Servo control based multilayer flame laminating mechanism

A technology of flame compounding and servo control, which is applied in the direction of controlling lamination, lamination, lamination device, etc., can solve the problems of different shrinkage, material wrinkling, and no major improvement in the production compounding process, so as to achieve overall quality improvement , surface smoothness, and the effect of avoiding changes in the amount of retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

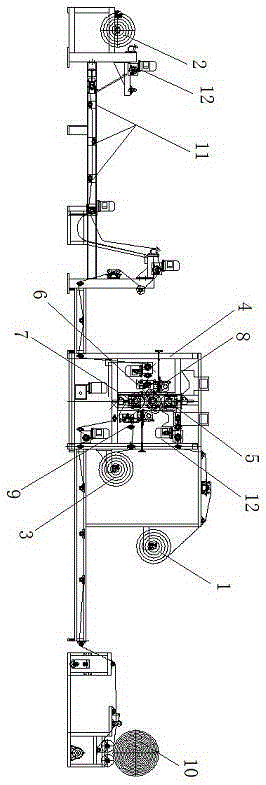

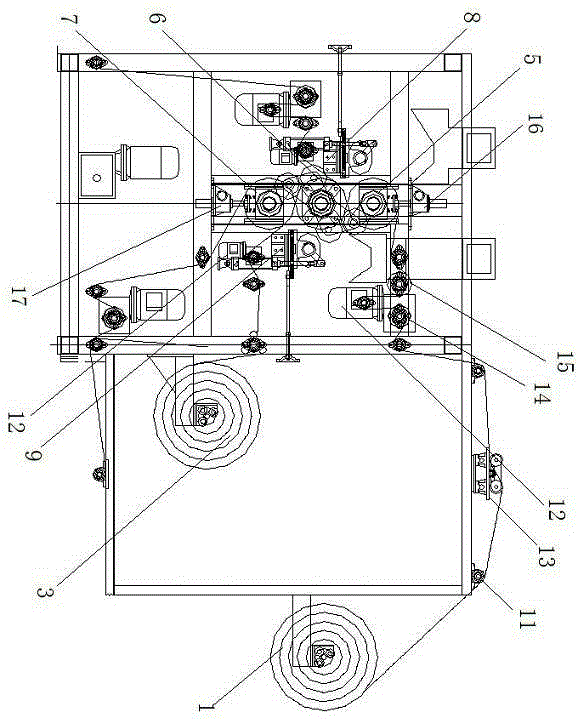

[0030] like figure 1 and figure 2 A servo-controlled multi-layer flame composite mechanism is shown, which includes a discharge mechanism, a flame composite mechanism and a material receiving mechanism; a grass-roots spreader 1 for placing grass-roots raw materials is arranged in the discharge mechanism, The first fabric expander 2 for placing the first fabric fibers and the second fabric expander 3 for placing the second fabric fibers, the base layer expander 1, the first fabric expander 2 and the second fabric expander The cloth devices 3 all use three-roller cloth expanders, the base material is sponge, and the first fabric fibers and the second fabric fibers can be any textiles.

[0031] The flame recombination mechanism includes a main frame 4, and the first water-cooled roll 5, the second water-cooled roll 6 and the third water-cooled roll 7 are arranged in the main frame 4 in order in the vertical direction, wherein the first water-cooled roll 5 is in contact with th...

Embodiment 2

[0041] As an improvement of the present invention, such as figure 1 and figure 2As shown, in the discharging mechanism, the servo traction devices corresponding to the grass-roots cloth expander 1 and the first fabric expander 2 and the second fabric expander 3 respectively include a pneumatic deviation correction device 13 and an opening and closing device. The width device, the opening device includes a rubber rough surface roller 14 and a metal opening roller 15; the pneumatic correction device 13, the rubber rough surface roller 14 and the metal opening roller 15 are set up in sequence along the direction of the raw material. With the above-mentioned design, it can keep the base material / fabric fiber above the set transmission direction in real time during the transmission process through the setting of the pneumatic deviation correction device, so as to avoid its deviation during the transmission process, thus causing the base material and fabric fiber The fabric fibers...

Embodiment 3

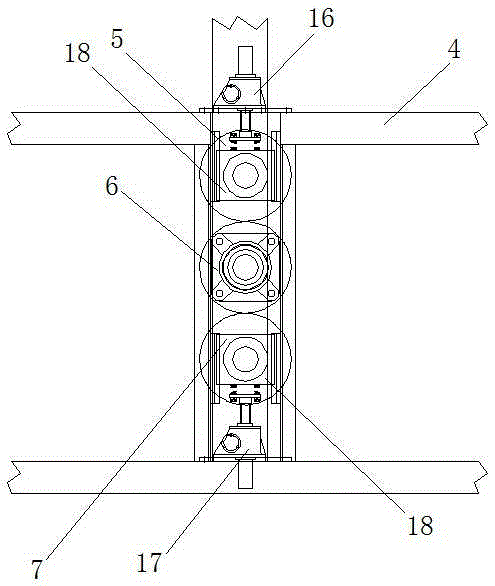

[0044] As an improvement of the present invention, such as image 3 and Figure 4 As shown, the first water-cooled roll 5, the second water-cooled roll 6 and the third water-cooled roll 7 are connected to each other; the main frame 4 is provided with a step-up and lowering device, which includes the first water-cooled roll 5 The upper hydraulic cylinder 16 above, and the lower hydraulic cylinder 17 arranged below the third water-cooled roller 7, the push rods of the upper hydraulic cylinder 16 and the lower hydraulic cylinder 17 all extend vertically, and they are respectively connected to the first water-cooled roller 5 And the third water-cooled rollers 7 are connected to each other. With the above-mentioned design, it can make the first water-cooled roller, the second water-cooled roller and the third water-cooled roller The position in the vertical direction can be adjusted. Since the tension generated by multiple water-cooled rollers on the base material / fabric fibers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com