Engineering machinery and engineering machinery control method

A technology for construction machinery and controllers, applied in mechanical equipment, cranes, transportation and packaging, etc., can solve problems such as container collision, engine aging, and reduced engine working life, so as to reduce sealing requirements, reduce use costs, and reduce control cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

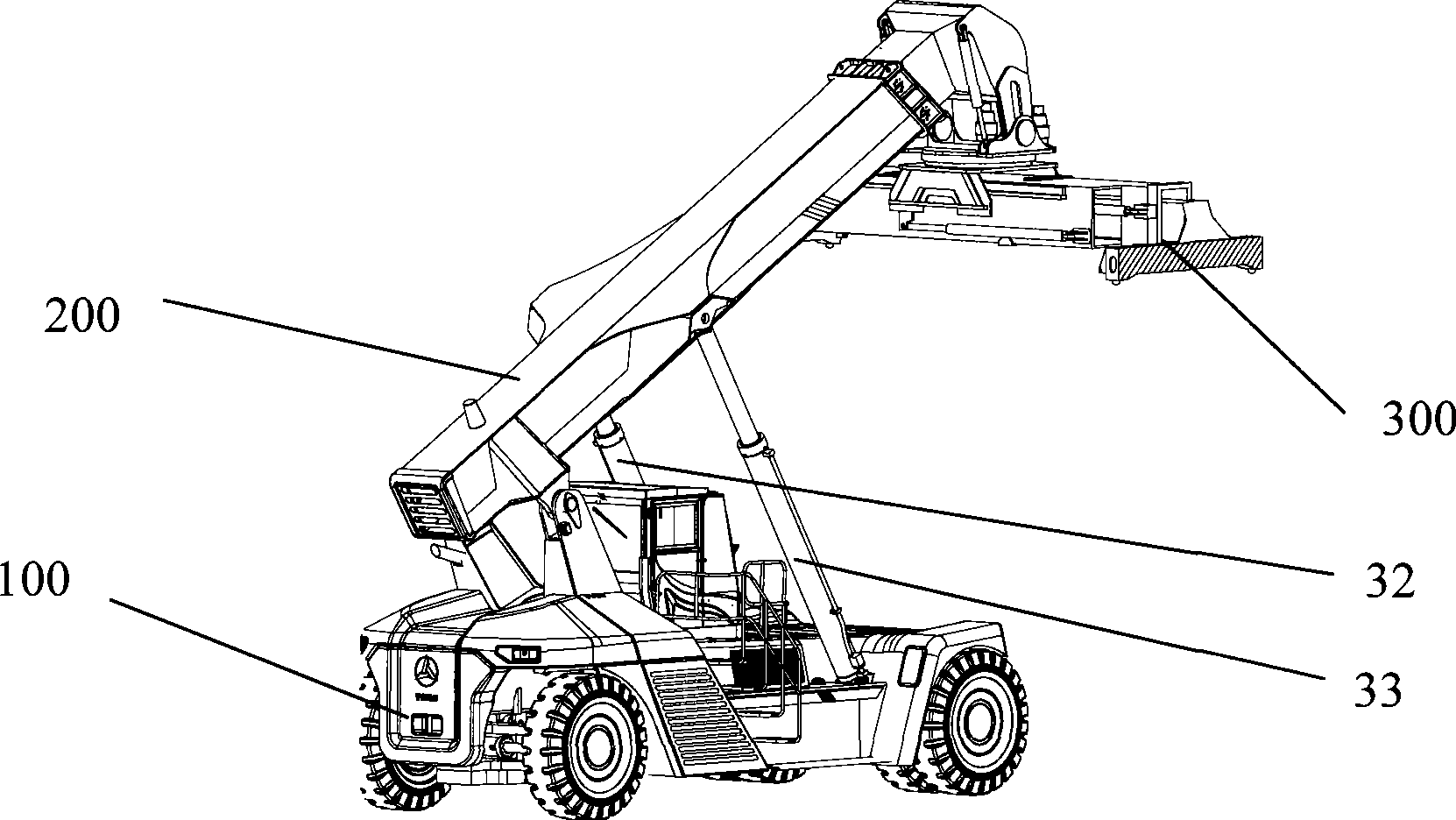

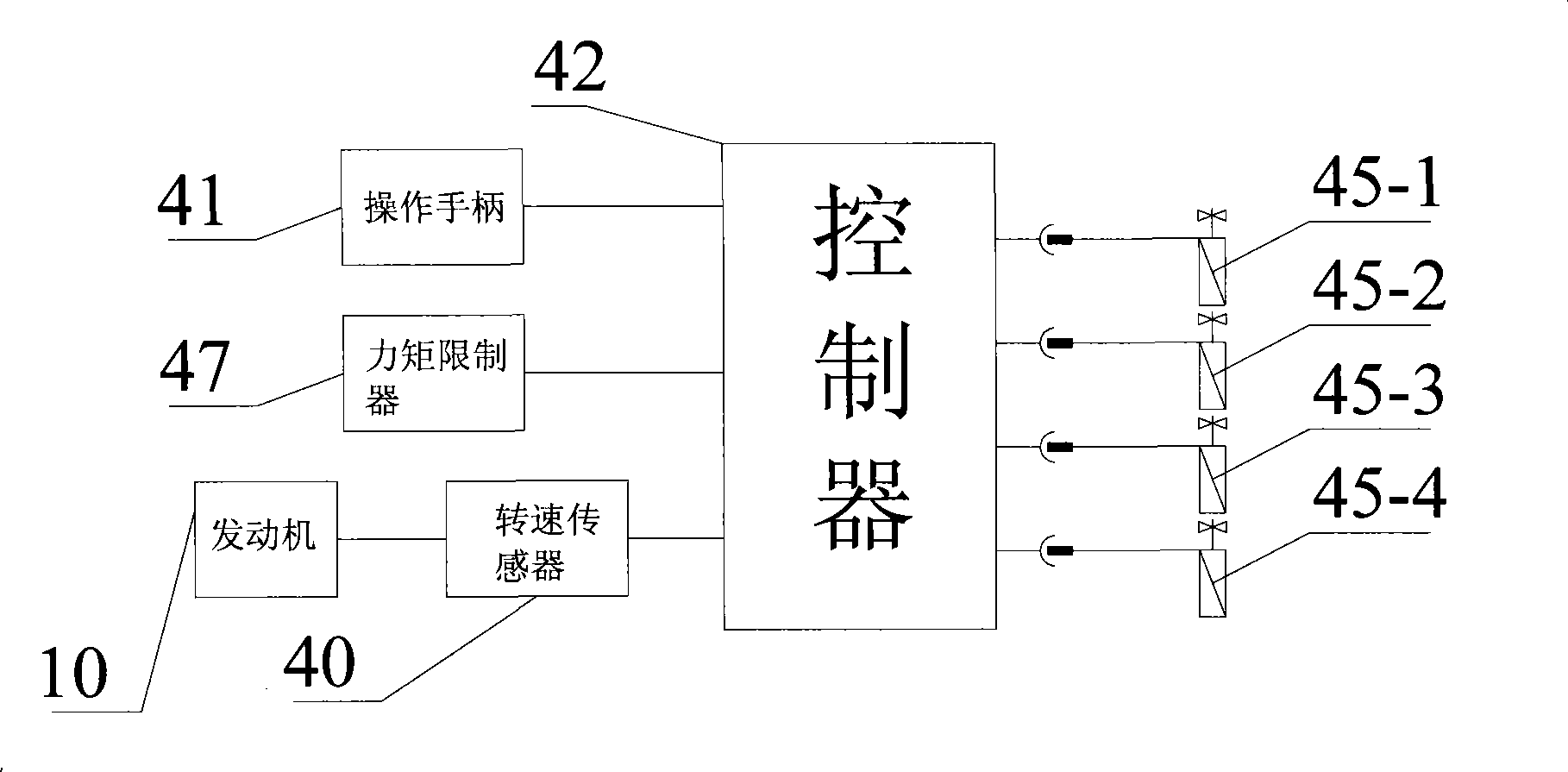

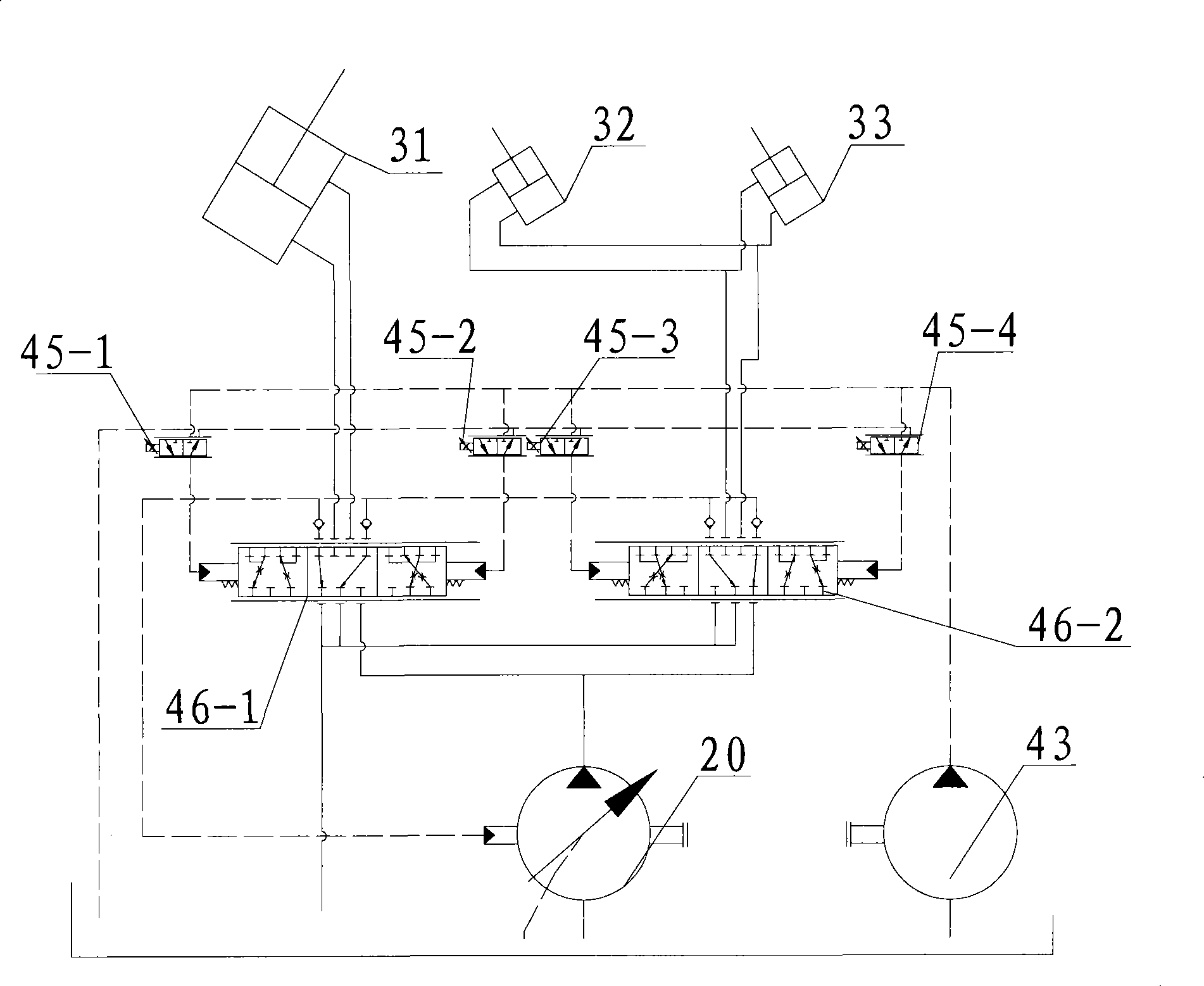

[0036] Embodiment 1 provides a container reach stacker, combined with figure 2 and image 3 , the container reach stacker includes an engine 10, a variable hydraulic pump 20, a telescopic oil cylinder 31, a left pitching oil cylinder 32, a right pitching oil cylinder 33 and a control system.

[0037] In this example, the variable hydraulic pump is preferably a swash plate variable displacement plunger pump with a pressure compensation variable mechanism. The swash plate variable displacement piston pump is convenient for displacement adjustment; Return to original displacement. Those skilled in the art can understand that the variable variable hydraulic pump can also be a variable variable inclined-axis plunger pump, or a variable variable vane pump.

[0038] The control system includes a speed sensor 40, a torque limiter 47, an operating handle 41, a controller 42, an auxiliary hydraulic pump 43, four proportional pressure valves 45-1 to 45-4 and two proportional reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com