High-speed multi-section pole piece manufacturing equipment

A kind of equipment and high-speed technology, applied in the field of high-speed multi-stage film making equipment, can solve the problems that the unloading device is difficult to complete fast unloading, cannot realize high-speed multi-stage punching, and cannot meet the requirements of production, so as to prevent deviation and respond Quick action, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

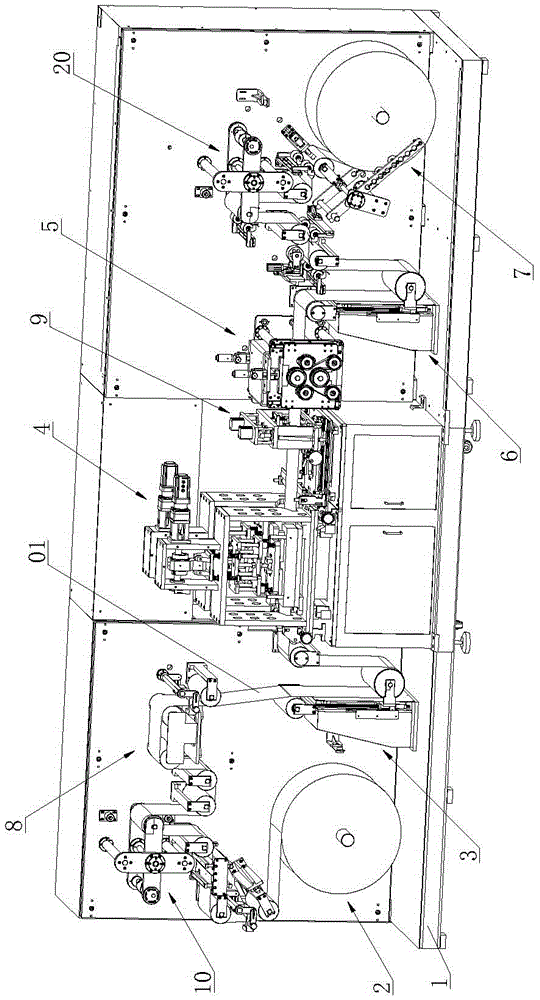

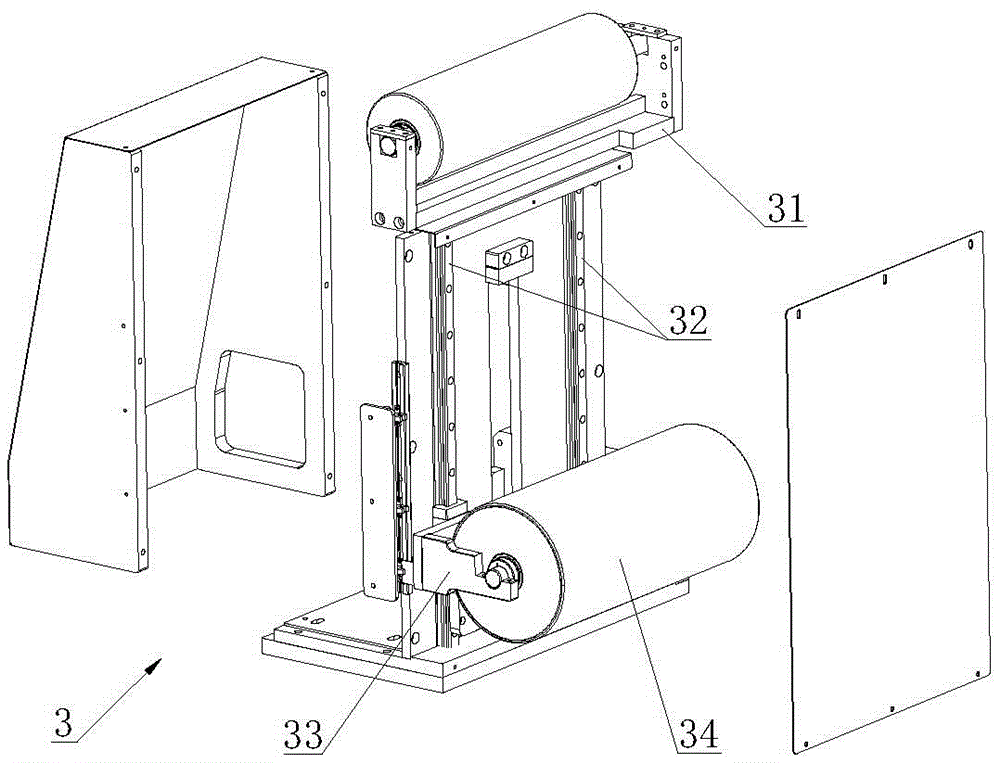

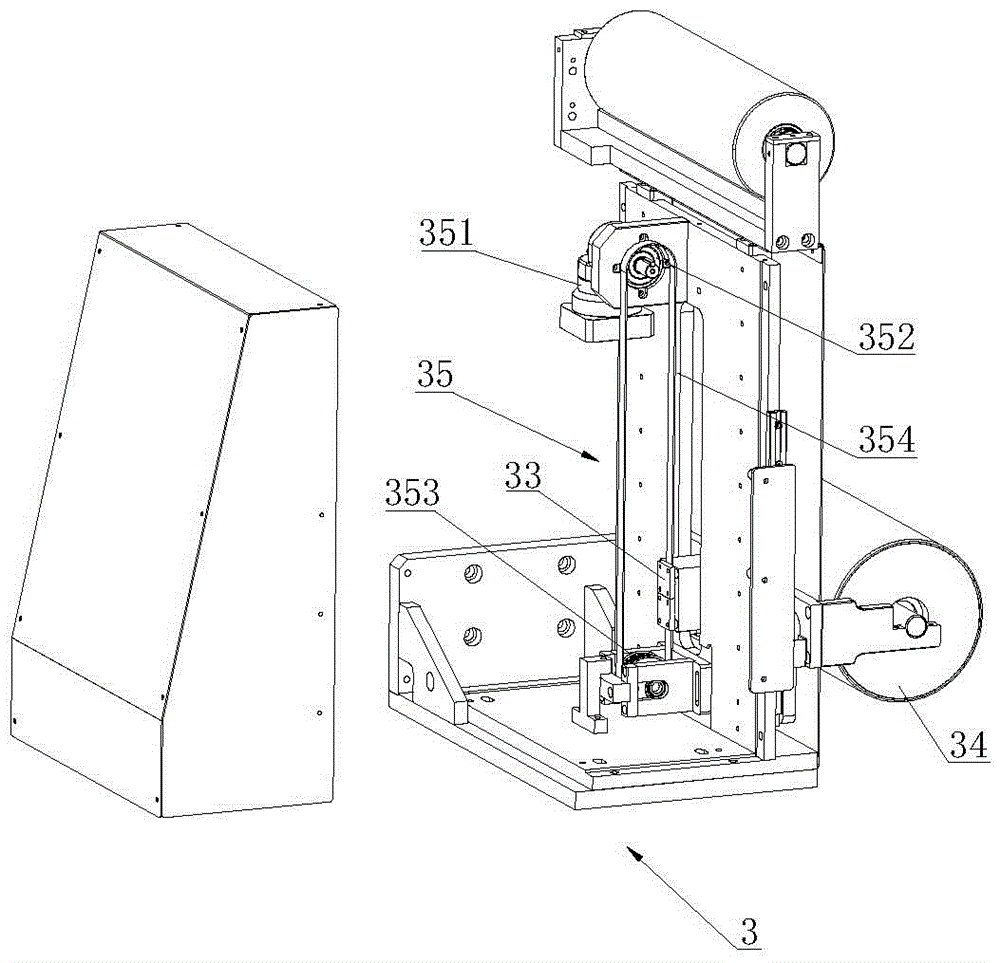

[0025] like Figure 1 to Figure 7 As shown, a high-speed multi-stage film production equipment includes a frame 1, and also includes a discharge device 2, a discharge buffer device 3, a pole piece punching device 4, and a traction device that are sequentially arranged on the frame 1 along the feeding direction. 5. Receiving buffer device 6 and receiving device 7.

[0026] In practical applications, the discharging device 2 continuously discharges the pole piece tape 01 at a constant speed, and the discharge buffer device 3 buffers the pole piece tape 01 . After the pole piece punching device 4 has punched the pole piece once, the traction device 5 pulls the pole piece strip material 01 at h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com