Tinsel coating control system and method

A control system and metal foil technology, applied in the direction of winding strips, function indication, thin material processing, etc., can solve problems affecting coating quality and equipment accuracy, system jitter, uncontrolled tension, etc., to achieve improved coating The effect of quality and equipment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and cannot be used to limit the protection scope of the present invention.

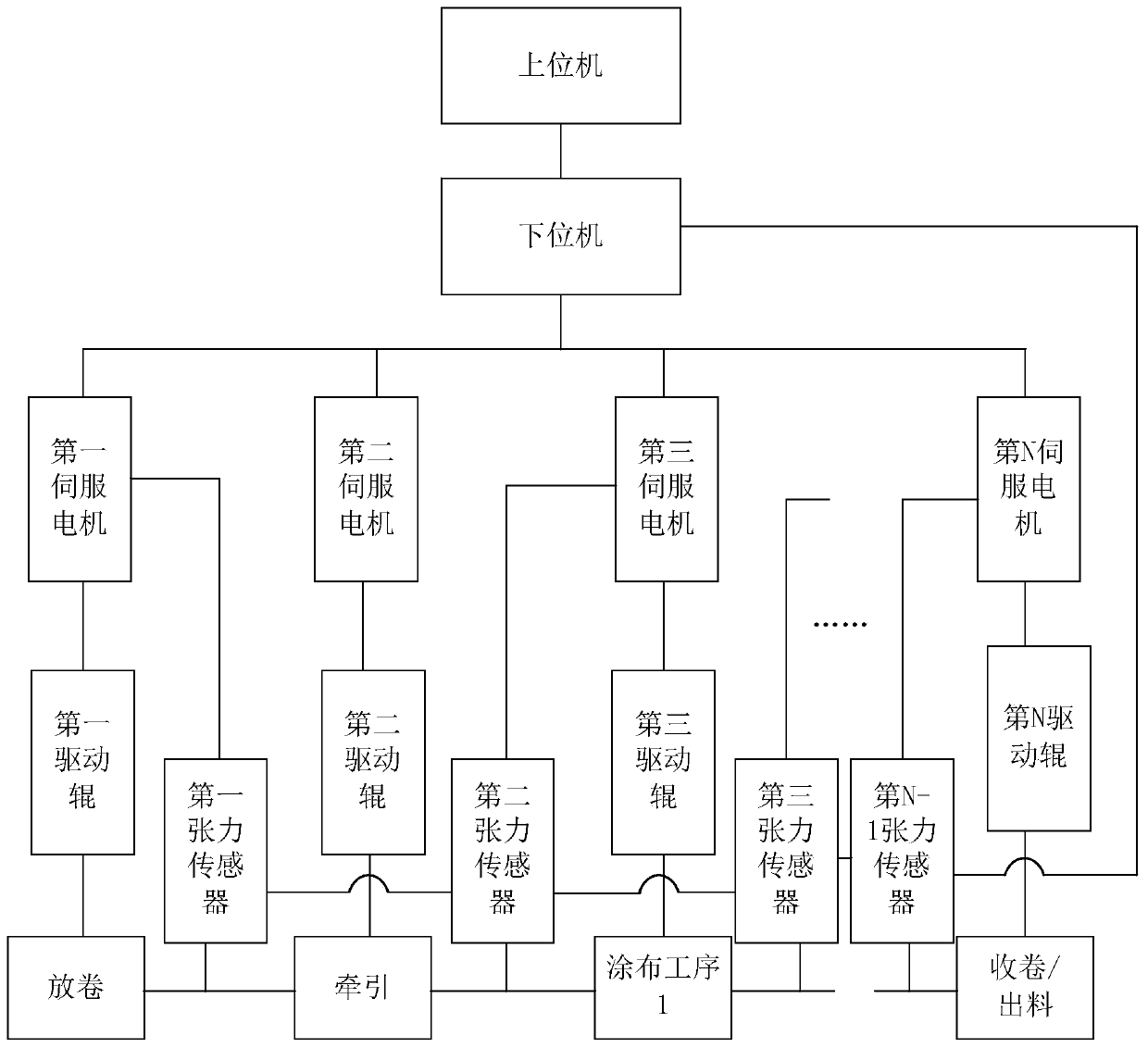

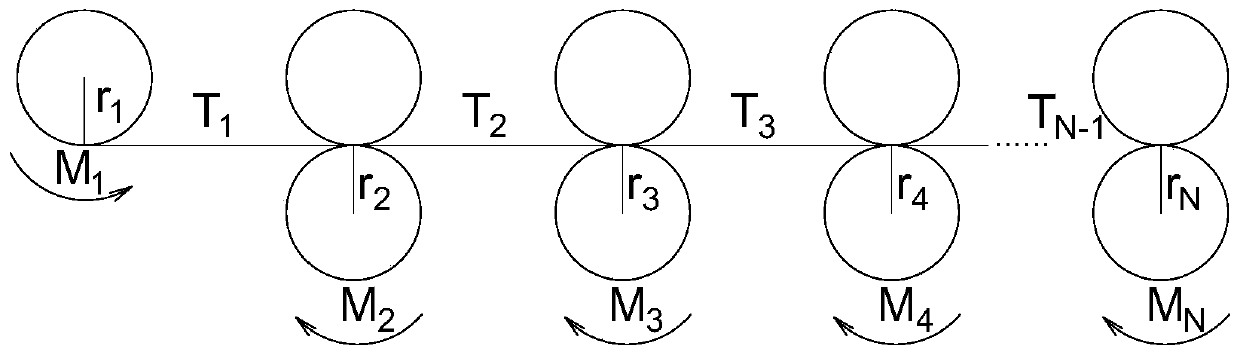

[0049] figure 1 It is a schematic diagram of the implementation of the metal foil coating control system provided by the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown in the figure.

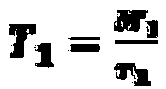

[0050] The metal foil coating control system includes N servo motors communicating with the lower computer and N-1 tension sensors corresponding to the N servo motors for collecting the tension of the metal foil at the corresponding position;

[0051]The N servomotors are respectively denoted as the first servomotor, the second servomotor, ...,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com