Carbon fiber spreading frame grouped torque control device and control method thereof

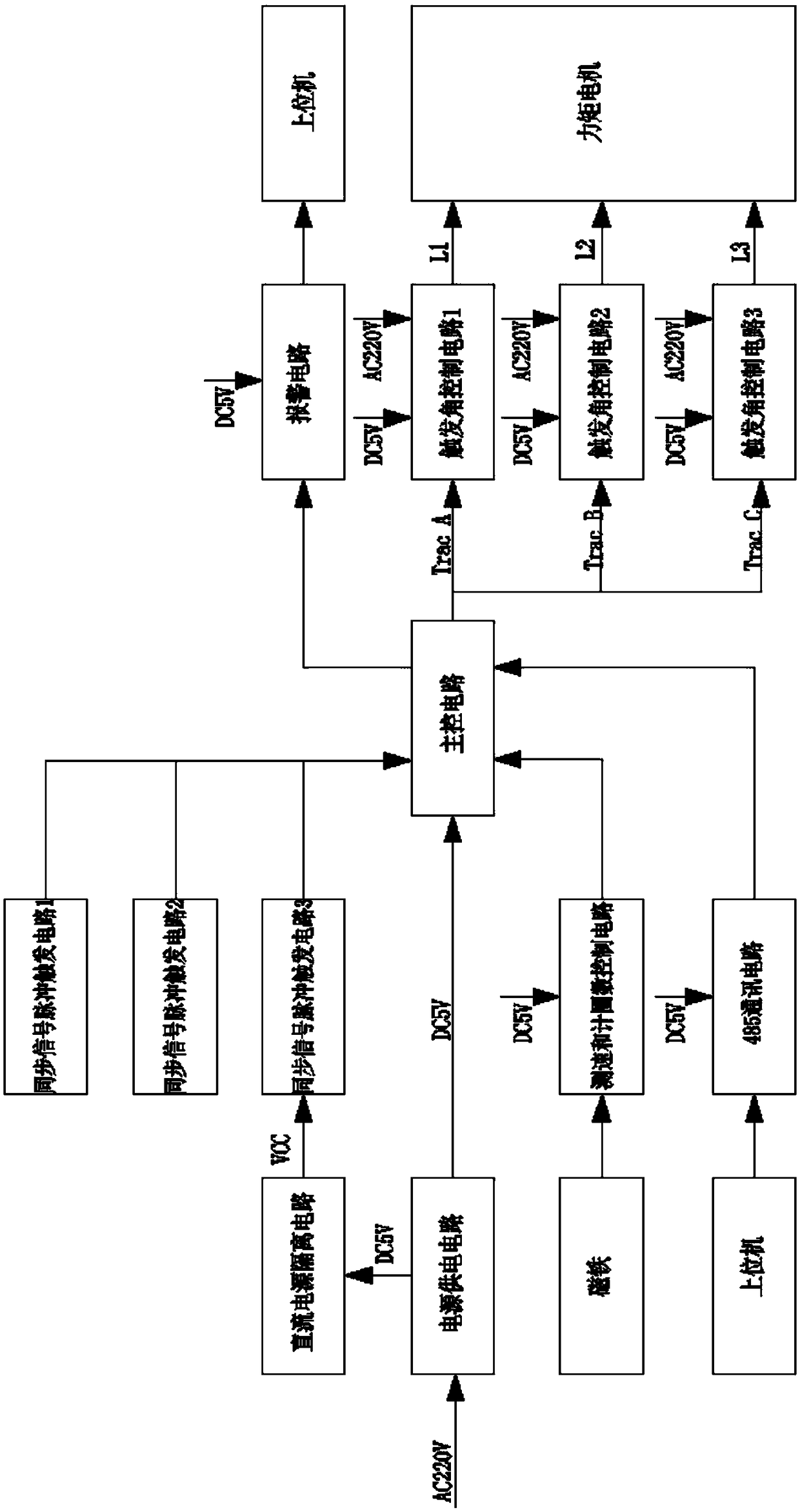

A control device and control method technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the waste of labor and time, at least dozens of torque motors are needed, and as many as one or two hundred , Implement cost improvement and other issues, to achieve the effect of reducing control costs, saving manpower and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

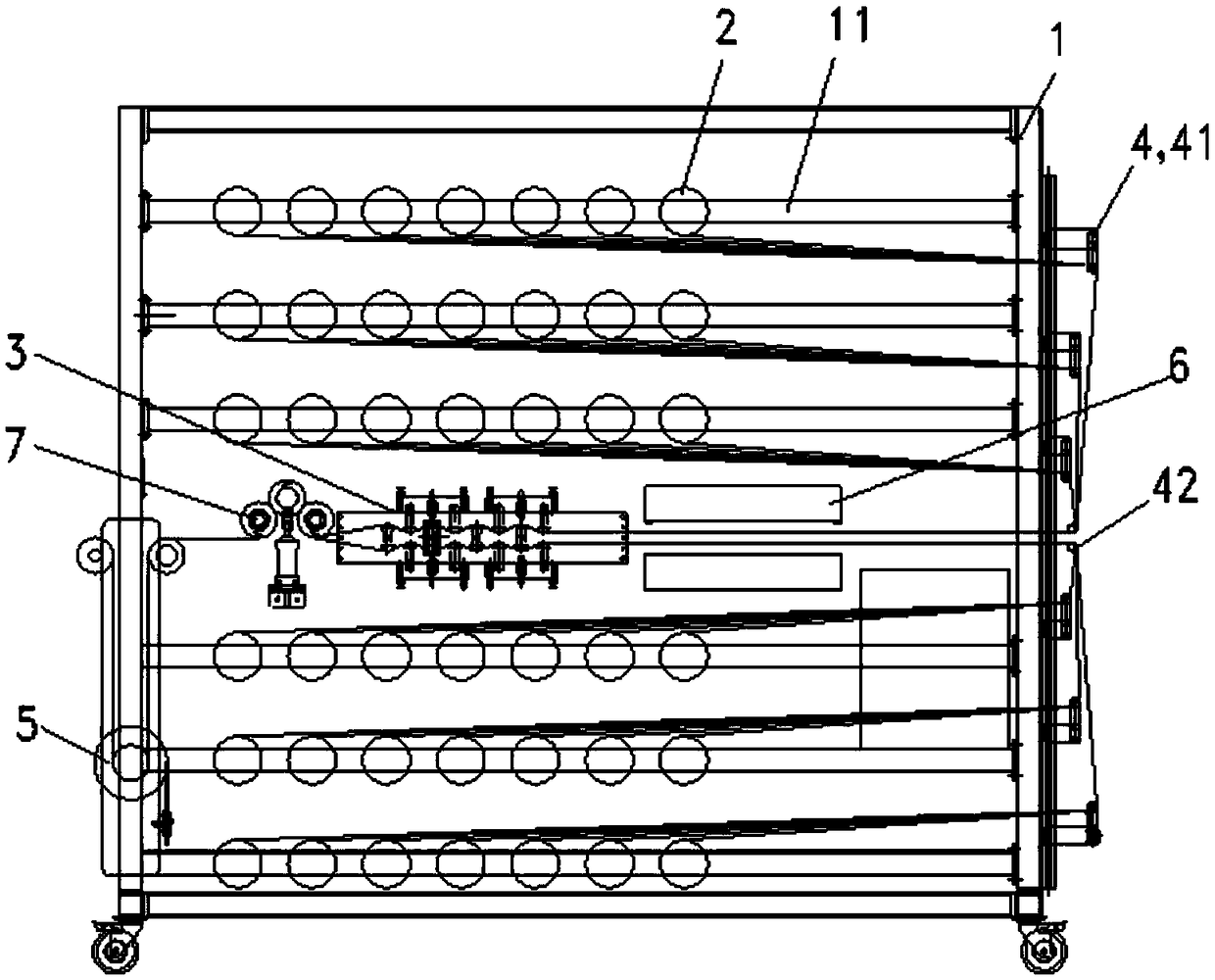

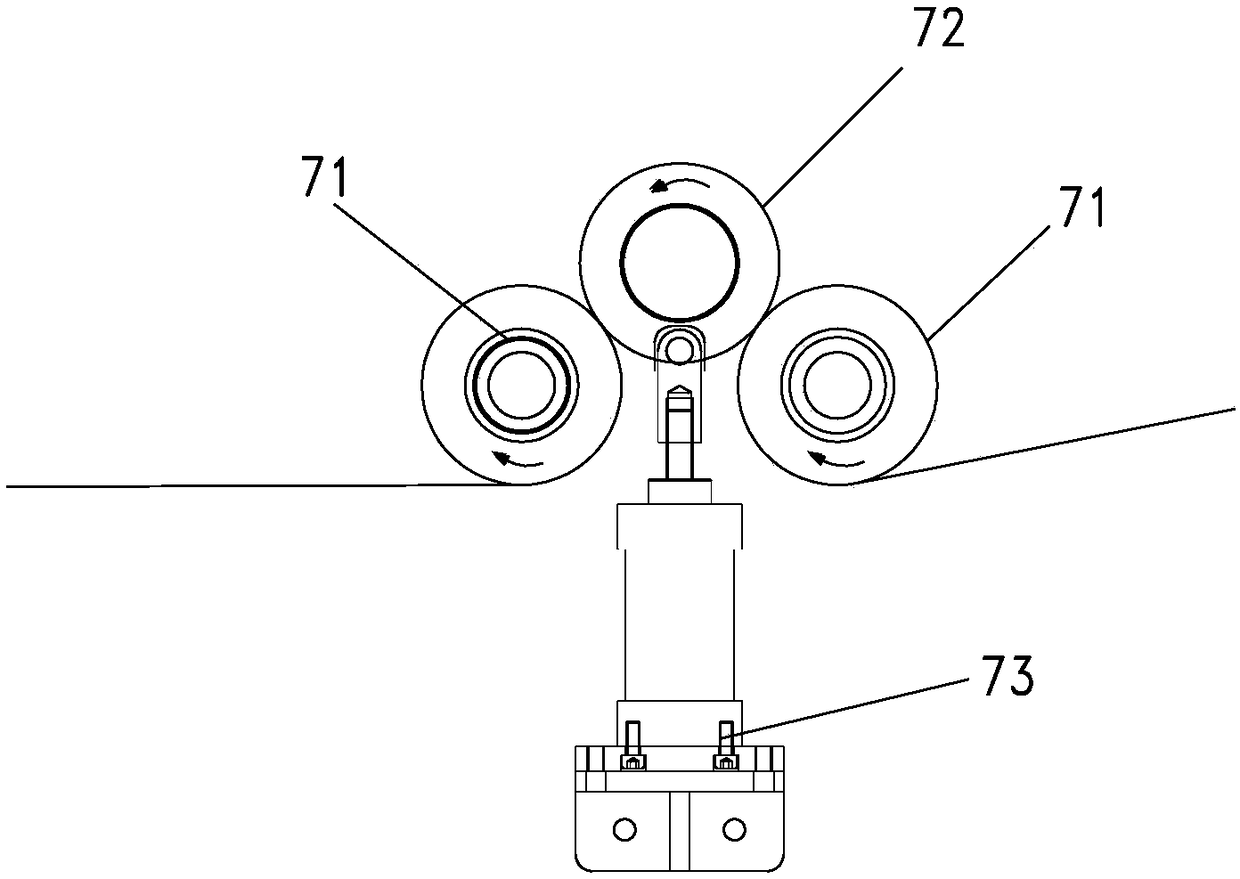

[0032] The carbon fiber spreading creel grouping torque control device in the present invention includes: frame 1, yarn tube 2, fiber spreading device 3, yarn guide device 4 and yarn storage device 5; frame 1 is provided with at least two layers for yarn alignment The number of bobbins 2 set on each layer of the frame 11 is equal, and the number is greater than or equal to 2. Among them, the yarns on the bobbins 2 in the same arrangement position in each layer of bobbins 2 The yarns all arrive at the yarn guide 4 at the same angle, and are collected by the yarn guide 4 and sent to the spreading device 3. After spreading, the yarn reaches the yarn storage device 5 for storage. In this embodiment, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com