Patents

Literature

61results about How to "Tension remains constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

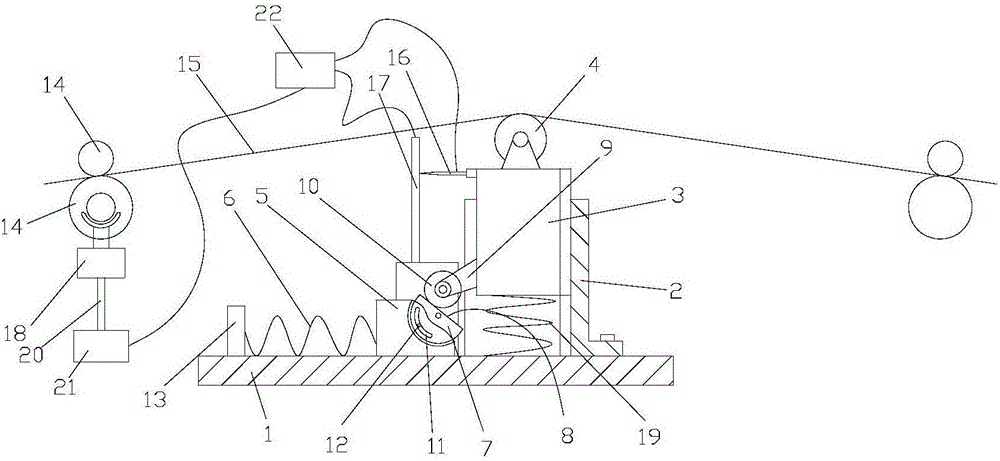

Carbon cloth tension automatic control device in low temperature carbonization furnace system

InactiveCN101419472AChange running speedChange speedHeating/cooling textile fabricsMechanical pressure/force controlFuel cellsAutomatic control

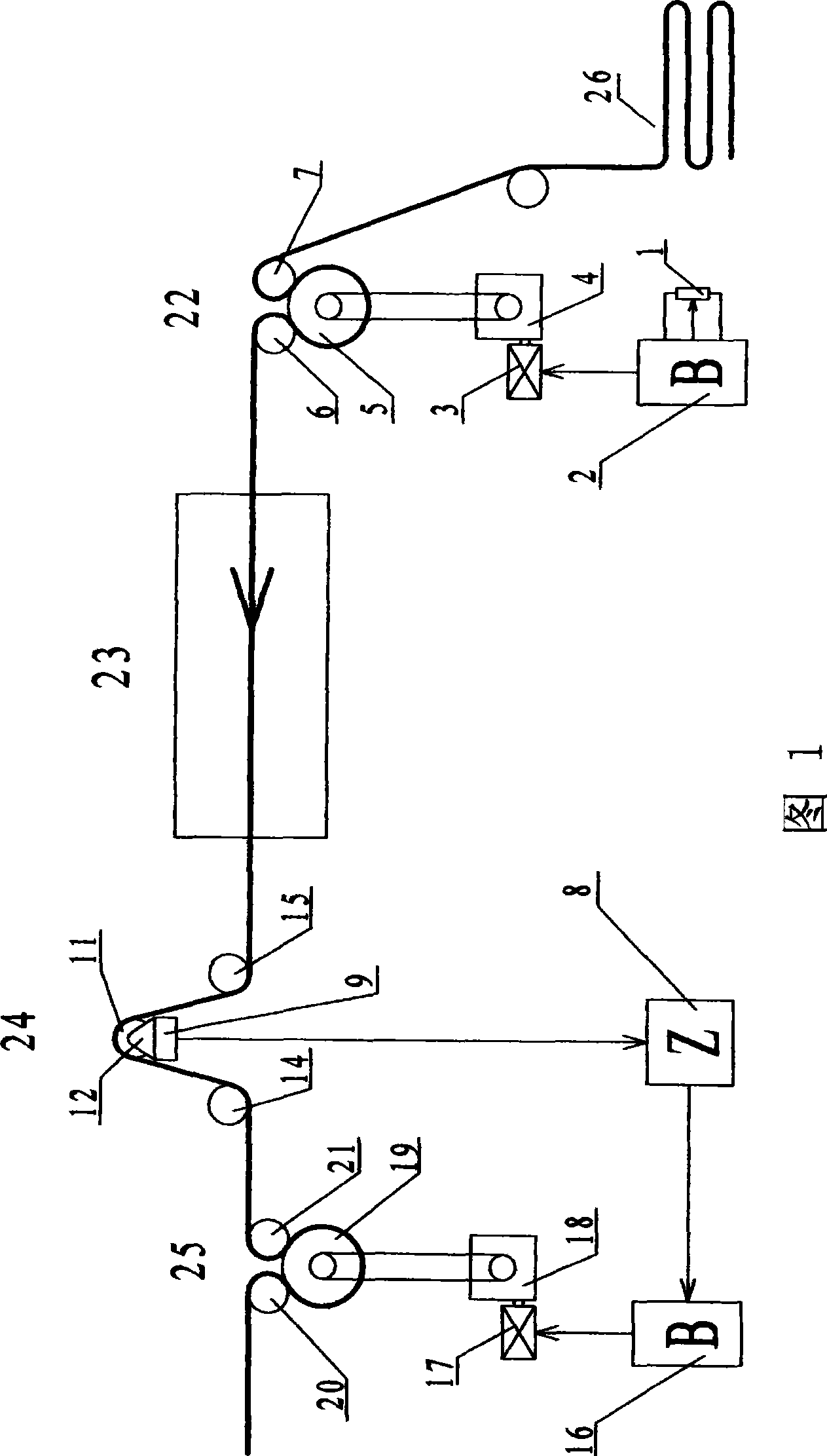

The invention relates to an automatic carbon cloth tension controlling device in a carbon cloth low-temperature carbide furnace system used by a fuel battery in the automatic control field. The device comprises a potentiometer, an inlet frequency variation controller, an inlet driving roller, a tension controller, a tension roller, an outlet frequency variation controller and an outlet driving roller. The inlet driving roller is positioned in front of a low-temperature carbide furnace; the inlet frequency variation controller, the potentiometer and the inlet driving roller form a closed loop feedback chain; the tension roller and the outlet driving roller are sequentially positioned behind the low-temperature carbide furnace; the tension controller is respectively connected with the tension roller and the outlet frequency variation controller; and the outlet frequency variation controller is connected with the outlet driving roller to output the carbon cloth. A tension sensor in the invention measures and obtains an instant tension value of the carbon cloth and is controlled by a feedback closed loop so that the carbon cloth tension control achieves high accuracy, satisfactory stability and fast response. Manual adjustment of the potentiometer can stabilize the invention in a new and balanced feedback loop so as to perform fine adjustment to the carbon cloth of different materials and to facilitate technical operations.

Owner:SHANGHAI SXCARBON TECH

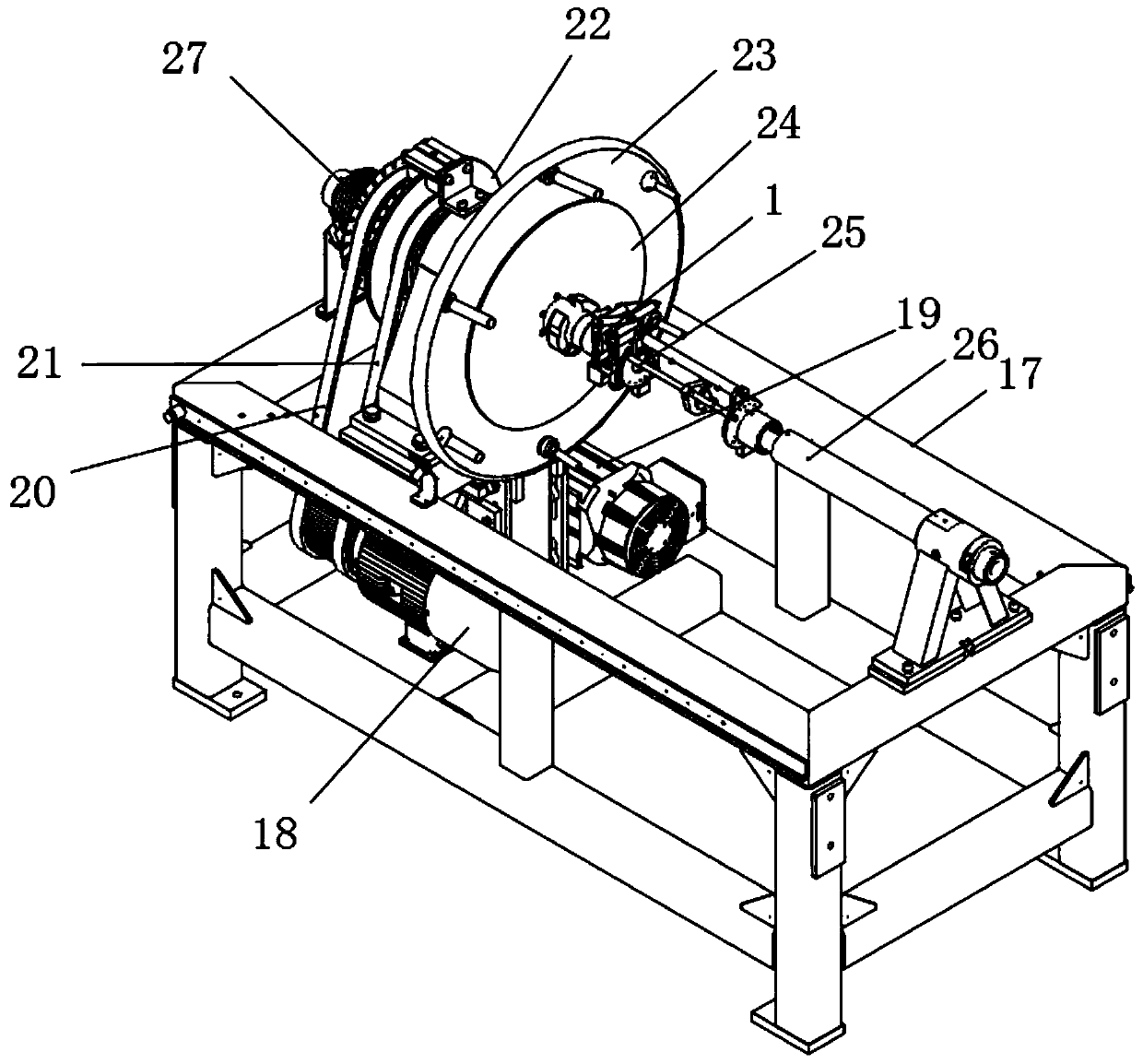

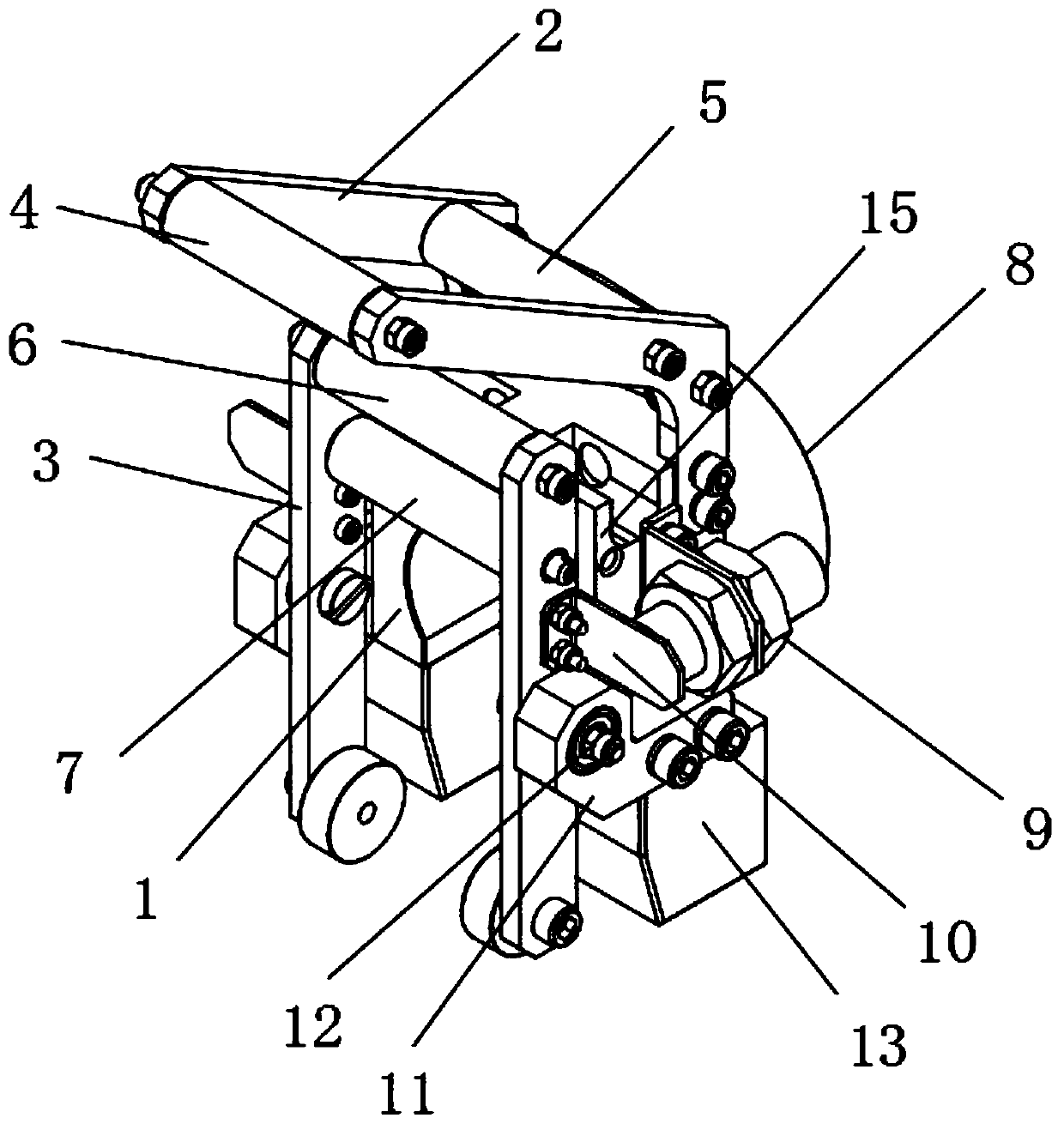

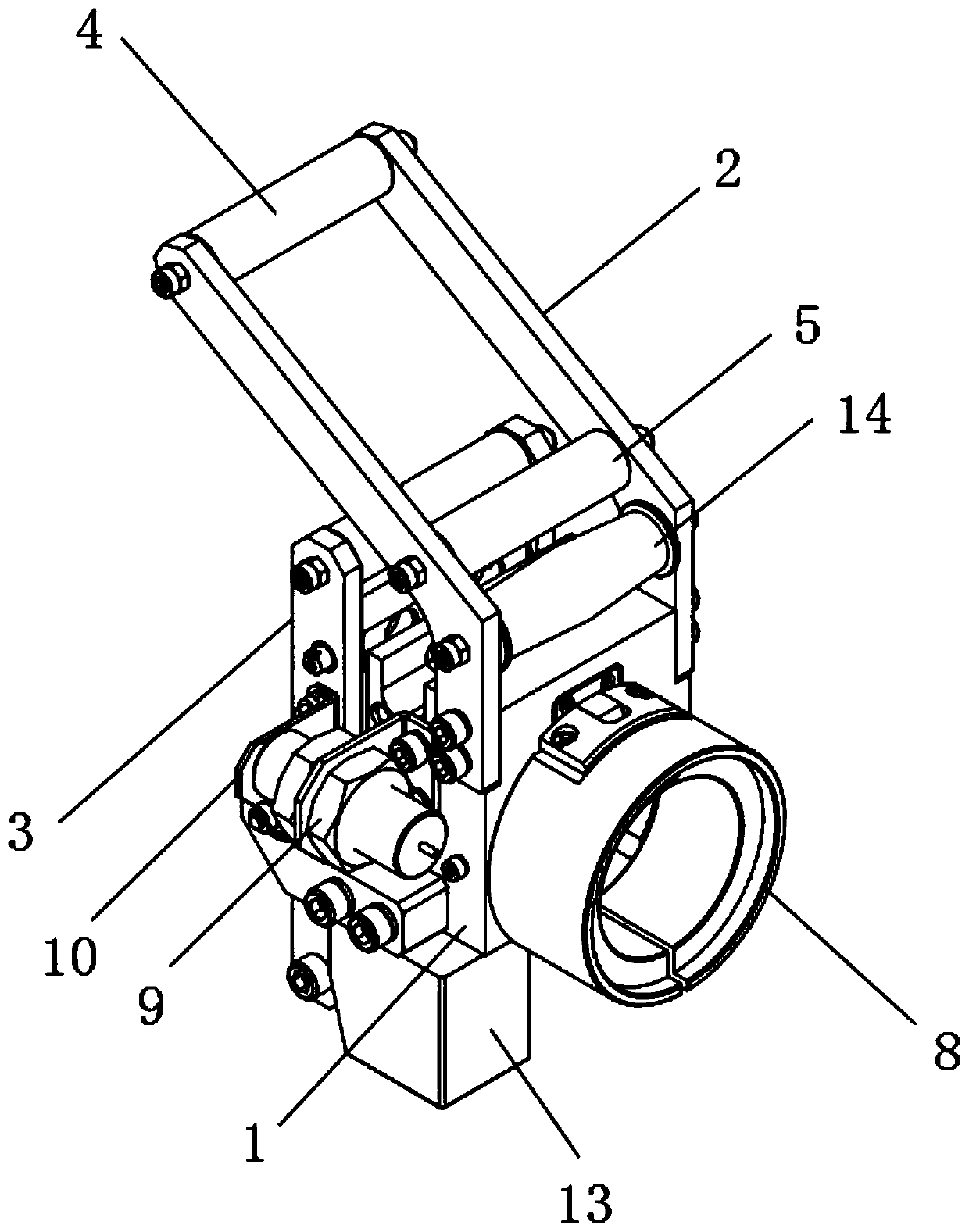

Steel strand tightening and taking-up device

The invention discloses a steel strand tightening and take-up device, and relates to the technical field of steel strand winding. A tightening unit comprises a base, wherein two strand inlet rollers are rotationally arranged on one side edge of the base, a wedge plate is fixedly arranged on the other side edge of the base, double clamping plates are arranged in the base in a lifting mode, a strandwinding roller and a strand outlet roller are rotationally arranged in the double clamping plates, and the strand winding roller is arranged in a sliding movable seat; and the take-up unit comprisesa bottom plate, wherein a storage rack is arranged on the bottom plate in a reciprocating sliding mode, clamping air cylinders are fixedly arranged at the two ends of the storage rack, and a winding drum is clamped between the two clamping air cylinders. A steel strand sequentially penetrates through the strand inlet rollers, the strand winding roller and the strand outlet roller at preset positions, travels a snake-shaped route, and is tensioned by preset tension and then wound on the peripheral side of the winding drum, and when the winding drum drives the steel strand to be wound layer by layer, the double clamping plates rise gradually and are pushed by the wedge plate, so that the penetrating and winding stroke of the steel strand in the base is reduced, the steel strand can be prevented from being excessively tensioned or loosened while the original tensioning force is kept, and the stability and neatness of steel strand winding are ensured.

Owner:天津市宝丰源钢绞线制造有限公司

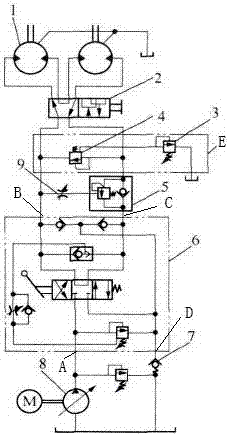

Passive type constant tension hydraulic control system of mooring winch

PendingCN107500150AGuaranteed tensionAvoid damageServomotorsWinding mechanismsFuel tankBack pressure

The invention relates to a passive type constant tension hydraulic control system of a mooring winch. The passive type constant tension hydraulic control system comprises a hydraulic pump, a two-directional hydraulic motor and a reversing valve, wherein an oil outlet of the hydraulic pump is connected with an oil port A of the reversing valve; a back pressure valve is connected in series between an oil port D of the reversing valve and an oil tank; a first oil feeding / discharging opening of the two-directional hydraulic motor is connected with an oil port B of the reversing valve through a first oil guide pipe; a second oil feeding / discharging opening of the two-directional hydraulic motor is connected with an oil port C of the reversing valve through a second oil guide pipe; a balance valve is connected in series between the first oil feeding / discharging opening of the two-directional hydraulic motor and the oil port B of the reversing valve; a control oil port of the balance valve is connected with the second oil guide pipe; a needle adjustment valve is connected in series between the control oil port of the balance valve and the second oil guide pipe; the passive type constant tension hydraulic control system further comprises a pilot overflow valve connected in parallel with the two-directional hydraulic motor; and a remote control port of the pilot overflow valve is connected in series with a remote control overflow valve. The system is high in reliability, easy to operate and low in cost.

Owner:江苏威和海洋工程设备有限公司

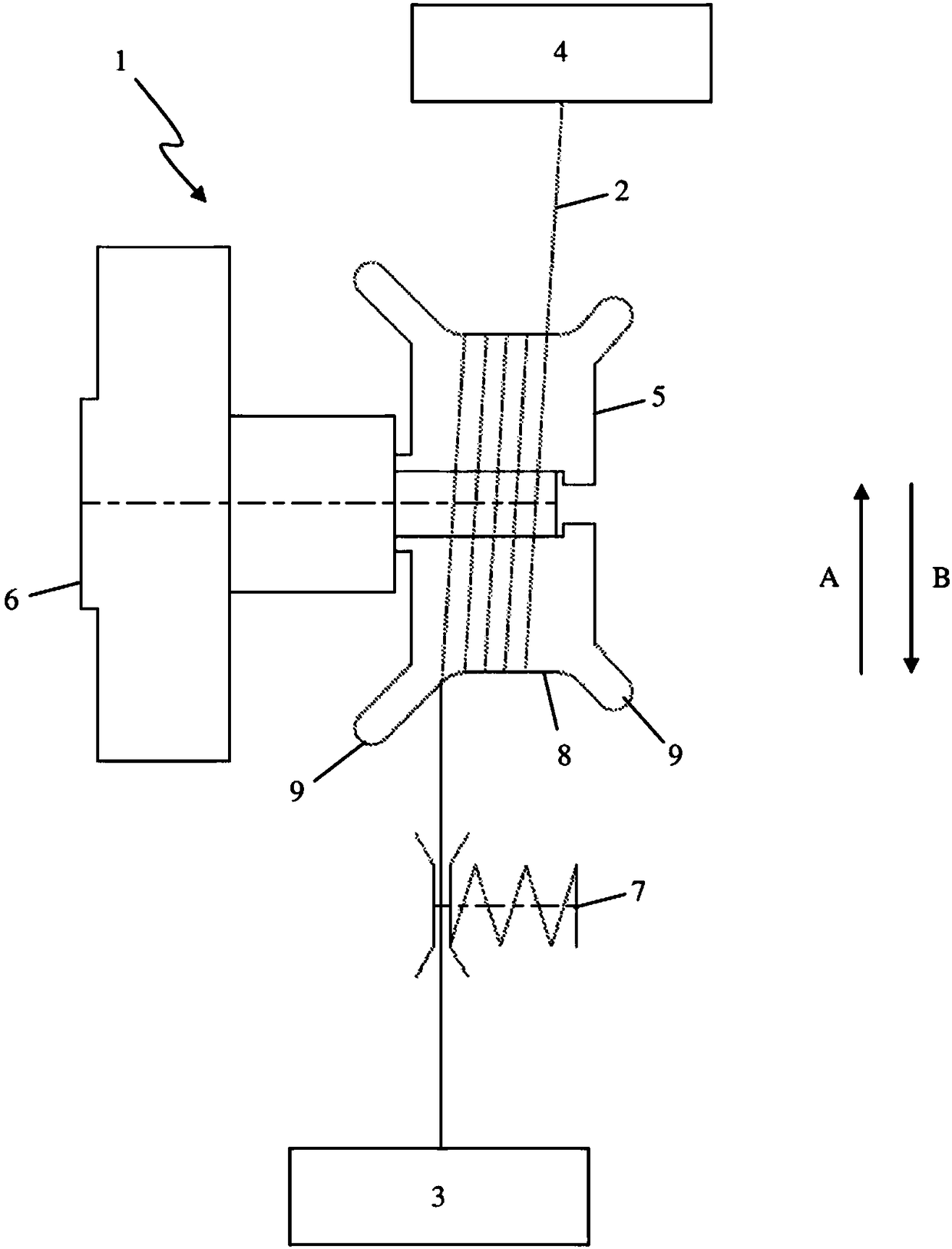

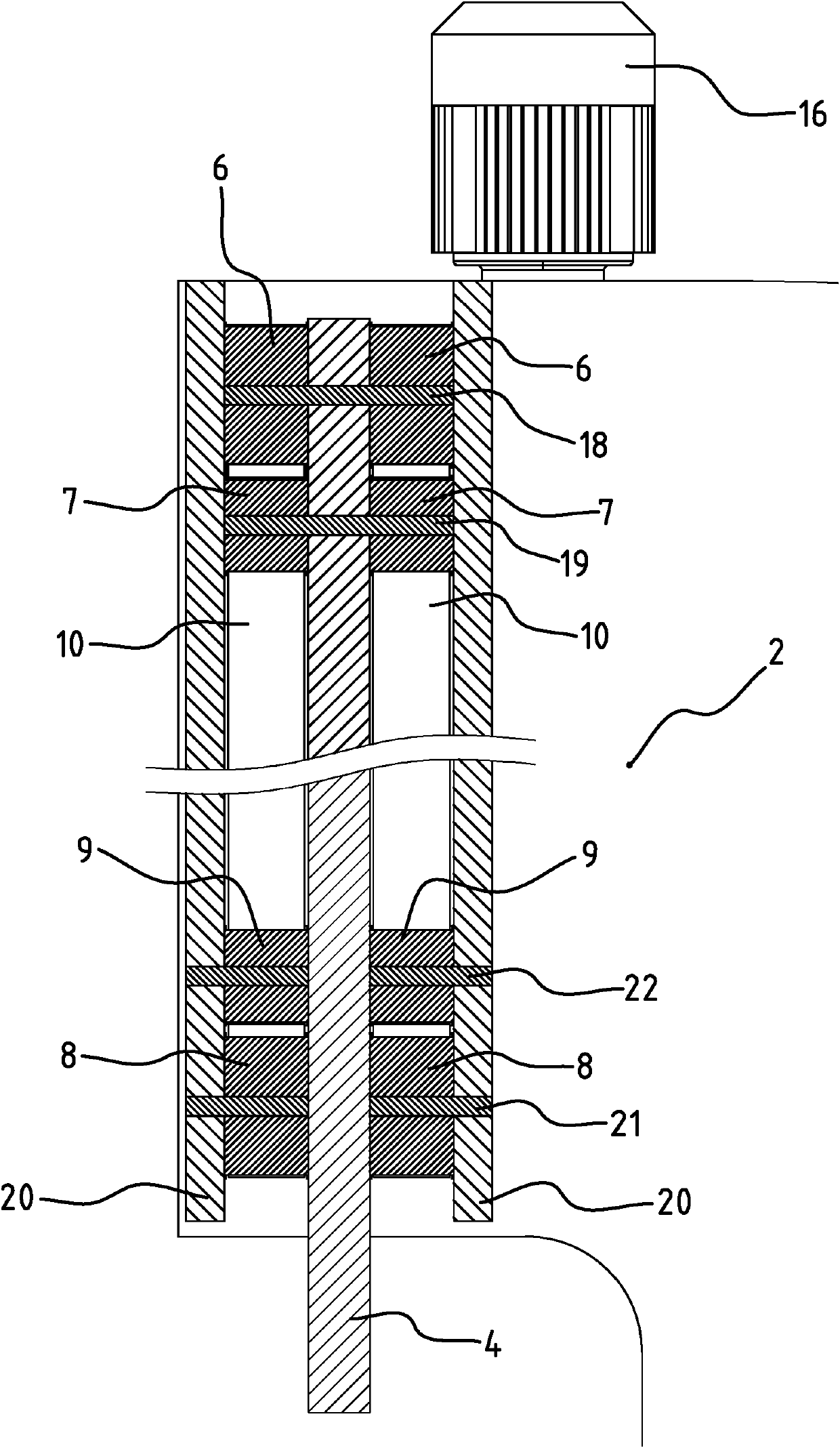

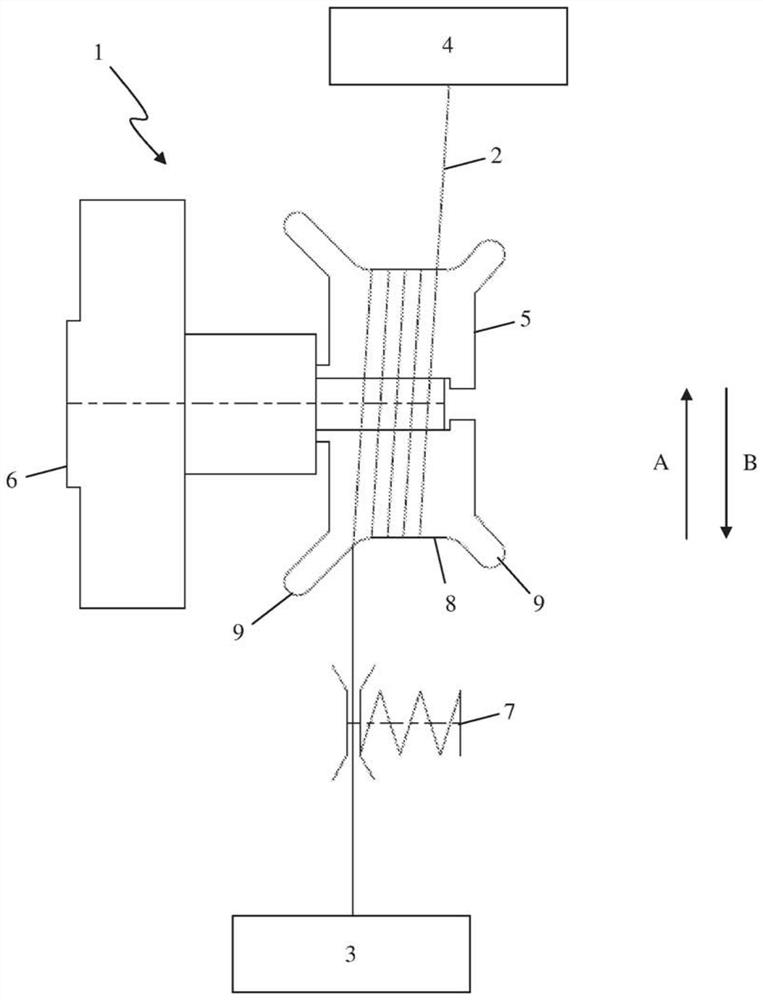

Yarn tensioning system and method for keeping a yarn which is taken from a yarn storage system to a yarn take-off system of a weaving machine under tension

ActiveCN108349680ACalculate lengthRelease feasibilityFilament handlingPile-fabric loomsYarnStructural engineering

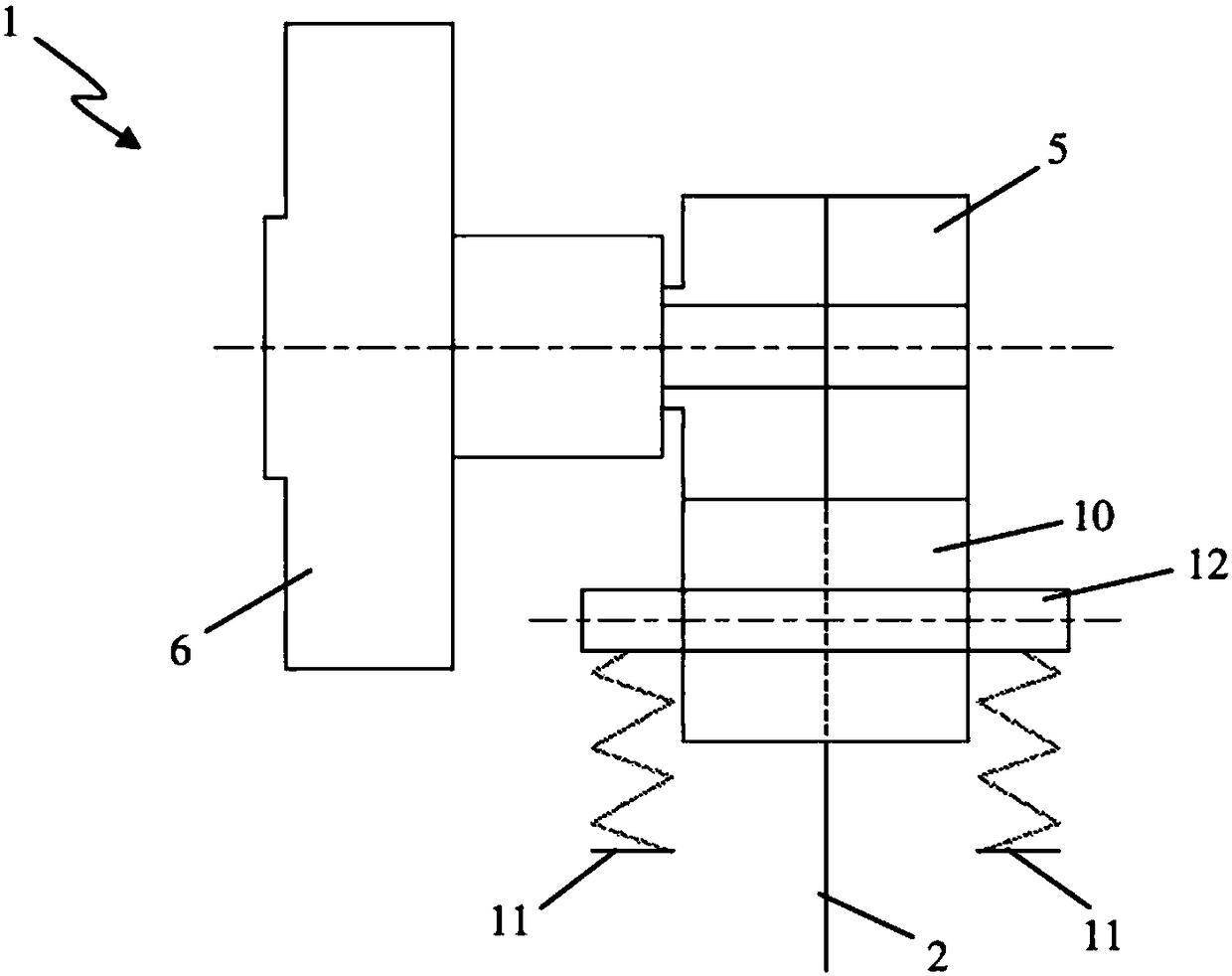

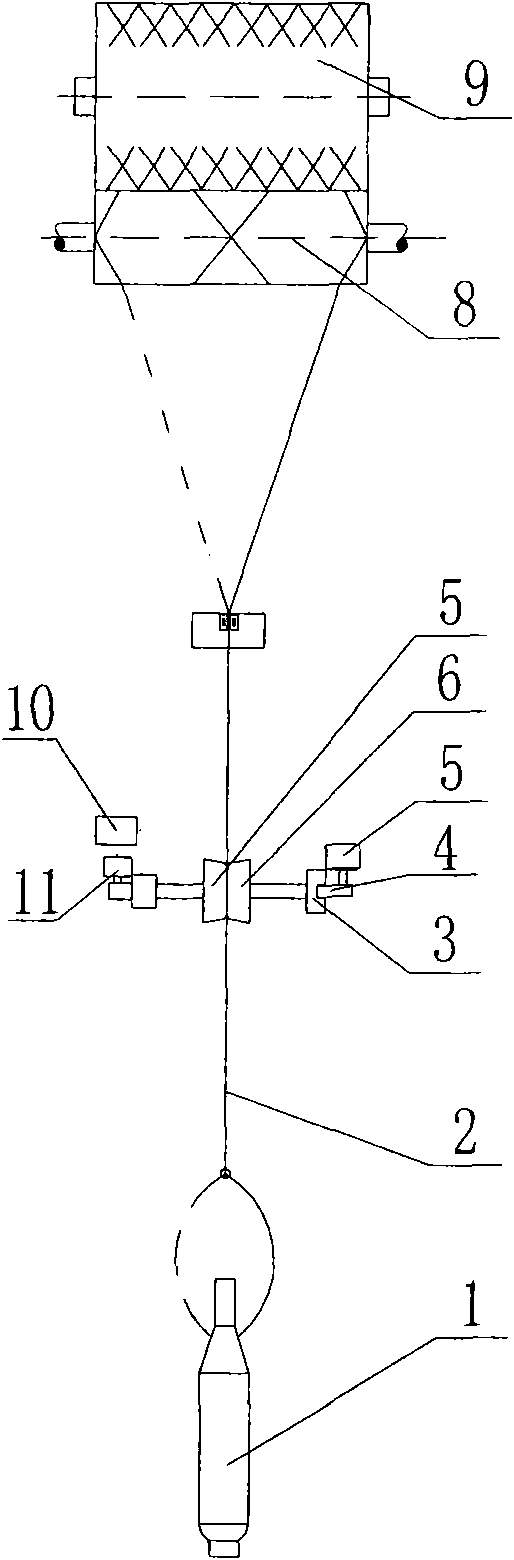

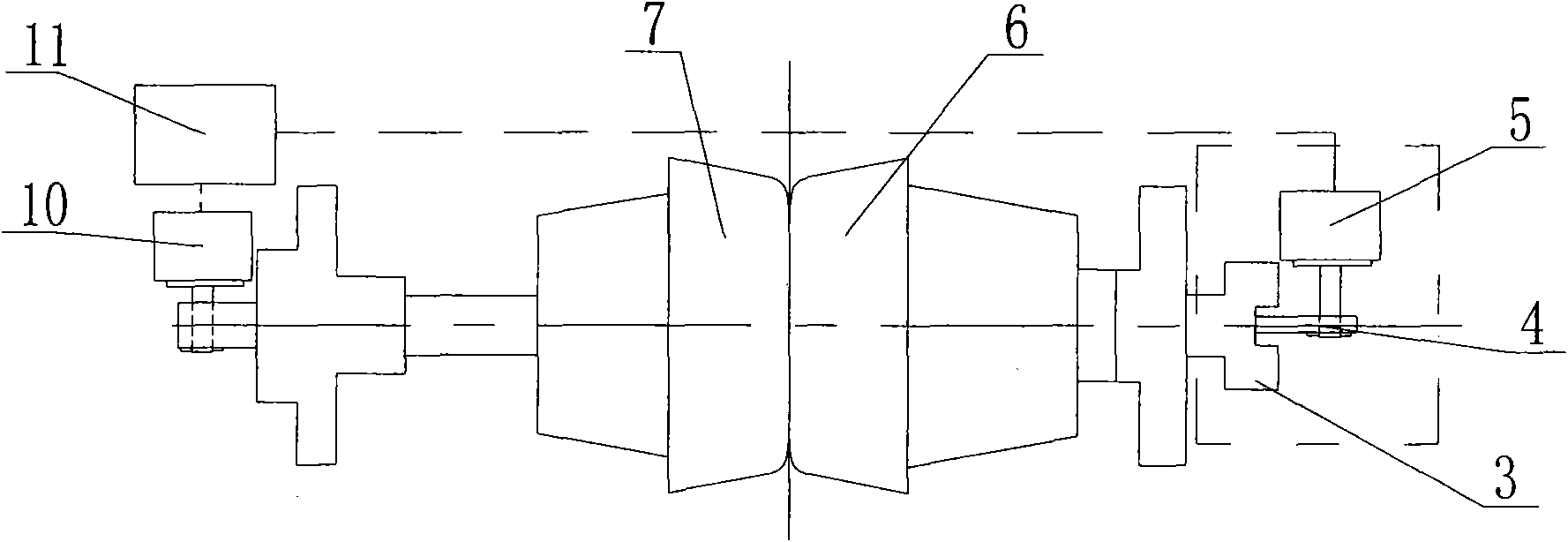

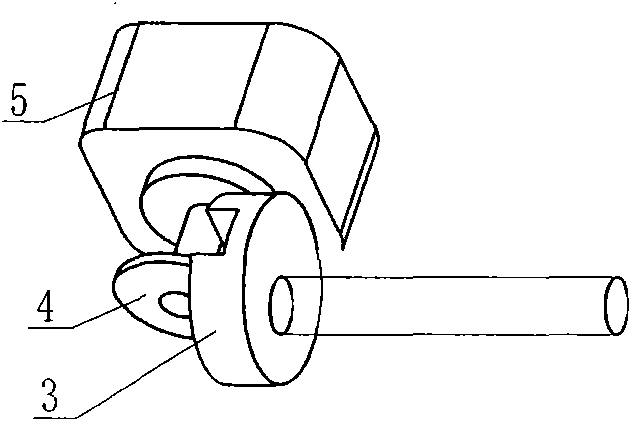

The present invention relates to a yarn tensioning system (1) for keeping at least one yarn (2) which is taken from a yarn storage system (3) to a yarn take-off system (4) of a weaving machine under tension, comprising a brake roller (5) around which the yarn (2) is at least partially wound and a motor (6) for supplying a torque to the brake roller (5), which is actuable in generator operation tokeep the yarn (2) under tension between the brake roller (5) and the yarn take-off system (4). In addition, the present invention relates to a weaving machine comprising such a yarn tensioning system(1) and a method for keeping at least one yarn (2) under tension which is taken from a yarn storage system to a yarn take-off system.

Owner:N V MICHEL VAN DE WIELE

Tension control device and tension regulation method of automatic winder

The invention provides a tension control device of an automatic winder, which comprises a fixed tension disc and a movable tension disc clamping yarns, and is characterized in that the fixed tension disc and the movable tension disc are provided with a tension disc rotary driving mechanism which is composed of a first stepping motor and a transmission component; a rotatable movable tension disc is movably sheathed on one end of a tension shaft; a cam is arranged on the shaft of a second stepping motor; the cam triggers the other end of the tension shaft to displace, and regulates the interval and the magnitude of the holding force of the movable tension disc and the fixed tension disc; the first stepping motor and the second stepping motor are controlled by a stepping motor controller. The tension control device has simple and compact structure, good reliability and stability, and convenient regulation. The tension regulation method of the automatic winder provided by the invention can accurately control yarn tension, leads the yarn tension to be kept constant, and improves the stability of yarn tension, the reliability of the system operation and the molding quality of cone yarns.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

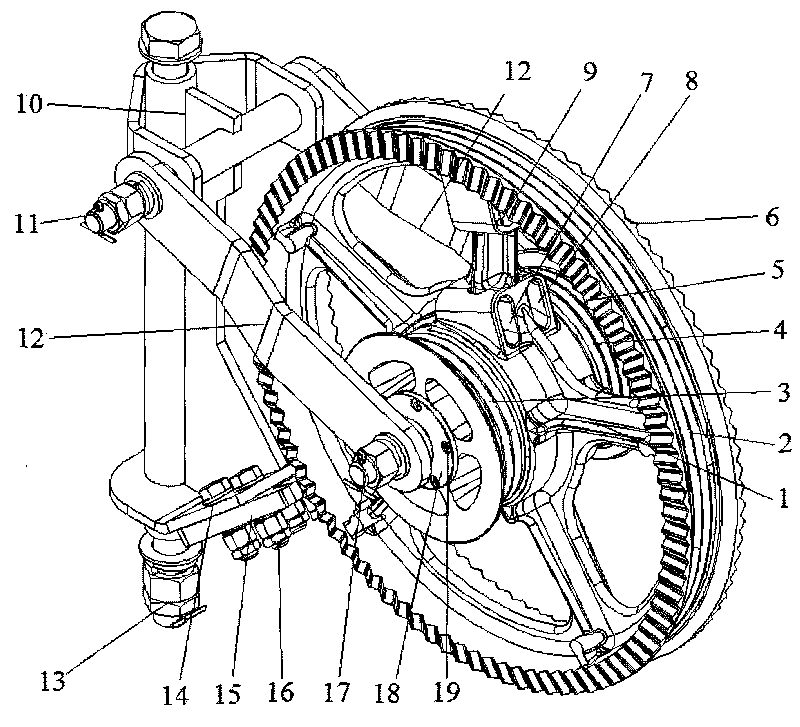

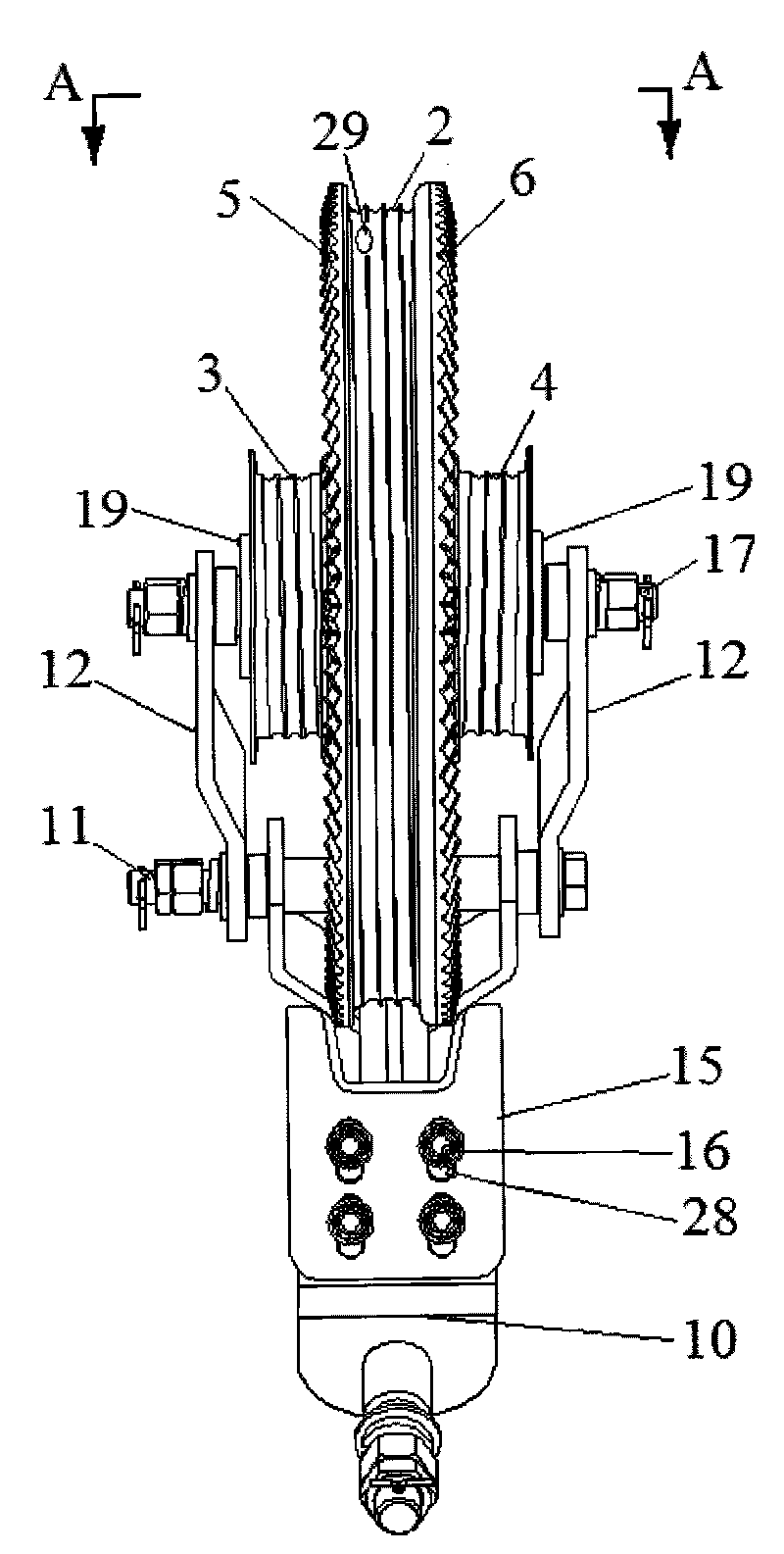

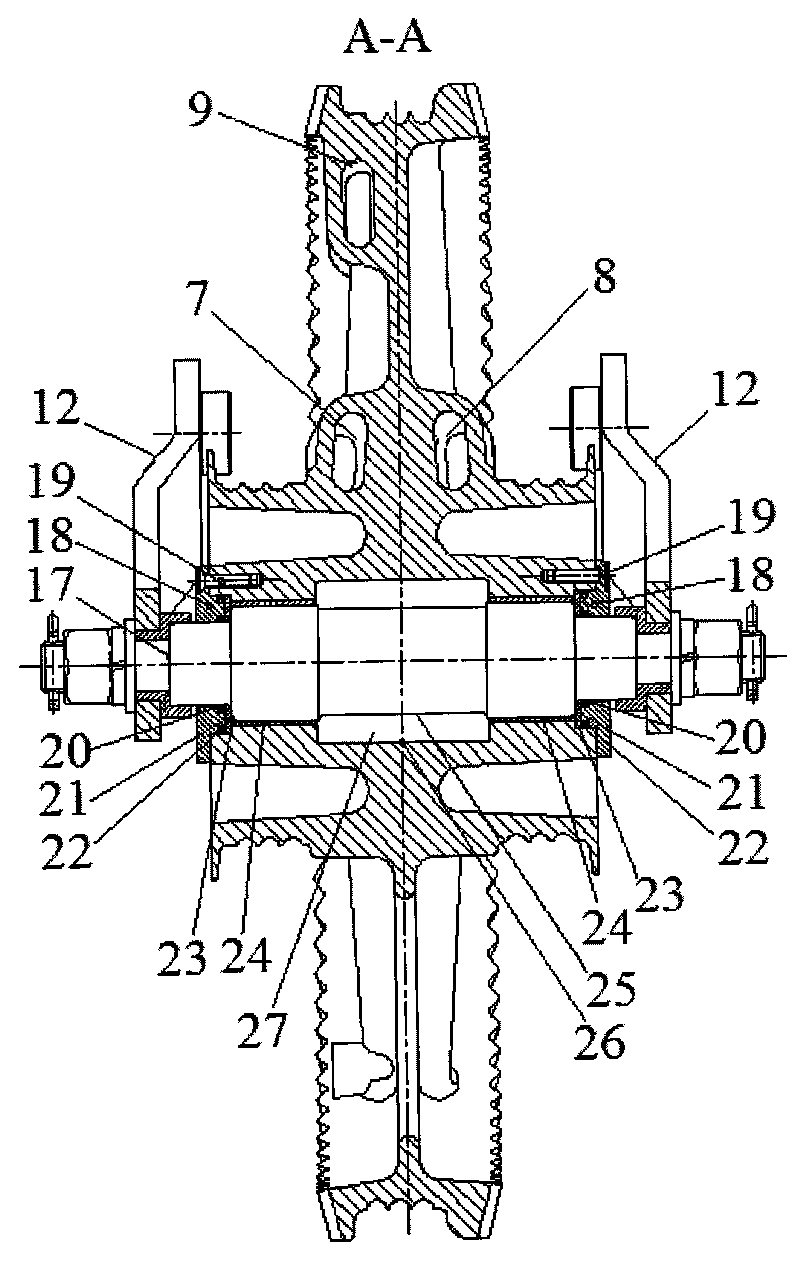

Side braking ratchet wheel tension compensation device of electrization railway

ActiveCN101695907ASolve the problem of broken teethSafe and reliable brakingTrolley linesEngineeringContact line

The invention relates to a side braking ratchet wheel tension compensation device of an electrization railway, comprising a braking support frame. The braking support frame is connected with a ratchet wheel shaft through two rotary arms; the ratchet wheel shaft and a ratchet wheel body are coaxially arranged through a sliding bearing made of self-lubricating composite material; the ratchet wheel body can rotate around the ratchet wheel shaft and consists of a hub, a plurality of radial plates and a wheel flange; a tension wheel groove A and a tension wheel groove B are respectively arranged at the two sides of the radial plates of the ratchet wheel body and the outer circumference surface of the hub; rope troughs are arranged in the two grooves; the outer circumference surface of the wheel flange is provided with a ratchet wheel trough the bottom of which is cast with a rope trough and a steel wire rope hole; braking gear rings are symmetrically cast on the two sides of the wheel flange; and the lower end of the braking support frame is fixedly connected with a buffer brake device. The invention is suitable for a working state that a carrier cable and a contact line slowly change under the influence of environment temperature, overcomes the defects of frequent off-line, arc discharge, burning of a contact line and the like of a pantograph of a locomotive, is free from oil injection and maintenance and has long service life.

Owner:SHAANXI FLYWHEEL HIGH SPEED RAIL EQUIP CO LTD

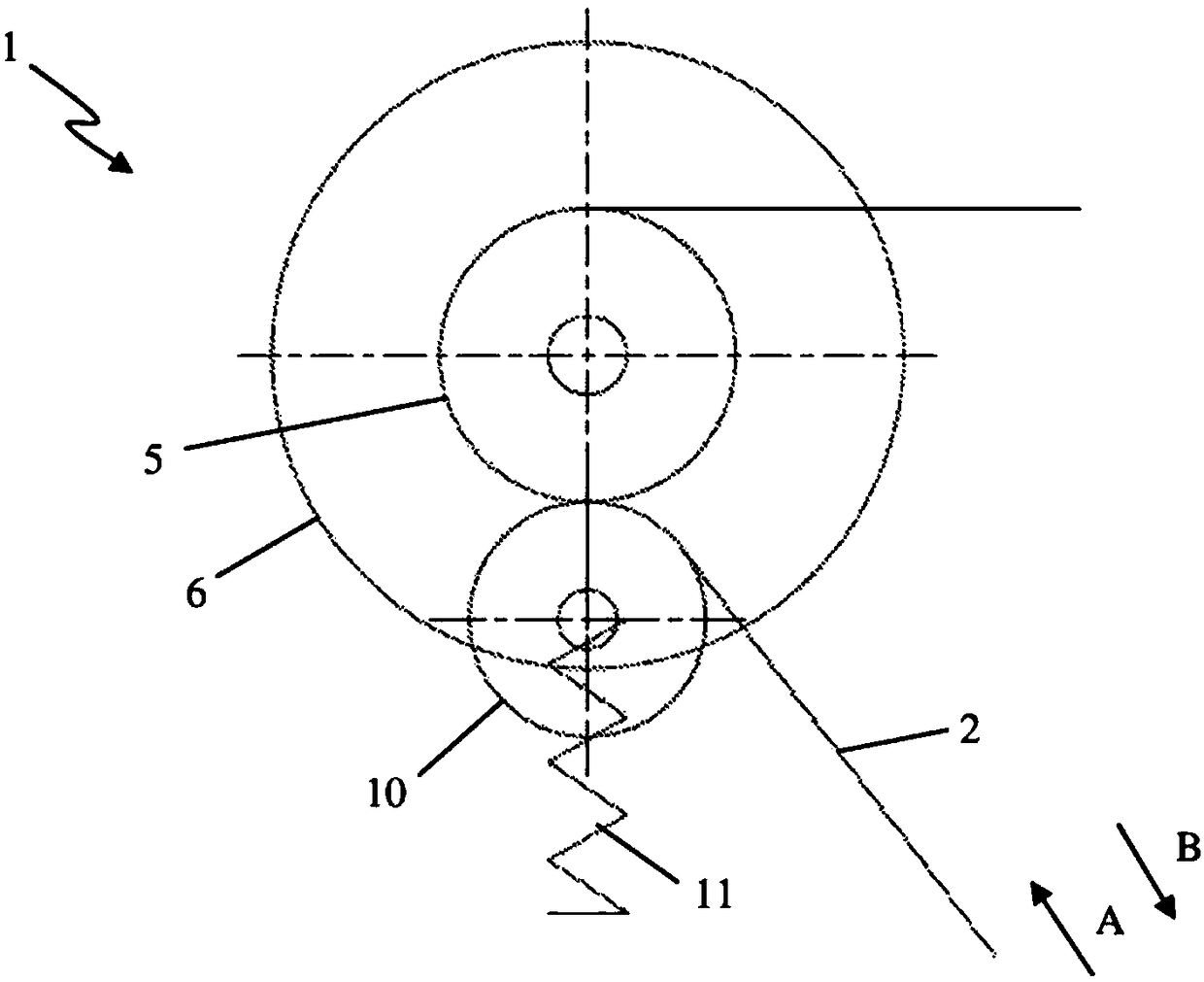

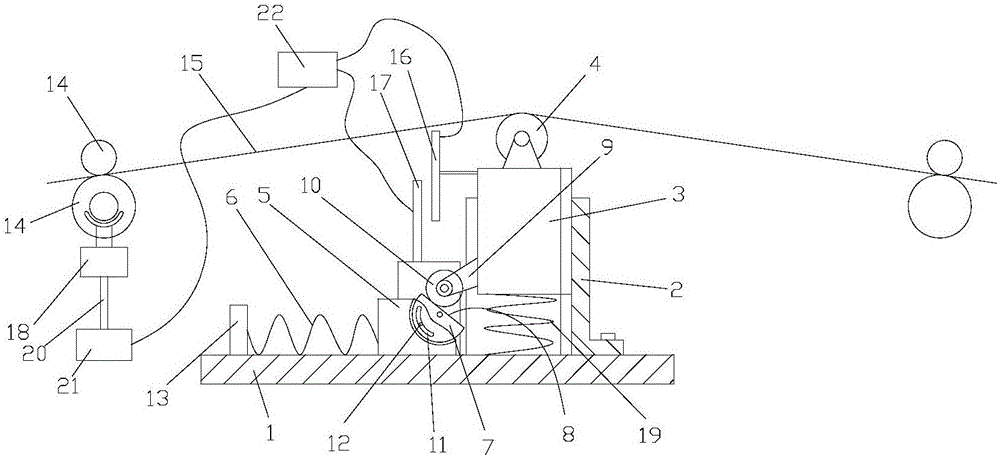

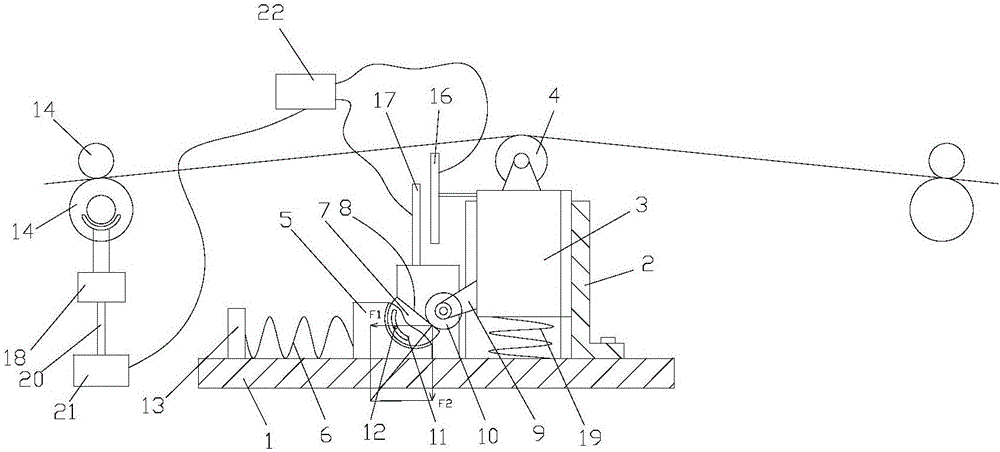

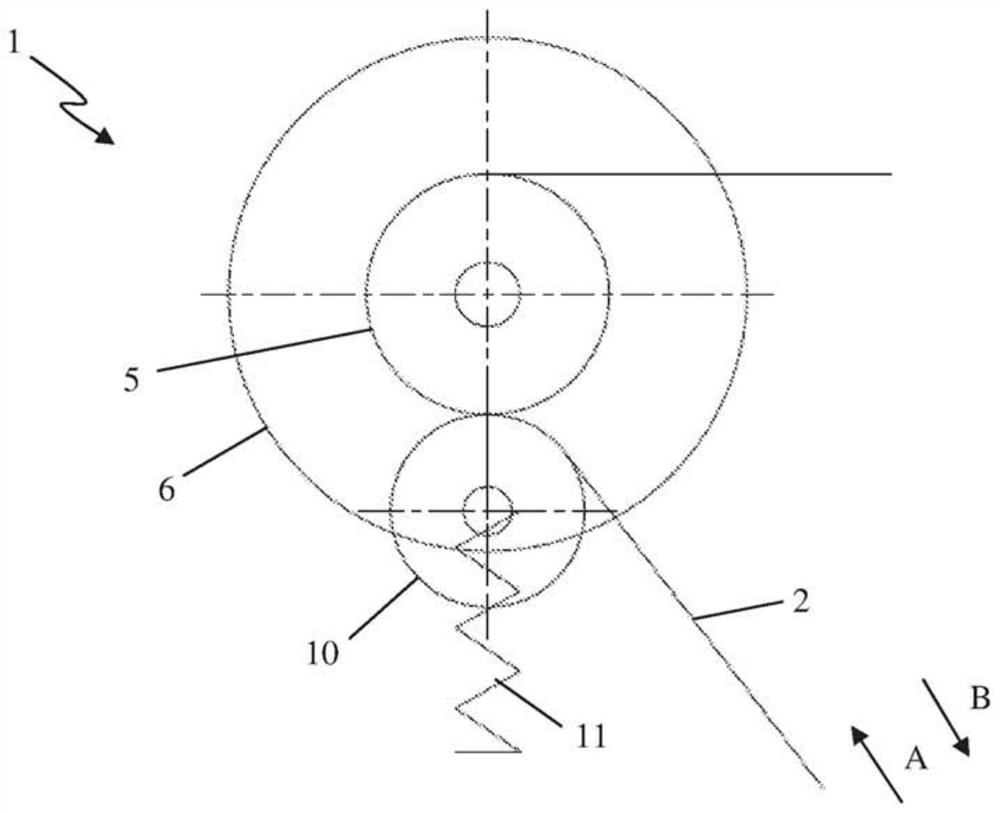

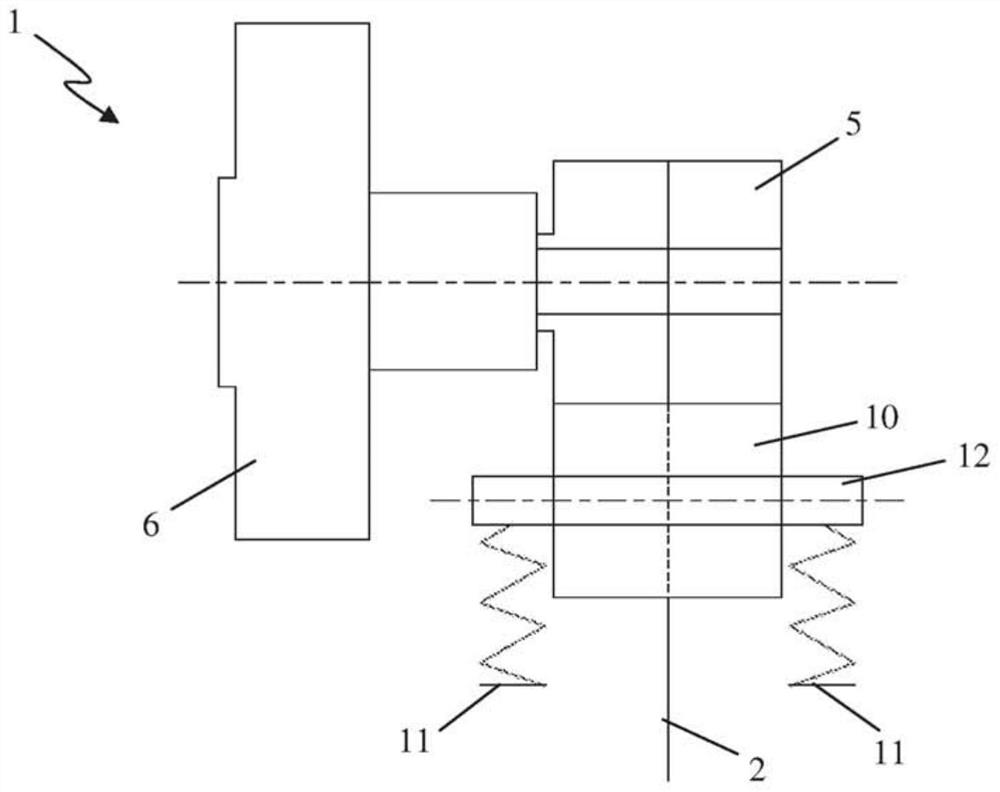

Tensioning device capable of achieving automatic adjustment

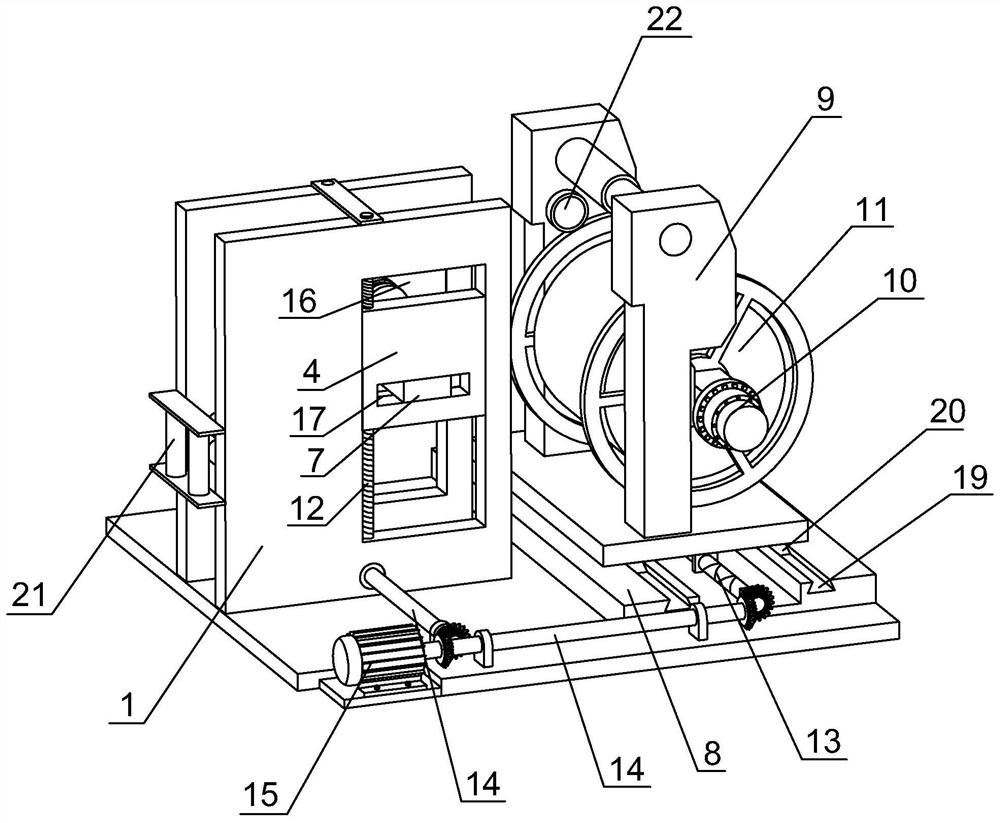

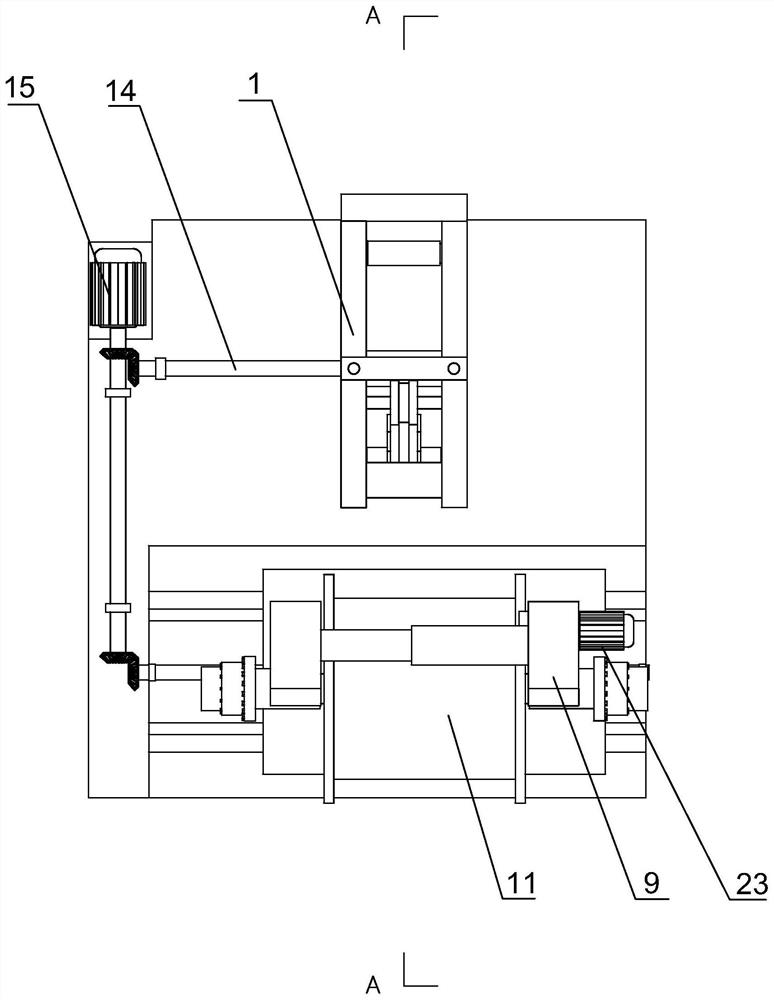

The invention discloses a tensioning device capable of achieving automatic adjustment. According to the tensioning device capable of achieving automatic adjustment, a sliding block is provided with an inclined plane with the tilting angle capable of being adjusted; and a guide post is provided with a guide part which stretches out of a guide sleeve and travels on the inclined plane, so that the inclined plane forces the guide part to drive the guide post to move vertically, and a tensioning wheel can be driven to move. By means of the tensioning device, the equivalent elastic coefficient of each spring can be changed by changing the tilting angle of the inclined plane, and therefore different tension ranges can be provided, namely the high range or the low range. Moreover, the influence on the elastic coefficients by spring failure can be compensated for by adjusting the tilting angle. Tension change caused by pressure variation between driving rollers can be adjusted through an adjusting mechanism, and accordingly the tension can be basically kept constant. In addition, the comovement relation between the movement directions of the tensioning wheel and the driving rollers is established through a sliding resistor, a controller and a servo motor, and thus the automatic adjustment function of the tensioning wheel is improved.

Owner:赵旭

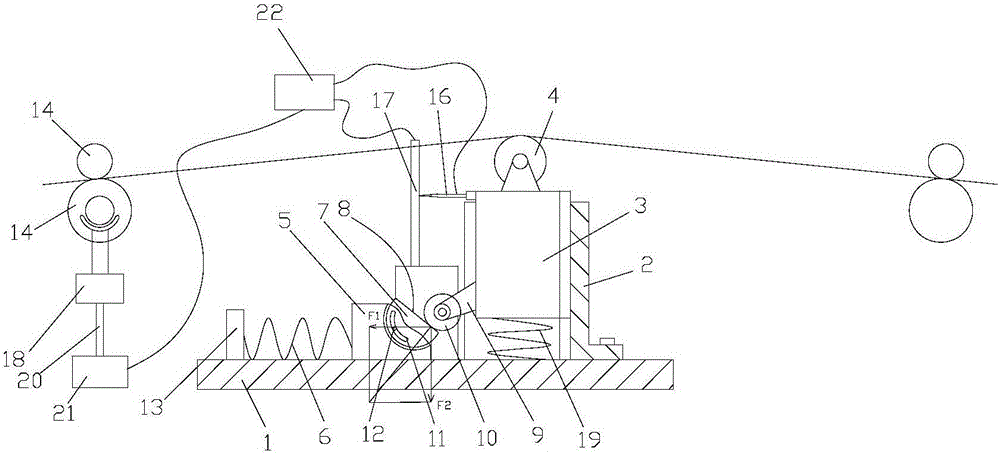

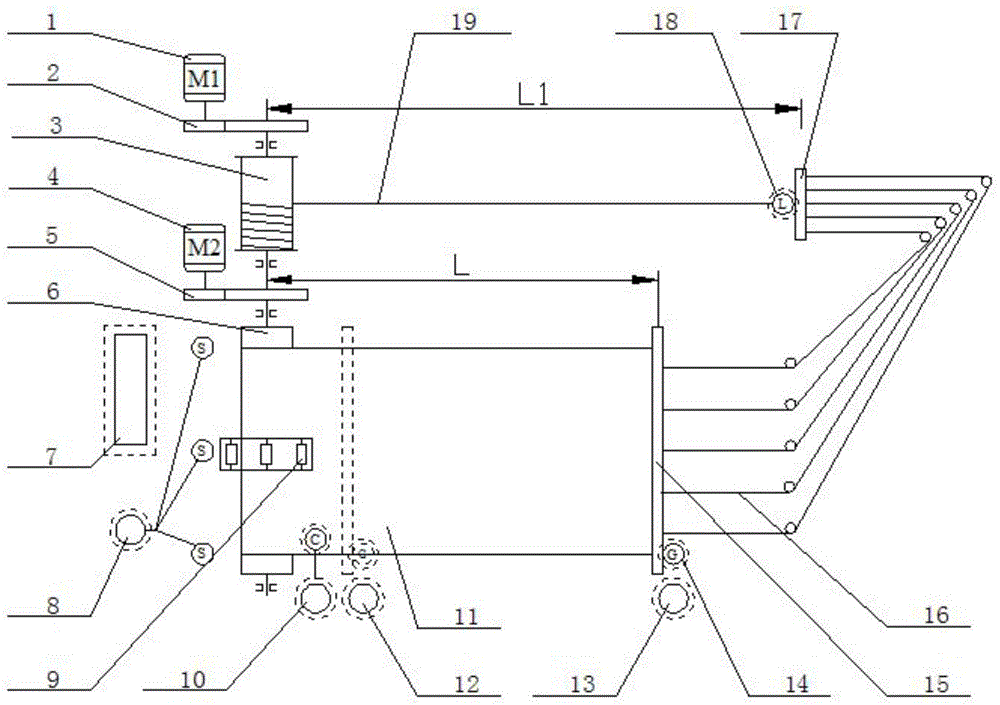

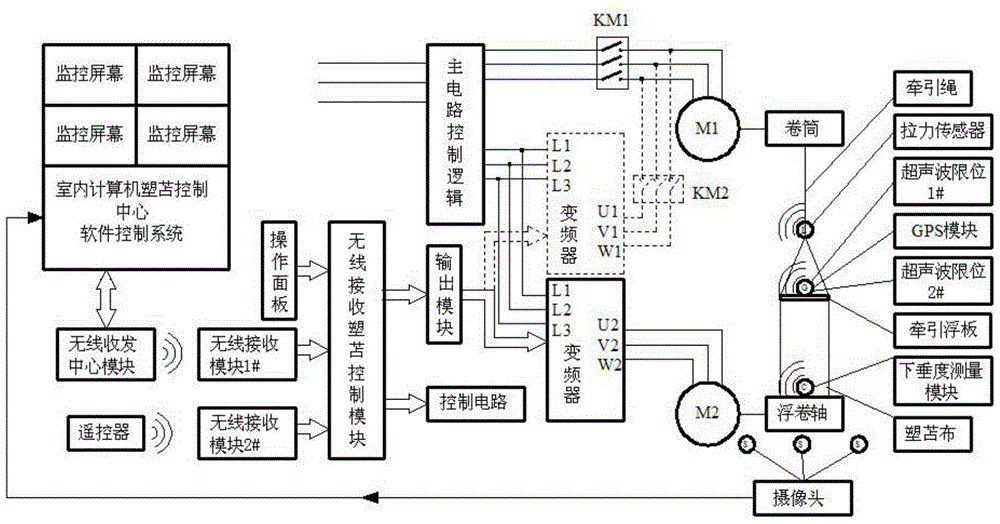

Automatic control device for floating winding type plastic cloth of salt pond

InactiveCN105217501AImprove reliabilityImprove securityWinding mechanismsAutomatic controlAutomatic train control

Th invention relates to an automatic control device for a floating winding type plastic cloth of a salt pond. The automatic control device is characterized in that the automatic control device comprises the plastic cloth, a floating winding shaft, a floating winding shaft motor, a floating winding shaft reduction gearbox, a traction floating plate, a floating plate traction rope, a winding drum, a winding drum reduction gearbox, a winding drum motor and a control device body; one end of the plastic cloth is wound around the floating winding shaft; the floating winding shaft is driven by the floating winding shaft motor and the floating winding shaft reduction gearbox; the other end of the plastic cloth is fixed to the traction floating plate; the traction floating plate is connected with the winding drum through the floating plate traction rope in a wound mode; the winding drum is driven by the winding drum motor and the winding drum reduction gearbox; the floating winding shaft motor and the winding drum motor are controlled by the control device body synchronously. The automatic control device is scientific and reasonable in design. The key technical problem of automatic control over a plastic cloth system of the salt pond is solved. Automatic cooperative control over the whole process of spreading and traction of the plastic cloth in the floating winding type plastic cloth system is achieved.

Owner:TIANJIN BOYADA TECH +1

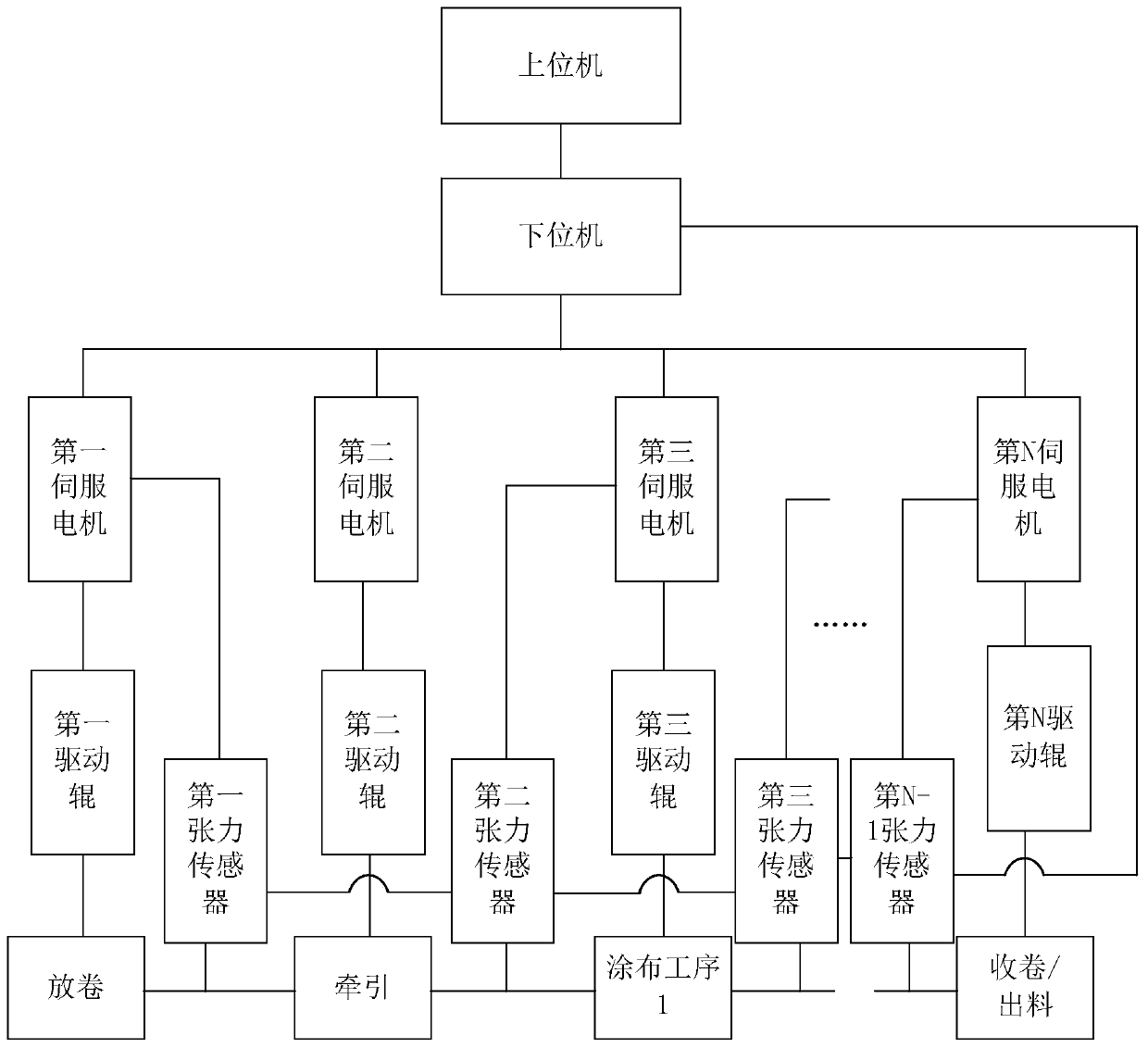

Tinsel coating control system and method

ActiveCN111591813ARealize closed-loop controlGuaranteed tensionFunction indicatorsWebs handlingLoop controlControl system

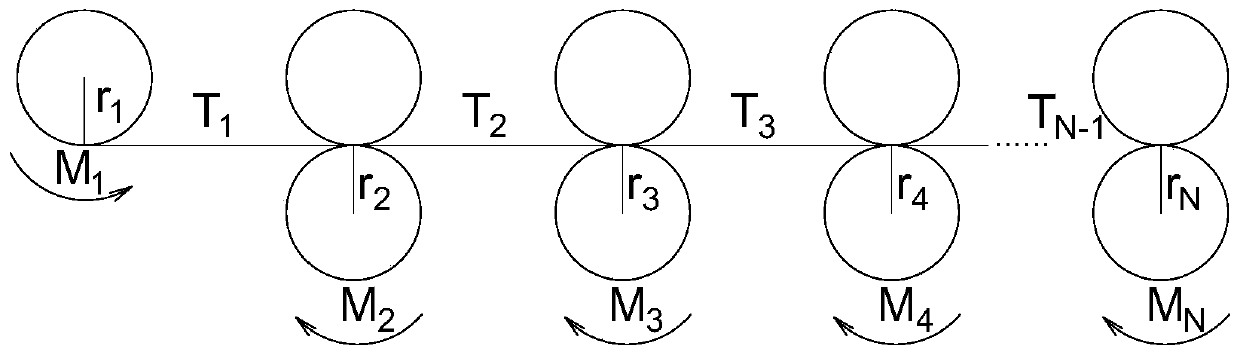

The invention relates to the technical field of coating processes, and provides a tinsel coating control system and method. The system comprises N servo motors in communication and interaction with alower computer and (N-1) tension sensors which correspond to the N servo motors and are used for collecting the tension of tinsel at the corresponding position. The tension sensors feed back tension values to corresponding response motors achieving closed-loop control, the corresponding servo motors adjust the torque of a driving roll according to the fed-back tension values, the constant tensionof the tinsel is kept, closed-loop control over tinsel coating is achieved, and the coating quality and the equipment precision are further improved.

Owner:QINGDAO GUILAI TECH CO LTD

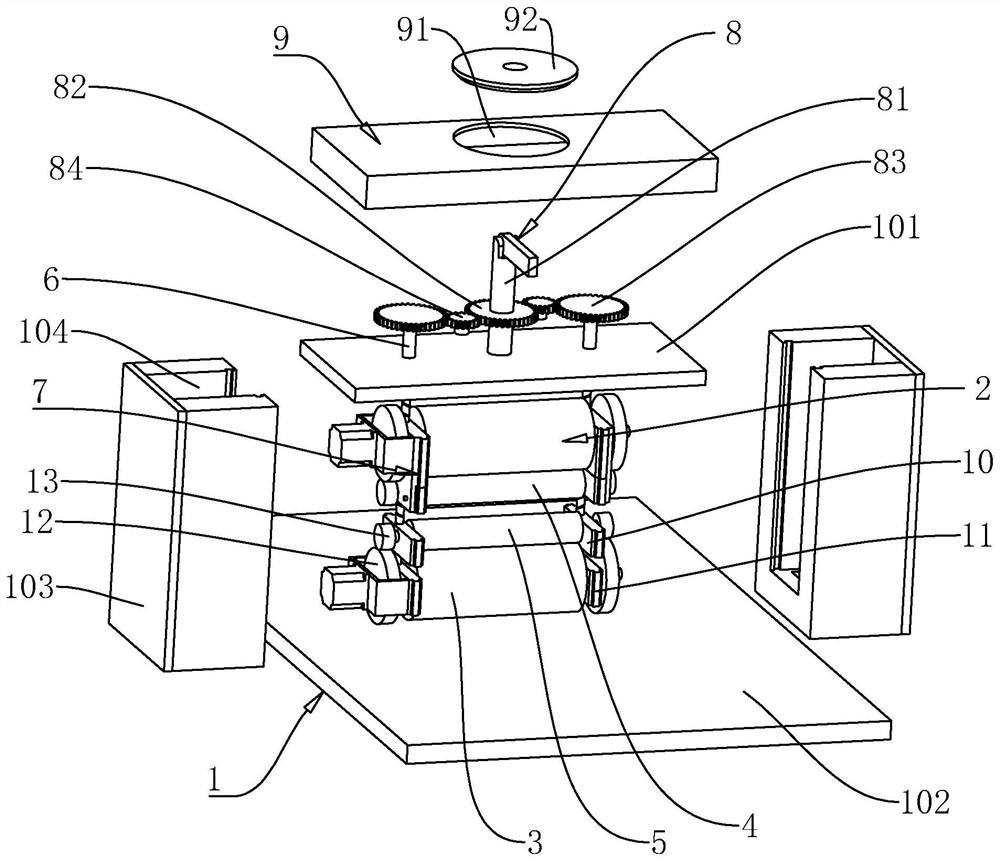

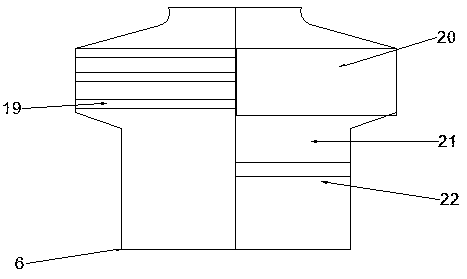

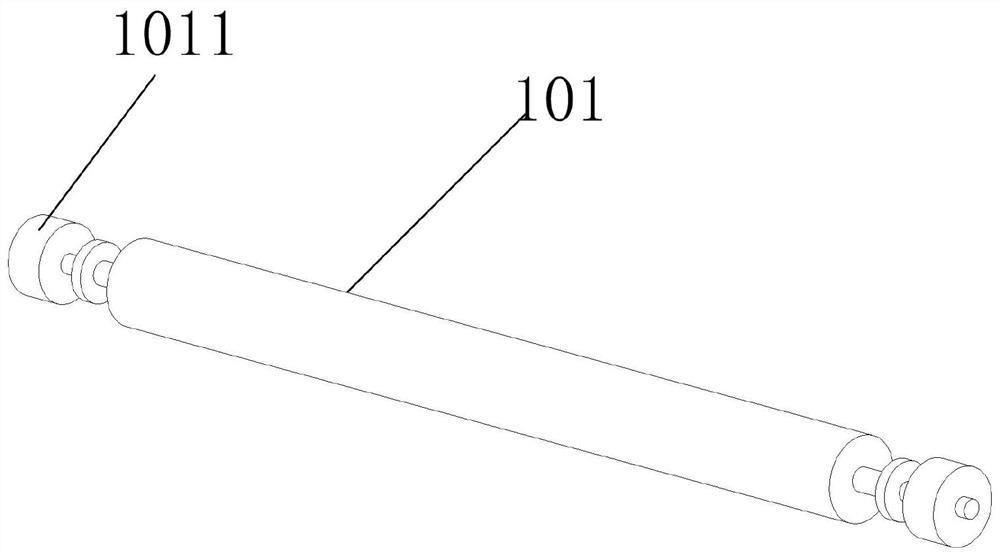

Four-roller tabletting device

InactiveCN112453057AUniform thicknessAvoid the phenomenon that the middle is thick and the sides are thinMetal rolling stand detailsTensioning/braking arrangementsVertical planeClassical mechanics

The invention relates to a four-roller tabletting device. The four-roller tabletting device comprises a rack, an upper supporting roller, a lower supporting roller, an upper rolling roller, a lower rolling roller, a roller distance adjusting assembly used for adjusting the distance between the upper rolling roller and the lower rolling roller, and a power assembly driving the upper supporting roller, the lower supporting roller, the upper rolling roller and the lower rolling roller to rotate, wherein the power assembly comprises a motor driving the upper supporting roller and the lower supporting roller to rotate correspondingly, the roller distance adjusting assembly comprises lead screws arranged on the two sides of the rack correspondingly, two sliding pieces matching with the two leadscrews correspondingly and a driving piece for driving the lead screws to rotate, the two ends of the upper supporting roller and the two ends of the upper rolling roller in the length direction are installed on the two sliding pieces correspondingly, the upper supporting roller is located over the upper rolling roller, the lower supporting roller is located under the lower rolling roller, the central axes of the upper supporting roller, the lower supporting roller, the upper rolling roller and the lower rolling roller are located on the same vertical plane, the diameters of the upper supporting roller, the lower supporting roller are consistent, and the diameters of the upper rolling roller and the lower rolling roller are consistent, the diameter of the upper supporting roller is largerthan that of a upper rolling pipe. The four-roller tabletting device has the effect of improving the accuracy of the rolling thickness of a metal sheet.

Owner:深圳盛大首饰有限公司

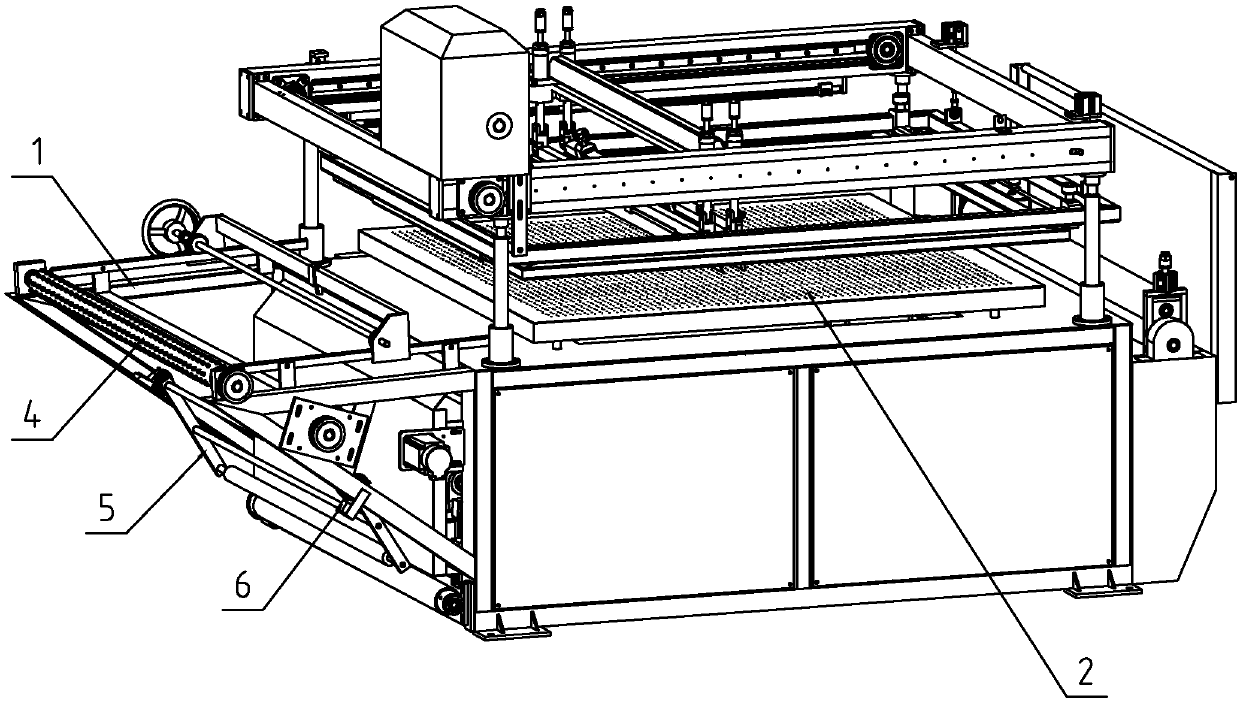

Tensioning device for screen printing machine

PendingCN109605916AReduce pulling forceImprove printing and drying effectScreen printersMagnetic powderMagnetic particle clutch

The invention discloses a tensioning device for a screen printing machine. The technical scheme of the device is characterized by comprising a machine frame, a printing device and a drying device; themachine frame is further provided with a printing tensioning mechanism and a drying tensioning mechanism; the printing tensioning mechanism comprises a tensioning roller and a tensioning motor, wherein the tensioning roller is used for allowing a strip-shaped material to be wound therearound, and an output end of the tensioning motor is provided with a magnetic powder clutch used for driving thetensioning roller to maintain the constant tension of the strip-shaped material; and the drying tensioning mechanism comprises a gravity tensioning frame capable of tensioning the strip-shaped material wound around the tensioning roller under the action of gravity, wherein the gravity tensioning frame is located at a feeding end of the drying device, one end of the gravity tensioning frame is rotationally connected to the machine frame, the other end of the gravity tensioning frame is provided with a gravity roller, and the gravity tensioning frame can maintain the strip-shaped material woundaround the tensioning roller in a tensioned state through the gravity roller under the action of gravity in the process of axially rotating around the machine frame. The tensioning device can keep thestrip-shaped material automatically tensioned, so that the printing effect and the drying effect of the strip-shaped material are improved.

Owner:温州欧宏机械有限公司

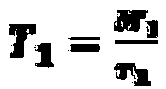

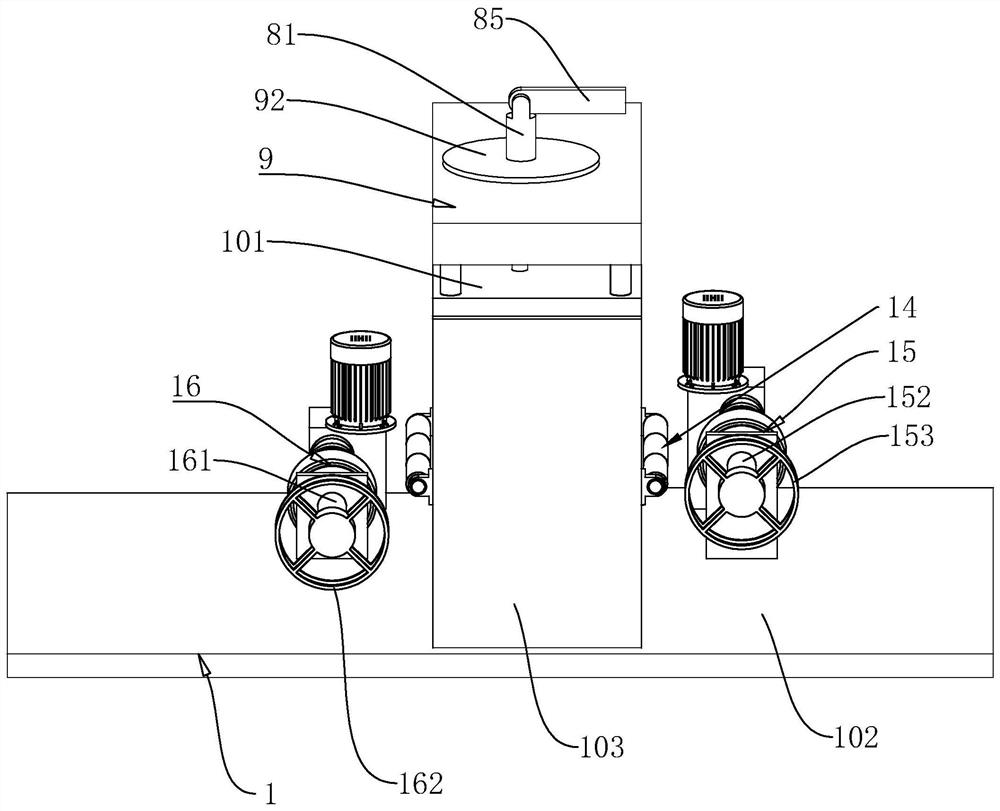

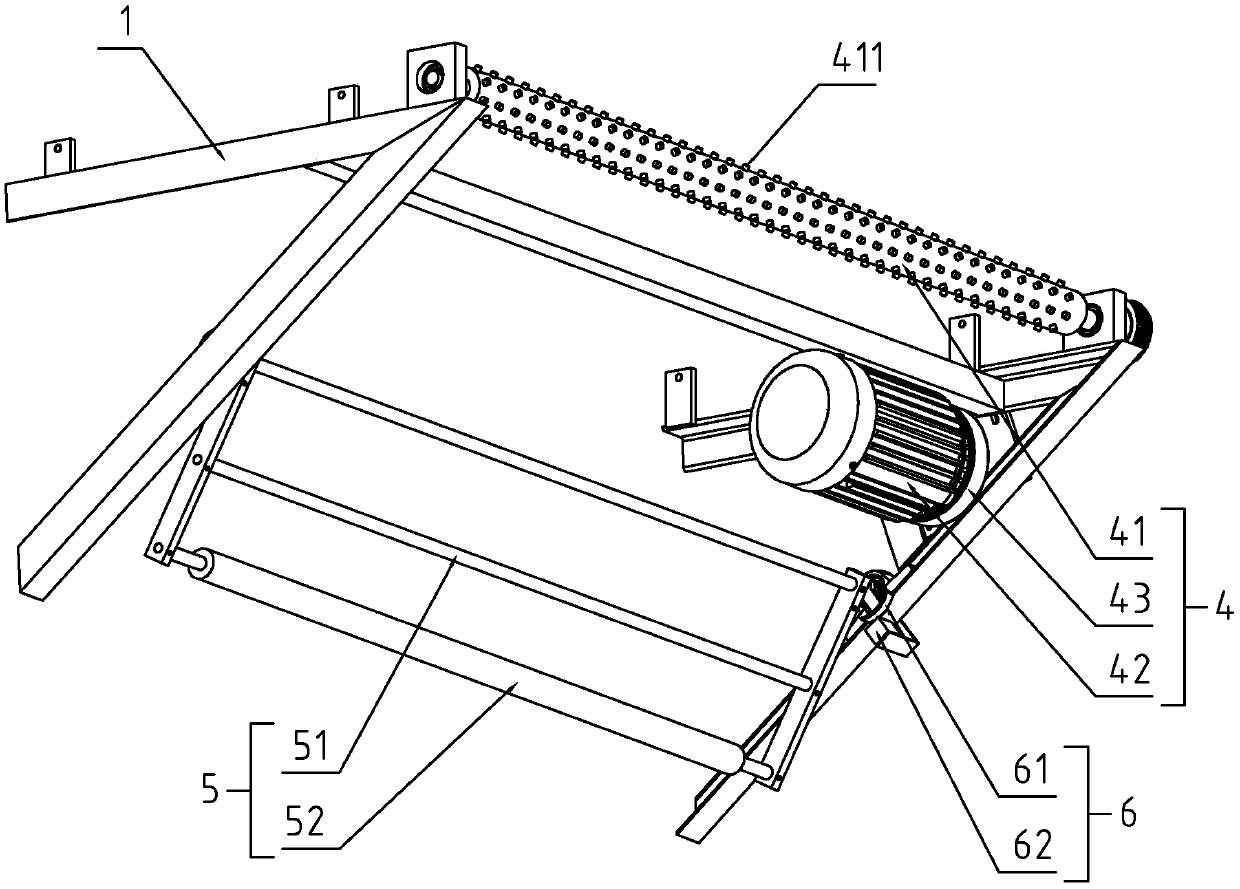

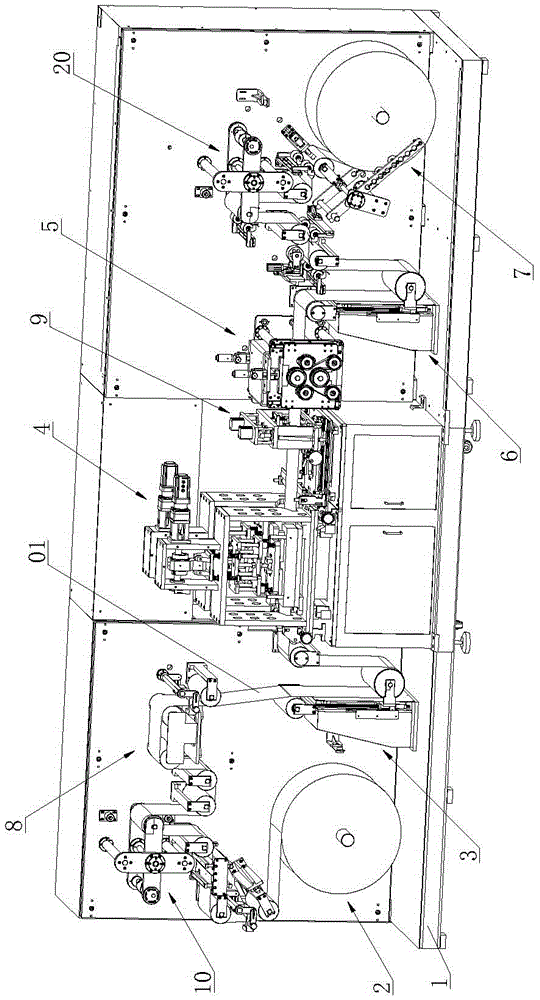

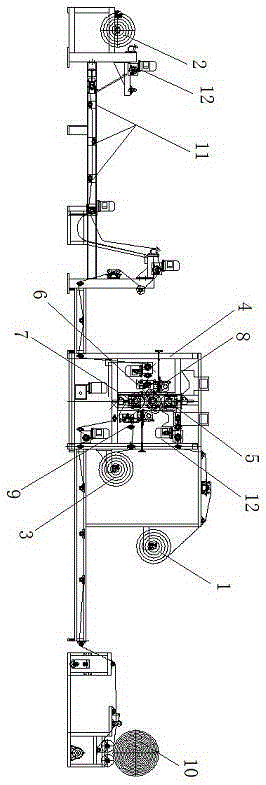

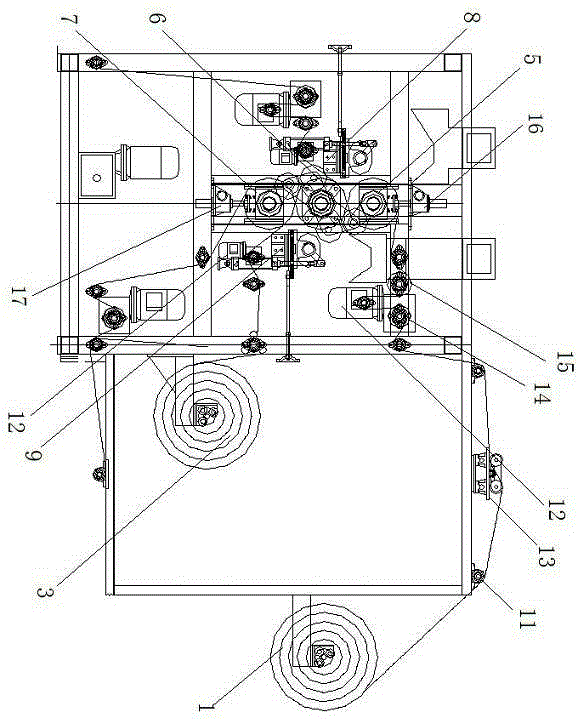

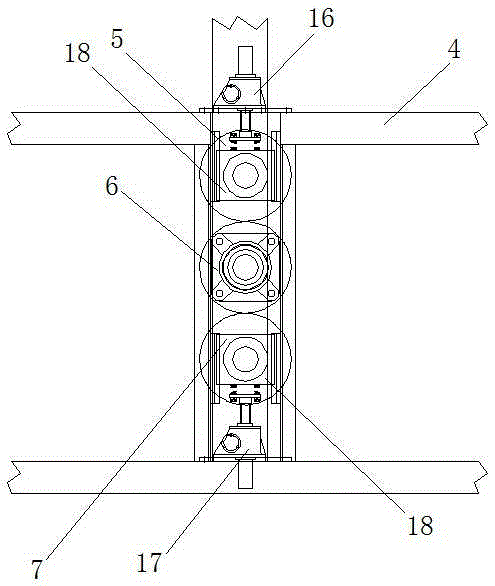

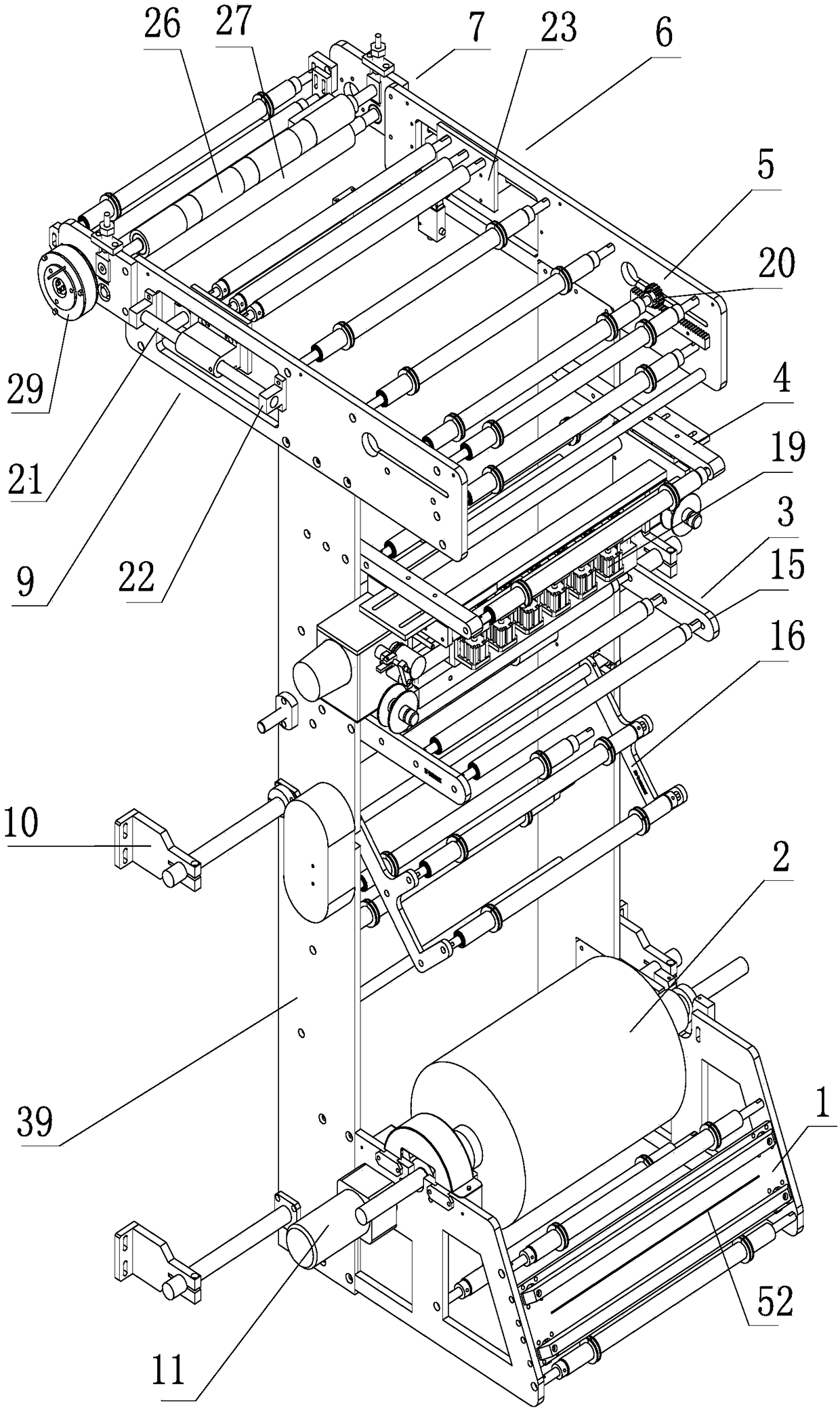

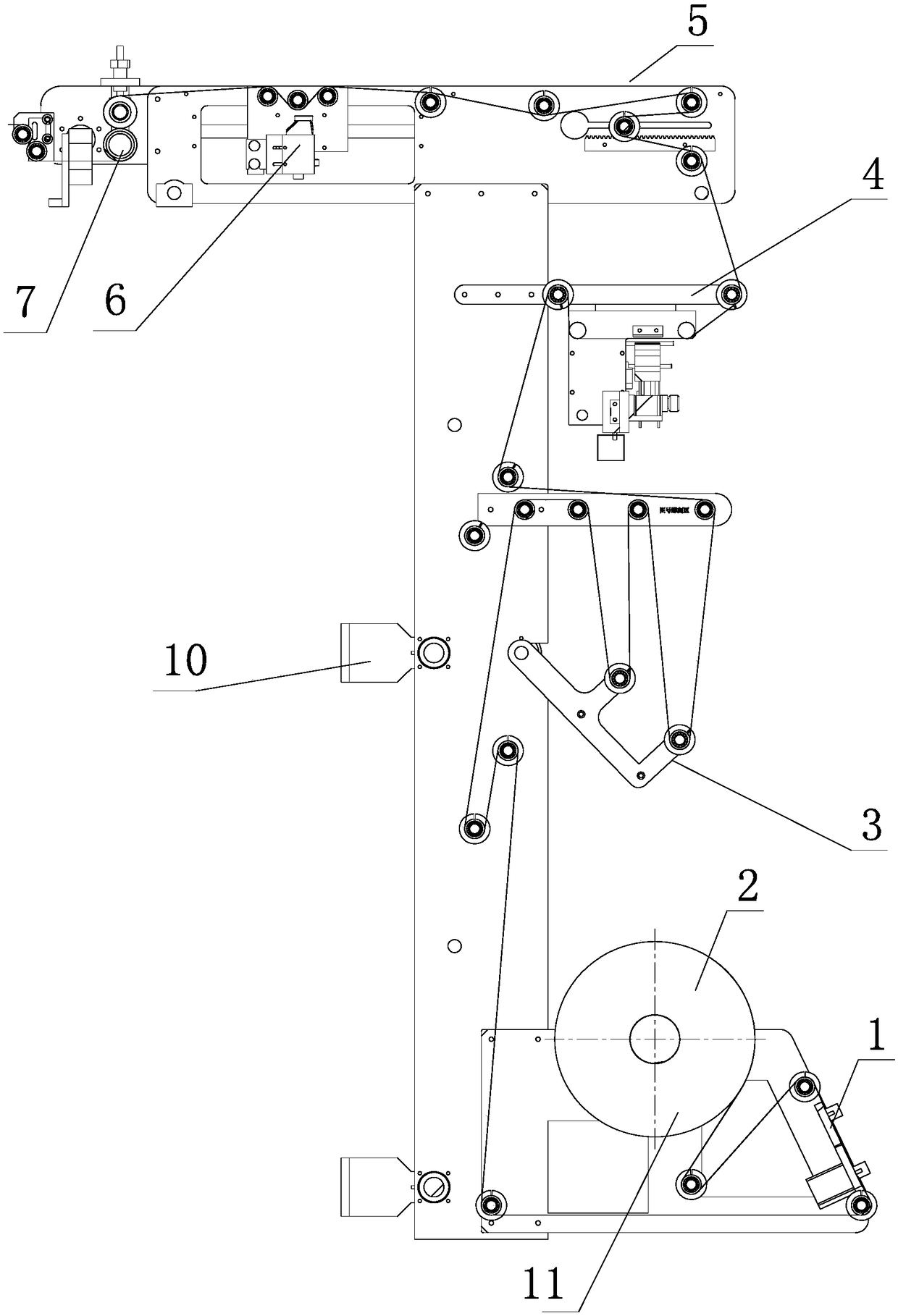

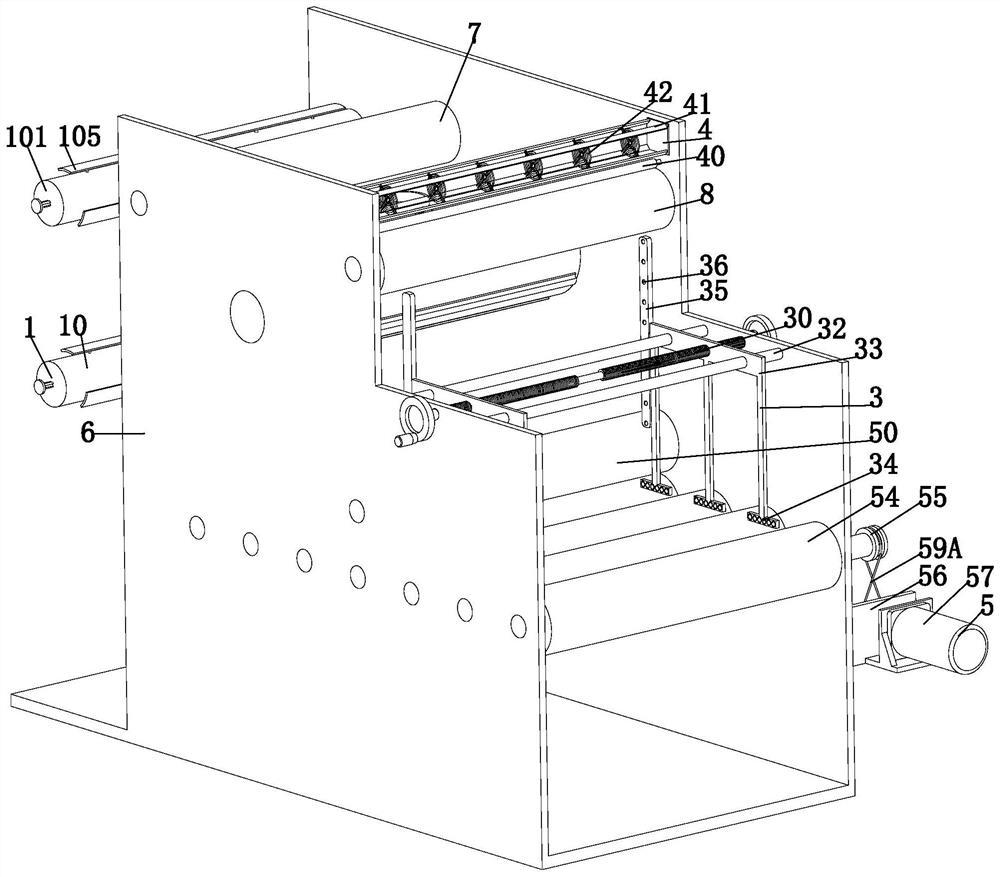

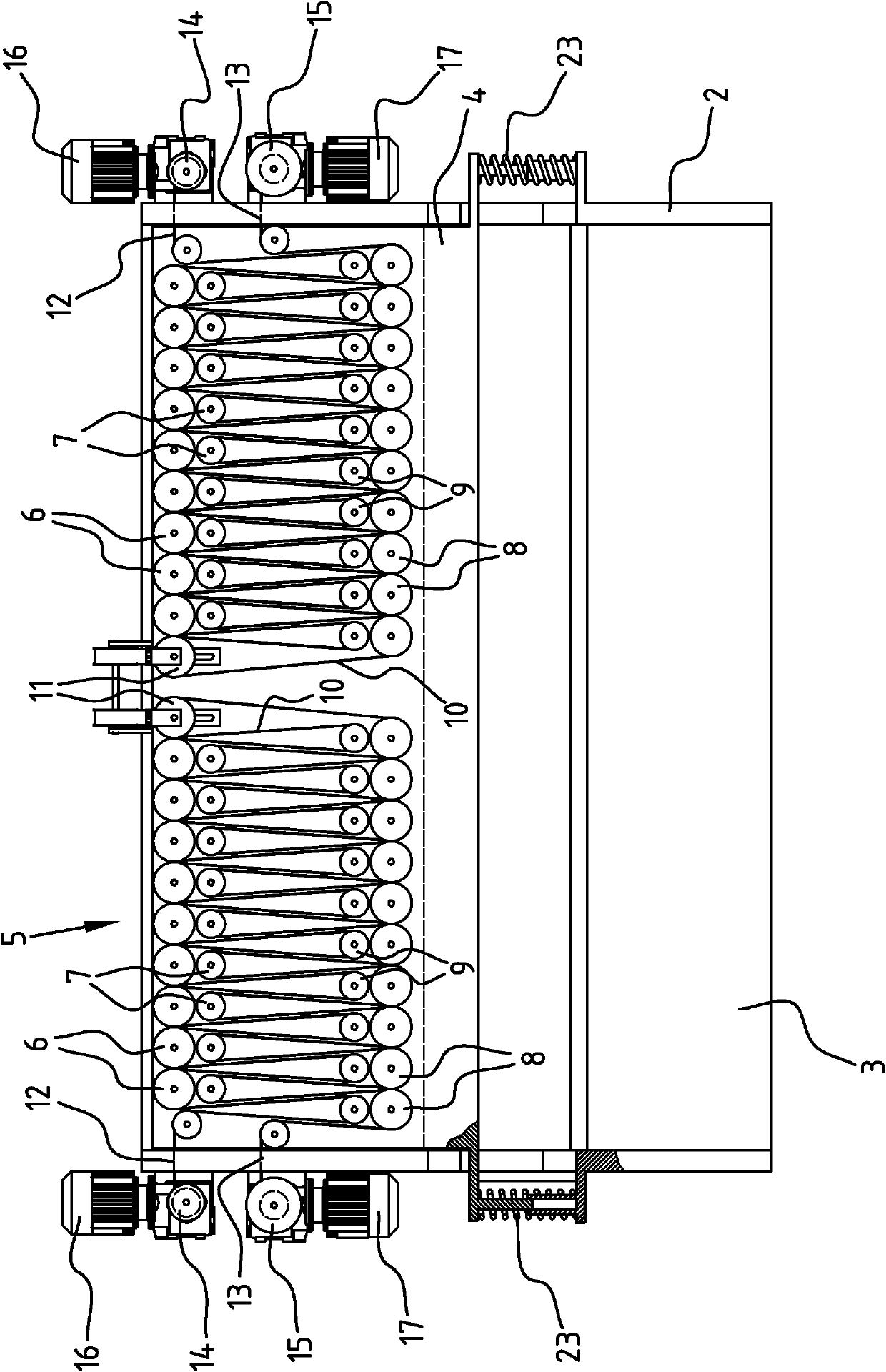

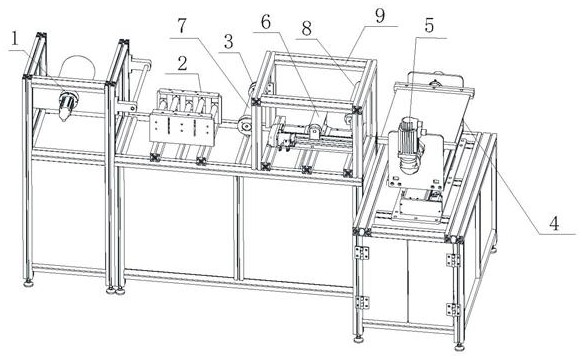

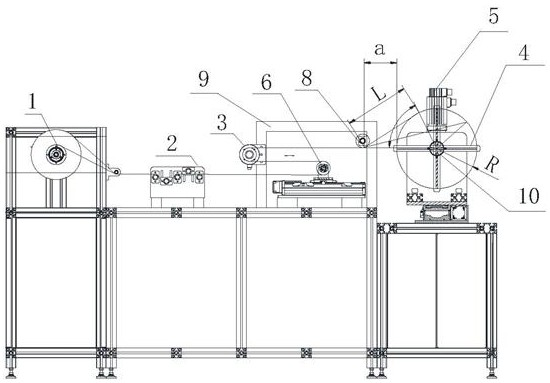

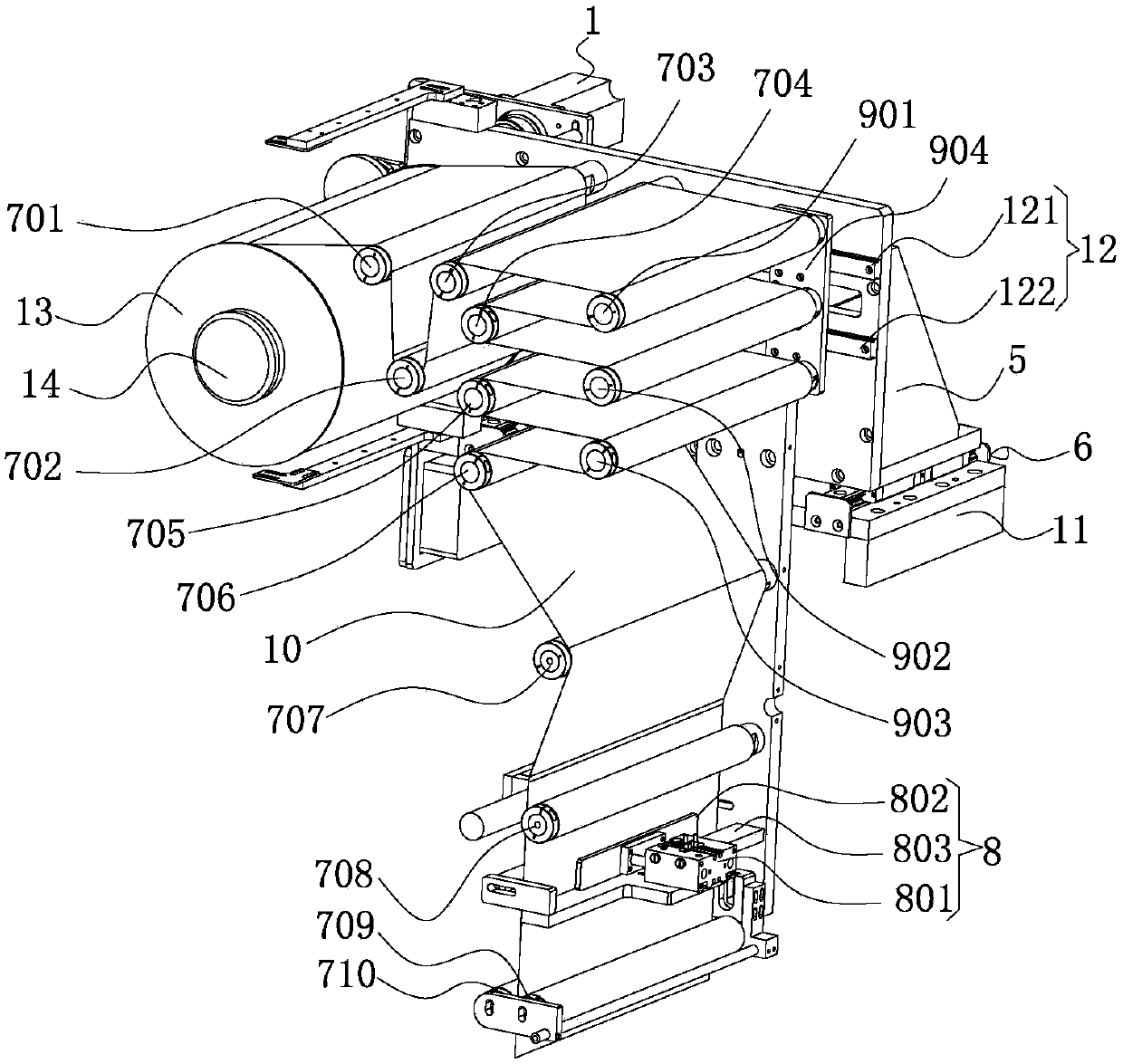

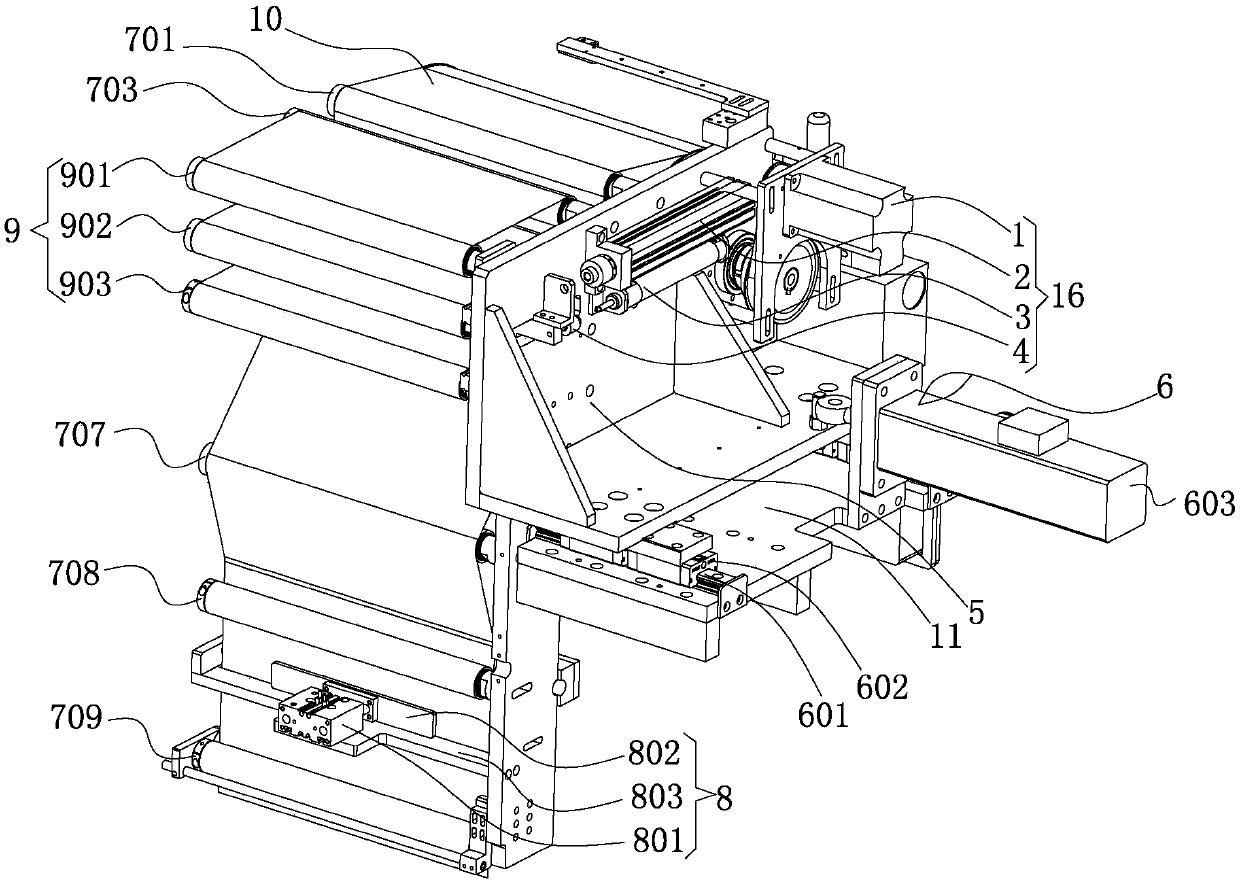

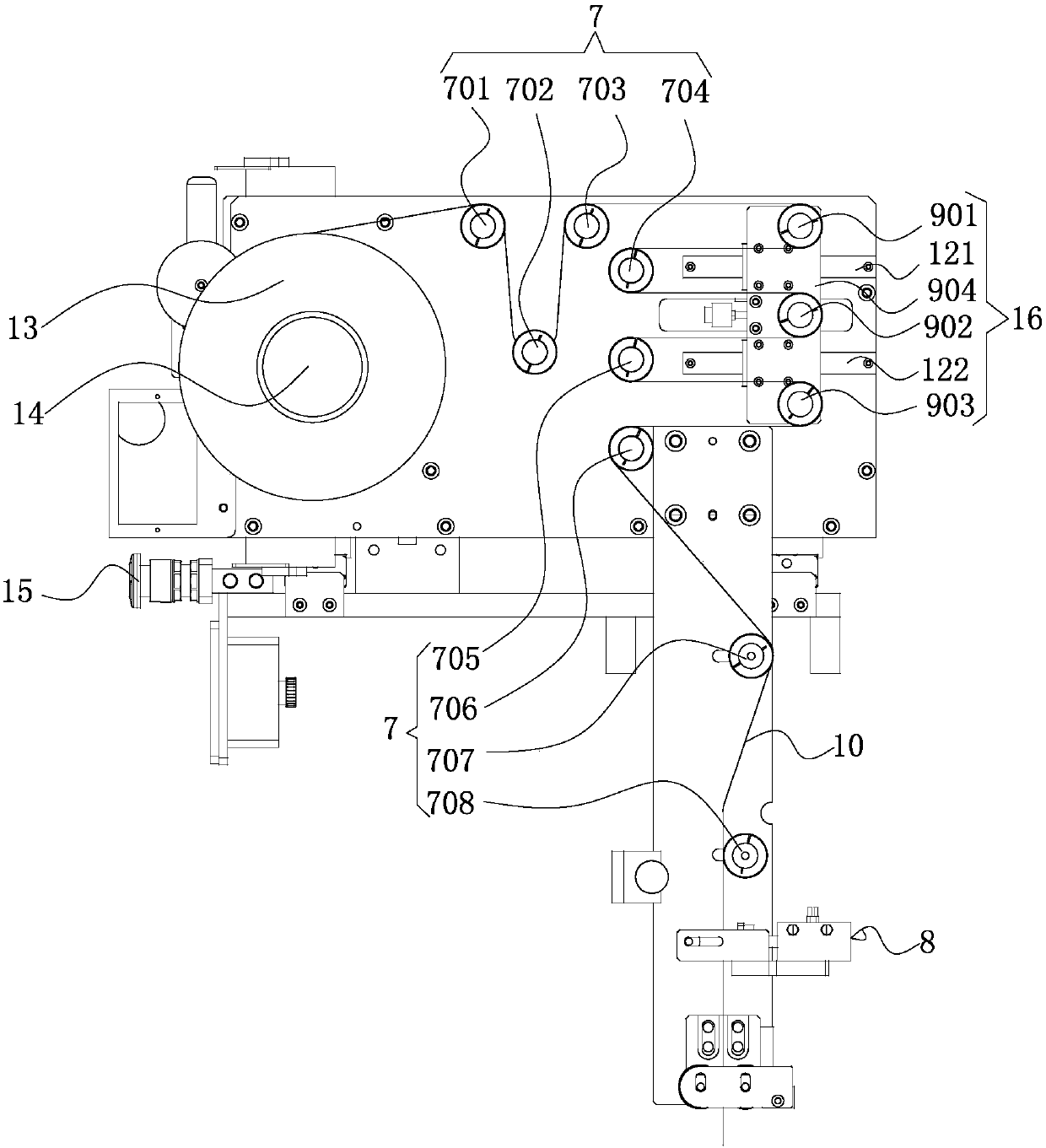

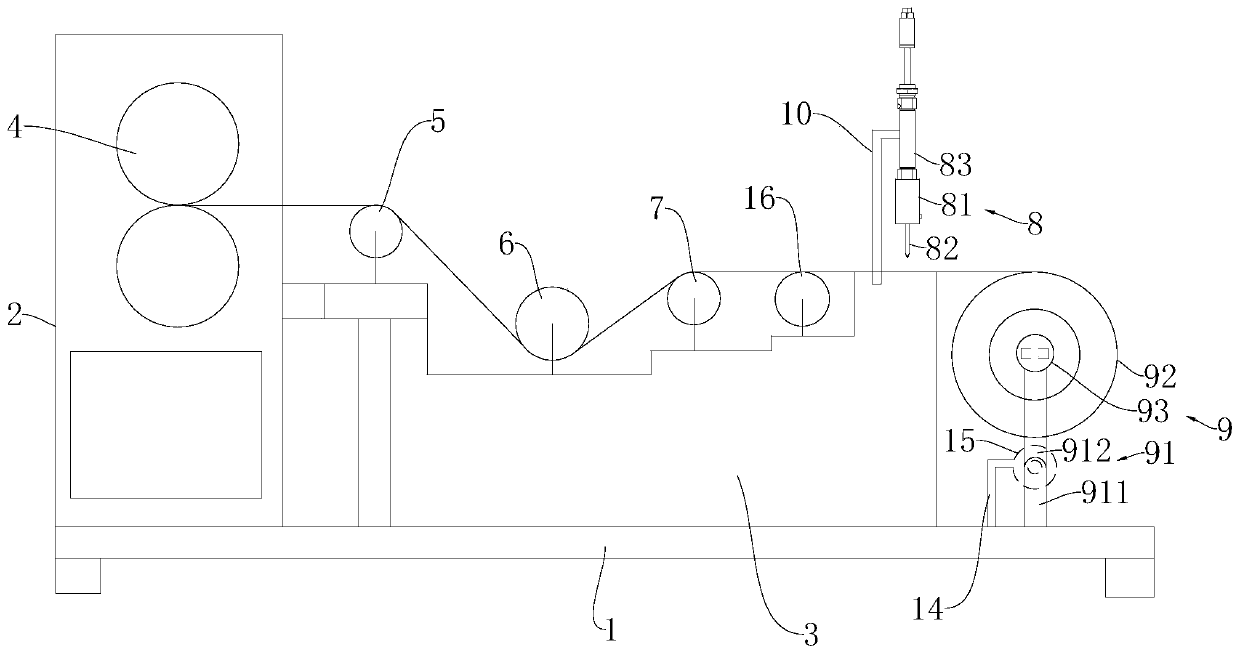

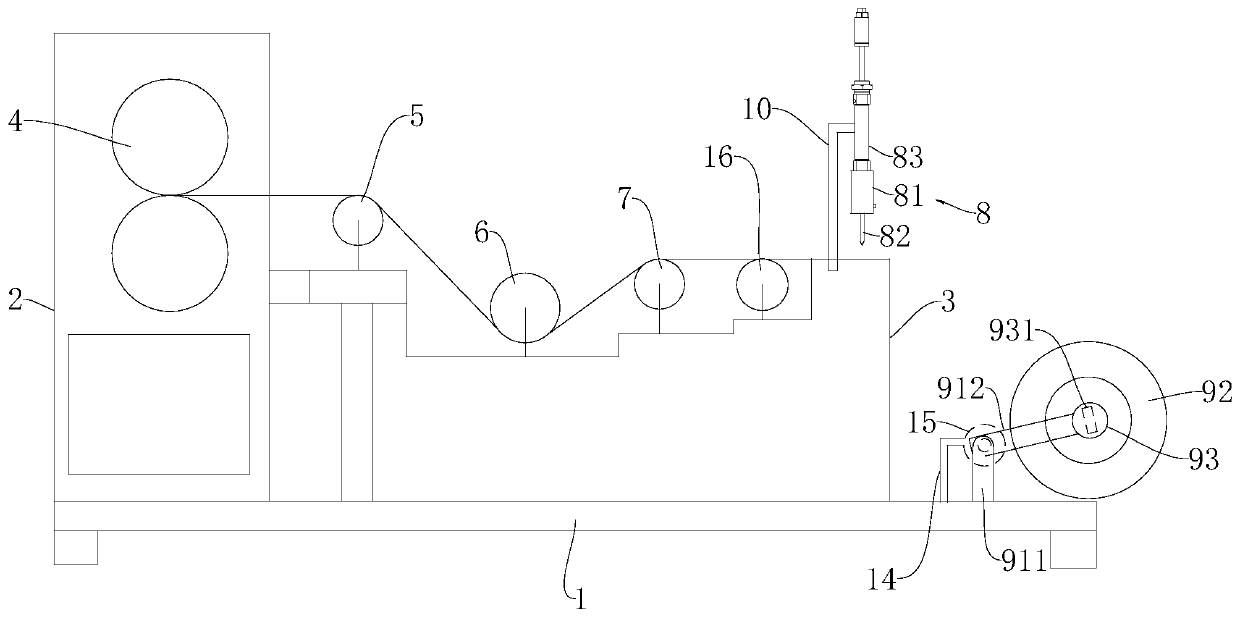

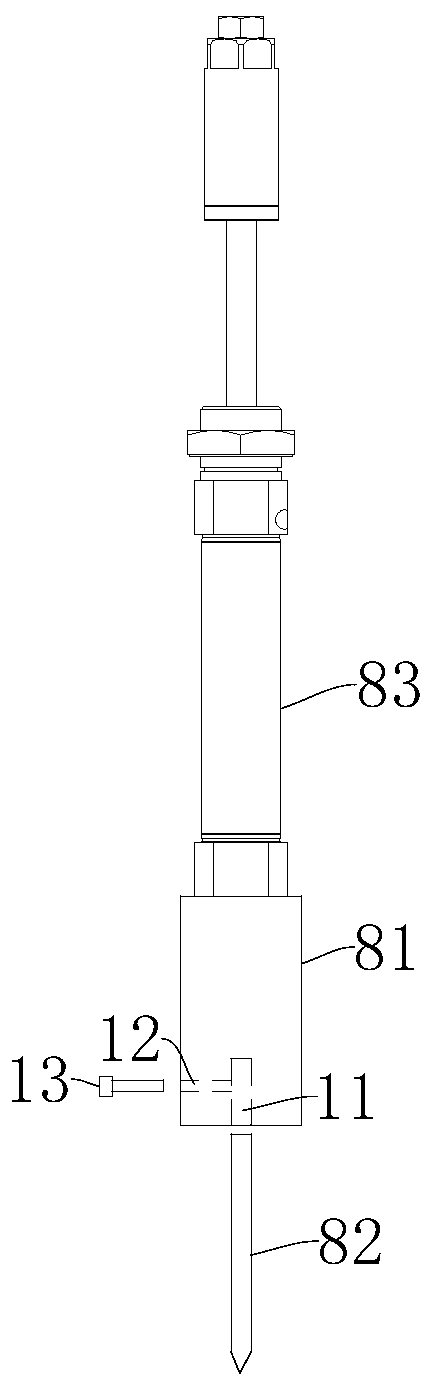

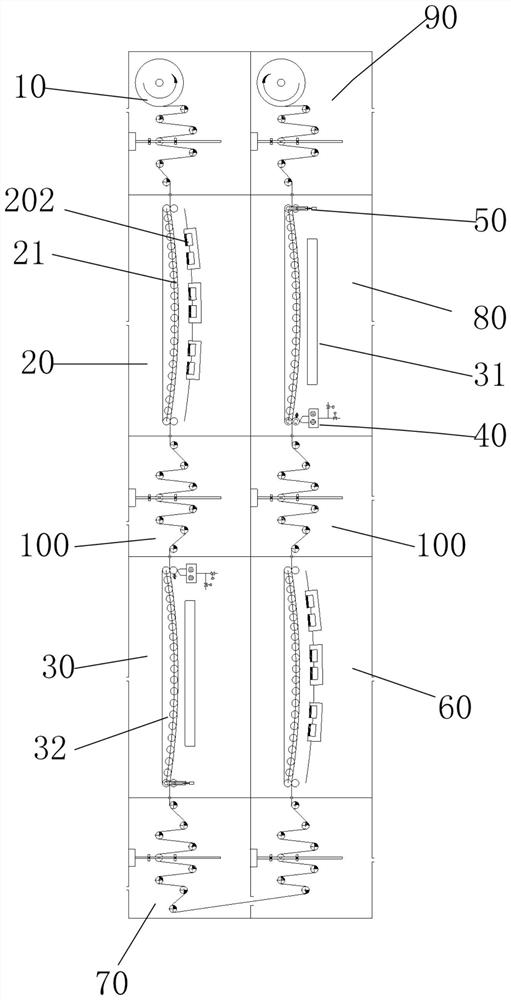

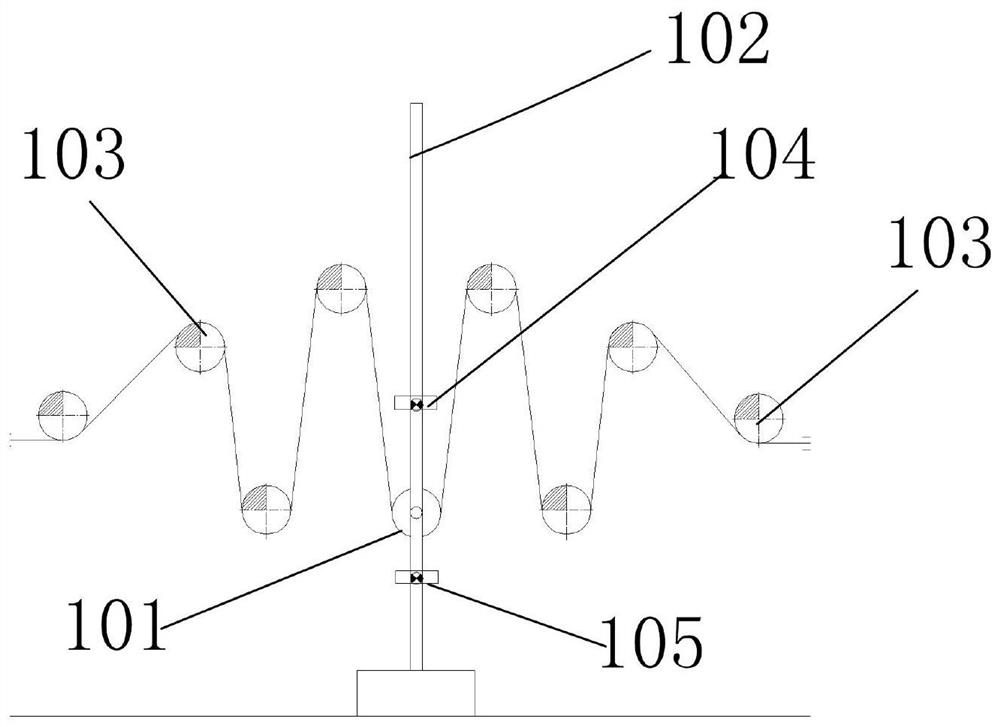

High-speed multi-section pole piece manufacturing equipment

ActiveCN105428596ATension remains constantConstant tensionElectrode manufacturing processesPunchingPole piece

The invention relates to the technical field of electronic element processing equipment and in particular to high-speed multi-section pole piece manufacturing equipment. The high-speed multi-section pole piece manufacturing equipment comprises a rack, and also comprises a material discharging apparatus, a material discharging caching apparatus, a pole piece punching apparatus, a draft gear, a material collecting caching apparatus and a material collecting apparatus that are arranged along a material conveying direction in sequence. The pole piece strip is cached by the material discharging caching apparatus and the pole piece punching apparatus, so that the draft gear is high in material pulling speed so as to realize the high speed punching on the pole piece strip by the pole piece punching apparatus; meanwhile, the feed amount of the required pole piece strip for punching in each time is unequal, the draft gear can rapidly pull the cached material according to punching needs; the draft gear is high in response speed, so that the high-speed multi-section punching and pole piece manufacturing is realized, and the production efficiency is greatly improved; and the material discharging apparatus and the material collecting apparatus perform uninterrupted pole piece strip collection at a constant speed to enable the pole piece strip to be kept at constant tensile force so as to improve the material conveying precision and to effectively prevent the phenomenon of off tracking of the pole piece strip and the like.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

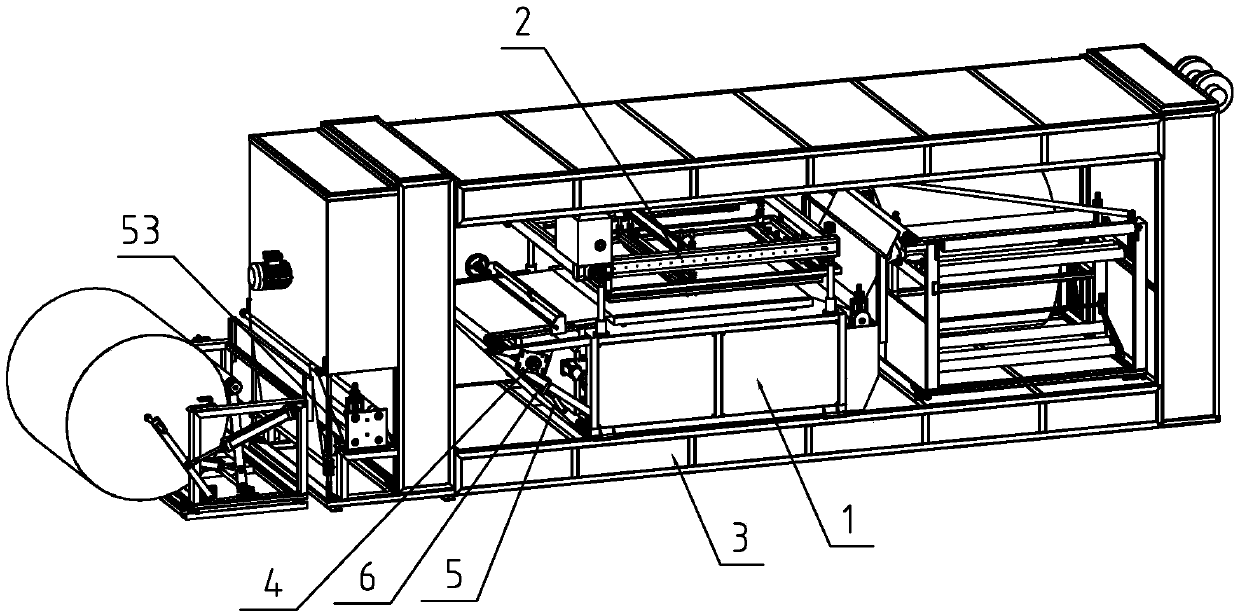

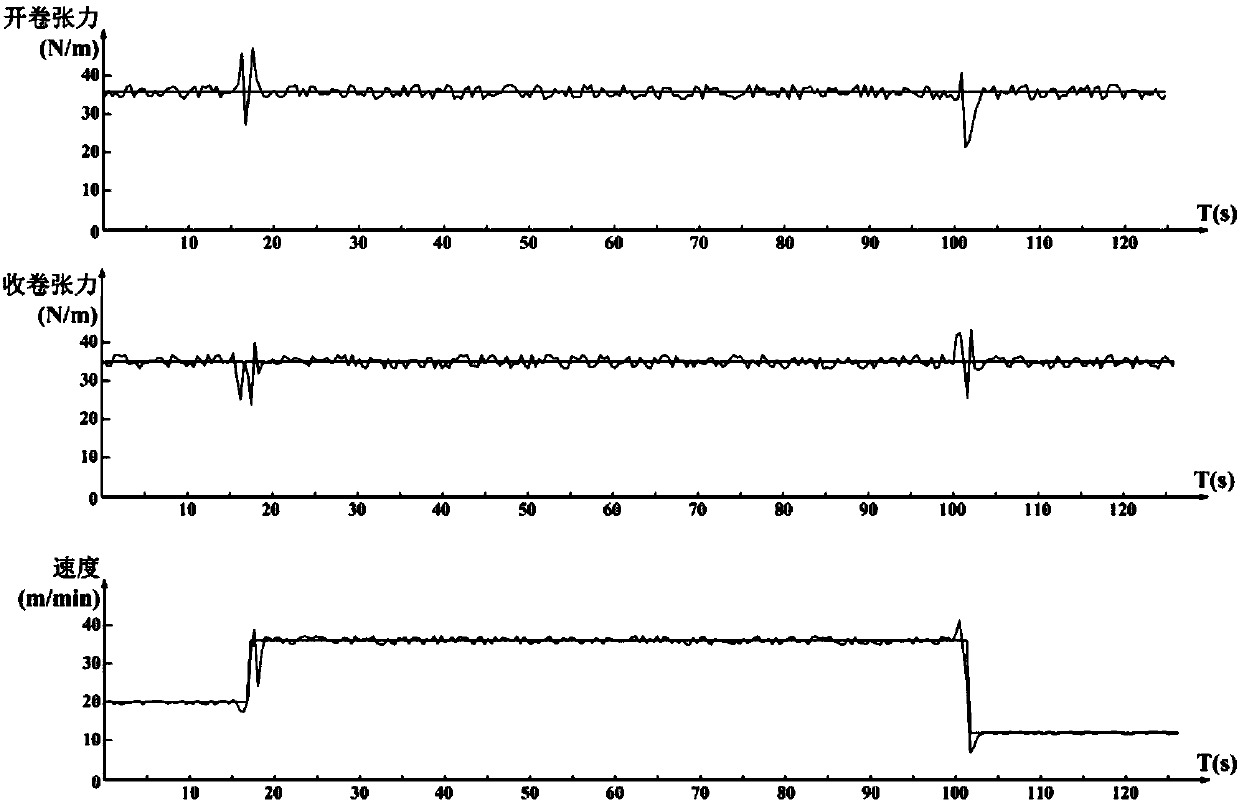

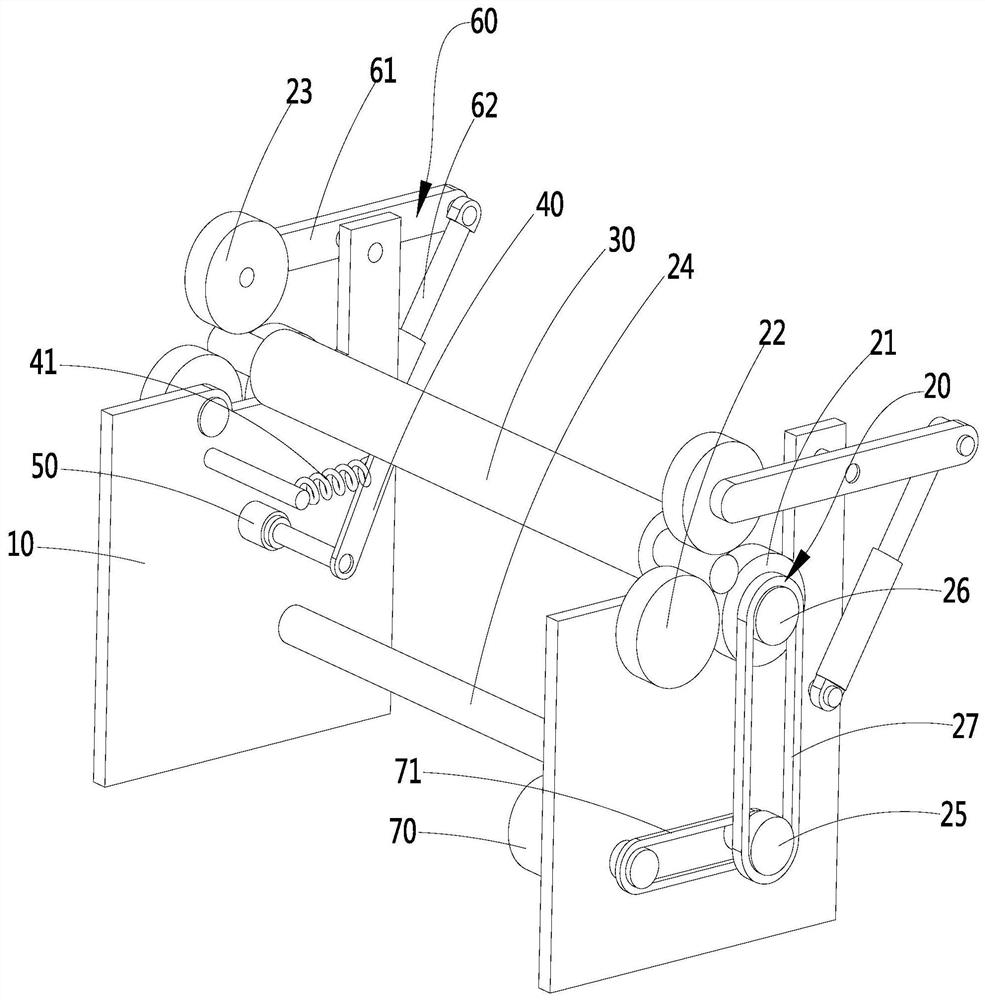

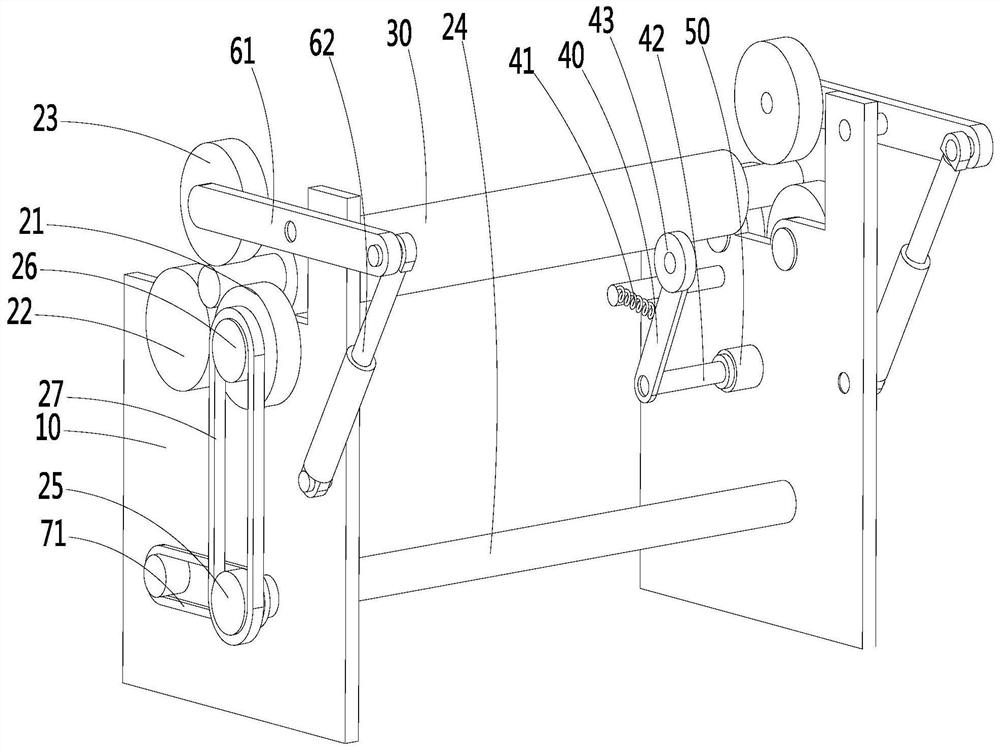

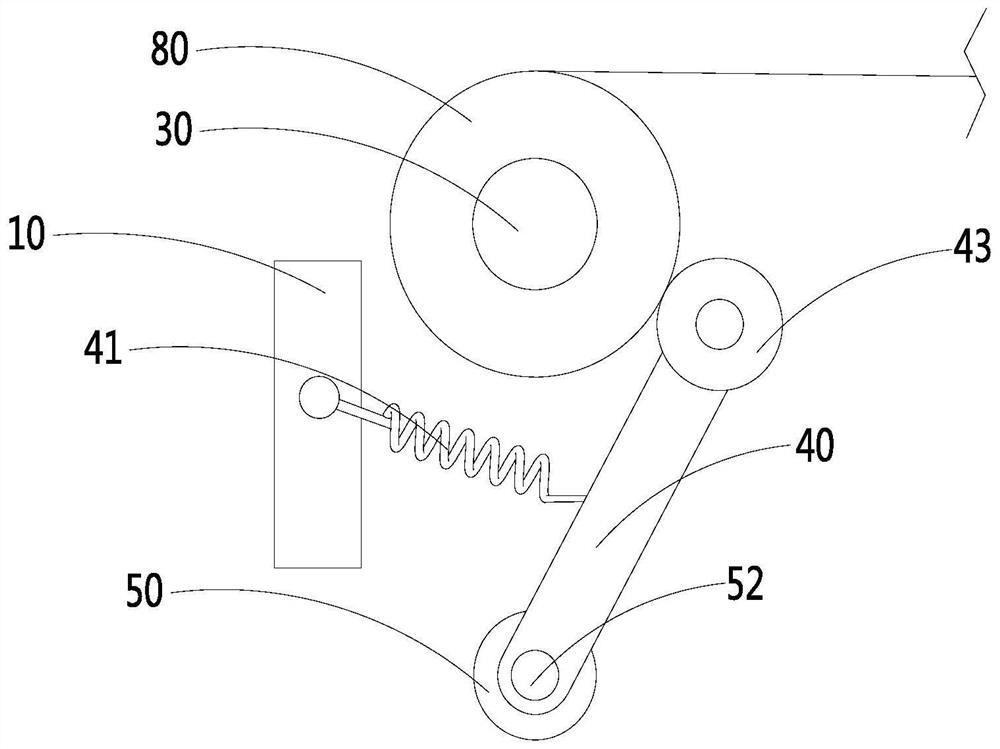

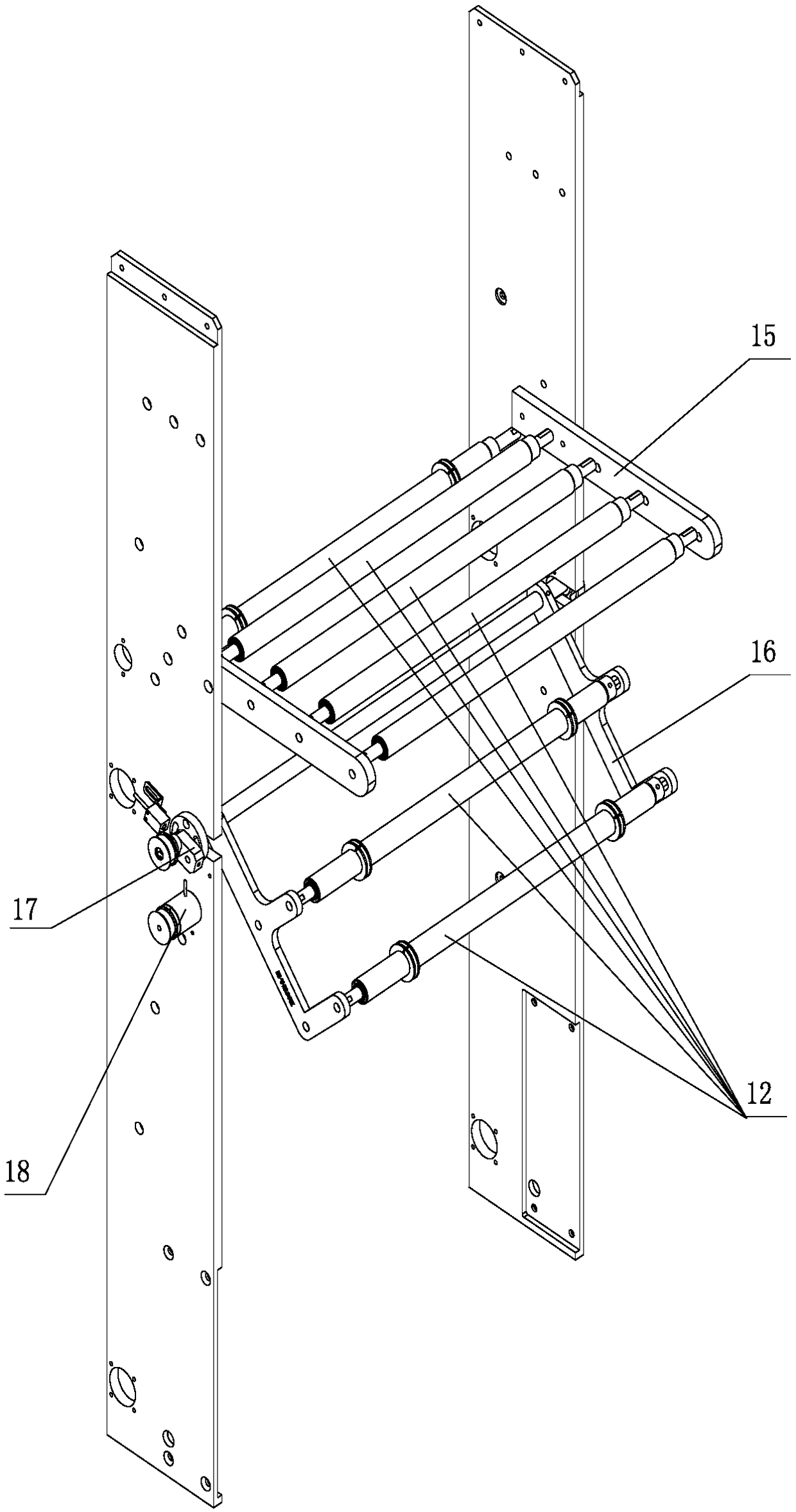

Servo control based multilayer flame laminating mechanism

ActiveCN105252874ATension remains constantAvoid changes in retractionControlling laminationLaminationTraction systemElectric machinery

The invention discloses a servo control based multilayer flame laminating mechanism. The servo control based multilayer flame laminating mechanism comprises a discharging mechanism, a flame laminating mechanism body and a receiving mechanism. A base-layer cloth pay-off device and multiple fabric pay-off devices are arranged in the discharging mechanism. The flame laminating mechanism body comprises a main machine frame, wherein multiple pairs of water cooling rollers are arranged in the main machine frame, and one flame jet device is arranged between any one pair of water cooling rollers and the corresponding fabric pay-off devices respectively. The fabric pay-off devices and the base-layer cloth pay-off device are respectively and correspondingly provided with a servo traction device, the water cooling rollers are controlled through a servo motor, and the servo motor is mutually and electrically connected with a traction servo motor in a servo traction system. The servo control based multilayer flame laminating mechanism adopting the technical scheme can achieve synchronous processing of multilayer composite materials through the structural layout of all mechanisms and accordingly can be applicable to efficient production of complicated composite materials.

Owner:YANCHENG XUHUA MACHINERY

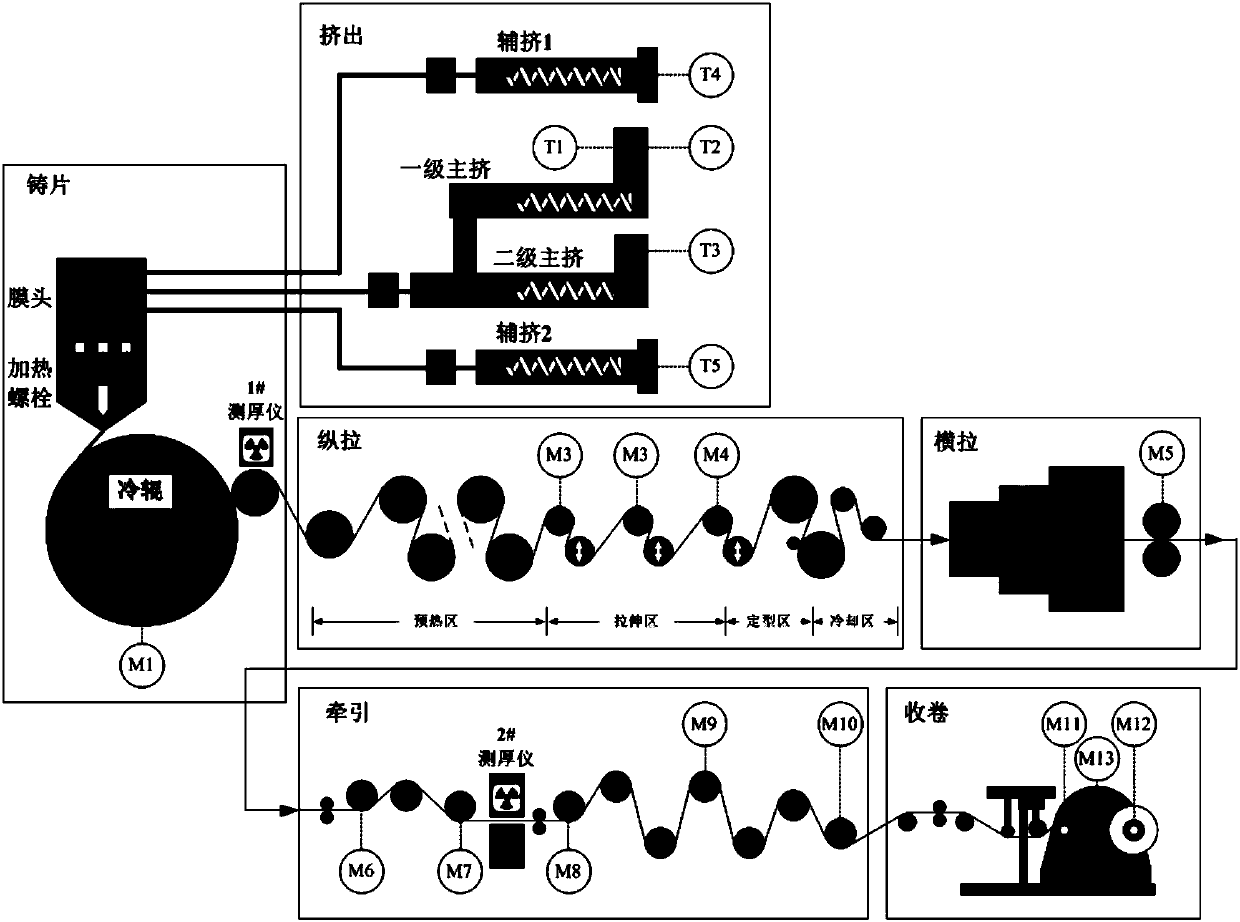

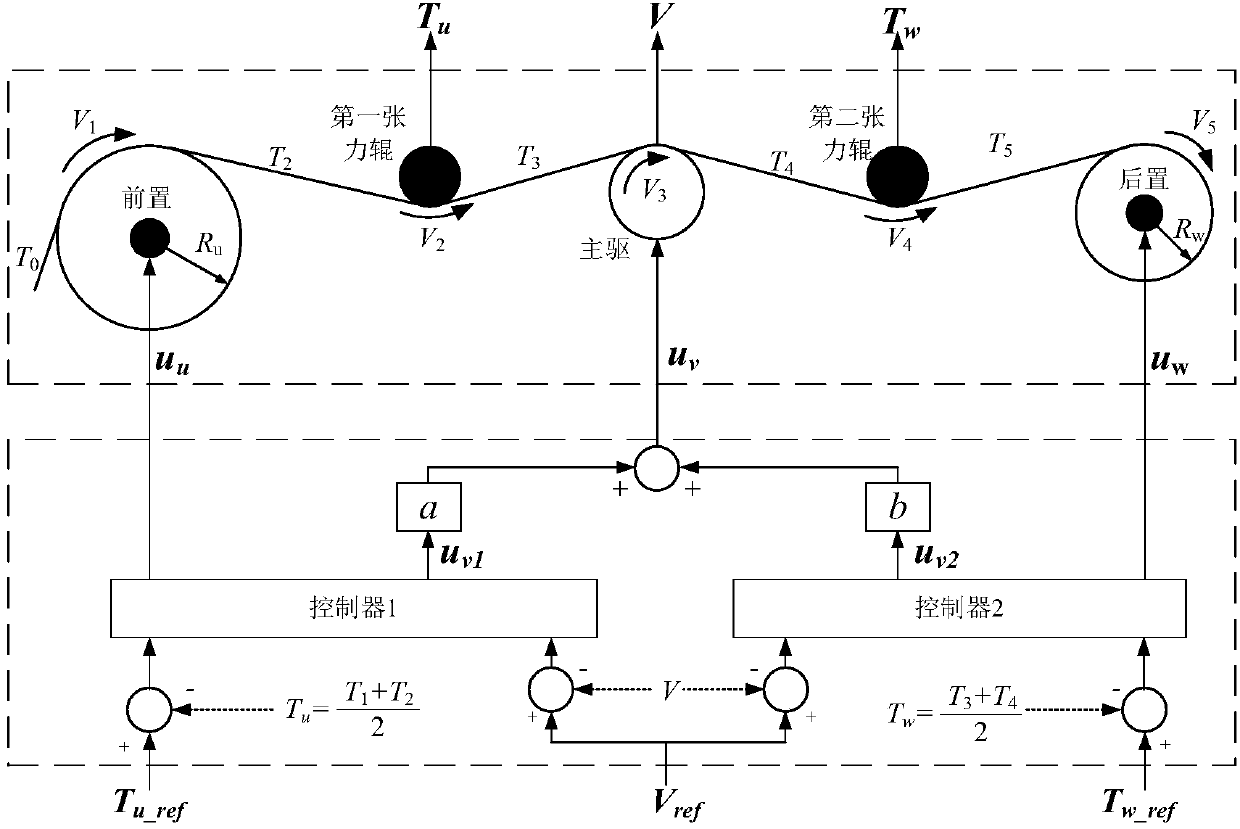

Control method of BOPP (Biaxially-oriented Polypropylene) biaxial stretching system

The invention provides a control method of a BOPP (Biaxially-oriented Polypropylene) biaxial stretching system. With regard to an arbitrary three-motor subsystem in a stretching section of the system,the system comprises a prepositioned shaft, a first tension roller, a main driving shaft, a second tension roller and a post-positioned shaft; two distributed controllers are used for controlling, wherein the first controller is used for controlling a prepositioned shaft motor and a main driving shaft motor and the second controller is used for controlling the main driving shaft motor and a post-positioned shaft motor; meanwhile, the first controller and the second controller are used to share one part of output through superposition of control factors a and b, so as to control the main driving shaft motor. According to the method provided by the invention, the two continuous controllers are used share one part of input and output through superposition of the control factors, so that thedecoupling capability of speeds and tension of the system can be remarkably improved; the subsystem is expanded into a multi-motor winding system in a biaxial stretching process; meanwhile, a thin film longitudinal and transverse thickness control model is also designed, so that synchronous and accurate control on the speeds, the tension and the speed of a stretching process is realized.

Owner:WUHAN UNIV OF SCI & TECH

High-precision wire mesh drawing mechanism and weaving equipment

PendingCN112027749AImprove efficiencyGood net effectWebs handlingStructural engineeringMechanical engineering

The invention provides a high-precision wire mesh drawing mechanism and weaving equipment, and belongs to the technical field of wire mesh weaving equipment. The high-precision wire mesh drawing mechanism comprises a rack, a transmission assembly, a winding roller, a swing rod, an absolute value encoder and a controller. Wherein the winding roller is erected on the driving assembly and is in powerconnection with a driving assembly. The swing rod continuously abuts against the outer edge face of a high-precision wire mesh roll wound on the winding roller. The absolute value encoder measures the rotation angle of the swing rod. According to the high-precision wire mesh drawing mechanism provided by the invention, a high-precision wire mesh to be wound can keep constant tension in the feeding process, the high-precision wire mesh is prevented from being pulled to be damaged, the mesh roll can be ensured to be rapidly taken out after winding of the winding roller is finished, the mesh drawing effect is good, and the product quality is guaranteed.

Owner:英凯模金属网有限公司

Concentric wrapping device capable of actively releasing belt

PendingCN111524658ATension remains constantHigh precisionCable/conductor manufactureMode controlTransmission belt

The invention discloses a concentric wrapping device capable of actively releasing a belt. The device comprises a base and a tension control device body, wherein a first motor is fixedly mounted in the base, a second motor is installed on one side of the first motor, the output shaft of the first motor is connected with an outer belt wheel through a first conveying belt, the output shaft of the second motor is connected with an inner belt wheel through a second conveying belt, and the outer belt wheel is connected with an inner rotary disc through an inner rotary shaft. In the prior art, the existing concentric wrapping device lacks an automatic tension adjusting part, and the pay-off tension cannot be kept in a constant state all the time; and the traditional concentric wrapping device adopts an open-loop mode to control a motor to passively release a belt, so that the tension cannot be monitored and controlled in real time, and the tension cannot be accurately controlled so as not toovercome the problems of the influence of mechanical damping and the like and not to achieve the precise control of small-tension belt release. According to the invention, the problems in the prior art are solved.

Owner:HEFEI SMARTER TECH GROUP CORP

Efficient paper conveying device used for bag package mechanical production equipment

PendingCN109292509ARealize the automatic correction function of deviationWith automatic deviation correction functionWebs handlingRolling paperControl system

The invention discloses an efficient paper conveying device used for bag package mechanical production equipment. The efficient paper conveying device comprises a paper film changing mechanism and a swing shaft roller tensioning and alarming mechanism, wherein the paper film changing mechanism is arranged at the bottom of a paper supporting frame, and the swing shaft roller tensioning and alarmingmechanism is arranged in the middle of the paper supporting frame. Two horizontal plates are fixed to the top of the paper supporting frame. A coding position adjustment mechanism is arranged betweenthe two horizontal plates. Tracking optoelectronic switch position adjustment mechanisms are arranged on the two horizontal plates. A film damping mechanism is arranged at the rear end of the top ofthe paper supporting frame. A paper film deviation rectifying mechanism is also arranged on the paper supporting frame. In the paper conveying process, a roll paper film driving motor continuously operates in small-fluctuation and speed-variation modes, so that a swing arm of a swing shaft roller of the paper conveying device is kept swinging by a small angle within a small range, and the rotatingspeed of the roll paper film driving motor is automatically matched with the paper consuming speed of a packaging machine in the continuous operating process; and when the movement range is too largeand exceeds a set value, an encoder feeds a signal back to a control system to achieve automatic halts, an alarm is given when no film is available or when film supply is abnormal, and thus, continuous and stable tension is provided for a paper supply system.

Owner:天津瑞泰包装机械股份有限公司

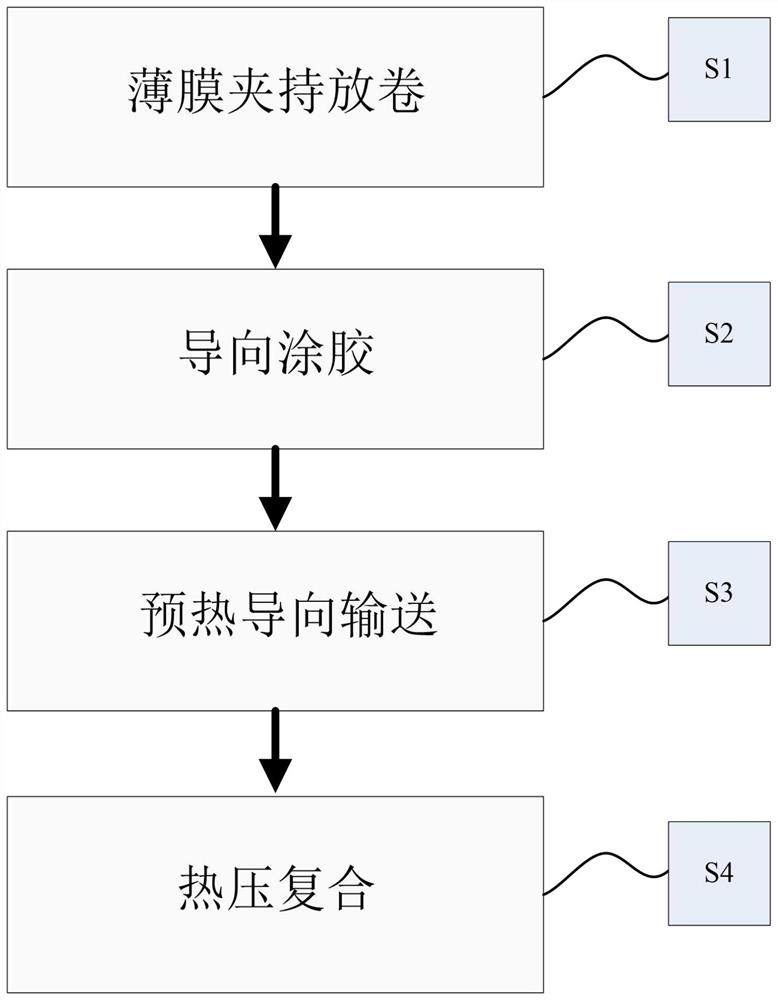

Film coating process for manufacturing packaging container

InactiveCN113500820ATension remains constantPrevent unbalanced transmission forcePaper-makingBox making operationsAdhesiveMechanical engineering

The invention provides a film coating process for manufacturing a packaging container. The film coating process comprises a winding mechanism, a coating mechanism, a guide mechanism, a drying mechanism, a conveying mechanism, a main beam plate frame, a guide roller I and a guide roller II. The film coating process solves the problems that clamping and fixing of an unwinding winding drum and a winding drum have limitation at present, and winding drums with different types and sizes cannot be clamped, so that the manufacturing of the film coating process is relatively single, and production and processing of film coating processes with different sizes cannot be realized; in the winding and unwinding processes, the execution actions cannot be synchronized, the tension in the film coating process is influenced to be constant, the film transmission stress is unbalanced, and the film is wrinkled or torn; no guide motion track exists for the transmission of paper printed matters and films, the deviation condition is easily caused after the films and the paper printed matters are compounded, and the film coating quality is influenced; and the coating of an adhesive on the surfaces of the films cannot be uniformly controlled, the coating flow speed of the adhesive cannot be controlled, and the film coating process is influenced.

Owner:武汉众诚科技有限公司

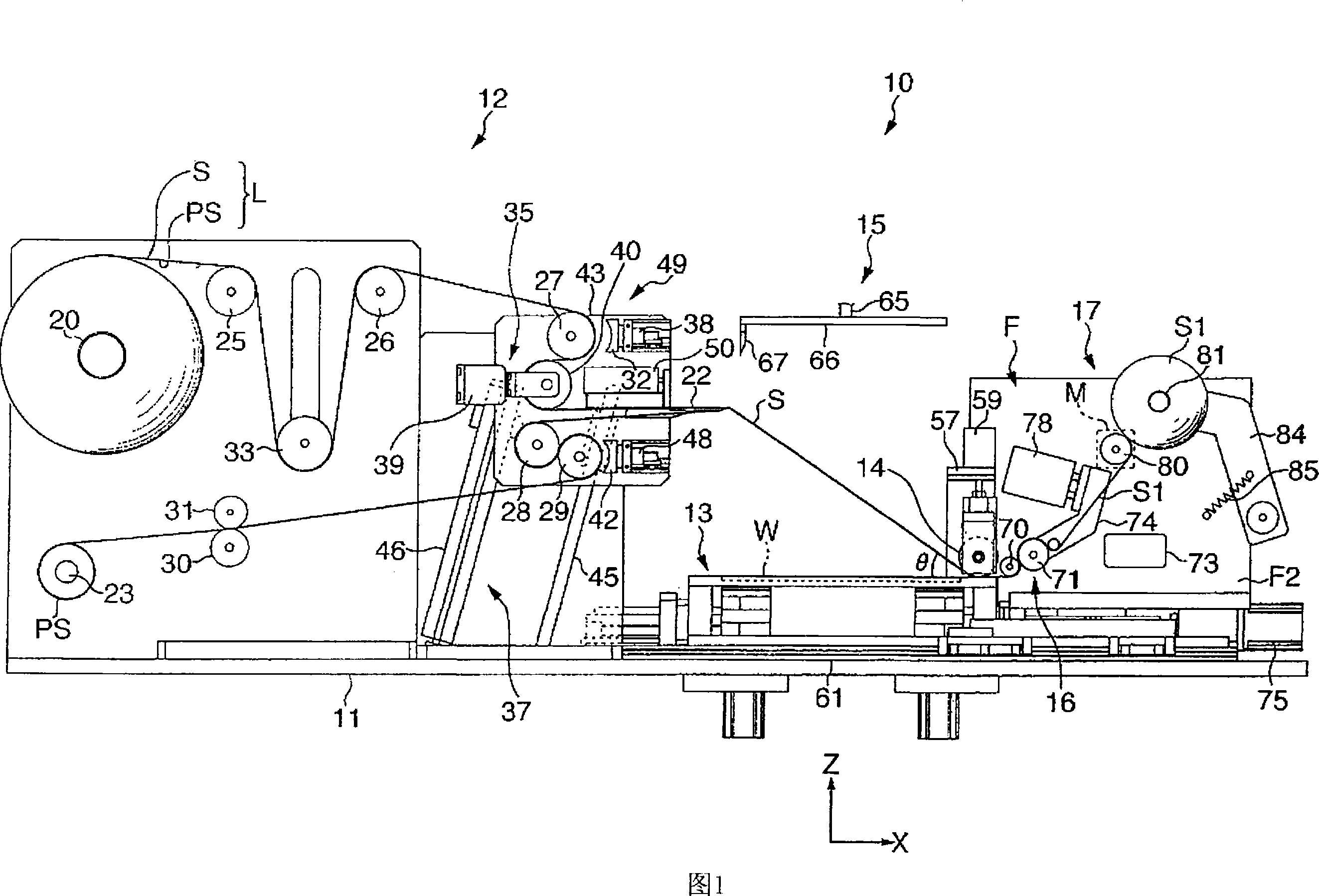

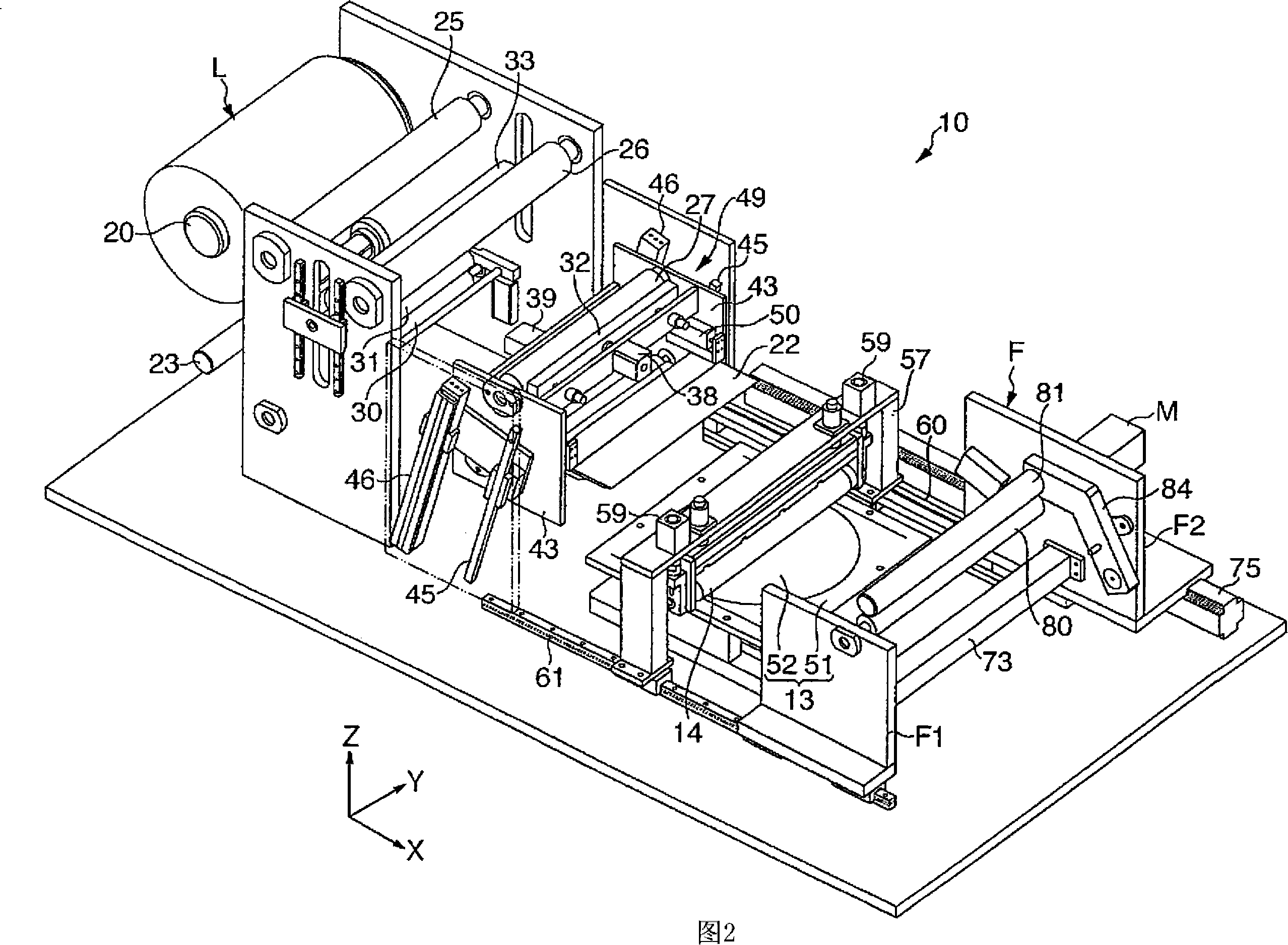

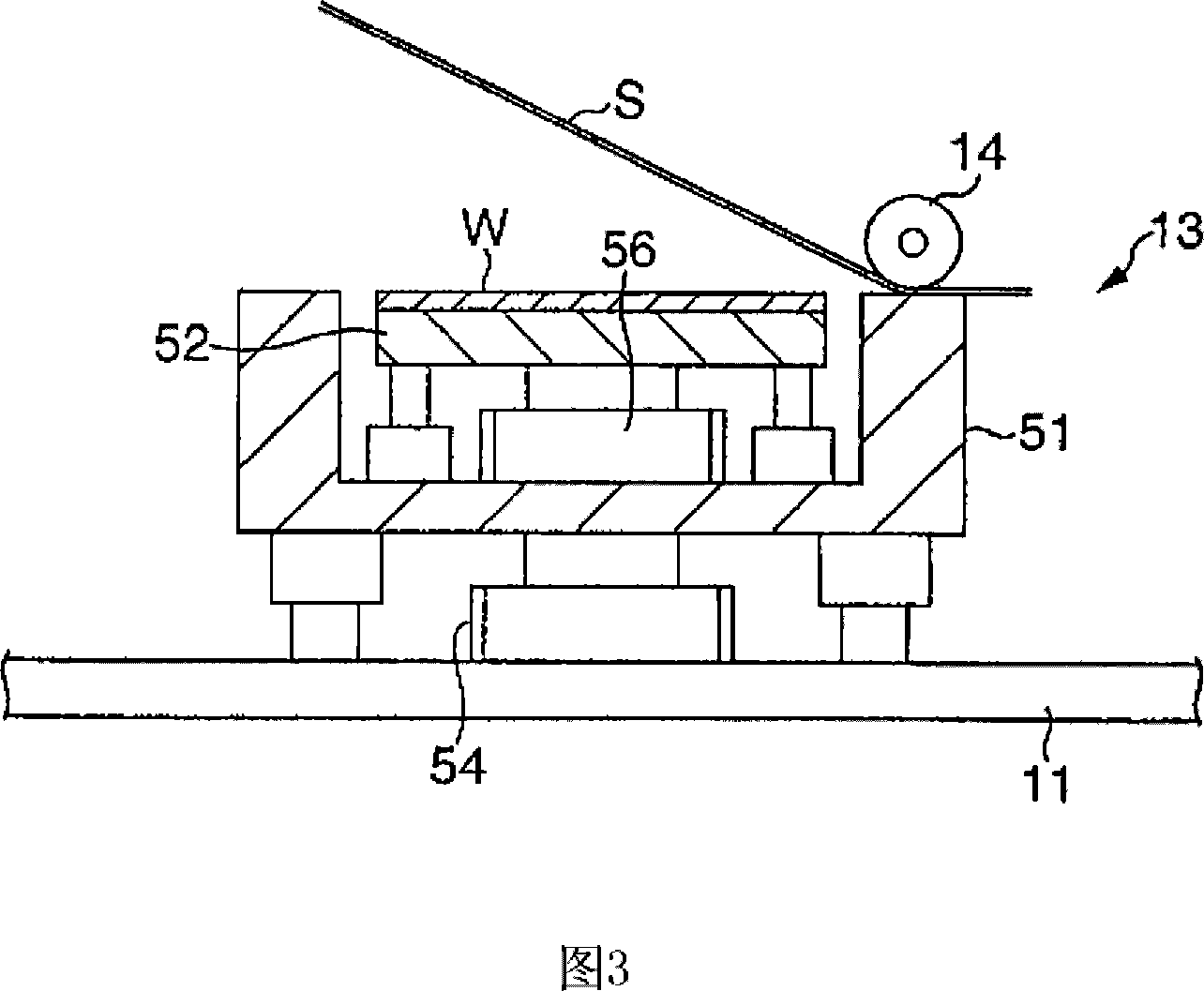

Sheet adhering apparatus and sheet adhering method

ActiveCN101213647AAvoid warpingAvoid wrinklesSemiconductor/solid-state device manufacturingAdhesivesEngineeringMechanical engineering

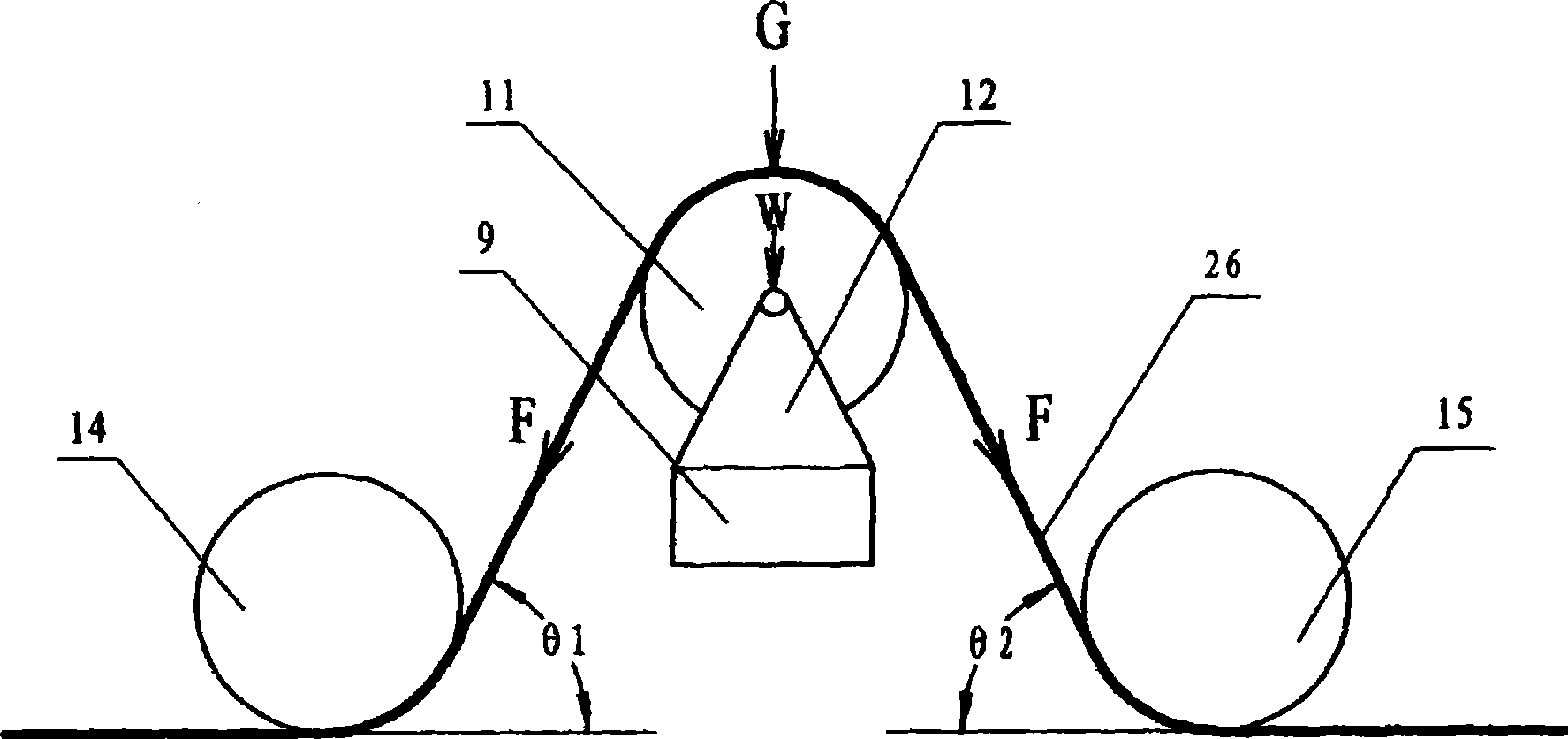

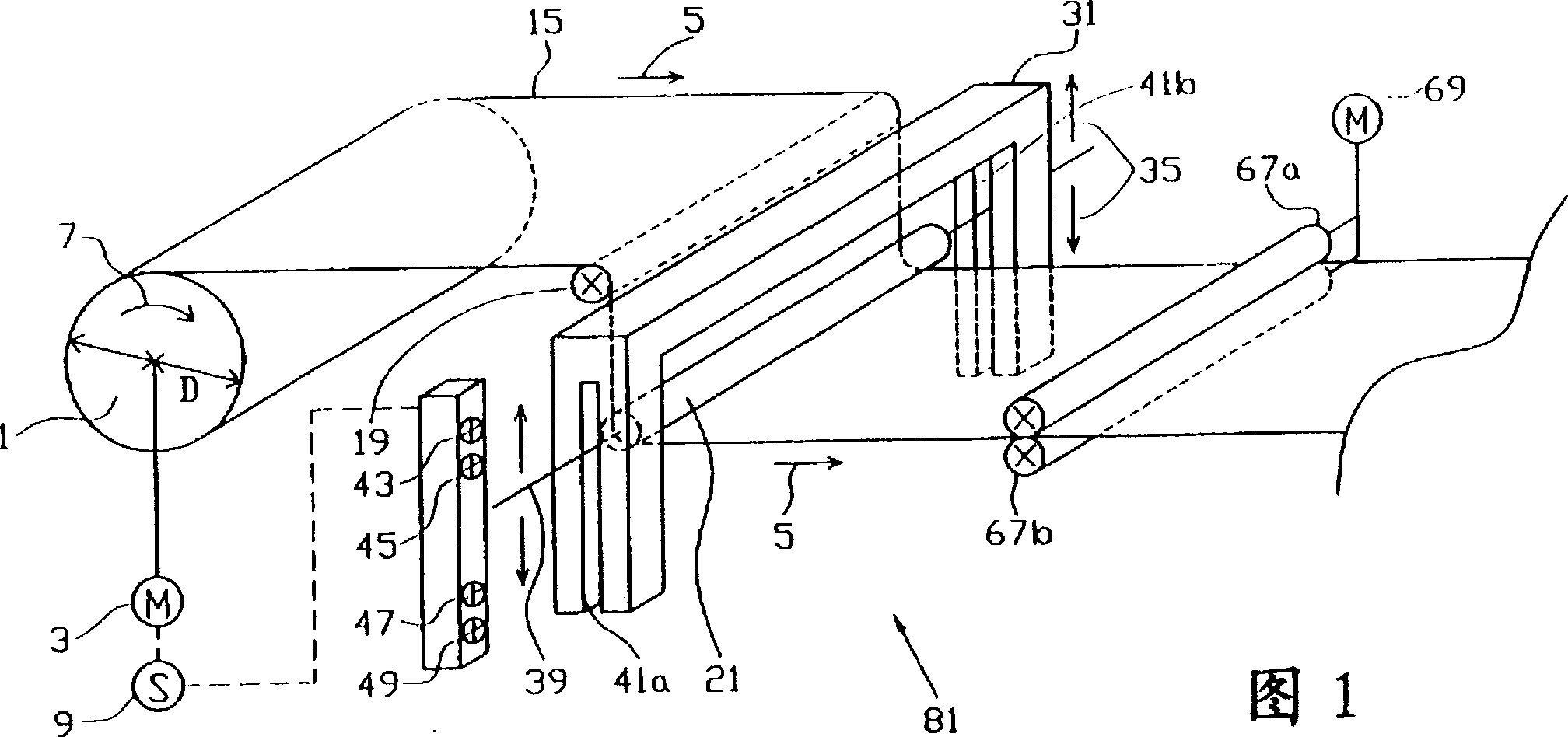

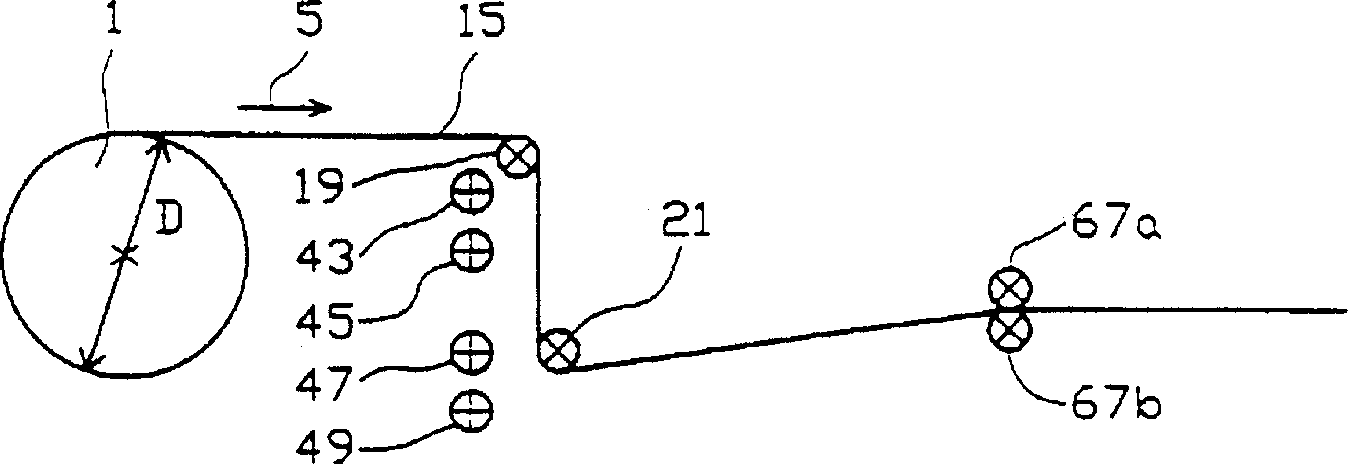

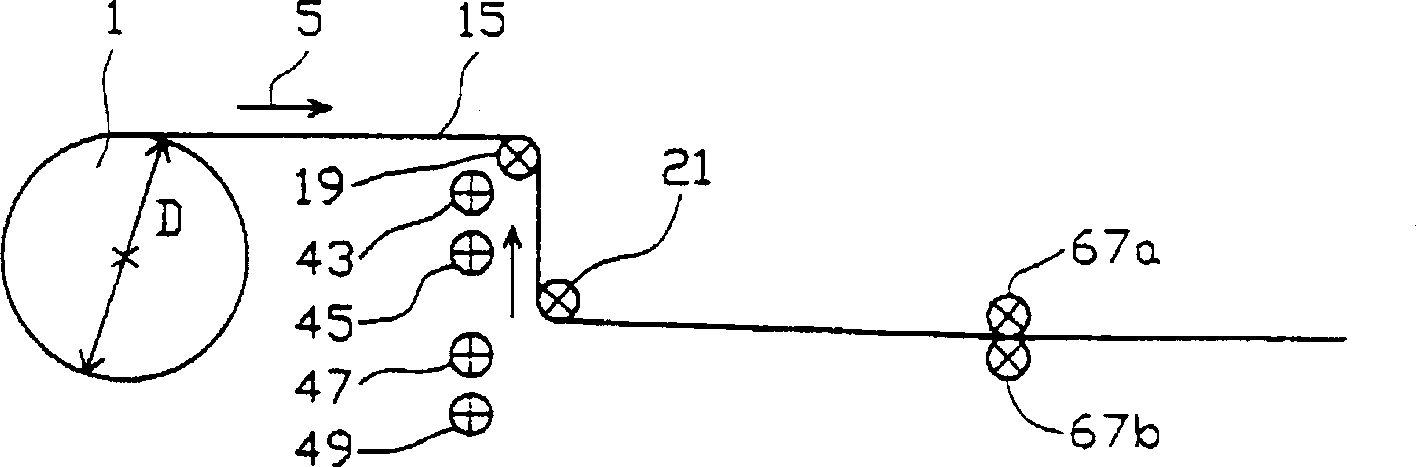

A sheet sticking device (10) comprises: a sheet guide unit (12) for guiding an adhesive sheet (S) to a position facing a semiconductor wafer (W); and applying a pressing force to the above-mentioned adhesive sheet (S), A pressure roller (14) for attaching the adhesive sheet (S) to the wafer W. The above-mentioned sheet guide unit (12) includes a tension measurement mechanism (35) for measuring the tension of the adhesive sheet (S) between the guide head (49) and the pressing roller (14), the tension measurement mechanism (35), through the Keeping the above tension constant can prevent air bubbles from being mixed between the adhesive sheet (S) and the wafer (W) and warpage of the wafer after the sheet is pasted.

Owner:LINTEC CORP

Apparatus and method for supplying foils

InactiveCN1131162CSimple designQuick correctionWrapping material feeding apparatusSpeed/accelaration controlMotor driveEngineering

Owner:INDAG GMBH & CO BETRIEBS KG

Driving means and device for working sheet-like material

ActiveCN102089144AIncrease the lengthTension remains constantPortable liftingPress ramPhysicsLeather belt

Owner:NIVORA IP

Tension device capable of achieving automatic adjustment

The invention discloses a tension device capable of achieving automatic adjustment. The tension device capable of achieving automatic adjustment is characterized in that a sliding block has an inclined surface of which the inclination angle can be adjusted; a guide part which stretches out of a guide sleeve and travels on the inclined surface is arranged on a guide pillar, so that the inclined surface forces the guide part to drive the guide pillar to vertically move to drive a tension wheel to move; the equivalent elasticity coefficient of springs is changed through changing the inclination angle of the inclined surface, and different tension ranges, namely, relatively high ranges or relatively low ranges, are further provided; besides, through adjusting the inclination angle, the influence on the elasticity coefficient can be compensated when the springs lose efficacy; tension change caused by pressure change between driving rollers is adjusted through an adjusting mechanism, and the tension basically remains constant; and besides, a linkage relationship between motion directions of the tension wheel and the driving wheels is established through two capacitance pieces, a controller and a servo motor, and the automatic adjustment function of the tension wheel is improved.

Owner:赵旭

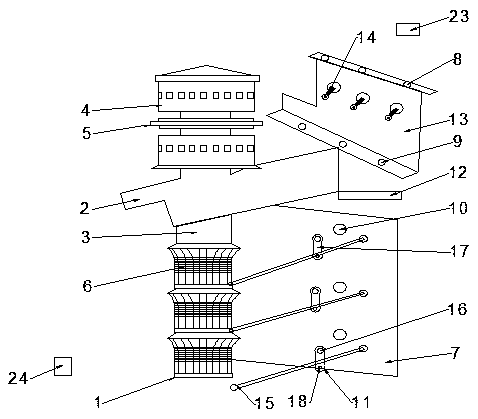

Constant-tension yarn storage device for flat plate winding of carbon fiber yarn and control method

The invention relates to the technical field of yarn storage, in particular to a constant-tension yarn storage device for flat plate winding of carbon fiber yarn and a control method. The device comprises an unwinding device for unwinding the yarn on a spool at a constant speed; a fiber spreading device for carrying out fiber spreading operation on the yarn; a tension detection device for detecting the tension of the yarn; and a winding device which further comprises a yarn winding plate for winding the yarn and a driving motor, wherein the yarn winding plate is driven by the driving motor to rotate at a constant speed so as to wind the yarn obtained after fiber spreading. An automatic yarn storage device is further arranged between the winding device and the fiber spreading device and used for compensating for the difference value between the yarn unwinding amount of the unwinding device and the yarn winding amount of the yarn winding plate in real time, so that the speed and tension of the yarn passing through the fiber spreading device are kept constant, the product quality is improved, and the practicability is achieved.

Owner:NEWTRY COMPOSITE

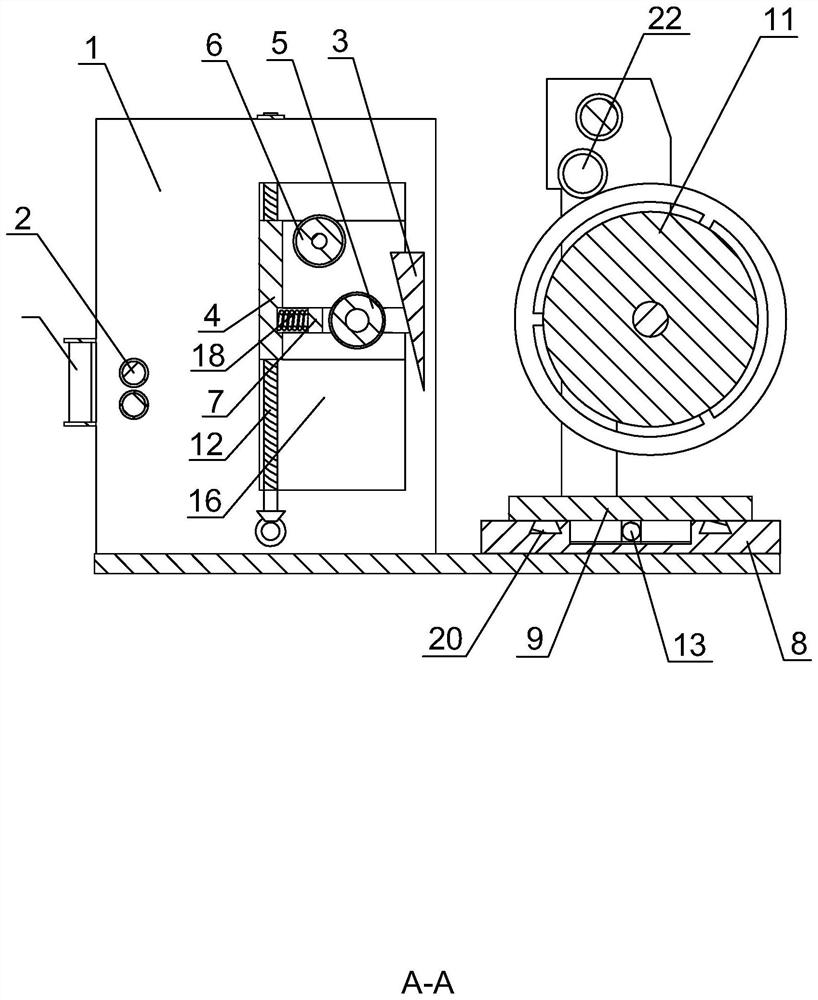

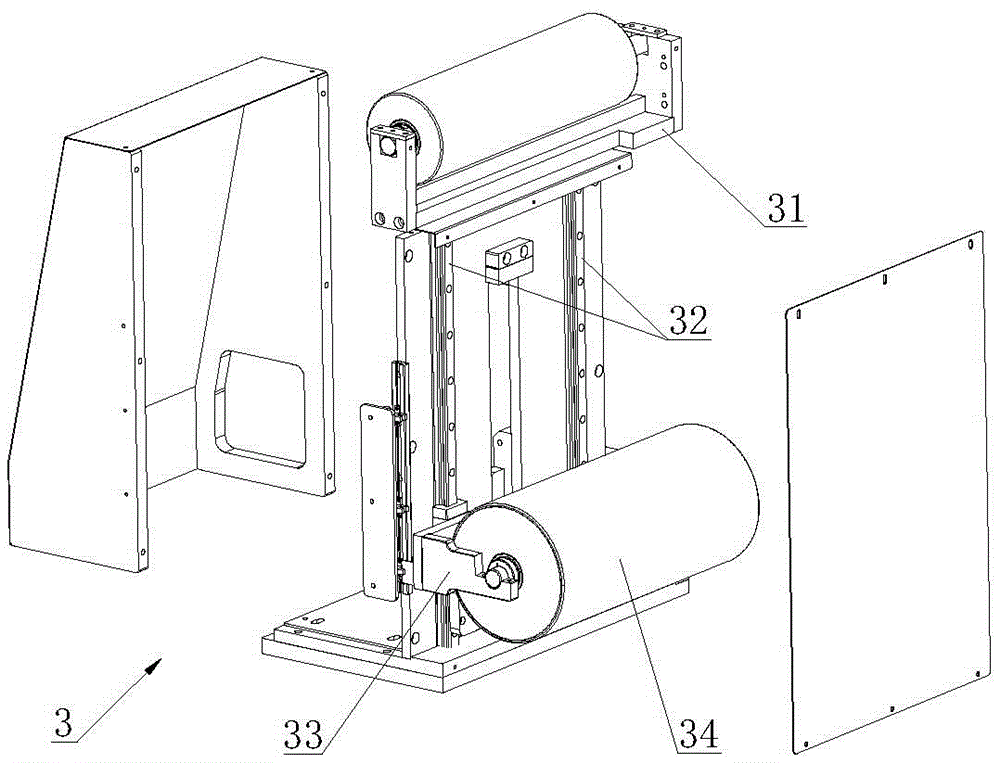

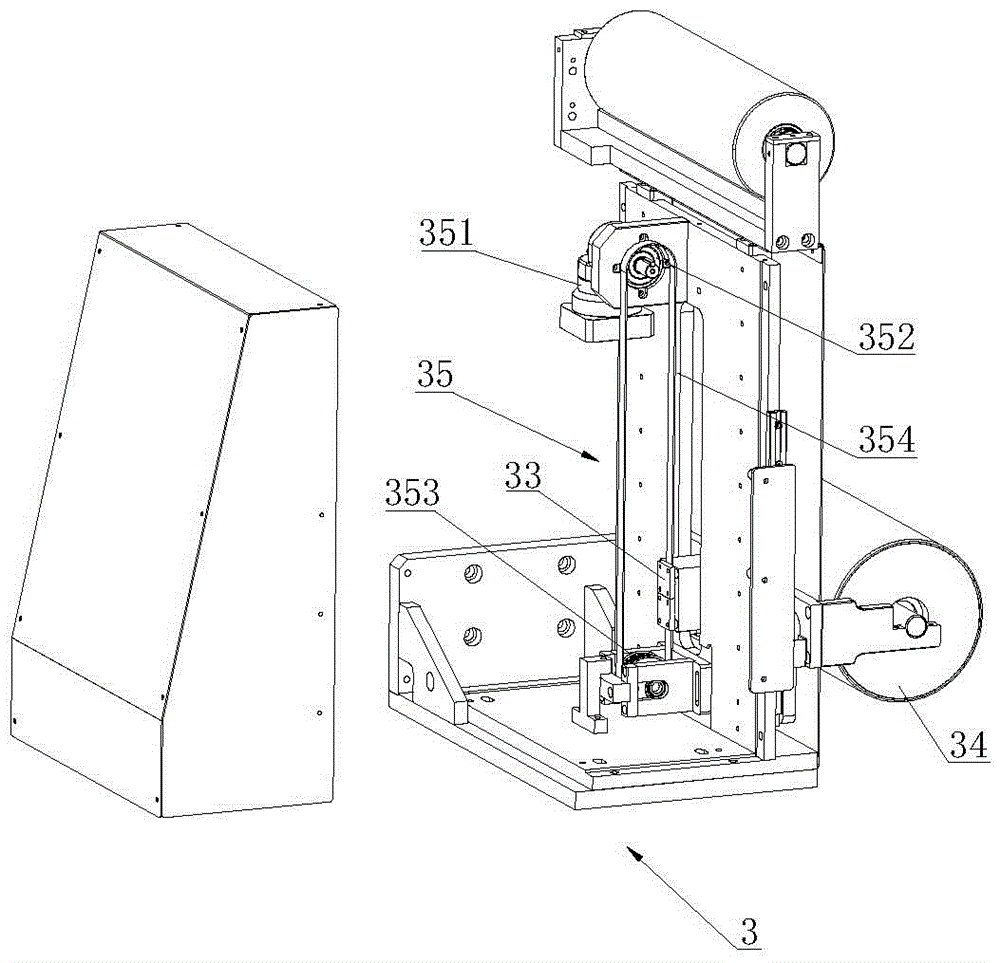

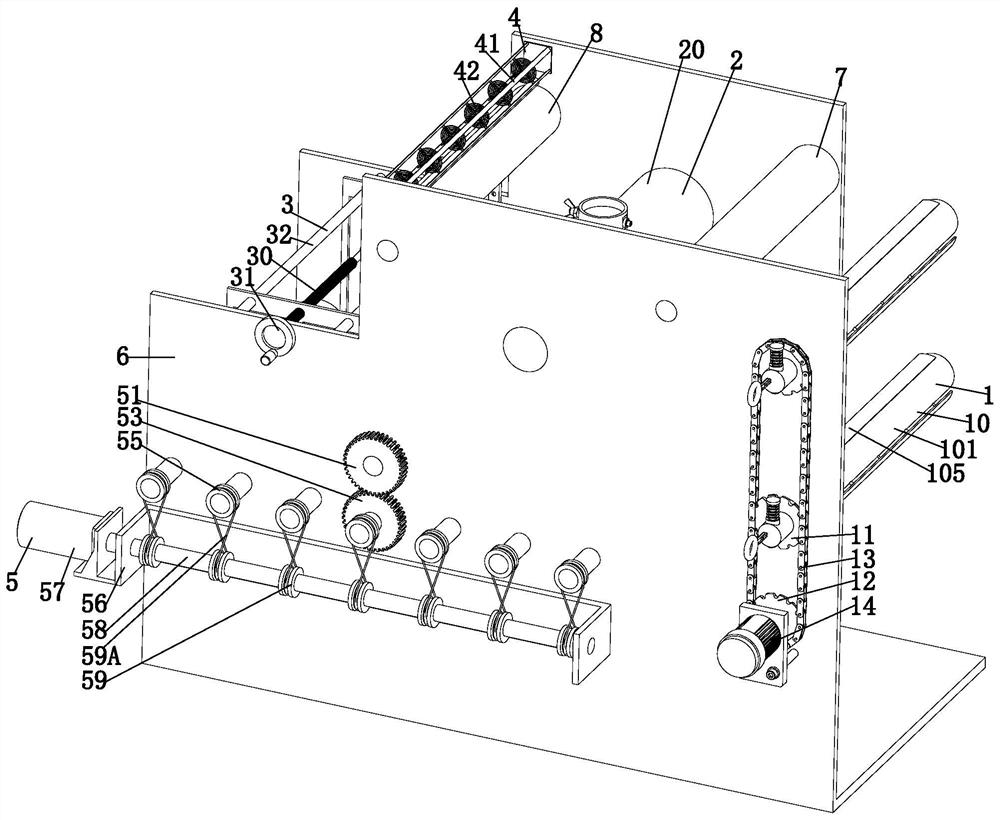

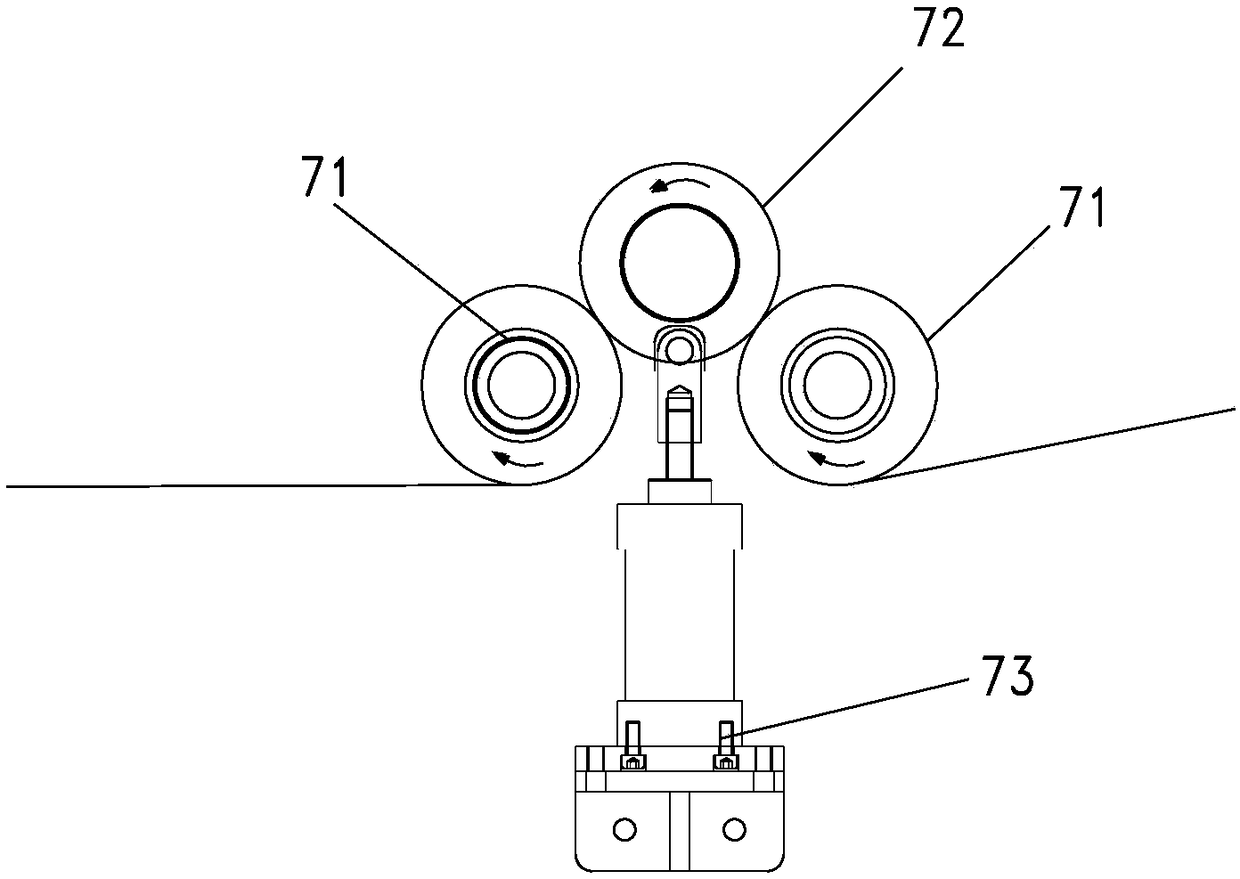

Membrane tension control device for stacking machine

PendingCN107745991ATension remains constantNot easy to wrinkleAssembling battery machinesFinal product manufactureMembrane tensionStack machine

The invention discloses a membrane tension control device for a stacking machine. The membrane tension control device for the stacking machine comprises a base, a vertical plate assembly mounted on the base, a servo motor arranged on the vertical plate assembly, a membrane winding drum shaft mounted on the vertical plate assembly and connected with the servo motor, and a passing roller set used for guiding membranes and further comprises a membrane tension control mechanism. The membrane tension control mechanism comprises a guiding sliding rail mounted at the front end of the vertical plate assembly, a moving seat mounted on the guiding sliding rail, a floating roller set mounted on the moving seat, an air cylinder mounted at the rear end of the vertical plate assembly and used for driving the moving seat and the floating roller set to move on the guiding sliding rail, a potentionmeter and a pressure regulating valve mounted between the air cylinder and the moving seat. In the membrane tension control device of the stacking machine, the tension of the membranes is kept constant through the membrane tension control mechanism, the tension changing speed of the membranes keeps pace with the stacking speed, accordingly, the membranes stacked on pole pieces are flat and not liable to wrinkle, and are prevented from being pulled apart, and thus the quality is improved.

Owner:东莞市沈海自动化科技有限公司

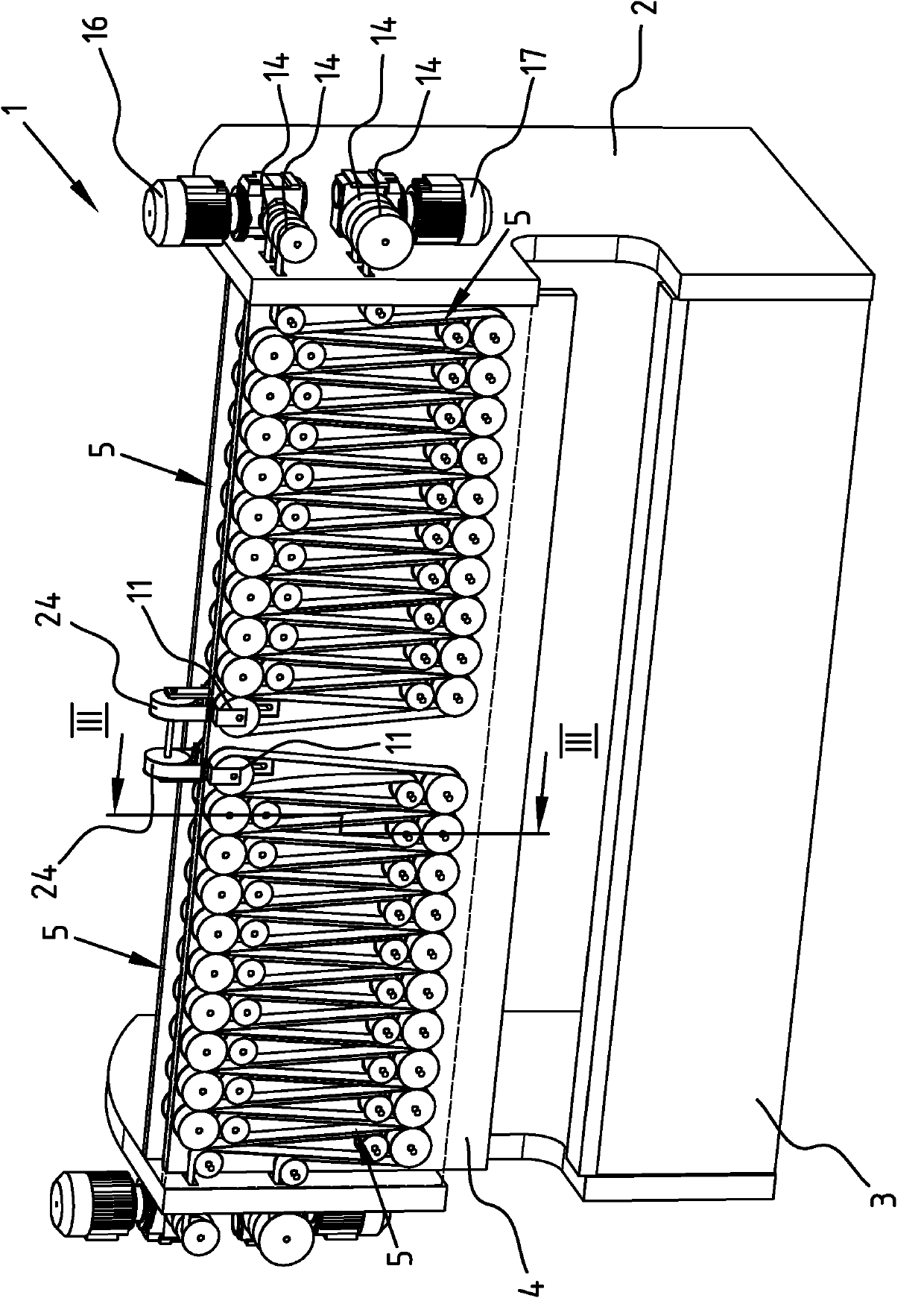

Yarn tensioning system and method for maintaining yarn under tension

ActiveCN108349680BRelease feasibilitySave energyFilament handlingPile-fabric loomsYarnClassical mechanics

The invention relates to a yarn tensioning system (1) for holding under tension at least one yarn (2) withdrawn from a yarn storage system (3) to a yarn delivery system (4) of a loom, It comprises a brake roller (5) on which the yarn (2) is at least partly wound, and a motor (6) providing torque to the brake roller (5), said motor being actuatable in generator operation to The yarn (2) is held under tension between the braking roller (5) and the yarn delivery system (4). Furthermore, the invention relates to a weaving machine comprising such a yarn tensioning system (1), and a method for maintaining under tension at least one yarn (2) withdrawn from a yarn storage system to a yarn delivery system.

Owner:N V MICHEL VAN DE WIELE

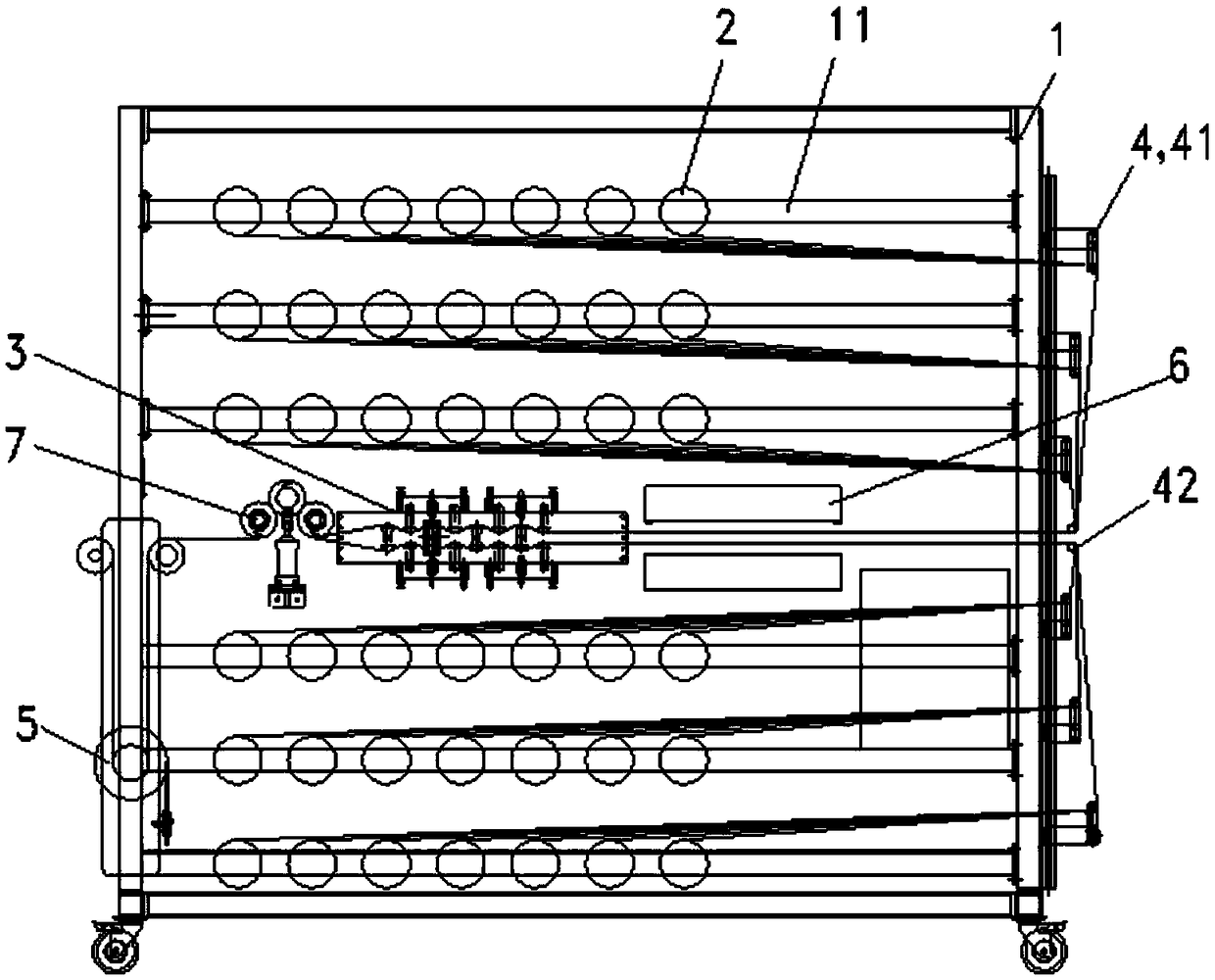

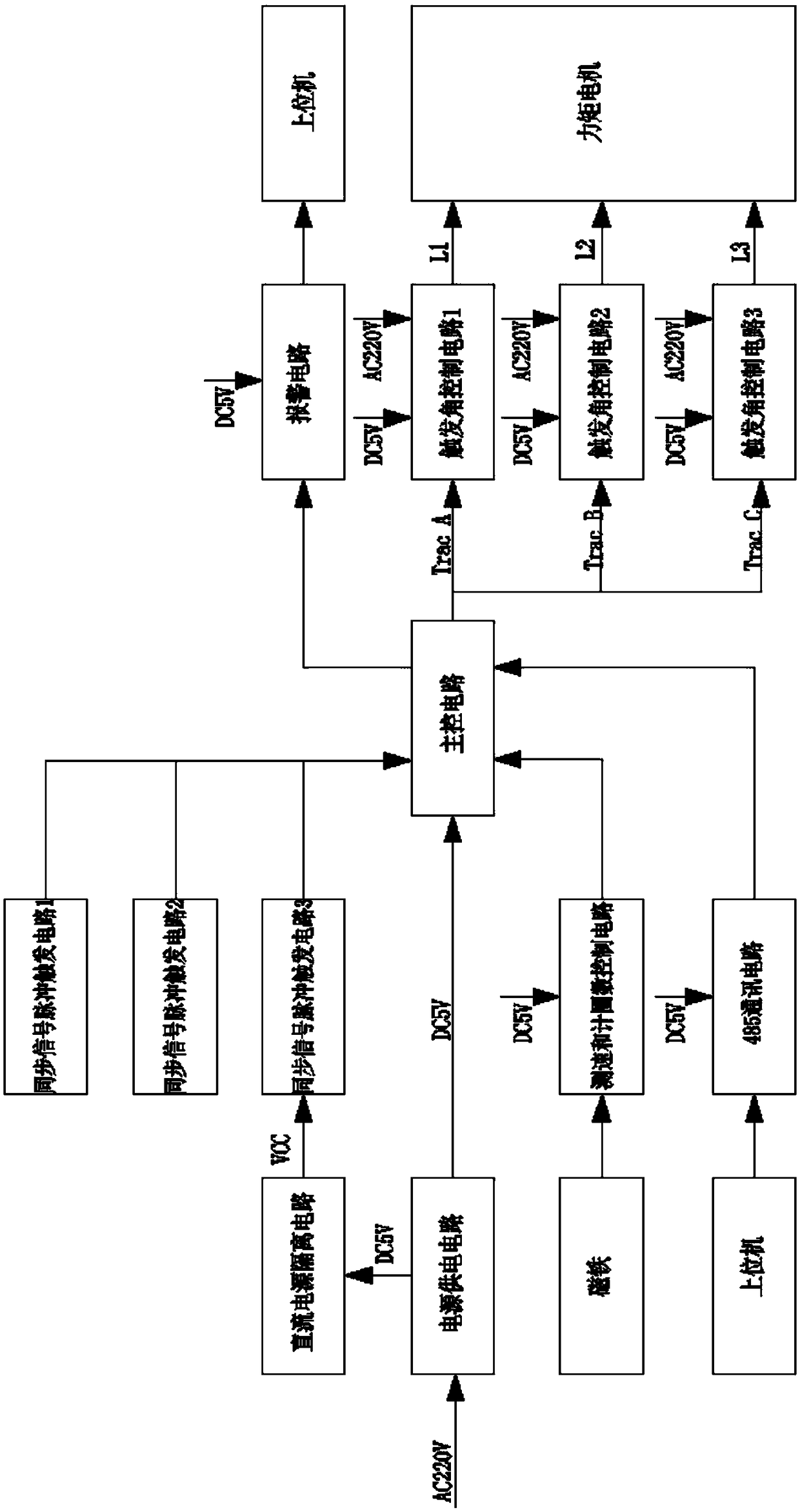

Carbon fiber spreading frame grouped torque control device and control method thereof

PendingCN109230870ALower control costsTension remains constantFilament handlingElectric machineryYarn

The invention relates to the technical field of motors, in particular to a carbon fiber spreading frame grouped torque control device. The device includes a rack, spools, a fiber spreading device, a yarn guide device and a yarn storage device. The rack is provided with at least two layers of support frames used for installation of the spools, the number of the spools arranged on each layer of thesupport frames is same, and the number is more than or equal to two. The spools, same in arrangement position, in each spool layer reach the yarn guide device at the same angle and are transferred tothe fiber spreading device through gathering of the yarn guide device, and after fiber spreading, yarn reaches the yarn storage device for storage. According to the technical scheme, the motor controlcost is effectively reduced, and labor and time cost brought by manual debugging are saved. Moreover, the invention further requests a control method for the carbon fiber spreading frame grouped torque control device.

Owner:NEWTRY COMPOSITE

Yarn conveying device used for knitting machine

InactiveCN108978016AComprehensive contactPositive yarn feeding and stabilityWeft knittingWarp knittingYarnEngineering

The invention discloses a yarn conveying device used for a knitting machine. The device comprises a body. A fixing seat is arranged on the body. A rotary shaft is installed in the middle of the fixingseat. A main shaft vertically penetrates through the fixing seat. Driving belt pulleys and a clutch are arranged on the rotary shaft on the fixing seat. The rotary part at the bottom of the fixing seat is equipped with yarn conveying wheels. A yarn penetrating board is fixed below the fixing seat. The yarn penetrating board is vertically arranged besides the yarn conveying wheels. Third yarn guide eyes are arranged in the yarn penetrating board. The yarn penetrating board is equipped with a tension regulator. A yarn cleaning device is arranged at the lower end of the fixing seat. A wire rackis fixedly connected on the fixing seat. The wire rack is equipped with a micro-adjusting yarn-pressing device. The top end and the bottom end of the wire rack is equipped with multiple first yarn guide eyes and second yarn guide eyes. The yarn conveying device is clean in structure such that yarns have certain tension force and helps evidently reduce processing cost of broken yarns. The yarn conveying wheels can automatically clean residual filaments in order to increase quality of fabric on the knitting machine.

Owner:伊婕

Pole piece winding equipment

The invention discloses pole piece winding equipment. The pole piece winding equipment comprises a support. The top of the support is provided with a first rack and a second rack located on the rightside of the first rack. The first rack is provided with pull rolls. The second rack is provided with a guide wheel, a first driving wheel, a second driving wheel, a tension detector and a cutting device from left to right in sequence. The top of the support is further provided with a winding device located on the right side of the cutting device. The winding device comprises an angle adjustable supporting rod arranged on the top of the support, a winding drum arranged at the top end of the supporting rod and a winding motor arranged on one side of the winding drum and connected with the winding drum. The winding drum is internally provided with a frequency converter. Thus, the pole piece winding equipment provided by the invention brings convenience to people for use.

Owner:浙江猫头鹰网络科技有限公司

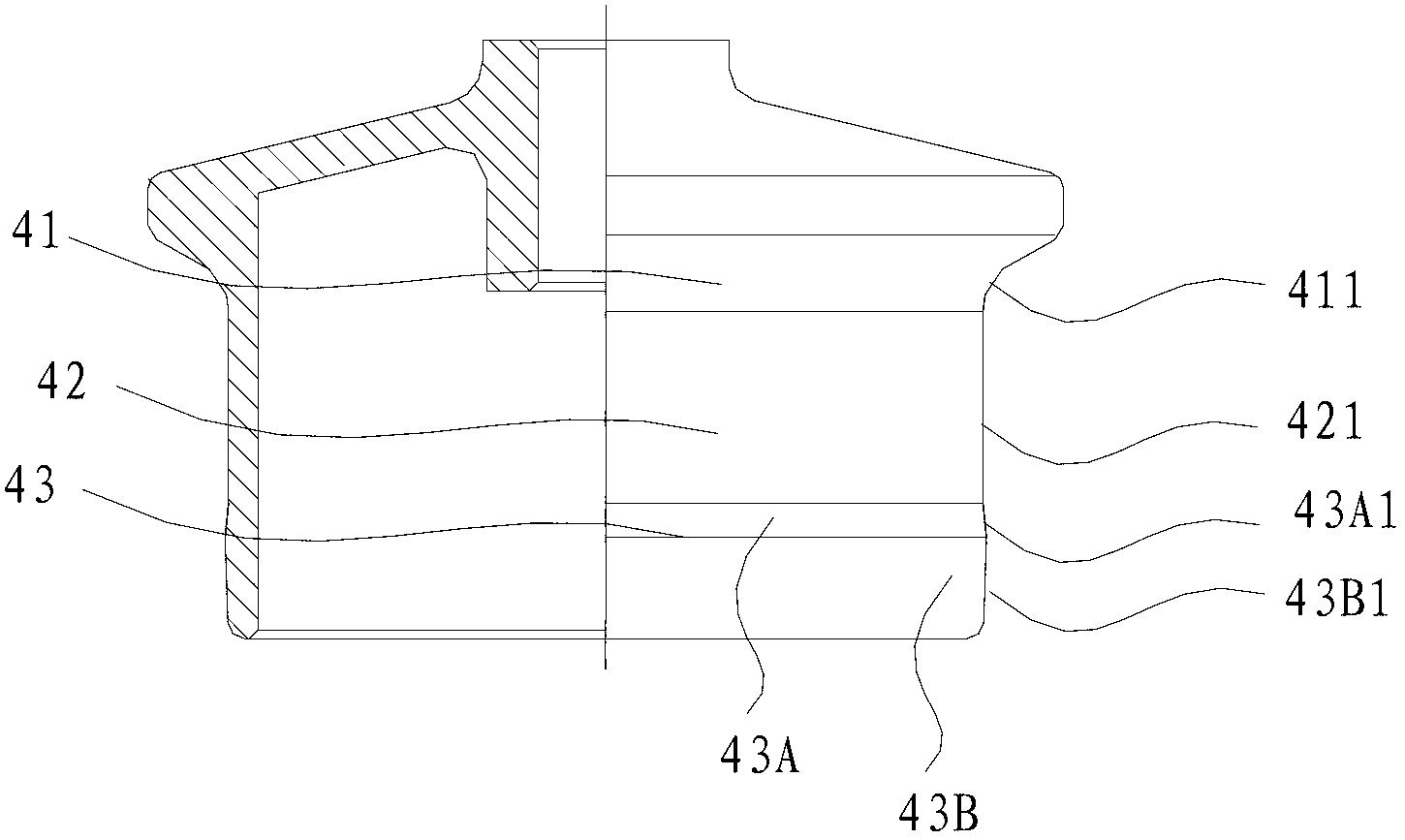

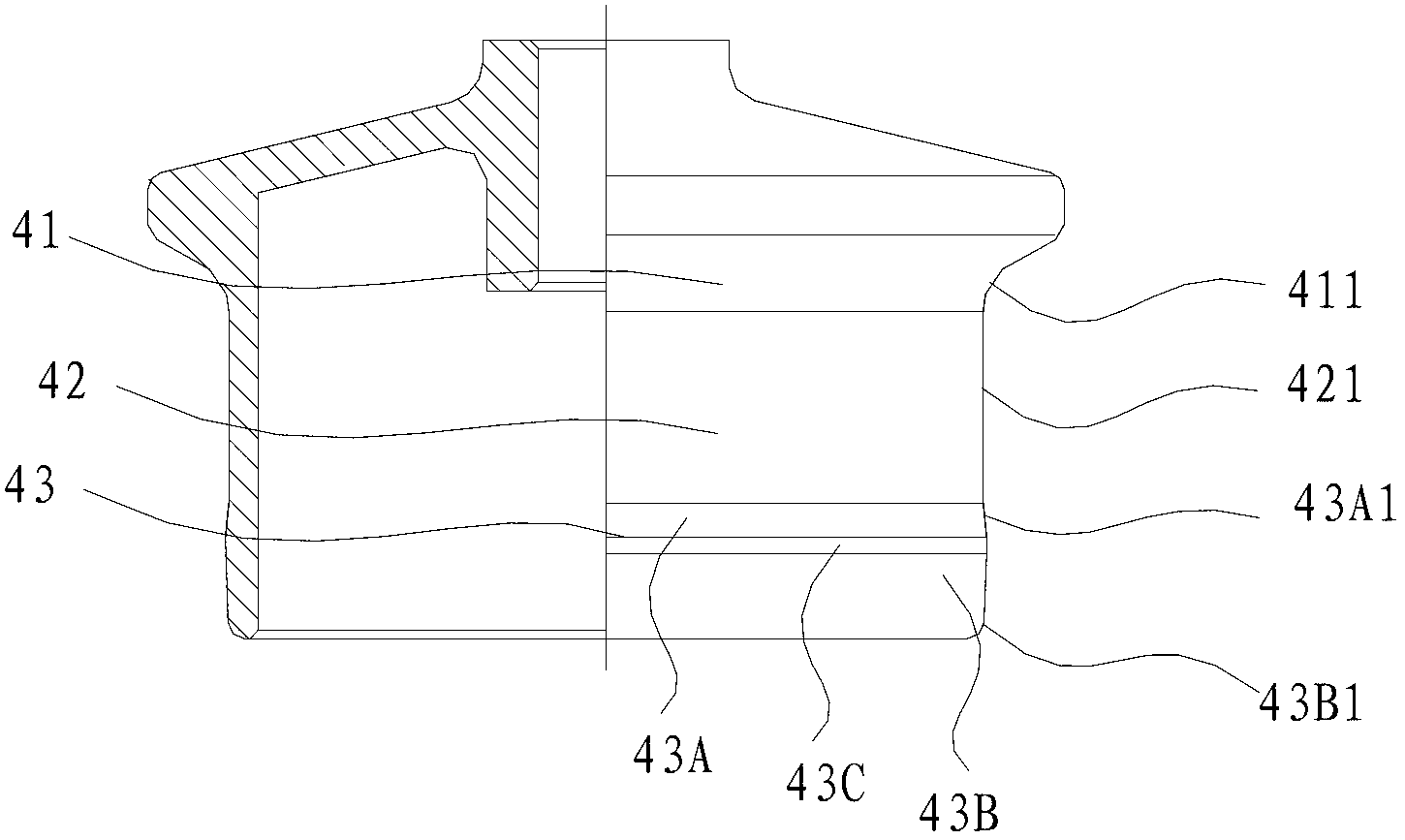

Yarn delivering wheel for knitting machine

The invention relates to a knitting machine, particularly to a yarn delivering wheel for the knitting machine. The yarn delivering wheel sequentially comprises a yarn feeding cone, a yarn storage column and a waste silk leading-out body which are connected into a whole from top to bottom; the yarn feeding cone comprises a large upper part and a small lower part; the waste silk leading-out body comprises a waste silk temporary storage cone with a small upper part and a large lower part and a waste silk leading-out cone with a large upper part and a small lower part; the outside wall of the yarn feeding cone, namely a yarn feeding region, is an arc surface which inclines inwards from top to bottom; and an angle between an upper inclined surface and the outside wall of the yarn storage column is more than 150 degrees. The yarn delivering wheel for the knitting machine has the advantages of novel structure and capability of automatically removing residual waste silk, so that the tension force for delivering yarn for a knitting yarn delivering device keeps constant, therefore the quality of fabrics on the knitting machine is improved.

Owner:CIXI SUN TEXTILE SCI & TECH

PET film double-sided rapid coating and coating equipment

PendingCN111785916AEasy to produceIncrease productivityElectrode rolling/calenderingElectrode thermal treatmentMetallic electrodeElectrical battery

The invention discloses a PET film double-sided rapid coating and coating equipment. The equipment comprises an unwinding mechanism for conveying a PET film in a first direction, a first coating mechanism, a first drying and calendering mechanism, a reversing mechanism which is used for overturning the front and back surfaces of the PET film, a second film coating mechanism which is the same as the first film coating mechanism in structure and is arranged right above the first drying and calendering mechanism, a second drying and calendering mechanism which is the same as the first drying andcalendering mechanism in structure, and a winding mechanism which is used for recycling the PET film in a second direction. According to the invention, a plurality of vacuum cavities are arranged, themechanisms are respectively arranged in respective cavities to enable the PET film of a battery pole piece to pass through all the mechanisms in sequence, the processing and forming of the aluminum film and the copper film and the functions of coating the positive electrode material and the negative electrode material are completed at one time, and the processing of the cathode metal electrode, the cathode material, the anode metal electrode and the anode material of the battery can be completed in one unwinding and winding process, so that the production process of the lithium ion battery issimplified, the production efficiency is improved, and the cost is reduced.

Owner:JILIN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com