Yarn delivering wheel for knitting machine

A technology of feeding pulley and knitting machine, applied in the field of feeding pulley, can solve the problems of uneven yarn feeding tension, yarn breakage, hindering yarn feeding, etc., and achieves the effects of novel structure, constant tension and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

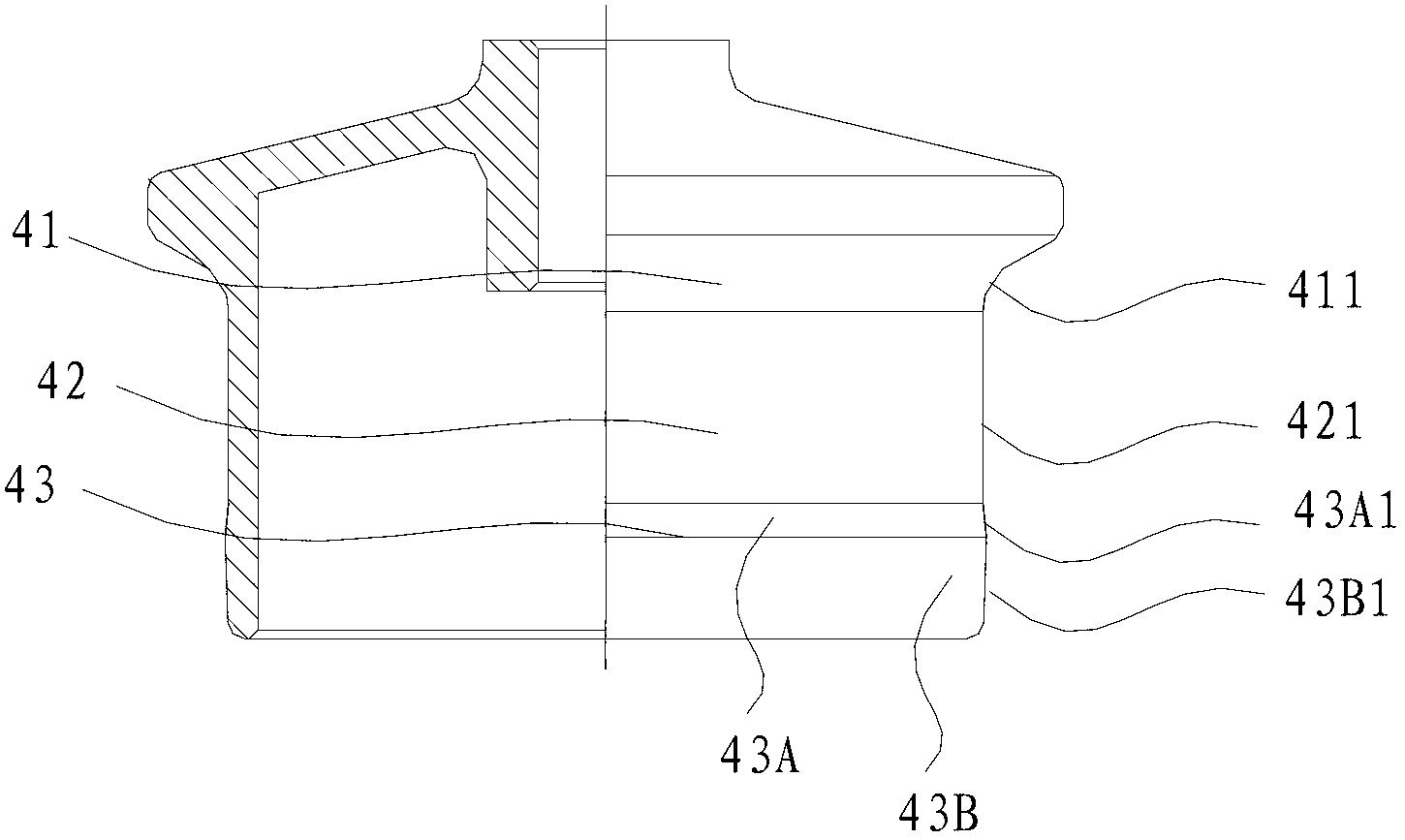

[0014] like figure 1 The thread feeding wheel on the shown knitting machine, the thread feeding wheel includes from top to bottom successively a connected upper, lower, and lower yarn introduction cone 41, yarn storage cylinder 42 and waste silk exporter 43, and the waste silk is exported The body 43 includes a waste silk temporary storage cone 43A with a small top and a large bottom and a waste silk exporting cone 43B with a large top and a small bottom. The outer wall surface of the yarn introducing cone 41, that is, the yarn introducing area 411, is an arc surface inclined from outside to inside from top to bottom. The outer wall surface of the yarn storage cylinder 42 is the yarn storage area 421, and the outer wall surface is a plane. The outer wall surface of the waste silk temporary storage cone 43A and the waste silk exporting cone 43B is the waste silk exporting area, the outer wall surface of the waste silk temporary storage cone 43A is an upper slope 43A1, and the ...

Embodiment 2

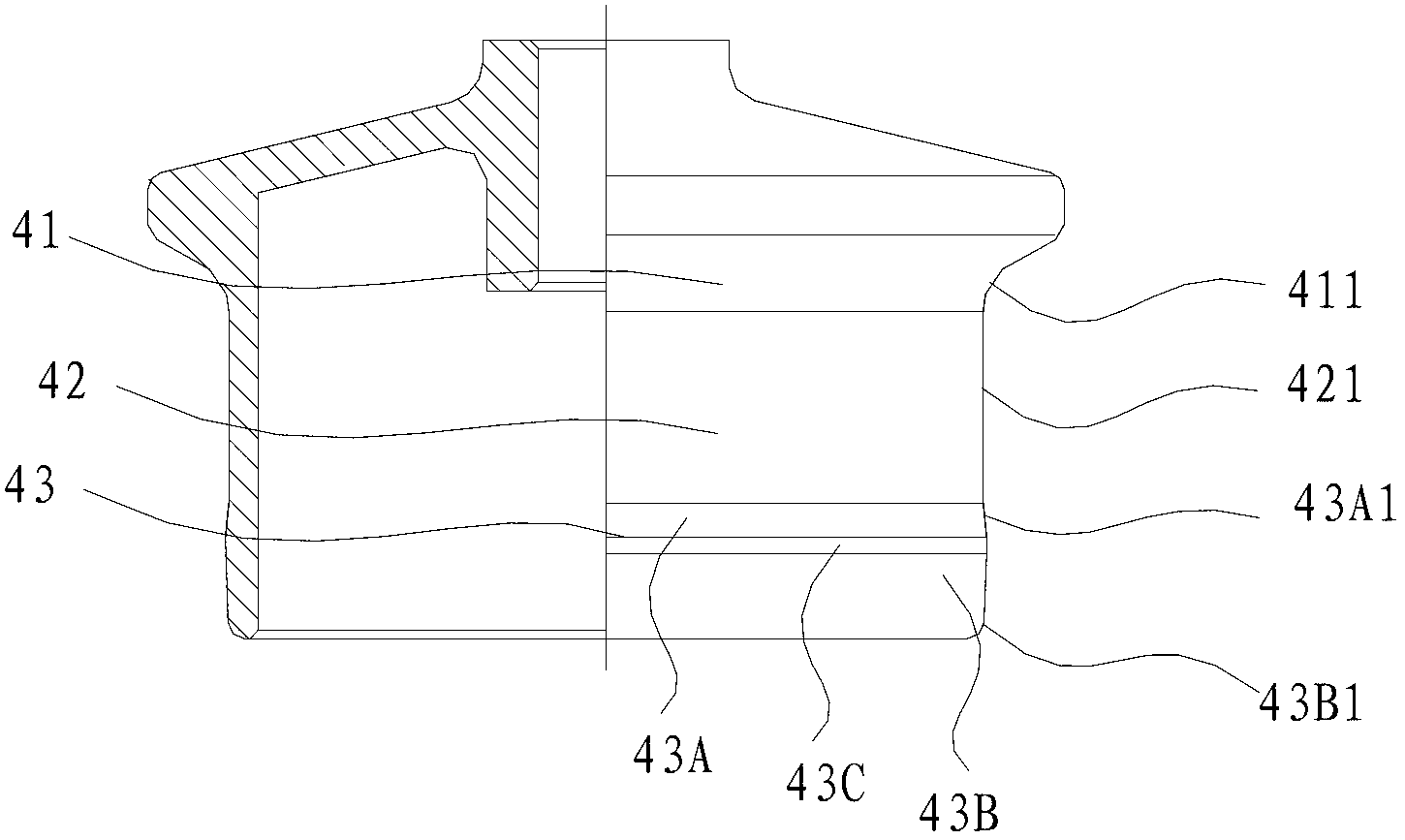

[0019] like figure 2 The structure and data of the wire feeding wheel on the knitting machine shown are the same as in Embodiment 1, the only difference is that the waste silk export body 43 also includes a waste silk transition cylinder 43C, and the waste silk temporary storage cone 43A and the waste silk export cone 43B pass through The waste silk transition cylinder 43C is connected, and the diameter of the waste silk transition cylinder 43C is the same as the diameter of the top of the waste silk export cone 43B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com