Patents

Literature

33results about How to "Prevent loose situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

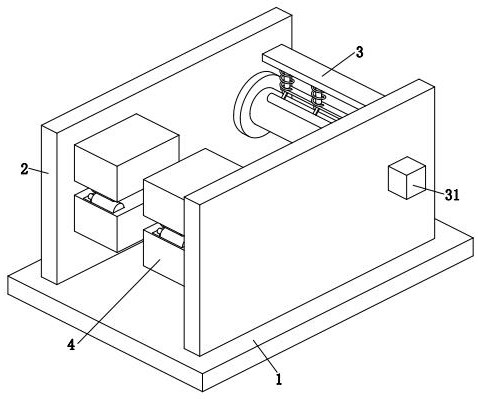

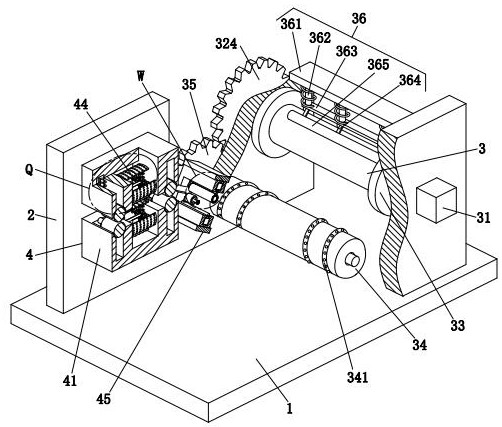

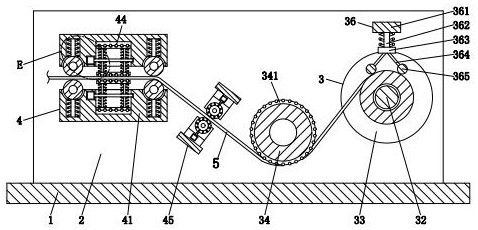

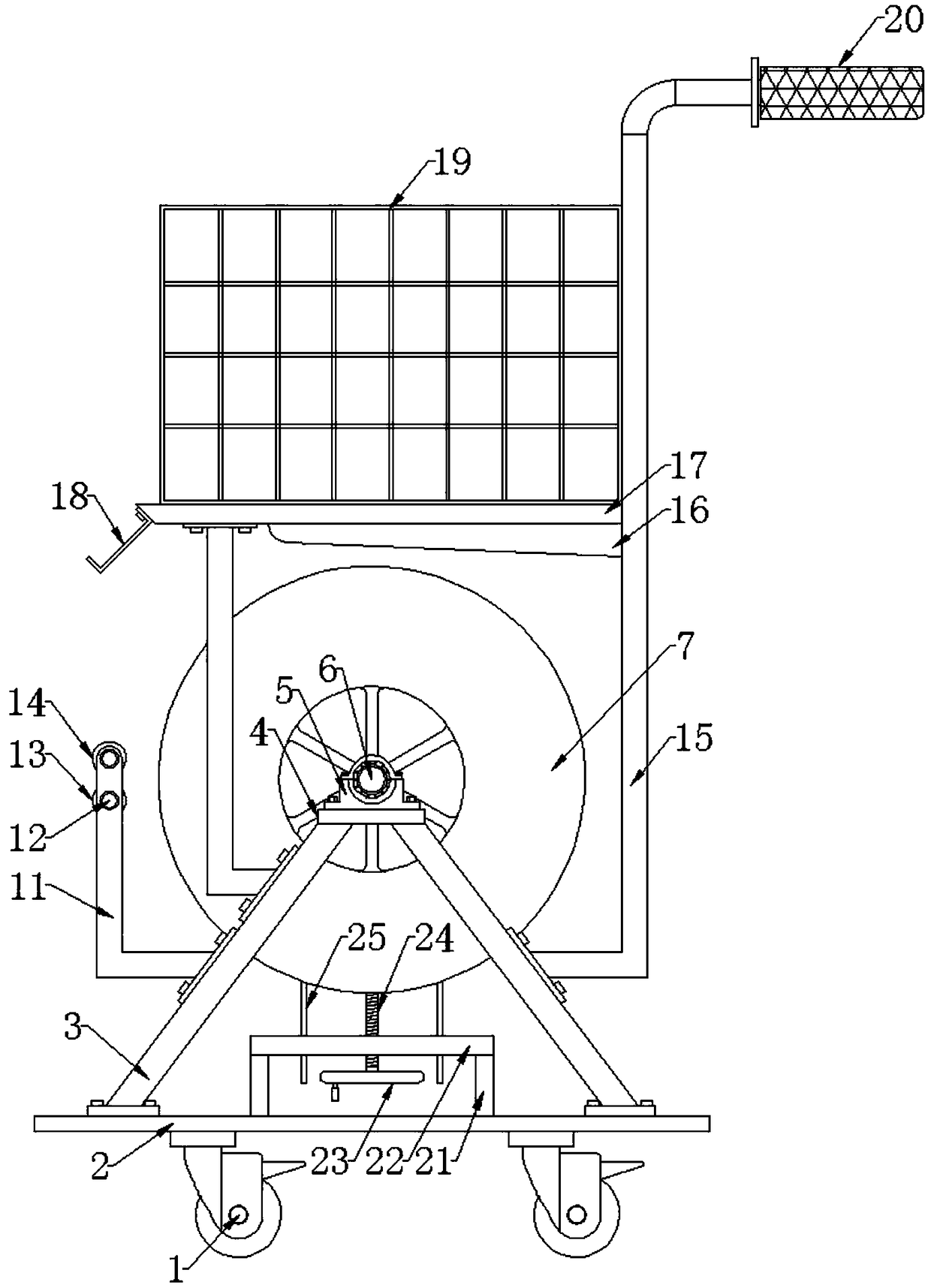

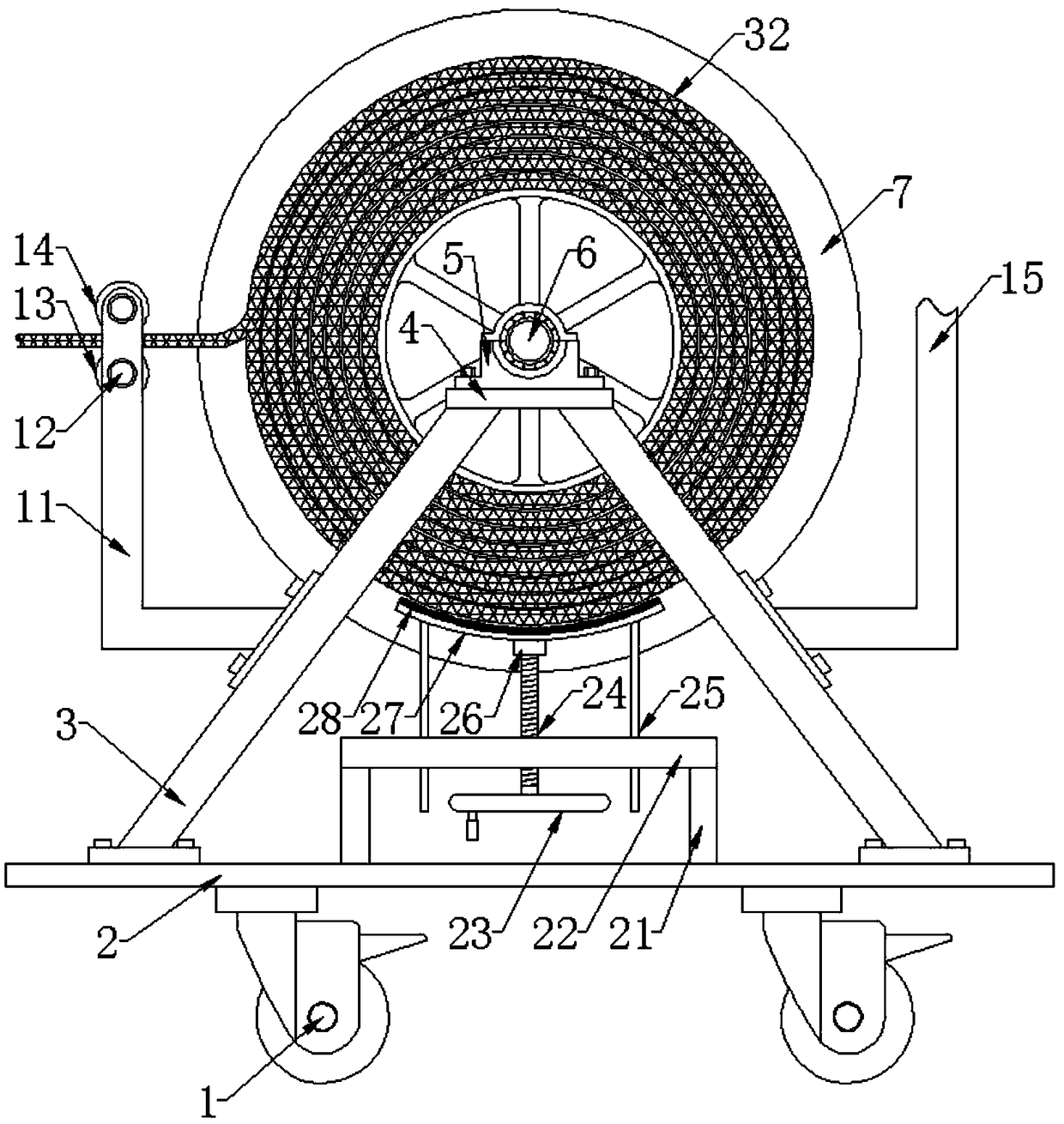

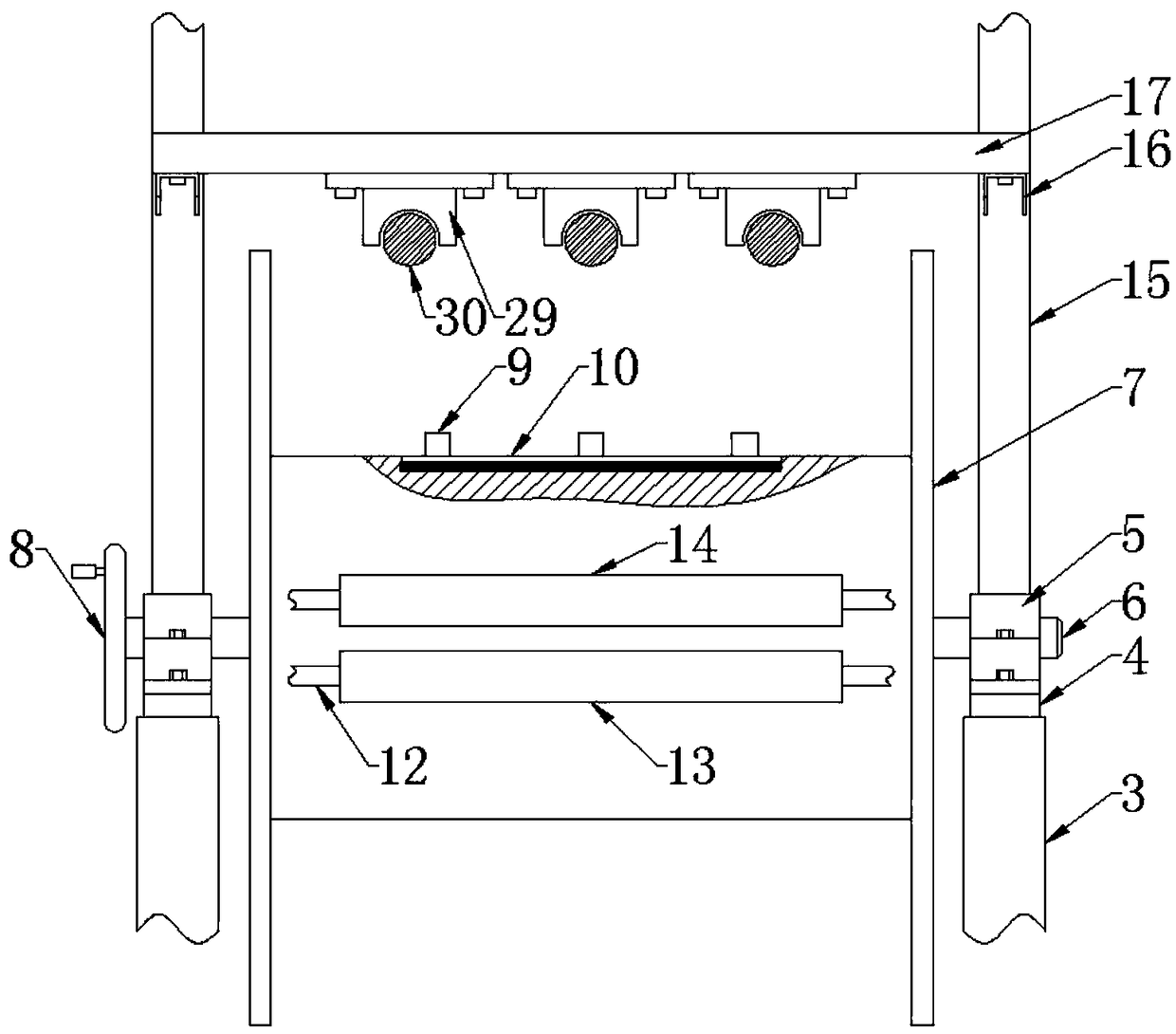

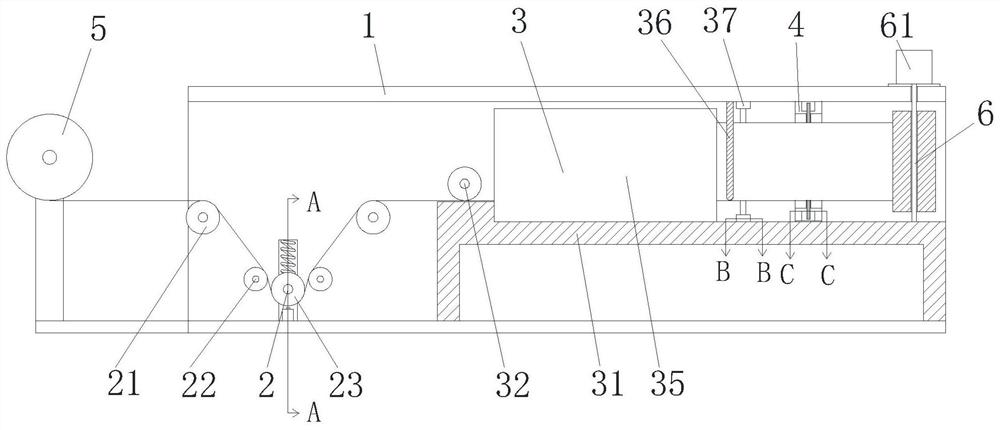

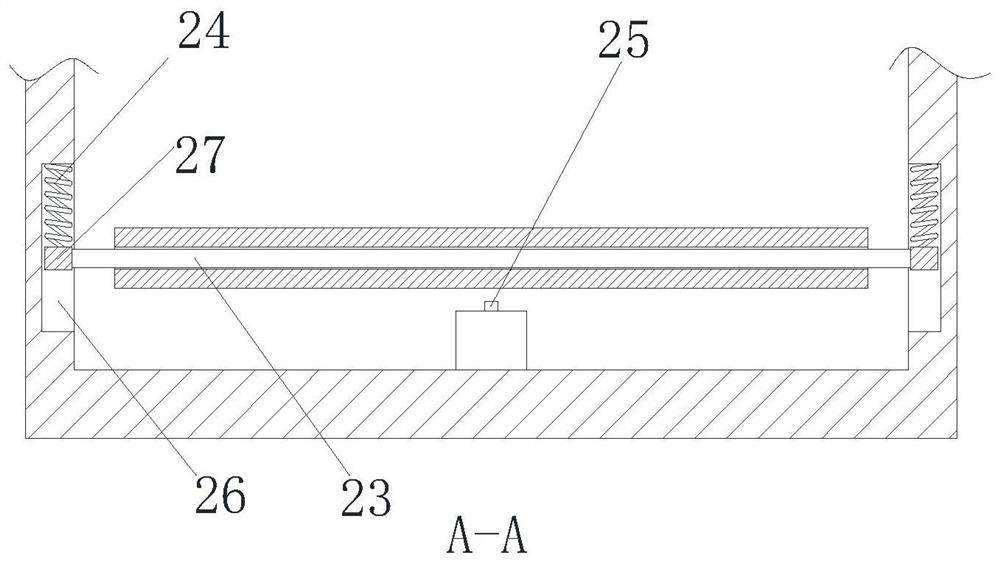

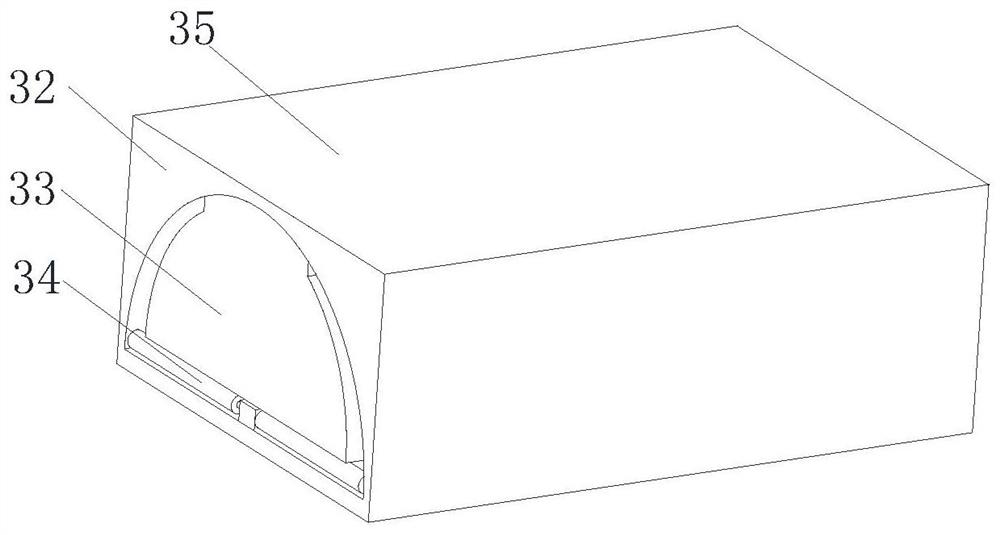

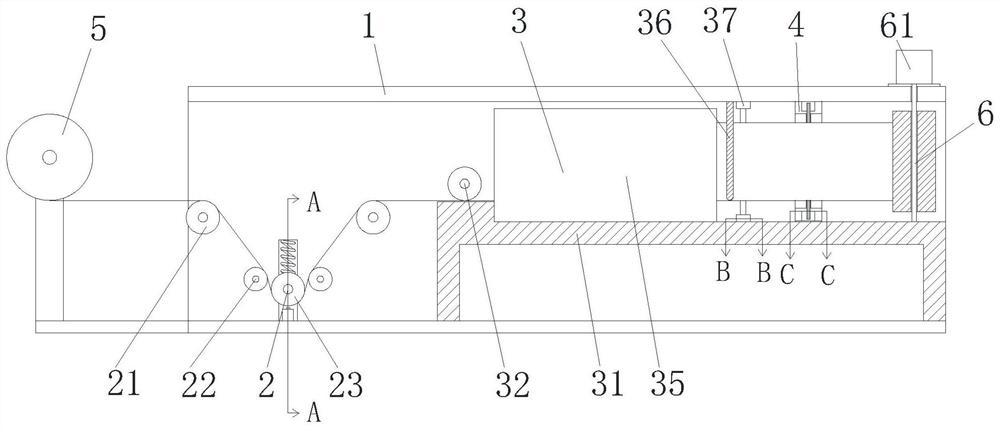

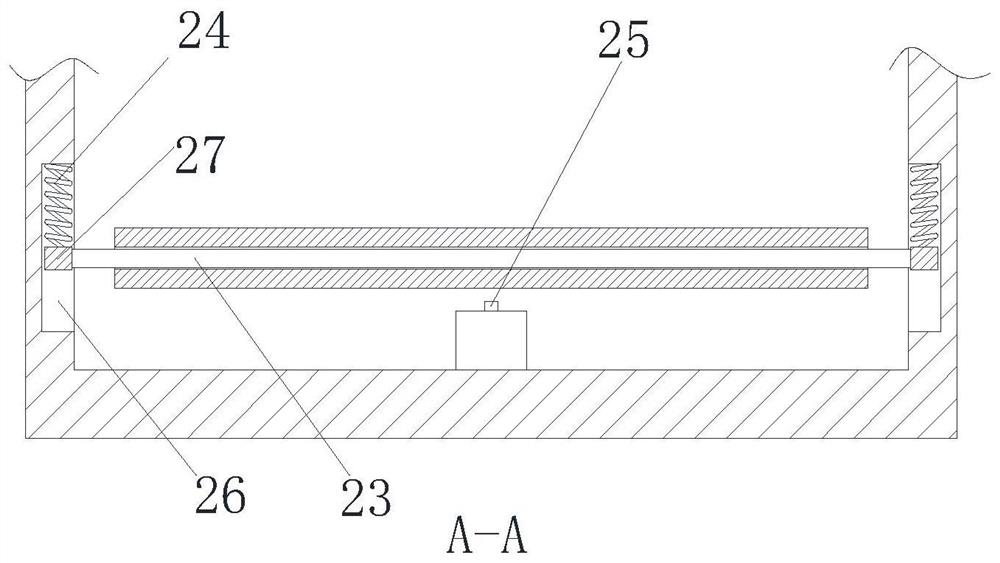

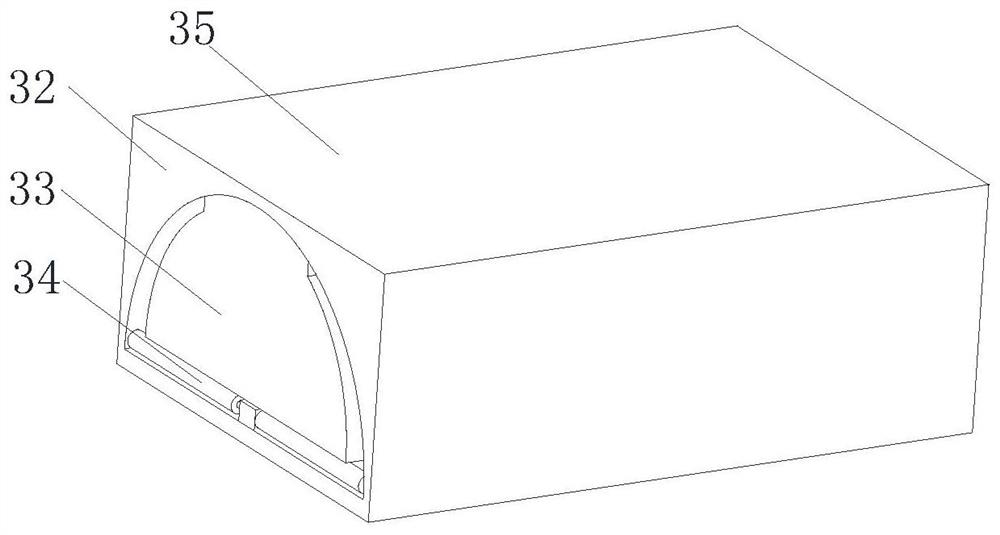

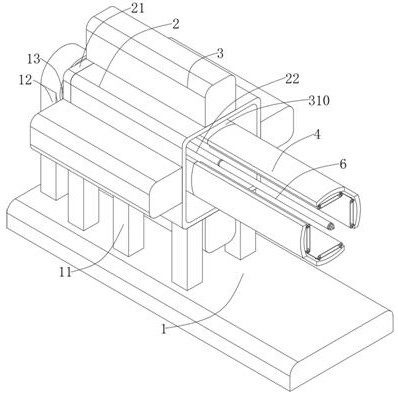

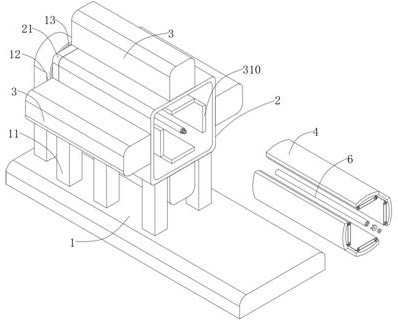

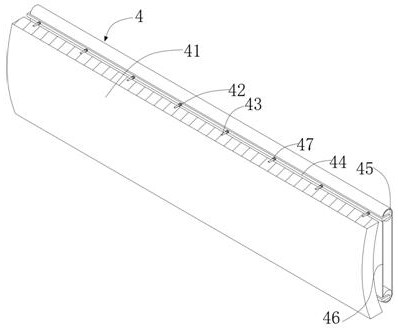

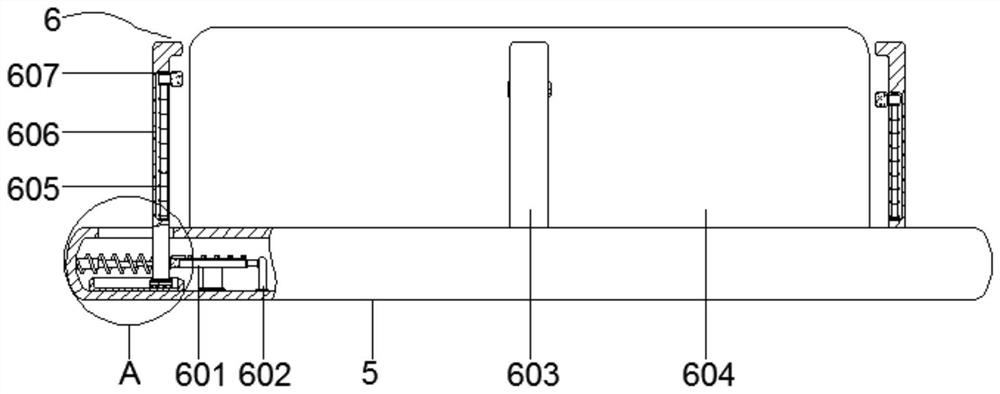

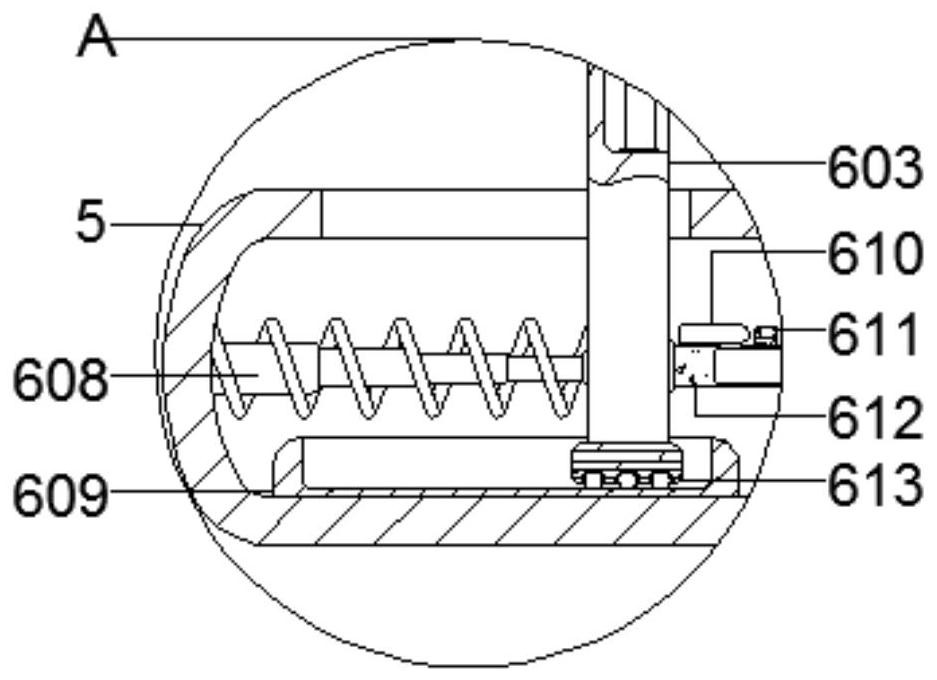

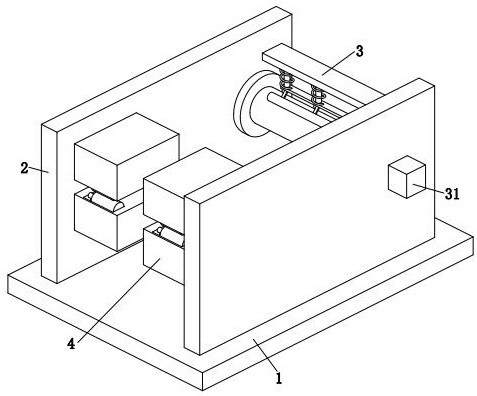

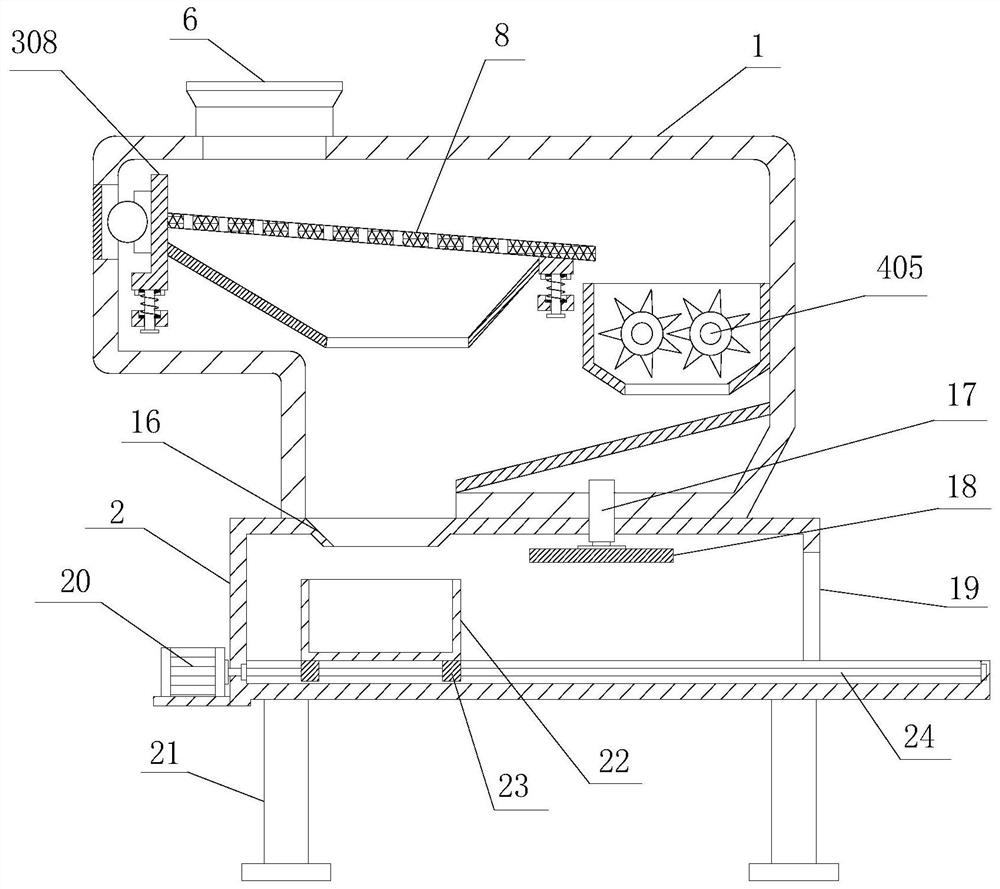

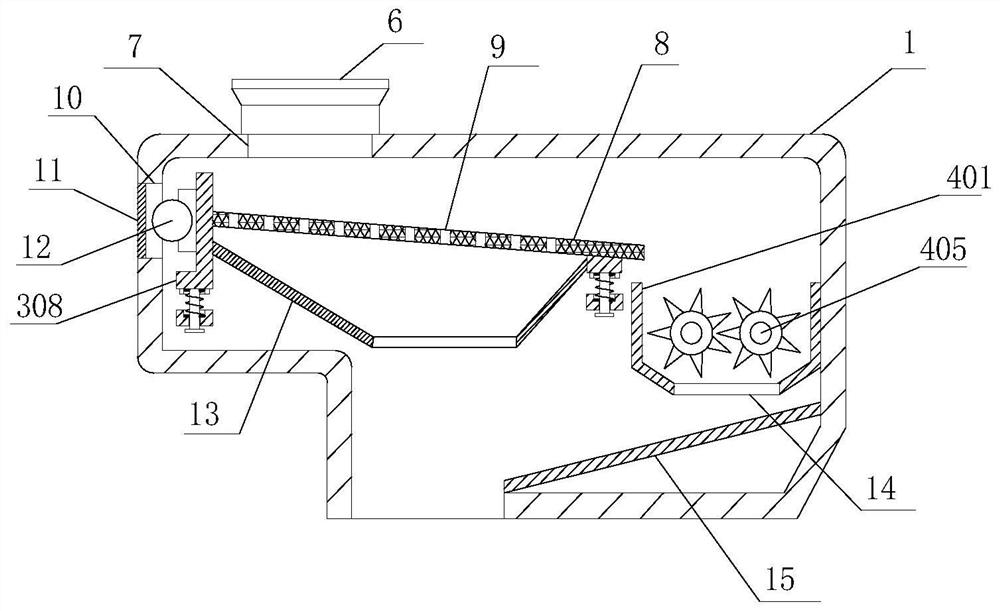

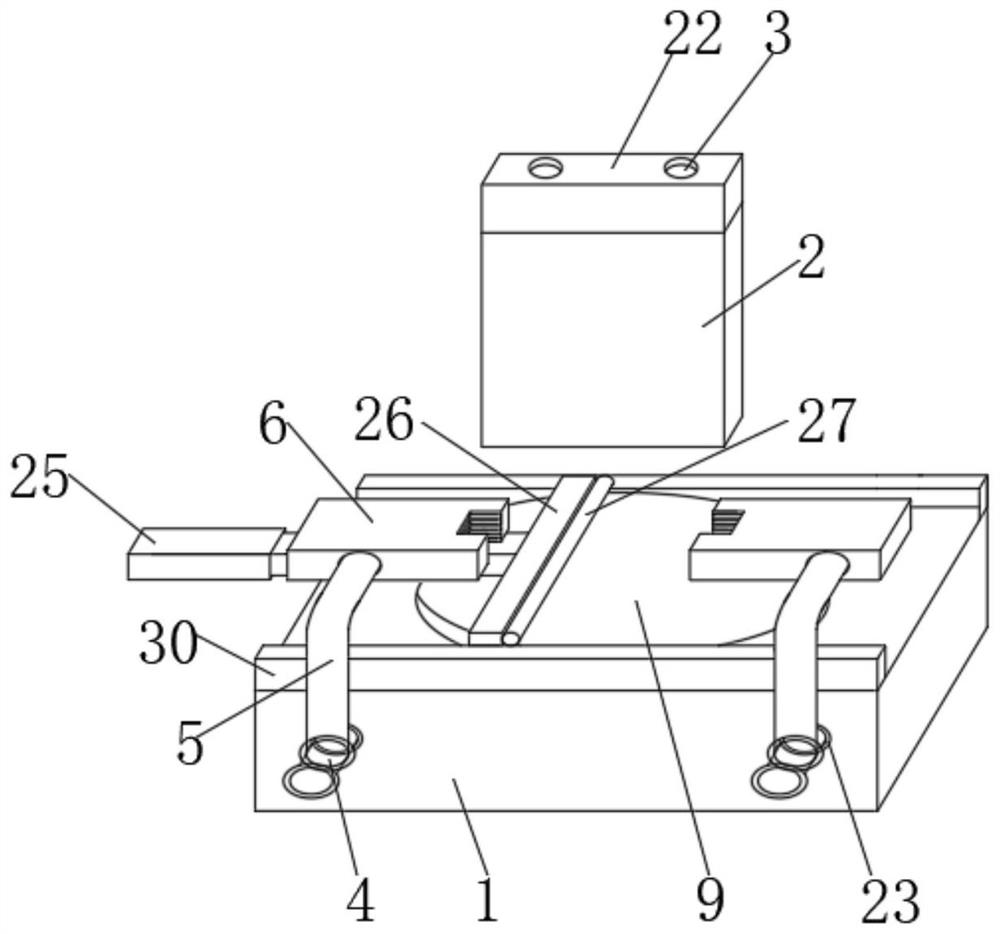

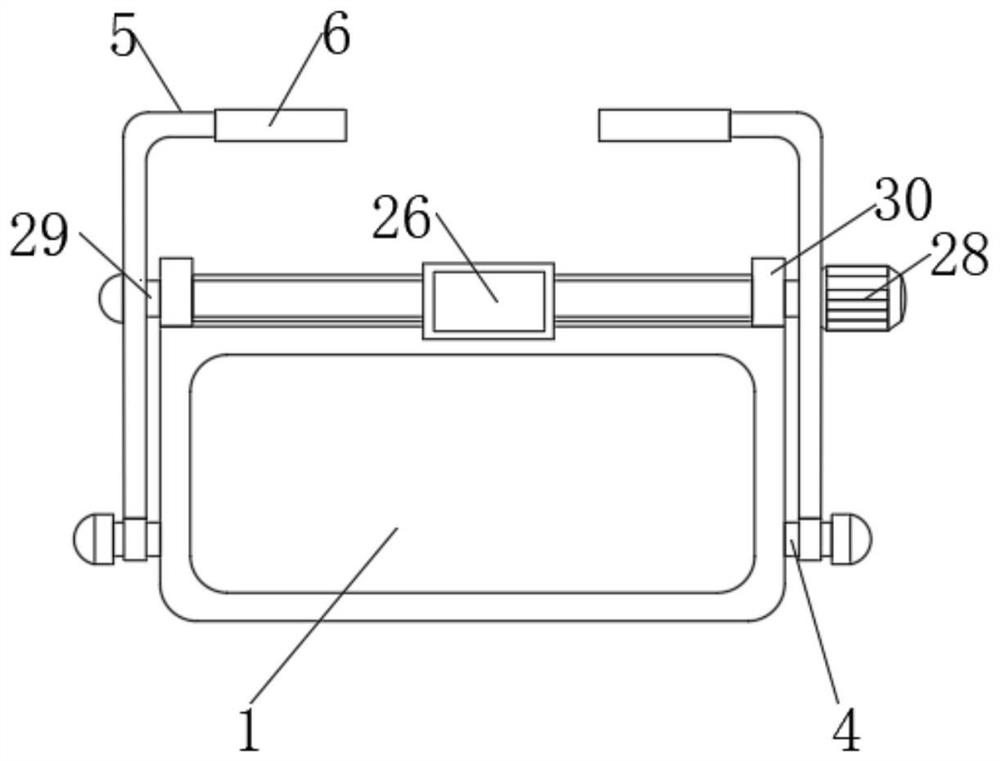

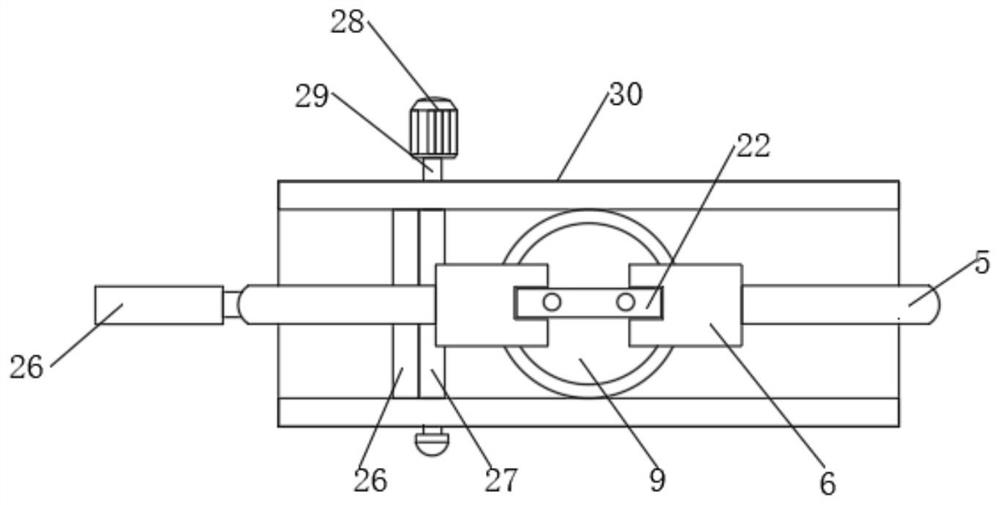

Garment fabric production, conveying and winding machine

ActiveCN113387220AEnsure compactnessGuaranteed cleanlinessMechanical cleaningPressure cleaningWinding machineWorkbench

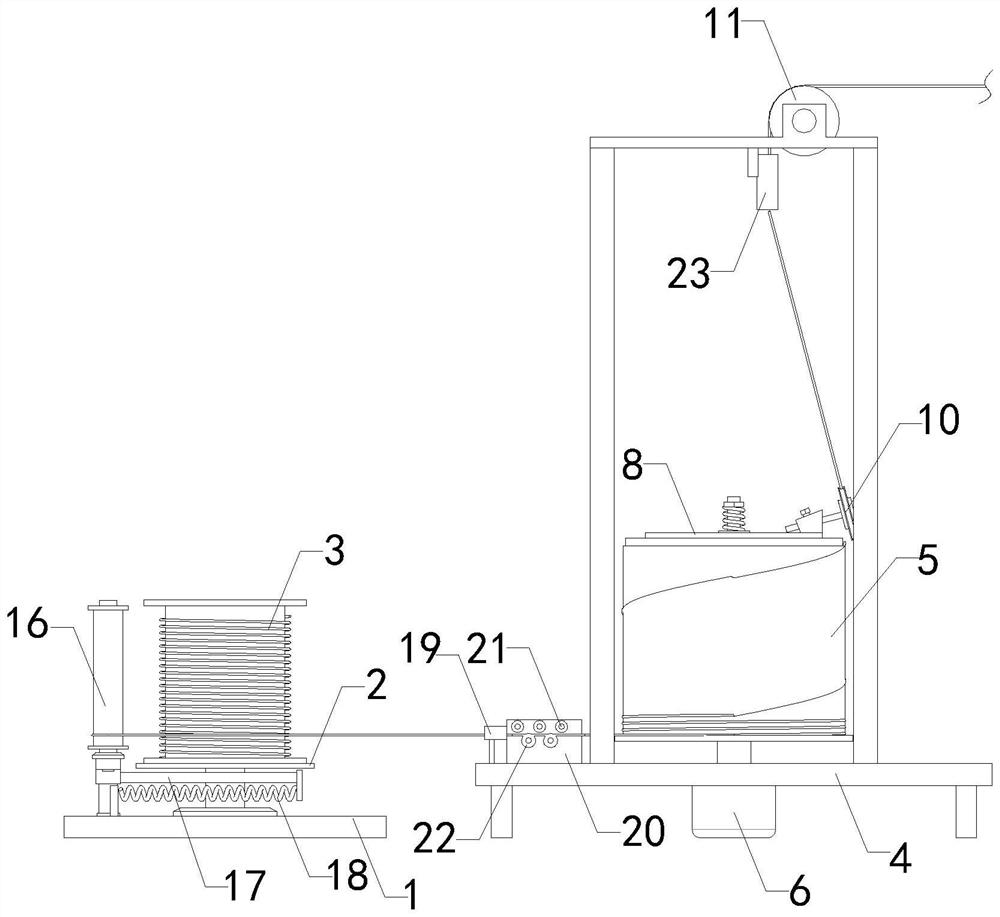

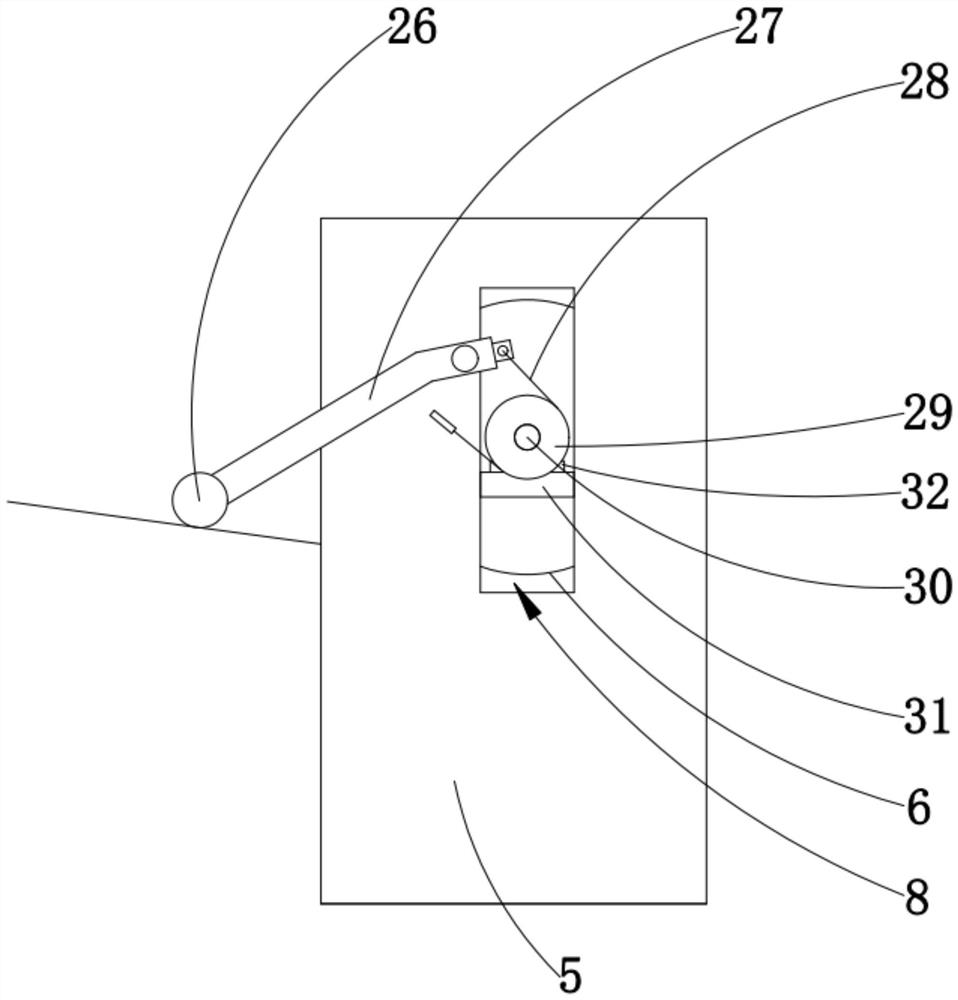

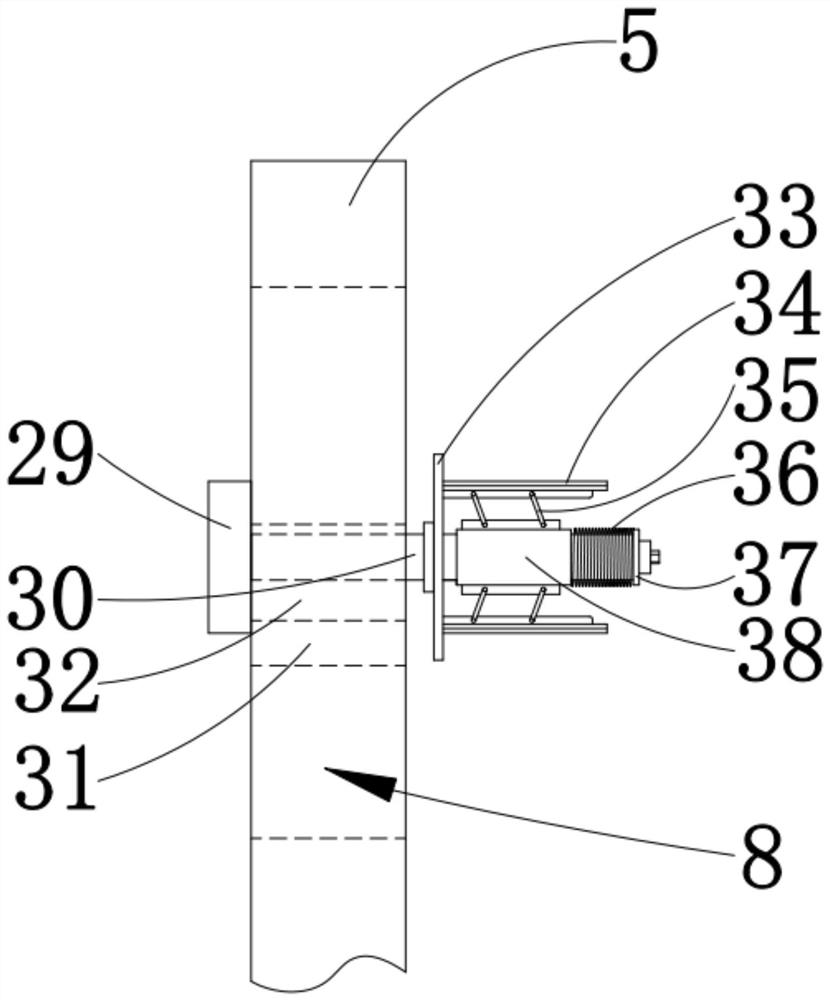

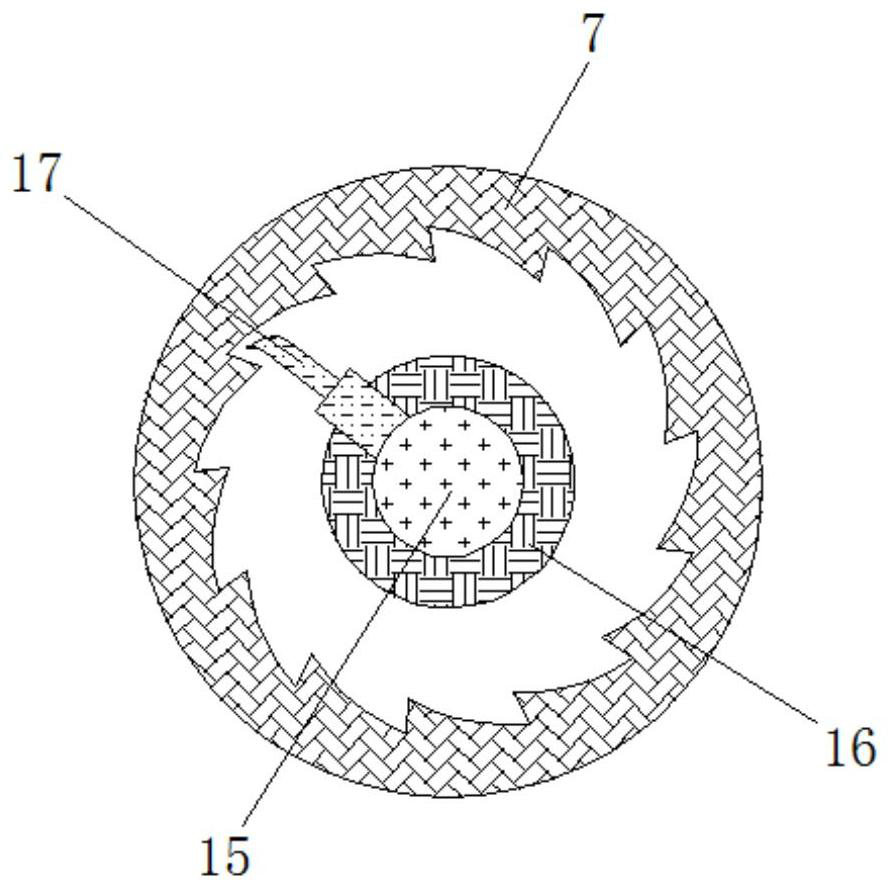

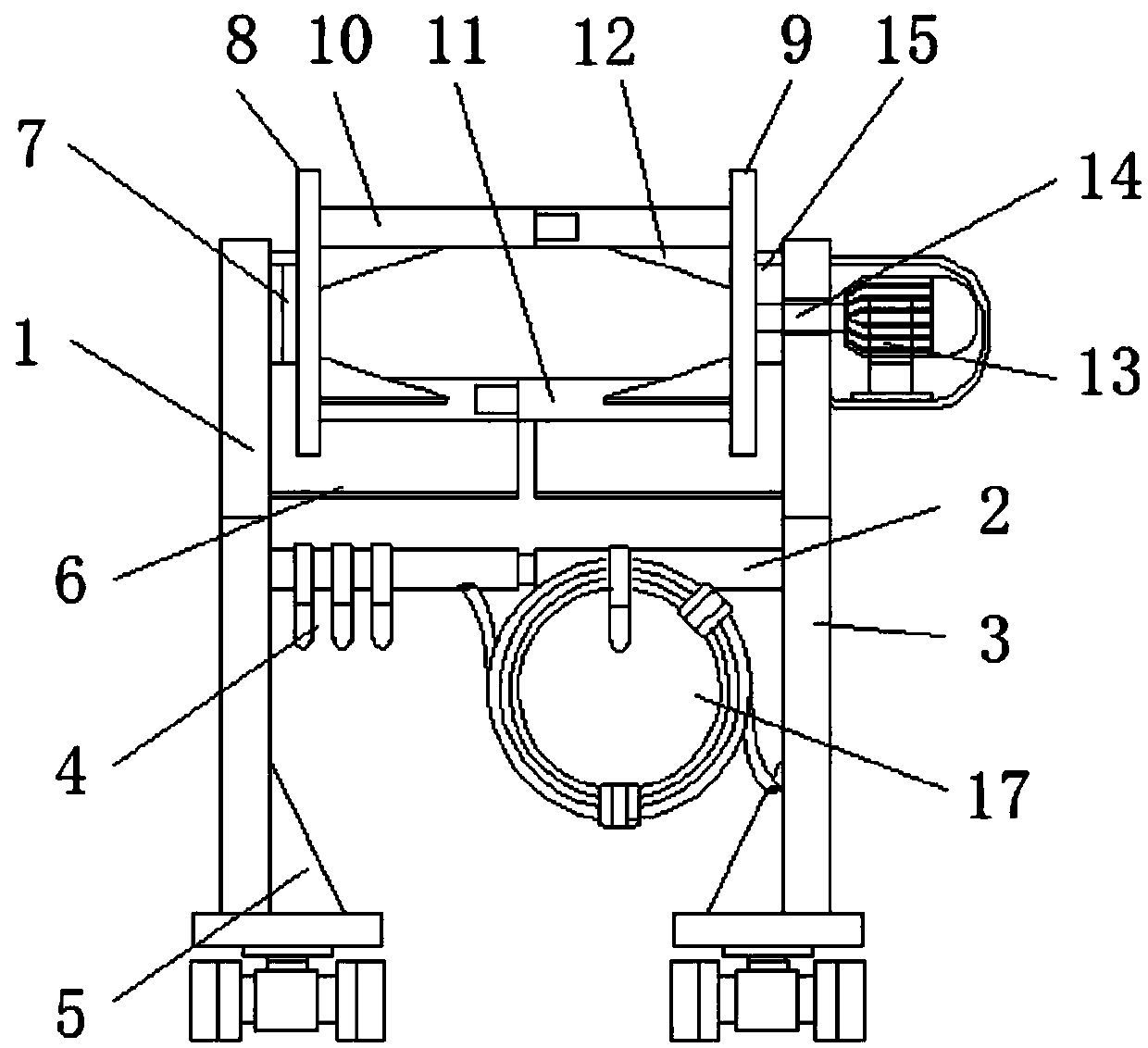

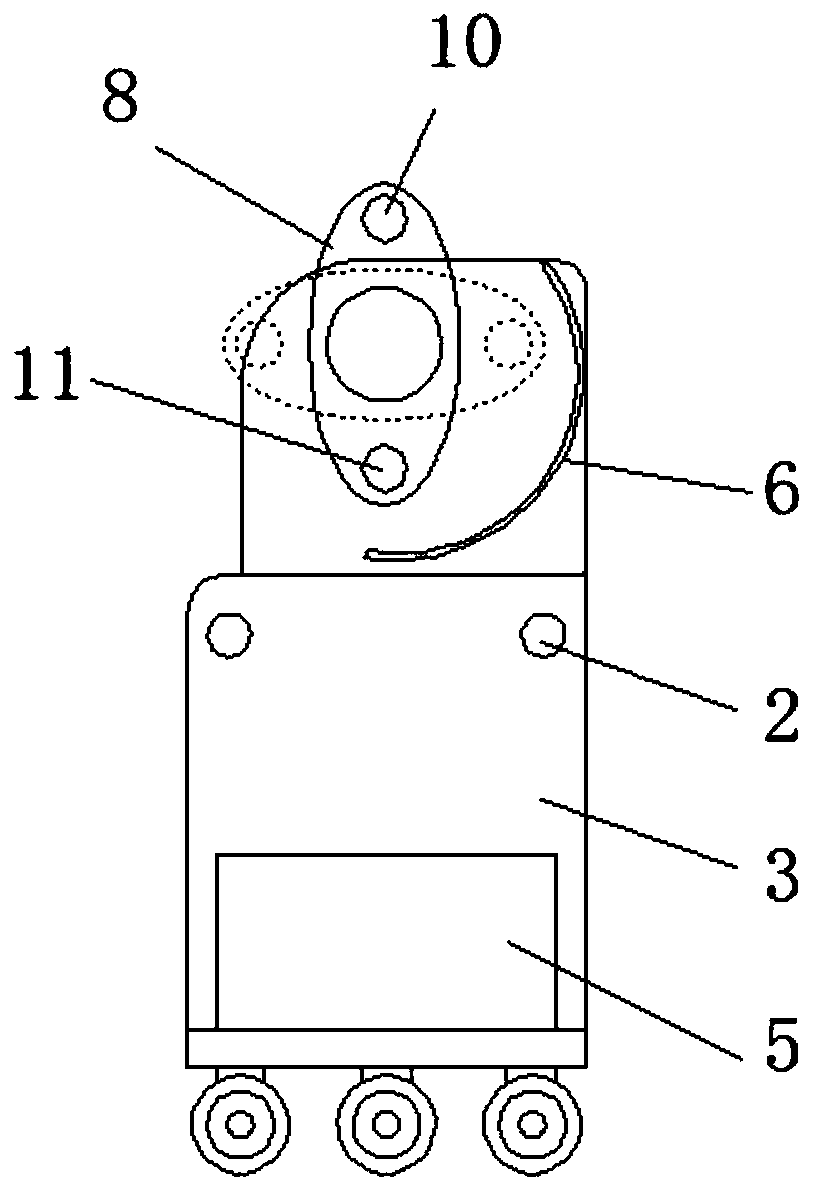

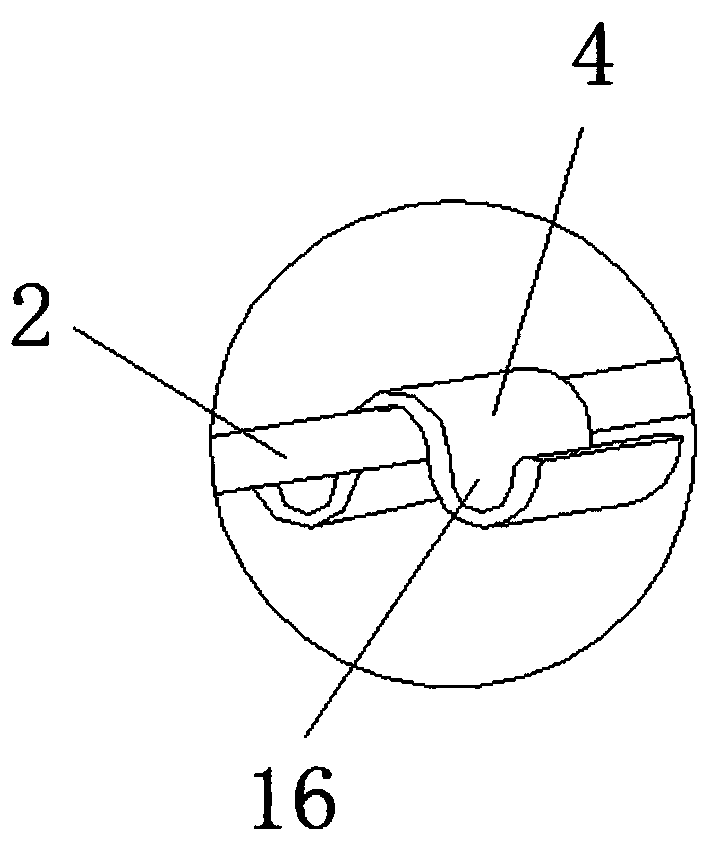

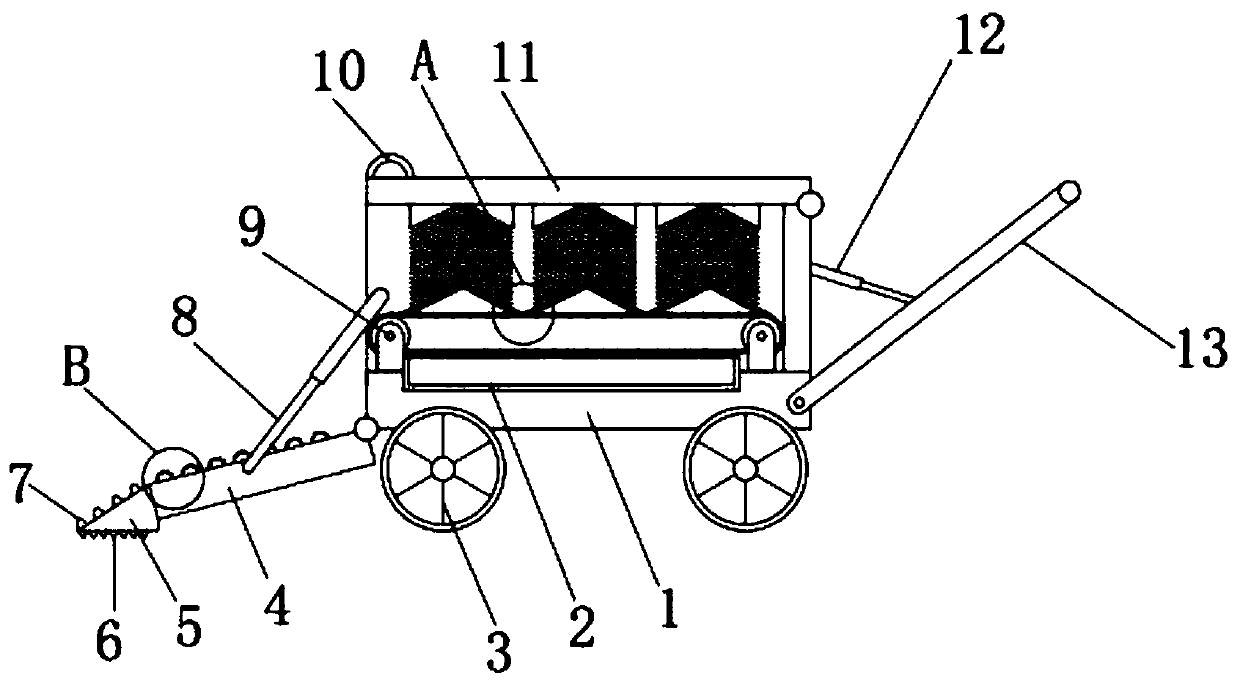

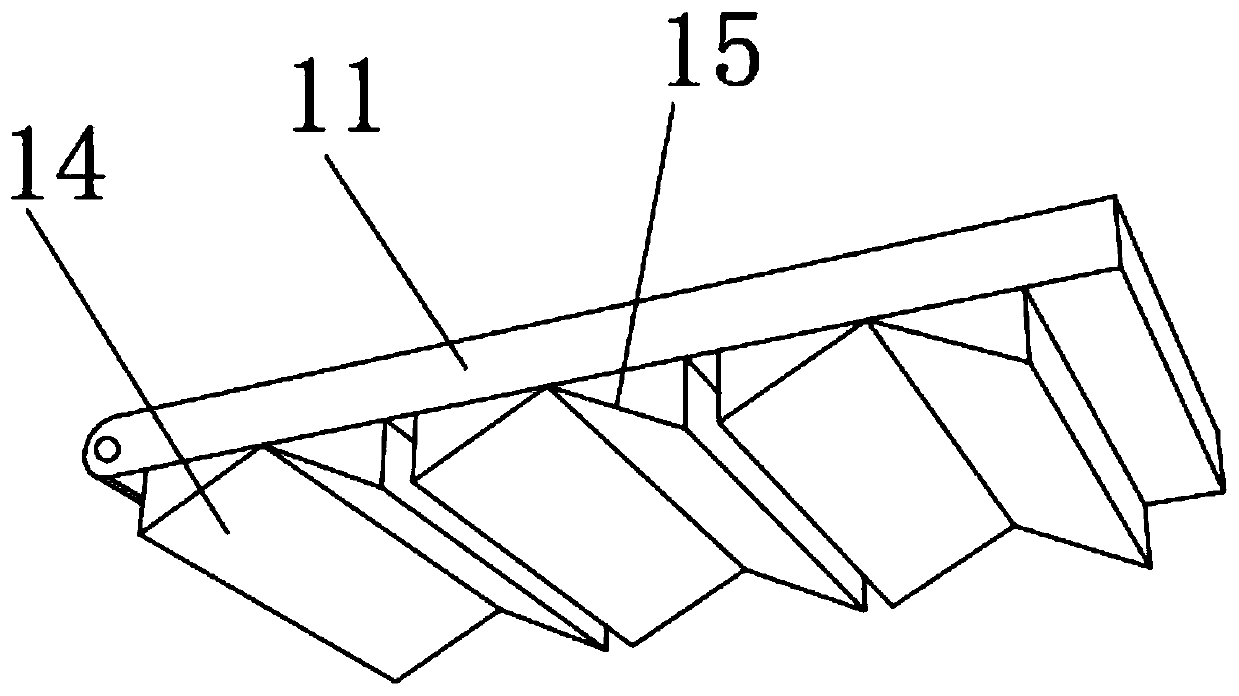

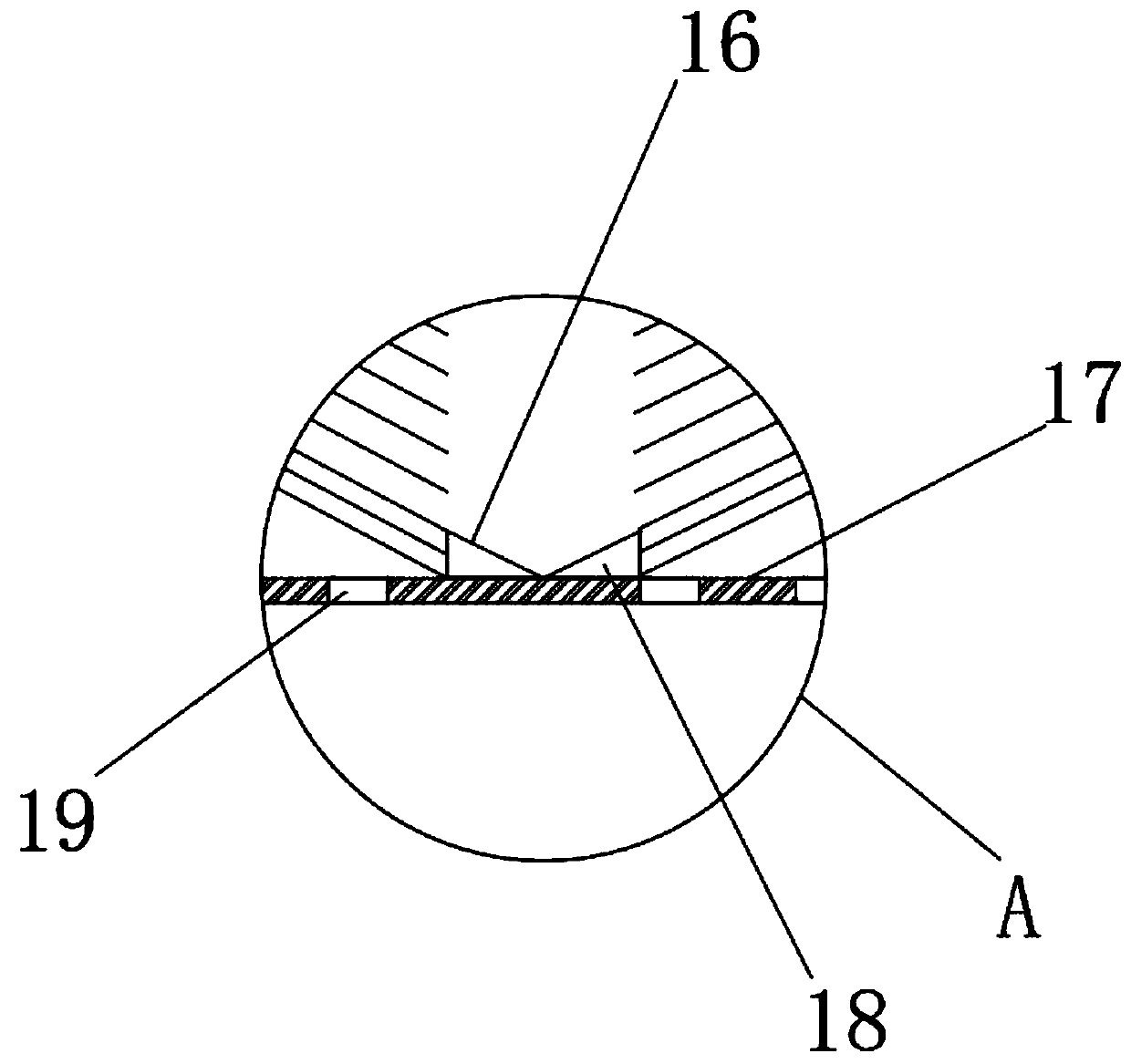

The invention relates to the technical field of garment fabric winding, in particular to a garment fabric production, conveying and winding machine. The machine comprises a workbench, supporting plates, a winding unit and a flattening unit, the supporting plates are fixedly installed at the upper end of the workbench in a front-back symmetry mode, the winding unit is arranged on the right sides of the opposite ends of the supporting plates, and the flattening unit is mounted on the left side of the opposite ends of the supporting plates. The problems existing during garment fabric winding can be solved that traditional winding equipment cannot effectively conduct flattening treatment on garment fabric during garment fabric winding, so that the flatness of the garment fabric cannot be ensured, and dust and thread residues on the surface of the garment fabric cannot be removed through the traditional winding equipment, so that the cleanliness of the garment fabric is influenced. The two sides of the garment fabric can be stricken through the flattening unit, so that the flatness of the garment fabric is ensured; and dust and thread residues left on the surface of the garment fabric can be sucked out, and therefore the cleanliness of the garment fabric can be guaranteed.

Owner:江苏柏盛家纺有限公司

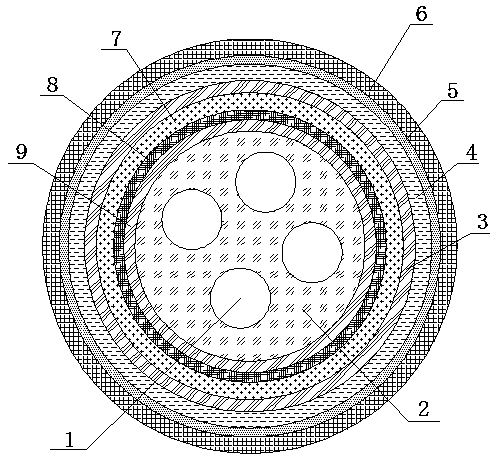

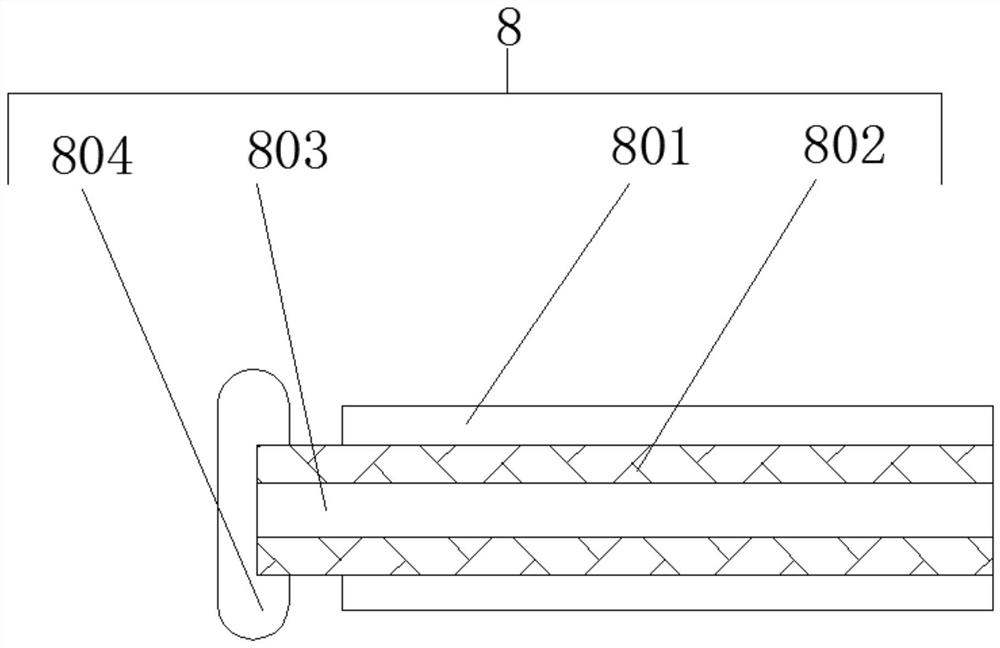

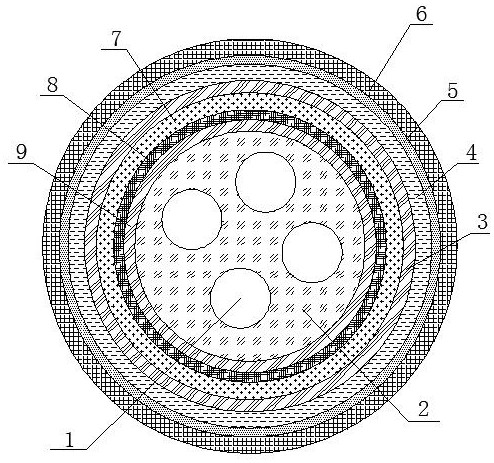

Inorganic mineral insulated flexible fireproof cable

ActiveCN109727712AReduce nudityLong fire resistanceClimate change adaptationFlexible cablesElectrical conductorCeramic composite

The invention discloses an inorganic mineral insulated flexible fireproof cable. The inorganic mineral insulated flexible fireproof cable comprises a plurality of cable cores. Each cable core comprises an electrical conductor and a ceramic composite tape coating the electrical conductor, the ceramic composite tapes are coated with metal foil material coatings which are selected from one in the group of copper, nickel, nickel alloy, titanium, steel or stainless steel. The cable cores are coated with a first mica tape, the first mica tape is externally provided with a flameproof fabric, an insulating refractory layer is arranged at the outer portion of the flameproof fabric, a second mica tape is arranged at the outer portion of the insulating refractory layer, a basalt fiber fireproof layeris arranged on the outer layer of the second mica tape, and a jacket layer is arranged at the outer layer of the basalt fiber fireproof layer. The inorganic mineral insulated flexible fireproof cableemploys a multi-layer fireproof layer design, has a good heat and fire resistance at a high temperature, and can maintain the state of the cable at the high temperature for a long time.

Owner:四川新蓉电缆有限责任公司

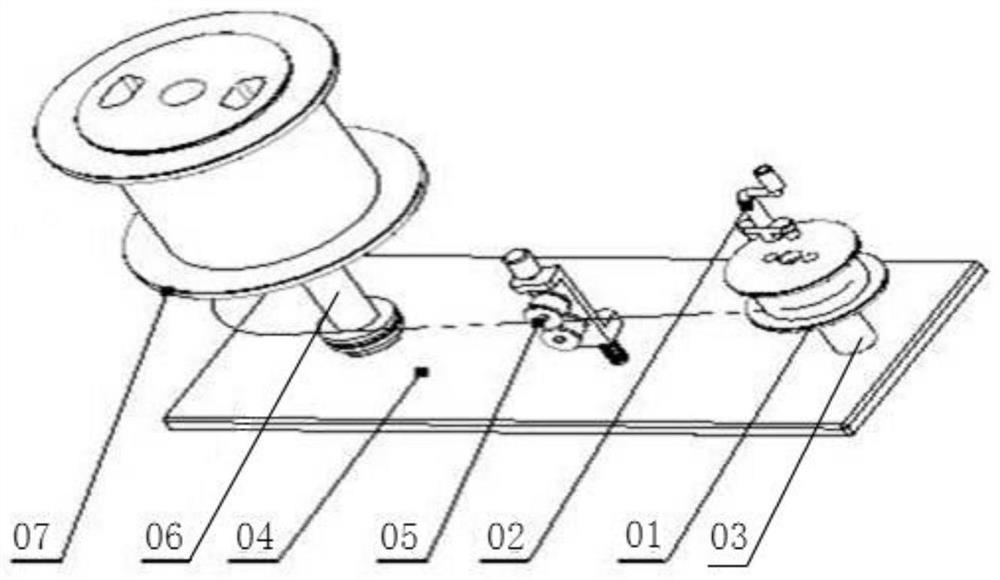

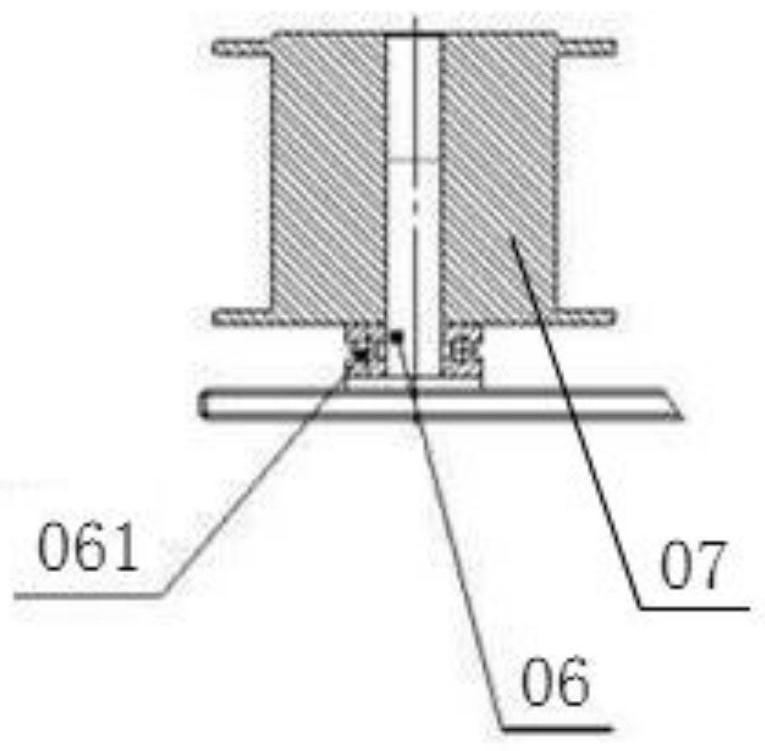

Fiber winding and unwinding device group of bare fiber

The invention belongs to the technical field of photo-communication, and discloses a fiber winding and unwinding device group of a bare fiber. The fiber winding and unwinding device group of the barefiber comprises a fiber winding device and a fiber unwinding device; the fiber winding device comprises a first fiber winding disc, a crank and a first rotating shaft; the first rotating shaft is sleeved with the first fiber winding disc, and the crank is fixedly arranged on the first winding disc; the fiber unwinding device comprises a clamping block, a connecting shaft, a second fiber winding disc, a fiber unwinding rod and nuts; the clamping block is arranged on a station, one end of the connecting shaft is fixed on the clamping block, the other end of the connecting shaft penetrates through a central through hole of the second fiber winding disc and a through hole of the fiber unwinding rod in sequence and is fixed through the nuts; the through hole of the fiber unwinding rod is internally provided with a ball bearing, the fiber unwinding rod is a straight rod, the middle section of the straight rod is provided with a threaded hole, the threaded hole is used for installing a ball screw, the tail end of the straight rod is provided with an arc-shaped sliding groove, and the arc-shaped sliding groove is tangent to the second fiber winding disc. The fiber winding and unwinding device group of the bare fiber solves the problems that the fiber winding and unwinding efficiency of bare fiber in the prior art is lower and fiber damage is easy to cause.

Owner:GUANGXUN SCI & TECH WUHAN

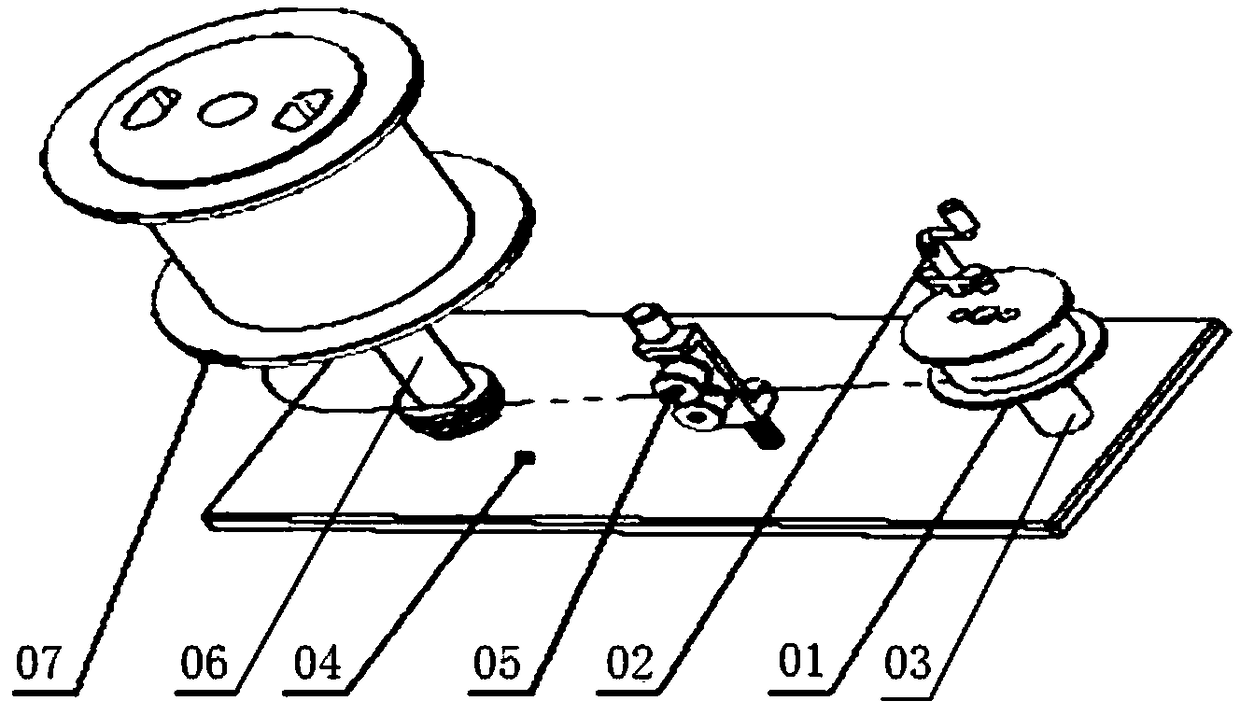

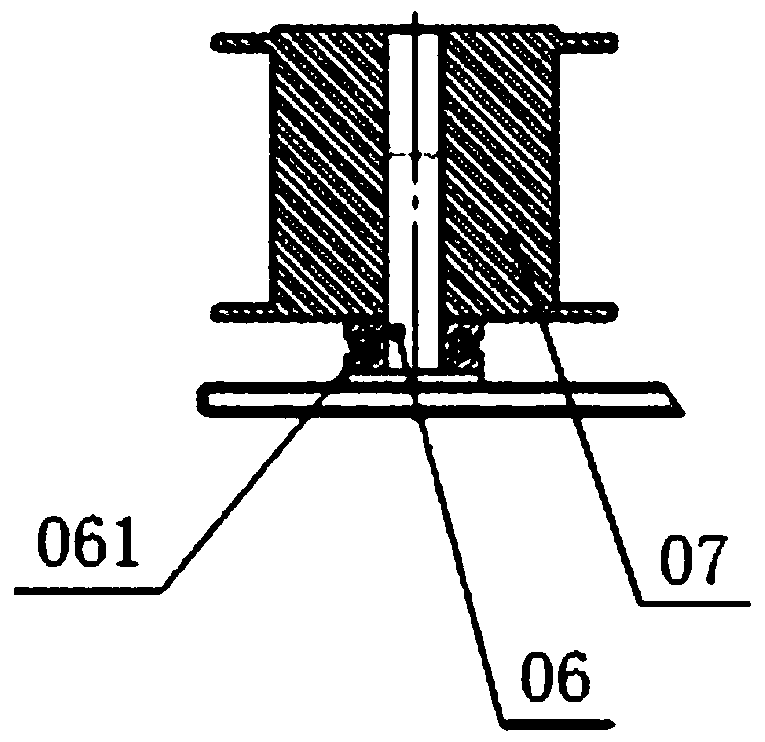

Novel automatic wire feeding device of splayed nail machine

PendingCN114180404AGuaranteed normal operationAvoid entanglementFilament handlingElectric machineryStructural engineering

The invention relates to the technical field of auxiliary wire feeding devices of splayed nailing machines, in particular to a novel automatic wire feeding device of a splayed nailing machine. The invention discloses a splayed nail machine which can effectively prevent iron wires from being loosened and wound together, guarantee normal operation of the splayed nail machine, reduce potential safety hazards and improve production efficiency, and comprises a wire feeding mechanism and a wire feeding mechanism, the wire feeding mechanism comprises a base, a rotating disc is rotationally installed on the base, an iron wire tray is installed on the rotating disc, and the wire feeding mechanism comprises a rack. An iron roller and a driving motor for driving the iron roller to rotate are arranged on the rack, a circular groove is formed in the top end of the iron roller, a brake drum is installed in the circular groove, a brake pad on the outer side of the brake drum makes contact with the inner side wall of the circular groove, an iron disc is arranged at the top end of the brake drum, a compression spring is installed at the top end of the iron disc, and a wire guide wheel is arranged on the outer side of an iron wire. A wire feeding wheel is arranged at the top end of the machine frame and located above the iron disc.

Owner:安平县三兴金属丝网制造有限公司

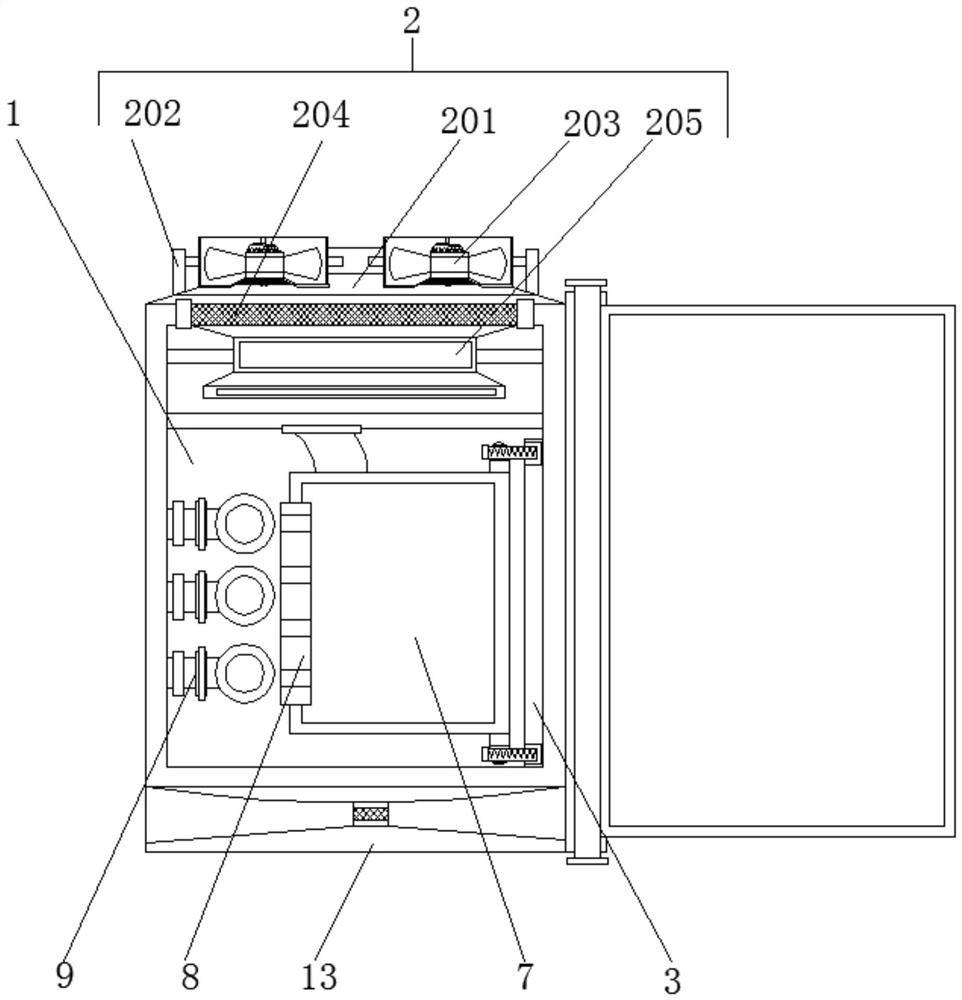

High-low voltage switch cabinet with waterproof and dustproof functions

PendingCN113224664AWith waterproof and dustproof functionGuaranteed tightnessBus-bar/wiring layoutsPipesElectrical and Electronics engineeringThreaded rod

The invention discloses a high-low voltage switch cabinet with waterproof and dustproof functions. The high-low voltage switch cabinet comprises a high-low voltage switch cabinet box and a wire bunching mechanism, the upper portion of the outer wall of the high-low voltage switch cabinet box is provided with a matched air dispersing mechanism, one side of the inner wall of the high-low voltage switch cabinet box is fixedly provided with a matched fixing block, the outer wall of a first threaded rod is provided with a matched positioning frame, and the outer wall of the positioning frame is fixedly provided with a matched waterproof box. According to the high-low voltage switch cabinet with the waterproof and dustproof functions, through the arrangement of a threading mechanism, wire ends generated in the waterproof box can be correspondingly threaded out, and meanwhile, the relative sealing performance of the waterproof box can be well guaranteed while the wire ends are threaded out; and meanwhile, the wire bunching mechanism is arranged in a matched mode the wire ends can be collected correspondingly, and the situation that the thread ends are loosened correspondingly when the cabinet uses the wire ends correspondingly can be well prevented.

Owner:江苏照亮电力安装有限公司

Placement rack for flexible graphite ground wires

The invention discloses a placement rack for flexible graphite ground wires, and relates to the technical field of electrical equipment. The placement rack comprises a bottom plate and roller supporting frames; the roller supporting frames are mounted on the bottom plate in a bilateral symmetry mode, and first mounting plates are arranged at the tops of the roller supporting frames; bearing seatsare mounted on the first mounting plates through screws, and the bearing seats are internally provided with roller bearings and rotationally provided with roller supporting shafts; first hand wheels are arranged at the left ends of the roller supporting shafts, and rollers are fixedly mounted on the roller supporting shafts; three pins are arranged on the working faces of the rollers, and magnetsare arranged under the pins; vertical supporting plates and horizontal supporting plates are arranged under the rollers, and the horizontal supporting plates are mounted on the upper end face of the bottom plate through the vertical supporting plates; and threaded rods are mounted on the horizontal supporting plates in a threaded mode, and the tops of the threaded rods are provided with connectingblocks and connected with arc-shaped stop plates through the connecting blocks. Wiring noses on the graphite ground wires are clamped into the pins on the rollers, and then the ground wires can be stored by shaking the first hand wheels.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

Non-woven fabric environment-friendly bag forming and processing equipment

ActiveCN111805933AReduce the probability of errors when folding in halfPrevent retractionDomestic articlesNonwoven fabricMechanical engineering

The invention discloses non-woven fabric environment-friendly bag forming and processing equipment. The non-woven fabric environment-friendly bag forming and processing equipment comprises a supporting frame, a tensioning device, a folding device, a heat sealing device, a non-woven fabric roller frame and a forming environment-friendly bag roller frame. The non-woven fabric environment-friendly bag forming and processing equipment can solve the following problems that firstly, when existing non-woven fabric environment-friendly bag forming and processing equipment is used for folding a piece of non-woven fabric in half in the processing process, the non-woven fabric is prone to being mistakenly folded, and the situation that the non-woven fabric is stirred and wound together occurs; and secondly, when the existing non-woven fabric environment-friendly bag forming and processing equipment is used for processing, a hot melting device carries out melting excessively, the folded non-wovenfabric is prone to breakage in the pulling and winding process, the non-woven fabric is not stopped in time after breakage, and the non-woven fabric is retracted back into the equipment, so that the working efficiency is affected. According to the non-woven fabric environment-friendly bag forming and processing equipment, the error probability when the non-woven fabric is folded is greatly reduced, the processing quality is improved, the non-woven fabric can be prevented from retracting in time when the non-woven fabric is broken after being melted and scalded, and the working efficiency is improved.

Owner:江西远业环保科技有限公司

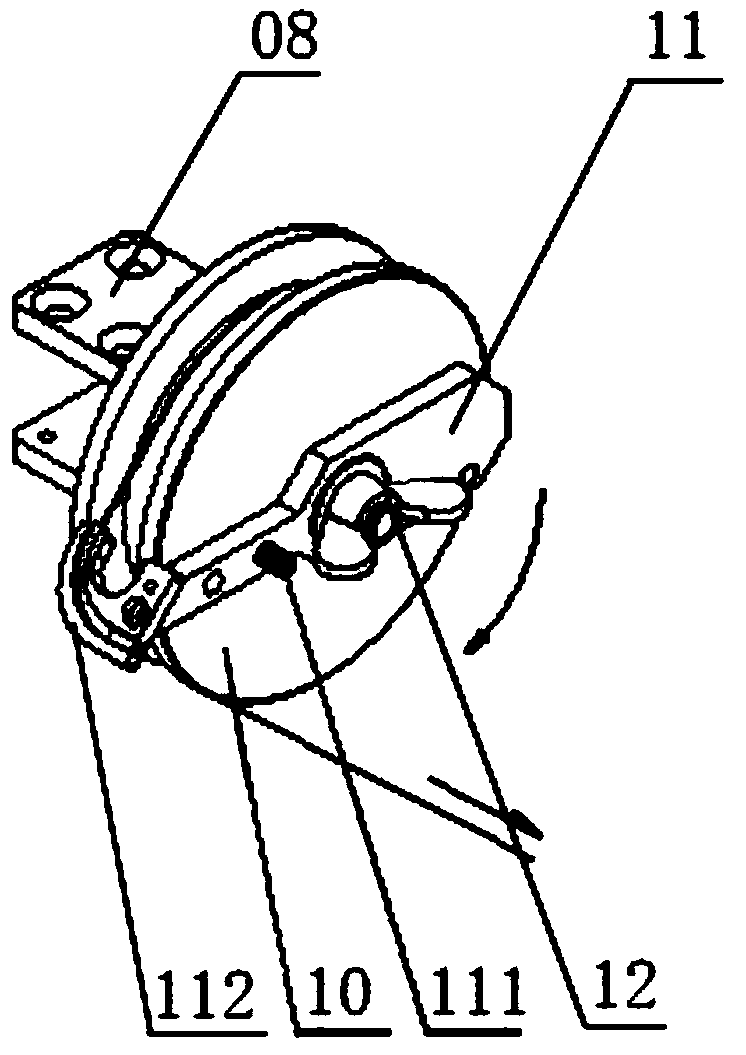

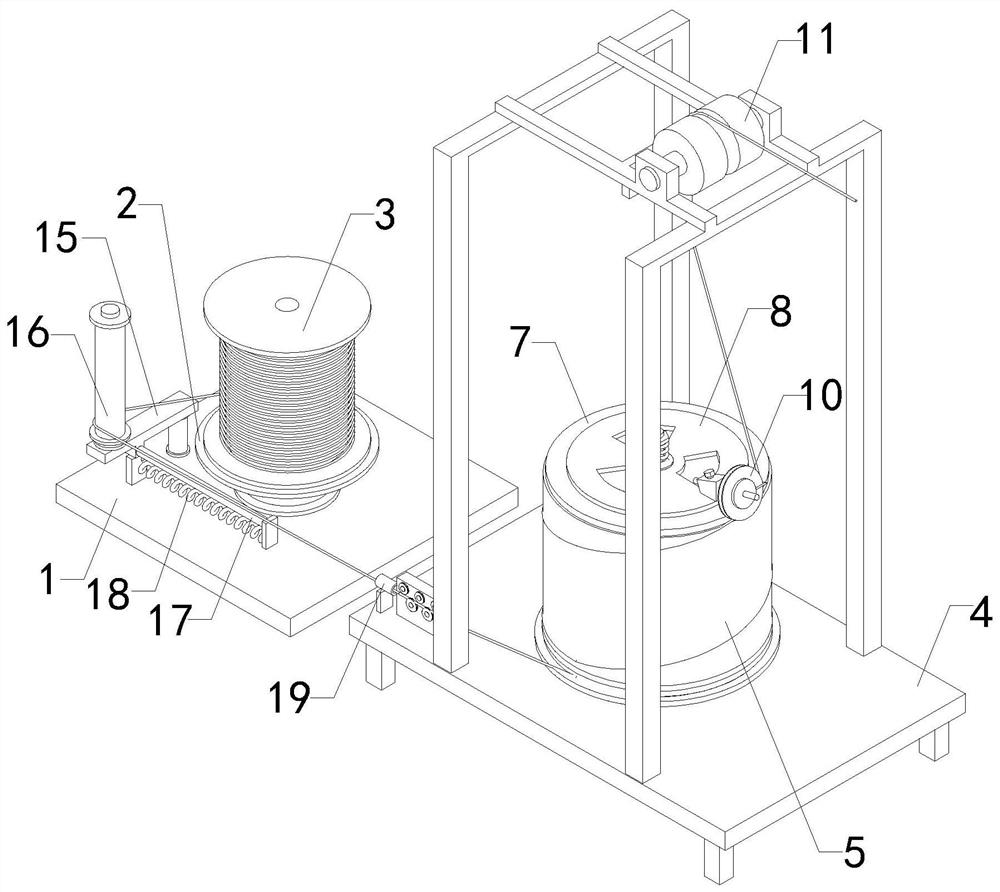

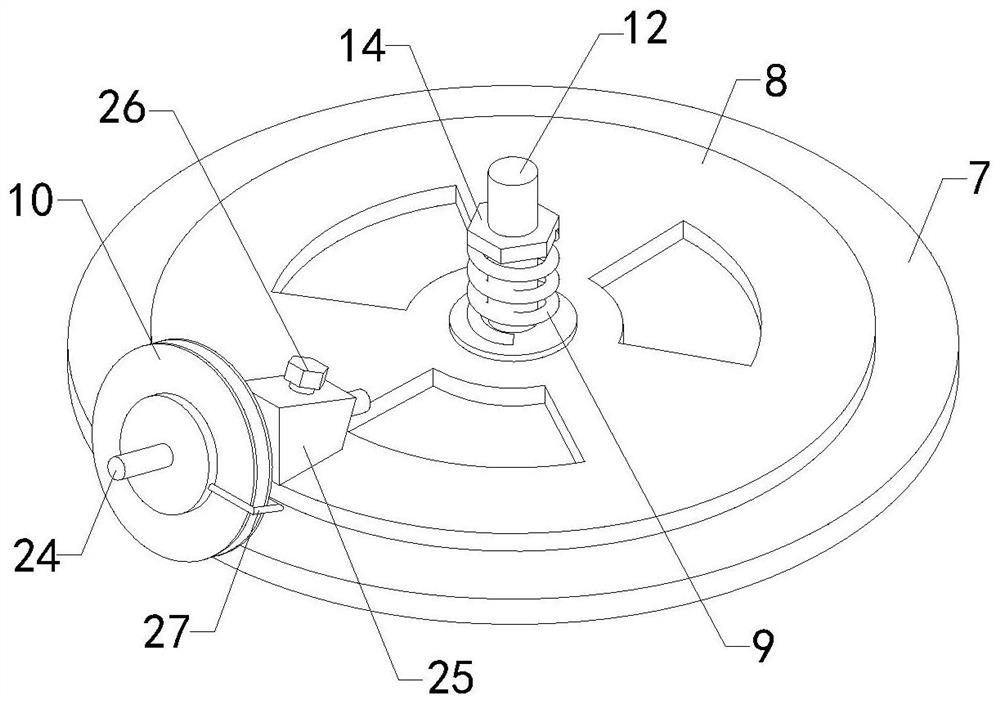

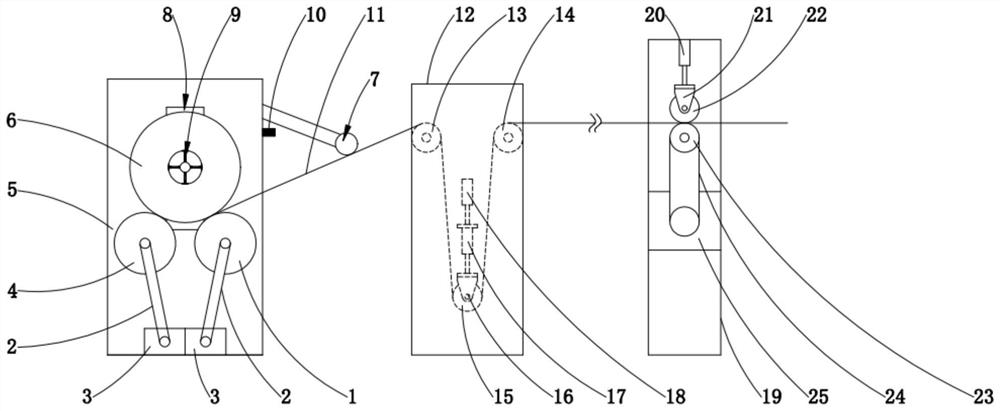

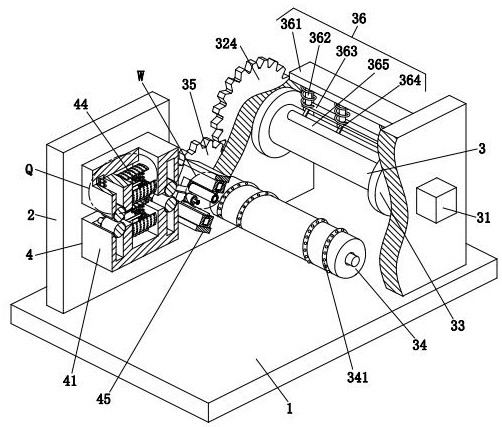

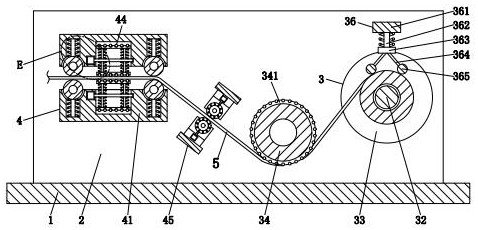

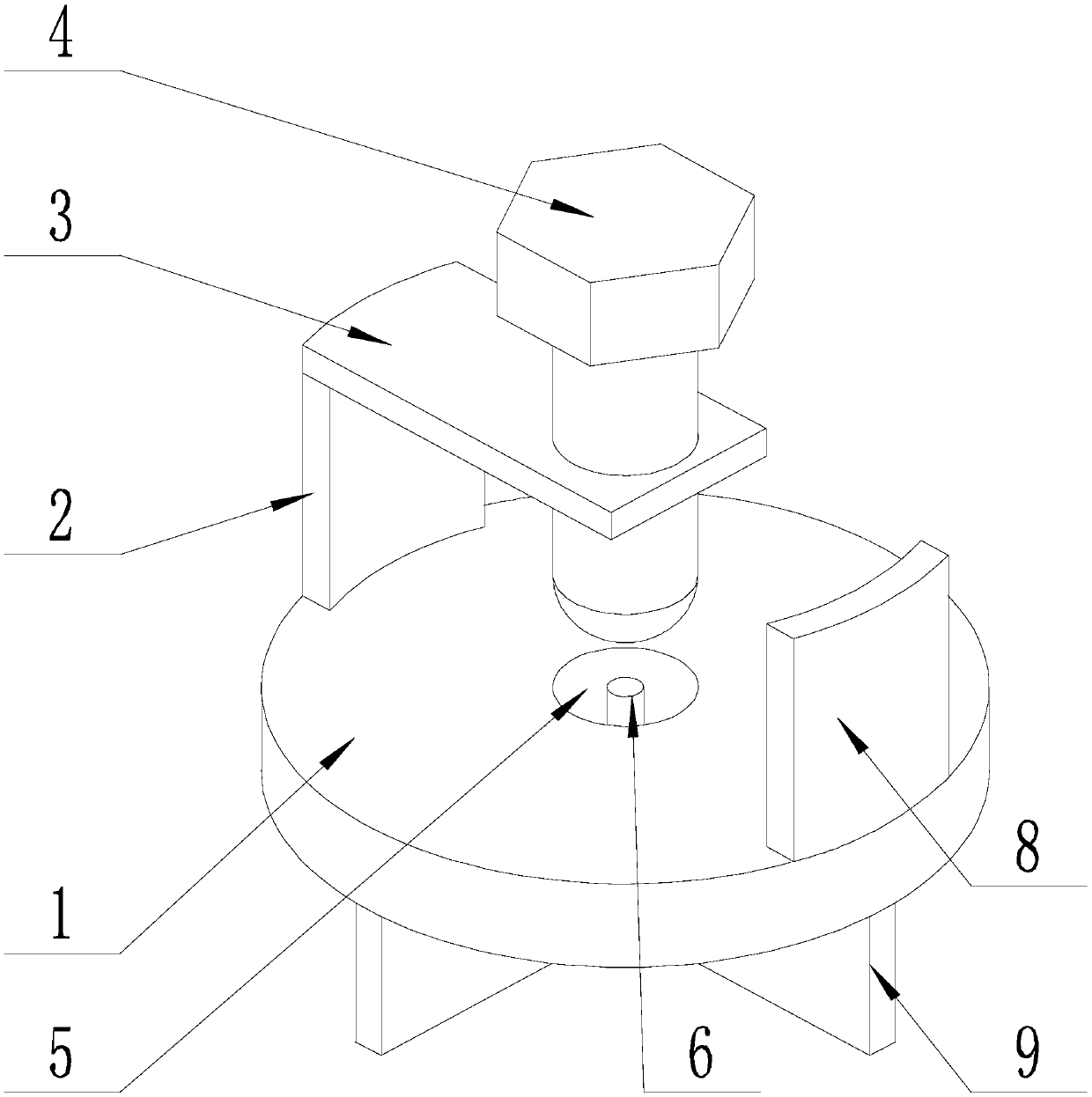

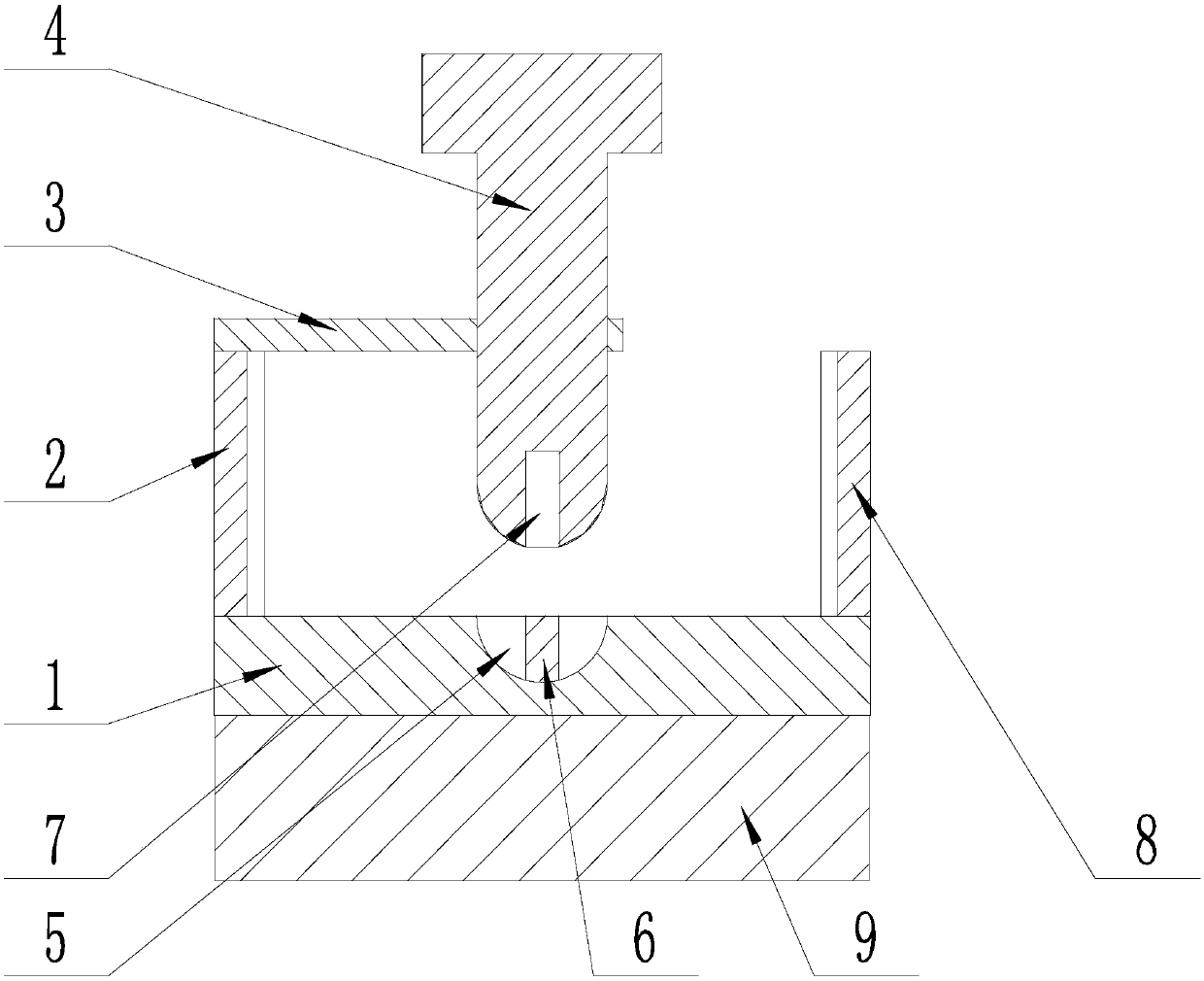

Production line of warm edge spacing bar

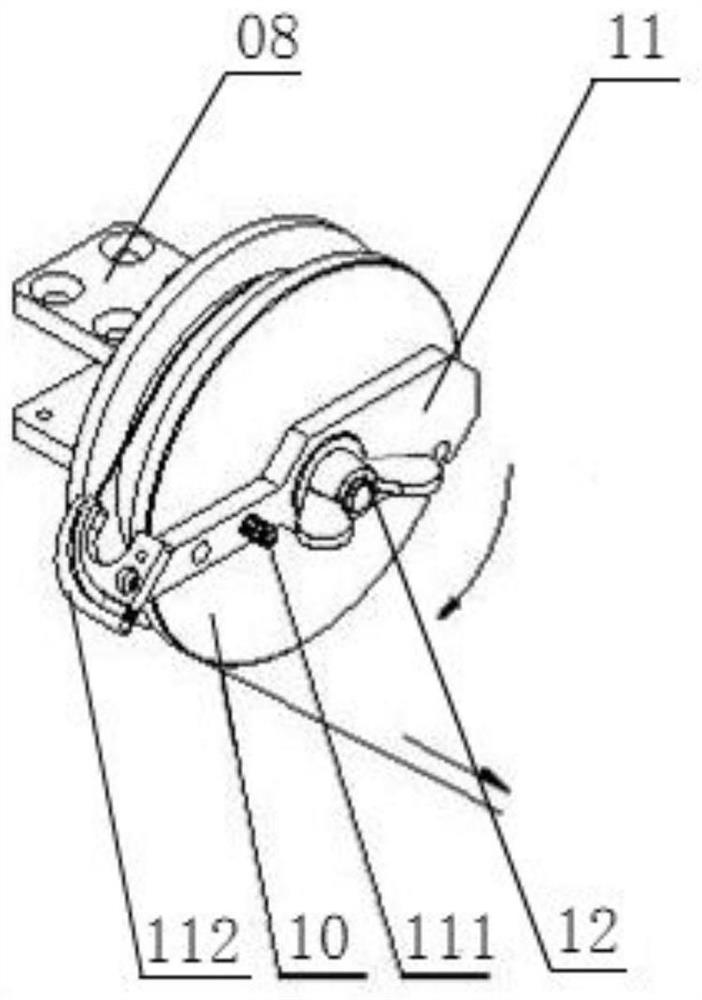

InactiveCN111842548AStable unwindingPrevent loose situationsMetal-working feeding devicesMetal working apparatusProduction lineBrake

The invention discloses a production line of a warm edge spacing bar. The production line of the warm edge spacing bar comprises an uncoiler and a traction device; the uncoiler comprises a first rack;a central shaft and a support mechanism are arranged on the first rack; the support mechanism is arranged at one end of the central shaft; the uncoiler also comprises a front driving roller, a rear driving roller and a synchronous brake mechanism; a coiled metal sheet is placed above the middle of the front driving roller and the rear driving roller; the central shaft is in sliding fit with the first rack along the vertical direction; the synchronous brake mechanism comprises a brake wheel, a brake belt and a cantilever; the brake wheel is fixedly arranged on the central shaft; the cantileveris rotatably connected with the first rack; the fulcrum of the cantilever is positioned above the brake wheel; one end of the brake belt is fixed on the first rack, and the other end of the brake belt is fixed at one end of the cantilever; the brake belt is wound around the brake wheel from the lower part of the brake wheel; and a guide wheel is arranged at the other opposite end of the cantilever. According to the production line of the warm edge spacing bar, the problem that the coiled metal sheet is easy to loosen when the traction device of the existing production line of the warm edge spacing bar is in a sudden stop.

Owner:山东亚鑫华数控设备有限公司

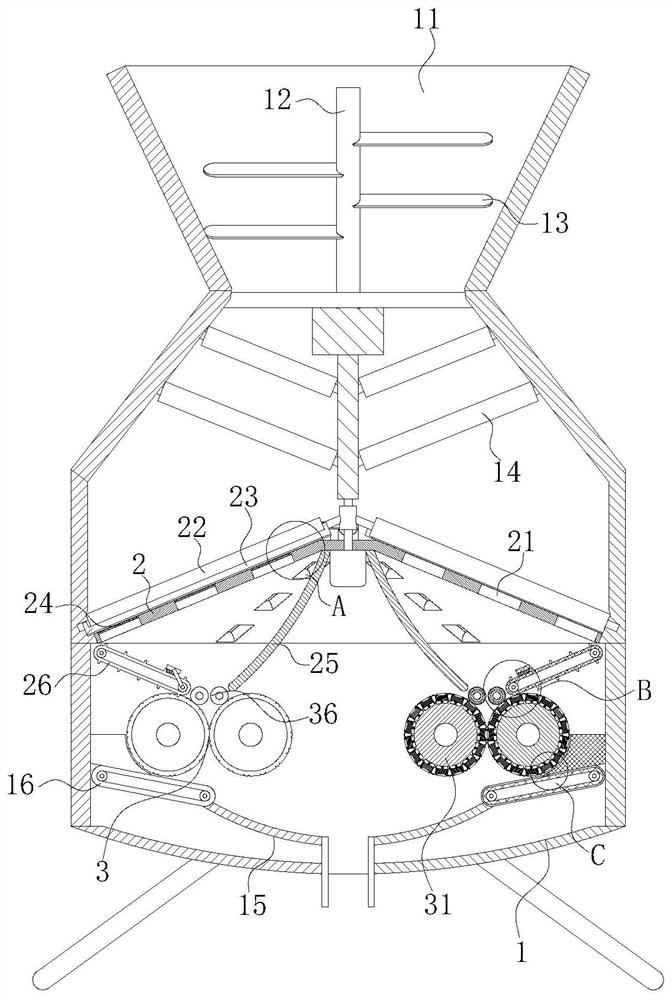

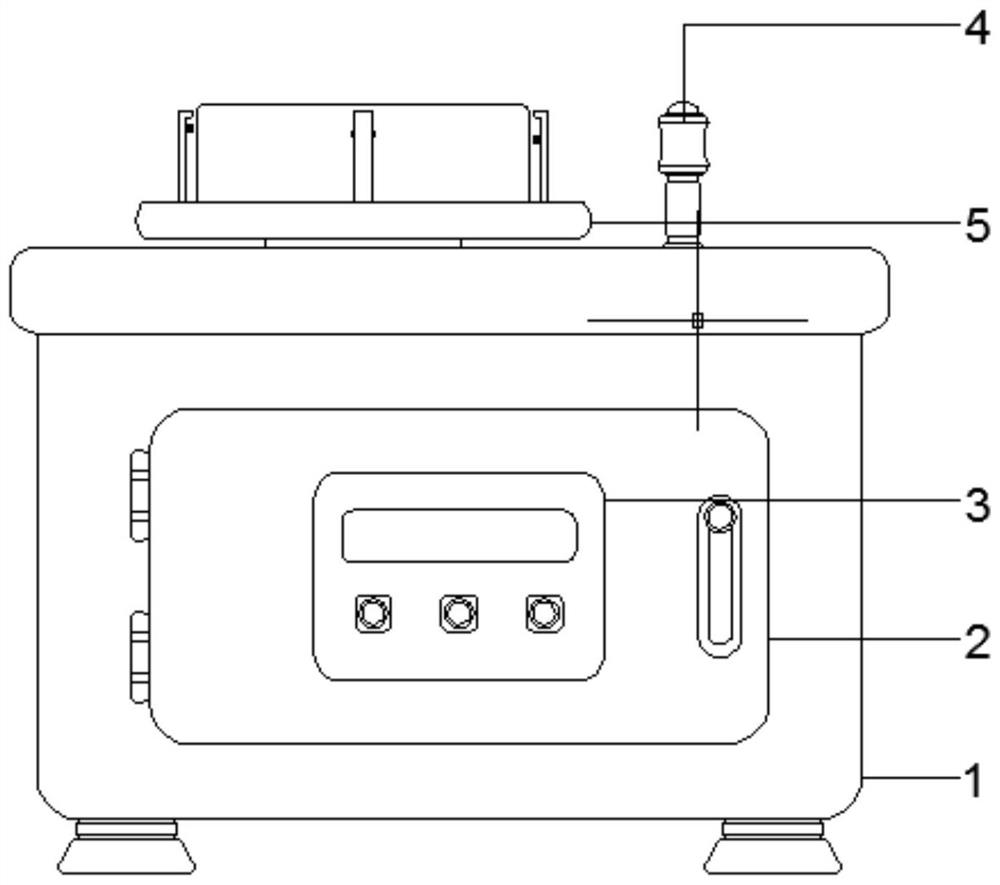

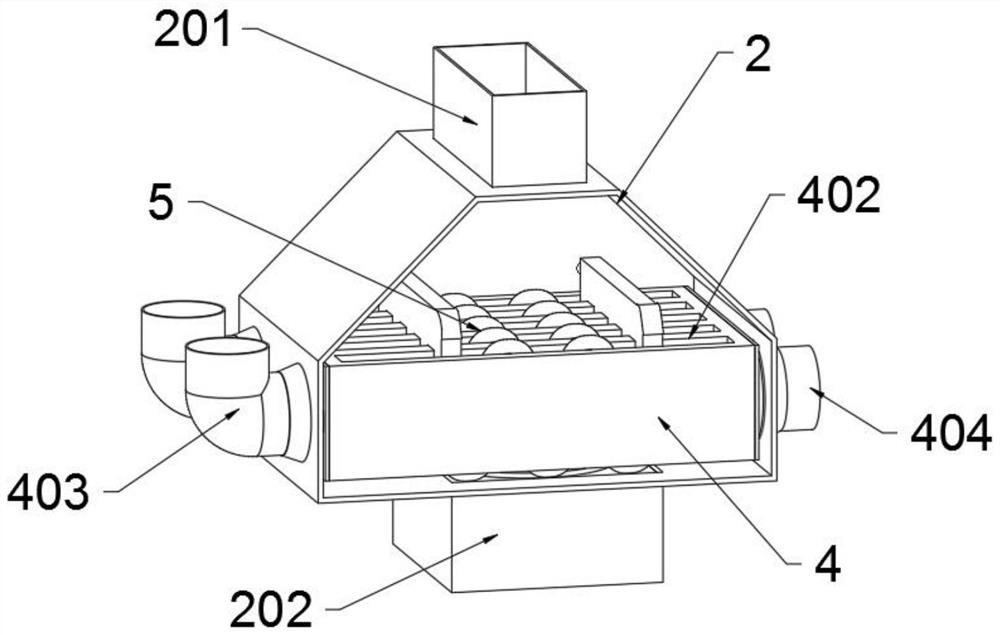

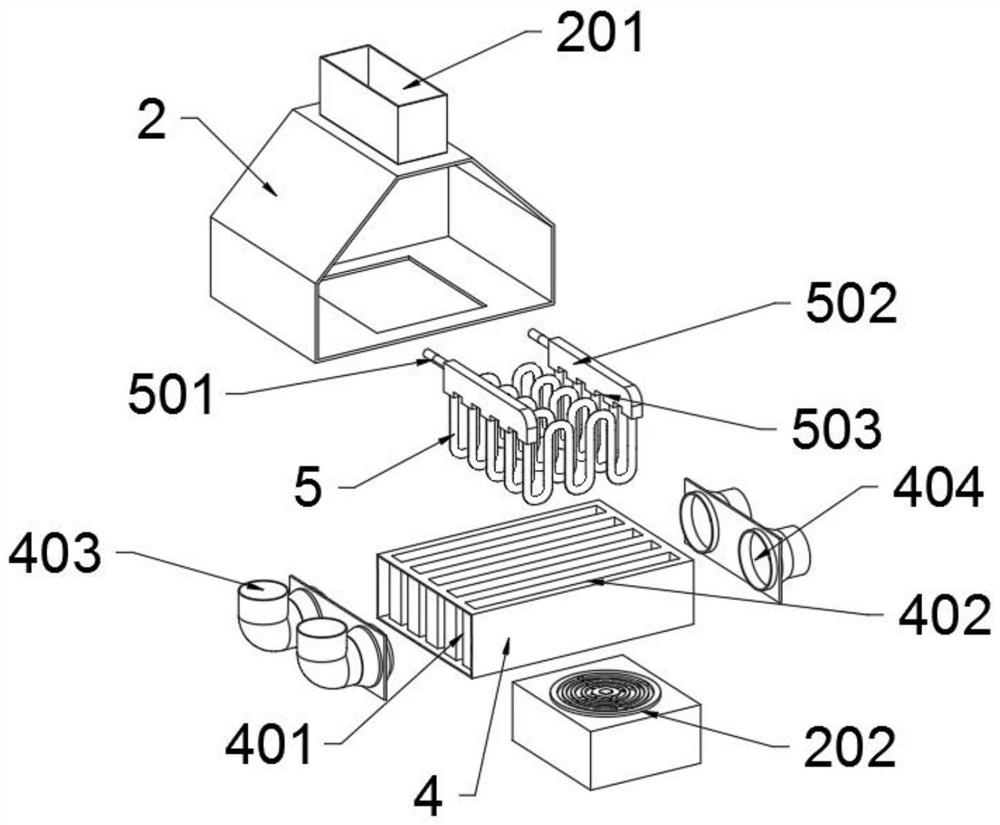

Environment-friendly biomass fuel particle forming device

InactiveCN112280607AIncrease temperaturePrevent the problem of loose shapeBiofuelsSolid fuelsEngineeringMechanical engineering

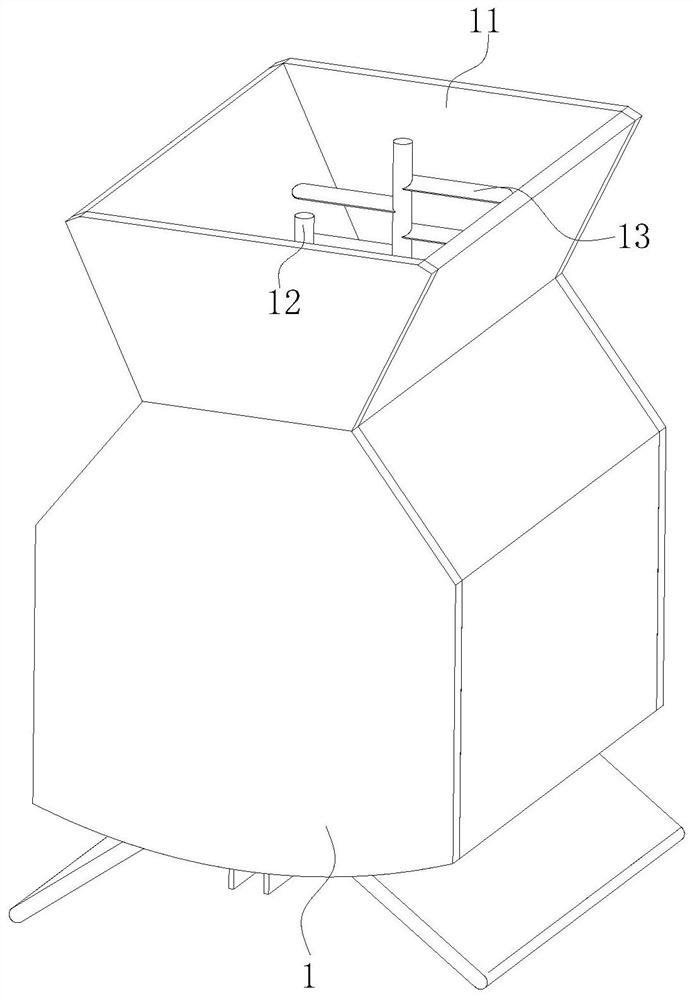

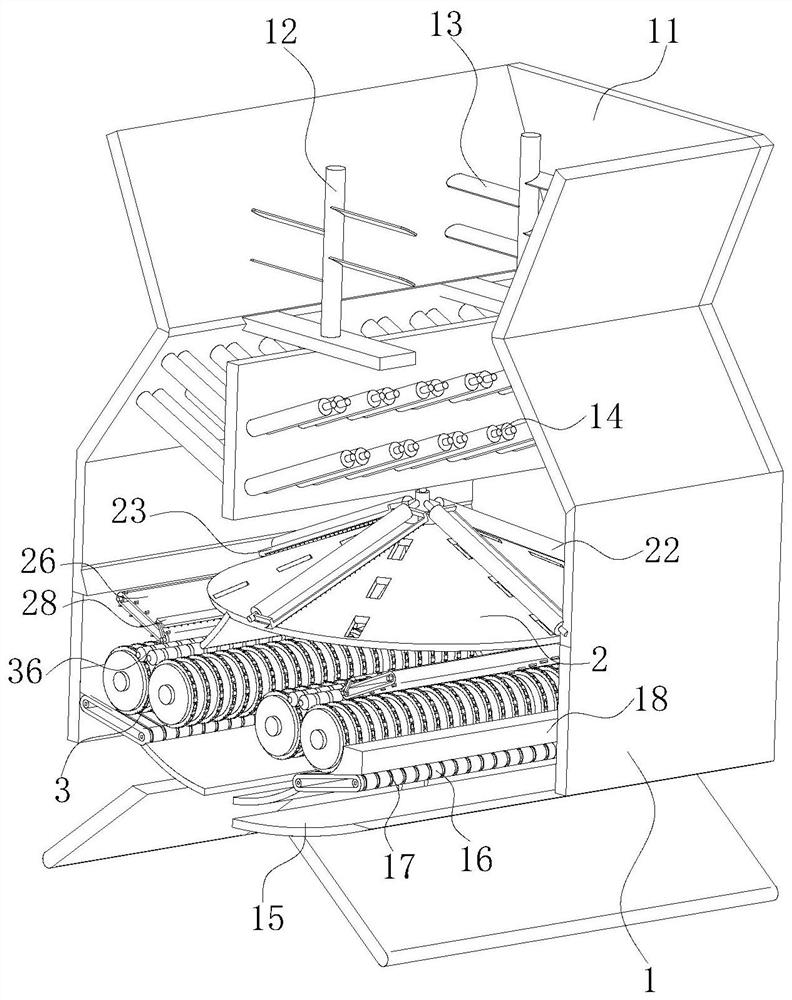

The invention belongs to the technical field of biomass fuel particle forming devices, and particularly relates to an environment-friendly biomass fuel particle forming device. The device comprises abody; the upper surface of the machine body is fixedly connected with a feeding bin; a rotating rod is rotationally connected into the inner wall of each supporting plate through a motor; uniformly arranged rotating blades are fixedly connected into the inner wall of each rotating rod; a partition plate is fixedly connected to the position, below each supporting plate, in the inner wall of the body; and uniformly arranged extrusion roller groups are rotationally connected into the inner walls of the two sides of the partition plates through rotating shafts. The biomass fuel particle forming device is mainly used for solving the problems that an existing biomass fuel forming device carries out forming by pressing raw materials out of screen holes through large pressure, however, by means ofthe mode, the needed pressure is too large, the load on a pressing plate of the forming device is large when the forming device works for a long time, and therefore the forming device is prone to being damaged, and meanwhile, a sieve pore plate for shaping deforms under the action of large extrusion force for a long time, so that the shaping effect of the raw materials is influenced.

Owner:安徽农腾新能源科技有限公司

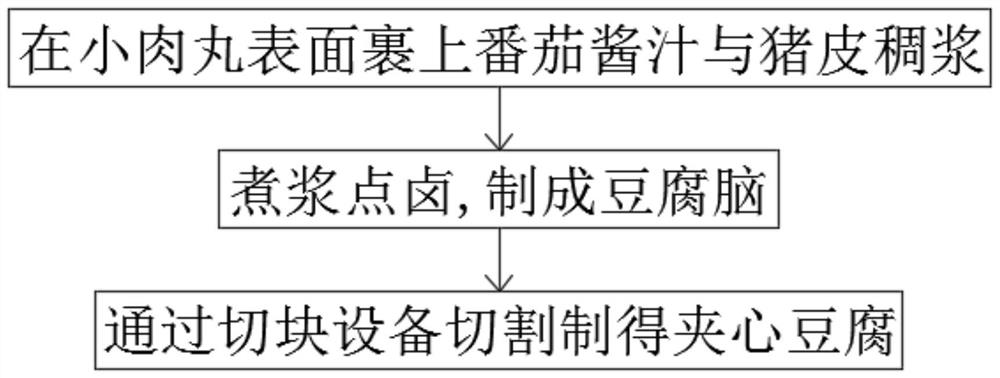

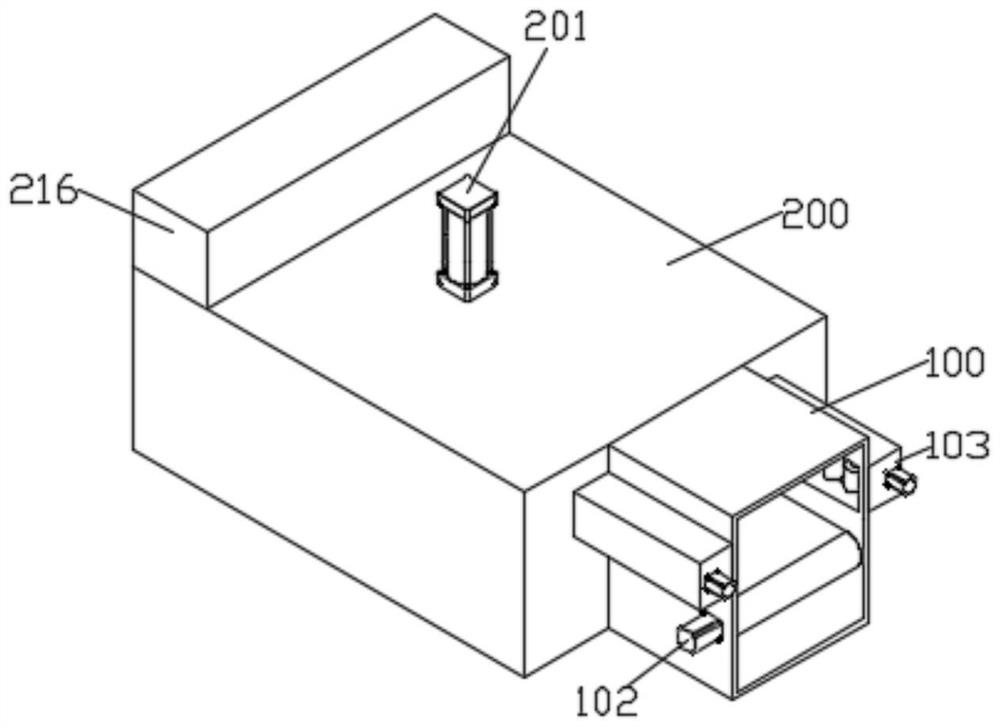

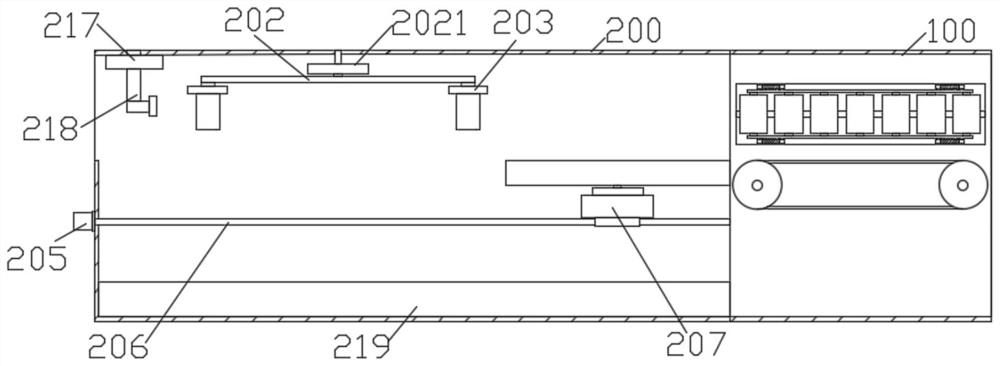

Processing method of sandwiched bean curd

PendingCN114041565APromote circulationIncrease physical strengthNatural extract food ingredientsFood ingredient functionsBiotechnologyAngelica Sinensis Root

The invention discloses a processing method of sandwiched bean curd. Tomato sauce and pigskin thick paste are wrapped on the surfaces of small meat balls, the tomato sauce is fused with the ampelopsis grossedentata fragrance, the nutrition is richer, the taste is rich in layering sense, the tomato red oil is adopted, the taste is sour, sweet and spicy, the flavor is full, lotus stamen, angelica sinensis and other components are added, the health-care value is higher, the synergistic effect is achieved, and the appetite is promoted. By arranging a limiting air cylinder and a limiting plate at the same time, bean curds of different sizes can be limited, the situation that the bean curds are loosened in the dicing process is prevented, by arranging a filter plate and a bean curd liquid collecting box, bean curd liquid in the bean curds in the dicing process can be effectively collected, a second rotating air cylinder is arranged, and two liftable cutter holders are matched, so that transverse and longitudinal dicing treatment of the bean curd is completed while the bean curd is conveyed in a one-way mode, the bean curd can be conveyed while being diced, and efficient processing of the bean curd is guaranteed.

Owner:马鞍山江心绿洲食品有限公司

A non-woven environmental protection bag forming processing equipment

ActiveCN111805933BReduce the probability of errors when folding in halfPrevent retractionDomestic articlesStructural engineeringNonwoven fabric

The invention discloses a non-woven environmental protection bag molding processing equipment, which comprises a supporting frame, a tensioning device, a folding device, a heat sealing device, a non-woven fabric roller frame and a forming environmental protection bag roller frame. The present invention can solve the following problems. First, the existing non-woven environmental protection bag forming processing equipment is easy to make mistakes when folding a piece of non-woven fabric in half during the processing process, and the non-woven fabrics are entangled together. Second, the present invention During the processing of some non-woven environmental protection bag forming processing equipment, the folded non-woven fabric is prone to breakage during the pulling and winding process when the hot-melt device is excessively scalded, and the non-woven fabric is not stopped in time after breaking. Falling back into the device affects work efficiency. The non-woven environmental protection bag forming processing equipment provided by the invention not only greatly reduces the probability of making mistakes when the non-woven fabric is folded in half, improves the quality of processing, but also can prevent the non-woven fabric from shrinking in time when the non-woven fabric breaks after being melted and ironed. , improve work efficiency.

Owner:江西远业环保科技有限公司

An inorganic mineral insulated flexible fireproof cable

ActiveCN109727712BReduce nudityLong fire resistanceClimate change adaptationFlexible cablesMetallic foilCeramic composite

The invention discloses an inorganic mineral insulated flexible fireproof cable. The inorganic mineral insulated flexible fireproof cable comprises a plurality of cable cores. Each cable core comprises an electrical conductor and a ceramic composite tape coating the electrical conductor, the ceramic composite tapes are coated with metal foil material coatings which are selected from one in the group of copper, nickel, nickel alloy, titanium, steel or stainless steel. The cable cores are coated with a first mica tape, the first mica tape is externally provided with a flameproof fabric, an insulating refractory layer is arranged at the outer portion of the flameproof fabric, a second mica tape is arranged at the outer portion of the insulating refractory layer, a basalt fiber fireproof layeris arranged on the outer layer of the second mica tape, and a jacket layer is arranged at the outer layer of the basalt fiber fireproof layer. The inorganic mineral insulated flexible fireproof cableemploys a multi-layer fireproof layer design, has a good heat and fire resistance at a high temperature, and can maintain the state of the cable at the high temperature for a long time.

Owner:四川新蓉电缆有限责任公司

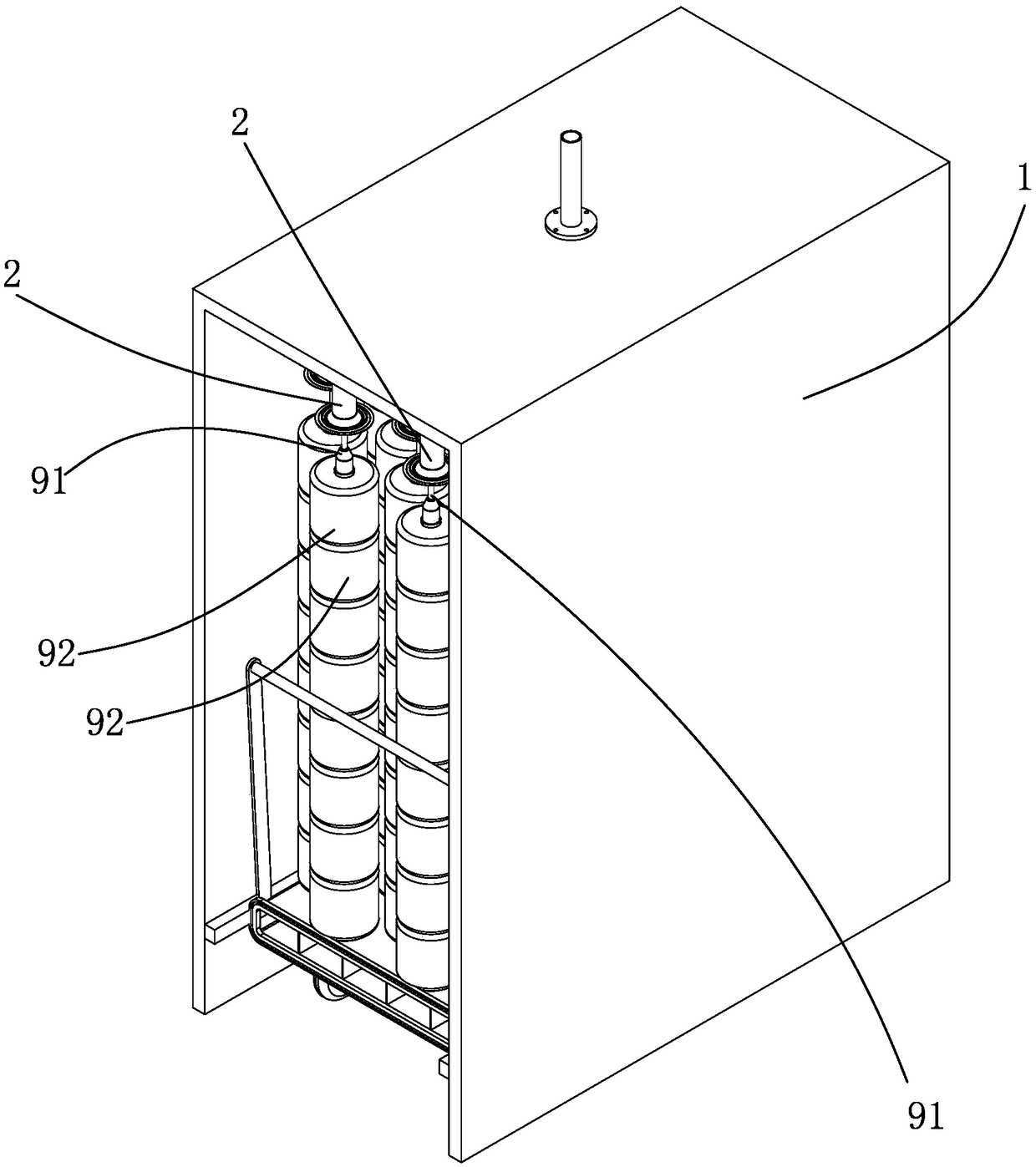

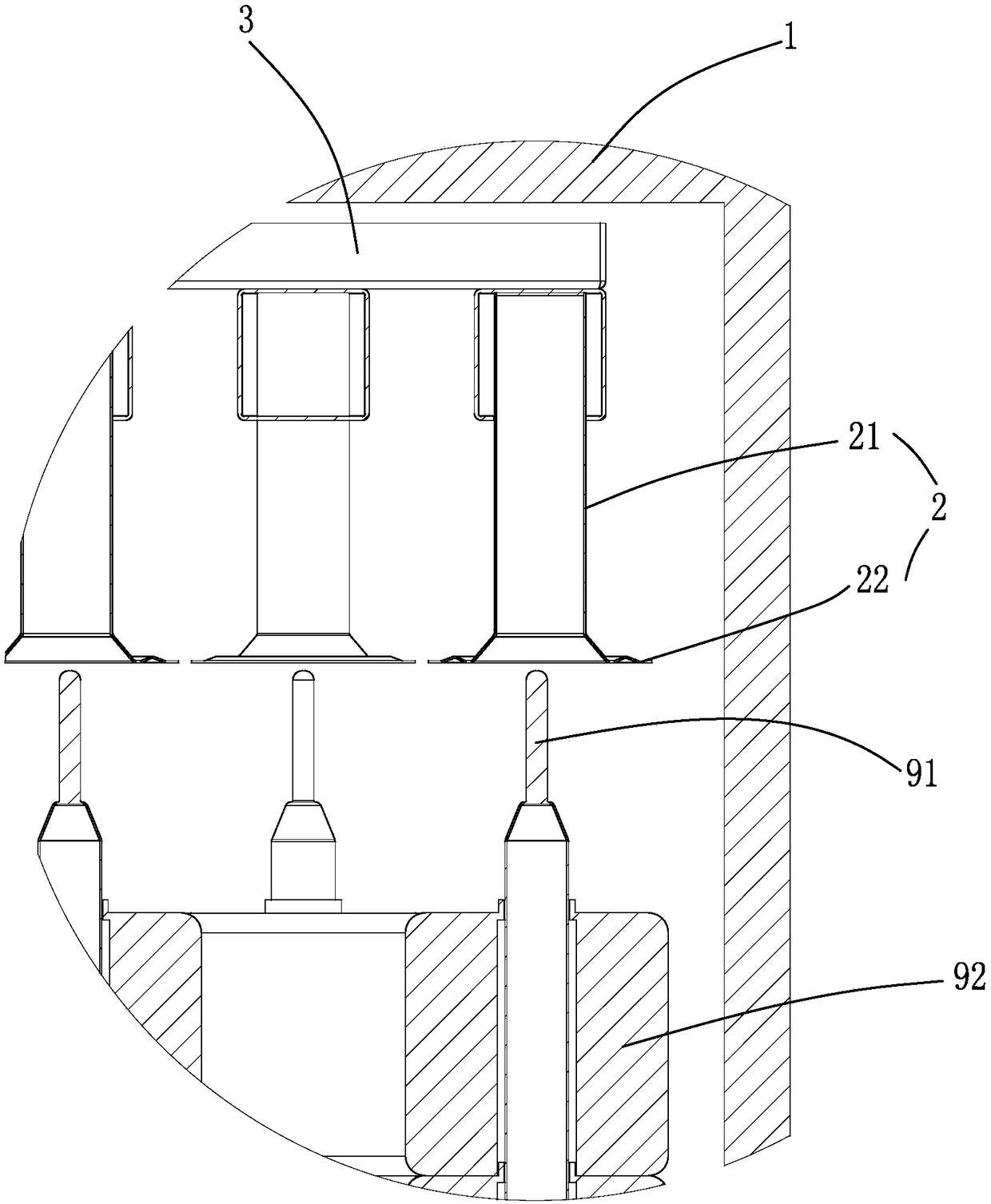

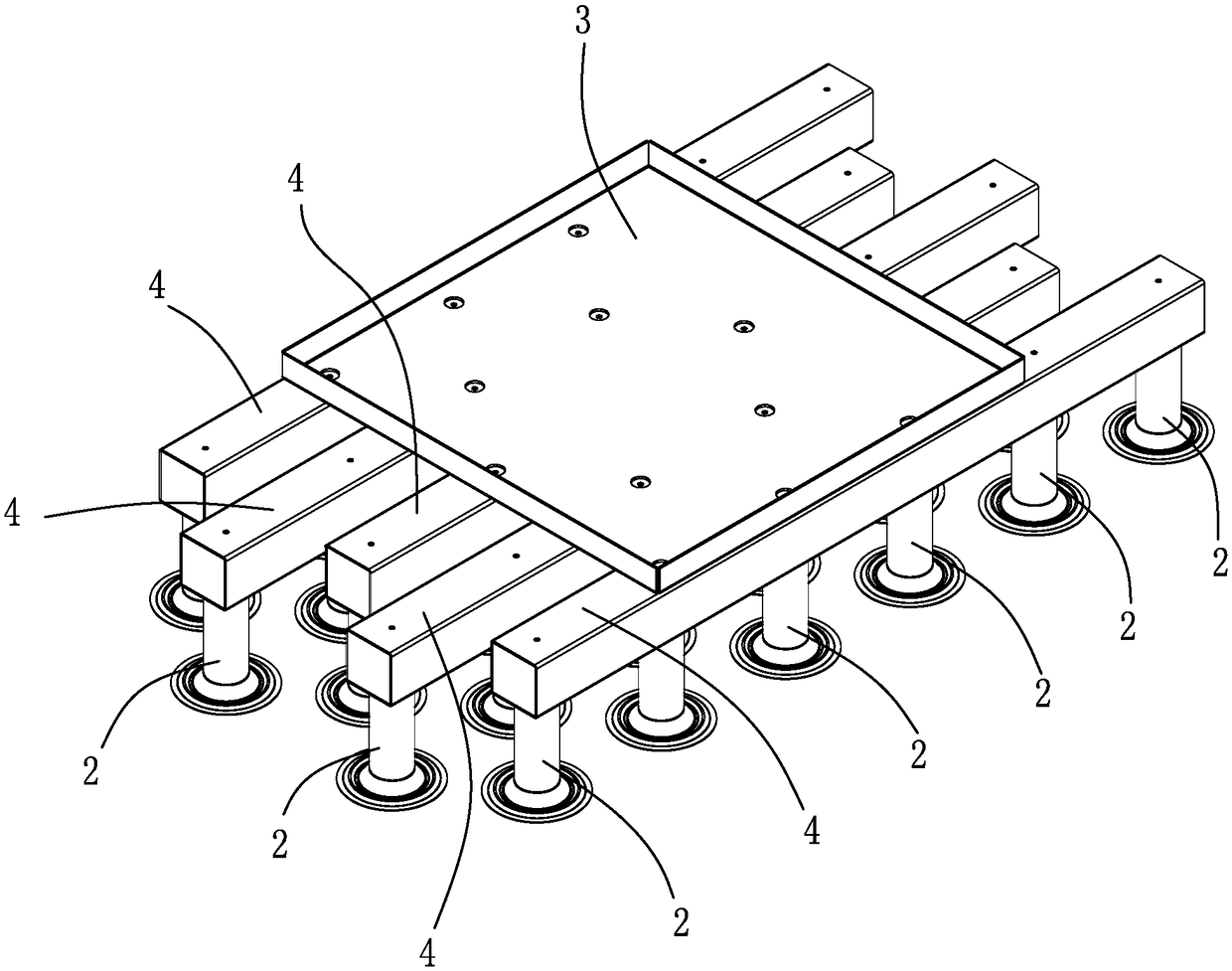

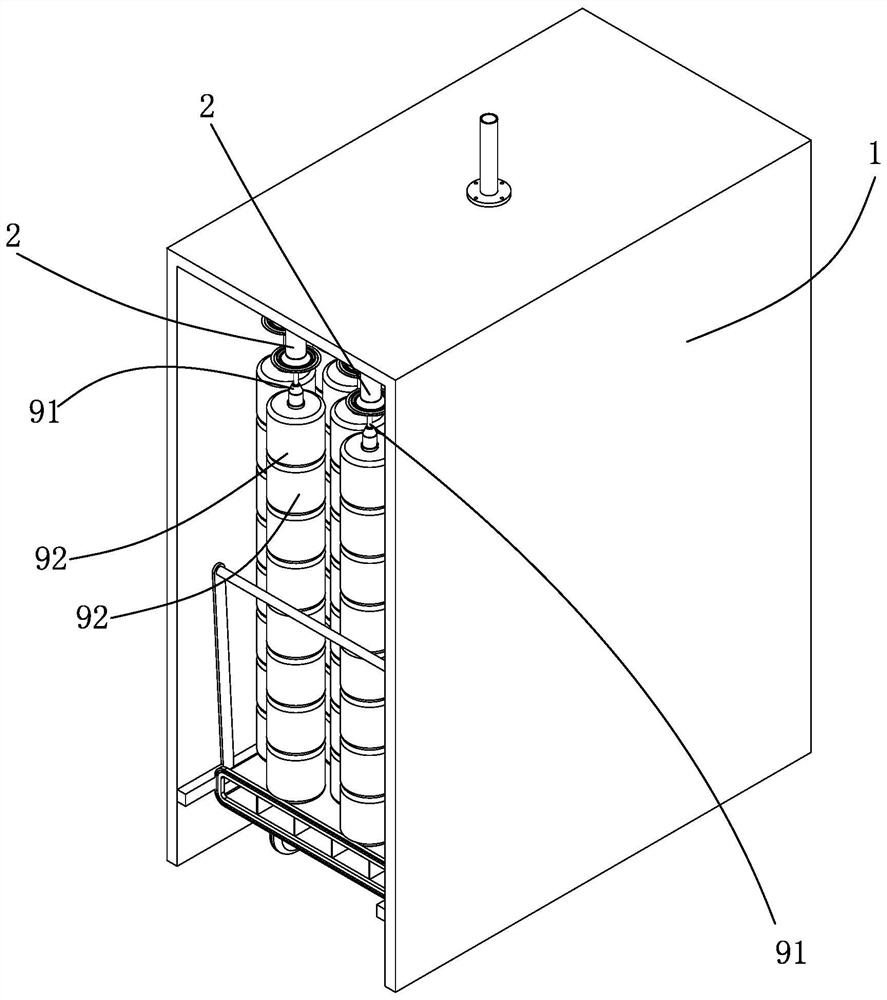

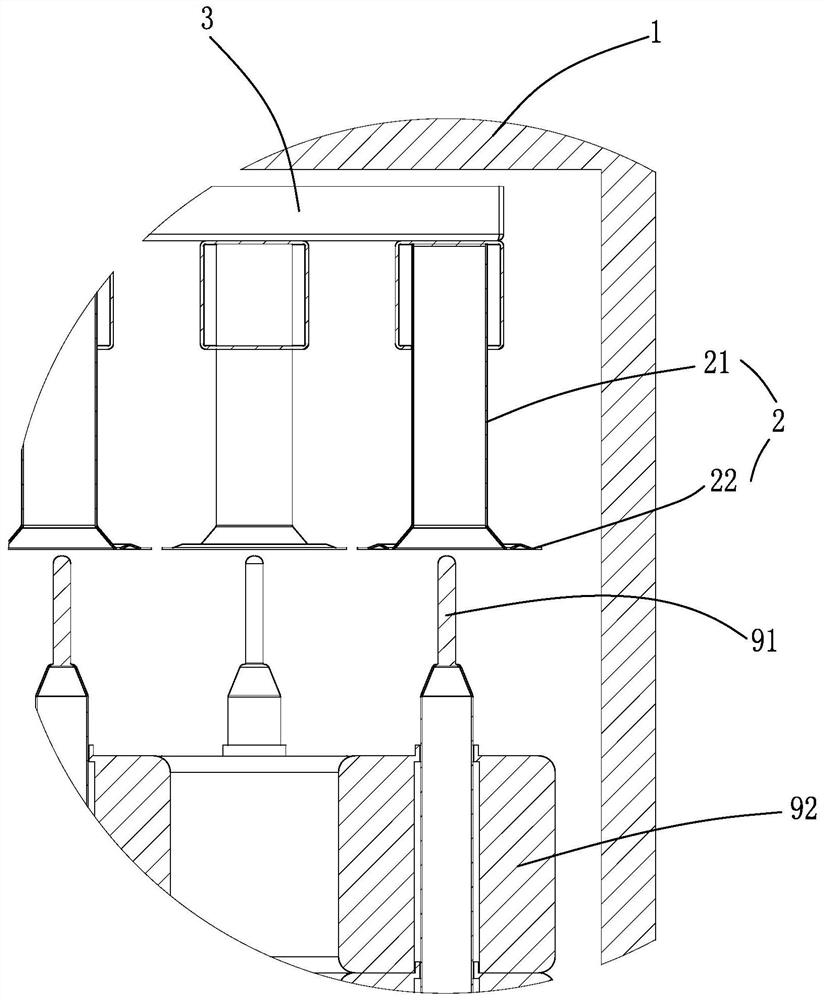

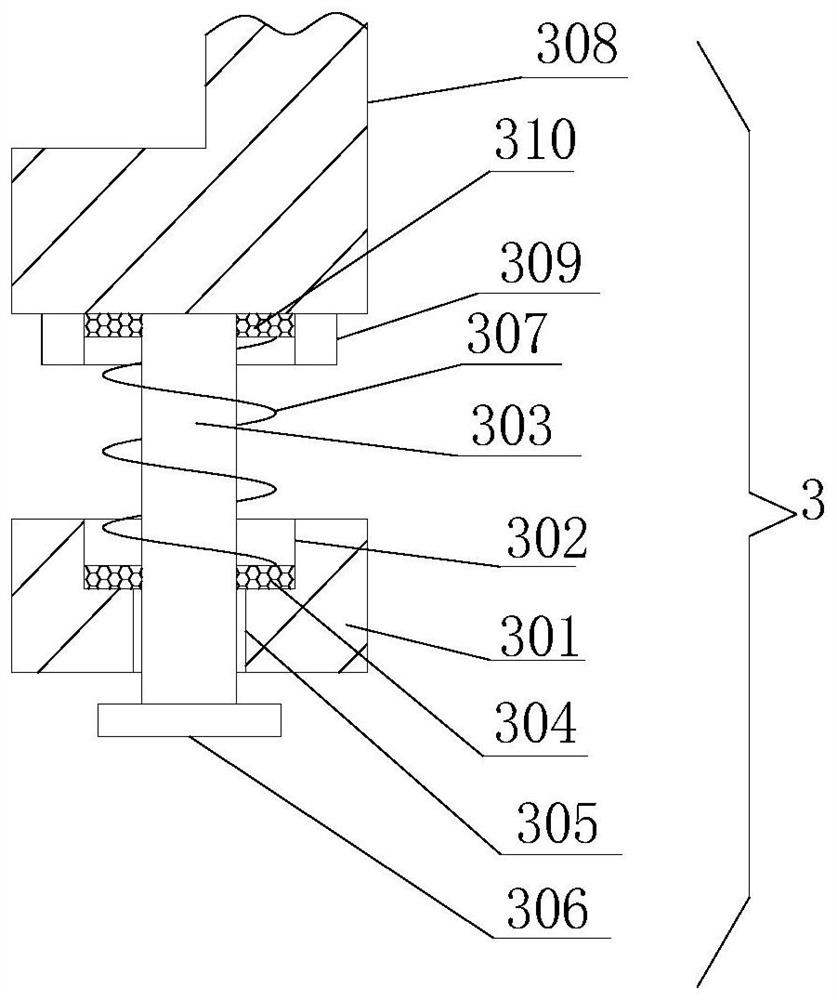

Yarn pressing device used for auxiliary drying

ActiveCN108642771AImprove drying efficiencyHigh degree of automationLiquid/gas/vapor removalTextile treatment carriersYarnEngineering

The invention belongs to the technical field of cone yarn drying, and particularly relates to a yarn pressing device used for auxiliary drying. The yarn pressing device comprises yarn pressing flow-guiding heads in a drying furnace and driving components for driving the yarn pressing flow-guiding heads to move vertically in the drying furnace, a yarn shaft containing portion is arranged on each yarn pressing flow-guiding head, wherein a yarn shaft located below each yarn pressing flow-guiding head extends into the corresponding yarn shaft containing portion after the yarn pressing flow-guidinghead moves downwards, and the yarn pressing flow-guiding heads move downwards to press the upper ends of cone yarn installed on the yarn shafts in series and force hot wind guided into the yarn shafts to be guided out radically along the yarn shafts and penetrate through the cone yarn installed on the yarn shafts in series from inside to outside; then the hot wind flowing out from peripheral wallthrough holes of the yarn shafts will not flow out from the upper portions of the yarn shafts in the axial direction of the yarn shafts after being blown into the yarn shafts, it is prevented that most hot wind directly flows out from the upper ends without passing the cone yarn, and therefore drying efficiency is improved. The yarn pressing flow-guiding heads automatically press on a yarn trolley through the driving components, human participation is not needed, and therefore the automation degree is greatly increased.

Owner:GAOWANLI TECH ZHONGSHAN CO LTD

Yarn pressing device for auxiliary drying

ActiveCN108642771BPrevent outflowImprove drying efficiencyLiquid/gas/vapor removalTextile treatment carriersYarnEngineering

The invention belongs to the technical field of cone yarn drying, and particularly relates to a yarn pressing device used for auxiliary drying. The yarn pressing device comprises yarn pressing flow-guiding heads in a drying furnace and driving components for driving the yarn pressing flow-guiding heads to move vertically in the drying furnace, a yarn shaft containing portion is arranged on each yarn pressing flow-guiding head, wherein a yarn shaft located below each yarn pressing flow-guiding head extends into the corresponding yarn shaft containing portion after the yarn pressing flow-guidinghead moves downwards, and the yarn pressing flow-guiding heads move downwards to press the upper ends of cone yarn installed on the yarn shafts in series and force hot wind guided into the yarn shafts to be guided out radically along the yarn shafts and penetrate through the cone yarn installed on the yarn shafts in series from inside to outside; then the hot wind flowing out from peripheral wallthrough holes of the yarn shafts will not flow out from the upper portions of the yarn shafts in the axial direction of the yarn shafts after being blown into the yarn shafts, it is prevented that most hot wind directly flows out from the upper ends without passing the cone yarn, and therefore drying efficiency is improved. The yarn pressing flow-guiding heads automatically press on a yarn trolley through the driving components, human participation is not needed, and therefore the automation degree is greatly increased.

Owner:GAOWANLI TECH ZHONGSHAN CO LTD

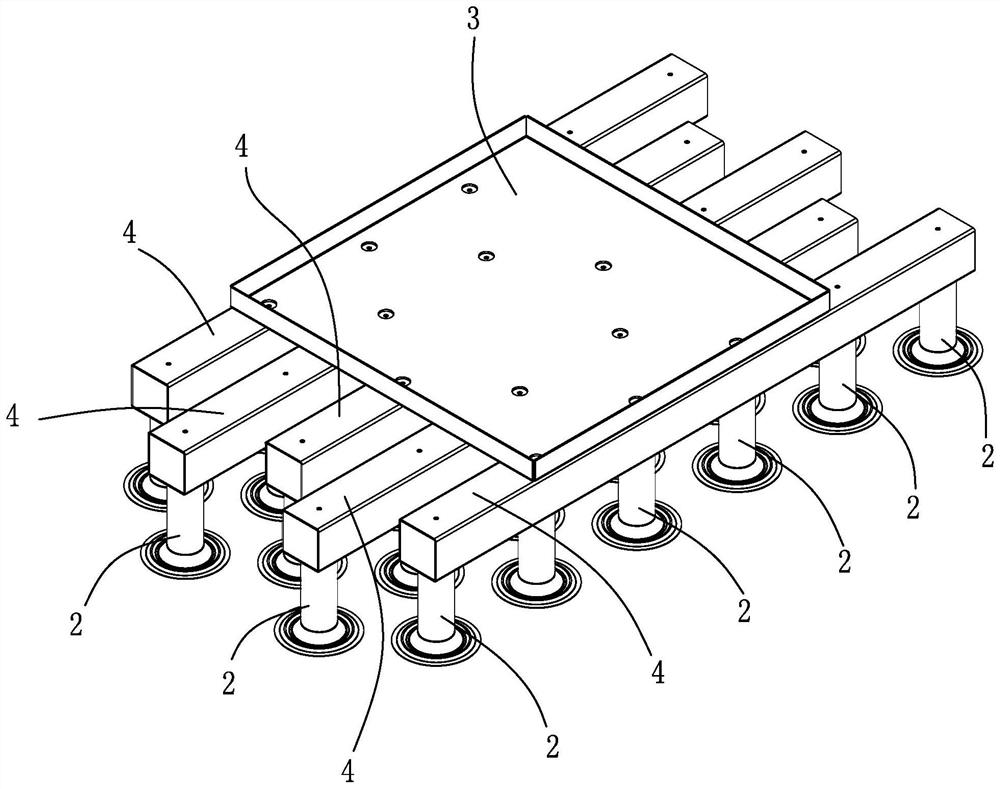

Anti-loosening EPE (Expanded Polyethylene) coiled material winding equipment

InactiveCN114572730APrevent loose situationsGuarantee the quality of windingPackage recyclingWebs handlingElectric machineryStructural engineering

The EPE coiled material winding equipment comprises a base, a plurality of supports are fixedly connected to the top face of the base, a square shell is fixedly connected to the top ends of the supports, the two ends of the inner side of the square shell are each of an opening structure, one end of the square shell is fixedly connected with a side plate, and four power shells are fixedly connected to the four sides of the outer side wall of the square shell correspondingly; two sliding square holes are formed in the side, close to the square shell, of the power shell, two through openings are formed in the positions, corresponding to the two sliding square holes, of the side wall of the square shell, two sliding square columns are slidably connected into the two sliding square holes and the two through openings respectively, and the ends of the two sliding square columns are located in the square shell and fixedly connected with a movable plate. The four pressing assemblies are arranged, the four pressing assemblies can be driven by the small gear motor to move slowly, elastic pressing belts on the pressing assemblies make contact with pearl wool rolls in the rolling process all the time during rolling, force is applied to the pearl wool rolls to press the pearl wool rolls, the situation that the pearl wool rolls are loose during rolling is prevented, and the rolling quality is guaranteed.

Owner:滁州天鸿新型包装材料有限公司

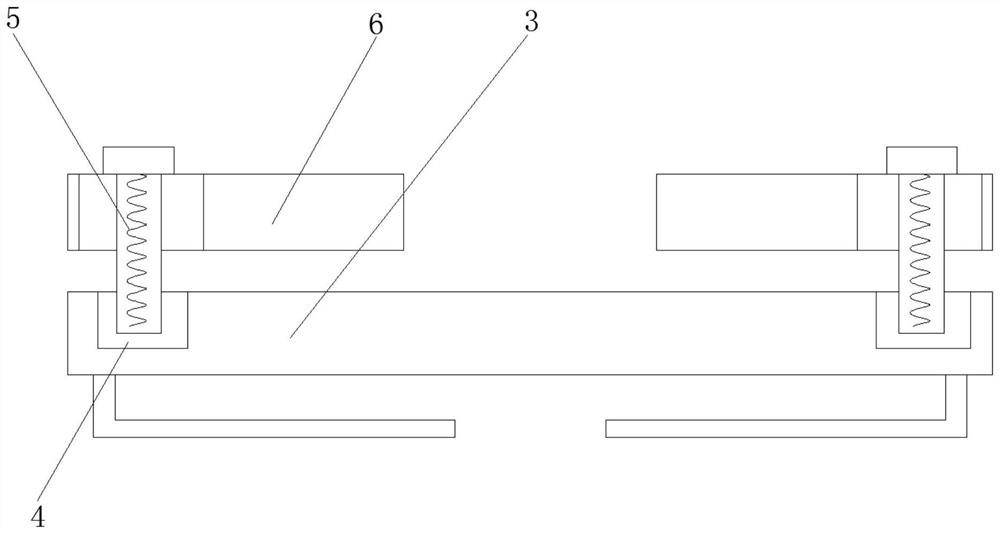

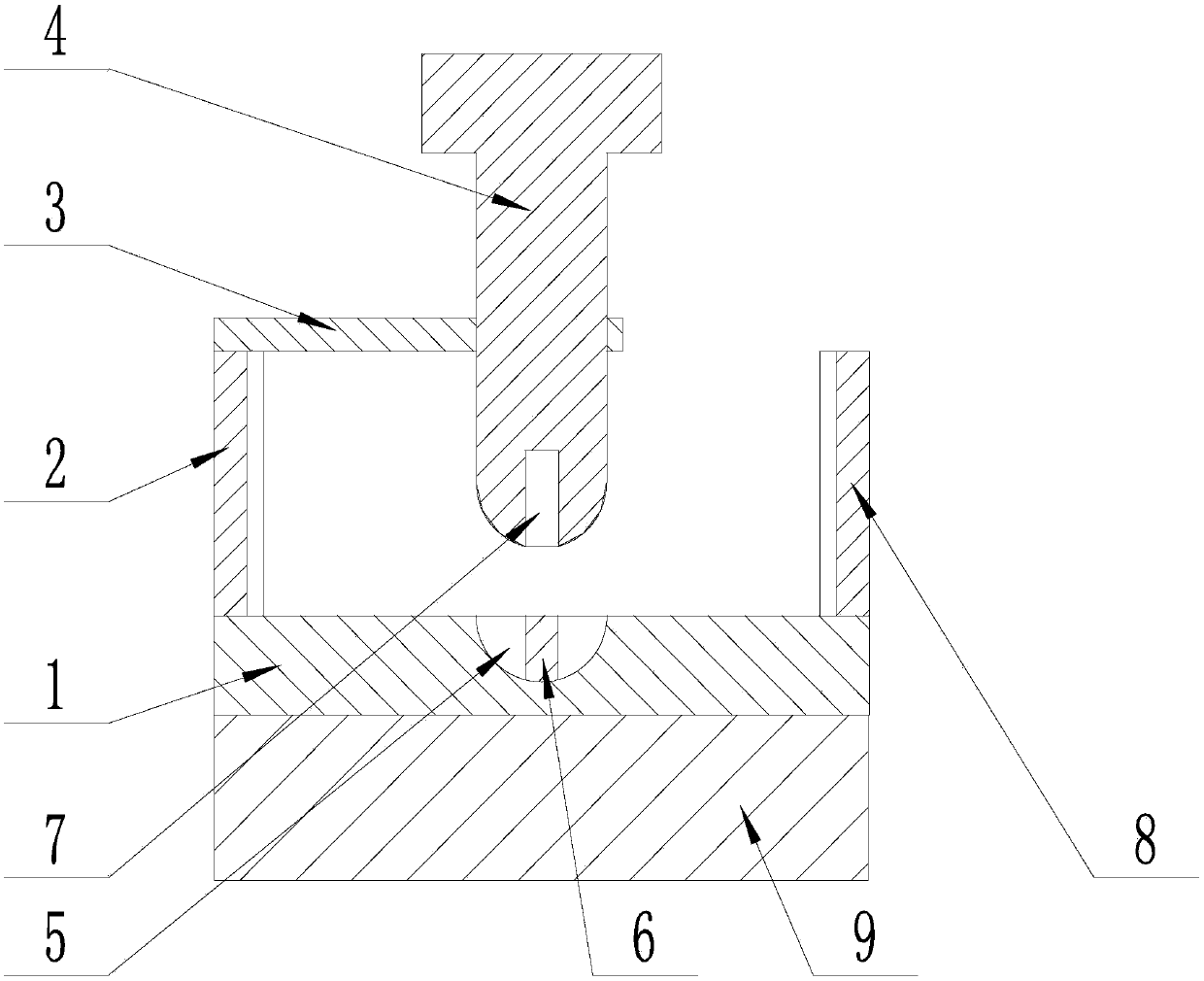

Device for preventing wire coil from being loosened

The invention discloses a device for preventing a wire coil from being loosened. The device comprises a bottom plate and a bolt, wherein a first supporting plate is arranged at one end of the upper surface of the bottom plate, one end of the supporting plate is connected with the bottom plate, the other end of the supporting plate is connected with a flat plate, the flat plate is located right above the bottom plate and is parallel to the bottom plate, a threaded hole is formed in the flat plate, a groove is formed in the upper surface of the bottom plate, the tail end of a rod part of the bolt penetrates through the threaded hole from the end, away from the bottom plate, of the flat plate, the tail end of the rod part of the bolt can be inserted into the groove by screwing the bolt, a guide shaft is arranged in the groove, a guide hole is formed in the tail end of the rod part of the bolt, and when the tail end of the rod part of the bolt is inserted into the groove, the guide shaft is inserted into the guide hole.According to the device for preventing the wire coil from being loosened, a wire coil storage device can be repeatedly used, the wire coil does not need to be tied through a rope, the labor intensity of workers is reduced, and the situation that the wire coil is loosened due to insufficient fastening force when the rope is adopted is avoided.

Owner:何茜

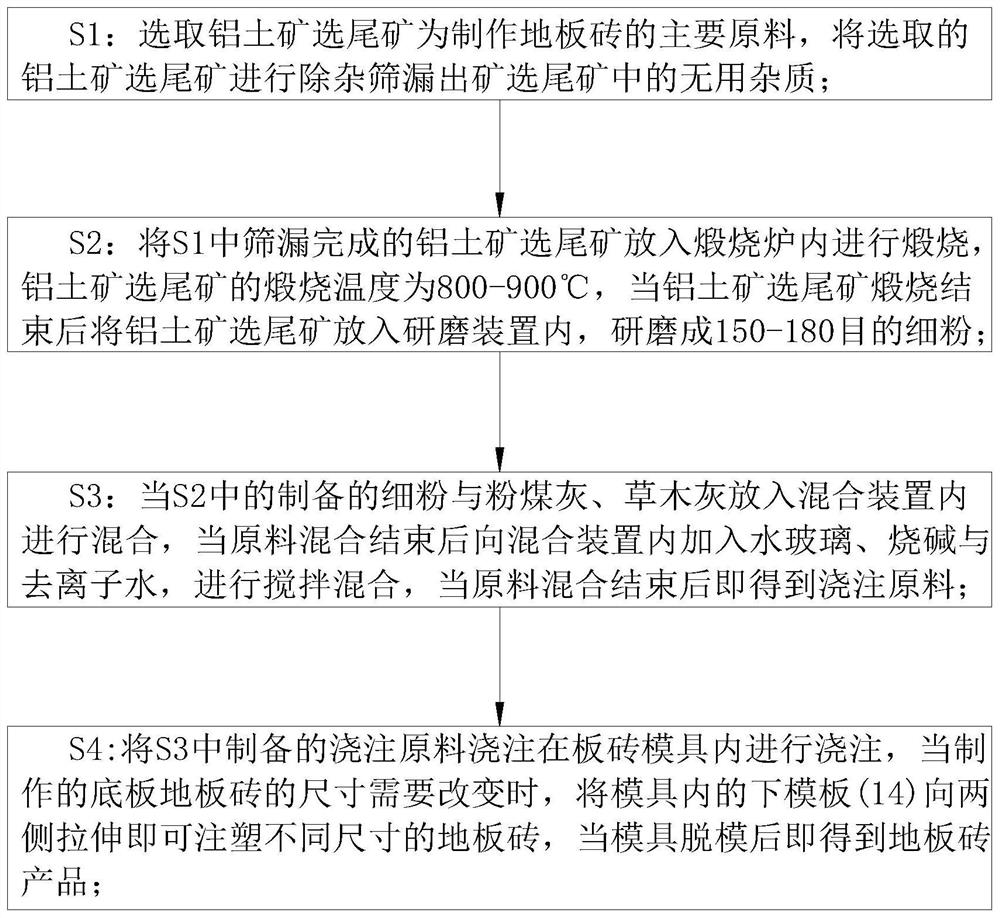

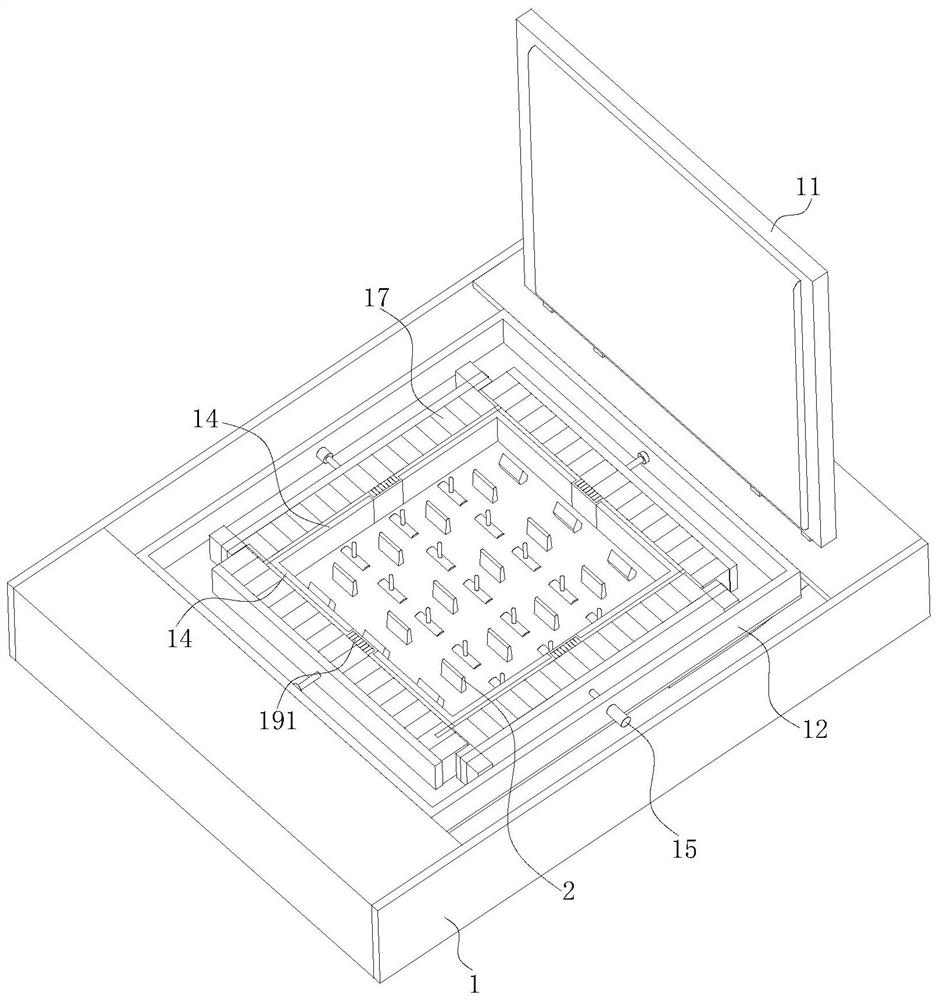

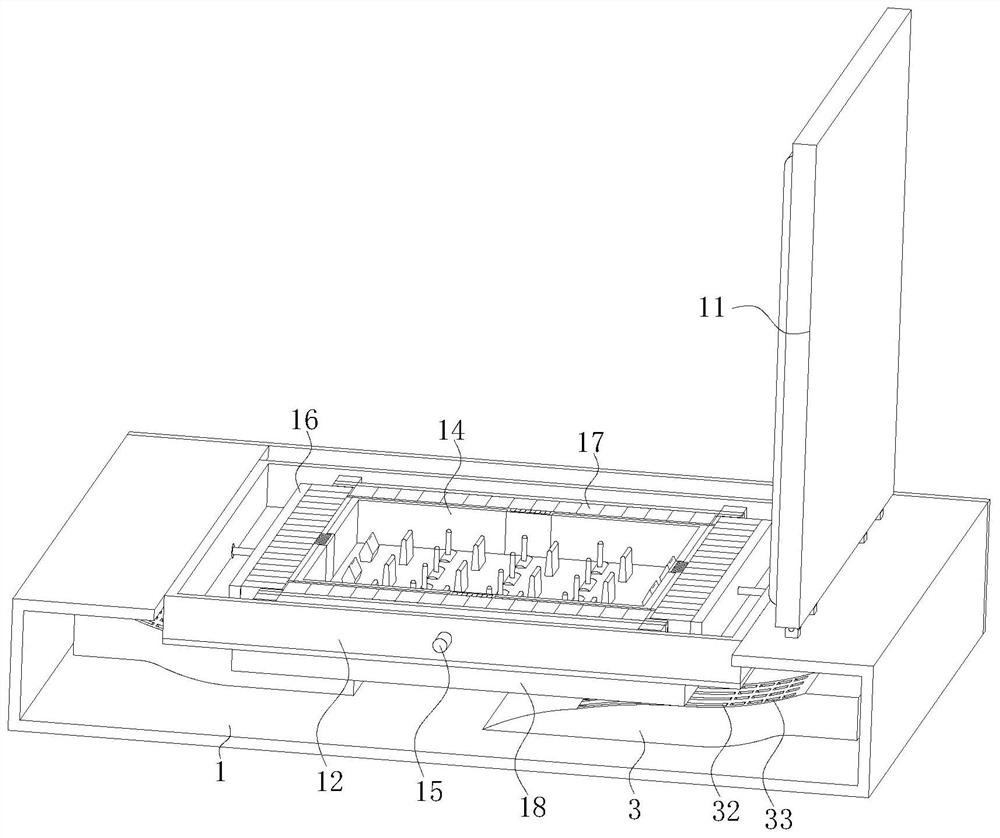

Method for preparing stone-like floor tiles from bauxite waste ore dressing tailings

InactiveCN112440371AReduced service lifeAvoid looseMouldsMould auxillary partsBrickMining engineering

The invention belongs to the technical field of stone-like floor tiles, and particularly relates to a method for preparing stone-like floor tiles from bauxite waste ore dressing tailings. A plate brick mold comprises a base; a lower mold bin is fixedly connected into a cavity of the base; sliding grooves are evenly formed in the inner wall of the lower mold bin, and sliding blocks are connected into the sliding grooves in a sliding mode; lower mold plates are evenly arranged in the lower mold bin; an interlayer is fixedly connected between every two lower mold plates; and the lower mold platescorrespond to each other and form a lower mold cavity. The method is mainly used for solving the problems that most of existing molds for manufacturing floor tiles are used for compacting raw materials in the molds, but the floor tiles manufactured by the mode are in a solid state, so that the material consumption of the floor tiles is increased to cause waste, and meanwhile, when bubbles exist in the raw materials or compaction among the raw materials is insufficient in the injection molding process of the raw materials, cavities exist in the manufactured floor tiles, so that the service life of the floor tiles is shortened.

Owner:安徽省红顺新材料科技有限责任公司

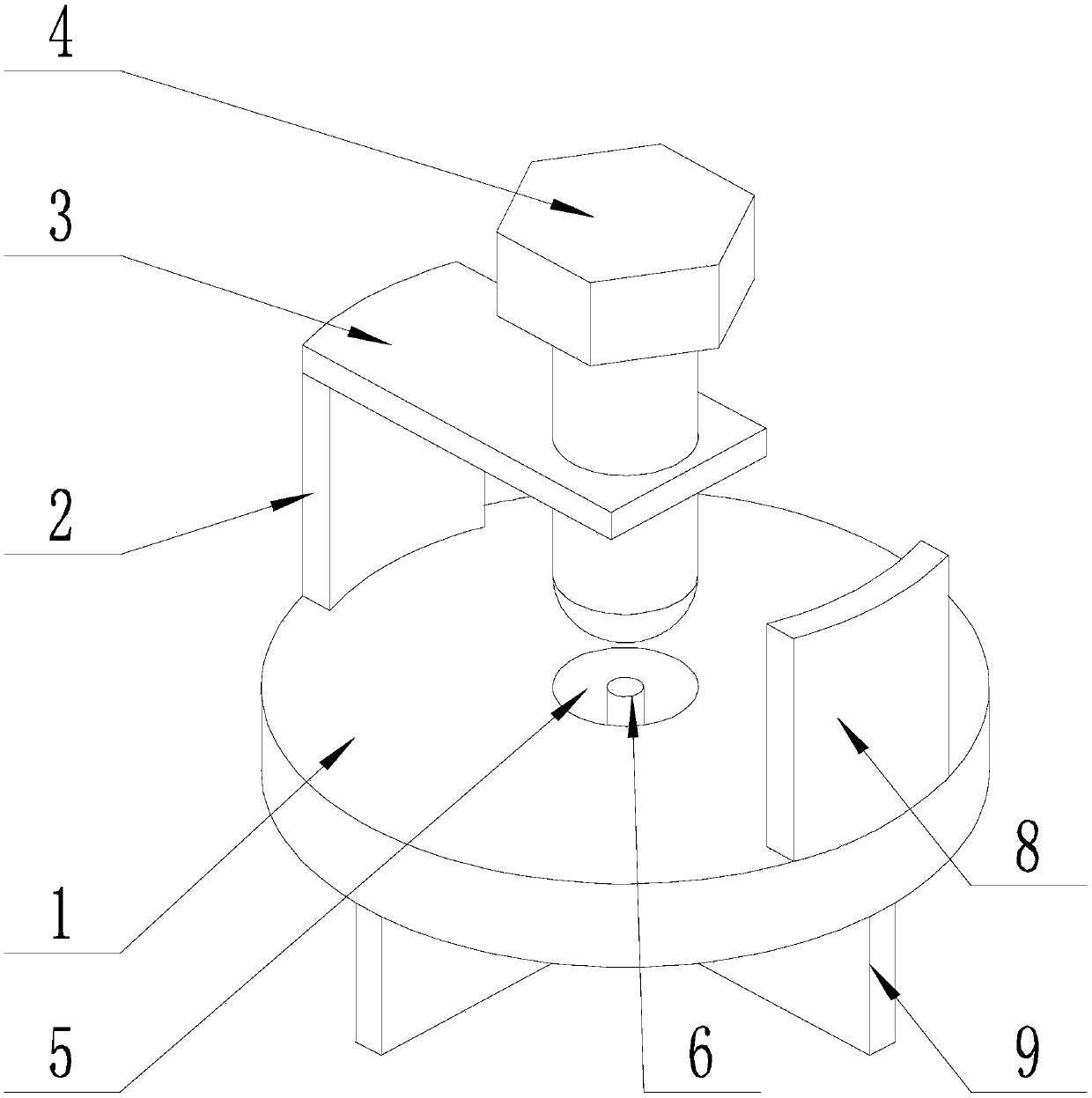

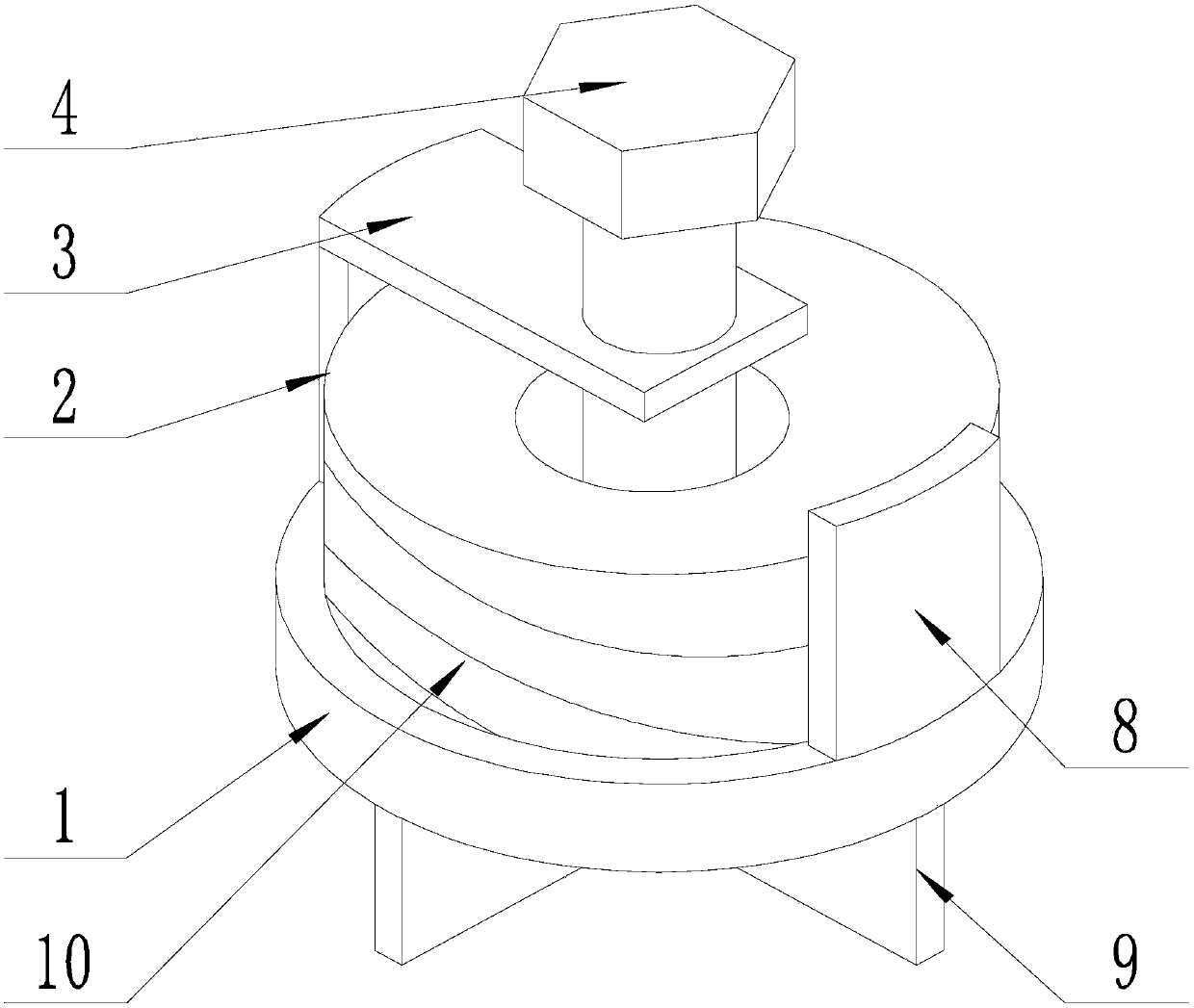

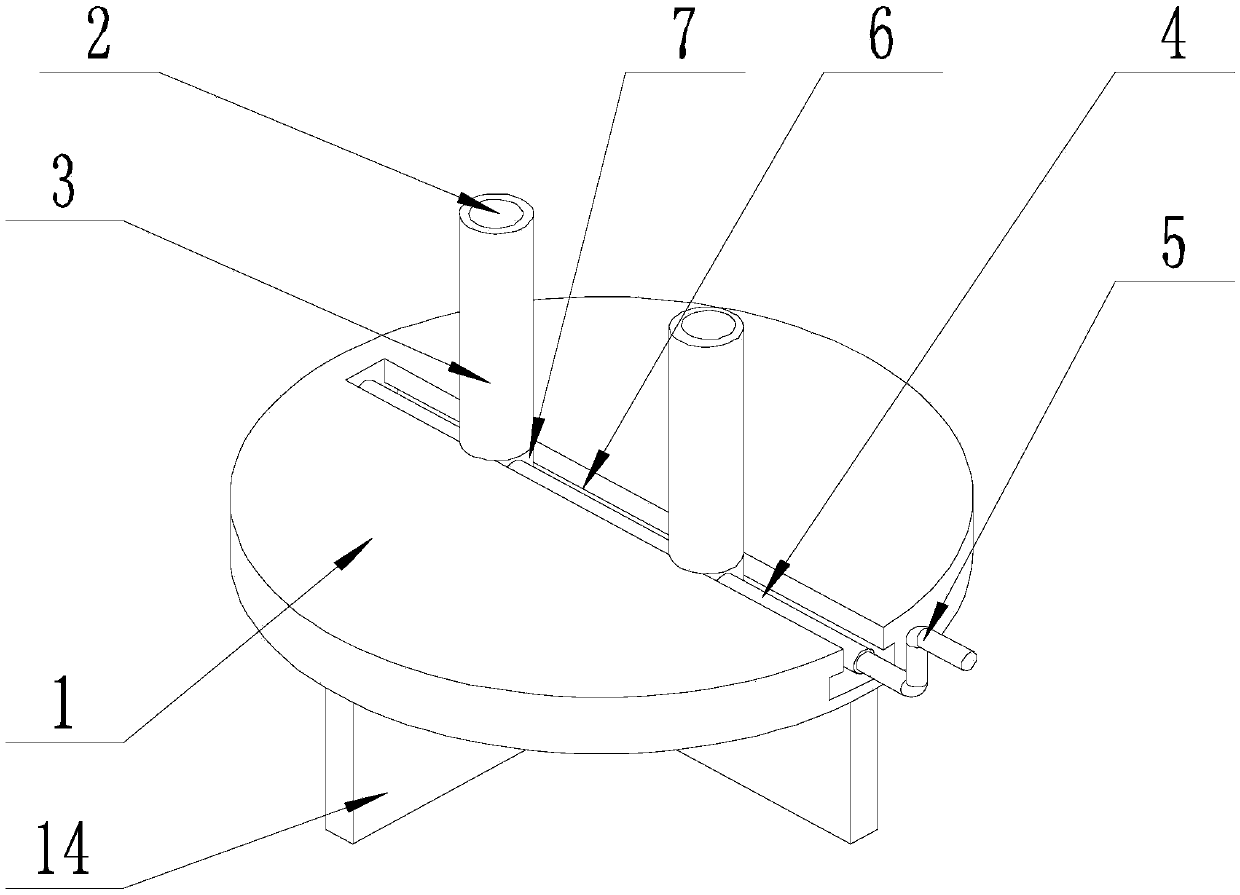

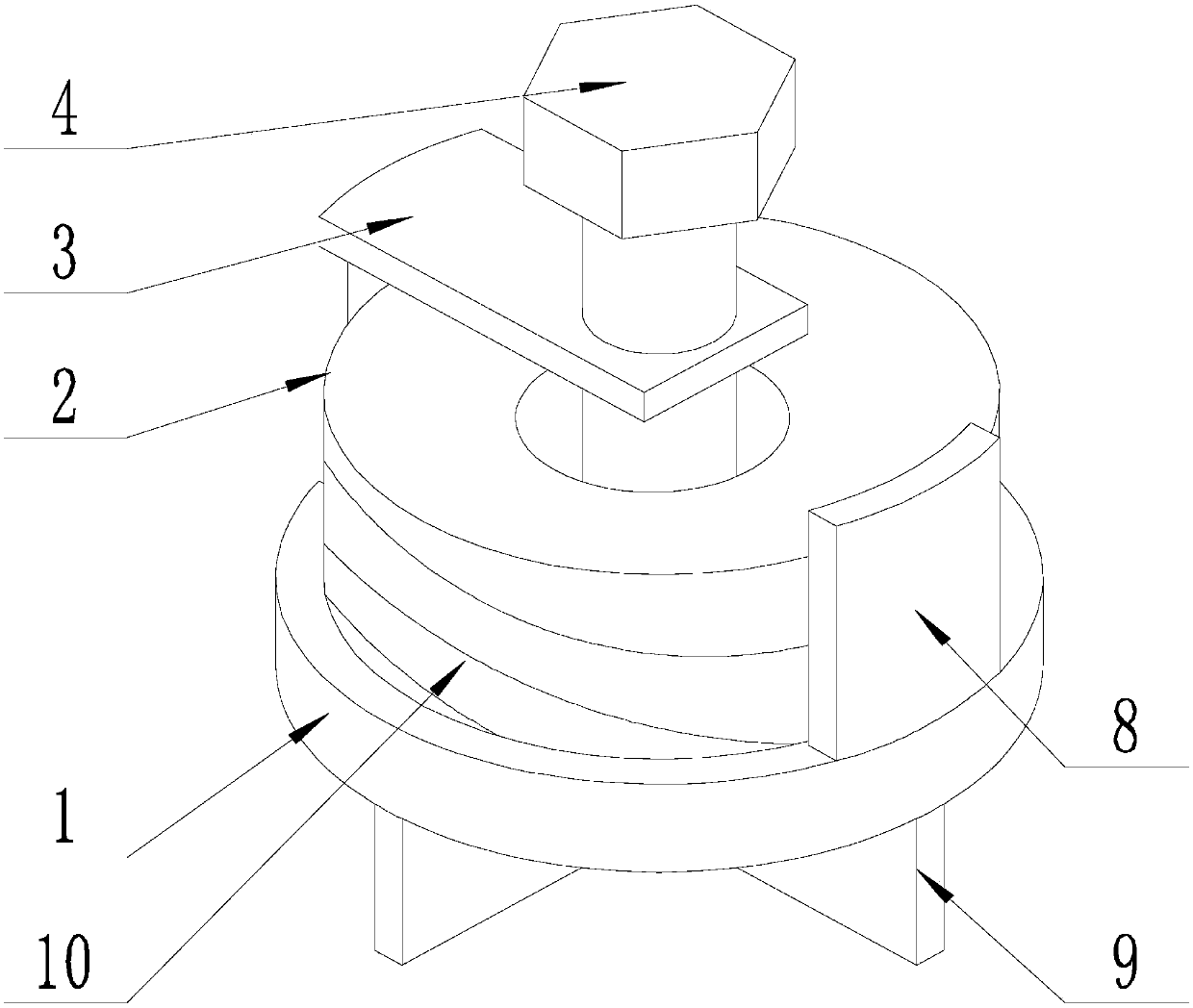

Wire rod storage device applied to construction engineering

InactiveCN110450999APrevent loose situationsReduce labor intensityBundling machine detailsWire rodEngineering

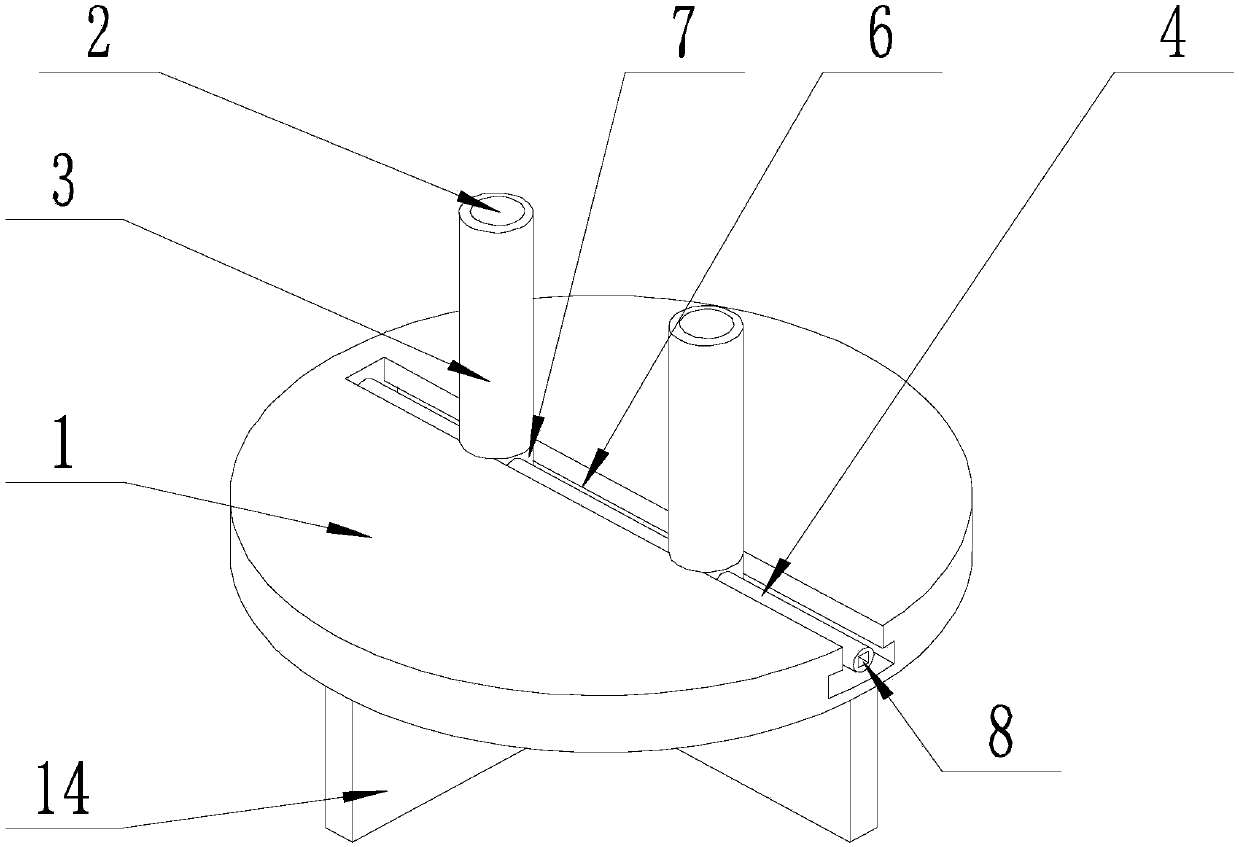

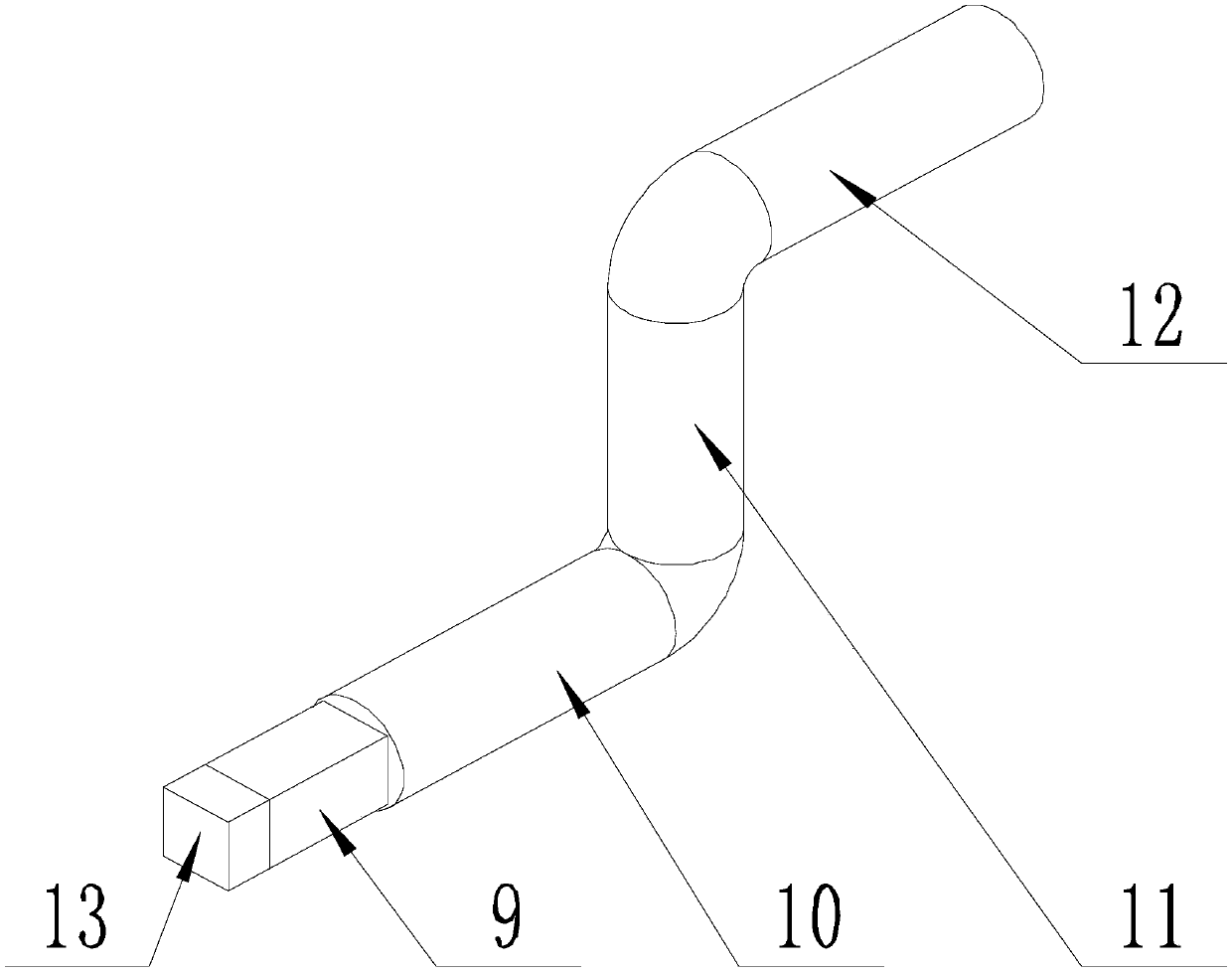

The invention discloses a wire rod storage device applied to construction engineering. The wire rod storage device comprises a bottom plate and a driving device, wherein the bottom plate is round, twolimiting shafts are arranged on the upper surface of the bottom plate, the axes of the limiting shafts are perpendicular to the bottom plate, the bottoms of the limiting shafts are arranged on the bottom plate in a sliding mode, the limiting shafts are symmetric along the center of the perpendicular bisector of the bottom plate, the driving device drives the limiting shafts to be close to or faraway from each other, and elastic rubber sleeves are arranged on the limiting shafts in a sleeving mode. According to the wire rod storage device, the storage device of a wire rod coil can be repeatedly used, and meanwhile, the wire rod coil is tightened and fixed by adopting a rotating handle, so that the labor intensity of workers is reduced, and the situation that the wire rod coil is looseneddue to insufficient fastening force when a rope is adopted is avoided.

Owner:何茜

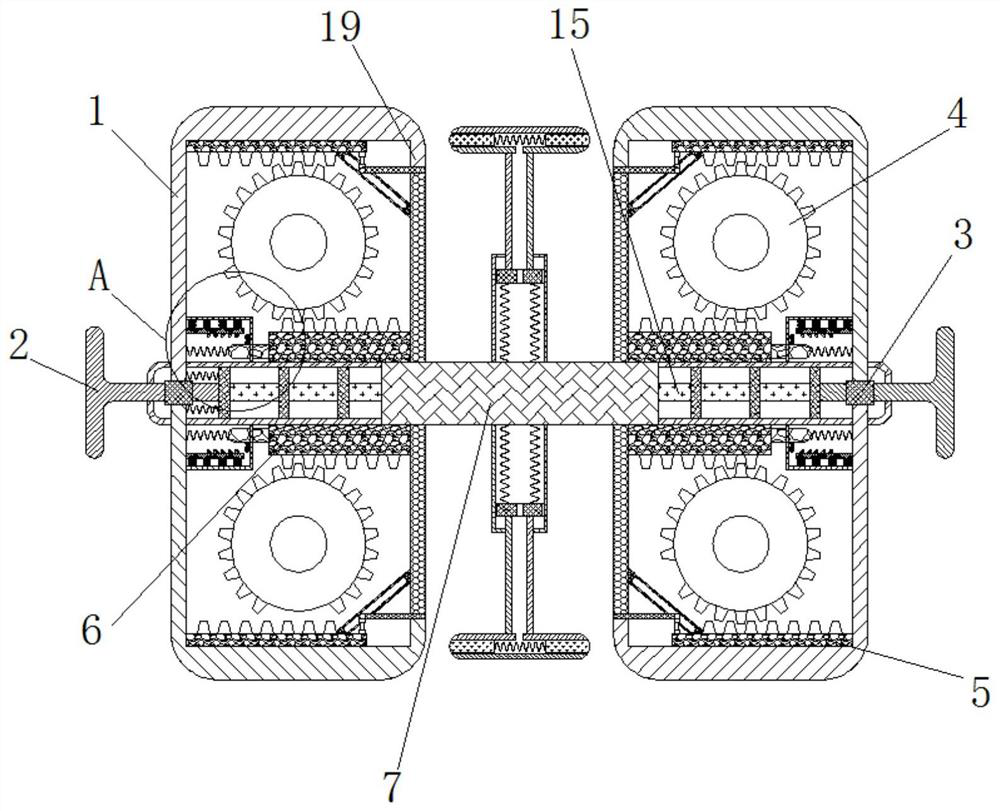

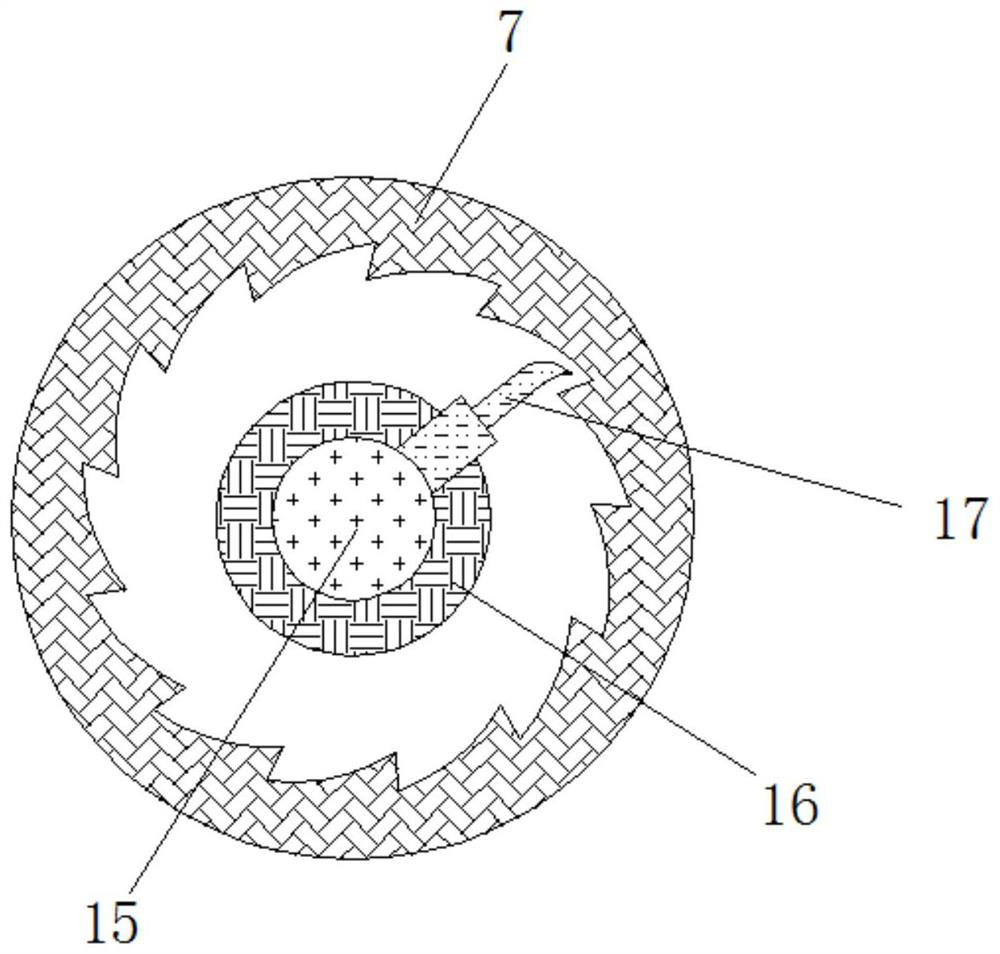

Redundant network cable collector based on gear rotation

The invention relates to the technical field of network science and technology, and discloses a redundant network cable collector based on gear rotation. The redundant network cable collector comprises outer frames, the outer side of each outer frame is fixedly connected with a clamping block, and the inner side of each clamping block is movably connected with a knob. According to the redundant network cable collector based on gear rotation, by pressing the knob on the left side, the part, clamped with the corresponding clamping block, of the knob is separated from the clamping block, then the knob is rotated to drive a corresponding center rod to rotate, the center rod drives a corresponding telescopic rod to move, a hook on the telescopic rod drives corresponding oblique teeth to move, the oblique teeth drive a corresponding rotating shaft to rotate, and the rotating shaft drives a corresponding limiting frame to move; and the limiting frame drives a corresponding communicating pipe to move, the communicating pipe drives a corresponding fixing plate to move, and at the moment, a hook on the right side is movably connected with the corresponding oblique teeth, the corresponding telescopic rod is extruded, a center rod on the right side does not rotate together with the center rod on the left side, and the purposes of collecting redundant network cables and rotating the knob clockwise on the left side to take up the network cables and rotating a knob clockwise on the right side to pay off the network cables are achieved; and the operation is more convenient.

Owner:烟台优德科技发展有限公司

Cable winding device for electric construction convenient to store

InactiveCN108675061AImprove retracting efficiencyEnergy savingCable installation apparatusElectric machineryConductor Coil

Owner:ANHUI ORIGINAL POWER PRODUCTIVITY PROMOTION CENT CO LTD

Straw stack conveying device for animal husbandry breeding

InactiveCN111497913ASimple loadingSimple cuttingHand carts with multiple axesHand cart accessoriesAgricultural scienceStraw

The invention belongs to the technical field of transportation devices, especially to a hay conveying device for animal husbandry breeding. Aiming at the transportation device in the patent, the design structure is simple; feeding and discharging of the straw stacks are very troublesome; the problem that grass stacks are disordered easily in the transportation process is solved; the device comprises a base, a rotating plate is hinged to the outer wall of one side of the base, a first circular protrusion is arranged on the outer wall of the top of the rotating plate, a second circular protrusion is arranged on the outer wall of the top of the first circular protrusion, and a landing plate is arranged at the end, away from the base, of the rotating plate. According to the feeding device, during feeding, the second push block can convey the straw stacks to the inner side of the conveying box during conveying of the conveying belt, the first push block can convey the straw stacks to the outer side of the conveying box during discharging and conveying of the conveying belt, feeding and discharging of the straw stacks are very simple, the whole straw stacks can be conveyed together in the conveying process, and the situation that the straw stacks are messy is not likely to happen.

Owner:张大秦

Winding and packaging device for USB data line production

The invention relates to the technical field of data line packaging, and discloses a winding and packaging device for USB data line production. A box door is fixedly installed on the front face of a box body, a control panel is fixedly installed on the front face of the box door, and a rotating shaft is fixedly installed at the top end of the box body. According to the winding and packaging device for the USB data line production provided by the invention, a first electric rotating disc is installed at the bottom end of the inner wall of a placement plate, a push rod is installed at the top end of the first electric rotating disc and movably connected with a first convex column, a transverse rod is installed at the bottom end of the first convex column and installed on the right side of a tension disc, then a spring telescopic rod is installed on the left side of the tension disc, a sliding block is installed at the bottom end of the tension disc and located in a movable groove formed in the top end of a fixed block, the tension rod is close to grooves on one side of a connecting block, spring rods are installed on the inner walls of the grooves, top blocks are installed on the outer walls of the spring rods, and the heights of the four grooves are different, so that the situation that a data line is loosened during winding can be prevented, and meanwhile, ladder-shaped arrangement can be carried out.

Owner:嘉兴市奥衡科技有限公司

A kind of bare fiber disk fiber pay-off device group

Owner:GUANGXUN SCI & TECH WUHAN

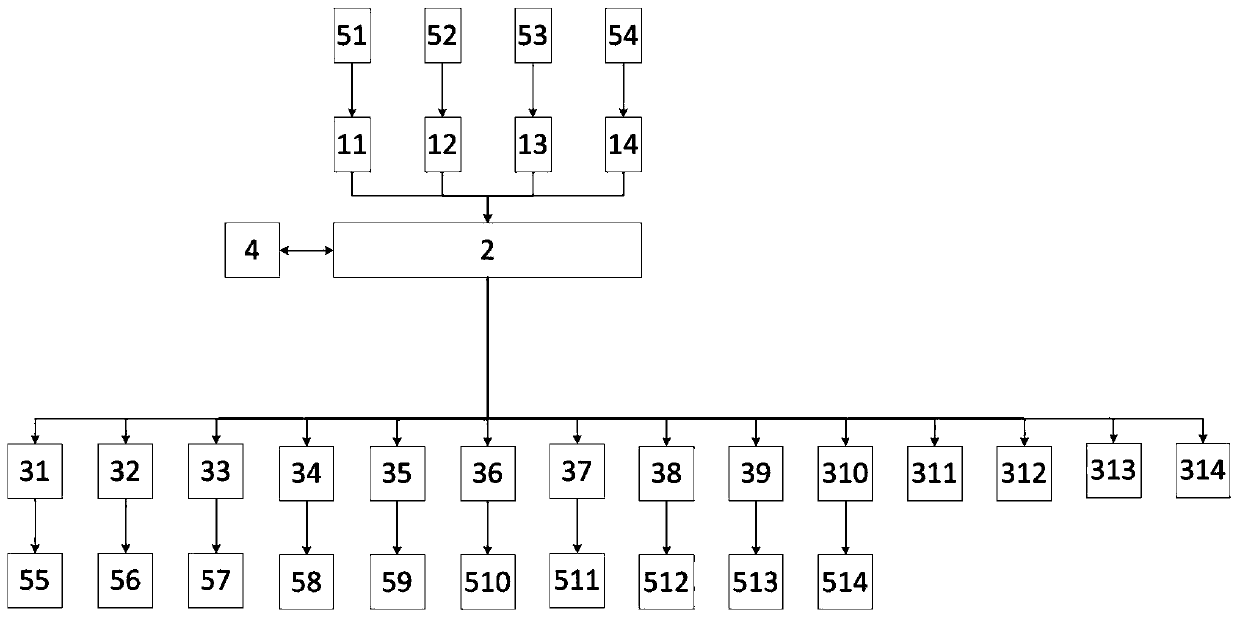

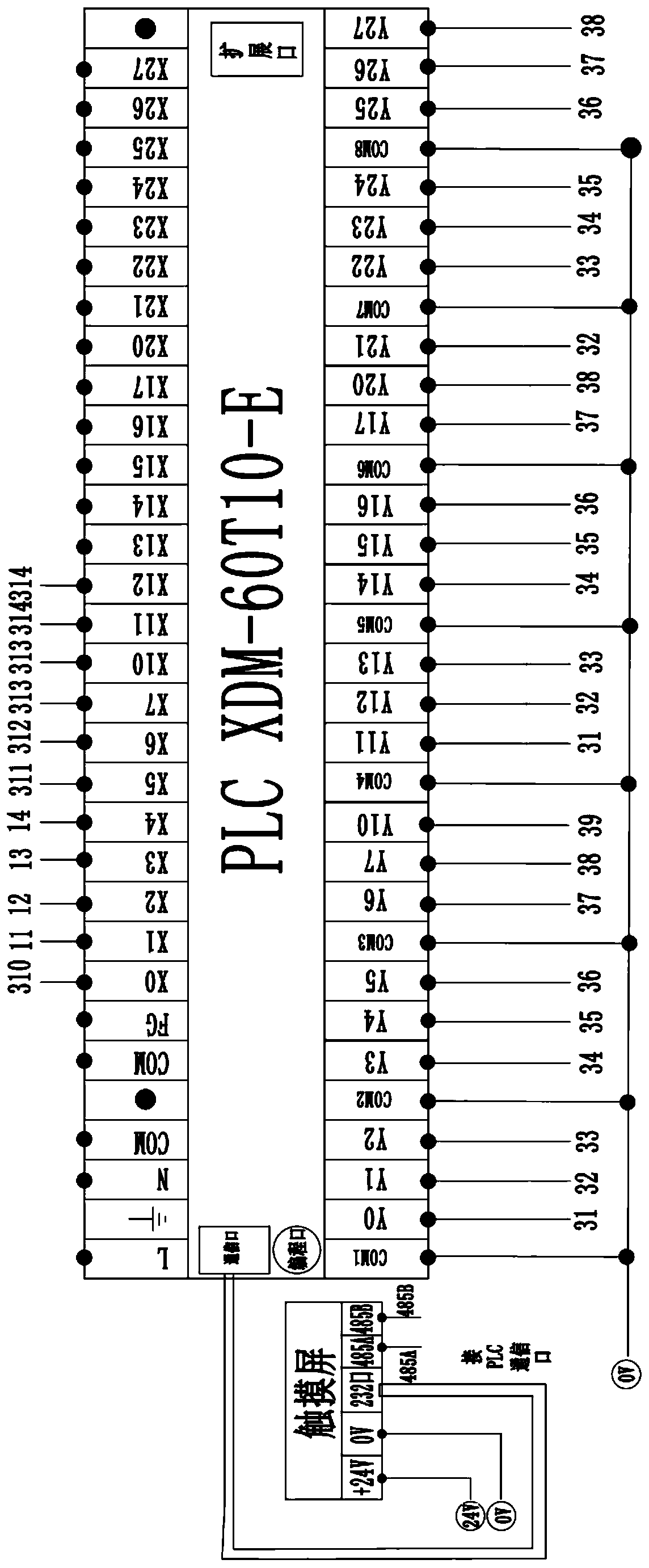

PLC-based disc-type motor stator coil inserting machine control system

PendingCN110083121ATension remains constantTight ruleProgramme control in sequence/logic controllersRound barCommunication interface

The invention discloses a PLC-based disc-type motor stator coil inserting machine control system. The system comprises a sensor detection portion, a PLC programmable controller, a control portion anda man-machine interaction portion. The PLC programmable controller comprises an analog input unit, an analog output unit, a switch quantity input unit, a switch quantity output unit, and a communication interface. The communication interface of the PLC programmable controller is connected to the man-machine interaction portion. The analog input unit and the switch quantity input unit of the PLC programmable controller are connected to the sensor detection portion. The analog output unit and the switch quantity output unit of the PLC programmable controller are connected to the control portion.A winding motor and a bobbin rotation motor control a winding round bar and a bobbin, which can effectively prevent a winding looseness condition caused by different speeds of the winding round bar and the bobbin during winding, and prevent wires from being entwined. A winding tension detection sensor is added so that a tension remains constant and inserted wires are tighter.

Owner:江苏科瑞德智控自动化科技有限公司 +1

Preserving agent for preserved eggs and application method

InactiveCN108201090AGood adhesionPrevent loose situationsEggs preservationFood ingredient as mouthfeel improving agentChinese cinnamonToxin

The invention discloses a preserving agent for preserved eggs and an application method. The preserving agent is prepared from the following raw materials in parts by weight: 3-8 parts of table salt,12-20 parts of chopped green tea, 3-8 parts of fresh ginger, 25-32 parts of plant ash, 22-28 parts of bran coats, 1-5 parts of edible white vinegar, 5-10 parts of soda powder, 3-8 parts of star aniseeds, 4-8 parts of Chinese cinnamon, 3-6 parts of fennel seeds, 2-6 parts of fructus tsaoko and 3-8 parts of yellow mud. The preserving liquid has the characteristics of being free from toxin to human bodies, and good in mouth feel.

Owner:贵州益沁园农业开发有限公司

Conveying and winding machine for garment fabric production

ActiveCN113387220BEnsure compactnessGuaranteed cleanlinessMechanical cleaningPressure cleaningWinding machineIndustrial engineering

The invention relates to the technical field of clothing fabric winding, in particular to a clothing fabric production, conveying and winding machine, comprising a workbench, a support plate, a winding unit and a leveling unit. A winding unit is arranged on the right side of the opposite end of the plate, and a flattening unit is arranged on the left side of the opposite end of the support plate; the invention can solve the problems existing in the winding of clothing fabrics: the traditional winding equipment cannot effectively wind the clothing fabrics. The clothing fabric is flattened, so that the flatness of the clothing fabric cannot be ensured, and the traditional winding equipment cannot remove the dust and thread ends on the surface of the clothing fabric, thus affecting the cleanliness of the clothing fabric; The two sides of the cloth are scraped to ensure the flatness of the clothing fabric; the present invention can suck out the residual dust and thread ends on the surface of the clothing fabric, thereby ensuring the cleanliness of the clothing fabric.

Owner:江苏柏盛家纺有限公司

Metal filing treatment device for metal material machining

InactiveCN112590285AAvoid manual removalReduce the amount of manual laborGrain treatmentsPressesMetallic materialsStructural engineering

The invention relates to the technical field of metal material machining, and discloses a metal filing treatment device for metal material machining. The metal filing treatment device comprises a first machine body, a second machine body, a vibration mechanism and a crushing mechanism, wherein the second machine body is fixedly arranged at the bottom of the first machine body; the vibration mechanism is arranged in the first machine body; the crushing mechanism is arranged in the first machine body; and the vibration mechanism comprises a fixing plate, a first spring groove, an inserting column, an inserting hole and a vibration spring. According to the metal filing treatment device for metal material machining, the vibration device is started to drive a fixing frame to vibrate, a screening plate is driven to vibrate at a high speed, so that metal filing falling onto the screening plate is screened, the metal filing with the relatively small size continues to fall off, the metal filingwith the excessively large size enters a crushing groove, the metal filing with the small size is prevented from being crushed, and the phenomenon that the amount of the metal filing with the small-size is large and compression is inconvenient is avoided.

Owner:恒凌金属制品(湖州)有限公司

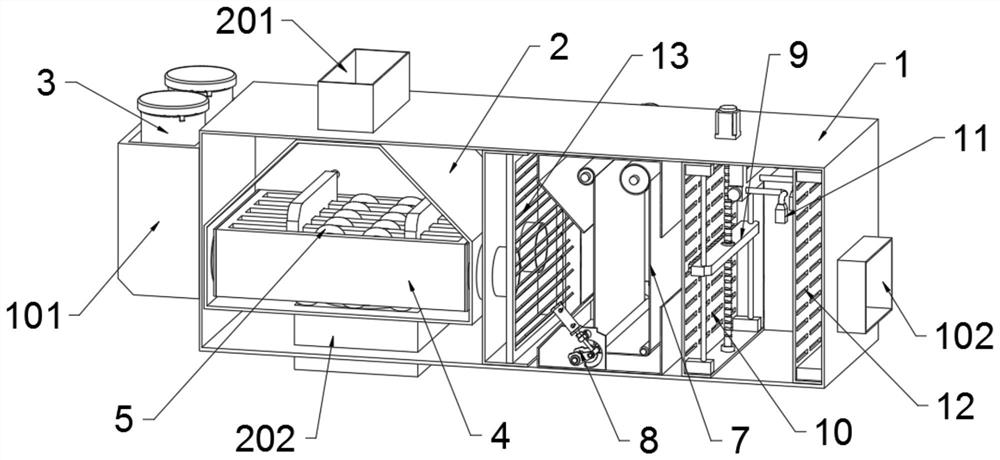

Heat recovery device of heating ventilation air conditioning system

ActiveCN112984631AIncrease inhalationReduce energy consumptionEnergy recovery in ventilation and heatingLighting and heating apparatusElectric machineryHVAC

The invention provides a heat recovery device of a heating ventilation air conditioning system, and relates to the technical field of air conditioning system equipment. The heat recovery device aims to solve the problems that in the using process of an existing heat recovery device of the heating ventilation air conditioning system, when a fresh air pipe sucks external fresh air, a large amount of resources are consumed due to the large suction amount, and meanwhile mist is gathered on a front water baffle, due to the fact that deposited water drops are prone to blocking vent holes of the front water baffle, air circulation in a device is reduced, heat recovery efficiency is affected, and the filtering effect of a cleaning filter material belt is greatly reduced due to the fact that the cleaning filter material belt is affected by moisture or hot air to be loosened. The heat recovery device comprises a shell, the shell comprises a sleeve frame and an air supply pipe, and an air supply pipe is arranged at the rear end of the shell. According to the heat recovery device, power is provided by a first motor, a shaft rod and a rotating plate continuously rotate, a transmission rod drives a pressurizing plug to reciprocate up and down in a fresh air penetrating pipe, and therefore the pressurizing effect is achieved, the suction amount of fresh air is increased, energy consumption is reduced, and capital consumption is reduced.

Owner:广东国祥环境科技有限公司

Method for preventing wire coil from being loosened

The invention discloses a method for preventing a wire coil from being loosened. The method comprises the following steps that step A, a bottom plate is placed on the ground firstly; step B, a bolt isrotated and withdrawn from a threaded hole; step C, the coiled wire coil is pushed from one side of a supporting plate to the upper surface of the bottom plate, and the axis of a central hole of thewire coil is enabled to coincide with the axis of a groove; step D, the head end and the tail end of a wire rod of the wire coil are placed in the groove; and step E, the tail end of a rod part of thebolt is enabled to penetrate through the threaded hole from the end, away from the bottom plate, of a flat plate and then is in threaded connection with the threaded hole, the bolt is rotated until the tail end of the rod part of the bolt is inserted into the groove, and the head end and the tail end of the wire rod are pressed in the wire coil. According to the method, the wire coil storage device can be repeatedly used, the wire coil does not need to be tied by ropes, the labor intensity of workers is reduced, and the situation that the wire coil is loosened due to insufficient fastening force when the rope is adopted for tying is avoided.

Owner:何茜

Lithium battery based on wireless charging technology

PendingCN112563557ARealize the rotation effectEasy to removeLi-accumulatorsCell component detailsElectric machineReciprocating motion

The invention discloses a lithium battery based on a wireless charging technology. Thelithium battery comprises a box body, a battery box, a battery cover and a fixing piece, wherein blocking pieces are fixedly connected to the two sides of the upper surface of the box body correspondingly, moving grooves are formed in the blocking pieces, a motor is arranged on one sides of the blocking pieces, asecond rotating shaft is in transmission connection with one side of the motor, the second rotating shaft is located in the moving groove, a cleaning brush is arranged on the surface of the second rotating shaft, and a moving block is rotatably connected to one side of the cleaning brush through the rotating shaft. Through the arranged cleaning brush, dust on the upper layer of the box body can be brushed away by rotating the cleaning brush, and the situation that the dust is accumulated on the box body and the induction effect between induction coils is affected is avoided; through the arranged second rotating shaft, the effect of rotating the cleaning brush can be achieved through rotation of the second rotating shaft; through the arranged motor, the rotating shaft can rotate; and through an arranged electric push rod, the adjusting end of the electric push rod can extend and retract back and forth, and reciprocating motion of a movable block on the box body is achieved.

Owner:杨成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com