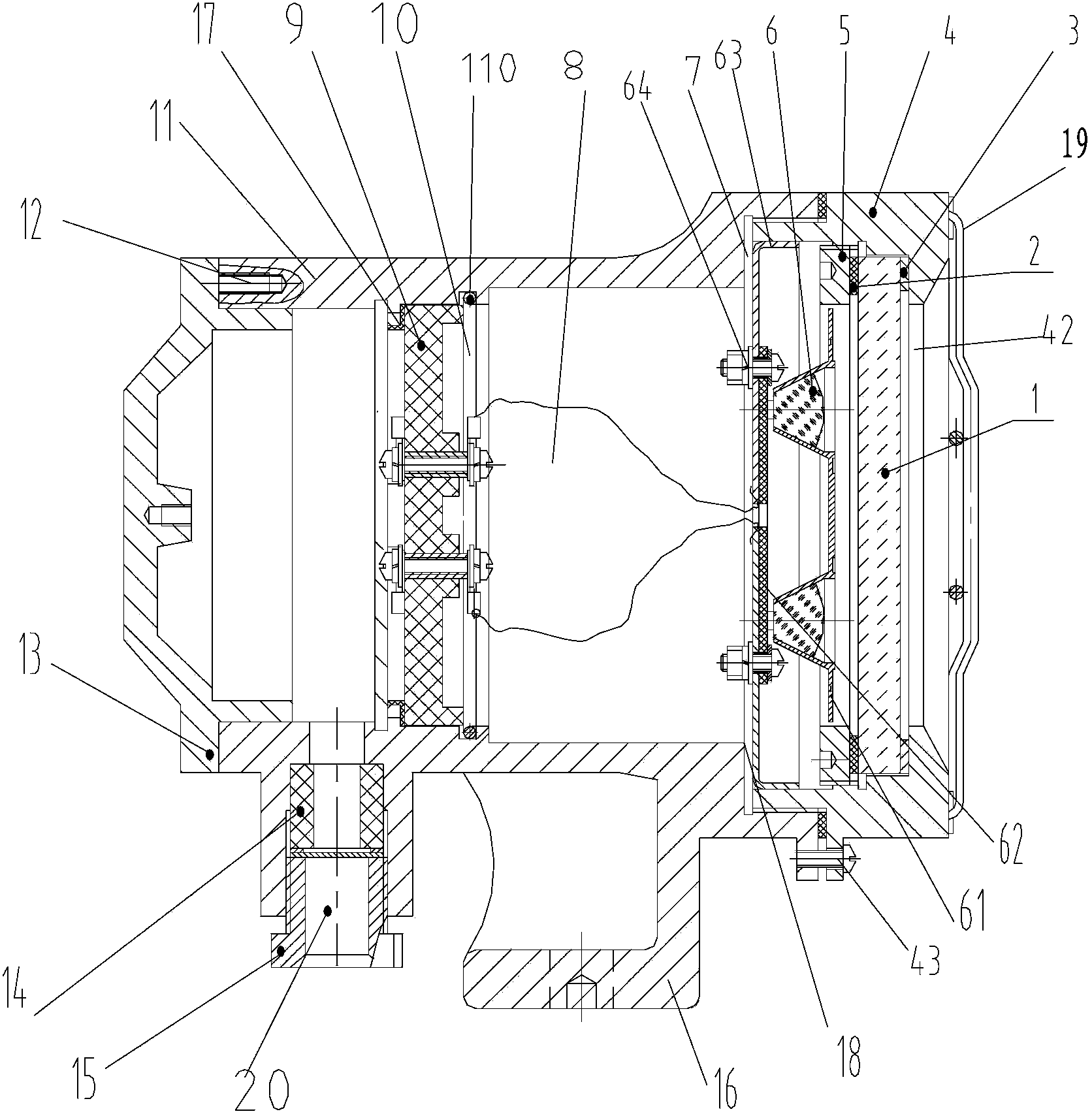

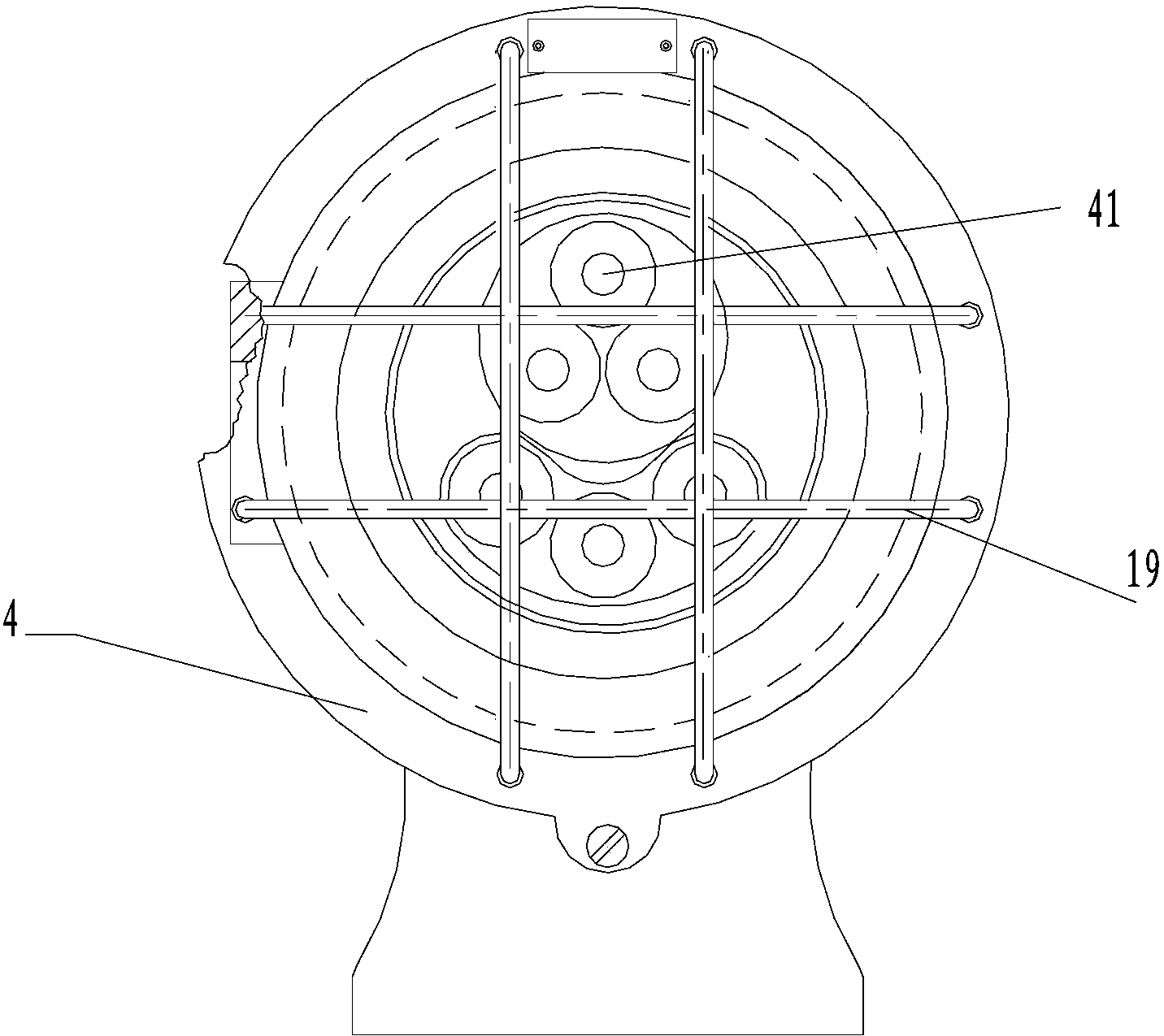

ActiveCN102853083AAvoid frequent maintenanceLow costEngine sealsMotive powerElectrical and Electronics engineering

The invention discloses a mud-prevention sealing device of a power head. The mud-prevention sealing device comprises a power head shock-absorbing device and a power head box body, wherein a shock-absorbing base plate is arranged at the bottom of the power head shock-absorbing device, an upper sealing pressing cover is arranged at the upper end of the power head box body, a sealing cavity is arranged between the shock-absorbing device and the power head box body, a labyrinth sealing structure is arranged between contact surfaces of the upper sealing pressing cover and the shock-absorbing base plate, and the inside of the sealing cavity and the inside of the labyrinth sealing structure is filled with lubricating grease. By the aid of the technical scheme, the service lives of gears, bearings, oil seals and gear lubricating grease inside the power head box body are prolonged, the problems of frequent maintenance of the power head and the high maintenance cost which are caused by the fact that mud enters the power head are avoided, and the overall performance of the power head is improved.

Owner:QINGDAO LOVOL EXCAVATOR

LED (Light Emitting Diode) mine explosion-proof locomotive lamp

InactiveCN103574397AImprove reliabilityImprove airtightnessLighting applicationsPoint-like light sourceFront coverEngineering

The invention relates to an LED (Light Emitting Diode) mine explosion-proof locomotive lamp, which comprises a front cover and a lamp tube. The front cover is connected with one end of the lamp tube through threads. The other end of the lamp tube is connected with a rear cover through threads. A front cover transparent mesh enclosure assembly, the lamp tube and the rear cover form a closed chamber in a surrounding manner. The LED mine explosion-proof locomotive lamp is characterized in that the lamp tube is provided with a first step surface and a second step surface; a light source device fixing plate, LEDs, a light reflecting plate, a light transmitting mirror and a circuit aluminum substrate are arranged on one side surface, facing to the front cover, of a light source fixing plate; a lamp holder inner chamber wiring board is connected with bolts for fixing a power driving device in a positioned manner; one side of the wiring board resists against the second step surface, and other side of the wiring board resists against a clamping ring; a wire incoming hole is formed in one end of the lamp tube, and a power line is connected with the power driving device of the wiring board through a wire incoming hole in a cable clamping and leading-in device. The LED mine explosion-proof locomotive lamp has the advantages that since the LEDs are used as illuminating light sources, the lamp is safe and reliable; since a thread explosion-proof and plane seam allowance explosion-proof design is adopted, and bolts capable of preventing a shell thread explosion-proof connection from getting loose are arranged as safety measures after the front cover and the lamp tube are fastened in an explosion-proof manner through the threads, the entire lamp has the effects of being very good waterproof, dustproof, explosion-proof, anti-seismic and safe.

Owner:杨玲

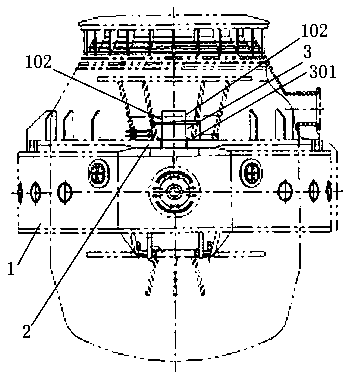

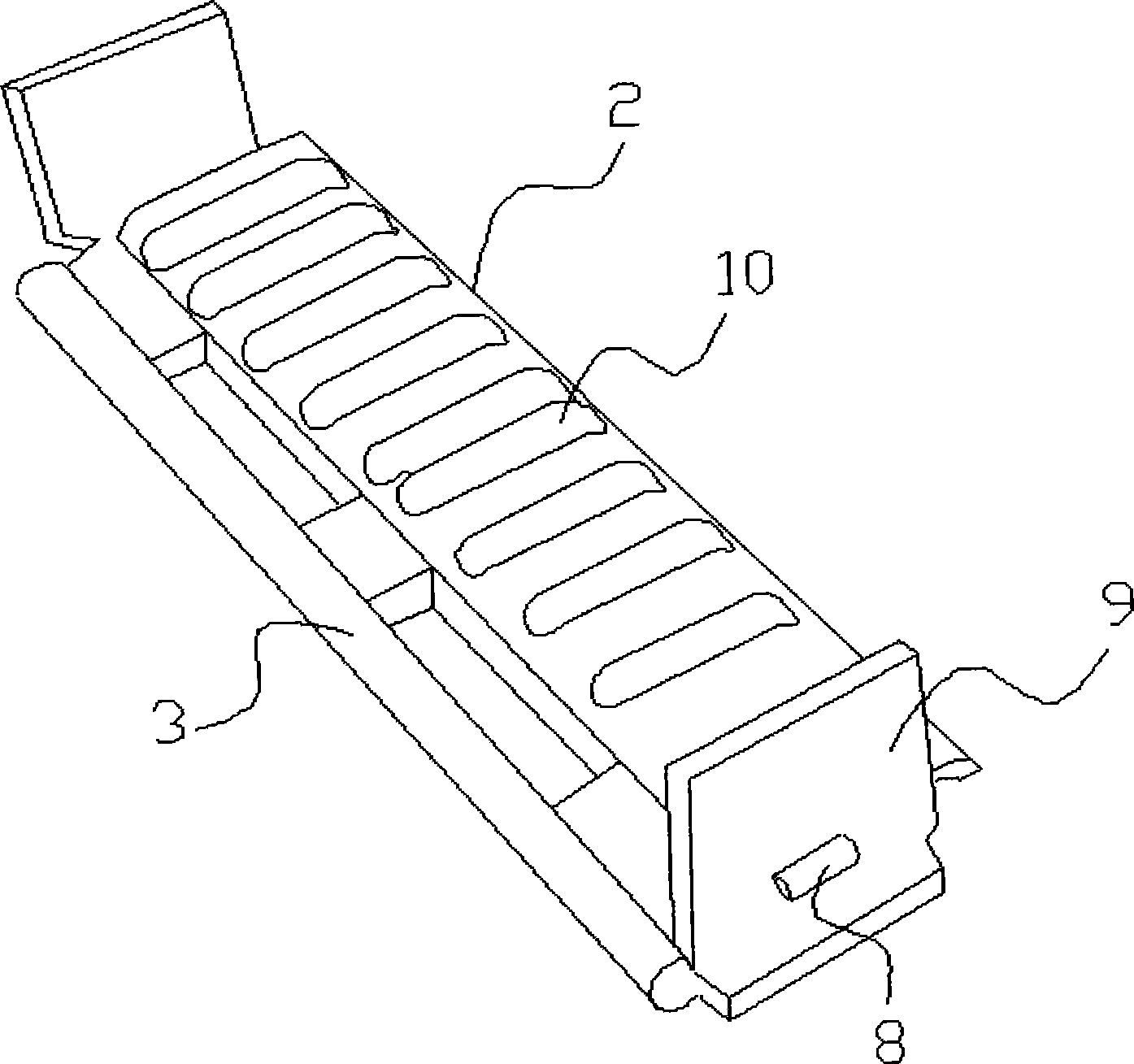

An induction wafer baking system

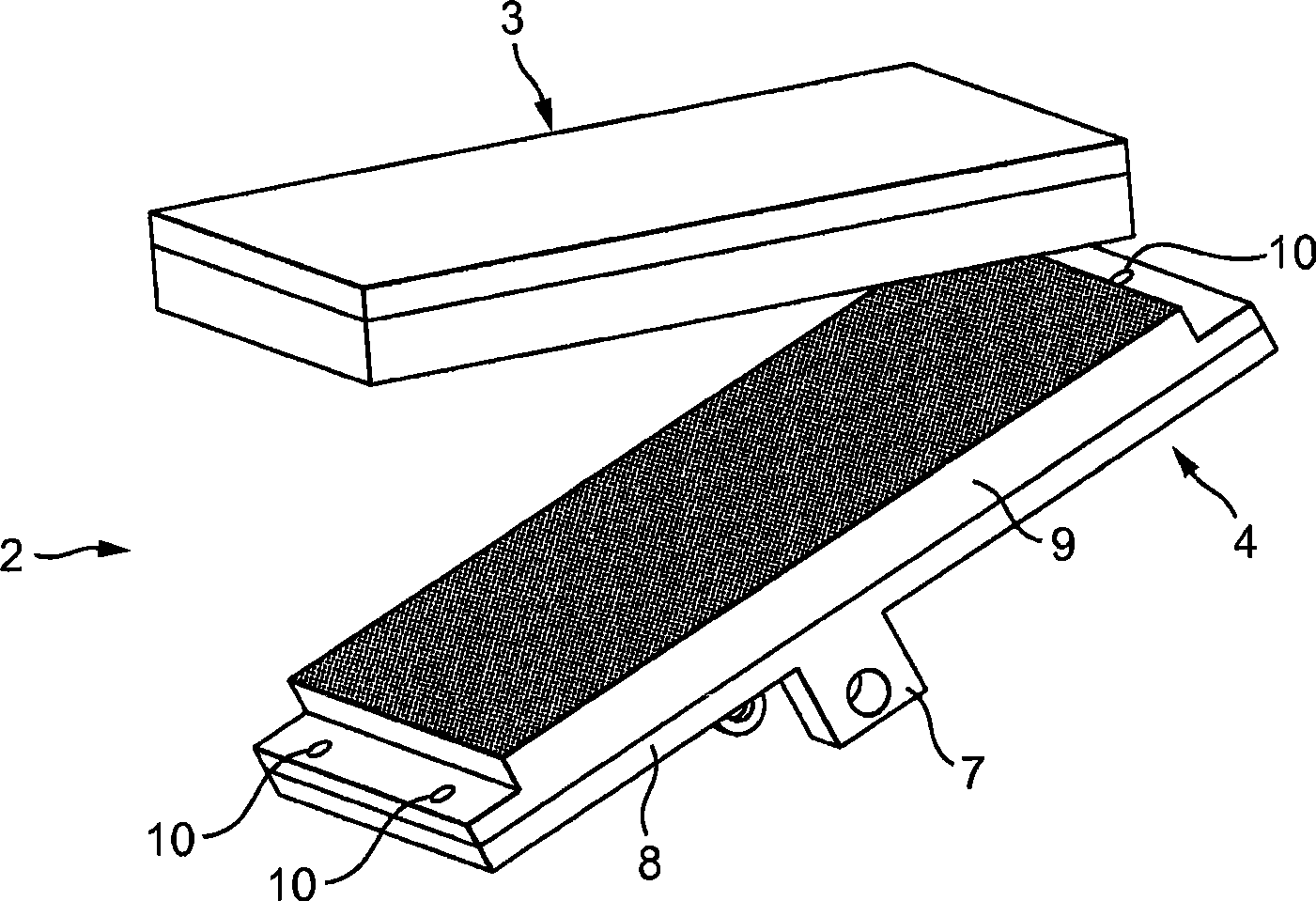

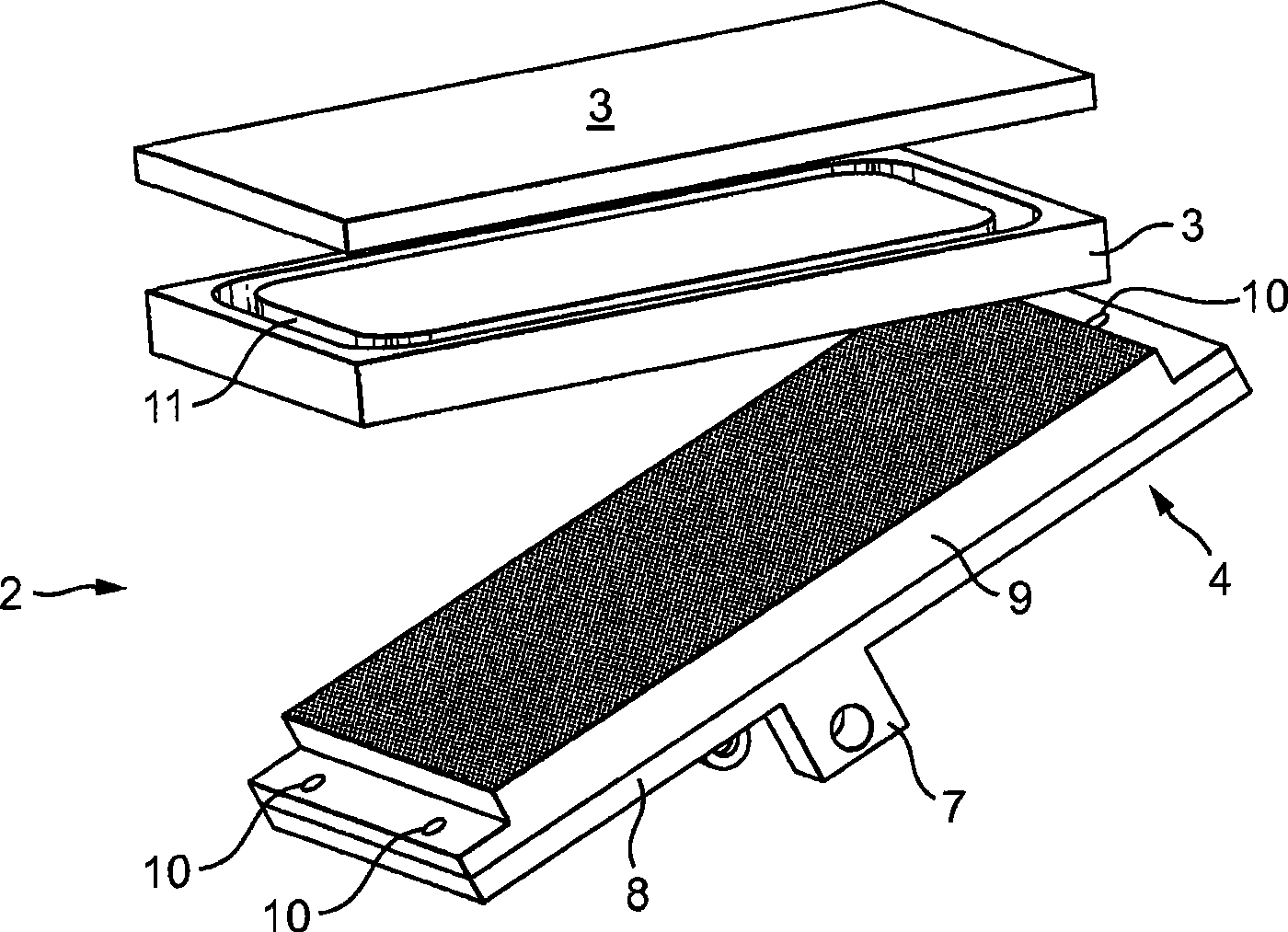

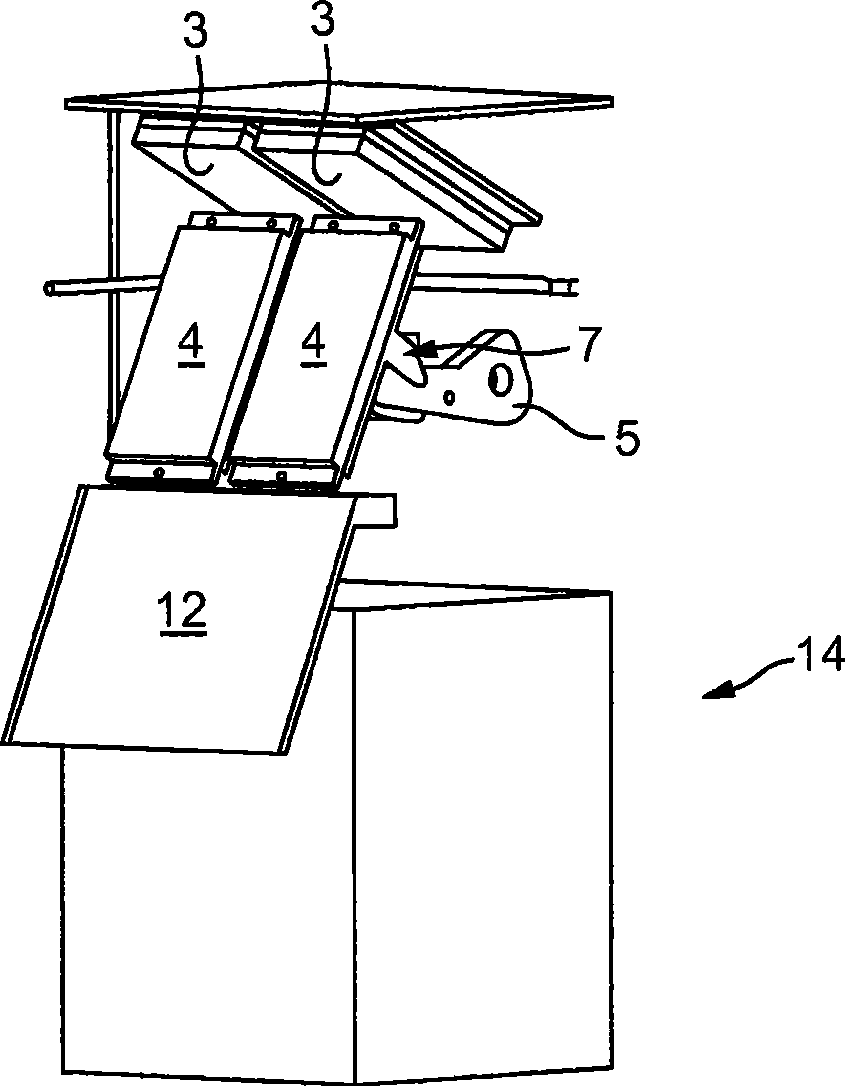

InactiveCN101511196ARegulated net outputAvoid wear and tearHollow article bakingProcess engineeringBakery equipment

The present invention relates to an automatic wafer baking apparatus (1) for baking wafers from a liquid or pasty dough, said apparatus (1) comprising at least two baking moulds (2), each having one pair of top (3) and lower (4) baking plates, said apparatus (1) further comprising moving means (5, 6, 7) for moving at least one plate relative to the other so that each baking mould (2) can move from a closed configuration to an open configuration, heating means for heating the plates (3, 4) to a predetermined baking temperature, means for injecting a predetermined quantity of dough between the baking plates (3, 4) of each mould (2), and means (12, 13) for removing a baked wafer from a baking mould (2), characterized in that each baking mould (2) is stationary in the apparatus (1) and is independent from the other(s).

Owner:NESTEC SA

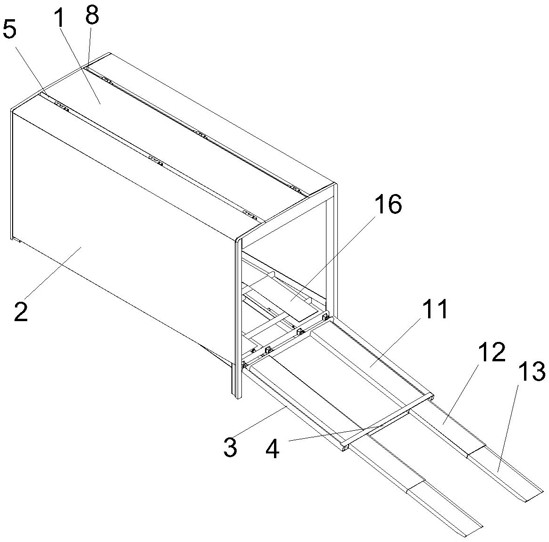

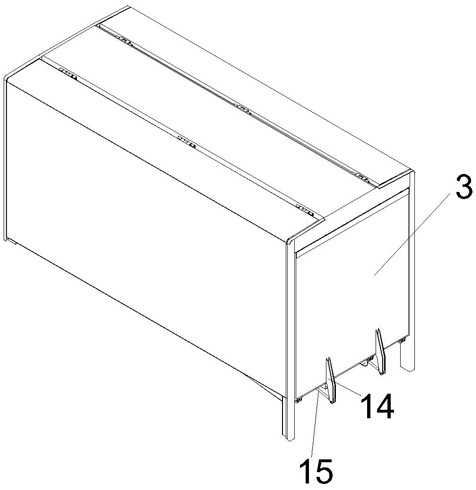

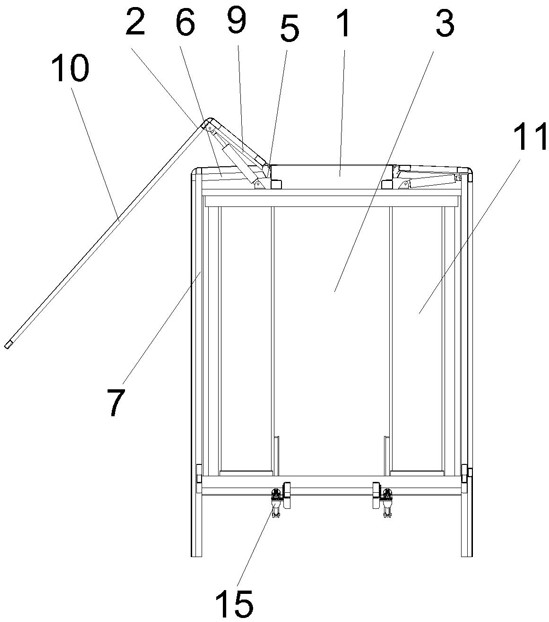

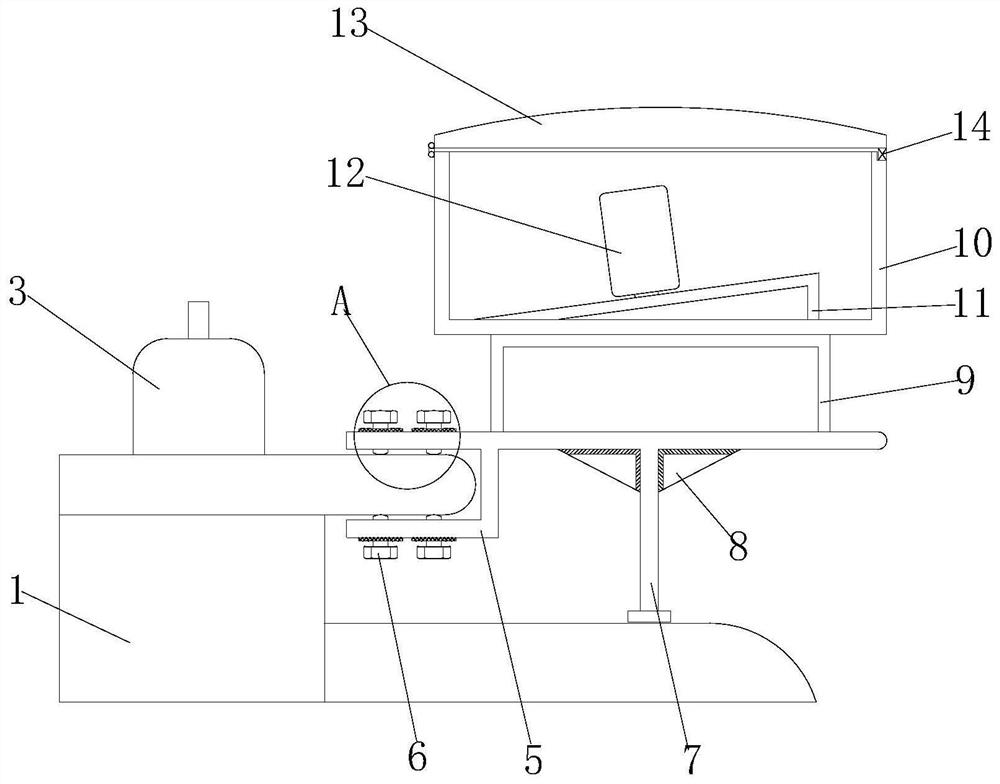

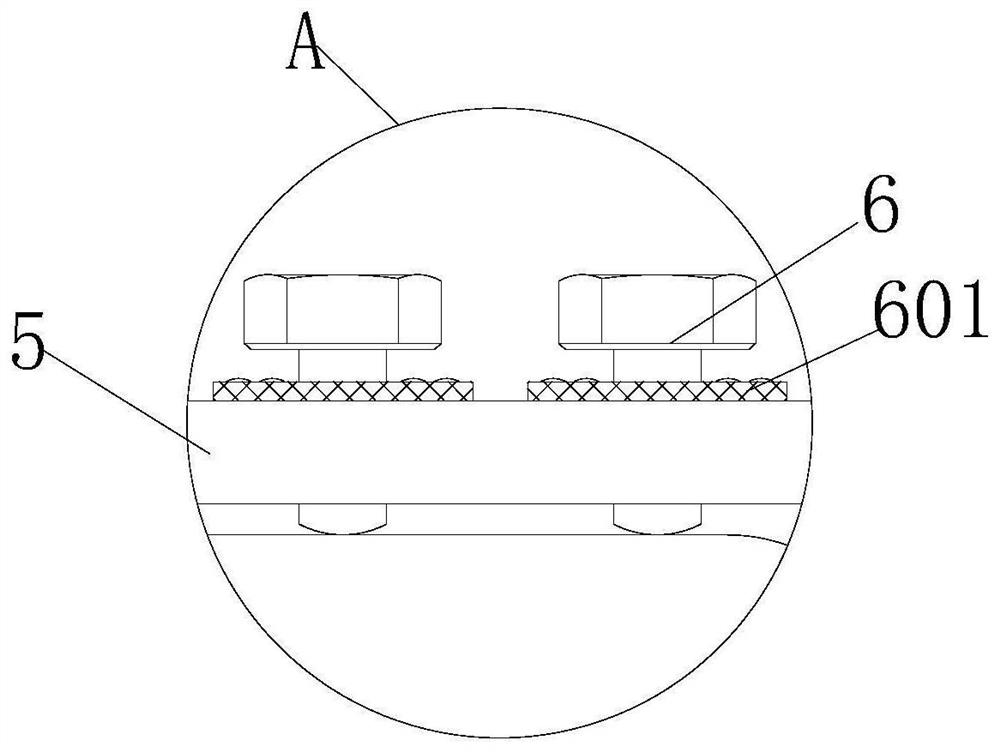

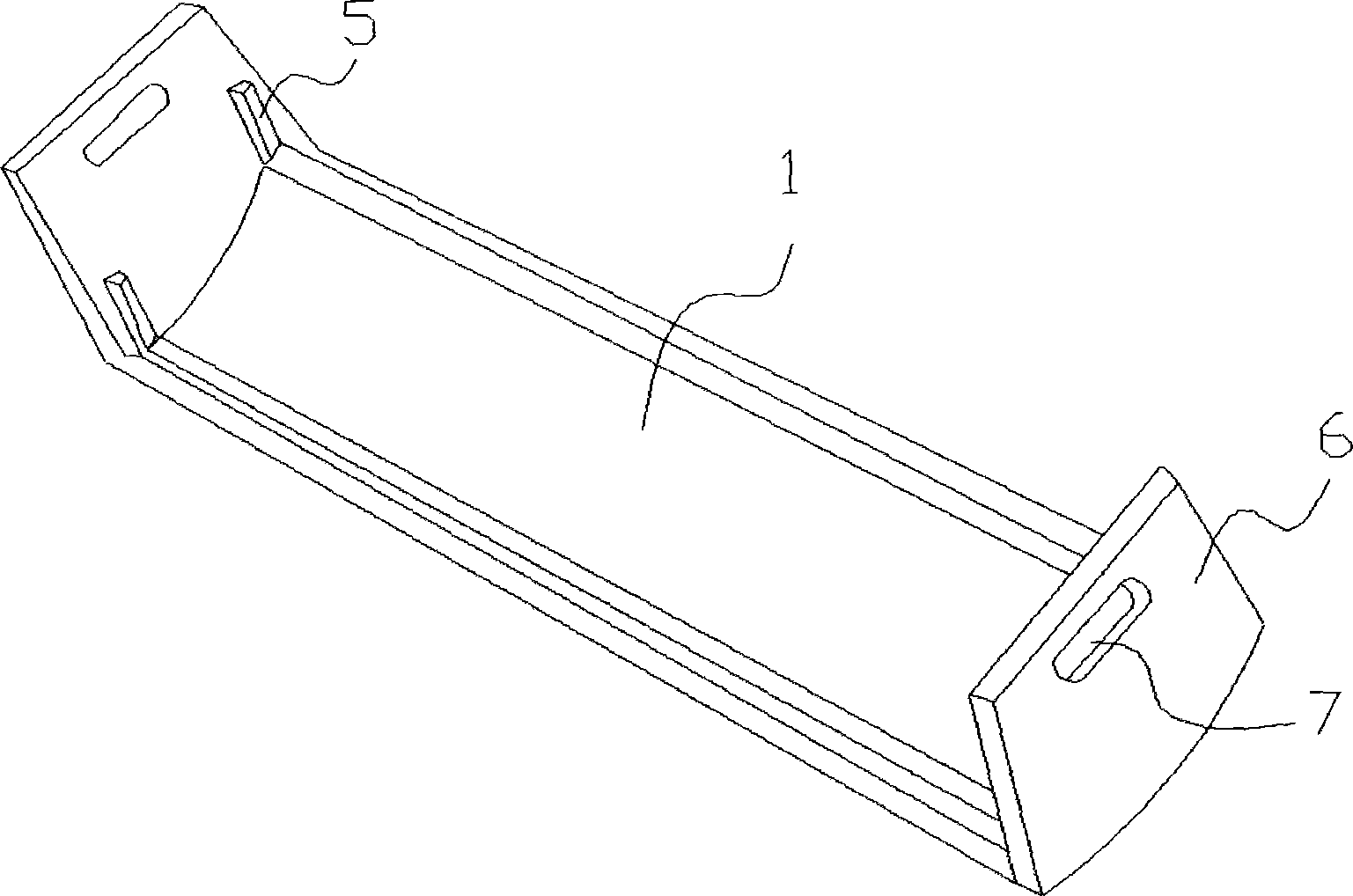

Transport vehicle rainproof compartment with crawling ladder

InactiveCN112810705APrevent infiltrationAvoid frequent maintenanceVehicle with loading rampLoading-carrying vehicle superstructuresBack doorCarriage

A transport vehicle rainproof compartment with a crawling ladder is disclosed and belongs to the field of transport devices, can guide rainwater to the ground and prevent the rainwater from seeping into a compartment, and meanwhile can support transported goods on the compartment through the telescopic ladder stand embedded in the compartment, so that the transported goods, especially special passenger vehicles, can enter the compartment more conveniently and quickly. The carriage comprises a carriage body, side wing doors and a rear door, the carriage body is hinged to the side wing doors and the rear door, and the carriage is characterized in that coherent water guiding grooves are formed in the top and the side of the carriage body and are adjacent to the sides of the side wing doors, water baffles matched with the water guiding grooves are arranged on the side wing doors, and when the side wing doors are closed, the water baffle extends into a groove of the water guide groove, the rear door is provided with an interlayer part, and a telescopic crawling device is embedded in the interlayer part.

Owner:SHENYANG TIANYING SPECIAL VEHICLE MFR

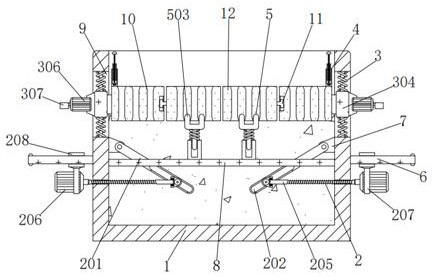

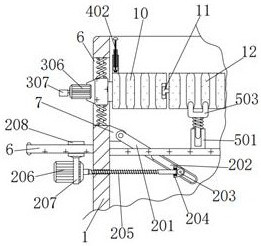

Solid waste bouncing sorting device

InactiveCN111871788APrevent falling and scatteringEasy to collect laterSievingScreeningElectric machineryStructural engineering

The invention discloses a solid waste bouncing sorting device which comprises a square frame, bent plates are fixedly connected to the left side and the right side of the inner wall of the square frame, control mechanisms are installed on the front faces of the two bent plates, and each control mechanism comprises an inclined plate, a sliding groove, a round rod, a triangular plate, a first threaded rod, a first motor, a support and a sleeve plate. The tops of the inclined plates are rotationally connected with the front faces of the bent plates, and sliding grooves are machined below the front faces of the inclined plates. The inclined plates are controlled to rotate through the control mechanisms, the distance between openings in the bottom of the square frame is adjusted, waste is prevented from falling and being scattered, later collection and arrangement are facilitated, the working difficulty is reduced, waste falling is avoided, equipment is prevented from being stuck, use is guaranteed, frequent maintenance is avoided, the service life is prolonged, through resilience force of a second spring of a supporting mechanism to a concave plate, supporting force of the center of the bottom of a sieve plate is guaranteed, sinking and deformation are prevented, normal use of equipment is guaranteed, practicability is improved, and popularization is facilitated.

Owner:孔令香

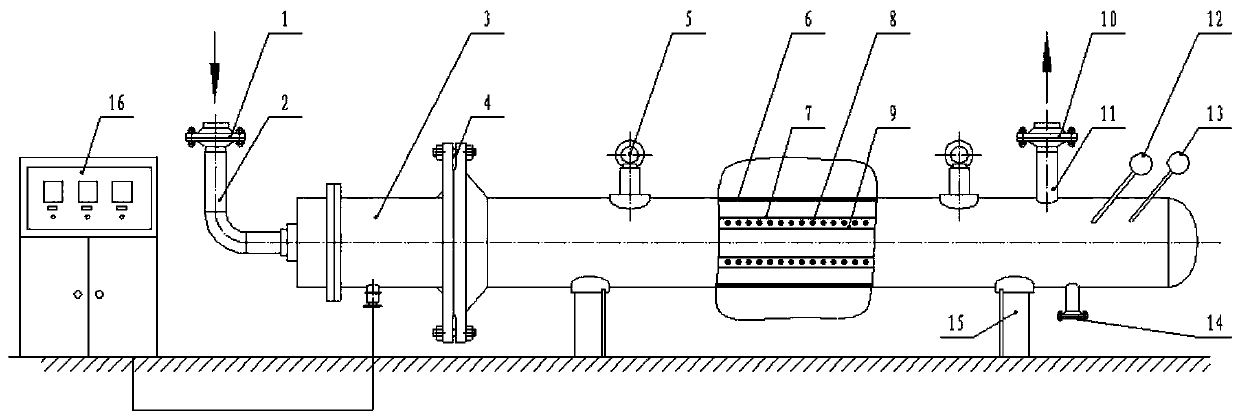

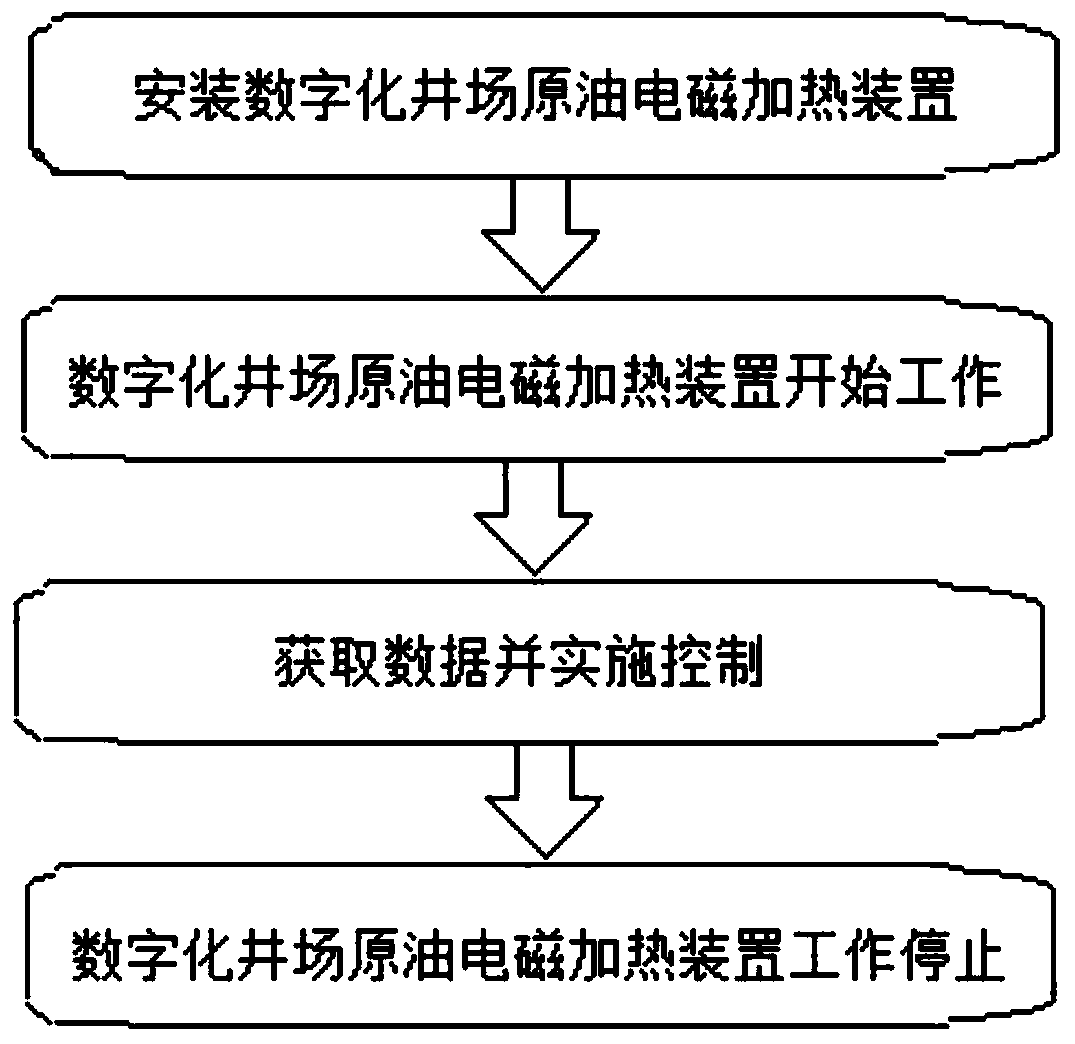

Digitalized well site crude oil electromagnetic heating device and heating method

PendingCN110608370AImprove thermal efficiencyShorten warm-up timePipe heating/coolingPipeline systemsFailure rateEngineering

The invention belongs to the technical field of crude oil heating and specifically relates to a digitalized well site crude oil electromagnetic heating device and heating method. The digitalized wellsite crude oil electromagnetic heating device provided by the invention is organically provided with an electromagnetic heating body used for heating crude oil passing through the electromagnetic heating body, a frequency conversion control cabinet being in wire connection with the electromagnetic heating body and used for changing the input power frequency supply frequency and a remote monitoringsystem being in electric signal connection with the frequency conversion control cabinet and used for receiving and transmitting electric signals and controlling starting and stopping of the frequency conversion control cabinet and can conduct one-way internal heating without a heat source and is high in thermal efficiency, safe, friendly to environment and energy-saving. The digitalized well site crude oil electromagnetic heating device and heating method have the characteristics of being high in electric heating thermal efficiency, low in failure rate and easy and convenient to maintain.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

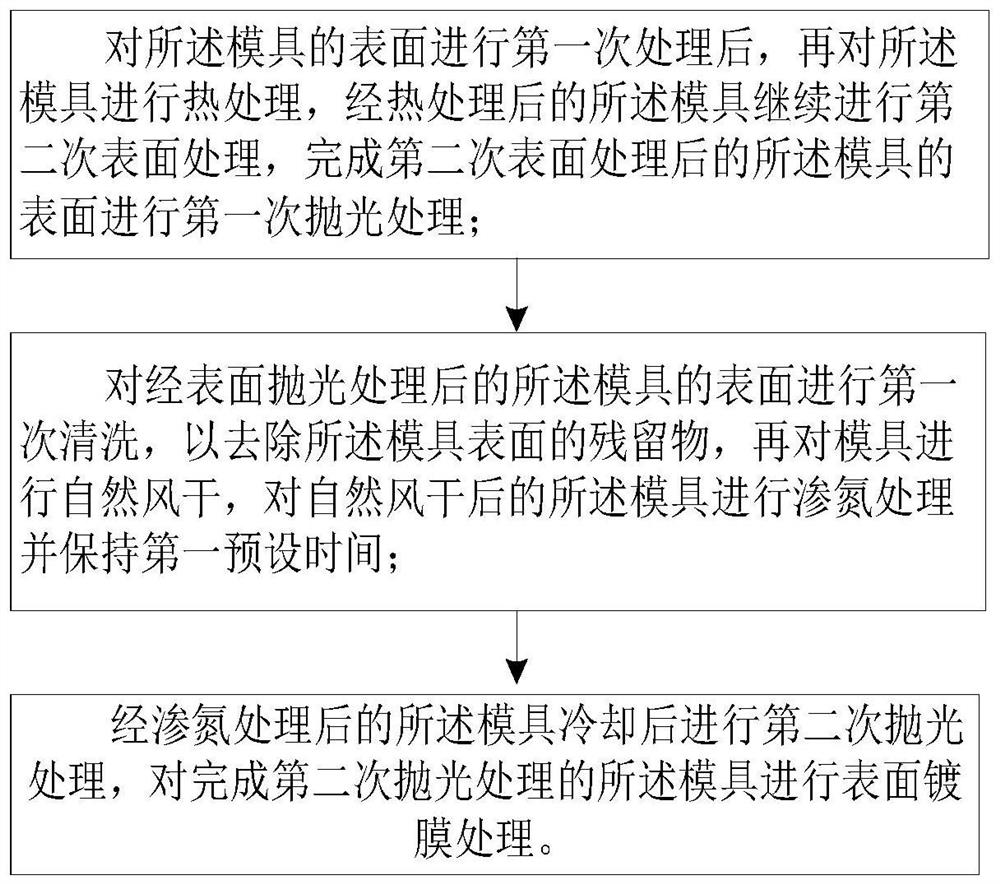

Mold machining method

PendingCN112706004AImprove structural strengthExtended service lifePolishing machinesVacuum evaporation coatingMachiningHeat treating

The invention provides a mold machining method. The mold machining method comprises the following steps that after the surface of a mold is subjected to first-time treatment, the mold is subjected to heat treatment, the mold subjected to heat treatment continues to be subjected to second-time surface treatment, and the surface of the mold subjected to second-time surface treatment is subjected to first-time polishing treatment; the surface of the mold subjected to surface polishing treatment is cleaned for the first time so as to remove residues on the surface of the mold, the mold is naturally air-dried, the naturally air-dried mold is nitrided, and keeping for a first preset time is carried out; and the mold subjected to nitriding treatment is cooled, then secondary polishing treatment is carried out, and surface coating treatment is carried out on the mold subjected to secondary polishing treatment. The problems that in the prior art, a cutter type mold is insufficient in structural strength, and the service life of the cutter type mold is shortened are solved.

Owner:ZHEJIANG JINGU CO LTD

Anti-Shock Check Valve

The invention provides an impact resisting check valve. The impact resisting check valve is composed of a valve body, a valve seat, a valve clack, an elastic piece and a valve cover. The valve clack is arranged on the valve seat in a vertical moving mode. The elastic piece is arranged on the valve clack in a sleeving mode to make the valve clack have the tendency of being closed to the valve seat. A guide sleeve and a fixing plug are fixedly arranged above a middle cavity of the valve body. The fixing plug is located in the middle of the guide sleeve and extends downwards. The upper portion of the valve clack is arranged in the guide sleeve in a vertical sliding fit mode. A receding space is arranged above the valve clack and located on the guide sleeve. A piston hole for the fixing plug to be inserted therein is formed in the valve clack. A through hole communicated with the middle cavity is formed in the bottom of the side wall of the piston hole. A buffering structure hole communicated with the piston hole and the middle cavity is formed above the through hole. The buffering structure hole vertically extends in the length direction of the buffering structure hole. The buffering structure hole is provided with an upper section and a lower section which are communicated. The moving speed of the valve clack is controlled through the relative position relation of the fixing plug and the buffering structure hole. Impact force produced between the valve clack and the valve seat when the valve clack is closed is prevented, and therefore the service life of the valve is prolonged.

Owner:NEWAY OIL EQUIP SUZHOU

Current transformer support frame

InactiveCN112331447ACross easilyEasy wiringTransformers/reacts mounting/support/suspensionTransformersInductorControl theory

The invention discloses a current transformer supporting frame, and the frame comprises a transformer; a high-voltage binding post and a low-voltage binding post are arranged at the top of the transformer, and a mutual inductance mechanism is installed on the right side of the top of the transformer. The mutual inductance mechanism comprises a support, a supporting rod, a transformer box and a transformer, and the left side of the support is clamped to a protrusion on the right side of the top of the transformer; bolts are installed at the upper end and the lower end of the left side of the support and are in threaded connection with the left side of the support, an installation base is fixedly connected to the top of the support, and a top transformer box of the installation base is movably installed at the top of the installation base. The three mutual inductors are installed on a fan-shaped sliding rail II, the three mutual inductors form a fan shape, and therefore wires can easilypenetrate through and be easily wired, the mutual inductor box is installed on the installation base, the installation base is fixedly connected to the support, the support is tightly connected to theprotrusion on the right side of the transformer through bolts, and the mutual inductor box is not prone to loosening.

Owner:GUIZHOU POWER GRID CO LTD

Method for realizing abrasion proof treatment to loader hopper and special welding wire thereof

InactiveCN101456123BImprove efficiencySuitable for mass productionArc welding apparatusWelding/cutting media/materialsIsosceles trapezoidSheet steel

The invention discloses a method for performing anti-wear treatment on a hopper of a loading machine, which comprises the following steps: using a low-carbon steel or low-alloy steel plate as a base plate, selecting a build-up welding flux-cored soldering wire of which the diameter is between 2.0 and 4.0 millimeters special for the hopper of the loading machine, and welding a wear-resisting layerof which the thickness is between 3.5 and 8.0 millimeters on the base plate by adopting a visible arc build-up welding or gas coverage build-up welding process to prepare a wear-resisting composite steel plate; by adopting a plasma cutting device, cutting out a left wear-resisting plate and a right wear-resisting plate in a right trapezoid shape respectively, a middle wear-resisting plate in an isosceles trapezoid shape, and two bottom plates in isosceles trapezoid shapes on the wear-resisting composite steel plate; leveling the plates; and putting the cut wear-resisting layers of the left wear-resisting plate, the middle wear-resisting plate, the two bottom plates and the right wear-resisting plate outwards, and welding the wear-resisting layers on the outside surface of the hopper bottomof the main cutting board side of the hopper respectively through gas shielded arc welding or welding rod arc welding so that the wear-resisting layers are integrated with the original hopper bottominto a whole. After the treatment by the method, the service life of the hopper is greatly improved, the frequent maintenances are avoided, the working efficiency of the loading machine is improved, and steel materials are saved.

Owner:SHANDONG LINGONG CONSTR MACHINERY

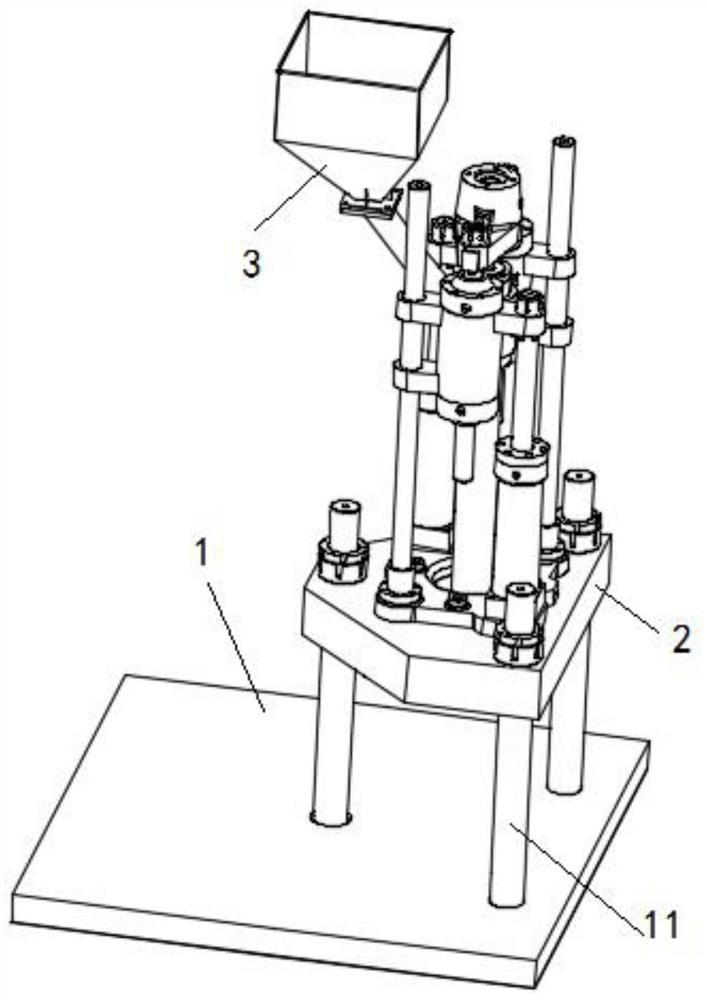

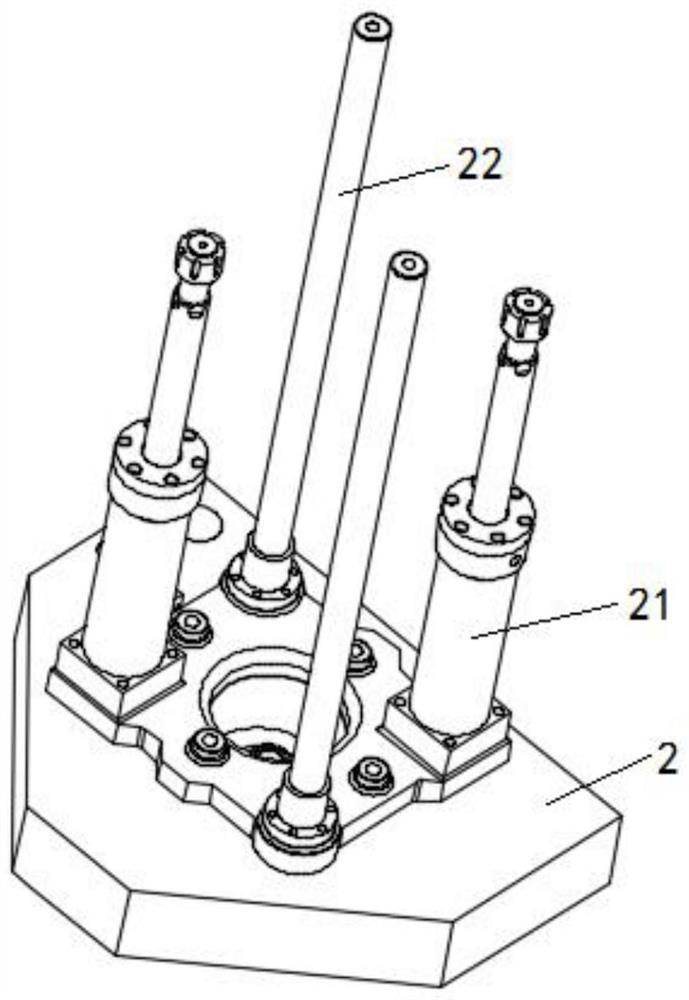

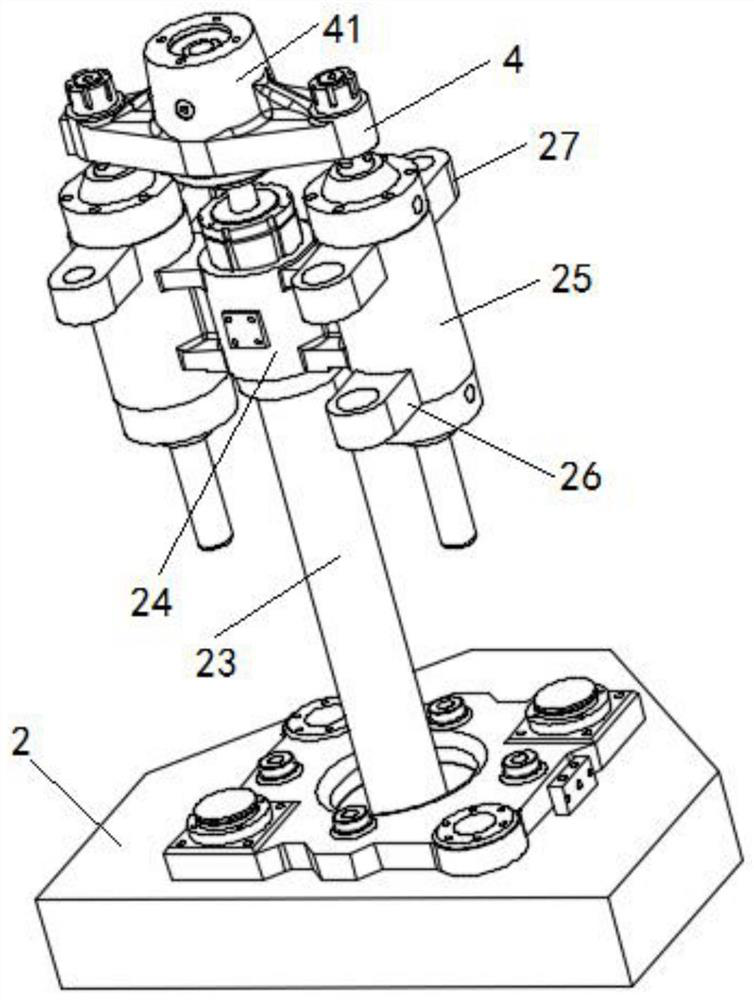

A wear-resistant casting of metal matrix ceramic composite material and its processing technology

ActiveCN111748717BImprove surface roughnessHigh activityFoundry mouldsFoundry coresCeramic compositeSpiral blade

The invention discloses a wear-resistant casting of a metal-based ceramic composite material and a processing technology thereof. The wear-resistant casting is prepared by processing the metal-based ceramic composite material; during processing, ceramic particles are used as a basis for modification treatment and mix the ceramic particles and the metal-based material through the mixing injection molding device. After the modified ceramic material and the metal-based material enter the injection molding reaction cylinder, the mixed material is stirred by the stirring blade at the bottom of the stirring rod, and the power motor Drive the stirring rod to rotate clockwise. When the stirring rod rotates clockwise, the mixed material in the injection molding reaction cylinder is first stirred by the stirring blade at the bottom, and the screw blade at the bottom will convey the mixed material from bottom to top, and the The upper spiral blade returns the mixed material moved to the upper part to the lower part, so that the material is fully mixed in the injection molding reaction cylinder. Compared with the traditional stirring method, the material can be mixed more uniformly.

Owner:马鞍山海华耐磨材料科技有限公司

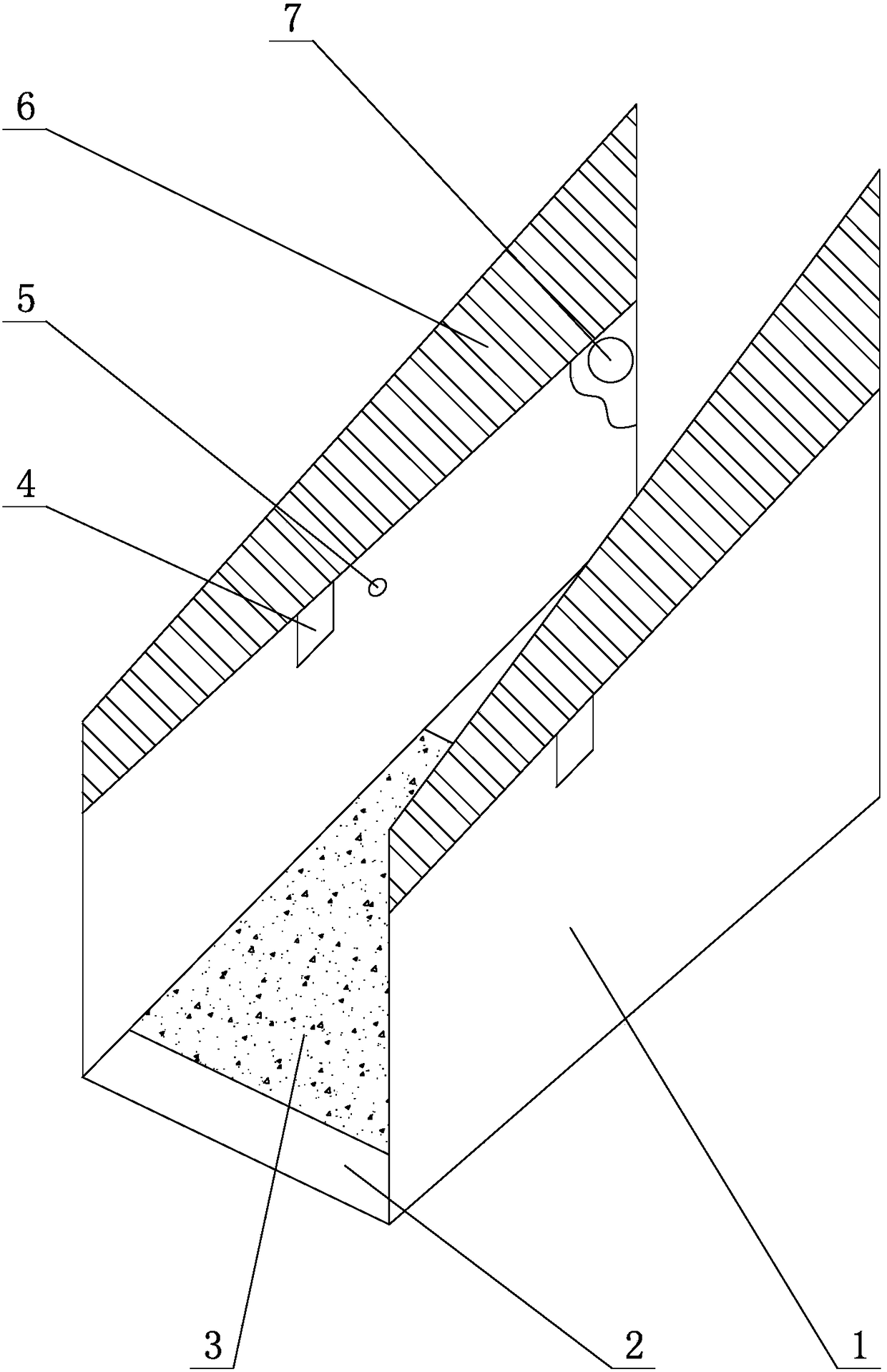

Well mouth ore discharging chute

InactiveCN109132426AWill no longer affect normal workEnsure personal safetyConveyorsControl devices for conveyorsSlagWear resistant

The invention belongs to the field of ore discharging mechanical equipment, and relates to a well mouth ore discharging chute. The well mouth ore discharging chute comprises an ore discharging chute body, wherein the ore discharging chute body comprises a bottom plate and chute ledges which are vertically upward on the two sides of the bottom plate, feeding holes are formed in the chute ledges onthe two sides of the ore discharging chute body, moreover, a protection plate is arranged above the chute ledges on the two sides, the height of the protection plate is gradually reduced from top to bottom, and a wear-resistant plate is arranged at the outlet portion of the bottom plate of the ore discharging chute body. According to the well mouth ore discharging chute, the structural design is reasonable, on one hand, the problem of blockage of the ore discharging chute can be solved conveniently, construction personnel do not need to work high above the ground, so that the personal safety of the construction personnel is guaranteed, moreover, the problem that slag collapse and falls off is solved, on the other hand, the inclination angle of the bottom plate of the ore discharging chuteis reduced, so that the ore discharging distance is lengthened, then the time of the construction personnel is saved, and the bottom plate is more wear-resistant.

Owner:ZIBO HUAYUAN MINING CO LTD

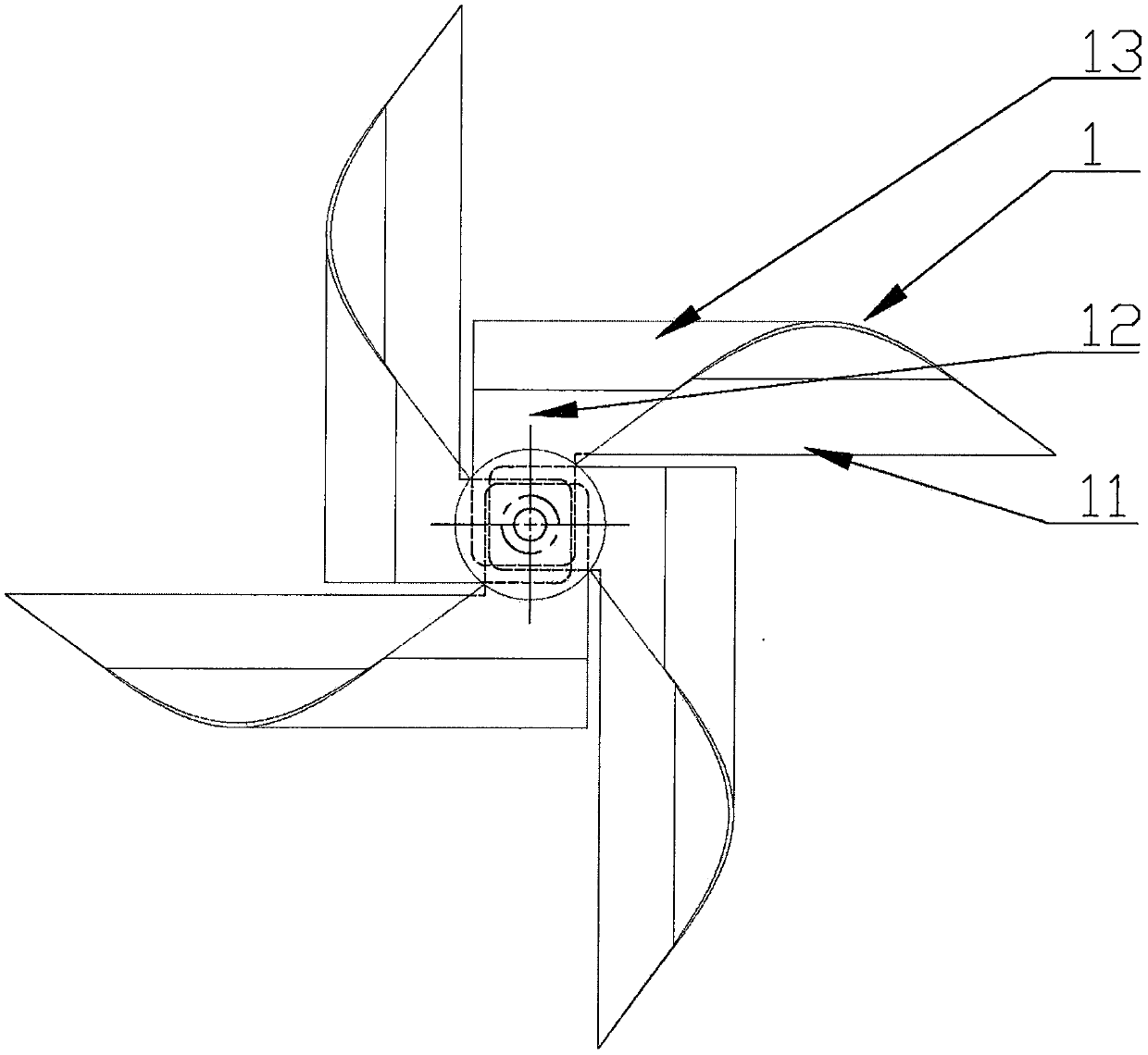

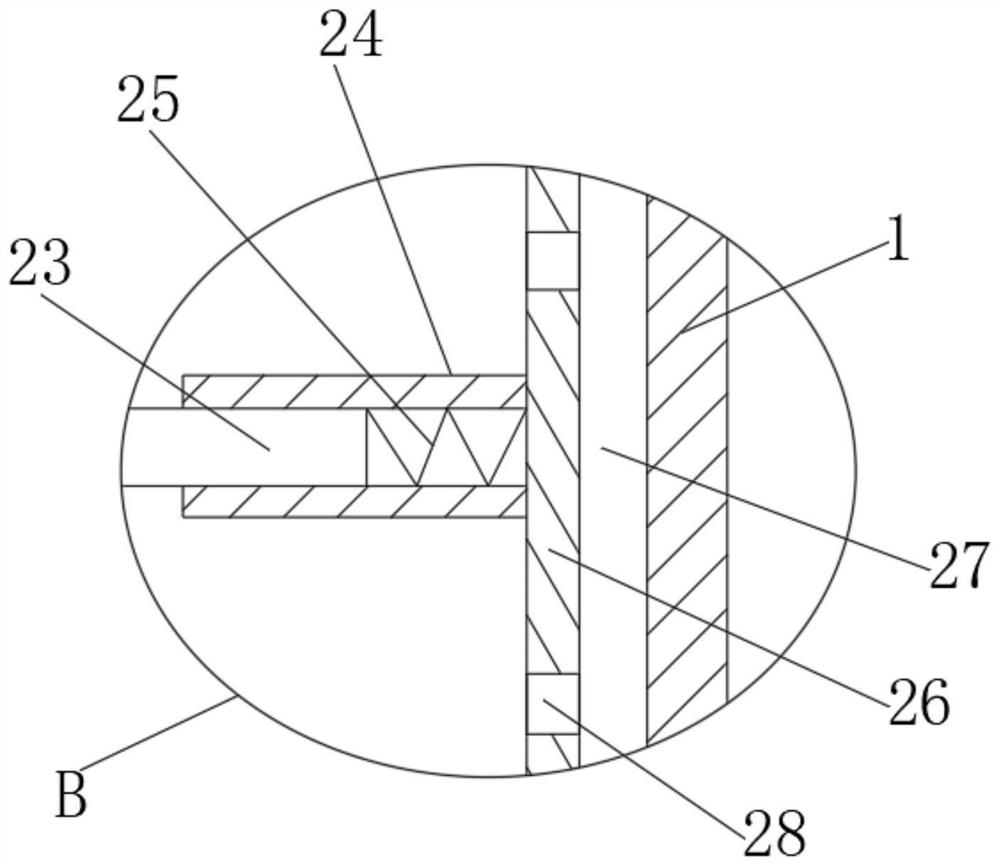

Non-friction type transmission pair capable of separation and joining

ActiveCN103939492AAvoid frequent maintenanceAvoid lifeMechanical actuated clutchesTorque transmissionEngineering

The invention discloses a non-friction type transmission pair capable of separation and joining. The transmission pair comprises a primary rotating part, a secondary rotating part and a transmission part. The primary rotating part and the secondary rotating part are arranged together coaxially in a sleeved mode and are matched in a rotating mode. Wheel teeth are arranged on the rotating matching face of the secondary rotating part. The transmission part comprises a floating block which is arranged on the rotating matching face of the primary rotating part in a floating mode in the radial direction and is in meshing transmission with the wheel teeth. The tangential direction angle of the action points of the floating block and the wheel teeth is continuously changeable. The primary rotating part and the secondary rotating part are in separation-and-joining transmission through the transmission part. The tangential direction angle of the action points of the floating block and the wheel teeth is continuously changeable in a certain range, continuously-changeable joining force is generated, when the tangential direction angle is large, equal-torque output can be achieved, torque transmission capacity is high, the application range is wide, meanwhile, the floating block and the wheel teeth are matched in a non-friction mode, the problem that due to part abrasion, maintaining is frequent, and service life is short can be avoided, and operation cost is lowered.

Owner:CHONGQING LONGWANG ELECTROMECHANICAL

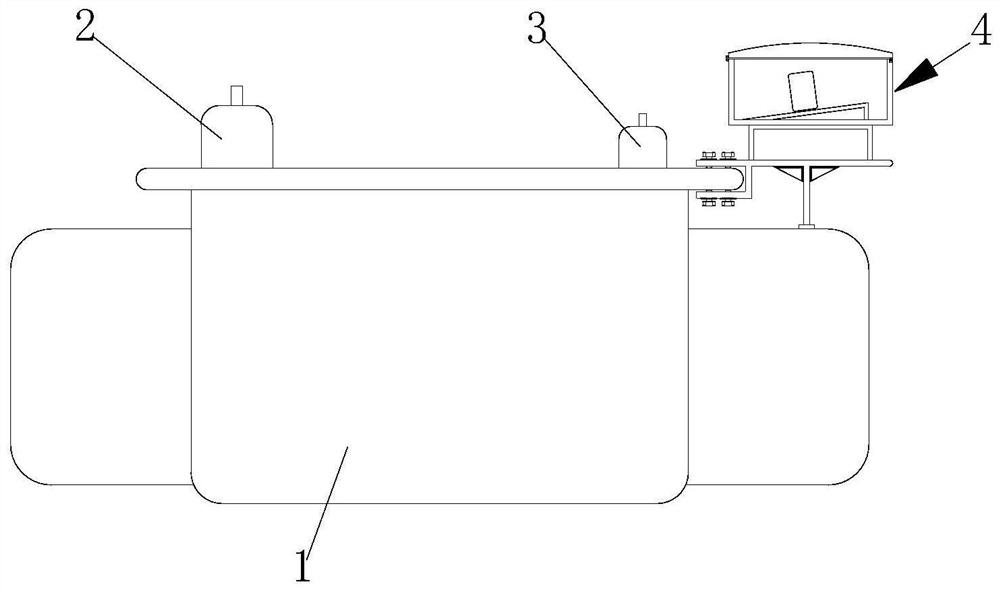

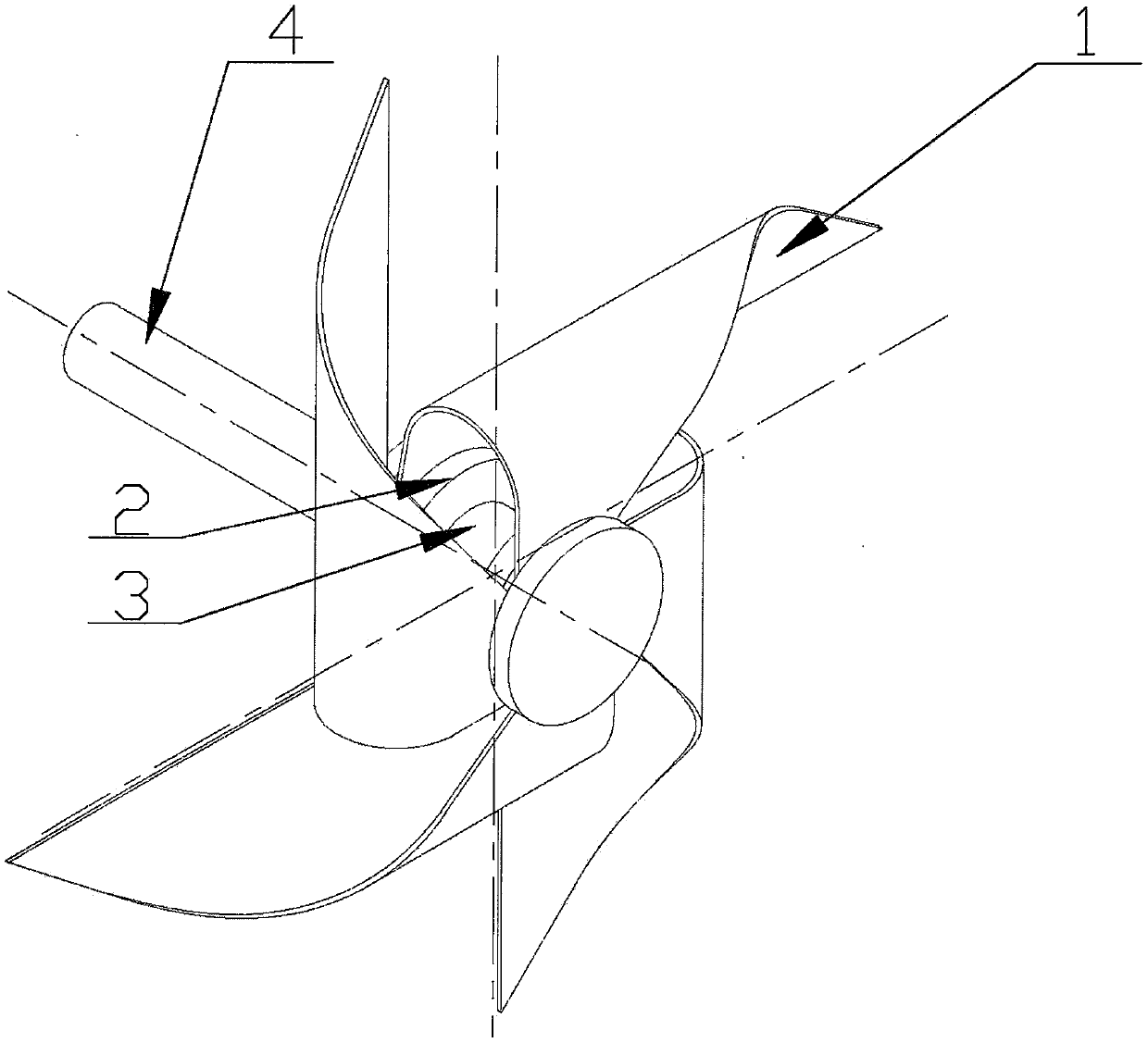

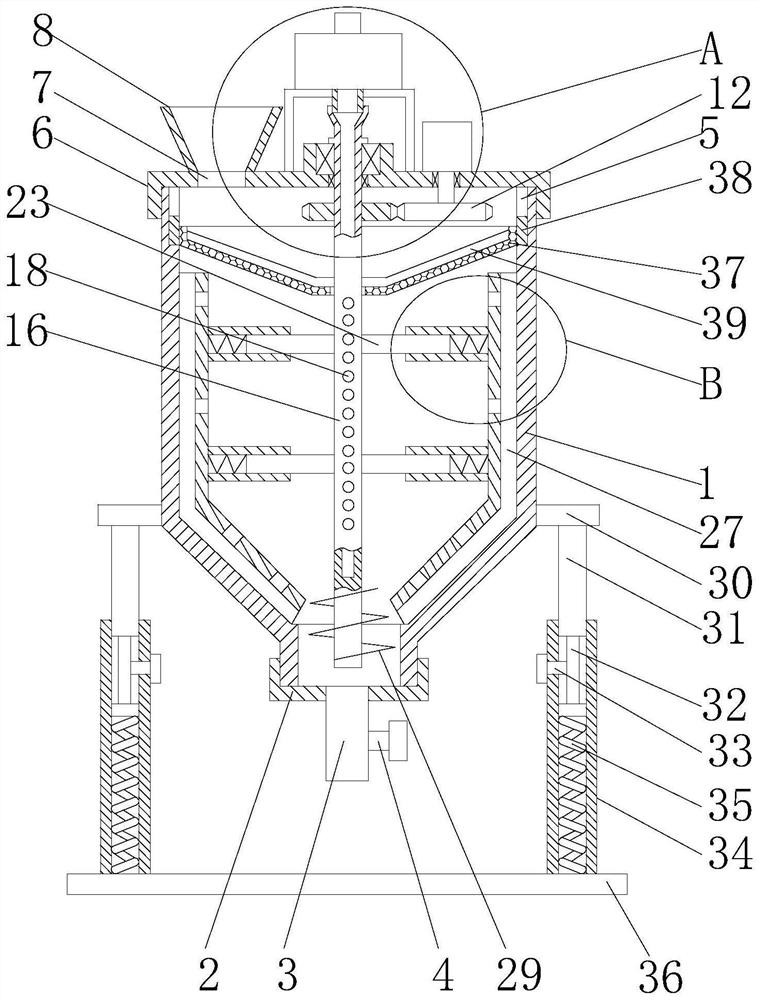

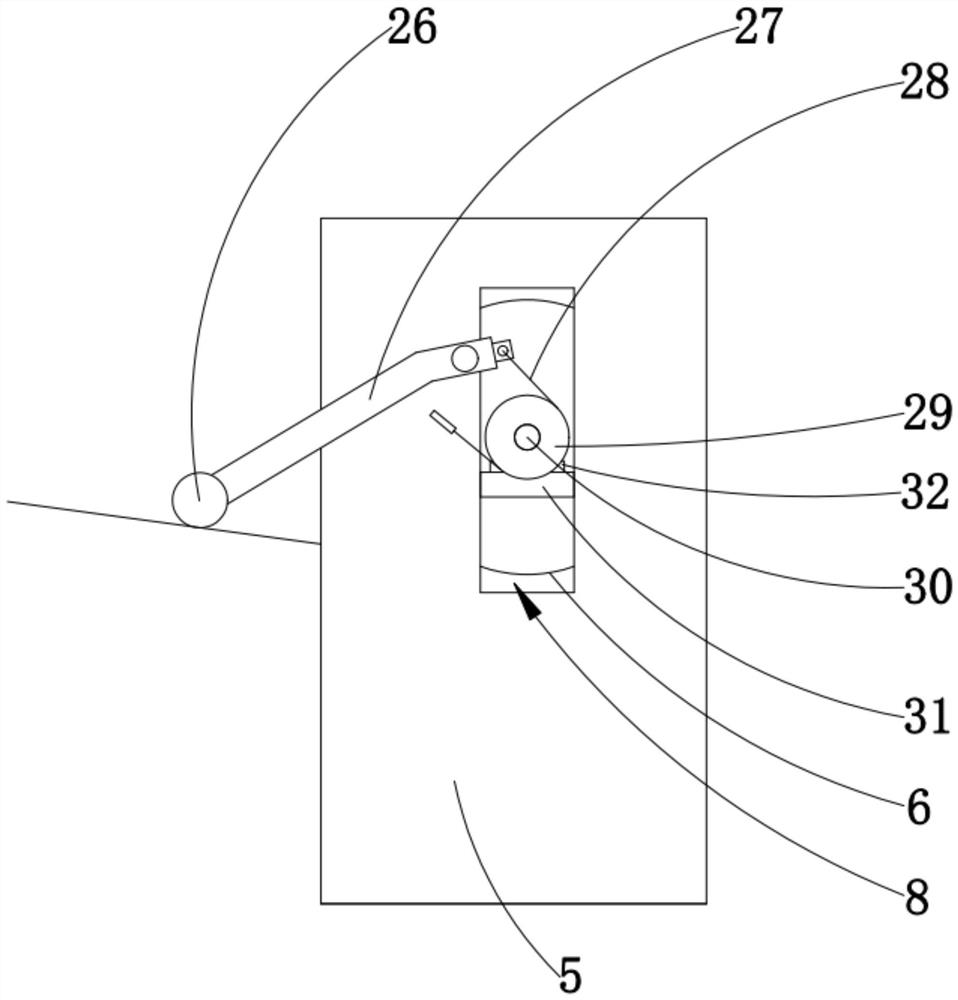

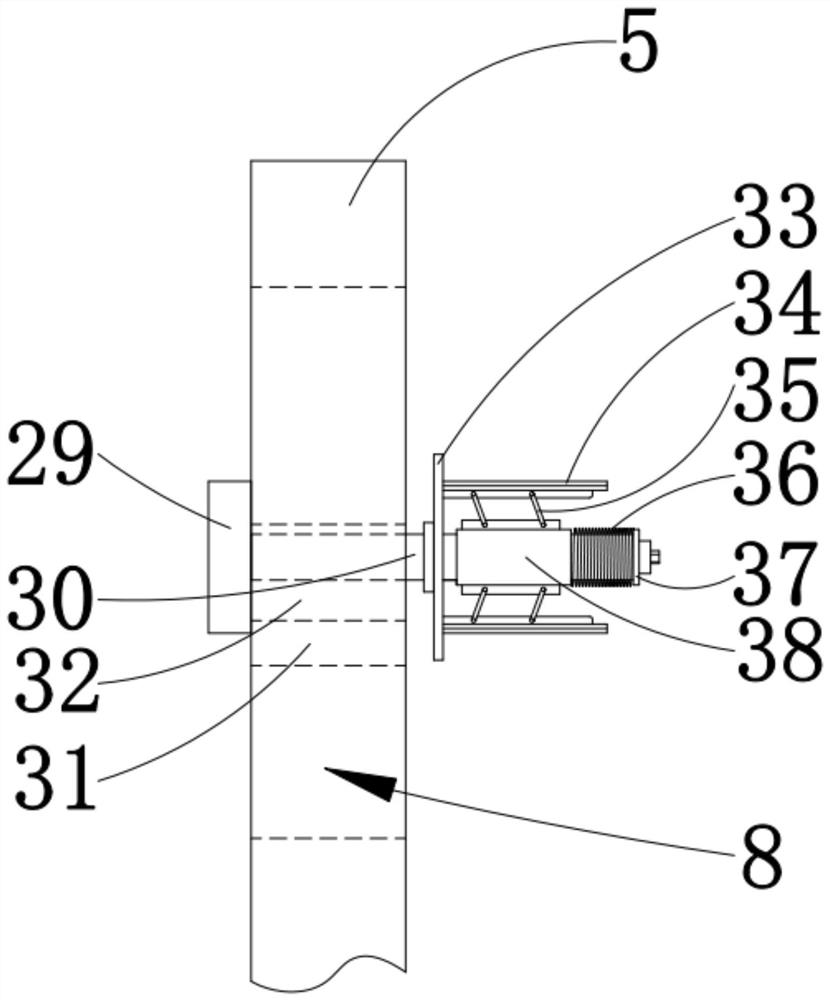

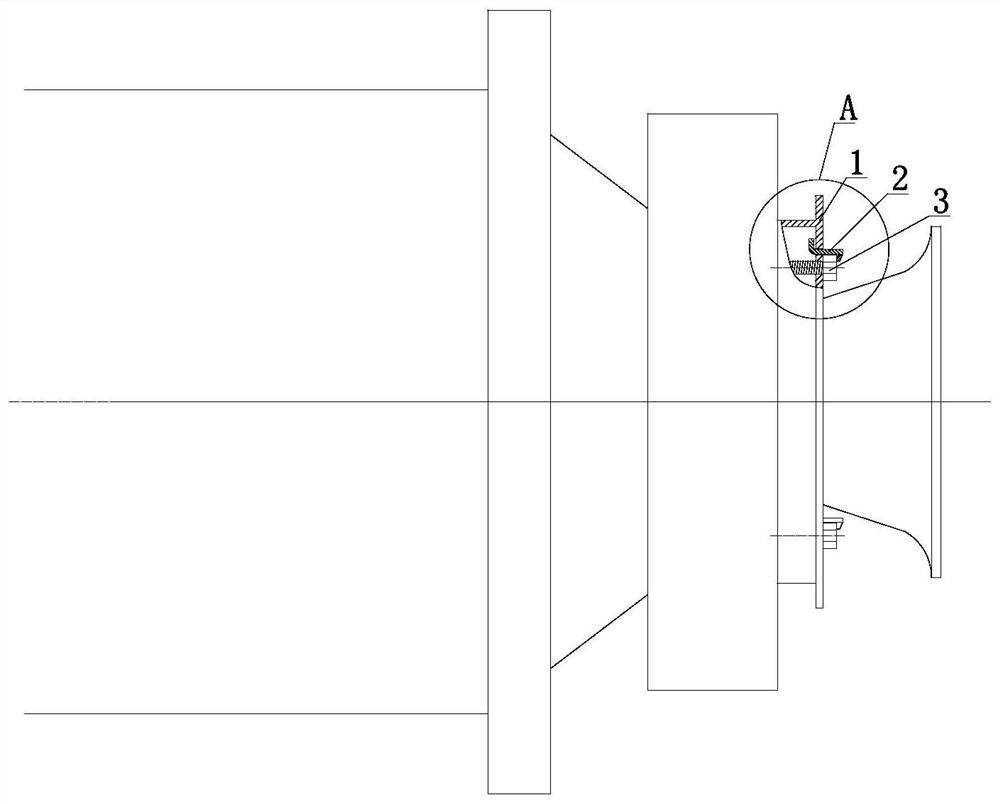

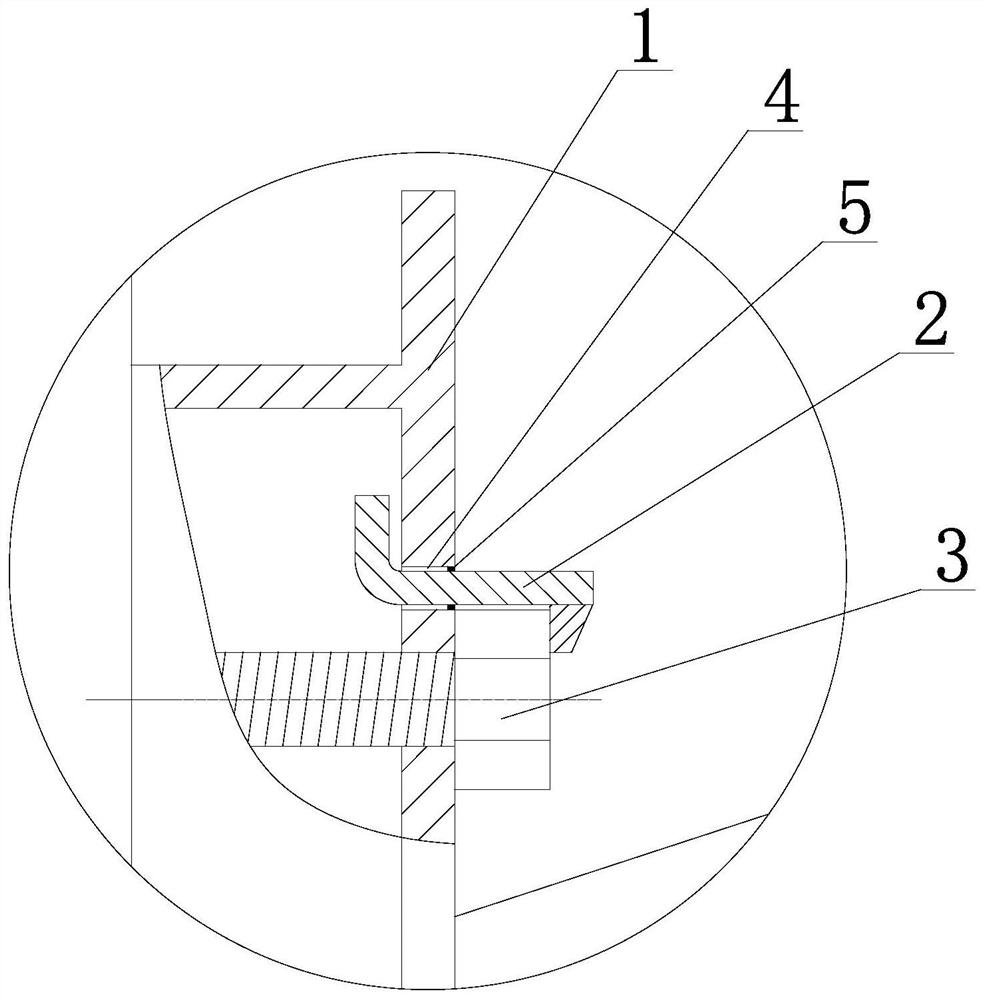

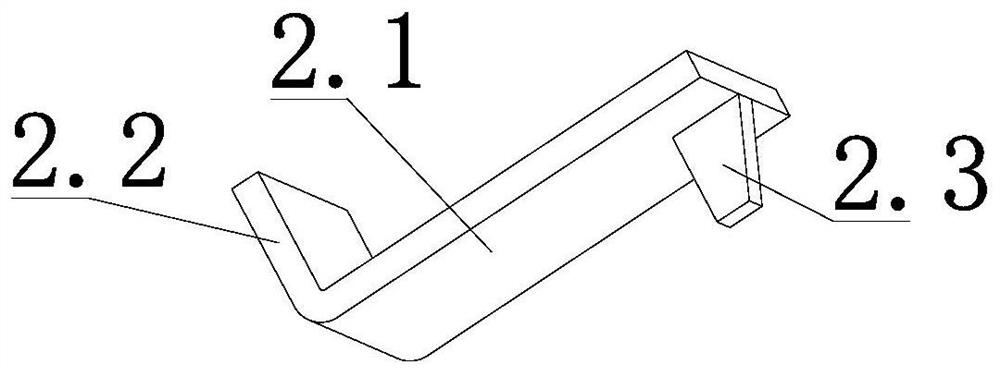

Jet stirrer

PendingCN109966944AEasy to install and useAvoid frequent maintenanceFlow mixersTransportation and packagingImpellerJet flow

The invention discloses a jet stirrer which is located in front of the jet direction of a jet pipe (5) in a kettle and installed on a kettle wall (6) through a pin shaft (4). The stirrer comprises animpeller (1), a clamping plate (2) and a separation sleeve (3). The outer edge of the impeller (1) is in a 45-degree slash shape. The jet stirrer has the advantages that the jet effect of the jet stirrer can be realized, the effect of changing the fluid direction through mechanical stirring can also be realized, fluid can be better mixed, energy can be sufficiently utilized when the rotary mixingof the jet stirrer is driven with the aid of jet, no leakage problem exists compared with a mechanical stirrer, installing and using are both quite convenient, and frequent maintenance is avoided.

Owner:浙江长城搅拌设备股份有限公司

Medicine material mixing device

InactiveCN111821904AEasy to wearImprove applicabilityTransportation and packagingMixer accessoriesRubber materialPharmacy

The invention belongs to the field of pharmacy and specifically relates to a medicine material mixing device. The device comprises a mixing box; the upper end of the mixing box is in threaded connection with a box cover; the box cover is provided with a feeding port; the upper end of the box cover is fixedly connected with a feeding hopper; the upper end of the box cover is fixedly provided with amotor; the lower end of a rotating shaft of the motor is fixedly connected with a driving gear; the left side of the driving gear is engaged with a driven gear; and a bearing seat is arranged at theupper end of the box cover, and a bearing is fixedly mounted in the bearing seat. The supporting rod is designed on the outer side of the rotating pipe assembly; a connecting sleeve is designed on theouter side of the supporting rod; a first spring is designed in the connecting sleeve; a supporting connecting strip is designed at the tail end of the connecting sleeve; an anti-abrasion strip is designed on the supporting connecting strip; the anti-abrasion strip is made of a rubber material; large abrasion to the mixing box is avoided; the anti-abrasion strip can be matched with mixing boxes with different diameters through matching of the supporting rod, the connecting sleeve and the first spring; applicability is better, and customization is not needed.

Owner:陈军

Fastener protecting cover

InactiveCN1448581AAvoid corrosionNot easy to rustRail fastenersRear quarterArchitectural engineering

The buckle protecting cover for railway use has one outwards extruding top cover and one lower arced protecting cover connected together. The protecting cover has symmetrical long slots in the loweredge and two side boards extending downwards. The circular top cover has one hollow raised part in the upper part. Shielding the buckle with the buckle protecting cover can protect the buckle from the erosion of wind ,rain and dirty water for no rust and less maintenance.

Owner:周宏特

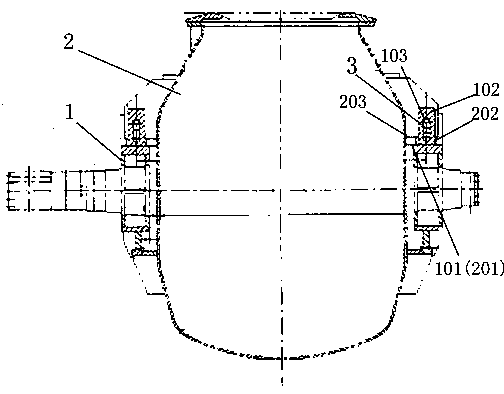

Online repair construction method for steel-making converter by means of laser strengthening

ActiveCN110158081AShorten the timeAvoid cases with low repair accuracyManufacturing convertersMetallic material coating processesEngineeringMachine tool

The invention relates to an online repair construction method for a steel-making converter by means of laser strengthening. The method is technically characterized in that machine tools with functionsof rough machining, finish machining and laser cladding are installed on two working platforms on the driving and driven sides corresponding to the position of a backing ring square column respectively; the machine tools are used for conducting rough machining, laser cladding and finish machining or manual fine grinding on working faces after build-up welding one by one; and after recombination of a furnace shell and a backing ring, two upper support adjusting base plates are symmetrically inserted into the gap between two side end faces of a square hole and the square column, stop plates areinstalled above the two upper support adjusting base plates separately, and online repair installation is completed. The method significantly improves the repair accuracy and repair efficiency, and is safe and reliable.

Owner:辽宁瀛寰科技有限公司

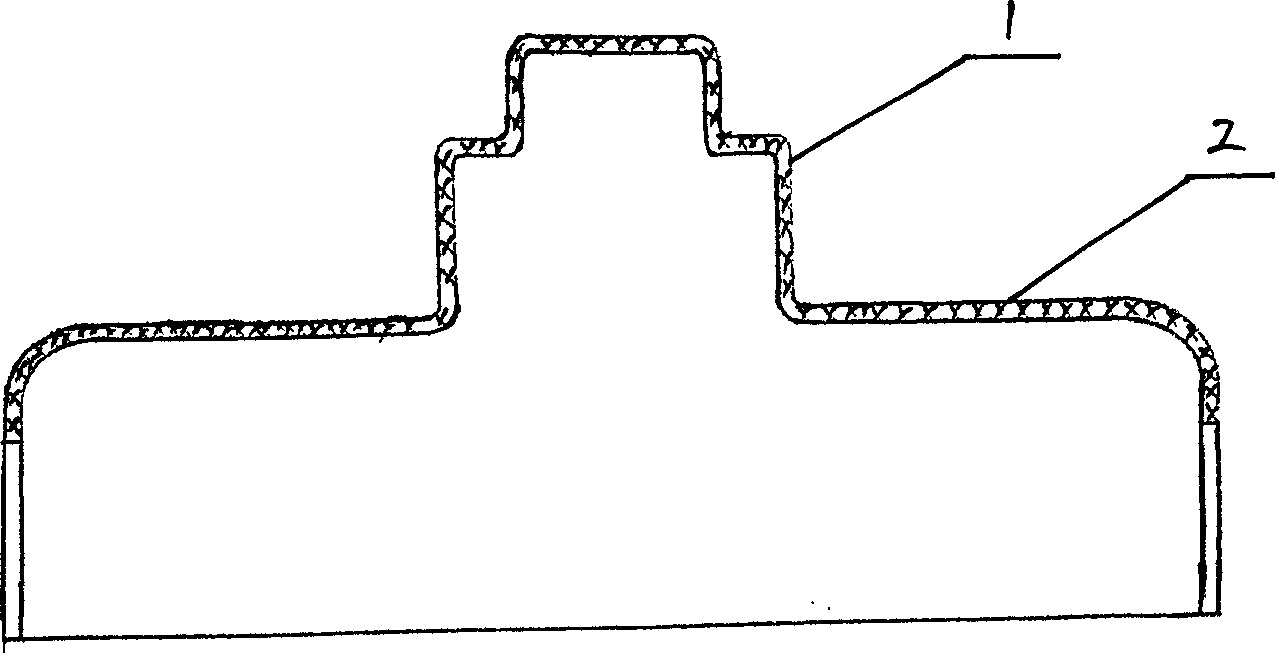

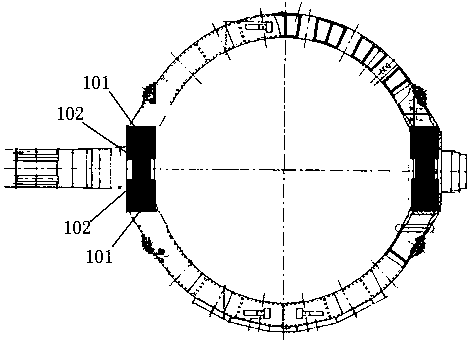

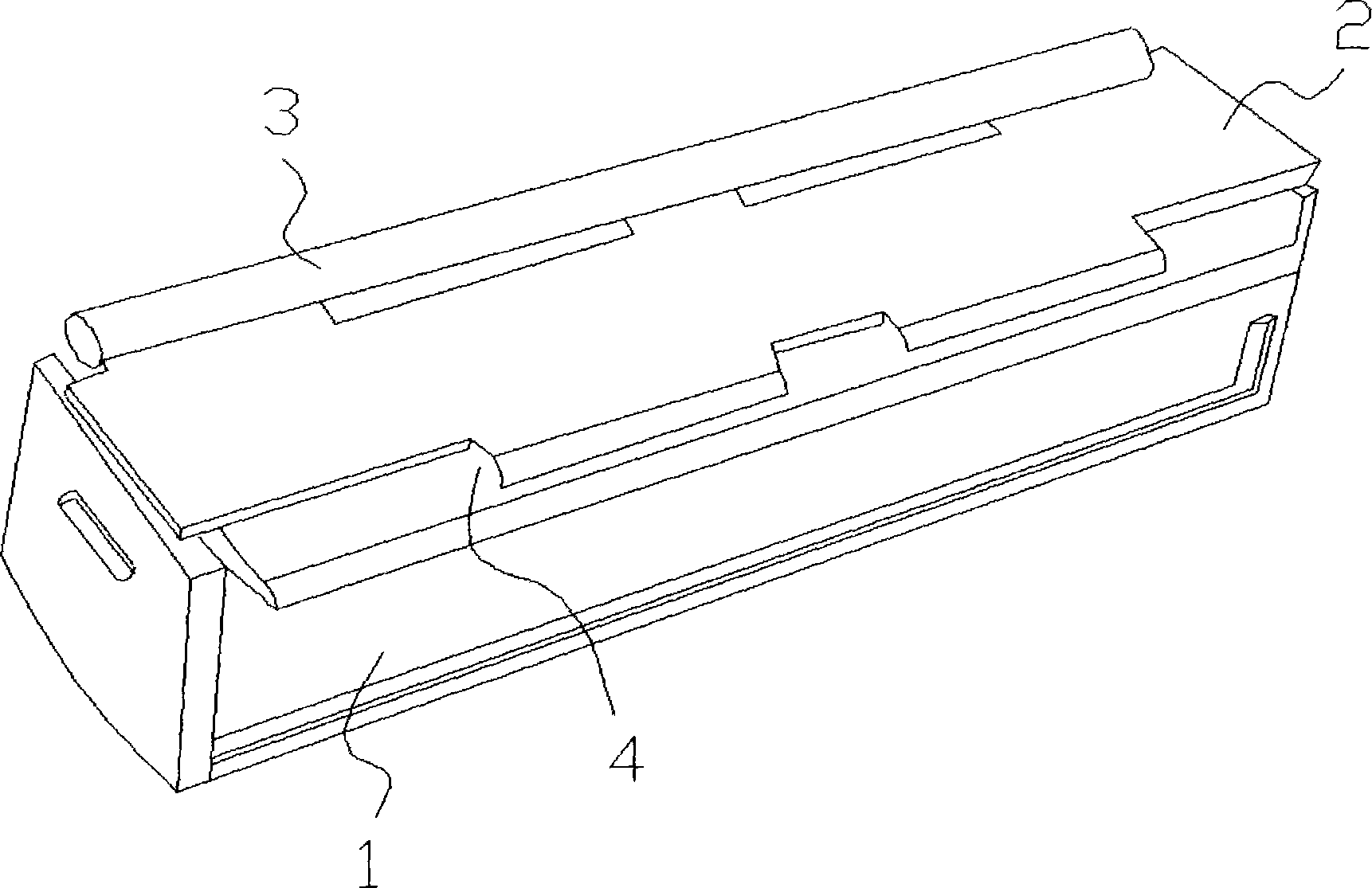

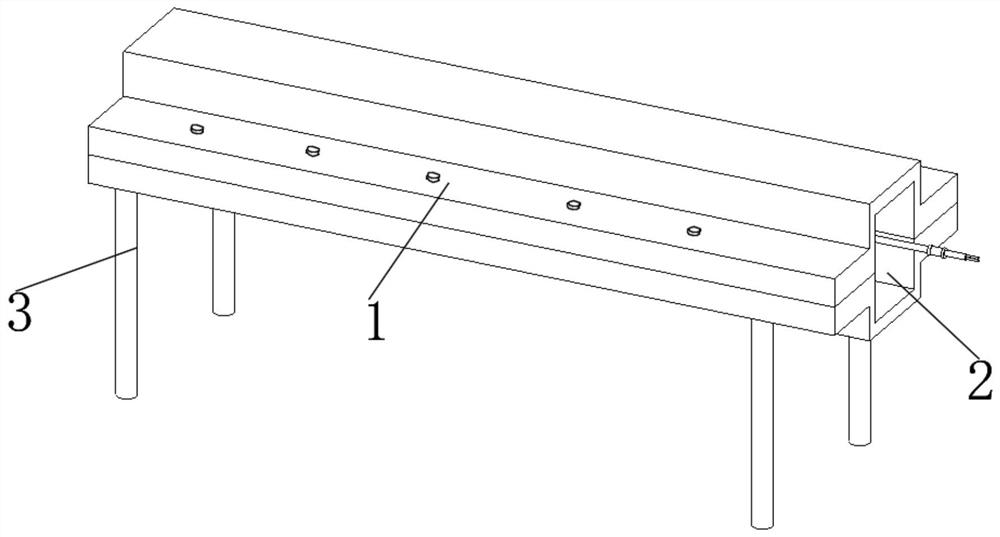

Production line of warm edge spacing bar

InactiveCN111842548AStable unwindingPrevent loose situationsMetal-working feeding devicesMetal working apparatusProduction lineBrake

The invention discloses a production line of a warm edge spacing bar. The production line of the warm edge spacing bar comprises an uncoiler and a traction device; the uncoiler comprises a first rack;a central shaft and a support mechanism are arranged on the first rack; the support mechanism is arranged at one end of the central shaft; the uncoiler also comprises a front driving roller, a rear driving roller and a synchronous brake mechanism; a coiled metal sheet is placed above the middle of the front driving roller and the rear driving roller; the central shaft is in sliding fit with the first rack along the vertical direction; the synchronous brake mechanism comprises a brake wheel, a brake belt and a cantilever; the brake wheel is fixedly arranged on the central shaft; the cantileveris rotatably connected with the first rack; the fulcrum of the cantilever is positioned above the brake wheel; one end of the brake belt is fixed on the first rack, and the other end of the brake belt is fixed at one end of the cantilever; the brake belt is wound around the brake wheel from the lower part of the brake wheel; and a guide wheel is arranged at the other opposite end of the cantilever. According to the production line of the warm edge spacing bar, the problem that the coiled metal sheet is easy to loosen when the traction device of the existing production line of the warm edge spacing bar is in a sudden stop.

Owner:山东亚鑫华数控设备有限公司

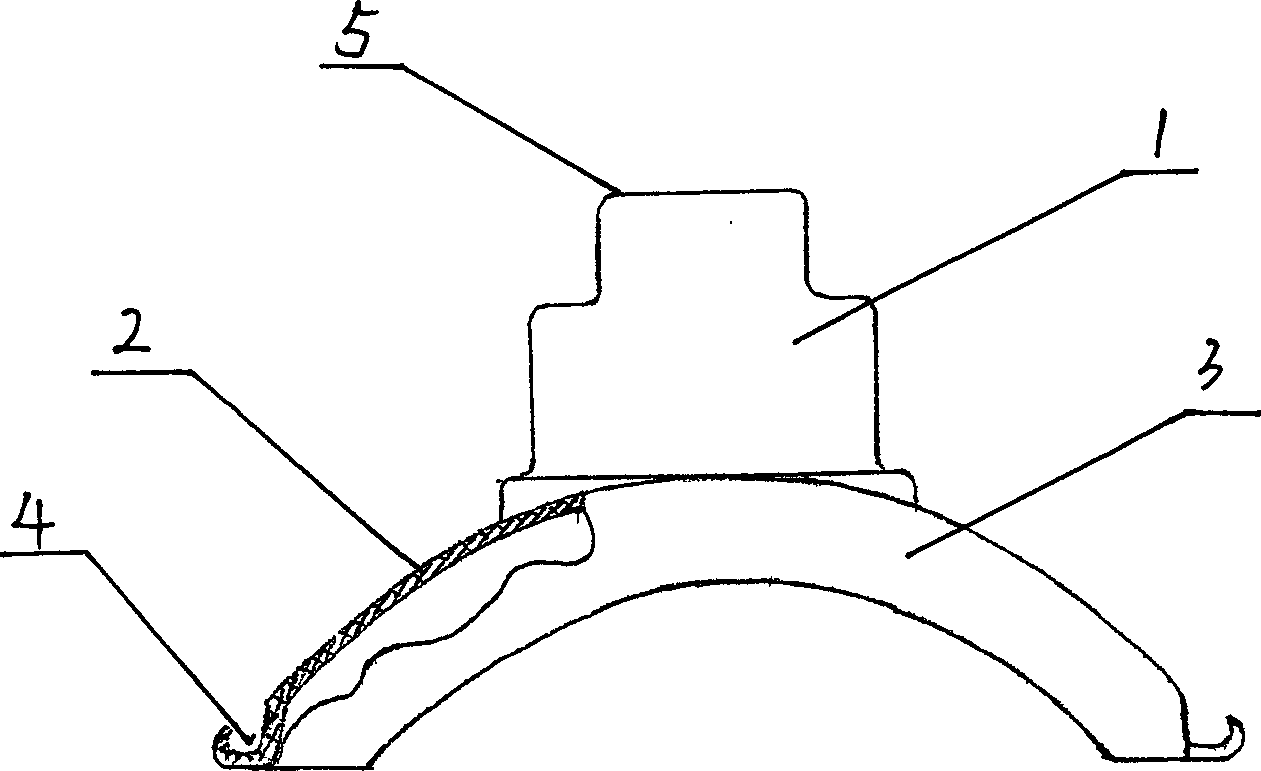

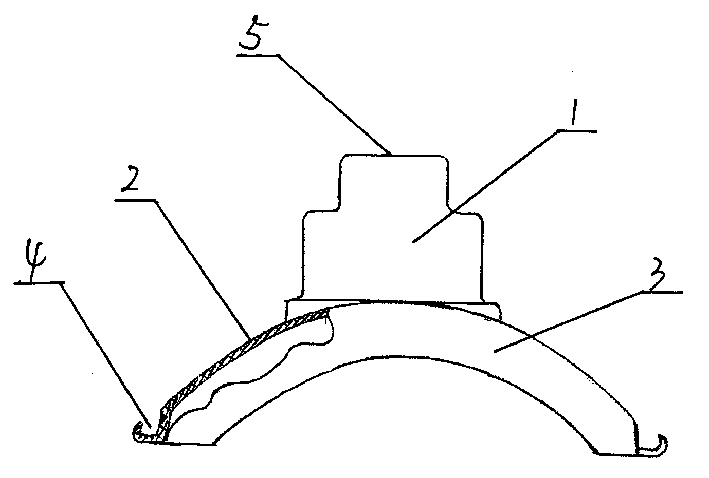

Bolt anti-loosening structure for hollow end cover of ball mill and installation method

InactiveCN111720417APrevent looseningCause downtimeNutsBoltsStructural engineeringMechanical engineering

The invention belongs to the technical field of loosening prevention of fixed bolts of heavy machinery, and specifically relates to a bolt anti-loosening structure for a hollow end cover of a ball mill and an installation method. The anti-loosening structure comprises a hollow end cover fixed at one side of the ball mill by bolts, a strip slot is formed in the hollow end cover above the bolts, a Z-shaped fastener passes through the hollow end cover, one end of the Z-shaped fastener is clamped in the hollow end cover, and the other end of the Z-shaped fastener is clamped on the bolts; and the Z-shaped fastener is composed of an L-shaped plate and a bolt clamping block, the L-shaped plate comprises a middle connecting part and a clamping part in the end cover, and the strip slot is matched with the L-shaped plate. With an ingenious structure, simple and convenient installation and disassembly, the bolt anti-loosening structure can prevent bolts from loosening effectively during equipmentoperation, avoid equipment shutdown and accidents caused by bolts falling, improve equipment operation efficiency, and avoid equipment shutdown affecting production and safety risks. The frequent maintenance, inspection and repair to the equipment are avoided, the labor is saved, and the labor cost is reduced.

Owner:SHANDONG HUALIAN MINING

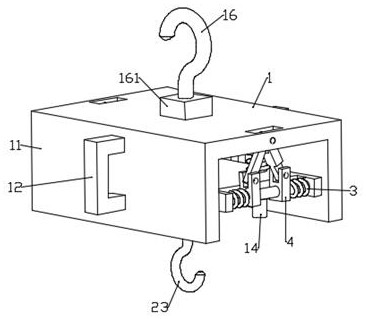

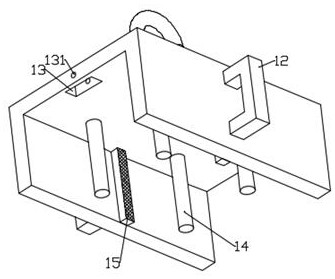

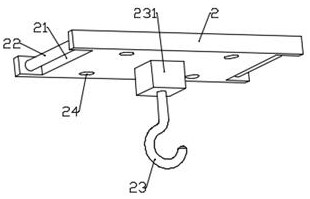

Special drilling balancer for hydrology and water resources

PendingCN112984034ABalance Relief PullReduce tensionSprings/dampers design characteristicsVibration suppression adjustmentsWater resourcesStructural engineering

The invention discloses a special drilling balancer for hydrology and water resources. The special drilling balancer comprises a mounting frame and a movable plate, a first lifting hook is mounted at the top end of the mounting frame, a pair of side plates are symmetrically arranged on the front side and the rear side of the bottom of the mounting frame, the front end and the rear end of the movable plate are slidably connected with the pair of side plates, a pair of through mounting grooves are symmetrically formed in the left end and the right end of the movable plate, connecting shafts are fixedly mounted in the mounting grooves, sliding blocks are slidably mounted at the two ends of the connecting shafts, hinge seats are hinged to one ends of hinge strips, the ends, away from the hinge seats, of the hinge strips are rotatably mounted at one end of the mounting frame, an auxiliary balance connecting mechanism is arranged between the movable plate and the mounting frame, and a second lifting hook is mounted in the middle of the lower end face of the movable plate. The tension of the movable plate can be balanced and relieved, the auxiliary balance connecting mechanism is arranged, the tension of hydrology and water resource drilling equipment can be further relieved, the balance effect of the balancer is improved, and the service life of the balancer is prolonged.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

High-effectively, energy-saving and environment-friendly heating device

InactiveCN102231921BFit closelySimple structureHeater elementsBiochemical engineeringMolecular materials

The invention discloses a high-effectively, energy-saving and environment-friendly heating device, relating to technical field of electrical heating. The high-effectively, energy-saving and environment-friendly heating device comprises a pedestal and a cover body and is characterized in that the pedestal and the cover body are made from high-molecular materials; clamping surfaces perpendicular to the top surface of the cover body are formed at the two ends of the cover body and clamping holes are formed in the clamping surfaces; clamping members perpendicular to the pedestal are arranged at the two ends of the pedestal, salient fasteners are arranged on the clamping members and the fasteners are matched with the clamping holes; and a clamping column is fixedly connected to one side of the pedestal and a clamping slot is arranged at the other side of the pedestal. The traditional resistor type heating device is used for heating by adopting a thermal conducting manner to waste a large amount of energy resources, such that the temperature of the external surface of the device can become too high, the production environment can become worse and the human body can be hurt greatly. According to the high-effectively, energy-saving and environment-friendly heating device disclosed by the invention, the temperature of the external surface can be felt with hands, and therefore the production environment is greatly improved and the cost of the traditional cooling device can be reduced.

Owner:王奉标

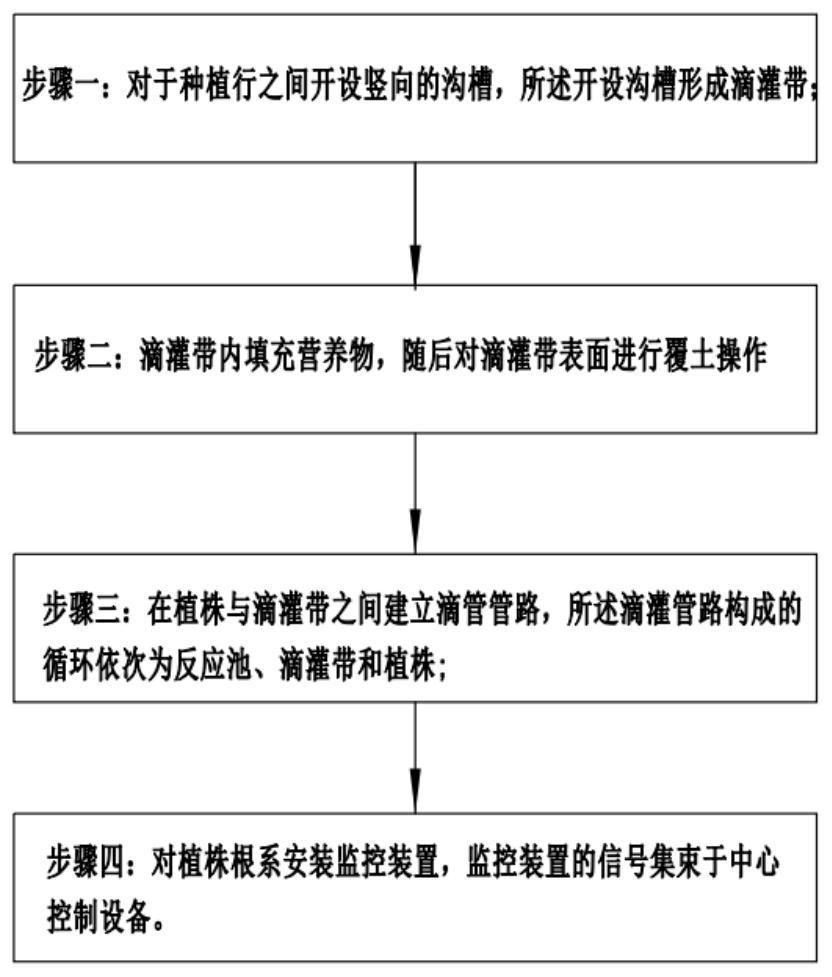

A seasonal maintenance-free drip irrigation method

ActiveCN111903300BAvoid frequent maintenanceAvoid frequent fertilizationClimate change adaptationWatering devicesAgricultural sciencePlant roots

The invention discloses a seasonal maintenance-free drip irrigation method in the field of plant irrigation to overcome the defect that artificial seasonal fertilization is required. In order to overcome the above defects, the technical solution includes the following steps; Open a vertical groove, and the groove is formed to form a drip irrigation belt; step 2: fill the drip irrigation belt with nutrients, and then cover the surface of the drip irrigation belt with soil; step 3: establish a drip pipe between the plant and the drip irrigation belt , the cycle formed by the drip irrigation pipeline is the reaction tank, the drip irrigation belt and the plants in turn; Step 4: Install a monitoring device on the root system of the plant, and the signal of the monitoring device is bundled in the central control equipment. Compared with the traditional integrated management technology of water and fertilizer, this In the technical solution, the preset nutrients in the drip irrigation belt are used to avoid frequent fertilization, and the frequent maintenance of plant fertilization operations is avoided after adding fertilizer once, and the labor cost is reduced.

Owner:CHONGQING ACAD OF AGRI SCI

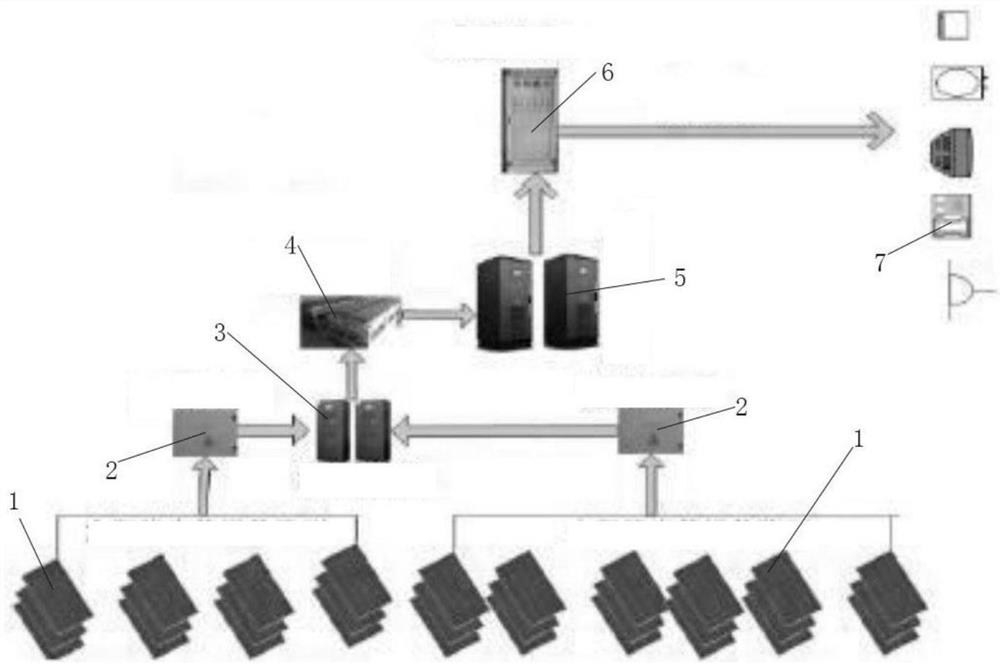

Plateau energy storage type photovoltaic off-grid power generation system and remote monitoring method

ActiveCN111446737BExtended service lifeAvoid frequent maintenanceBatteries circuit arrangementsPhotovoltaicsThermodynamicsOff-the-grid

Owner:西藏华阳供热工程服务有限公司

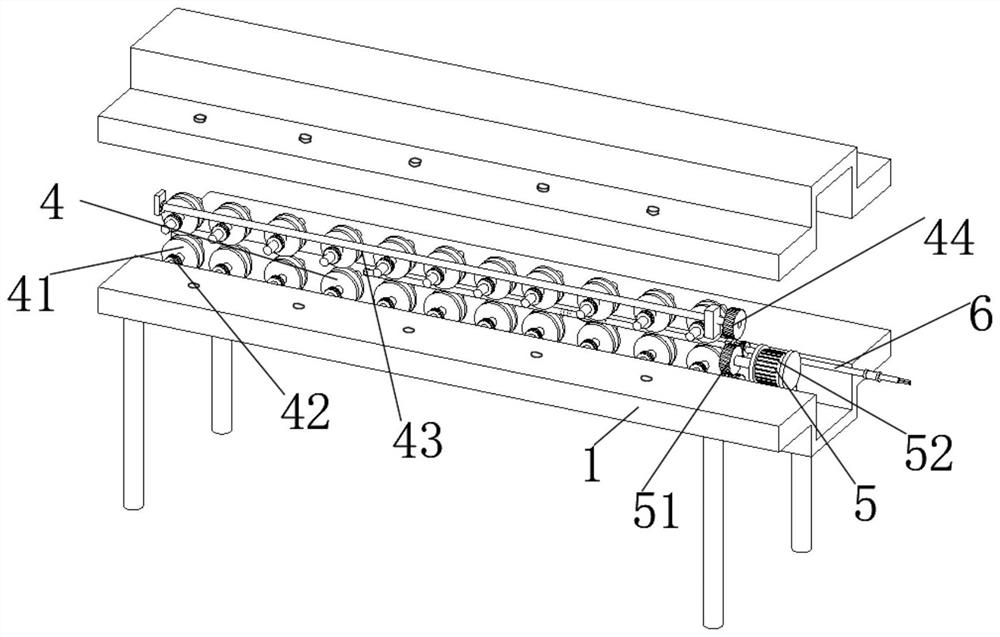

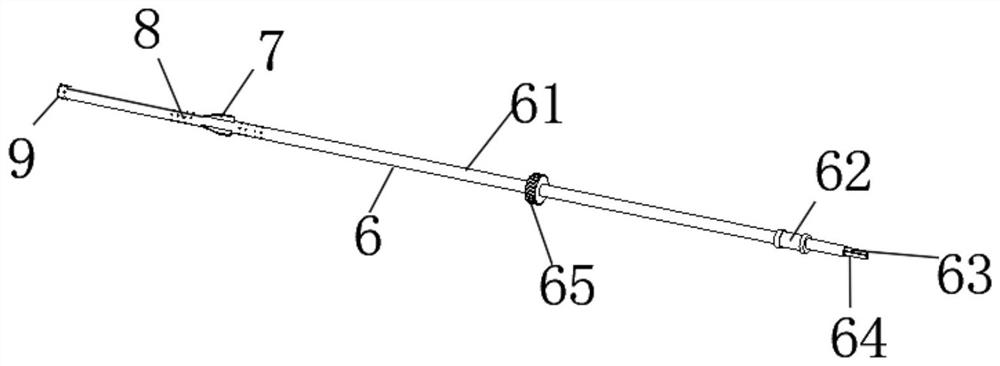

Sand blasting and rust removing production line for inner wall of copper pipe

InactiveCN113246029AThorough rust removalReduce usageHollow article cleaningAbrasive machine appurtenancesMetallurgySand blasting

The invention discloses a sand blasting and rust removing production line for the inner wall of a copper pipe, comprising mounting plates. Two sets of mounting plates are symmetrically arranged up and down; four sets of supporting rods are arranged at the bottom of the lower mounting plate; conveying assemblies are mounted in a mounting cavity defined by the two sets of mounting plates; a sand blasting and rust removing assembly is mounted between the conveying assemblies; and the conveying assemblies and the sand blasting and rust removing assembly are both connected with a driving assembly in an engaged mode. According to the sand blasting and rust removing production line for the inner wall of the copper pipe, a driving motor of the driving assembly can drive the conveying assemblies to drive the copper pipe to do a linear motion, meanwhile, a rust scraping knife on a rotating pipe of the sand blasting and rust removing assembly can be driven to rotate to scrape rust in the copper pipe, and secondary rust removing operation is carried out on the inner wall of the copper pipe through high-speed quicksand, so that more thorough rust removal can be conveniently carried out on the interior of the copper pipe; and two sets of worms and a set of rotating pipes are driven to move at the same time through one set of driving motors, the conveying and rust scraping effects on the copper pipe can be achieved, the number of motors is reduced, and the cost is reduced.

Owner:青岛华特防腐保温设备有限公司

Face recognition detection device

InactiveCN111507329AConvenient manual controlImprove reliabilityCharacter and pattern recognitionCleaning using toolsFace detectionStructural engineering

The invention discloses a face recognition detection device. The face recognition detection device includes a base, a controller is fixedly mounted on one side of the base; the face recognition detection device is characterized in that grooves are formed in the two sides of the top face of the base respectively, the rack is meshed with the gear, a hollow strip-shaped block is jointly and fixedly installed on the peripheries of the two belts, a plurality of dust suction holes are formed in the periphery of the strip-shaped block, a dust suction device is fixedly installed on the other side of the base, the dust suction device is fixedly connected with the strip-shaped block through a hose, and wiping cloth is fixedly installed outside the strip-shaped block. The face recognition detection device is suitable for face recognition devices arranged at entrances and exits of construction site entrance guard and subway stations. According to the device, the angle of the face detection devicecan be automatically adjusted; the lens of the face detection device can be aligned with the face of a user for scanning and recognition, the use is convenient, the user does not need to move his / herown position back and forth or stoop to align the face with the lens of the face detection device, the use time of the device can be saved, and the working efficiency of the face detection device is improved.

Owner:CHANGSHA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com