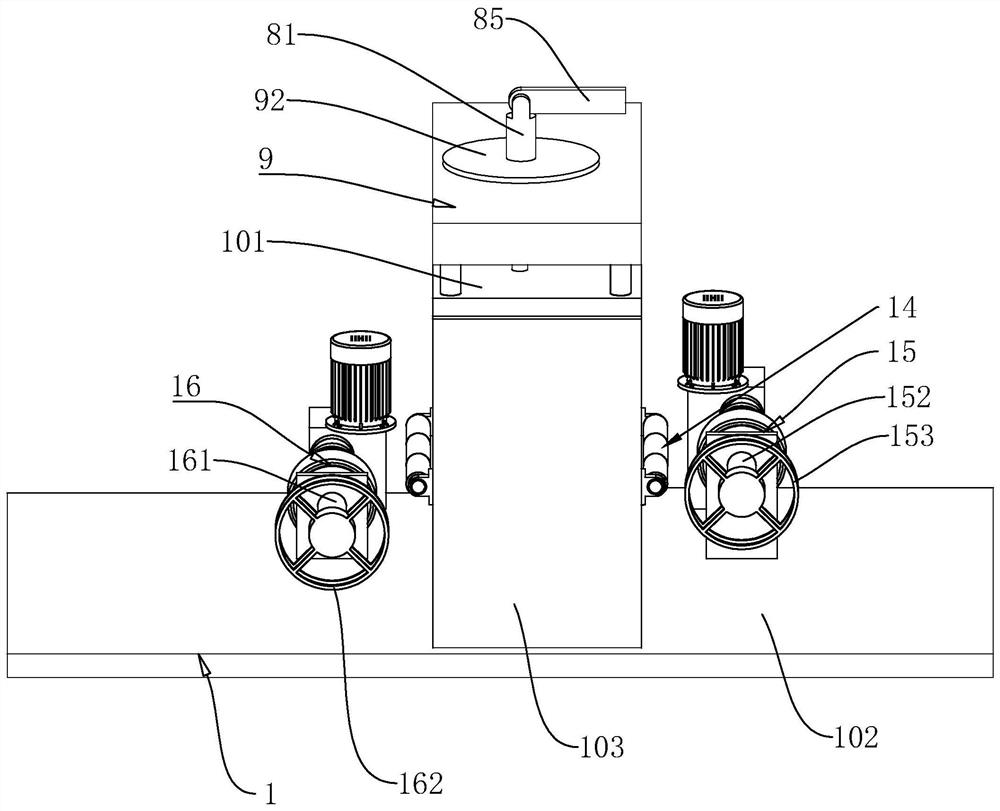

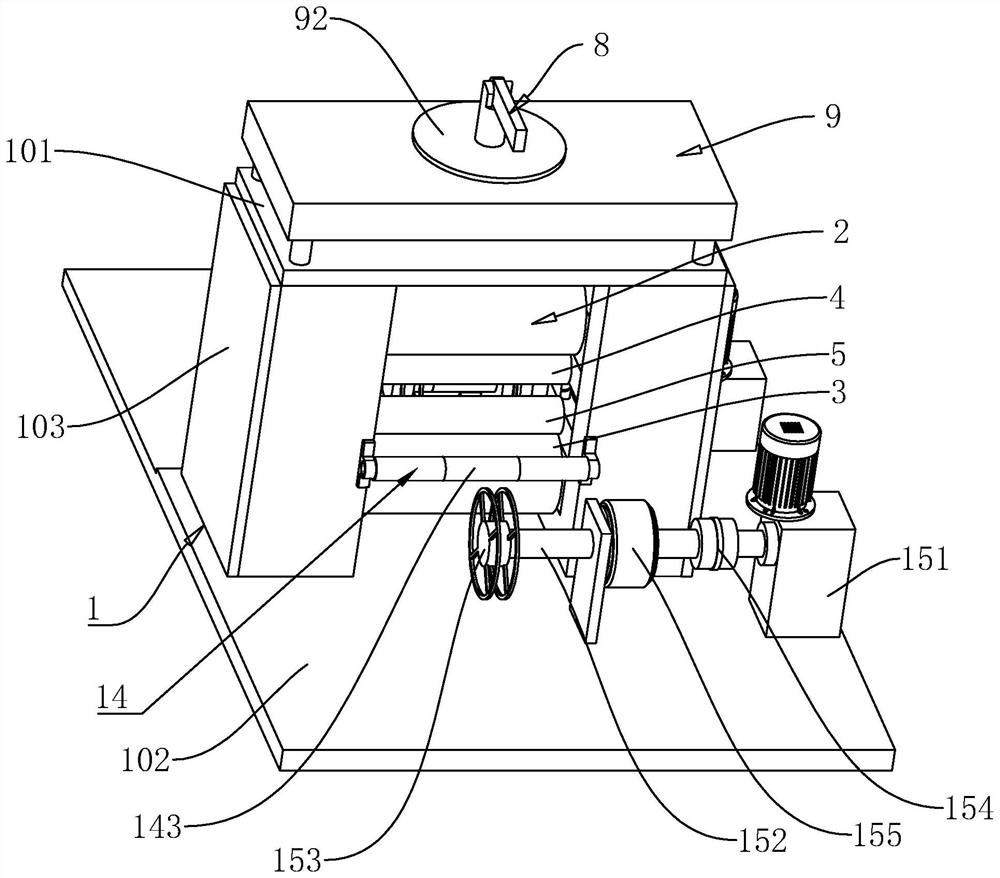

Four-roller tabletting device

A rolling and consistent technology, applied in braking/tightening devices, metal rolling, metal rolling stands, etc., can solve the deformation of two rollers, difficult to meet the precision of jewelry processing, and the thickness of the metal sheet on both sides. thin and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

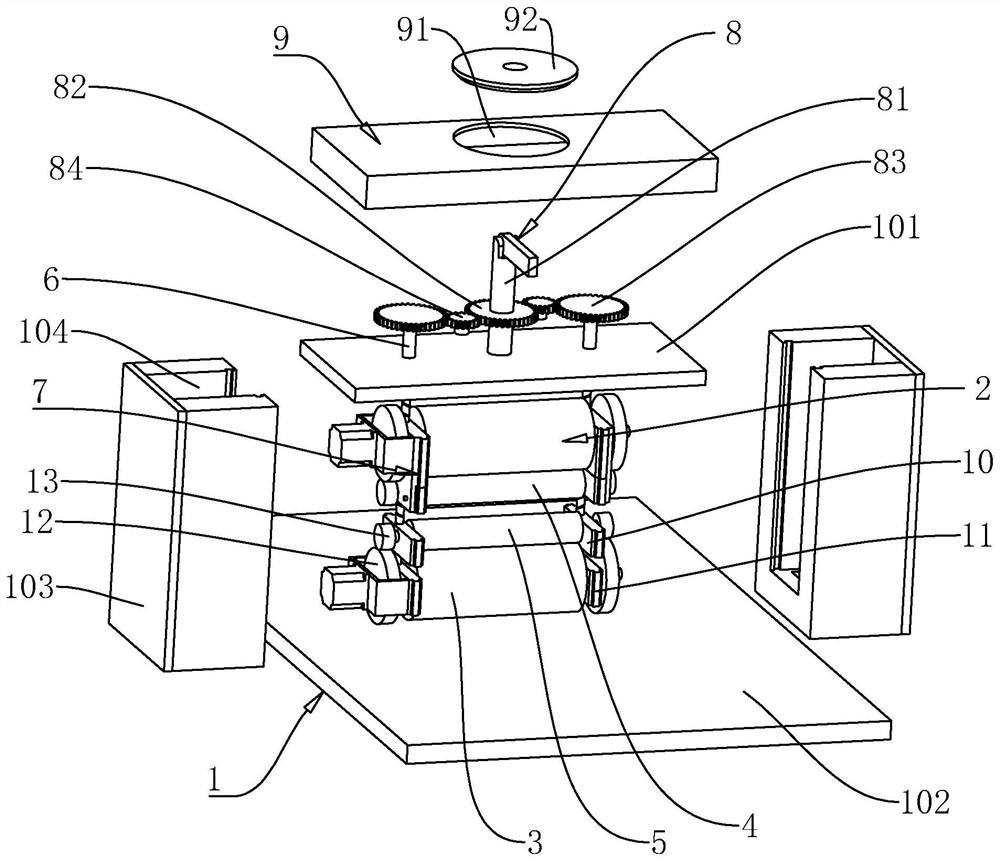

[0072] refer to Image 6 The difference between the second embodiment and the first embodiment is that the four-roller sheeting device is provided with a transfer assembly for receiving the metal sheet 105 from the unwinding assembly 15 to the winding assembly 16; when it is necessary to replace the rolled metal sheet 105, the conveying device is used to take the metal sheet 105 from the unwinding wheel 153 more conveniently and safely, take the metal sheet 105 through the gap between the upper rolling roller 4 and the lower rolling roller 5, and send it to the receiving roller. Reel 162.

[0073] refer to Figure 7 with Figure 8 The conveying device includes a conveying assembly for taking over the metal sheet 105 on the unwinding wheel 153, and a receiving assembly for receiving the metal sheet 105 on the conveying assembly to the winding wheel 162; the receiving assembly is arranged on the receiving The volume assembly 16 is away from the side of the rack 1 .

[0074]T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com