Passive type constant tension hydraulic control system of mooring winch

A hydraulic control system, passive technology, applied in the direction of the spring mechanism, fluid pressure actuating device, servo motor, etc., can solve the problems of low reliability, high cost, and complex equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

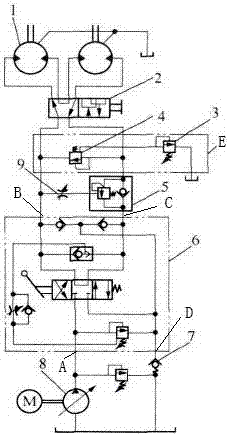

[0016] The passive constant tension hydraulic control system of the mooring winch of the present embodiment, as figure 1 As shown, it includes a hydraulic pump 8, a two-way hydraulic motor 1 and a reversing valve 6, and the reversing valve 6 is used to switch the inlet and outlet ports of the two-way hydraulic motor 1 so as to change the direction of rotation of the two-way hydraulic motor 1. The parking winch is driven by a two-way hydraulic motor 1; the reversing valve 6 has four oil ports A, B, C, and D, and the oil outlet of the hydraulic pump 8 is connected to the A oil port of the reversing valve 6. A back pressure valve 7 is connected in series between the D oil port of the reversing valve 6 and the oil tank 1; the first oil inlet and outlet port of the bidirectional hydraulic motor 1 is connected with the B oil port of the reversing valve 6 through the first oil guide pipe, so The second oil inlet and outlet ports of the two-way hydraulic motor 1 are connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com